Shortages of quality natural sand are creating headaches. Kayasand believes quarries can provide the solution.

DRUM UP SUPPORT

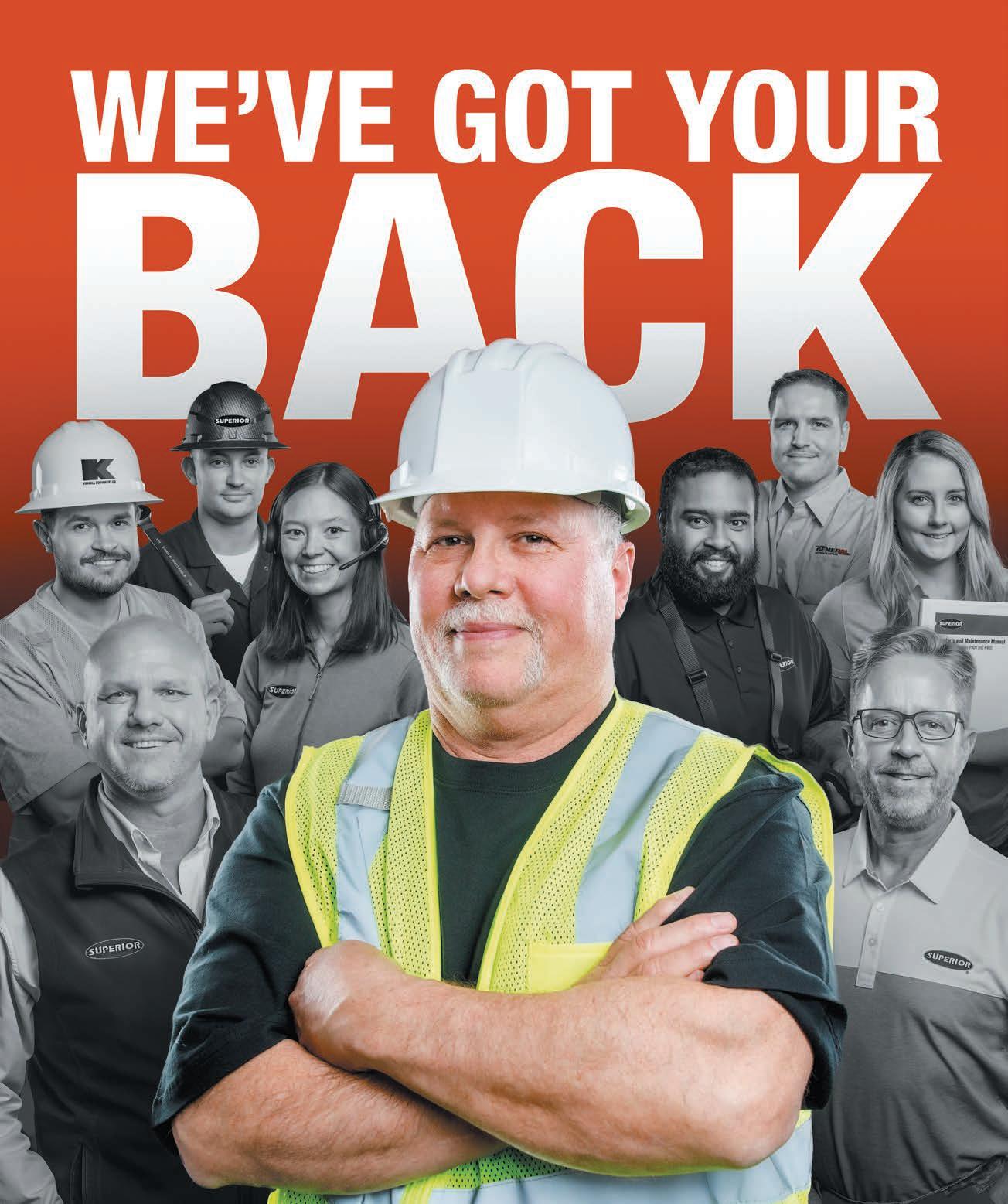

Tricon Equipment is supplying its customers with heavy-duty screening equipment.

since they launched Brooklyn

Shortages of quality natural sand are creating headaches. Kayasand believes quarries can provide the solution.

DRUM UP SUPPORT

Tricon Equipment is supplying its customers with heavy-duty screening equipment.

since they launched Brooklyn

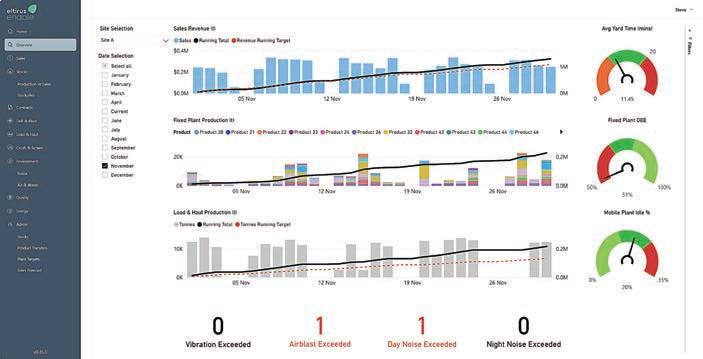

Komatsu’s Smart Quarry Site is an innovative fleet management solution designed to empower site and project management personnel with unparalleled production visualisation for quarry and major civil construction sites. With a simple glance, you gain access to real-time animated insights into every aspect of your production machines, as well as the material they are handling, extracting, shifting, or placing.

Sustainability – it’s a word you’ve no doubt heard a million times at this point, and for good reason.

Governments around the world have pledged to reduce their carbon emissions by 2050, a herculean task that relies on industry support.

The impacts of this have flown through the extractive industries, especially as incentives are pushing quarries to adopt environmentally friendly methods.

However, sustainability goes a lot further than just looking after the environment. A sustainable industry is one that continues to flourish well into the future.

As conditions change, the industry needs to be able to adapt and change with them.

Quarrying is currently undergoing a digital transformation, which is helping to reduce costs and improve productivity.

There are still many challenges that digital technology alone cannot solve, such as the nationwide skills shortage.

The Institute of Quarrying Australia (IQA) 2024 conference in Adelaide attempts to tackle these important topics.

The conference focuses on the future, recognising innovation as a key strategy to keep the industry moving forward to create growth opportunities.

It also aims to highlight examples the resources industry can learn from that could create opportunities for industry growth, employment, training, and overall development.

Attendees at the conference can gain valuable insights into evolving customer requirements, meet key decision makers and industry professionals, and showcase their organisation’s products and services.

In addition, there will be a combination of field trips and site visits, and a three-day program that explores the latest developments within the industry.

Quarry, as the official magazine of the IQA, will be on the ground at the show, shining the spotlight on what the industry has to offer. We look forward to learning more about the latest innovations.

William Arnott Editor

A SUSTAINABLE INDUSTRY IS ONE THAT CONTINUES TO FLOURISH WELL INTO THE FUTURE. AS CONDITIONS CHANGE, THE INDUSTRY NEEDS TO BE ABLE TO ADAPT AND CHANGE WITH THEM.

Published by:

379 Docklands Drive

Melbourne VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

Chief Executive Officer

John Murphy

john.murphy@primecreative.com.au

Managing Editor

Paul Hayes paul.hayes@primecreative.com.au

Editor

William Arnott william.arnott@primecreative.com.au

Journalist

Adam Daunt adam.daunt@primecreative.com.au

Business Development Manager

Les Ilyefalvy les.ilyefalvy@primecreative.com.au

Client Success Co-ordinator

Janine Clements janine.clements@primecreative.com.au

Art Director

Michelle Weston

Subscriptions

T: 03 9690 8766

subscriptions@primecreative.com.au

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published. © Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

THE MOBICAT MC 110 EVO2 AND MOBICONE MCO 90 EVO2

TEAM PLAYERS THAT WORK TOGETHER INTELLIGENTLY AND STRENGTHEN EACH OTHER. In linked plant combinations, the MOBICAT MC 110 EVO2 jaw crusher and the MOBICONE MCO 90 EVO2 cone crusher really flex their muscles. SPECTIVE makes both plants easy and intuitive to operate. Also, an advanced drive concept ensures greater effi ciency with lower consumption. Maximum throughput is achieved thanks to the material fl ow concept coordinated via line coupling across both crushing stages. Go for the perfect team!

www.kleemann.info

Safety is an important and integral part of the IQA’s mission. The IQA held two more safety and health conferences with the 10th NSW Quarries Health & Safety Conference, held at the Western Sydney Conference Centre.

There are always a range of topics across these conferences with updates from regulators and speakers on the importance of safety and health in the workplace. More recently these topics have extended to not only includes physical safety but an emphasis on psychosocial safety in the workplace. At the NSW conference, we had two sessions on managing psychosocial risks at work with information-sharing from UNSW academic dean Carlo Caponecchia and practical applications by Charlotte Kelly and Paul Slough from Hanson. Keynote speaker Steve Simpson discussed unwritten ground rules and change management, an interactive and interesting perspective on different workplaces, their cultures and ways to help change culture for the better.

In north Queensland, Chris Wilson, quarry manager at Wolffdene, a Hanson Quarry, gave a presentation on redesigning site movements, acceptable controls and verification techniques. The attendance at these conferences continues to grow.

The feedback from attendees was positive and we thank our sponsors and exhibitors for attending and supporting these major events on the calendar.

Our AGMs have commenced and will continue through until the IQA Board AGM in October. All IQA members appreciate the work that committees do throughout the year and the time committed to bringing together networking events, site tours and education which benefits the quarrying sector. To date a small number of committees have elected

their 2024–25 chairs and committee members.

