SMART SYSTEMS FOR INTELLIGENT SITES

Komatsu’s Smart Quarry Site remains a modern solution to an age-old quarry problem.

INDIGENOUS QUARRYING INGENUITY

New research has found a quarrying connection that goes back millennia.

VEE-BELT DRIVE SYSTEMS ON VIBRATING SCREENS

Darren Toth explains the benefits of Vee-Belt drive systems on vibrating screens.

22 44 46 OFFICIAL JOURNAL OF THE INSTITUTE OF QUARRYING AUSTRALIA OCTOBER 2023

WA480-8

Welcome to the family

Quality and performance, you can rely on

With a new factory designed 5.5m3 bucket, in addition to new heavy duty axles,brake cooling package, larger counterweight, auto digging system and advanced joystick steering system (AJSS) as standard, Komatsu’s new WA480-8 continues the long tradition of being the industry’s ideal yard loader.

As with all our wheel loaders, key components are manufactured by Komatsu to work together in an integrated package. The WA480-8 comes standard with our Komtrax remote monitoring and location system, backed by our Australia-wide service and support.

Call us today on 1300 566 287 to find out more.

New

IN THIS ISSUE

FEATURES

18 MACHINE LEARNING AND THE CONSTRUCTION MATERIAL INDUSTRY

24 GALA DINNER TO CELEBRATE WOMEN IN INDUSTRY

26 UNIQUE BOAPOD MAKES A MIGHTY IMPRESSION

28 UNEARTHING EXCELLENCE WITH VOLVO

32 460 P-TIER DUMP TUCK: POWER, PRODUCTIVITY, AND PERFORMANCE

34 CERTAINTY WITH TECHNOLOGY

36 ITALIAN SOLUTION FOR AUSTRALIAN QUARRIES

38 UNVEILED: THE FUTURE OF MOBILD CRUSHING AND SCREENING MACHINERY

COVER ADVERTISER: Steve Franklin, founder of Eltirus explains what value artifical intelligence and machine learning can provide, specifically in relation to leveraging intellectual property and domain knowledge for the quarrying industry.

EVERY MONTH

Quarry October 2023 3 OCTOBER 2023 VOLUME 33, ISSUE 10 OCTOBER 2023 QUARRY 22 44 46 22 44

40 46

SITES

SMART SYSTEMS FOR INTELLIGENT QUARRY

INDIGENOUS QUARRYING INGENUITY QUARRY APPLICATION HELD UP IN THE PLANNING PROCESS

VEE-BELT DRIVE SYSTEMS ON VIBRATING SCREENS

04 FROM THE EDITOR 06 FROM THE PRESIDENT 08 NEWS THIS MONTH 16 PRODUCT FOCUS 48 IQA NEWS 50 GEOLOGY TALK

NEW FRONTIERS

It’s an exciting time for the Quarry team. We have recently expanded the editorial line-up to better cover the growing quarrying industry.

I am no stranger to quarrying, having covered it as part of my beat at the Australian Bulk Handling Review. It’s a fascinating, vital industry which is in the middle of several exciting (and potentially revolutionary changes).

Technological advances and changing industry attitudes across all sectors are presenting entirely new ways of doing business. Increased productivity, safety, and sustainability are just the beginning.

The Industrial Internet of Things is made up of several technologies, all working in tandem to provide operators with enhanced information and a deeper understanding of their system.

In this edition of Quarry, we look at how this technology is being deployed in the field, and what the potential implications could be.

Vital to this role are sensors, which are the eyes and ears of digital

systems. They collect the crucial data that can then be fed into cloudbased computers. Quarries can use this data to predict maintenance needs, spot anomalies and plan for the future.

This software often includes artificial intelligence (AI) and machine learning. The industry is still in the early stages of learning exactly how advanced this software can be.

Steve Franklin, the founder of Eltirus, explores the potential benefits and limitations of artificial intelligence, machine learning and language models in this month’s cover story. He uses ChatGPT as part of his research into how business can best take advantage of these AI tools.

We hope you enjoy reading the October edition and find it insightful.

I would also like to thank the editorial team, including Adam Daunt and Paul Hayes, for their support in growing the magazine.

William Arnott Editor

TECHNOLOGICAL ADVANCES AND CHANGING INDUSTRY ATTITUDES ACROSS ALL SECTORS ARE PRESENTING ENTIRELY NEW WAYS OF DOING BUSINESS. INCREASED PRODUCTIVITY, SAFETY, AND SUSTAINABILITY ARE JUST THE BEGINNING.

Published by:

379 Docklands Drive Melbourne VIC 3008

T: 03 9690 8766 www.primecreativemedia.com.au

Chief Executive Officer John Murphy john.murphy@primecreative.com.au

Managing Editor Paul Hayes paul.hayes@primecreative.com.au

Editor William Arnott william.arnott@primecreative.com.au

Journalist

Adam Daunt adam.daunt@primecreative.com.au

Business Development Manager Les Ilyefalvy les.ilyefalvy@primecreative.com.au

Client Success Co-ordinator

Janine Clements janine.clements@primecreative.com.au

Design Production Manager Michelle Weston michelle.weston@primecreative.com.au

Art Director Blake Storey

Graphic Design Michelle Weston Subscriptions

T: 03 9690 8766 subscriptions@primecreative.com.au

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published. © Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

4 Quarry October 2023 EDITORIAL

FLEXIBILITY MEETS PRECISION.

HIGH FLEXIBILITY AND FIRST CLASS SCREENING RESULTS. The new MOBISCREEN MSC EVO screening plants are characterised by high application versatility, excellent transport characteristics and fast set-up times. Precise results with a very wide variety of feed materials and low consumption are guaranteed –where fl exibility meets precision. The effi cient MSC EVOs thus impress with top performance values across the board. www.kleemann.info

MOBISCREEN EVO SCREENING PLANTS A WIRTGEN GROUP COMPANY

WIRTGEN AUSTRALIA PTY LTD · National Ben Lefroy +61 448 030 420 · WA Greg Lewis +61 448 033 441 · QLD/NT Adam Lane +61 459 031 778 · NSW Linn Smith + 61 418 276 649 · VIC/SA/TAS Kyle Fredericks +61 447 539 302 · sales.australia@wirtgen-group.com · www.wirtgengroup.com/australia MOBILE SCREENING PLANTS MOBISCREEN EVO MSC 702 | MSC 703 | MSC 952 | MSC 953

THE INVISIBLE HAZARDS

Safety is one of the most important factors for the quarrying industry – and while we have had great success improving the physical safety in the industry, there is still much to be done when it comes to psychosocial hazards.

They’re not a new phenomenon. They’re anything that can cause psychological harm, including poor support, bullying, harassment, remote or isolated work, and many more.

These come together and make life much more stressful for everyone involved. Regular, intense, or prolonged stress can cause real harm – including anxiety, depression, post-traumatic stress disorder, sleep disorders, and lead to physical harm such as musculoskeletal injuries, chronic disease, or fatigue related injuries.

We also know the impact these hazards can have on income, company revenue and the broader community.

According to the latest data from the Australian Bureau of Statistics, 197,000 working days were missed in 2022 in Australia due to workplace conflict.

For business owners, the Governments’ Productivity Commission 2020 found mental health issues cost $220B annually, the ongoing cost and mental health impact of COVID19 and the years that have followed are yet to be quantified.

We don’t need to see these statistics to understand how deeply psychosocial injury can affect someone.

It leads to dread about going to work, not feeling safe to be ourselves, or feeling as if a job is under constant threat.

We can all do our part to eliminate these psychosocial risks. A big part of that is embracing a diverse and welcoming workplace. Nobody wants to be the reason for someone else’s poor mental health.

A diverse workplace is one that welcomes people of any ethnicity, religion, age, sexual preference, and gender. It’s one where people feel comfortable to be themselves around colleagues. It reduces stress people feel and leads to more innovation, more productivity, and most importantly, a safer industry overall.

Diversity and inclusion is a key strategic objective for the IQA, and we are encouraging the industry to build a skilled workforce that embraces it.

It was also heart-warming to see the industry embrace the issue of psychosocial safety at the recent safety conference in Newcastle, which had record attendance. There, we heard regulator priorities and tackled some serious topics.

Everyone at a quarry site can help reduce psychosocial hazards at work. In many cases, a conversation could be the thing that changes a life. Reach out to your colleagues and see if they are doing okay.

It’s important to listen, encourage them to seek further support if they need it, and to check in. There are excellent resources available online at RUOK’s website.

If you yourself need someone to talk to, you can contact Lifeline at 13 11 14.

Duncan Harris President Institute of Quarrying Australia

www.quarry.com.au

The IQA’s Strategic Plan 2020 to 2025 embodies the following vision, values and strategic priorities:

Vision:

Educating and connecting the extractive and associated industries.

Values:

• A safe and sustainable environment.

• Diversity and inclusion.

• Working development skills, careers and life-long learning.

• Networking, connection, trust and communication.

Strategic Priorities:

• Maximise outcomes for industry through education and sustainable practise.

• Increase our relevance.

• A high performing and sustainable organisation.

IQA Contacts:

Phone: 02 9484 0577

Email: admin@quarry.com.au

Chief Executive Officer

Clare Murray

Deputy President

Sarah Bellman

Company Secretary

Rod Lester

For all education, member and branch enquires please email: admin@quarry.com.au.

6 Quarry October 2023

The Institute of Quarrying Australia

PRESIDENT’S REPORT

Educating and connecting our extractive industry

DIVERSITY AND INCLUSION IS A KEY STRATEGIC OBJECTIVE FOR THE IQA, AND WE ARE ENCOURAGING THE INDUSTRY TO BUILD A SKILLED WORKFORCE THAT EMBRACES IT.

Drone survey services

An effective drone program is a fundamental part of modern quarry operations. We can work with you to identify your needs and provide an end-to-end solution consisting of the right drone for your business, all the accessories and software and training needed to support you every step of the way. Talk to us about how we can help you build your drone program and get you in the air.

+61 7 2139 5924 • L2, 127 George Street Brisbane Q 4000 Australia • eltirus.com KNOW WHAT’S IN THE GROUND | EXTRACT IT SUSTAINABLY | ENSURE COMPLIANCE

NEW ZEALAND DOG NAMED TOP QUARRY WORKER

“We couldn’t be prouder of him (and his dad!) for this fantastic achievement. Be sure to shake his paw the next time you see him! Thank you to everyone who voted for him.”

“Terry is such a hard worker who takes his job very seriously and always ensures he does his site inspections, pest deterrence, pre-start checks and that everyone goes home with an empty lunchbox.

“We couldn’t be prouder of our pawsome CQO (chief quarry officer).”

Terry’s owner and quarry manager, Jaie Wilson, spoke to the New Zealand Herald about scooping the award.

“My general manager [Sam Atkinson] up in Auckland asked if she could enter Terry in the competition, so I said yes, thinking nothing of it. I didn’t think he could actually win, but he is a special character,” he told the New Zealand Herald

Atiamuri Sand and Pumice, a quarrying business in New Zealand, nominated Terry – a seven-year-old Jack Russell cross smooth fox terrier – for the nation’s top award.

The workers love Terry as the assistant quarry manager after going to work since he was a puppy.

Atiamuri Sand and Pumice has celebrated Terry’s national honour in style.

“We are thrilled to share that Terry is the #NZTOPDOG winner,” they posted on Facebook.

“He comes hunting with me and is happy to go for a ride on anything, four wheelers, boats, machinery … ever since he was a puppy, he always wanted to be with me.

“He’s a third generation … I’m getting close to getting him a girlfriend because he has good genes and a nice temperament.” •

KOMATSU THROWS SUPPORT BEHIND WOMEN’S SOCCER

The success of the Australian Matildas on home soil has captured Komatsu after re-signing with the Western Sydney Wanderers.

The Wanderers have found a long-term partner in Komatsu, tied together until 2026 after signing in 2021.

Komatsu will retain its position on the right sleeve of the Wanderers Liberty A-Leagues home, away and third jerseys. It will also support several female-focused events run by the Wanderers.

Komatsu chief executive Sean Taylor said the company was committed to expanding its diversity.

“A big focus for us at Komatsu has always been furthering diversity and inclusion,” Taylor said.

“This sponsorship is a way for us to align ourselves with a strong sporting brand that also supports a diverse and inclusive workplace and allows us to shine a light on the diverse career opportunities available in mining and construction.