Special mention should go to Craig ‘Shine’ Summerfield. Shine has held the role of Chair of the Southern NSW Region Sub-Branch for just two years, he has been a Fellow and a member of the Institute since 2008. His commitment to the IQA’s vision of education and connection has resulted in significant membership growth, offering facilities for faceto-face education, and support for branch networking events, including site tours. His enthusiasm is further reflected in his work, which led to the boards and members’ support for renaming the sub-branch from the Illawarra sub-branch to the Southern Region sub-Branch, a name more representative of the regional membership landscape. Although Shine has stepped down from his role as Chair of the Southern NSW Region subbranch this year, he will continue to be a member of the IQA. We have welcomed Michael Holz, FIQ and quarry manager of Benedict Industries, as his successor.

and

Another special mention must go to Tinus Nagel who has stepped down as the Chair of the WA branch after four years but has agreed to remain on the committee into 2024–25. Tinus was instrumental in sponsors in Western Australia, securing a number of partnerships last year. Tinus is always in attendance at meetings, encouraging of young members and Women in Quarrying. He has been a positive role model enabling a young member to step up and take the reigns under his leadership. The IQA welcomes Johan Barnard into the position of Chair for 2024–25.

Duncan Harris President Institute of

Quarrying Australia

ALL IQA MEMBERS APPRECIATE THE WORK THAT COMMITTEES DO THROUGHOUT THE YEAR AND THE TIME COMMITTED TO BRINGING TOGETHER NETWORKING EVENTS, SITE TOURS AND EDUCATION THAT BENEFITS THE QUARRYING SECTOR.

The IQA’s Strategic Plan 2023 to 2026 embodies the following vision, values and strategic priorities:

Vision:

Thriving communities supported by a sustainable industry

Operational Priorities:

• Deepen industry participation

• Sustainable revenue streams

• Highly capable team

• Technological innovation

• Effective engagement

• Great governance

Strategic Priorities:

• Support industry participants with compliance and regulation

• Build a diverse and skilled industry workforce

• Foster strong industry connectivity

IQA Contacts:

Phone: 02 9484 0577

Email: admin@quarry.com.au

Chief Executive Officer

Jane Schmitt

Deputy President

Michael Close

Company Secretary

David Cowie

For all education, member and branch enquires please email: admin@quarry.com.au.

Eltirus Exploration, Geological Modelling, and Resource Assessment services.

We work with quarry operators to explore, model, and assess your resource, increasing certainty of operation and reducing risk. Our experienced geological team help identify gaps in understanding, create exploration programs, and manage the program for you. Whether it be field mapping or blast hole, RC, aircore or diamond drilling, we not only help you explore and assess your deposit, but also ensure outputs are accessible through the use of world-class geological modelling software that provides you with interactive models that truly make a difference on the ground and in the field.

Metso has confirmed its acquisition of Jindex in an agreement that expands its offering in slurry handling capabilities.

Jindex is an Australian-based company that specialises in valves and process flow control. The acquisition will add to Metso’s existing slurry handling portfolio including slurry handling and hydrocyclones, including equipment, parts, after-

market and lifecycle services and digital services. The equipment offering includes slurry pumps, pipes, hoses, valves and hydrocyclones.

“This acquisition is yet another important step in the development of Metso’s Pumps business line offering to bring us closer to being our customers’ lifecycle partner of choice,” Metso’s head of pumps Tiago Oliveira said.

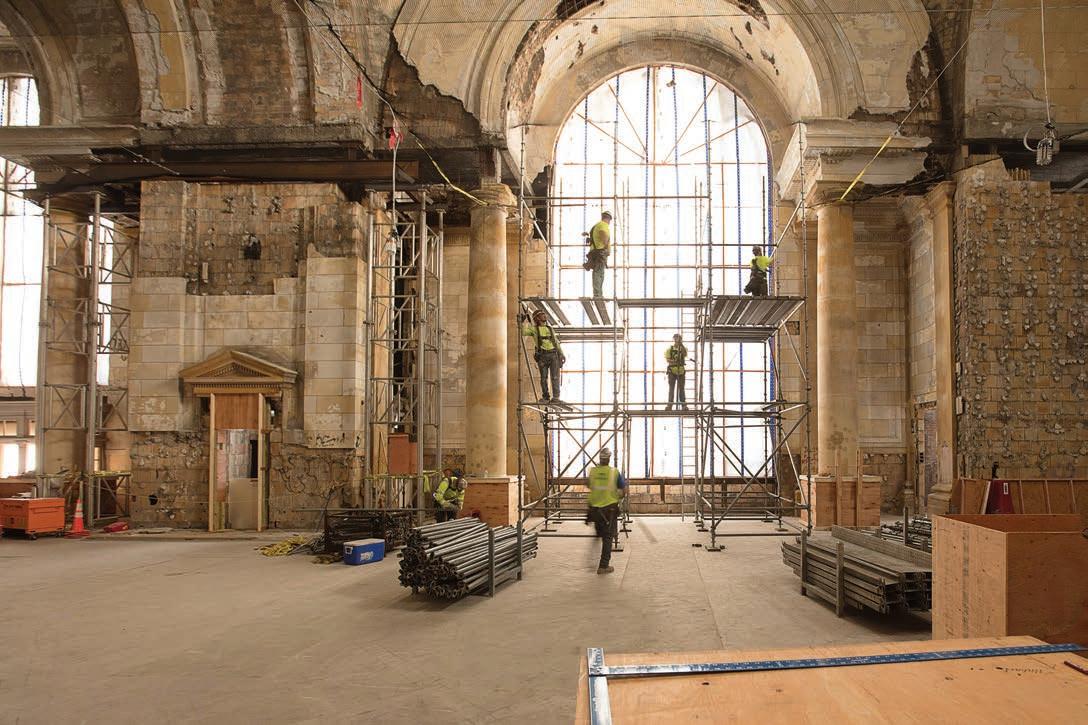

Boral’s newest cement facility has become fully operational in a major boost to the Victorian economy.

The Geelong facility has the capacity to grind 1.3 million tonnes annually, including granulated blast furnace slag and clinker.

“Our state-of-the-art cement facility in Geelong is now up and running,” the company said. “We’re excited about the positive impact this facility will have on sustainability and the local community.”

The company will use slag, a by-product of steel manufacturing, to help reduce

“JINDEX HAS EXTENSIVE EXPERTISE AND STRONG CAPABILITIES IN VALVE TECHNOLOGY AND CONTROL EQUIPMENT, AS WELL AS IN MANY TYPES OF SLURRY VALVE PROJECTS, AND THUS THEIR PRODUCTS COMPLEMENT OUR OFFERING WELL.”

TIAGO OLIVEIRA

Flow and isolation control play a vital role in ensuring smooth slurry handling to maximize the productivity and efficiency of minerals processing plants. In the past, we have collaborated with Jindex on many customer projects and are now glad to welcome the Jindex experts to the Metso team.

“Jindex has extensive expertise and strong capabilities in valve technology and control equipment, as well as in many types of slurry valve projects, and thus their products complement our offering well.”

Jindex is a privately owned technology company established in 1995. The company is based in Sydney, Australia, and has 25 employees. Jindex serves the mining and minerals processing sector with approximately 50 per cent of sales in Australia.

“This is a great development and an exciting next step. The Jindex product offering and our technical expertise in valves are an excellent addition to Metso’s Pumps business and will enable Metso to provide more extensive flow control solutions to the mining industry,” Jindex managing director Stephen Fowler said.

“We look forward to contributing our unique knowledge and experience as part of the Metso team, and providing enhanced outcomes to all our collective customers.” •

landfill waste and substitute cement in concrete products.

The new facility is located near Lascelles Wharf and features a covered conveyor system to reduce local truck traffic.

Clinker and slag are unloaded from ships and delivered to the site via covered belt conveyors situated on Lascelles Wharf. Following processing, the final cement product is transported to the Victorian market via enclosed tanker trucks.

Boral invested heavily to bring the Walchs Road, North Shore location to life. It began construction in 2018. •

Delta Rent operates one of the largest earthmoving equipment rental fleets of more than 450 high performance machines in Australia.

We understand that production is key for quarry owners and operators. In particular, the importance of high optimisation rates for the heavy plant and machines required to process raw materials and meet demand.

24/7 service Australia wide

Our late model, low hour and meticulously maintained fleet – combined with expert 24/7 advice and analysis from an experienced and professional sales team – ensures our clients maximise production output without compromising quality, safety or environmental performance standards. Expert advice and analysisPurpose built fleets tailored

55-ton payload

Move more material in less time

6x6 traction

Unstoppable in tough terrain

Haul Assist

Optimise your hauls with real-time data

Spacious cab

Comfortable and ergonomic design

Robust design

Built for the toughest quarry conditions

Fast cycle times

Get more done in less time

Sometimes, quarry operators need an extra machine to get a job done without the risk of a full-scale financial investment.

A rental hire can help quarries add the missing piece to their fleet without that risk.

Delta Rent operates one of Australia’s largest earthmoving equipment rental fleets, featuring more than 450 high-performance machines.

The company can provide quarry operators with complete fleet packages comprised of newgeneration, low-hour machines with an extensive range of attachments to suit their project specifications. Nothing in Delta’s fleet is over 6000 hours to ensure operators receive the latest and best equipment.

Delta Rent has some of the latest industry machines available for hire, including the HD785 and HD605 Komatsu rigid haul trucks, Hitachi and Komatsu excavators from 60t to 125t, and Hitachi Komatsu and Volvo excavators from 30t to 60t. Delta also has Hitachi excavators from 8t to 30t for smaller-scale jobs.

In line with an industry continuously embracing technology, Delta Rent’s fleet has full GPS tracking and telematics reporting supported by the OEM.

Delta Rent, committed to fast service, offers all customers round-the-clock support and transport and logistics support to relieve the pressure of organising machinery on-site.

For more information, visit deltarent.com.au

To submit new product and equipment releases, email: les.ilyefalvy@primecreative.com.au

For the past 100 years, Kleemann GmbH has been designing, evolving, and manufacturing machines for the mining, quarrying, and recycling industries.

As a powerful mobile cone crusher, the Mobicone MCO 90 EVO2 has been designed to overcome evolving challenges in different applications. An optimised throughput can be guaranteed for natural stone, recycled asphalt or river pebble applications, thanks to the machine’s design and flexibility. With the increasing demands that are placed on modern crushing plants, their complexity also increases. At the same time, the technology must be safe and as simple as possible to master – and without long training sessions.

This is the strength of the spective operating concept. The Mobicone MCO 90 EVO2 can be operated simply and intuitively with the various Spective components. Along with the touch panel, the holistic operating concept includes a Spective intuitive operating concept for a better result.

The Mobicone MCO 90 EVO2 also features the innovative D-Drive “dieseldirect-electric” drive concept and excels with its dynamic performance combined with low fuel consumption. The MCO 90 EVO2 stands out with its holistic drive concept with an efficient diesel-direct drive whereby the crusher is driven directly via a fluid coupling from the diesel engine.

The power and load-dependent fan ensures a low-noise and even more economical operation. The generator is driven direct by a cardinal shaft and the drive system pumps are activated via a clutch coupling, which can draw on the

full power of the diesel engine. All other hydraulic pumps are for auxiliary and set up functions and for the cooler drive are also driven via the gearbox.

The MCO 90 EVO2 can come in two configurations with either a large single deck 16’x5’ (4.87x1.52m) or a large double deck 16’x5’ (4.87x1.52m) post screen box and recirculating conveyor and mid fine product belt, creating a closed loop operation with the benefit of having two classified products on the ground or opt for it without the post screen box option making it an open circuit crusher.

For more information, visit wirtgen-group.com

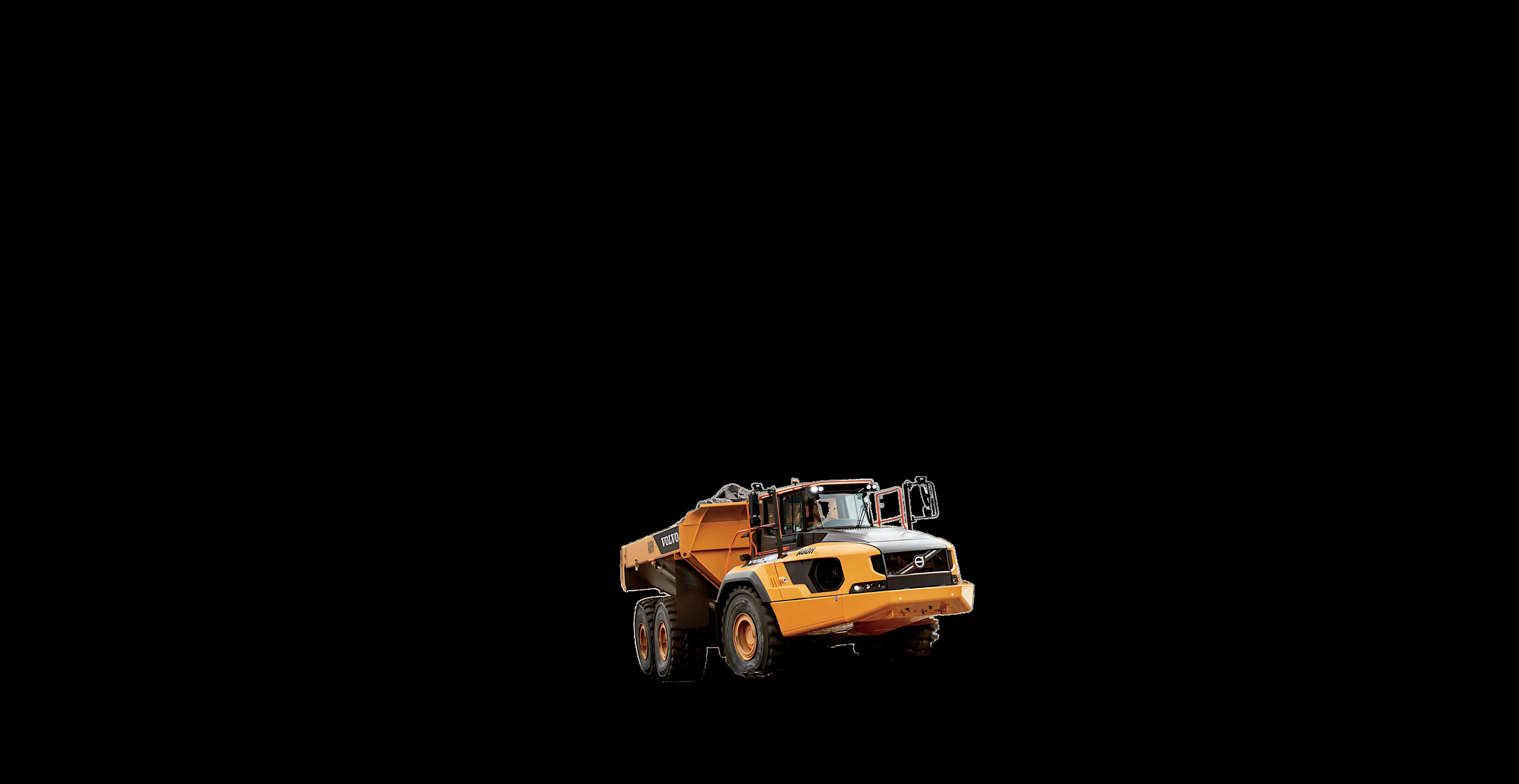

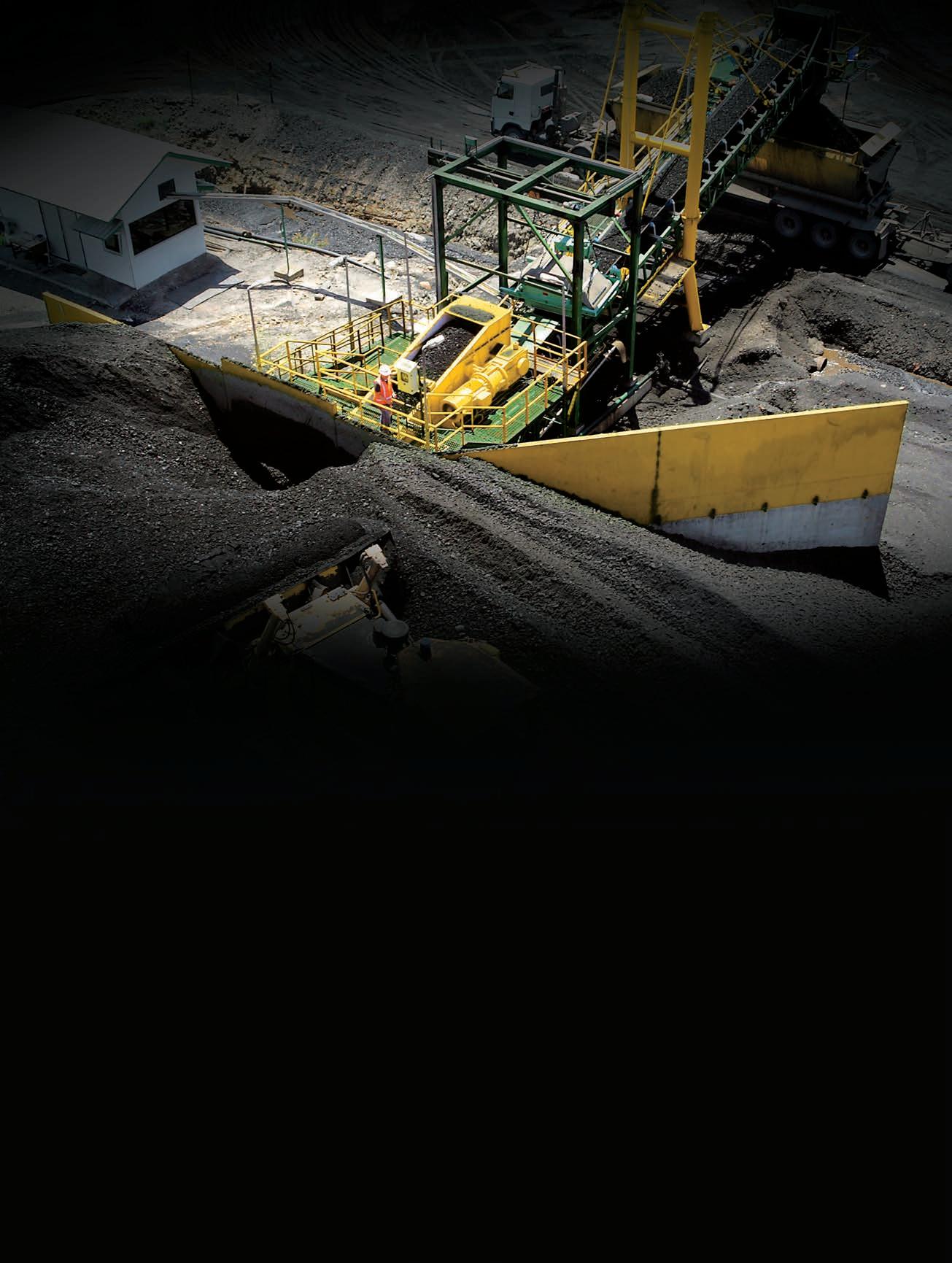

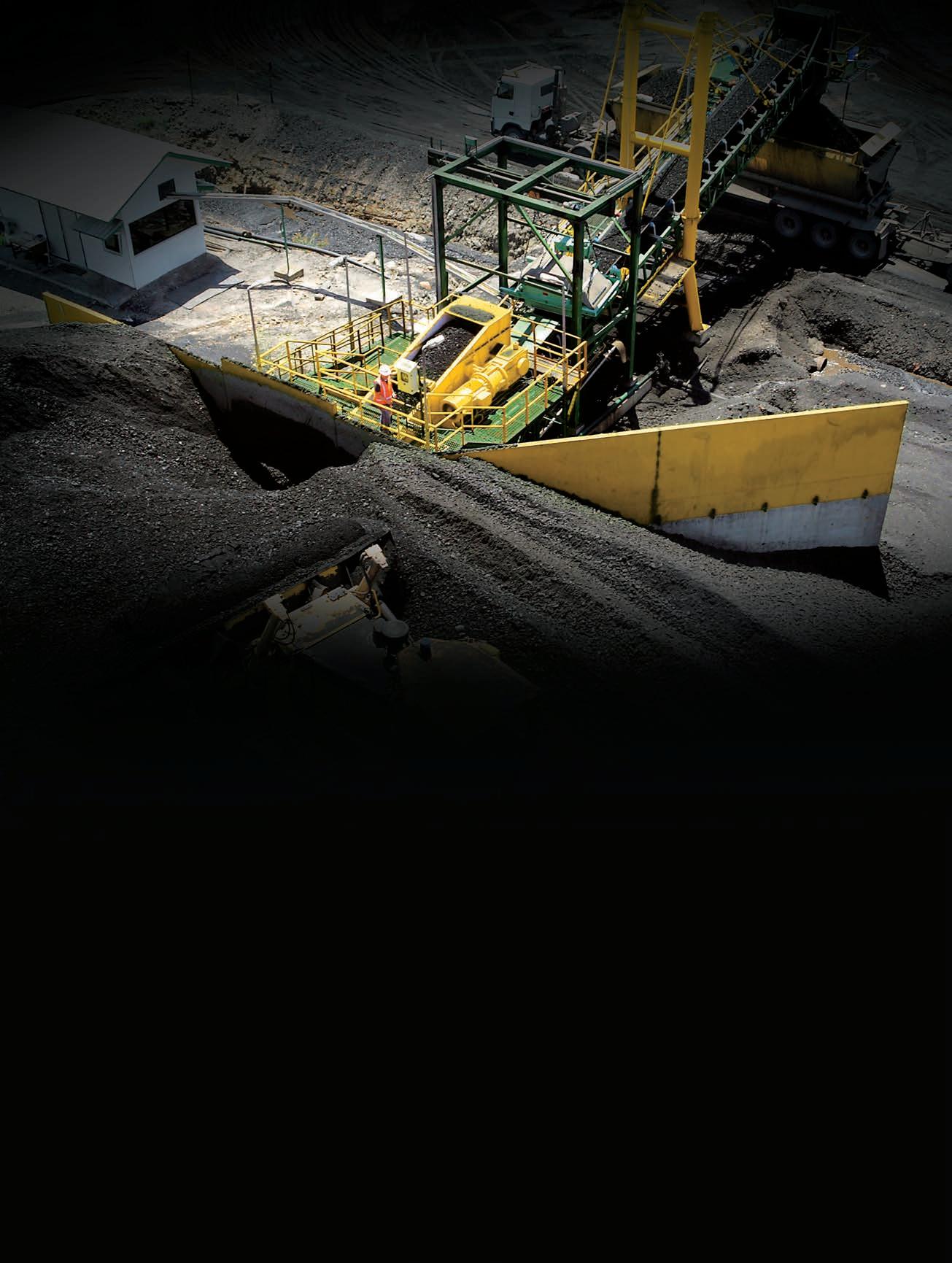

As sustainability becomes increasingly important, Smart Quarry Site can help quarries reach their targets.

As requirements for ESG reporting become more stringent for many Australian businesses, including quarries, it’s important that OEMs continue to support their customers with data and insights that not only drive their business forward but also help them meet and track any sustainability metrics.

Komatsu Australia is strongly committed to environmental best practices and continuously focuses on reducing its environmental impacts and carbon footprint while supporting customers on the net-zero journey through research and development efforts, product support, and expert advice.

Aaron Marsh, national product and solution manager from Komatsu Australia, said it’s important the company meets the challenge of sustainability across all its sectors.

“Quarries are continuously working to extract aggregates, so machines need to be productive and efficient to meet production targets. But quarry fleets now also need to be

monitored to manage emissions, with some fleets not having the technology in place to support this or to see where they need to make improvements,” he told Quarry

“This is where systems like Komatsu’s Smart Quarry Site (SQS) can support fleet operators. It’s our innovative fleet management solution that focuses on five essential areas: site management, production optimisation, machine health monitoring, proactive maintenance and enhanced safety for quarry operations.

“It was designed to give a real-time overview of an entire quarry fleet, and caters to not only Komatsu equipment, but a wide range of other equipment types and various machine makes, making it the ideal choice for managing mixed fleets efficiently.”

SQS allows users to manage and review site carbon emission trends in approximately realtime. Marsh said the data aggregation from the site visualisation dashboards provides

information to site operators, managers, and executives on several measures.

“These include total accumulated fuel, footprint tonnes of CO2, average CO2 per hour, average CO2 per tonne and calls out CO2 by machine utilisation in working and idle hours, really focusing on the effective utilisation of quarry fleets. We also measure the emission trends and load and haul circuits by trucks to understand the emission impact of a particular circuit or material,”

reporting in the dashboard a quarry site can make changes to optimise fleet, pit, load and haul and focus on effective utilisation of the fleet especially around litre per tonne.

“This can lead to immense savings in fuel efficiency. In one of our customers sites, we have seen a measurable saving of 8.6 per cent on litres per tonne, which is equivalent to 81,000 litres of fuel and a CO2 saving of 217 tonnes over 12 months of operation.”

It’s vital for a quarry owner and manager to track material moved, as quarries have multiple benches and at time move multiple materials.

“Productive throughput to the crusher and ROM is critical, and SQS reports all of this in almost real time to the site allowing site managers to create targets or tonnes per hour KPIs, and act on them immediately,” Marsh said.

“Tracking where material is picked up and where it has been dropped off is also critical, and many of our customers are also running material hoppers and tracking there stockpile movements through SQS, giving them another level of data to track and understand their productivity.”

Marsh said that tracking effective utilisation is key and not all utilisation is the same.

“Simply increasing utilisation alone is not effective, unproductive cycles, inefficient operations and double handling all require more machine hours and higher fuel burn that can contribute to your emission trends and carbon footprint,” he said.

“Managing bottlenecks and stoppages is a thing of the past now thanks to SQS. To be able to see the fleet activity in almost real time allows the site manager to understand bottlenecks, activities and delays, with SQS

automating 95 per cent of this reporting and providing the visualisation to the user as if the quarry manager is standing right in the pit with the machines.

“At one of our SQS customer sites, the quarry management team, through this visualisation, decreased idle time on the load and haul trucks by ight per cent and the face loader increased utilisation by seven per cent, a significant effective utilisation increase.”