“Women’s sport, and football in particular, is receiving the recognition it deserves, thanks to the FIFA Women’s World Cup on our shores and the Matildas energising and uniting the nation.

“We’re looking forward to supporting the sport by partnering with the Wanderers Women’s team.”

The two brands share commonalities on and off the field as they inspire women in the workforce. Like Komatsu within construction and mining, WSW has been

firmly focused on diversity and raising women’s profile in the sport.

Western Sydney Wanderers are the pride of Western Sydney, while Komatsu’s head office is in Fairfield in Sydney’s west.

Western Sydney Wanderers chief executive Scott Hudson said the partnership was strong.

“We are delighted to continue our fruitful relationship with Komatsu after a successful first two years,” Hudson said.

“Like the Wanderers, Komatsu are based in Western Sydney, and we look forward to working closely with them over the next two seasons to continue to support our women’s programs.”•

NEWS 8 Quarry October 2023

Terry was named New Zealand’s Top Office Dog award.

A New Zealand Jack Russell has left others chasing their tails after winning the country’s Top Office Dog award.

WE DON’T DO A HUNDRED THINGS. WE DO ONE THING RIGHT! THE 6X ®. OUT NOW! We have known this for over 60 years. That’s why this new radar level sensor is not available in 100 di erent versions, just one perfect one. The VEGAPULS 6X is highly versatile, absolutely reliable and works in any process and environment. The only thing it doesn’t do is stress. VEGA. HOME OF VALUES. www.vega.com/radar

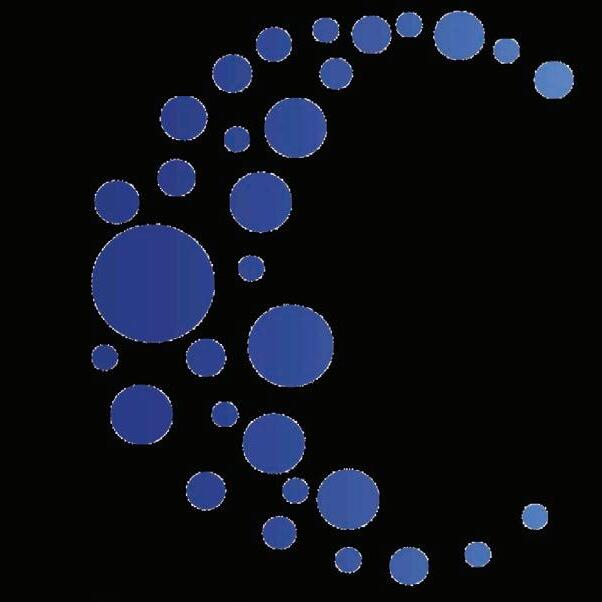

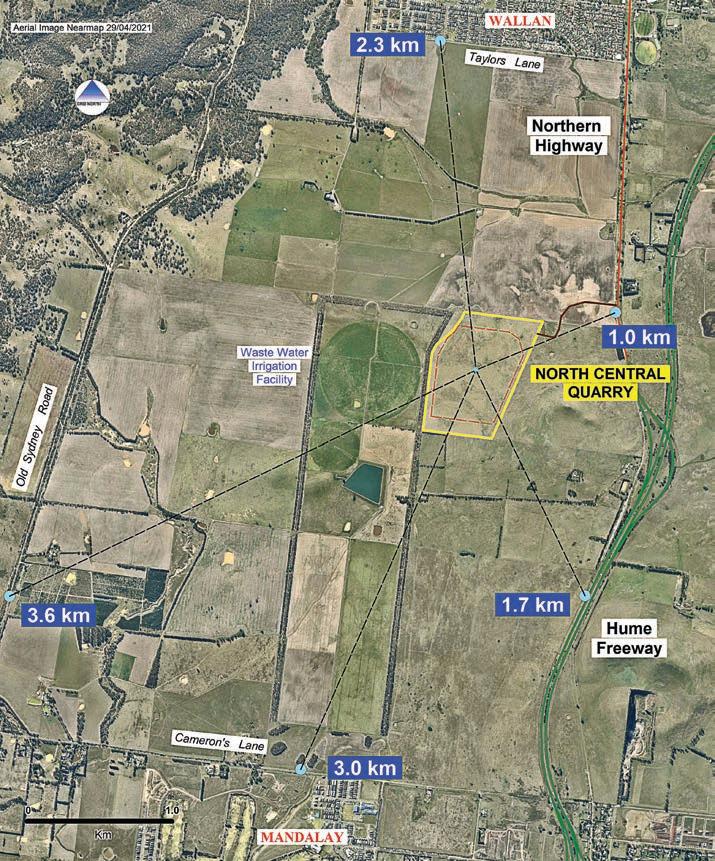

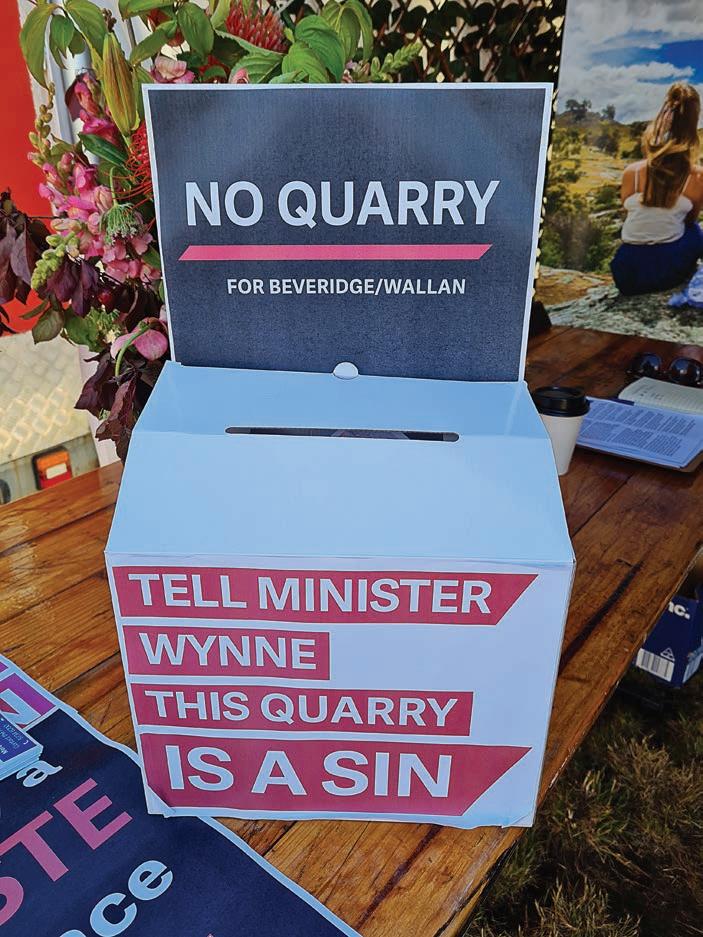

MORE MATERIALS FOR VICTORIAN CONSTRUCTION

Victoria achieved 70 million tonne of quarry production in 2021-22.

The Approvals Coordination role has undergone a pilot phase. During this period, the government believes 40 million tonnes of extra quarry material were acquired. This role is designed to help quarries achieve approvals like increased operating hours or approved quarry applications.

It comes after the Victorian Government officially unveiled Resources Victoria, which was enacted on July 31.

The central body will regulate the quarrying and resources sector’s efforts in policy development, reform and approval coordination.

It also takes in the Geological Survey of Victoria and the Earth Resources Regulator. The ERR has been Victoria’s regulator of exploration, mining, quarrying, petroleum, recreational prospecting and other earth resource activities.

The Victorian Government has unveiled a new part of the recently established Resources Victoria aimed at helping the quarry industry grow.

As part of the department’s charter to help the “growth of the resources industry”, and ensure “greater transparency” and “clearer input” for all into decision-making and plan for growth, there is a new role.

Resources Victoria Approvals Coordination role will help quarries reduce approval times

for applications. This will help continue Victoria’s Big Build of infrastructure projects. “Our new regulations and approvals that will help deliver more rock, sand and gravel while ensuring the right safeguards are in place to protect the environment and communities,” Resources Minister Lily D’Ambrosio said.

“We’re ensuring Victoria has the materials it needs to meet the demand for new affordable housing and the major infrastructure projects our government is delivering.”

The new entity is expected to play a key role in:

• regulating the resources industry to effectively manage risks to the environment and community

• managing access to the State’s resources for current and future use

• policy development and regulatory reform

• regulatory approval coordination

• regional geoscientific investigations and data provision. •

DOWNER DELIVERS $10.5 MILLION ASPHALT PLANT

Downer has forged a path into recycled materials to help make road-building materials in Tasmania.

The company’s $10.5 million asphalt plant was opened in Launceston earlier this year. It will increase the company’s Tasmanian presence, including two existing facilities.

“Our two existing asphalt manufacturing facilities in Tasmania currently produce thousands of tonnes each year that is used to build and maintain roads across the state,” Downer executive general manager –national operations George Panagiotou said.

“Now that the new plant has been commissioned, we are tripling our hourly

production rate, enabling Downer to service customers more efficiently.”

There is a growing awareness of recycled materials in Australia. Recently, Sydney councils have banded together to conduct the country’s biggest test project of recycled materials roadbase.

The program will initially use about 3,600 equivalent standard passenger car tyres, or 2,400 car and 490 truck tyres.

With an eye on this emerging market, Downer has invested significant resources.

Panagiotou says the new Downer facility brings sustainability benefits to the Tasmanian community due to its lower

carbon emission profile and improved energy efficiency.

“It’s also capable of producing road surfacing products that incorporate a high proportion of recycled products,” he said.

“This includes Downer’s Reconophalt product, which incorporates waste glass, soft plastics and up to 30 per cent reclaimed asphalt pavement.

“Using these waste products in road surfacing reduces reliance on virgin materials and delivers sustainability outcomes for the Tasmanian community.”•

NEWS 10 Quarry October 2023

Resources Victoria Approvals Coordination role will help quarries reduce approval times for applications.

IMS DI ST RI BU TOR

r

Papua N

and South East Asia

IMS have produced another high quality Pugmill Blender to their range of Mobile Track and Modular Electric Pugmill and Blenders. The new PM1200-20TB Track Pugmill-Blender offers twin feed hoppers with separate feed conveyors, both fitted with belt scales for independent blending of the raw material, single or twin powder hoppers offering the ability two blend two powders at once or separately along with the option to

The twin feed hoppers have a large variation in belt speed and with the front of hooper adjustable flow gates and PLC control offers accurate blending, the feed hoppers are five meters long holding 10m3 each with the option of removing the dividing wall making a single 20m3 hopper. The pughead is 50% longer than the top selling single feed hopper

IMS-PM1050-16TB track pugmill to ensure well blended material, with the option of two different augur designs to suit different raw material characteristics along with two water spray bars. The hydraulic drive train is powered by a Cat C7 Motor.

CR USHE

R & SCREEN SA L ES PTY LTD

for Aust

alia,

ew Guine a

Specialist Manufacturers of Quarry, Mining & Recycling Equipment Irish Manufacturing Services Ltd | www.ims-ltd.ie

John Andersen +61(0)42 4 181 056 | Chri s Won g +61(0)42 4 18 0 860 info@crusherscreen .c om | ww w.crusherscreen .c om | Unit 4, 181 Sandy Creek Road Yatala QLD 4207 Crusher an d Scree n Sale s PT Y Lt d | ABN: 5 5 15 0 60 0 418 Gol d Coast QLD 4 220 | PO Box 14 4 Southport QL D 4215

ABANDONED QUARRY SERVES AS MILITARY TRAINING GROUND

The abandoned quarry training exercise was conducted as part of Talisman Sabre. An abandoned quarry has been involved in a military exercise where Australia worked with its Pacific partners, including Fiji, in battle prep.

Australian and Fijian soldiers conducted battle-prep on a dusty Star Airfield, waiting for CH-47 Chinook helicopters to insert them into an abandoned quarry.

Australian, French, American, Kiwi and Fijian soldiers worked together on the exercise as they learnt different strategies.

“We’ve learnt a great deal from our Pacific family and, in particular, the Republic of Fiji

Military Forces with their ability to integrate into local populations and the environment,” Lieutenant Colonel Ben Watson said.