Komatsu’s expert team visits each quarry site before they start using Smart Quarry Site, to make sure the technology is set up to reach the right targets and troubleshoot any issues the users have.

“When you partner with Komatsu, you don’t just get the product, but a full-service solution backed by our team,” Marsh said.

“Newer quarry models, like our HD605-10, now come with SQS as standard, meaning quarry site managers and operators will have the technology they need to make smart, informed decisions at their fingertips.

“We want to make sure we are fully supporting our customers with solutions and insights right across their quarry site – whether that be metrics for ESG reporting, understanding their productivity levels or maximising their fleets to be more efficient and profitable.”

Komatsu is a platinum partner of the IQA 2024 National Conference in Adelaide from October 15–17. The Komatsu team at the conference will be able to discuss the benefits of the Smart Quarry Site and how it can benefit your quarry. •

For more information, visit komatsu.com.au

Precisionscreen has adapted its range to suit the growing need for mobile quarrying equipment.

Given the Australian geography, precoating equipment needs can vary from state to state and from the major aggregate players to the small, independent contractors.

However, precoating can be expensive, so it is imperative to do it as efficiently and effectively as possible.

Precisionscreen’s 3000 and 6500 Precoater models have been proven popular in South Australia, Western Australia, and the Northern Territory. Due to the nature of their work, more job sites in these regions need mobile equipment, whereas eastern states like New South Wales have a greater demand for quarrybased precoating.

Since the Brisbane-based manufacturer bought the two models to market, the industry needs in those regions have been in demand.

Jonny McMurtry, Precisionscreen’s chief operating officer, estimates the Brisbanebased company has sent eight to ten mobile Precoaters to South Australia, the Northern Territory, and Western Australia in the past 12 months.

“It’s been a consistent demand; it usually comes in waves, but it has been a consistent demand for those styles of machines and that type of precoating application,” he said.

“Those states west of New South Wales and Queensland focus more on mobile precoating. I think the distance between centres and capitals is probably one of the main reasons they do.

“The fact they can couple it up and conduct precoating by the side of the road or quarrybased precoating – whichever they need –makes it a particularly sought-after machine.”

Operators can use the Precoater 3000 and 6500 models for job-site-specific applications while maintaining quick and effective delivery.

The Precoater 3000 has an eight-by-fourfoot screen box, a 3000-litre tank, and a tail conveyor that can discharge over four metres. It has 12 individually controlled precoat spray nozzles across three bars attached to the tumbler chute. The 3000 model can deliver a consistent throughput of more than 120 tonnes per hour.

For those needing a greater capacity, the 6500 model offers a bigger build. The larger

model is equipped with a 6500-litre tank, a ten-by-five-twin-deck screen box, and a discharge point of more than four metres. It comes with more precoater nozzles (14), which deliver a greater throughput rate of more than 150 tonnes per hour.

Both models use PLC electronic panels and machine controls to make them easier for operators to control. Precisionscreen partnered with electronic hardware supplier IFM to upgrade the previous hydraulic controls. Operators can start and stop material flow remotely using these controls, and the equipped CAT engines have a shutdown function to ensure operator safety.

As an Australian-based manufacturer, Precisionscreen can modify the Precoaters to suit the customer’s requirements from its Wacol headquarters, including adding extra filters or modified spraying systems.

The the 3000 and 6500 Precoaters have earned plenty of repeat customers.

“Over the past four to five years, it has probably been a 50-50 split where we’ve had customers adding onto their fleet or replacing existing machines.

“But the last eight to ten machine sales over the past year or so, 50 per cent have probably been new companies where it’s been their first machine, and they’re entering this market.

“[The 3000 and 6500] cover both bases. If customers have bigger demands, they can lean towards the 6500, whereas the 3000 can still cover many applications and customer requirements , including high volume daily production, where needed.”

In addition to the 3000 and 6500 Precoaters, Precisionscreen’s Scorpion Precoater is an adaptation of the company’s Scorpion Reclaimer Screening Plant with an added precoating conveyor.

It is equipped with an eight-by-four-foot two-deck screen box, an onboard precoat chute, and an independent feeder belt with variable speed. The Scorpion Precoater’s specially designed chute allows material to be sufficiently tumbled and turned while the precoat nozzles coat the material quickly and efficiently.

“It’s a cost-effective way for quarry-based precoating to occur. It has all the same elements as our road-towable machines, the same Australian-designed screen boxes and all the fabricated framing, but it is a semimobile application,” McMurtry said.

“It achieves an adequate tumble and coating on your aggregate with the precoat liquid, but

it caters more to the companies coming to the quarries to collect the material.”

As the quarrying industry shifts and costs catch up with operators at all levels, some are looking at ways to adapt operations to be more cost-efficient.

Alongside this trend, Precisionscreen has noticed an increased demand for precoat attachment kits. These packages transform standard conveyors into precoater conveyors thanks to the hydraulically-driven precoat pump. It pumps the material to the tumbler chute, which can hang off most conveyors in the industry, where the material is coated quickly and efficiently.

McMurtry said the company can adapt the precoat kits to suit most conveyors with information from the customer.

“All of a sudden, you’ve got a quarrybased precoating conveyor from a preexisting conveyor that you might have already on site,” he said.

The company supports customers across Australia in achieving the most from their Precoater machines. Through a combination of its internal staff and state-based contractors, Precisionscreen has a network of experts to help quarry companies and contractors.

Precisionscreen will attend the IQA 2024 National Conference in Adelaide from October 15–17. •

For more information, visit precisionscreen.com.au.

Tecweigh’s latest conveyor belt scales are designed for weighing in all conditions in the quarry industry.

In an industry that needs tailored solutions and quick turnarounds, Tecweigh’s Australian advantage has shone through for the customers in the quarry sector.

The Australian manufacturer has been producing a range of conveyor belt scales, weigh belt feeders and volumetric feeders for two decades from its Melbourne headquarters.

Being an Australian-made brand ensures Tecweigh’s custom-engineered products can perform dynamic measuring in the harshest of conditions.

Barry Gamble, Tecweigh’s business development manager, said being a local manufacturer has allowed the company to keep costs down and ensure continued supply.

“We do all our manufacturing in Carrum Downs, Melbourne, which gives us a fast response time,” he said.

“We can normally deliver what the client needs within seven to 10 days.”

Dynamic measuring is a key component in the quarrying industry which helps relay accurate throughput information.

Without accurate information about how much material is being conveyed, monitoring, storage management and feed metering become incredibly difficult.

To ensure its products are reliable in Australia’s often-harsh conditions and provide accurate information, Tecweigh uses stainless steel, hermetically sealed IP68 load cells designed to provide accuracies of ± 0.5 or ± 0.25 per cent for its weigh belt feeders and conveyer belt scales.

The weigh idler system has been designed to be easy to calibrate to provide consistent accuracy.

Its weigh belt feeders can also be manufactured to specific lengths and widths, using powder-coated mild steel or stainless steel, depending on the application.

“Custom designs are our standard. Whether it is chemicals, crushed stone, sand, coal, or materials that are low density, sticky, or abrasive, we specialise in building the equipment needed to accurately weigh it,”

Gamble said.

“Our products are also designed for heavy-duty work and have been proven over time to be accurate in some of the world’s harshest environments.”

With more than 100 years of industry experience collectively among its employees, the company is continuing to look for new innovations.

The fact it is based in Australia means Tecweigh can also offer local after-sales support. The company maintains a significant stock inventory for its conveyor belt scales, volumetric feeders, and weigh belt feeders. It also offers field service support and spare parts supply.

From humble beginnings, Tecweigh has built its bespoke business to provide weighing-in-motion solutions for industries nationally and internationally.

The company has built a long-lasting relationship with its own local suppliers and aims to further grow in the industry. •

For more information, visit tecweigh.com.au

At 40 tons and over 30 feet long, safety comes first. By combining cameras, radar, and machine learning, obstacle intelligence gives operators eyes in the back of their head. To protect your crew, and other investments, like never before.

Returning for the fourth time, John Deere’s annual Technician of the Year Awards are set to recognise unsung heroes.

When Caleb Dover visited the Ulverstone Show in Tasmania as a young child, it set him on an award- winning career path.

For Dover, the day spent exploring the historic equipment in Ulverstone ignited a passion for restoring machinery, a journey that continues to this day, filled with pride and a sense of accomplishment.

He kept that passion as a young apprentice with Midland Tractors in Latrobe in Tasmania’s North West, where Dover was crowned John Deere’s inaugural Australian and New Zealand Parts Apprentice of the Year in 2021.

“At the time, when I was an apprentice, it felt like the pinnacle of my career,” he said.

“I care deeply about my customers, the John Deere brand, and making sure I always do my job to the absolute best of my ability, so winning the award and getting recognised for the care and effort I put in felt like a vindication of all that work.

“To this day, it still means a lot to me, and I look back on it as one of my proudest moments.”

Three years after that success, Dover has advanced his career and relocated to Western Australia, where he helps those in the Wheatbelt region as the parts manager for AFGRI Equipment in Wongan Hills.

While he may have moved to the other side of the country, his approach to the role is based on the same fundamentals that earned him award recognition three years ago. As he leads a team of four in the parts department, Dover has invested in professional development through John Deere University to expand his skill set.

“I’ve always focused on finding new solutions for customers, and this role allows me to do that,” Dover said.

“I enjoy having some younger people to mentor and encourage them to give that high level of customer service.

“My journey shows how you can end up in a management role in a completely different part of the country than you started because of the strong John Deere network.”

Caleb’s career journey and accomplishments are one of the many success stories that have emerged since John Deere launched its Technician of the Year Awards.

The awards recognise an Australian and New Zealand winner across several categories. The Service Apprentice and Parts Apprentice of the Year awards will be chosen from a combined pool of applicants from both countries.

In their fourth iteration, the awards will see finalists tested at John Deere’s Australian headquarters in early September before

the award night is held at a gala dinner on September 5 in Brisbane.

“This year, contestants will complete additional technical testing before they can move to the in-person testing at our Crestmead head office, and they must also hit specific training targets,” John Deere Australia and New Zealand director of aftermarket and customer support Emma Ford said.

“We want to ensure our technicians are best equipped to meet the needs of our customers and John Deere’s ever-expanding portfolio of equipment.

“Continuous investment in building capabilities is key to what sets a John Deere technician apart, so it’s important our awards program assesses both the technicians’ technical skills and their commitment to ongoing training.”

Nominations have increased by 30 per cent compared to 2023, with more than 130 technicians being submitted across the eight award categories.

“We’re incredibly proud to highlight the invaluable service they provide and the role they play in helping industries and communities thrive,” Ford said.

Dover encouraged technicians to nominate for the event due to its positive impact on his career to date.

“Winning the award helped build trust, respect, and a better relationship with our customers, and it helped people understand that the service we offered was among the best in the country. We had the certificate to prove it,” he said. •

For more information, visit deere.com.au

The Next Generation Diesel-Electric Mobile Jaw Crusher

The Lokotrack LT400J is a robust hybrid mobile jaw crusher ideal for primary crushing of hard rock and producing recycled aggregates. Its new diesel-electric power system and improved usability ensure maximum uptime, while its modular design allows for easy upgrades to meet evolving market needs.

For more information on the extensive range of Metso mobile plants, email us today at metso@tuttbryant.com.au!

Caterpillar’s VisionLink Productivity platform aims to ramp up quarry production by eliminating inefficiencies.

As a quarry manager or owner, it may seem overwhelming to oversee everything that happens on the site. They prioritise increasing material output and monitoring machinery to improve productivity and prevent downtime. However, the limited workforce means the challenges lie in managing these tasks effectively throughout the workday.

Caterpillar has created a solution to address these concerns and give quarry workers an accurate picture of what happens across their site.

VisionLink Productivity is a cloud-based platform that enables workers to see critical business insights, spot inefficiencies, and turn accurate information into ways to improve production and safety.

While workers can gather a wealth of data on the machine’s health, production levels, fuel burn, and idle time, VisionLink Productivity consolidates it all. It can be scaled across multiple quarry sites.

For businesses with multiple quarry sites, which run bigger operations with multiple fleets and job sites, seeing how an individual machine performs against the rest of the organisation is imperative to making informed decisions.

Using the VisionLink Productivity platform, managers can drill down into the data while getting a high-level overview of the operation.

“It allows your people to get a high-level overview of your operation and drill down to find the detailed information that you need to make the right business decisions,” a Caterpillar spokesperson said.

“VisionLink Productivity gives the decision maker an accurate picture of their operation and providing them with opportunities to implement change and make improvements to machine utilisation and operational efficiency.”

Quarry operations involve a lot of work, including extraction, processing, and transporting the material. Managers need to understand how long specific functions take, including empty and load times, site travel times, and dig and wait times, which are fundamental to getting the most production out of the quarry.

Caterpillar’s cloud-based platform tracks all of these measures and enables managers to spot inefficiencies, failures and bottlenecks on site from which they can produce better processes.

In one example, if a manager could track machine movement and see how long each machine spent in each part of the cycle, they could slow down machines in the return phase. This would reduce excessive wait times and needless fuel consumption.

“Being able to include your operators in this review, with powerful visuals including maps and graphs, allows you to work together to identify inefficiencies and find solutions,” a Caterpillar spokesperson said.

“Discussions like these – based on hard data – strengthen partnerships with operators. It facilitates objective,

Eltirus founder Steve Franklin looks at the past, present and future of digital transformation in Australian quarries.

In 2016, Eltirus collaborated with Fulton Hogan at the Stonemaster quarry near Brisbane as one of the early adopters of digital transformation.

Since that time, many of what were then novel ideas have become commonplace across the industry.

We thought it was time to revisit where things were, how we see things now and what the future might look like.

Site surveys were generally conducted once a year by aerial survey. The aerial survey companies determined site extraction volumes for royalty calculation purposes and not much else. Drone survey was in its infancy and regarded as little more than a novelty.

While geological drilling was conducted, there was very little done with the data. At best, cross sections were created in printed in paper reports and there was generally no way to correlate these to the field.

Most design work was conducted in either AutoCAD or Geovia Surpac. Getting accurate survey data to design with was incredible difficult – I remember spending a week manually editing the contours from a site flyover to try and create a surface to design to.

If software was used, it was generally to create concept designs or final pit shells (often without ramps).

Drone survey has tended to become ubiquitous. Companies are either employing drones themselves or getting contractors to fly their sites for them.

The focus tends to be towards drone survey for stockpile measurement, with a lesser number of sites flying “whole of site” on a regular basis. Where whole of site flights are conducted, they are generally not flown using a “terrain following” method, resulting in reduced accuracy where there are significant differences in elevation between the top and bottom of the quarry.