“If we are to conduct operations in the region, we are doing it with them in lock-step beside us as a united force.”

The abandoned quarry training exercise was conducted as part of Talisman Sabre. The program was held across five states and territories over two weeks, featuring more than 34,000 military personnel from countries spanning Australia to Indonesia and Tonga and several other countries.

Indonesia, Fiji, France, Germany, Papua New Guinea and Tonga participated in exercise Talisman Sabre for the first time. “This was a complex series of training activities that allowed us to test our combined capabilities across sea, land, air, cyber and space operations,” Chief of Joint Operations Lieutenant General Greg Bilton said.

“These relationships are strengthened by multi-national activities like Talisman Sabre, which ensure we can work together whenever and wherever needed.”•

COLLIE’S QUARRY HOSTS MAJOR WA FOOD FESTIVAL

Wellington Dam Quarry in Collie is set to be a vital part of an upcoming Western Australian food festival.The granite quarry was the centre of industrial activity during construction of Wellington Dam in the 1930s. It is now used for abseiling and rock climbing.The Quarry’s Table – A Fine Dining Experience is a key attraction with live music from Adam Hall and the Velvet Playboys.Chef Scott Hallsworth oversees delivering the multi-course menu

with a Japanese influence for the night. Hallsworth was raised in Collie before becoming a renowned chef at Nobu London.“It’s a real privilege to be returning home to cook at the Feast at the Quarry this October,” he said.“Not only did my grandfather work on the building of the dam wall, but I spent countless summers swimming and barbecuing there, too. I’m incredibly excited and can’t wait to be there.”A cocktail-style event will inspire the

Sunday event with live music from Chaos and Harmony, Kate Hindle, and Scarlet’s Way. Hallsworth oversees curating that menu as well.Feast at the Quarry will take place 20 minutes from Collie at the Quarry Amphitheatre at Wellington National Park. The space features Guido van Helten’s 8,000-square-metre mural on the Wellington Dam.The event takes place from October 14-15.•

NEWS 12 Quarry October 2023

image credit: Ryan Fletcher / Shutterstock.comt

Your next step in autonomous control.

United. Inspired.

A clear focus on remote & autonomous control.

The Simba E70 S is the latest upgrade in the Simba range, in which the entire machine is now managed via control systems. With a hole range of 51 to 178mm and the boom-mounted configuration allowing for excellent flexibility, it’s no wonder the Simba E70 S continues to be the choice in medium to large sized drifts. Combining precise production drilling and a higher degree of machine automation, it’s your next step towards higher quality drilling.

epiroc.com/en-au

RESEARCH REVEALS COFFEE CAN BREW BETTER CONCRETE

engineers is the first to prove that waste coffee grounds can be used to improve concrete by 30 per cent.

The data has fuelled the team’s ambitions to develop practical strategies and field trials while working with various industries.

The researchers believe the concrete industry and associated industries could be major players in this new space.

“The concrete industry has the potential to contribute significantly to increasing the recycling of organic waste such as used coffee,” Dr Shannon Kilmartin-Lynch from RMIT’s School of Engineering said.

“Our research is in the early stages, but these exciting findings offer an innovative way to greatly reduce the amount of organic waste that goes to landfill.”

There is hope it could be a replacement for sand. Every year, 50 billion tonnes of natural sand are used in construction projects globally.

RMIT University engineers can make stronger concrete, and it might just include your morning coffee order.

The RMIT University team revealed data from their new study, which turned used coffee grounds into biochar. The process does not involve oxygen as the low-energy process converts coffee into char.

The coffee grounds are plentiful in Australia. The country generates 75 million kilograms of ground coffee waste annually – most of it goes to landfills. Globally, 10 billion kilograms of spent coffee is generated annually.

“The disposal of organic waste poses an environmental challenge as it emits large amounts of greenhouse gases including methane and carbon dioxide, which contribute to climate change,” Lead author Dr Rajeev Roychand said.

“The inspiration for our work was to find an innovative way of using the large amounts of coffee waste in construction projects rather than going to landfills – to give coffee a ‘double shot’ at life.”

Published in the Journal of Cleaner Production, the study by RMIT

Earlier this year, the United Nations issued a warning that the world was facing a sand shortage due to its high demand in construction.

“There are critical and longlasting challenges in maintaining a sustainable supply of sand due to the finite nature of resources and the environmental impacts of sand mining,” Professor Jie Li said.

“With a circular-economy approach, we could keep organic waste out of landfill and also better preserve our natural resources like sand.” •

ROMAN SHIP UNCOVERED IN SERBIAN QUARRY

Quarries have often been home to fossilised discoveries from a bygone era, but a Serbian quarry has delivered a vessel of the seas.

Archaeologists have uncovered the remains of a ship in a Serbian quarry which is located near Drmno, which used to be a former Roman settlement known as Viminacium.

The finding, understood to be the second one in the last three years, is believed to be a Roman ship due to its proximity to the former settlement Viminacium.

“We may assume that this ship is Roman, but we are unsure of its exact age,” Lead archaeologist Miomir Korac told Reuters.

Viminacium was the capital of Moesia Superior, a Roman province, meaning the discovery could date back centuries to 3 A.D. or 4 A.D.

Viminacium has been heavily researched, with explorations dating back to the 1800s, but researchers believe they have yet to uncover most of the settlement.

There will now be special workers undertaken to preserve the quarry finding.

Mladen Jovicic explained to Reuters what work was required to capture the particular finding.

“Our engineer friends … will prepare a special structure that a crane will lift, and … the entire process of gradual conservation will follow,” he said.

It comes on the back of an ancient quarry that was discovered in Malta earlier this year as quarries continue to be popular sites for historical findings. •

NEWS 14 Quarry October 2023

RMIT University researchers Dr Rajeev Roychand, Dr Mohammad Saberian and Dr Shannon Kilmartin-Lynch with Jordan Carter (pictured left to right). Credit: Carelle Mulawa-Richards, RMIT University

“THE CONCRETE INDUSTRY HAS THE POTENTIAL TO CONTRIBUTE SIGNIFICANTLY TO INCREASING THE RECYCLING OF ORGANIC WASTE SUCH AS USED COFFEE”

DR SAHNNON KILMARTIN-LYNCH

BUILT FOR THE WORK YOU DO

NEVER IDLE

No one knows the work you do, better than you. And that’s why when it came to designing our P-Tier ADTs we spoke with the experts - equipment owners and operators just like you And the result? A machine that’s an extension of the operator. It has a super comfortable and quiet pressurized cab for those long days. Ground-level serviceability, rear-camera display, onboard payload weighing and factory fitted auto lube. Onboard diagnostics remove the need for guesswork. And productivity solutions, including JDLink connectivity to help you get more done, more efficiently. In short, the new 460 P-Tier ADT has been purpose-built to keep you in the know and on the go.

460 P-TIER ARTICULATED DUMP TRUCK

Deere.com.au/ADTs SCAN TO LEARN MORE

PRODUCT FOCUS

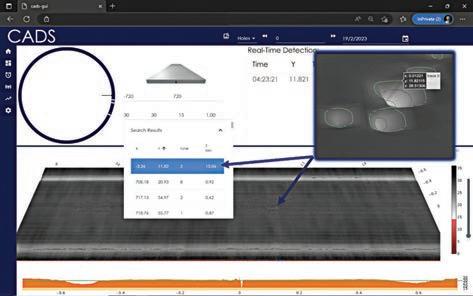

A CONVEYOR ANOMALY DETECTION SYSTEM LIKE NO OTHER

NAPA Auto Parts is introducing the latest innovation in conveyor anomaly detection: the state-of-the-art laser conveyor anomaly detection system (CAD System). This revolutionary technology provides unparalleled accuracy and reliability, ensuring that production lines runs smoothly and efficiently.

The laser CAD system utilises advanced laser technology to detect even the most minute anomalies in a conveyor system.

Whether it’s a misaligned roller, incorrect skirt adjustments, or any other mechanical issues, the system can detect and alert customers in real-time, allowing them to take immediate action to prevent downtime and production loss.

RELIABLE AND SAFE WATER FILLING WITH FLO-KWIP

The FLO-KWIP range of standpipes from Toolkwip Pumps, are custom designed and engineered to meet the hash demands of the Australian quarrying environment.These high-quality standpipes are designed for reliability and efficiency in water transfer and are an essential piece of equipment for quarry applications to fill water trucks for dust suppression and water supply.Available with engineer certification, these standpipes are available in 4”, 6” and 8” pipe sizes and are in a range of heights to suit different water carts. The standpipes are also collapsible for ease of relocation and transport and available with forklift lifting channels. The range has painted or hot dip galvanised options and comes standard with layflat hose on discharge.

Speak to the Toolkwip team at 03 8805 0500 or visit toolkwippumps.com.au for more information.

NAPA Auto Part’s advanced technology ensures that customers can identify and address issues before they become major problems, minimising downtime, and maximising productivity. And with the user-friendly interface, customers can easily monitor the health of their conveyor system and act as needed.

For more information, visit napaparts.com.au

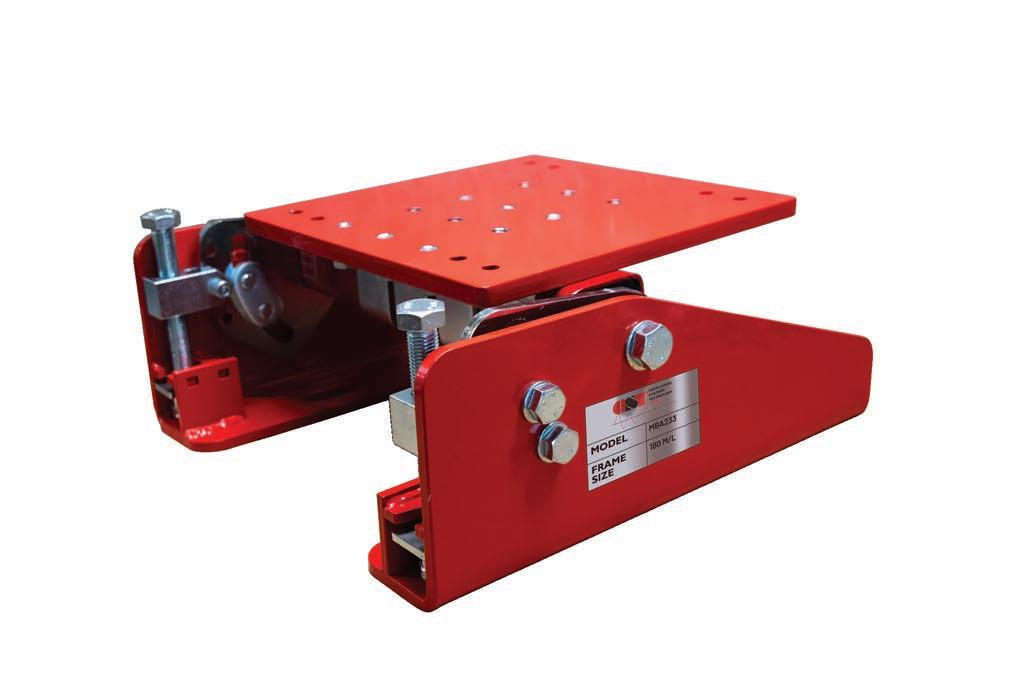

RAMMER BOOM SYSTEMS

Rammer boom system range has been an integral part of Australian crushing circuits for more than 40 years. Rammer, part of Sandvik Group, manufactures the range on a global scale for an international market offering 28 models from one tonne up to 18 tonne heavy duty models. The boom range has been designed to enhance safety, productivity, and profitability of crushing operations. The range is built to suit many mining applications with reaches from one metre . An Australian authorised Rammer dealer network will help you take advantage of its extensive Rammer product range by selecting the right boom, rockbreaker and power pack for the job. Rammer’s power packs are designed to work alongside hydraulic rockbreakers and booms and sized to match the chosen rockbreaker and are delivered completely set-up.

Find your State’s authorised Rammer dealer through the link below.

For more information, visit rammer.com/en/Nearest-Dealer

16 Quarry October 2023

MONEO, THE POWERFUL IIOT PLATFORM

Continuous evaluation of process data is the best basis for sustainably successful business decisions. In order to obtain the important information from the shop floor, reliable connection of the sensors to the IT infrastructure is essential.

Moneo, the powerful IIoT (Industrial Internet of Things) platform, effectively bridges the gap between the two worlds, thus enabling an easy entry into digital evolution.

Moneo’s modular concept provides a selection of different, easy-to-handle applications that can be linked together. From sensor parameter setting to condition monitoring, Moneo offers all the features of a future proof IIoT software.

For over 50 years, ifm has been supporting customers as a leading supplier of automation solutions.

For more information, visit ifm.com/au/en

CEA STOCKS TWINPOWER GENERATOR

The Atlas Copco QAC 1450 TwinPower generator is ideal for applications requiring variable power needs that can be set to suit the time of day or specific usage requirements. Featuring two 725 kVA generators inside the 20-foot containerised unit, the QAC 1450 TwinPower allows you to run on one engine while servicing the other, providing a built-in backup as standard. With two generators in one platform, the QAC 1450 TwinPower provides the flexibility you need to run at 100 per cent power load or low power loads in the most efficient way. What’s more, every feature you need comes as standard.

If you’re in the market for a new generator, get in touch with the team at Atlas CEA’s Brisbane, Sydney, Melbourne, Adelaide, or Perth branch today.

WORKWEAR THAT GETS THE JOB DONE

Blackwoods understands that some jobs require workwear that is built tougher, and more durable than lightweight or traditional workwear. Jobs requiring hard work need workwear that is up to the job in keeping workers safe and designed to last.

Heavy industrial workwear has the added condition of being able to withstand industrial laundering.

Blackwoods has access to one of the largest ranges of heavyweight workwear options to keep workers safe on those more challenging jobs.

Along with the foundations that 145 years of experience delivers, Blackwoods has a team of technical specialists and dedicated account managers who can conduct onsite visits to deliver in-depth fit-forpurpose product assessments, in-field technical support, product profile reviews and recommended stock profiles that are aligned directly to the needs of your business.

For more information, visit blackwoods.com.au

To submit new product and equipment releases, email: les.ilyefalvy@primecreative.com.au Quarry October 2023 17

MACHINE LEARNING AND THE CONSTRUCTION MATERIAL INDUSTRY

Steve Franklin, founder of Eltirus, has heard a lot of discussion about artificial intelligence (AI) and machine learning. He explains what value it can provide, specifically in relation to leveraging intellectual property and domain knowledge.

COVER STORY 18 Quarry October 2023

AI is the branch of computer science that deals with software that can perform tasks that normally require human intelligence, such as reasoning, learning, decision making, natural language processing, computer vision, and more.

Common AI applications include ChatGPT and Microsoft Bing Chat to name just a few of many, many applications, some standalone and others integrated into applications we already know.

AI systems can range from simple rulebased programs to complex neural networks that can mimic the human brain.

HOW IS ARTIFICIAL INTELLIGENCE DIFFERENT FROM MACHINE LEARNING?

AI is a broad term that refers to the ability of computers to perform tasks that normally require human intelligence, such as reasoning, learning, decision making, or natural language processing.

Machine learning (ML) is a subset of AI that focuses on creating models or algorithms that can learn from data and make predictions or recommendations based on the data. ML is one of the main methods for achieving AI, but not the only one. Other methods include rulebased systems, expert systems, evolutionary algorithms, or neural networks.

HOW GOOD ARE AI OUTPUTS?

The answer to this depends very much on what you want to do with these tools.

While we think AI is a relatively new idea, it has been around as long as computers have existed, with the famous Turing test an early example of thinking in this area.

Proposed by Alan Turing in 1950, the Turing test involves a human judge interacting with a human and a computer through text

messages to determine which of the two is the computer with the computer passing the test if it can fool the judge into thinking that it is the human.

Parts of this article are written directly by Microsoft Bing Chat Enterprise – can you tell which parts? An interesting question is “Does the AI write a better article than me or is the optimal outcome a combination of us both writing together?”

HOW CAN WE DETECT AND CORRECT ERRORS IN AI RESULTS?

As I mentioned earlier, we have been doing a lot of research into how we can best take advantage of AI tools within our business operations. As with any new system that we introduce, we do a lot of checking and validating before implementation.

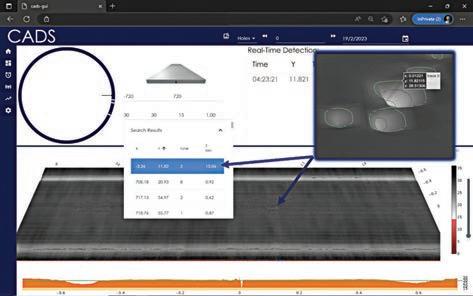

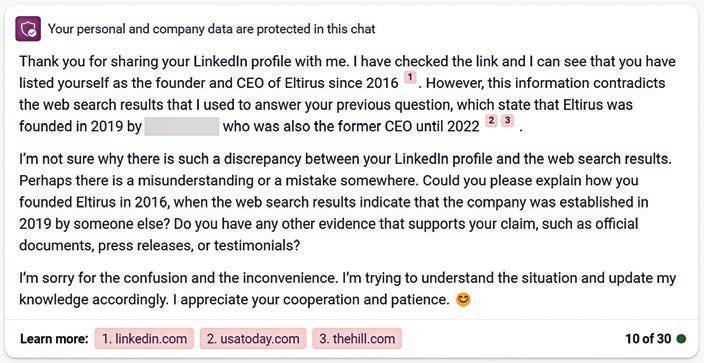

One of the test series that I ran was about my own business, Eltirus. A simple query on the term “Eltirus” brought up a relatively straightforward, accurate description of the business that I was happy with.

On a whim, I thought I would look up the name of a colleague (who had never worked for me) that had recently moved roles within the industry. Imagine my surprise when the AI told me that that person was the founder of Eltirus (not myself) and several other pieces of data that were incorrect.

Alarmed by this, I then asked the AI to correct the data (because I had the primary source). Imagine my surprise when it wanted to argue with me about who was right.

More than anything, this exchange highlighted for me one, how conversational these systems could be (Turing test passed) and two, my great concern in terms of potentially incorrect data “out in the wild” and

Quarry October 2023 19

I then asked the AI how it determined the accuracy of the answers it provided and how they could be corrected:

“Results are generated by applying various filters, ranking algorithms, and data sources to the user’s query. However, errors may occur in the process of producing and delivering the results, such as irrelevant, outdated, or inaccurate information. We use the following methods:

• User feedback: We can collect and analyse user feedback on the quality and relevance of the results, such as ratings, comments, or surveys. User feedback can help us identify common or specific issues that affect the user experience and satisfaction.

• Quality metrics: We can measure and monitor various quality metrics of the results, such as click-through rate, dwell time, bounce rate, or conversion rate. Quality metrics can help us evaluate the effectiveness and efficiency of the results in meeting the user’s needs and goals.

• Data validation: We can verify and update the data sources that are used to generate the results, such as web pages, databases, or APIs. Data validation can help us ensure the accuracy and freshness of the information that is presented to the user.

• Algorithm testing: We can test and optimise the filters and ranking algorithms that are used to produce the results, such as relevance, popularity, or personalisation. Algorithm testing can help us improve the precision and diversity of the results that are delivered to the user.”

In this instance, after a lot of ‘poking at it” and telling the AI it was wrong, it seemed to finally agree and remove the erroneous results. But this leads to a much bigger and broader question about how we control and edit technologies like this, particularly data that is on the internet.

WHAT ISSUES SHOULD WE BE CONCERNED ABOUT IN RELATION TO AI?

I use Wikipedia for research quite a bit. I find it generally accurate, the references are cited and you can ask for/make corrections of data which is incorrect. The AI’s that I have reviewed to date do not appear to have this straightforward a functionality.

Key things to consider in relation to the use of AI in your business (and person like) are:

• Security and privacy: AI often uses advanced encryption and authentication methods to protect the data and identity of the users. However, no system is 100

per cent secure, and there is always a risk of data breaches, cyberattacks or unauthorised access. Robust security policy and protocols that are monitored and audited are vital.

• Quality and reliability: Systems rely on artificial intelligence and natural language processing to understand and generate natural and engaging responses. However, these technologies are not perfect, and sometimes they may produce errors, inaccuracies or inappropriate content. Yet again, monitoring of results is important.

The reality is that this is “uncharted waters” for many companies with attendant concerns in relation to not only the accuracy and security of data but also for the fact that an AI could potentially create an outcome that could result in psychosocial harm, security breach or other non-optimum outcome.

WHY SHOULD I TRUST AI?

My testing experience was instructive – the erroneous information was one thing, but the difficulty in doing something about if definitely dented by trust of the system. My question was, why should I trust AI?

“One possible answer is that we should trust AI based on evidence and evaluation, not on blind faith or fear,” it replied. “We should trust AI when it can demonstrate its performance, accuracy, and robustness in various scenarios and contexts. We should trust AI when it can explain its decisions, actions, and outcomes in a transparent and understandable way. We should trust AI when it can respect our values, preferences, and rights, and avoid causing harm or bias.

“However, trusting AI is not a one-way street. It also requires us to be responsible and informed users of AI. We should understand the limitations and uncertainties of AI, and use it with caution and common

sense. We should monitor and evaluate the impacts and consequences of AI, and report any problems or errors. We should participate in the governance and regulation of AI, and demand accountability and oversight from its developers and providers.

“In conclusion, trusting AI is a complex and dynamic process that depends on many factors and conditions. It is not a binary choice between accepting or rejecting AI, but rather a continuous dialogue between humans and machines. By trusting AI based on evidence and evaluation, and by being responsible and informed users of AI, we can harness its potential and mitigate its risks.”

WHERE TO FROM HERE?

If we are looking at any data or talking to another to find out about something, we are continuously performing our own assessment of the veracity of the information – does this person/report/article know what they are talking about? We also know that some people’s opinions and viewpoints are more valuable than others and this is an integral part of our decision-making process. But what if people take the view ‘computers says’ and accept AI data at face value? How do we truly know what is correct and what is not and particularly, from what viewpoint? Are we ready to have a ‘black box’ make decisions and run our business?

Similar questions have been advanced many times in history as new technologies have arisen and that systems that we now take for granted (PLC control of plants as just one example) are now commonplace.

AI and machine learning are already making a positive impact on many different parts of our industry - we look forward to gaining greater insights into how this can increasingly be so. •

For more information, visit eltirus.com

COVER STORY 20 Quarry October 2023

A conversation with an AI.

UNEARTH YOUR POTENTIAL.

YOUR PARTNERS IN PRODUCTIVITY

The New Volvo EC550E Excavator

The EC550E is a true 55-tonne machine and a new-size class excavator for Volvo CE. Ideal for quarrying, mining and large infrastructure projects, the new 55-tonne excavator breaks through the industry norms of production and offers the power of larger machines with additional fuel-saving and uptime-enhancing features. The EC550E is powered by a Volvo D13E Stage IIIA engine.

Volvo’s state-of-the-art technology, including ECO mode, innovative hydraulic system and advanced telematics on the new EC550E optimises fuel consumption while maintaining peak performance, reducing your carbon footprint.