While drone technology is commonplace on many sites, we find that the results can be quite variable. While a whole of site survey can “look ok”, the reality is often very different, particularly if the site uses Ground Control Points (GCPs) to provide accuracy rather than high accuracy systems such as post-processing kinematic and real-time kinematic (RTK).

By way of example, if the site relies on GCPs for accuracy, it often only needs one or two of them to be moved or lost to destroy the accuracy in that area, resulting in warping that you won’t see unless you do a crosssection comparison or other quality check.

Most quarry companies do not have their own technical teams with many relying on a range of small consulting groups and independent contractors to perform these functions for them. This is often further

broken down at state and even site level such that there is not a consistent approach to data management. In many cases, consulting groups and contractors will have a more comprehensive set of data than the client. This is risky.

We have seen instances where an independent contractor has performed all of the geological or engineering work for a client over many years, only to get sick or go out of business and with it, went much of the client’s data.

Even worse is the fact that because work is conducted by multiple or independent parties, there is often a lack of consistency in conventions such as file naming or data structures. Not only does this increase the likelihood of errors and data loss it results in a level of risk that is unacceptable.

Where companies are creating their own technical teams, they are also facing the need to update their software. Advanced geological software such as Leapfrog Geo is a quantum leap when compared to past systems. Instead of manually having to add data and reinterpret models, new software allows for automatic addition and re-creation of models, saving hundreds of hours of work. Likewise, mining software programs such as Deswik.Suite can manage and manipulate massive point clouds, create and manipulate solids and automatically create quarry designs based on geotechnical and operational parameters.

These new generation software packages open up the opportunity to provide new insights, get work done faster and make it accessible to other stakeholders.

It is now possible to provide site users with complex extraction and geological models through web browsers that give new levels of access and insight and that facilitate collaborate between technical and field users and allow people in the field to provide real time feedback about what they are encountering to help ensure that technical staff are continually updated on developments and can update the models to increase both their accuracy and relevance.

Given the free AusCORS network widely available across the country, we see this ultimately displacing paid RTK services and sites relying on GCPs.

We also expect to see a rise in “drone in a box” technology as the issues around flying beyond line of site are resolved.

The key thing we see as important is providing better, more consistent access to data for decision making.

Whether you choose to work with external partners or build your own technical team, putting in place the workflows, approvals, data structures, file naming and colouring conventions is vital. We see these systems being setup in such a way as to provide secure access to all relevant stakeholders who need access to it – internal or external.

The types of data that we expect to see centralised:

• All geological drill hole and sampling data with relevant test results attached and accessible by the relevant geological modelling systems.

• Geological modelling systems that contain all the different geological models for each site and the different versions and interpretations of these.

• Optimised pit designs and stages for each site.

• Detailed designs for each site and the related survey files for consumption by 3D machine guidance, drill rig hole navigation systems, autonomous equipment

In all instances we would also expect to see systems that logged who added/changed and edited data to ensure that there is a clear chain of responsibility of action.

MDM is a good example) will also include approvals workflows and the attachment of all relevant unstructured documents to them. These systems already exist in the mining industry and could be re-purposed for the construction materials industry.

While there is a lot of discussion about AI and its potential impact on the industry, we see it following hand in glove with work carried out to sort out data management first.

For example, we have a knowledge base of some five hundred articles detailing how we do our work. This is probably our greatest asset and we spend a considerable effort on creating and maintaining it. The opportunity to access this knowledge through an AI engine which can also potentially look at how we have done similar jobs and studies in the past will be game changing.

Likewise, where it could look at geological data in one quarry and consider similarities or problem-solving approaches from other sites might result in substanital gains.

Note that the key thing is bringing the data together and in a consistent fashion, if the true value of it is to be realised.

One of the greatest advances that will occur is around resource optimisation to maximise net present value (NPV). Tools such as Deswik.GO can consider the pit shape and extraction sequence as determined by cost and revenue, geological and geotechnical data, mining rules and capital requirements, bringing a substantial difference to pit design

and scheduling – in fact, it’s a quantum leap and deserves considerable attention at COO, CFO and board level

The ability to be able to clearly determine the amount of material needs to be stripped and when can improve resource NPV by 2040 per cent. It also provides accurate stage shells for effective scheduling (the absence of which is a primary barrier to this activity) and help ensure that critical supply contracts can be met and reserves better understood.

As we gain access to more and more data systems, whether they be machine telematics systems, weighbridge, environmental and

Operational data reporting systems like Eltirus Enable help to bring together all the different types of data into a cohesive whole and provide an “executive summary”. This is invaluable not only for providing that overview of critical forward-looking metrics, but also to provide a clean, comprehensive and collated data set that can then be effectively utilised by machine learning and AI tools.

Autonomous operation is all around us and has been for many years. While there is much discussion about whether you could trust to drive a manned vehicle in an area where autonomous haulers are in operation, we forget the fact that every time we fly in a commercial airliner, the vast majority of the flying is done by the aircraft itself – including landing. By way of example, auto-land technology has been around since 1968, and I can’t remember anyone expressing any concern about this before getting on a plane. Likewise, we see driverless trains and an increasing number of machines on quarries that provide a level of autonomous service. These comments are in no way to ignore or play down potential safety concerns, but more to say that we have solved similar, difficult autonomy problems before and with an extremely high level of safety and can likely solve this one too.

Innovation is the future. There are exciting developments in hand and on the way – make the most of them.•

For more information, visit eltirus.com

Meet the XD Series of heavy excavators – designed to tackle the toughest challenges. From Australia’s best-selling heavy excavator brand, the SK380XD and SK500XD represent the pinnacle of Kobelco’s legendary reliability, fuel efficiency and productivity.

Featuring a rugged machine body, and reinforced boom, arm and undercarriage to conquer the most punishing of worksites around the world, these machines deliver the lowest total cost of ownership in class.

XD Series. Built for power. Built for reliability. Built to last.

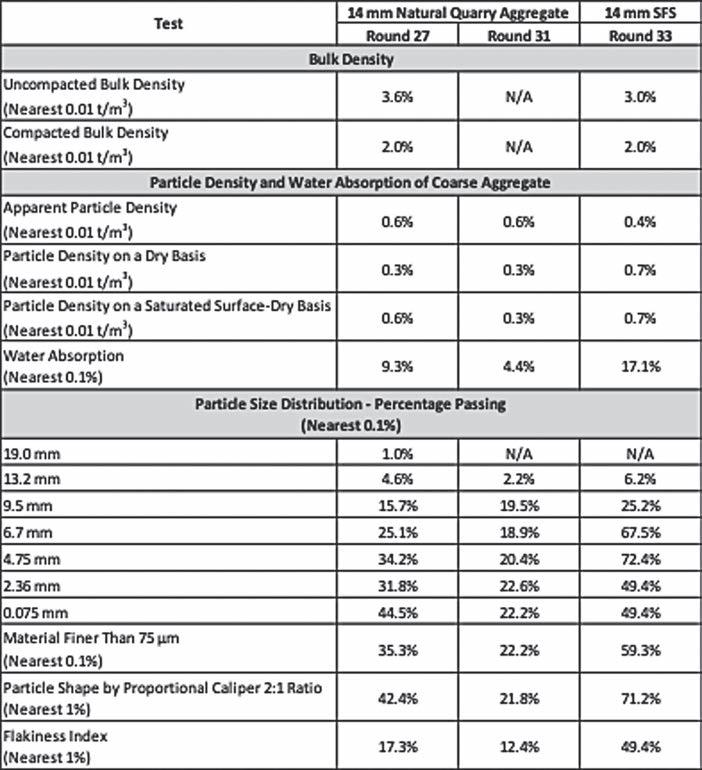

Shortages of quality natural sand are creating headaches for the concrete industry, but Kayasand believes quarries can provide the solution.

Sand remains a key component of concrete – but keeping up with demand is increasingly difficult.

In 2022, the United Nations Environment Programme (UNEP) called the global sand extraction rate “unsustainable”. The group urged for sand to be considered a “strategic resource” given its importance to construction and the environment.

“If we can get a grip on how to manage the most extracted solid material in the world, we can avert a crisis and move toward a circular economy,” Pascal Peduzzi, director of GRIDGeneva at UNEP, said at the time.

Not all sand is created equally, and the amount of sand required compared with the

Frank Grech, Kayasand’s national sales manager, told Quarry that there is another proven way.

“I have been in the industry for a long time,” he said. “When natural sand was readily available, there was no reason not to use it.”

“But now it’s getting much harder to access while demand is getting higher and higher. There’s also been a lot of publicity about the scarcity of quality natural sand, which is bringing it front of mind for people.”

Kayasand’s solution to the growing demand for quality concrete sand is its V7 engineered sand plants.

The specialist crusher and air screen technology was originally developed by

In fact, in a recent concrete trial with a normal Auckland mix design, sand engineered from Greywacke-based crusher dust was used to replace 100 per cent natural sand. The resulting concrete proved to be 24 per cent stronger and used 10 per cent less cement.

Grech said the final product is a concrete technologist’s dream.

“You don’t need to blend the product – it comes straight out, ready to go,” he said.

“That’s because we precisely control the shape and size of the sand particles, the levels of contaminants and consistency of the final product. Not only does engineered sand make the concrete mix stronger, but it also needs less cement to do it

Kayasand’s process can be meticulously controlled to meet certain specifications, if required. This also helps to improve the pumpability and finish of the final concrete mix.

In 2023, the company received a $3.5 million investment from New Zealand Green

The company has invited major aggregate suppliers to test out the plant to see if the

crushing technology could provide the right solution. One Australian supplier sent 40 tonnes of aggregate to the plant in New Zealand as a high volume trial.

Grech said Kayasand plans to expand across Australia and New Zealand.

“People are realising the full potential of what’s on offer, and that quarries play an important part in meeting the growing demand for concrete sand,” he said.

“The industry has been using concrete for a very long time. It allows builders to create versatile and durable structures – it’s even being used in 3D printing and precast construction.

“We want to help the industry innovate and believe quarries are part of the solution to meet the growing demand for concrete sand. We have the plant and equipment to help. Our technology is proven and it’s already out there in the market being used.” •

For more information, visit kayasand.com

Komatsu is known for its machinery but also makes reclaim feeders for the quarrying industry.