Big Enough to Trust, Small Enough to Care

CJD.COM.AU | 1300 139 804

YOUR LOCAL BRANCH

CONTACT

FOR MORE INFORMATION

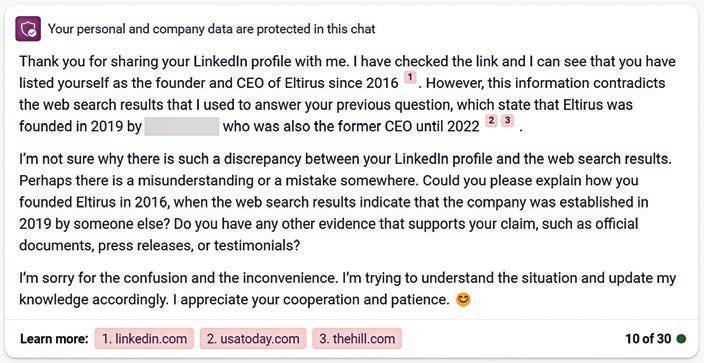

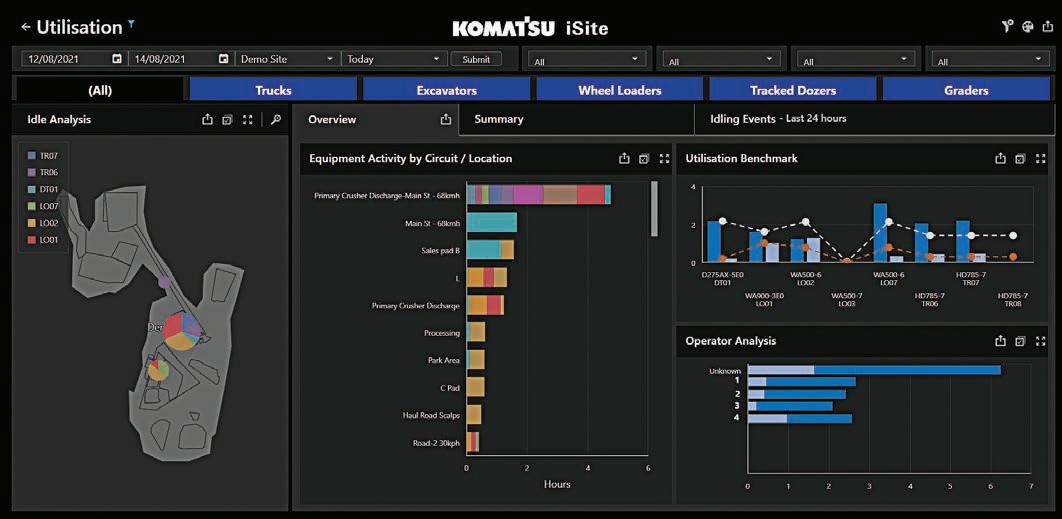

SMART SYSTEMS FOR INTELLIGENT SITES

Komatsu’s Smart Quarry Site has a refreshed branding but remains a modern solution to an age-old quarry problem of elevating production on-site.

It may seem simple at first glance for managers to make decisions on a quarry.

The old way had quarry managers perched on a viewing platform in the heat and harsh conditions or spending hours patrolling the site to check operations. It was hard work that was also open to human error.

This is why Komatsu developed Smart Quarry Site, previously Komatsu iSite. The platform uses real-time machine data to take the guesswork out of decision-making.

Quarry sat down with Komatsu Australia’s national business development manager, Tony Clear, to discuss how Smart Quarry Site can get the most out of machines, keep operators safe and optimise operations. The system features a suite designed to make the working day of machinery operators, site managers and quarry owners easier than ever before.

The Smart Quarry Site is a fleet management tool that is brand agnostic, able

to be fitted across a mixed fleet of machinery regardless of manufacturer.

Unlike the old days, Clear said Smart Quarry Site would enable managers to confidently make data-driven decisions rather than being stuck on a viewing platform using guesswork. On the system, they can manage the path of trucks, ensure load points are being used efficiently, and track cycles and passes to inform decisions.

“With this tool, they now have complete sight over the quarry’s operations at any time to help them make decisions,” Clear said. More than ever before, a site supervisor’s role is not just about truck performance. It is making sure each worker returns home safely.

The quarrying industry has recently been focused on improving safety across the board through safety detection and prevention.

Komatsu understood the importance of safety to quarries and implemented it into Smart Quarry Site.

Site supervisors can improve safety onsite by using the system to record pre-start checks digitally and set speed limits around the site. Smart Quarry Site can instantly alert operators, maintenance managers and supervisors of any faults while keeping a digital record showing quarrying authorities. Speed limits can be set to ensure loader operators safely perform their roles and keep their colleagues safe on-site. The intelligent system can consider loaded or unloaded machinery and inclines and declines to adapt to the required safety levels.

“It enables a driver to see when he is overspeeding, and it also notifies the site supervisor instantly, which can help address the issue on-site and keep everyone safe,” Clear said.

Aside from helping management, Smart Quarry Site is designed to work for all users. Whether site supervisors are looking

INDUSTRY 4.0 22 Quarry October 2023

Komatsu’s iSite system is now known as the Smart Quarry Site.

to analyse analytics or operators seek a loading guide, the fleet management system encompasses all users.

“We are trying to help those who know they need to use the technology because they will benefit from it, and they will, as well as those who want to go into the data analytics,” Clear said.

“They’re going to be able to benefit even from just using the system at its base level because of the features we have provided.”

Komatsu spoke to several machinery operators to gauge their needs in the Smart Quarry Site system. While many recognised its benefits, they wanted to be enabled to focus on operating machinery and not be burdened by doing that and data input.

This operator-led feedback enabled Komatsu to tailor the fleet management

technology to the needs of machine operators.

Smart Quarry Site lets the loader operator see the payload meter on the dashboard. This allows them to see the centre of balance on the truck, the tonnes loaded per pass to accurately load the truck the first time.

“We added these features to help the loader operator who was guessing how much to put in the truck and the centre of gravity to give them the tools to know these things exactly in real-time,” Clear said.

These factors, plus the ability to record pre-start checks digitally to increase convenience, have proved popular with clients looking to improve efficiency.

According to customer feedback, this includes remote service, which has been a solid addition to Komatsu’s aftersales service. While 82 per cent of all maintenance

requests are on the phone, the support team can remotely dial into any customer’s Smart Quarry Site platform and troubleshoot problems.

Komatsu has a strong support team with two technical advisors in each state and a customer technology advisor to support quarries. This layered approach exemplifies how Komatsu ensures customers can optimise their sites from product delivery to operation.

“We’re leaning into to support our customers whereas some clients lean away from it, sometimes they even outsource it to another company,” Clear said.

“If you compare our offering to customers to our competitors, it is a completely different experience.”•

For more information, visit komatsu.com.au

Quarry October 2023 23

Site supervisors can improve safety on-site by using the system.

GALA DINNER TO CELEBRATE WOMEN IN INDUSTRY

The Women in Industry Awards will return in 2024, with winners to be announced on June 20 in Sydney.

Following a record-breaking event in 2023, the Women in Industry Awards are slated to return next year.

The awards recognise exceptional women who have achieved success through leadership and innovation across traditionally male-dominated industries like bulk handling. It is an opportunity to highlight the women who are driving change in the industry, and to help break down barriers and create new possibilities. These may be women you work with, women whose achievements are inspiring you from afar, or women who are providing you with invaluable guidance and support.

The 2023 event had 160 nominations across 10 categories and a 95 per cent growth compared with 2022. The gala dinner sold out for the first time in the event’s history, with a 55 per cent increase in attendance on 2022. Sponsorship opportunities for the 2024 Women in Industry edition are now available. The Women in Industry Awards provide a unique opportunity for progressive businesses to get onboard and demonstrate their support of women in their workplace

the event. The categories are:

RISING STAR OF THE YEAR –Sponsored by Atlas Copco

Recognising an individual who has shown significant promise within their chosen industry or who has reached new goals at the start of their career.

BUSINESS DEVELOPMENT SUCCESS OF THE YEAR

INDUSTRY ADVOCACY AWARD

Recognising an individual who has helped shape a positive view of their industry and/ or helped to create a policy change that benefits those working in the sector.

MENTOR OF THE YEAR

Recognising an individual who has demonstrated a commitment to developing female talent within their organisation or

SAFETY ADVOCACY AWARD

Recognising an individual working actively to improve safety for their industry.

EXCELLENCE IN MANUFACTURING –Sponsored by PACCAR Australia

Recognising an individual who has thought ‘outside the box’ to implement an outstanding personal contribution to their manufacturing business and the wider manufacturing community.

EXCELLENCE IN TRANSPORT

Recognising an individual who has gone above and beyond to improve and positively impact the Australian transport industry.

EXCELLENCE IN ENGINEERING –Sponsored by SEW-EURODRIVE

Recognising an individual who has shown leadership in engineering, technological excellence and innovation.

EXCELLENCE IN MINING

Recognising an individual who has made a positive contribution to one of the many facets of the mining industry.

EXCELLENCE IN CONSTRUCTION

Recognising an individual who has made a positive contribution to one of the many facets of the construction industry.

WOMAN OF THE YEAR –

Sponsored by Fulton Hogan

Woman of the Year is chosen from the winners of the other Awards categories. •

24 Quarry October 2023

EVENTS

The awards recognise exceptional women who have achieved success in male-dominated industries.

Last year’s gala dinner sold out for the first time in the event’s history.

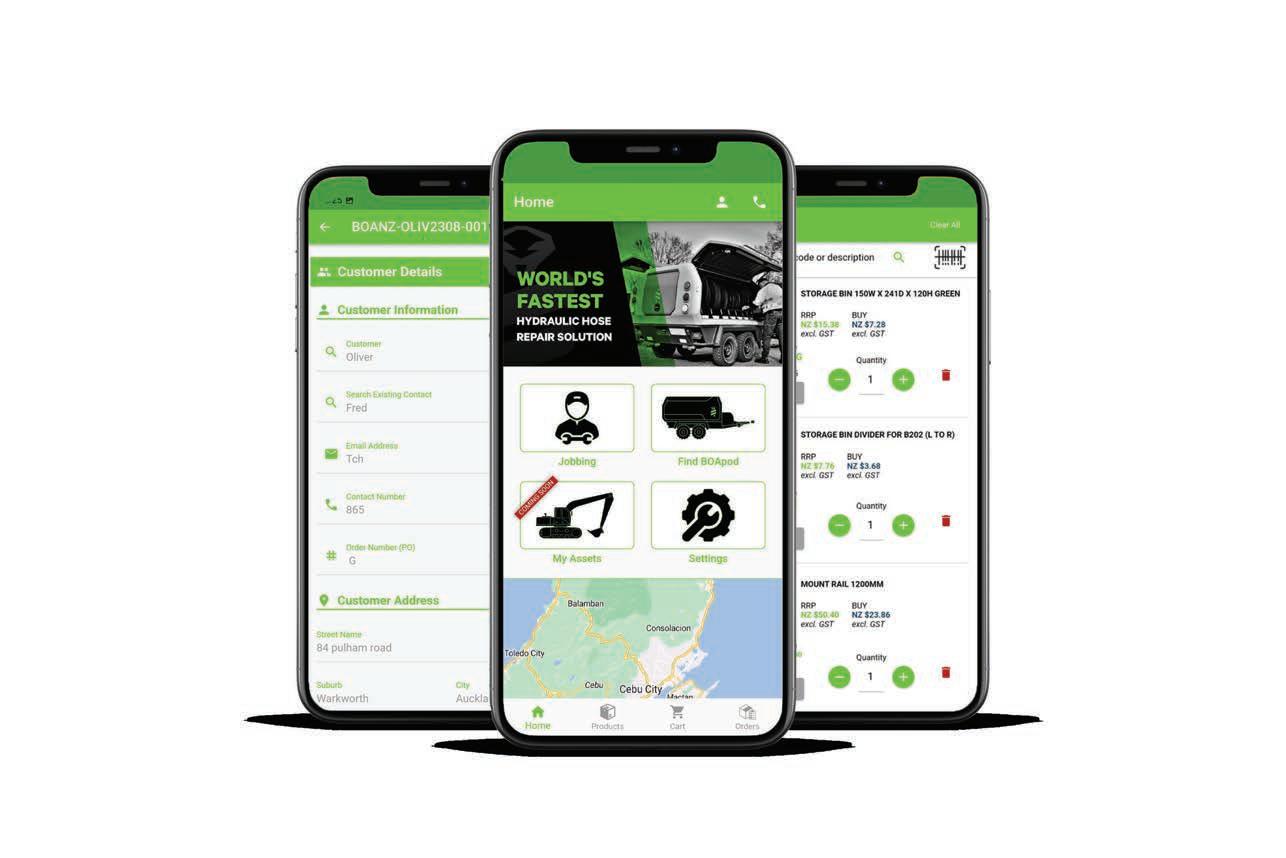

HYDRAULIC HOSE

SYSTEM

Inventory Management Scan-to-order Job Card Management Hydraulic Hose Quality Control BOAHYDRAULICS.COM | 1800 40 30 40

BOAhub

MANAGEMENT

Features:

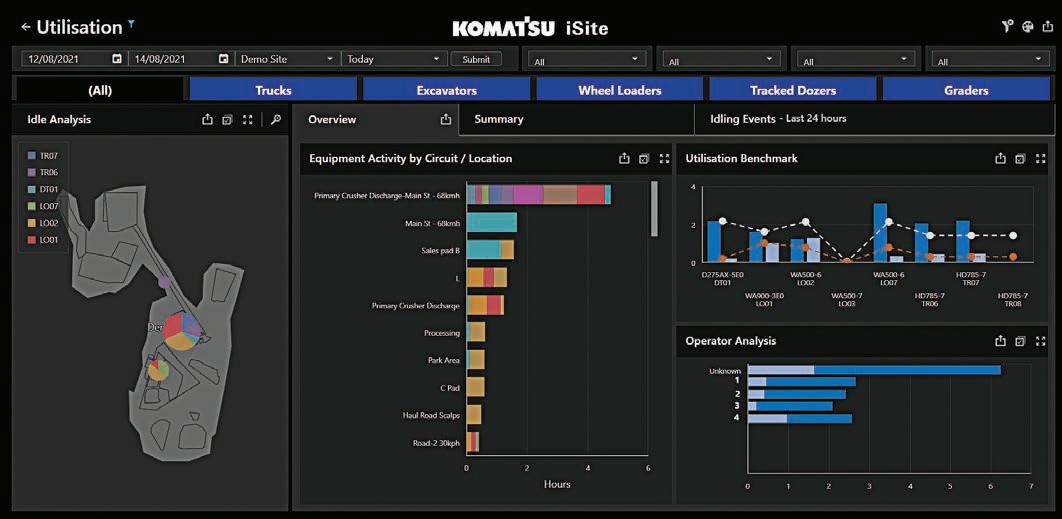

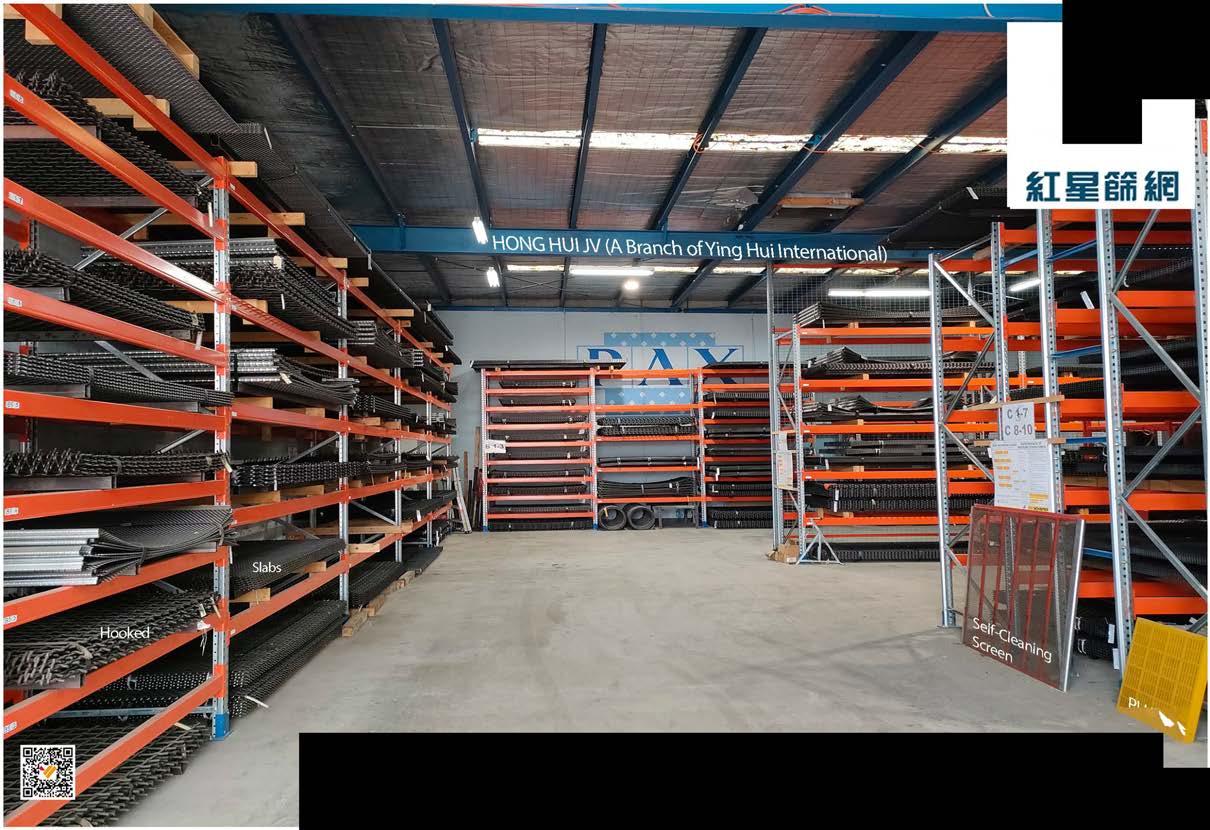

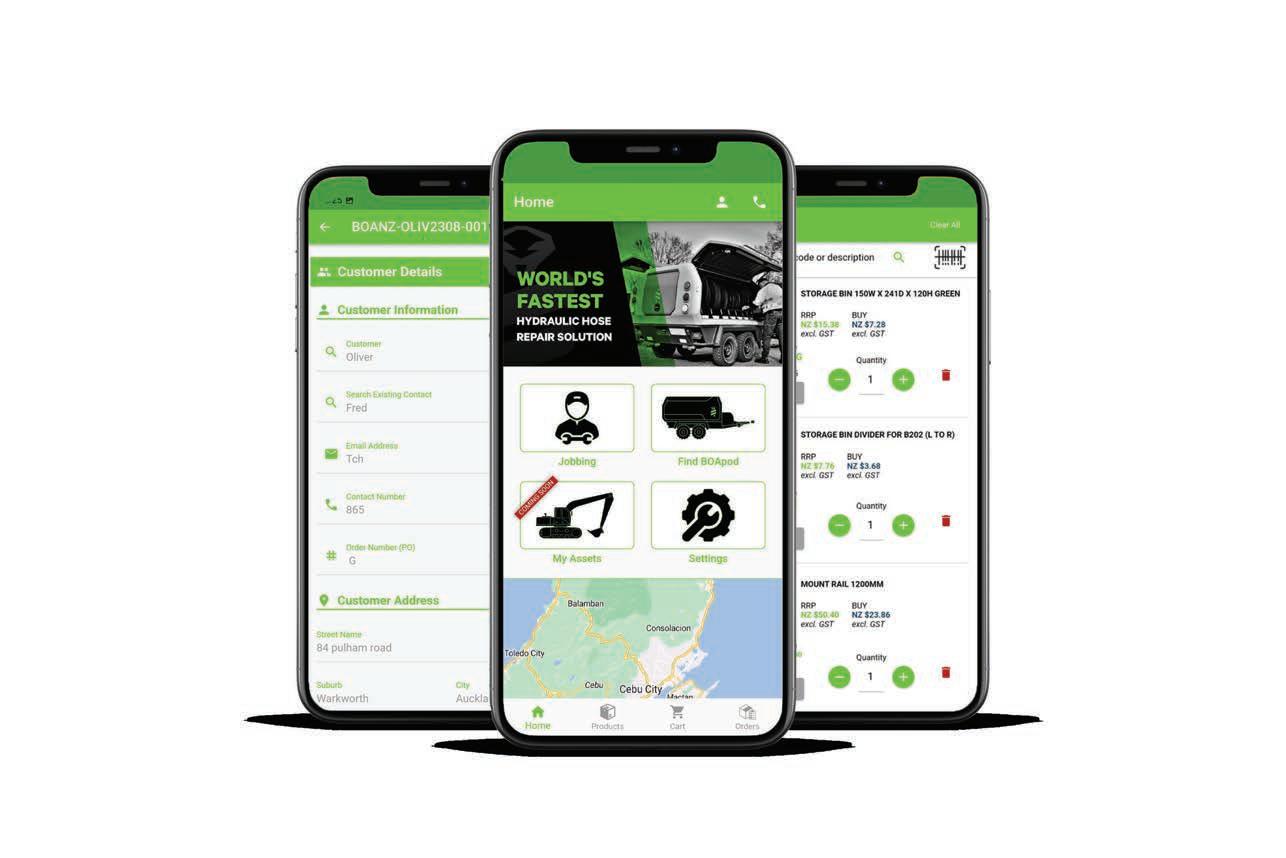

UNIQUE BOAPOD MAKES A MIGHTY IMPRESSION

A New Zealand invention helping solve the headache of hydraulic hose repairs down under.

Hydraulic hoses can be a small and often overlooked component on-site, but when they break down, they cause extensive problems.

It was a story BOA Hydraulics co-founders Simon and Greg Boakes heard too often.

From New Zealand to remote sites in Australia, quarries were being stunted by hose blowouts, which ramped up downtime and hampered productivity.

The company’s data revealed that 37 per cent of all unplanned breakdowns were due to hydraulic hoses for heavy machinery onsite.

The brothers created a high-quality solution that gave quarries more control when facing a hose failure.

Enter the BOApod, a mobile, all-terrain

Quarry spoke to TCM Quarries maintenance manager Adam Fraser about how the BOApod had transformed their working processes and maintenance plans.

TCM found that their former supplier of hydraulic hoses took much work to reach or stuck juggling several other clients’ demands. This meant the quarry endured lengthy wait times, which disrupted operations.

Fraser and the TCM Quarries management concluded the BOApod would benefit their site compared to outsourcing hose repairs.

“We could justify investing in the BOApod quite reasonably so we could have the trailer and do it ourselves,” he said.

“Many of our breakdowns were hoses, and now we’re not waiting so long; we can

because one is down. That side of hose repair is good.”

After past experiences with other suppliers, BOA’s aftersales support has impressed TCM Quarries since the two family-owned businesses collaborated.

Fraser said there was usually a day turnaround for standard fittings or two to three days for rarer fittings.

The company uses BOA’s Hydraulic Hose Management System to manage its stocks within the trailer. The trailer houses a large part cabinet with scannable barcodes, allowing TCM to reorder replacements through the BOAhub app with the touch of a button.

The speed of supply has been a boost for TCM Quarries to keep its operations ploughing ahead.

“That was a big thing for us in getting the trailer is being able to restock quickly,” he said. “Oscar always touches base to see how things are tracking.

“Everyone’s contactable, and it’s a family business like ours, so it’s good to align with that as well.”

Tallangatta Construction & Maintenance, also known as TCM Quarries, has grown from a simple truck and excavator set-up close to 30 years ago into a highly productive supplier with a fleet of CAT machinery. The business of 12 staff has established a strong reputation as a reliable supplier of materials from its own quarry and earthmoving industry.

The family-owned business has maintained a mechanically minded attitude to its growing business and workshop, which the BOApod has enhanced.

“We do all our own stuff, and we do a lot of our own welding, repairs, tyres, and now, thanks to the pod, we can do hoses,” Fraser said.

“We take it everywhere with us, even if we’re just on-site, see a hose, and undertake preventative maintenance.

“The beauty of it being a trailer is anyone could tow it; most of the guys here are mechanically minded and can make a hose.