Reclaim feeders are proven technology used to process and transfer material off-site.

Reclaim feeders are suited for continuous haulage. Their adjustable flow gates enable materials to transition from loading to discharge, and operators use variable-speed drives to manage the material flow to a downstream area such as transportation.

Komatsu has designed its reclaim feeders to be ideally suited to the quarrying

sector, with a range of features and an advanced control system.

Quarry owners are constantly looking to reduce maintenance, material waste, and energy costs while maintaining productivity to a maximum level. As a result, Komatsu’s critical aim is to balance costs against productivity.

According to the company, its reclaim feeders have an average in-service life of more than 20 years. Komatsu has used steel

components in a simple and effective design to maximise the durability and reliability of the reclaim feeder.

The Stamler RF-5 reclaim feeder can accept pre-engineered bolt-on/plugin options and upgrades to maximise performance. It also features modern safety features for on-site operation to keep operators safe, including emergency stops, covers, guards and screens. These minimise the operator’s contact with moving parts during operation and maintain a high level of safety.

When Komatsu designed the Stamler RF-5 reclaim feeder, it kept this front of mind and ensured its advanced control system, the Komatsu LINCS II package, could provide the data to achieve this goal.

Operators can use the LINCS II interactive touchscreen display to access real-time information, including power consumption, component condition, conveyor speed, and

service intervals. The data is displayed in a customisable dashboard and graphs that can be tailored to the quarry’s goals.

Operators and quarry managers can use this information to adjust performance to suit the applications and conditions. They can use remote access to control the machine and check machine health through the onsite network using a tablet or smartphone.

As operators and quarry contractors look to more versatile machinery, mobility has become a key feature of many machines. Komatsu’s reclaim feeders are no different. They are designed to be transported from site to site and handle a variety of applications,

ranging from aggregates to limestone and sticky materials.

Komatsu’s versatile machines are suited to Australian quarries, offering reliability and flexibility. With Komatsu’s focus on minimising the total cost of ownership, quarries can now purchase efficient material handling equipment they can truly rely on.

Komatsu will participate in the IQA 2024 National Conference in Adelaide this October, providing a platform for customers to explore its range of reclaim feeder in more detail. •

For more information, visit komatsu.com/en-au

When mobility and toughness matter, count on the Lippmann 300c and 400c. These mobile cone crusher plants were specifically designed to take on the most abrasive and toughest materials in aggregates and mining — all with mobile capabilities. Heavy duty cone crushers with an innovative material flow that maximizes capacity and throughput while delivering a consistently high quality product.

• MC400 High Speed Cone Crusher

• CAT C18 Engine

• Direct Drive

• 250mm Feed Opening

T: 1300 859 885

E: sales@triconequipment.com.au www.triconequipment.com.au

Effective and efficient.

The MDS M515 Heavy Duty Trommel excels at crafting rip rap and reclaiming rocks entangled with clay and other adhesive materials. Comes complete with fold out stockpiling conveyors and has four hydraulic jacking legs to raise the machine to increase stockpile capacities and lower for transportation. See triconequipment.com.au or call 1300 859 885

Superior’s Telestacker® Conveyor is a material handler’s most effective weapon against costly stockpile segregation. Its variable height, length, and axle positions allow for layered stockpile construction, which is key to achieving partially and fully desegregated piles. The design has been carefully fine-tuned for hard work and dependability in numerous applications. Call Tricon on 1300 859 885 or see triconequipment.com.au

Quarry sat down with Andrew Rankin, quarry manager at Boral Wollert, to see how the XMOR bucket is performing after one year.

After more than 12 months with the unique excavator bucket, Boral Wollert quarry manager Andrew Rankin was clear on the performance of the XMOR Bucket from ONTRAC Group.

“I had some doubts initially, as with anything you trial, but it’s been really good,” he said.

“And it’s been on some of the hardest rock as well. While it’s been on some of the softer stuff when it’s been on overburden, some of the rock we’ve been dealing with and the conditions, it’s been dealing with a lot of oversize; it hasn’t been all good digging.”

Boral’s Wollert Quarry is located about 30 kilometres from Melbourne CBD. Its materials supply some of Victoria’s biggest projects, including the North East Link.

In the 2023 August edition of Quarry, Boral confirmed a 45 per cent increase in bucket capacity in cubic metres since switching to the XMOR Bucket.

“I can tell you that it is using less fuel, the operators feel more comfortable with that bucket on it than a standard bucket digging, it’s more productive – we’ve done the numbers on that and they still stand up. And it’s probably more productive, like I said, in overburden or bulk density material,” Rankin said

While the quarry has seen benefits from the XMOR in its hard rock activities, it has found significant advantages from the bucket when it removed overburden.

“When you’re bulk digging overburden, that’s when you notice the major benefits … that’s due to the density of the product. With the hard rock, we’re still getting more capacity [compared to] a standard bucket, but stuff like sand, clays, all those materials, that’s where you get the full bang for buck out of the weight of the bucket,” Rankin said.

Rankin said that shots can vary from brickette size to larger sizes on site at Wollert and confirmed that a good blast allows them to maximise the XMOR Bucket’s performance up to 40 per cent increase in tonnes per hour output as an isolated loading tool.

“The feedback from operators is still good. They haven’t got the drag through the rock, which is harder on operator and machine [because] with the XMOR Bucket on, you haven’t got the surface contact area on the bucket that you’re scraping over when you’re digging shot rock, so it’s definitely smoother,” he said.

“As soon as you put a traditional bucket on it or they get on another machine, they comment that the machine is working harder and it’s harder on them. If you look at ergonomics in a machine, some of those are all around an operator and how he feels in it, so that’s a win in itself.”

The XMOR Bucket’s unique inverted tub and heel segment design enables it to have a greater capacity than a standard bucket whilst also reducing downtime.

Rankin said that the XMOR Bucket when compared to a traditional bucket, does not shy away from anything that a standard bucket would do. “I would say it’s better, it’s just the repair I was concerned about over the long term, but it’s passing that test.”

“To be fair, I expected that we’d get repair work on that design and probably on the keel, that always seemed to me the place that we’d have issues, and it has, but nothing major.”

“There’s no wash, hardly any there, which that’s one of the benefits of that buckets as well, and usually you need 12 months to identify that”

Rankin has been happy that the bucket’s unique design has enabled it to maintain its increased capacity. Other buckets can require the addition of another skin, which reduces capacity and increases the bucket’s weight.

“Generally, repair work on a standard bucket is building a skin in, or you do something, and you reduce volume again and add more weight to it. So, it would be comparable or maybe a touch better in the overall,” he said.

This is due to the high-quality Hardox 500 Tuf and Strenx Performance steel, which delivers high performance while ensuring a lower weight and flexibility compared to

standard buckets on the market.

“I had a manager say to me, ‘Oh, it looks flimsy’ I said, ‘Yes, it’s not though, it’s around that design that the strength comes from’. If you just look at it, it does look light, but it’s proved itself, definitely here.”

“Again, the whole bucket, if you can buy in in parts, that’s great. We haven’t had to do a side or a floor in it yet, which is great, but we’ve had some minor repair work done in that area, which isn’t unusual.”

As an Australian-owned and operated company, ONTRAC Group is the exclusive manufacturer and distributor of XMOR Buckets in the country and has the capability to provide full support in its facility.

The XMOR bucket’s benefits are still holding true since Quarry last spoke to Rankin 12 months ago.

“It’s been really good. We’ve had no problems getting parts for it or anything like that, and that can be an issue when you try

something new, and that was something I thought about initially,” he said.

“But there’s been no problems with that.”

After seeing how well the bucket performs, Rankin has recommended the product to other quarry managers.

“Other Boral sites have called me and managers from New South Wales, and I have recommended it. Especially the sites with the lower abrasion rates and the like,”

Rankin said.

Rankin said he had no regrets about the purchase of the XMOR Bucket which had helped Boral Wollert’s operations.

“Cheaper is not always the best, I’ve always been a big believer in let’s measure apples with apples,” he said.

ONTRAC Group will be at the IQA 2024 National Conference in Adelaide from October 15–17. The company will have team members at its stall to discuss what the XMOR Bucket could achieve on a site. •

For more information, visit ontracgroup.com.au

Quarry learns how Kobelco’s biggest production-class digger is helping quarries improve their productivity.

Designing quarrying equipment to be tough is an important part of the job. After all, if machinery breaks down, production stops.

But the team at Kobelco knew its largestever production-class excavator needed to be more than just tough. It needed to survive the worst a quarry could throw at it.

Mark Johnson, Kobelco Australia’s general manager of product and distribution, told Quarry that the SK850LC-10 is designed for the harshest conditions.

“Kobelco manufactures excavators for markets around the world,” he said. “That means we needed to design the machine to handle some of the most extreme conditions out there.”

The SK850LC-10 soon proved it could handle the harshest climates around the world and was well suited for work sites across Australia. Kobelco saw great potential for the excavator in quarry applications.

“Quarries generally have an asset lifecycle in mind when they purchase equipment and want to know that the product they buy will remain productive and efficient for that entire life cycle,” Johnson said.

The SK850LC-10 features a 12.9L turbocharged and intercooled 380kW engine, which delivers impressive power to tackle heavy-duty applications. Powerful bucket breakout force and arm tearout forces let operators deliver fast digging cycle times and outstanding productivity.

The massive machine can climb stockpiles with ease, thanks to its class-leading 653kN of drawbar pulling force. Three heavy-duty track guides are also installed on each crawler side frame to further increase undercarriage durability.

But what Johnson said surprised quarry customers the most about the excavators was its fuel efficiency.

“The SK850LC delivers an impressive average fuel consumption of under 50L per hour—substantially boosting operating profit in a production environment,” he said.

“Compared to similar machines of this size, that’s potentially a saving of 20L of fuel an hour. When you consider these excavators will be working long days, week on week, that’s potentially saving customers hundreds of thousands of dollars a year just on fuel costs.”

An enhanced hydraulic system design minimises hydraulic pressure resistance to reduce energy loss. The SK850LC also features Kobelco’s latest cooling system – a hydraulically-driven twin fan engine cooling system.