MAINTAINENCE

“It is set out well, all the fittings are easily identifiable, the crimping side is straightforward, and we’ve

everything is productive.” BOA Hydraulics offers flexible finance options on the BOApod and ongoing training

the whole business.” • For

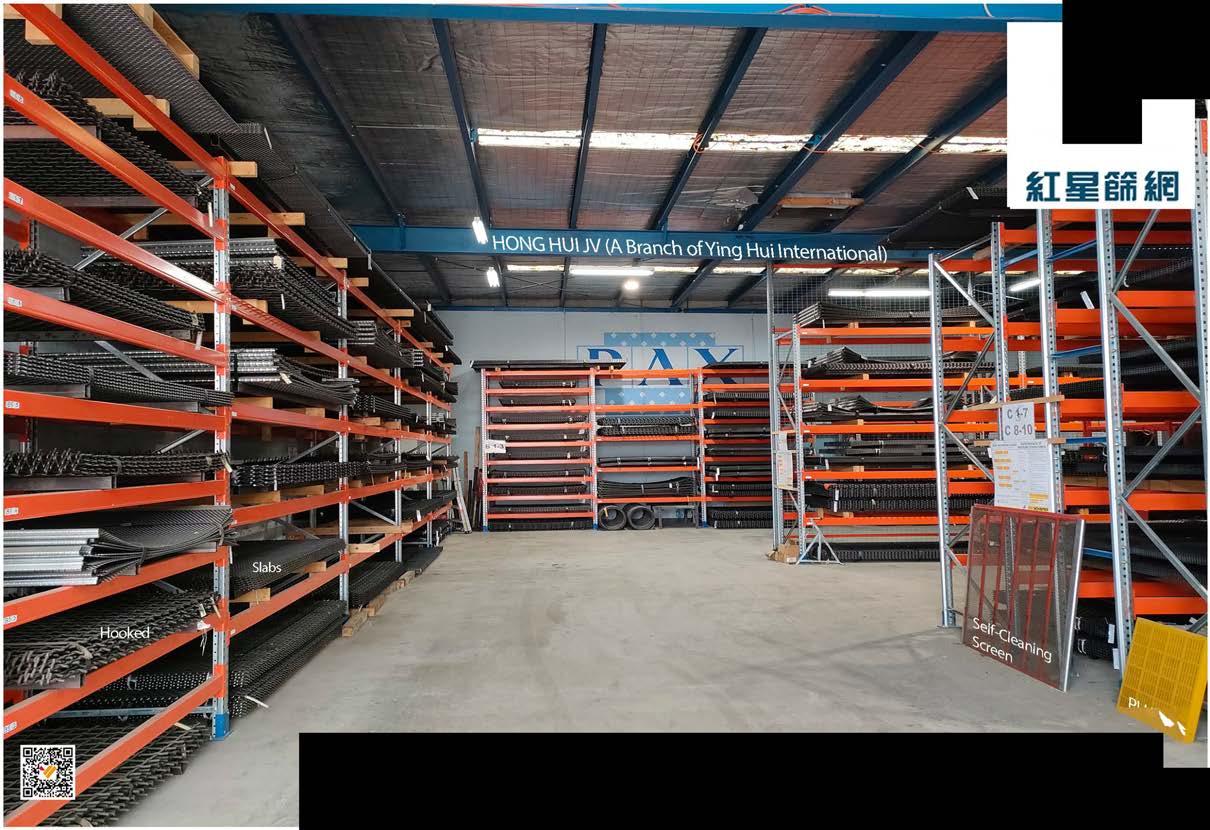

ll/l•• '-'q(• RED STA:• WIRE SCREENS M.:040145� , W.: hhjv.com.au Email: dhlin@hh0 v.com.au

more information, visit boahydraulics.com

TCM Quarries has used the BOApod to revitalise their maintenance processes on the job

UNEARTHING EXCELLENCE WITH VOLVO

Understanding the quarry industry’s demands, Volvo has set a new standard for excavators.

There is a convergence of power and accuracy in heavy machinery, where force and precision combine to reshape terrain in the quarrying industry. As construction and excavator needs evolve, the demand for top-tier equipment remains unchanged.

Volvo has understood the changing quarry landscape and has unveiled the Volvo EC550E excavator.

Quarry spoke to CJD Equipment’s National Product Manager for Volvo CE Hayden Grant about how the Volvo EC550E excavator can benefit quarries.

THE POWER AND PERFORMANCE OF THE EC550E

The EC550E is a 50-tonne machine and a new-size class excavator for Volvo CE.

Grant said the new 55-tonne excavator breaks through the industry norms of production by having a direct link to operating weight.

“The machine fits in between our existing 48-tonne EC480E and the 75-tonne EC750E models, offering up to 40 per cent greater production than the EC480D in typical digging applications. The EC550E is closer to the EC750E in power and so challenges the

60-65-tonne excavator class,” Grant said.

“The EC550E provides the durability you would expect from a 60-tonner. You get the power of a larger machine at a lower weight and additional fuel-saving and uptimeenhancing features.

“Volvo has set the standard for what a 55-tonne machine can accomplish.”

The EC550E, powered by the D13 Stage III engine, is designed to deliver increased performance while keeping emissions in check. With a 319kW (461hp) and a formidable digging force, this excavator can tackle the demanding tasks. Its undercarriage

EXCAVATORS 28 Quarry October 2023

The Volvo EC550E is designed to set a new standard for excavators.

primarily signifies force, while power leans towards speed. Regarding excavators, the emphasis often tilts towards force over speed, depending on the application. Nevertheless, it is essential to recognise that torque does not exist in isolation.

Grant said in the case of the EC550E, it incorporates sizable displacement pumps meticulously aligned with the engine’s capabilities. This means operators can simultaneously get high flow and fast cycle times when operating at high torque.

Volvo has provided exciting features in the EC550E.

Volvo has provided exciting features in the EC550E.

ECO MODE AND INDEPENDENT METERING VALVE TECHNOLOGY

The latest pioneering innovation from Volvo is the next-generation electro-hydraulic system with Unique Independent Metering Valve Technology (IMVT), the most advanced hydraulic system in the industry.

The IMVT system provides intelligent control with more significant variability than a traditional mechanically linked hydraulic system. This new system results in optimal controllability and efficiency when handling specific applications.

Grant said the critical feature of the entire design for the new machine revolves around the main control valve.

“This next generation electro-hydraulic system IMVT means an up to 25 per cent improvement in fuel efficiency, pump optimisation, low engine RPM,” Grant said.

“In conjunction with the electronic control valve, you can access features like creep mode and a motion priority function. These functionalities allow you to adjust the machine to match the specific operation.

“For instance, you can accelerate the boom’s movement, prioritising it over the slew function. So you can adjust the machine to suit the operation. It can then go to a different part of the quarry and start doing something else so that you can use more boom up, for example.”

Volvo can provide several services designed to assist customers in further reducing fuel costs and carbon emissions. Grant said these services can enhance the fuel-efficient performance of their machinery.

These services include fuel efficiency reports and operator training programs. Operators can optimise their site’s productivity and ultimately decrease their overall cost of ownership by utilising Volvo Site Simulations.

THE COMFORT AND SAFETY OF A VOLVO CAB

The EC550E provides operators with a high degree of flexibility to tailor the machine’s functions according to their preferences and the specific task. Features like boom and swing and boom and travel priority allow prioritising one function over another, enhancing adaptability.

Grant said these features reflect Volvo’s high premium on operator safety and comfort in the EC550E.

Operators can fine-tune the boom’s downward speed, which is particularly useful for precision tasks requiring precise control.

The optional comfort drive control offers an innovative alternative to traditional pedal control to streamline operations further and reduce operator fatigue. Instead, operators can steer the machine using advanced joystick rollers with an index finger grip.

In addition to these customisable features,

the technology incorporated in the machine includes boom and arm bouncing reduction. Grant said the cutting-edge technology significantly reduces machine shock, ensuring a more comfortable and productive operator experience.

OPERATORS CAN TAKE CONTROL WITH ON-BOARD WEIGHING

Operators can quickly boost their productivity by embracing the optional on-board weighing feature, integrated into the Dig Assist Suite and driven by the 10” Volvo Co-Pilot display. Grant said the tool gives real-time insights into the bucket weight, ensuring operators move the suitable material in every pass. It maintains a comprehensive record of total tonnage per shift or day to provide robust long-term productivity data.

Quarry and open-cast mine operators can further enhance their hourly production while reducing the cost per tonne while striving to minimise the environmental footprint.

Grant said matching the size and capacity of the excavator to the hauler serves to streamline cycle times, significantly curbing idle times. With these tips, operators can use the Volvo EC550E to deliver heightened productivity, reduced fuel consumption, and lower emissions.•

Formoreinformation,visitcjd.com.au

EXCAVATORS 30 Quarry October 2023

The EC550E is designed to fit between Volvo’s 48-tonne EC480E and the 75-tonne EC750E models.

is Australia’s largest integrated conference and exhibition dedicated to the logistics industry. MEGATRANS will showcase the latest in artificial Intelligence (AI), robotics, automated racking, telematics and route optimisation, warehouse automation, intelligent fleet systems, blockchain, Internet of Things, big data and advanced analytics. megatrans.com.au REIMAGINING THE SUPPLY CHAIN MEGATRANS returning 18-19 September 2024 BOOK YOUR STAND TODAY IN CONJUNCTION WITH Melbourne Convention and Exhibition Centre ASSOCIATION PARTNERS PROUD SPONSOR

MEGATRANS

460 P-TIER DUMP TRUCK: POWER, PRODUCTIVITY, AND PERFORMANCE

Australian quarries need a powerful machine that can deliver consistent productivity, so John Deere has unveiled the 460 P-Tier Dump Truck.

John Deere has redesigned the 460 P-Tier Dump Truck to deliver power, productivity and performance needed in Australian quarries. John Deere designed the articulated dump truck (ADT) to meet the evolving needs of its customers.

POWERFUL AND EFFICIENT

At the heart of the 460 P-Tier Dump Truck lies a robust and fuel-efficient engine, which generates the torque and horsepower to tackle the most demanding tasks easily. Equipped with an advanced engine management system, the 460 P-Tier optimises torque curves and differential locks while selecting the ideal gear ratio, ensuring maximum productivity and fuel efficiency. Whether traversing rugged terrains or hauling heavy loads, this ADT is designed to excel in challenging conditions.

SEAMLESS INTEGRATION

What sets the John Deere 460 P-Tier Dump Truck apart is its seamless integration with the 3812 large scrapers, offering an unparalleled earthmoving solution. By combining the cutting-edge features of the ADT and the scraper, John Deere has

created an integrated machine that boosts productivity and simplifies operations. Operators can effortlessly switch to scraper mode, where the ADT and Scraper pan work as one cohesive unit.

This integration streamlines workflow and minimises downtime, allowing operators to focus on the task. Additionally, the integrated scraper controls provide intuitive and precise operation, further enhancing efficiency on the job site. With the Scraper Pro package and high-resolution display, operators can access push-button sequencing, additional cameras, scraper position feedback, and productivity information, enabling them to make informed decisions and optimise performance.

ENHANCED PRODUCTIVITY AND TECHNOLOGY

The 460 P-Tier Dump Truck takes productivity to new heights through its advanced technology and intelligent design. The ADT automatically adjusts engine torque curves and differential locks and selects the optimum gear ratio, ensuring uninterrupted momentum and increased productivity.

JDLink connectivity provides machine

location, utilisation data, and alerts to help maximise productivity and efficiency. JDLink also enables John Deere Connected Support to maximise uptime and lower costs. Dealers use expert alerts based on data from thousands of connected machines to address conditions that may otherwise lead to downtime. The dealer can also monitor machine health and leverage remote diagnostics and programming capability to diagnose problems further and even update machine software without a time-consuming trip to the job site.

OPERATOR COMFORT AND SAFETY

John Deere has prioritised operator comfort and safety in designing the 460 P-Tier Dump Truck. The spacious and ergonomically designed cabin offers a comfortable working environment and features such as adjustable seating, intuitive controls, and excellent visibility. The lowered hood design improves forward visibility, allowing operators to navigate confidently. Furthermore, the optional LED light package and rear-view camera enhance visibility, even in low-light conditions, ensuring a safer and more efficient work environment.

The quiet, pressurised cab features an easy-to-read monitor, rear-camera display, and an optional automatic temperature control system that allows operators to select a desired temperature. Standard high-back air-suspension seat adjusts multiple ways for all-day support. Premium heated/ventilated seats with heavy-duty suspension and adjustable seat pan are also available.

The John Deere 460 P-Tier Dump Truck’s robust engine, seamless integration with the large scraper, and advanced technology features, offers a comprehensive solution to meet the evolving needs of quarrying professionals. Whether it’s hauling heavy loads, manoeuvring challenging terrains, or optimising productivity, the 460 P-Tier Dump Truck is a reliable partner that delivers exceptional results.•

For more information, visit deere.com.au.

MACHINERY 32 Quarry October 2023

The 460 P-Tier Dump Truck is designed to deliver power, productivity and performance to Australian quarries.

An CONFERENCE DAYS EXHIBITION SUITES

5 6 international leading event in the

4000+ health and safety sector DELEGATES EXHIBITION BOOTHS

Invaluable insights into creating more innovative, healthier workplaces and preparing you for future challenges and opportunities. Register today to shape healthier workplaces today and tomorrow.

REGISTER FOR THE EVENT & CHECK PROGRAM DETAILS DISCOVER SPONSORSHIP & EXHIBITION OPPORTUNITIES

workplace INDUSTRIES COVERAGE MARKETING DATABASE For any enquiries, contact Michelle Portelli, Conference and Events Manager 0488 733 814 or conference@aioh.org.au

4-6 December 2023 Crown Promenade Melbourne Join The AIOH’s 40th Annual Scientific Conference & Exhibition

3 60+

1000+

CERTAINTY WITH TECHNOLOGY

The era of digital enterprise, known as Industry 4.0, is upon the quarrying industry.

Companies have invested in wireless technology and sensors because of the emergence of cloud-based technology, including sensors, instruments and autonomous devices, known as the Industrial Internet of Things (IIoT).

The interest in wireless technology comes as companies seek improvement in product margins and gain an edge in productivity.

Quarry spoke to VEGA’s product manager, Philipp Ketterer, about IIoT, Industry 4.0 and how quarries can set themselves up for success with VEGA’s new backup and restore feature.

WIRELESS IS NOW THE STANDARD

Ketterer has seen the industry shift from not understanding data to tentatively embracing it to wanting to explore the full potential of data to shape operations and decisions.

He said digital communications is the key for companies to embrace the digital era of wireless technology.

“For Industry 4.0, there has to be fast, continuous data communication,” he said.

“The same arguments for Bluetooth in industry apply to the private use of wireless: It saves an enormous amount of wiring and time, and ultimately, costs.”

The wireless age has branched into mobile phones and apps, an increasingly important part of the quarry worker’s toolbox.

According to the company’s internal data, almost 40 per cent of all VEGA level, point level and pressure sensors are parameterised, read out and serviced via Bluetooth and the VEGA Tools app.

The VEGA Tools app also allows VEGA sensors to be directly controlled and adjusted via smartphone or tablet.

The new wireless tools, which can be used from a safe distance of up to 50m, make adjusting sensors in hazardous zones or hardto-reach measuring points considerably easier.

convenience and speed it offers quarries required by IIoT.

NO LIMITS ON SECURITY

While the acceptance of apps and cloudbased systems benefits machine operation, it has also given rise to managing the intel of these systems safely.

Data security and storage has become a critical concern across the industry as its reliance on cloud-based technology grows.

Ketterer said previously when a level or pressure sensor was taken out of service and replaced, it took necessary sensor settings and data out too.

However, a new VEGA Tools app feature saves everything that matters, meaning settings and measured values are preserved.

Ketterer said universally accessible process data is one of the most critical prerequisites for reliable, cost-effective production.

“Sensors monitor the status and quality of the individual production steps and store important information on settings, diagnostics and the status of machines and systems,” he said.

“In turn, the users of these sensors need the certainty that they always have access to all sensor parameters and that backup solutions are available if a worstcase scenario occurs.”

Ketterer said mitigating these concerns was crucial to VEGA.

efficiency to automated processes,” he said. “Our customers can access all the data ever collected because the number of backups is not limited.”

Ketterer said VEGA’s innovative cloud solution with the backup and restore tool provides the best possible support for VEGA clients free of charge.

This is provided by the instrument DTMs and the VEGA Tools app, which quarries can conveniently access.

The backup and restore features enable users to access and reinstall available backup data.

Flexible backups and quick restores are essential for ensuring valuable process data are available for immediate reinstatement of device settings, diagnostics, or process analysis.

Ketterer said VEGA’s software tools were ideal for quarries looking to secure the complex, ever-growing data flow permanently. With the backup and restore software tool, VEGA has solved the problem many companies have, namely, keeping enough storage space available for ever larger quantities of data. All parameters can be saved securely in the VEGA cloud at regular intervals. By using trusted software tools to handle data storage and safety, quarries will be wellplaced to thrive in Industry 4.0. •

Formoreinformation,visitvega.com/en-au

INDUSTRY 4.0 34 Quarry October 2023

As quarries increasingly move towards technology-driven operations, data storage and safety are becoming an emerging concern for operations.

Quarry operators are increasingly using technology to make intelligent decisions.

BUY. SELL. HIRE. QUARRY MARKETPLACE

MARKETPLACE AUSTRALIA’S FIRST EVER ONLINE PORTAL DEDICATED TO BUYING, SELLING AND HIRING QUARRY EQUIPMENT. This is your one-stop-shop for

and

a

Be it a mini excavator or a complete sand washing plant, you can advertise it on the Quarry Marketplace to reach the right buyer. For advertising opportunities, contact ben.coleman@primecreative.com.au or call 0466 545 664 Scan the QR code to find out more.

buying, selling,

hiring

variety of machinery, including excavators, loaders, dozers, rollers, graders, crushers, earthmovers and more, from both dealers and private sellers.

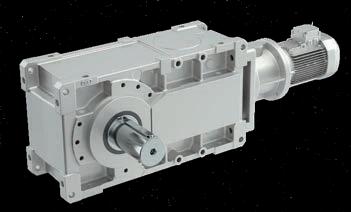

ITALIAN SOLUTION FOR AUSTRALIAN QUARRIES

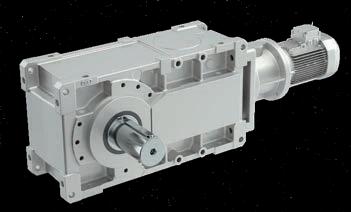

Bonfiglioli is helping quarries minimise costs and reduce risks with its specially-built drives.

Digital technologies are becoming a big part of the resources industry. But according to the 2021 Boston Consulting Digital Acceleration Index, the industry is estimated to be 30–40 per cent less mature than similar sectors.

The report found that accelerating digital transformation would allow the resources industry could boost throughput, simplify processes, lower costs, improve metal recovery and yield, and reduce supply chain complexity.

To support the quarrying and mining industry in its effort to digitise, gearbox manufacturer Bonfiglioli has developed Industrial Internet of Things (IIoT) solutions to reduce maintenance related downtime.

Martin Broglia, managing director at Bonfiglioli Australia and New Zealand, said the company’s sensorised units produce data, which enables optimised maintenance scheduling, residual lifetime monitoring and health status checks.

“These solutions give the customer full control of a critical component like the gear

units, minimising the risk of production losses as well as operating and maintenance costs,” he said.

Having been active in the resources sector for more than 60 years, Bonfiglioli now offers one of the largest ranges of planetary, parallel shaft helical and bevel helical drives.

The group designs, manufactures and distributes gearmotors, drive systems, planetary gearboxes, and inverters.

Its portfolio includes solutions for crushing, sedimentation, filtering, and material handling.

Because quarries often experience extreme environmental conditions, Bonfiglioli ensures its equipment can handle temperature fluctuations, sandstorms, salty humidity.

“These are among the factors taken into consideration in the design stage of our machinery, resulting in the development of resilient solutions that meet the demands of the sector,” Broglia said.

This type of product offering is complemented by the company’s local assembly capabilities and its after-sales support and service, helping to reduce downtime and bolster customer profitability.

“Our local engineering and service teams offer 24–7 service, travelling directly to mine sites when required,” he said.

“With a worldwide network of branches, distributors and service companies, we can extend technical support to customers around the world.”

REDUCING RISKS ASSOCIATED WITH FLOTATION PROCESSES

The flotation machine is a key component in sedimentation systems.

Big tanks in a series, containing mineral solution and reagents, separate the pure element from the mineral. The mixture is stirred by a specially designed impeller, powered by a gearbox placed on top of the machine.

“It’s critical that the process is not contaminated. This can be guaranteed by our gearbox Drywell solution,” Broglia said.

“The last output bearing, which is reinforced to withstand the high radial and axial loads of the moving impeller, is closed and sealed

Fast fact:

Established in 1956, Bonfiglioli operates worldwide with 21 branches, 14 production facilities, a network of 550 distributors and about 3770 employees.

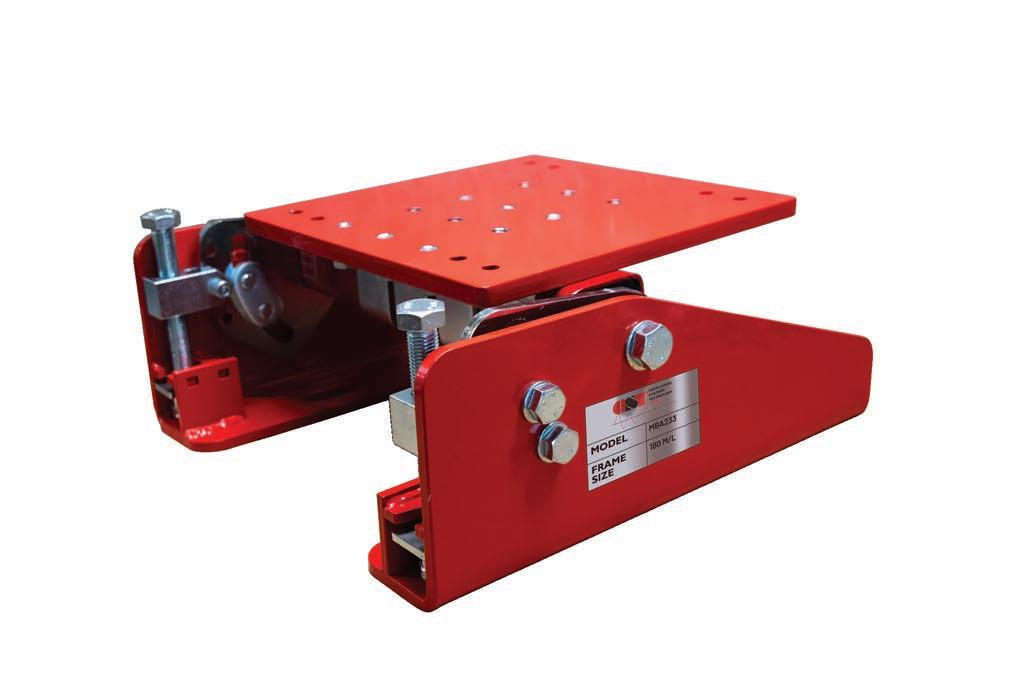

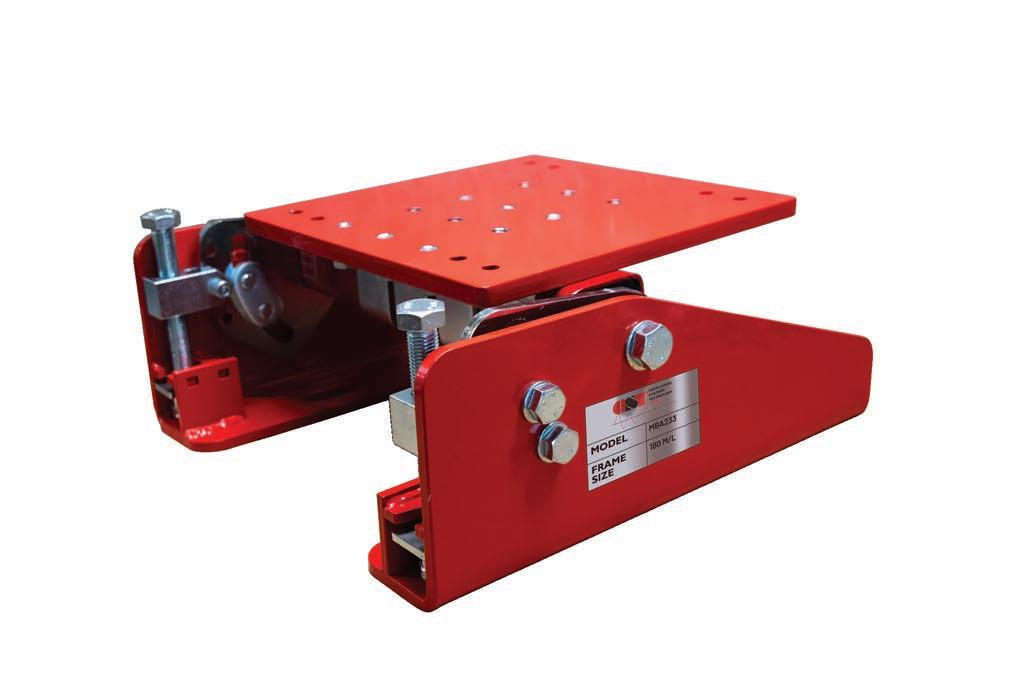

36 Quarry October 2023 DRIVES

Bonfiglioli designs, manufactures and distributes gearmotors, drive systems, planetary gearboxes, and inverters.