This hydraulic version also prevents over-cooling by use of integrated sensors to reduce the speed of the twin-fan unit, helping to improve fuel economy and reduce noise. A variable-geometry turbocharger contributes to lower fuel consumption, and a new selective catalytic reduction system decreases NOx emissions by 80 per cent to provide low operation emissions.

The operator can also choose from three modes: H-mode, S-mode and ECO-mode— allowing for minimum fuel consumption while optimising digging efficiency.

From the comfort of the cabin, the operator can also pre-set multiple attachment settings. The SK850LC comes factory equipped with bidirectional primary auxiliary hydraulics, along with proportional hand-controlled tilt/rotate piping and quick hitch piping as standard.

Johnson said the SK850LC features best-inclass lifting and digging performance.

“With the 8.25m and 3.6m heavy-duty boom and arm, the SK850LC has an operating capacity exceeding 10.6 tonnes at a reach of 11.6m.

“The SK850LC is also available in a mass excavation specification, with a shorter boom and arm as well as an optional heavier 3000kg counterweight—for applications which call for maximum bucket capacity and digging productivity.

“The larger machine lets quarries move more material and uses less fuel, improving the bottom line drastically.”

Comfort is another key part of productivity. Operators who dread getting into the cabin are likely to perform worse, which is why Kobelco prioritises ergonomics.

Because there can be a lot of vibration on a quarry site, the SK850LC features an air suspension seat. Combined with a 25 per cent reduction in lever control force, operators face less fatigue during long hours

of operation, while added climate control outlets and a spacious cab interior provide a comfortable work environment.

The high level of pressurisation in the large, sealed cab keeps out dust and ensures a quiet environment for the operator. A standard 12V port and AUX jack are provided, while the standard Bluetooth-integrated stereo system allows the operator to stream audio.

The operator-friendly colour multi-display LCD screen uses easily recognisable graphics for quick navigation of important information, including fuel consumption and maintenance intervals. An intuitive one-touch attachment mode switch lets the operator confirm the proper configuration at a glance.

A falling object protective structure top guard along with a front window guard and swing flashers come standard for enhanced jobsite safety. In addition to the rear-view camera, an optional right-side camera can be fitted, for easy safety checks around the machine.

Johnson said maintenance is made easy to ensure the machines can get back to work as quickly as possible.

“The new and improved hydraulic fluid filter in the SK850LC is regarded as the best in the industry, with a new cover that prevents contamination even when changing filters,” he said.

“Pressure sensors at the inlet and outlet of the hydraulic oil filter monitor pressure differences to assess filtration performance,

triggering a warning on the cab display screen if the filter needs to be replaced.”

A standard onboard grease gun on a retractable reel makes greasing the SK850LC a fast and convenient task. Kobelco has also installed a standard onboard refuelling pump to make the process faster and safer.

To further improve machine uptime the SK850LC is equipped with Kobelco’s K-Assist system. This remote diagnostic and troubleshooting system allows local dealers to provide advanced support for the machine without a technician being present.

The system monitors key system operational data, which can provide real-time and historical monitoring of the engine and hydraulic systems. The system enables a

Kobelco dealer to perform diagnostic testing and upload machine software, significantly reducing potential machine downtime.

“Our dealers are second to none,” Johnson said. “We have a large footprint throughout Australia, with a presence in every state and territory,” he said.

“They have factory-trained technicians and access to our national parts division, with more than $20 million worth of spare parts available.

“Last year, Kobelco was the top heavy excavator supplier in Australia – it was an enormous achievement and we are striving to continue this growth.” •

For more information, visit kobelco.com.au

At Kinder, we understand productivity.

Our engineers are experts in innovation with the ability to design bespoke solutions and provide products to suit all conveyor applications.

Selected to increase your efficiency and reduce downtimeIf it’s above, around or below the belt, we have the answer.

Unlock your productivity potential. Visit kinder.com.au

From its beginnings in the Victorian goldfields to its international presence today, Orica’s journey has been driven by innovation and excellence.

Jones, Scott, and Company began selling explosives in the Victorian goldfields in 1874. While the gold rush is long past, their small company, now called Orica, is one of the world’s leading mining and infrastructure resources companies.

When it comes to legacy, Orica’s impact can be seen in spades. From innovating across the quarrying and heavy industries through to the build of Australia’s first skyscraper, and the world’s first lead-free detonator, Orica has a rich and impactful legacy.

Sanjeev Gandhi, managing director and chief executive officer for Orica, said the 150th anniversary was a “significant occasion” for the company.

“Orica’s legacy is built on the trust our customers and partners place in us, and the

operators, business specialists, and onsite crew to support customers in mining, quarrying, construction tunnelling, and many other sectors.

worked for Orica for 29 years. In his current role, he serves as the territory manager for Orica’s metals team.

as the Australian branch of the British-based Imperial Chemical Industries (ICI) following mergers with Nobel Explosives and then ICI. As a trainee MMU operator in ICI Quarry Services in 1995, Whackett was part of a team that had seven employees at Beenleigh. Now, the Beenleigh site has 50 staff, while Whackett looks after the operations of Orica’s Queensland and Tasmanian plants as well as its commercial contracts in those states.

within the company, he believes two things have turned it into an international success.

did those years go? I have always enjoyed working for Orica and I think that is why the time has flown past. I regret that I did not start earlier with them sometimes.”

1984 to 1987, and Michael Deeley are credited with influencing the company’s culture. They ensured employees were heard by executives, including initiating town hall meetings.

the company, Hampson credits the focus on employees with making the company more “customer-orientated,” as ICI Australia took great care of its customers.

Australia. ICI Plc sold 62.4 per cent of it in 1997 and then the following year sold its global explosive business to Australia. In 1998, ICI Australia was listed on the Australian Securities Exchange (ASX) as Orica.

These two moves created the foundations for Orica, which many people would recognise today as an international presence in mining, quarrying and many other sectors.

improve the efficiency of their drill and blast operations while reducing overall costs. It allows quarry operators to design blasts according to performance objectives and presents drill and blast insights for continuous blast optimisation.

According to Whackett, the company’s embrace of technology in its innovations has been a key to its current success.

“I think ANE-based bulk explosives and electronics have been the two big important innovations. ANE bulk explosives make loading blasts with wet holes a lot easier and quicker and produce more consistent results, rather than using ANFO (Ammonium Nitrate Fuel Oil) and packaged products, like we used to back in the day,” he said.

“Blast pattern expansion combined with using ANE, mean lesser drilling and lower costs. The timely accuracy with electronics makes it easier to comply with Environmental restraints which means we can do larger blasts at these quarries to reduce the cost for the customer.” 4D technology takes bulk explosives to a whole new level and has revolutionised how customers blast compared to conventional solutions. The 4D bulk system allows for a tailored application of explosive energy, adjusting to the specific geology of each hole. This customisation reduces bulk explosives consumption, optimises fragmentation, and supports compliance and licence to operate in environmentally sensitive areas.

Since becoming Orica almost 30 years ago, the company has grown to serve more than 100 countries worldwide and has a market capitalisation of $9 billion.

It is focused on working with its customers and stakeholders to help transition

to net-zero operations through the advancement of technology.

“I think Orica will keep growing, helped by all the digital offerings we have now and the innovation of wireless blasting with WebGen,” Whackett said.

Broomhead said the Orica’s milestone was a “testament” to the company’s values.

“As we celebrate 150 years, we look back at a story of resilience, innovation,

and the unwavering commitment of our people,” he said. “Orica’s 150th milestone is a testament to the company’s strength, adaptability, and ability to thrive in a constantly evolving business landscape.” Orica will be attending the IQA 2024 National Conference in Adelaide from October 15–17.

For more information, visit orica.com

• Throughput rates up to 2,500 t/h

• Used extensively in the cement, aggregate and recycling industries.

• Capable of handling material up to 3m³

• High reduction ratio.

• Designed for economic processing of soft, medium-hard or hard rock.

• Modular system

• Feed sizes up to 450mm

• Reliable production up 700 t/h

• Designed for economic tertiary crushing of hard rock.

• Modular system

• Feed sizes up to 150mm

• Reliable production up to 160 t/h

• Production of crushed stone fines and high-quality stone chippings.

Find out what innovative features Volvo’s range of articulated dump trucks use to improve safety and productivity.

In the high-stakes world of heavy-hauling and opencast mines, the performance and reliability of an articulated dump truck (ADT) can spell the difference between success and failure.

Recognising this, Volvo has designed its range of ADTs to meet the rigorous demands of off-road terrains while maximising haulers’ stability and payload capacity.

Volvo’s ADTs offer some of the highest payload capacities in their class. Its range of models from the A25G to the A60H provides diverse options tailored to meet specific operational needs, ensuring optimal performance across various applications.

Part of this performance is due to the trucks’ articulated design, which allows for better weight distribution across the axles. This enables the truck to carry more without sacrificing stability or manoeuvrability.

They also feature a robust chassis design, with a strong, durable frame that can handle heavier loads without compromising structural integrity. The body itself is optimised to maximise volume, while onboard weighing system technology ensures optimal loading for each cycle.

Volvo articulated dump trucks feature a robust drivetrain specifically engineered for heavy hauling. This includes a high-

performance, low-emission Volvo diesel engine with electronically controlled fuel injection, ensuring low emissions and high performance. The drivetrain components are meticulously matched and designed for hauler applications, optimising power, and efficiency throughout the work cycle.

The trucks contains several innovative features, including:

• A dynamic drive system that adjusts gear shifting strategy based on payload and slope gradient, automatically selecting the best gear for maximum efficiency.

• The Volvo engine brake system controls downhill speed without overusing the brakes, improving brake life, and enhancing safety.

• Adaptive suspension that automatically adjusts to payload and ground conditions, improving stability and comfort.

• No -slip, no-wear differential locks that can be fully engaged when necessary, ensuring excellent grip in all conditions.

• High ground clearance, allowing the truck to navigate rough terrain more easily.

Volvo’s ADTs are equipped with features that enhance the operator’s safety and

ensure the well-being of pedestrians and other site users.

For example, Volvo allows operators to set safe dumping parameters based on the truck’s side inclination, preventing potential tip-overs during dumping operations.