12 minute read

QUARRIES USE WATER TOO

from Quarry Apr 2020

by Prime Group

QUARRIES USE WATER TOO: EFFICIENT WATER MANAGEMENT SOLUTIONS

Water and its usage is as vital as the aggregates quarries produce – particularly in practices such as sand processing. However, equipment can now be optimised to close the loop of water processing without impacting on productivity and profits and indeed boosting product solutions and innovations.

For an outsider, water management might not be the first thing that comes to mind when thinking about quarries. However, water availability and wastewater management have been a strong focus for quarrying and mining operators since the early 2000s when the states introduced mandatory licences for previously unlicensed water use for quarries.

Restrictions on water extraction from the natural environment have made the recycling of process water a must for quarrying operators. Operators must now compete for licences in fully utilised systems or in rural areas where there are no new water licences available for industry to expand, or where the total licensed extraction is actually being reduced.

The management of process water, reclaim systems, dust suppression and pit dewatering is essential to the success of a sand and aggregates project. By managing these processes efficiently, quarry sites can process more product faster, while lowering their water bill and eliminating the need for double handling.

Most quarries use water in the washing and processing of their products. For example, sand washing, a necessary step for producing high quality sand, utilises both recycled and clear water. Once the sand has been processed, wastewater containing product fines and additional wastewater run-off from the stockpiles make their way to storage or tailings dams. All these water sources need to be managed effectively for

Weir Minerals’ equipment can manage water more efficiently to provide a drier end product.

the quarry to keep their operational costs under control.

FROM A TO B “Maintaining the water level balance on site is very important to everyone,” Darren Van der Westhuizen, Weir Minerals’ territory manager for dewatering, explained. “No matter what you’re processing, you’ll always need to move water from point A to point B.”

The new decade has brought to light new problems for fluid transport, from the introduction of water restrictions on urban water supplies to climate change affecting the supplies of non-potable groundwater (rainwater, groundwater and stormwater). By transporting and making use of water already available on-site, quarries can reduce the cost of water licences and make their investment go further.

“Increased awareness of the positive outcomes achievable with efficient water management provides us the opportunity to partner with customers to explore and develop new and safer water management systems,” van der Westhuizen said. “We target the challenges the quarries are facing with regards to pumping water around the site with the focus to champion and provide the most optimum solution for each specific and unique application.”

Pumps designed to handle increased

suspended solids in water while operating at high discharge head pressures could be the answer. With the Warman DWU pump, Weir Minerals provides a pump built to transport surface water from dams and ponds on-site back to the washing circuit for recycling. Other onsite water sources, such as tailings dams, might make better use of a pump house or a customised Multiflo barge solution.

“There is more than one way to reclaim water at a quarry,” van der Westhuizen said. “We engineer our solutions in-house, so no matter the customer’s needs or budget, we can create a custom solution to get the most out of the water they already have on site.”

CLOSING THE LOOP In 2020 it’s no longer just about moving water around site, now quarries need to work toward closing the loop of water use in their processes. Regulatory and government bodies around the world have begun implementing guidelines for the management of water in quarries. These guidelines promote site water management proposals founded on the principles of waste minimisation and active promotion of the reduction, reuse and recycling of wastewater.

“More and more quarries are looking for equipment that will help them to reduce their water usage on site,” Steve Barnett, Weir Minerals’ sand and aggregates sales manager, said. “With the new guidelines, sites are re-evaluating their water management plans and seeing how an effective plan and change of equipment can contribute to their success.”

The new planning and allocation of water resources covers reducing, reusing, recycling and recovering water wherever possible. Equipment optimised to handle water not only reduces its losses and boosts efficiency but also frees up water resources that can be used elsewhere in the process for necessary site duties such as dust suppression. Installing equipment like the Weir Minerals sand wash plant, specifically designed to produce a drier end product, can improve water recovery by up to 35 per cent compared to common sand screw plants.

“We’re out on site with our customers every day,” Barnett said. “We see how hard they work, and we know how precious each and every recoverable resource is. Installing a custom-engineered solution such as the Weir Minerals sand wash plant doesn’t just provide customers with a drier aggregates product after processing but creates a whole new by-product in ready to use recycled water.”

THE NEW ECONOMY The conservation of water is a major consideration for a circular economy. As restrictions tighten, quarries are faced with a new question of how to close the loop and get the most from the water available. Weir Minerals’ solutions make it easy to optimise any site for efficient water management. With years of water transport expertise, and a portfolio of products designed to manage water efficiently, the Weir Minerals team works with quarries across the entire process to produce a high quality product while saving time and money, as well as water. •

Weir’s Multiflo pump units can transport water to where it is needed.

PORTABLE, MOBILE, MODULAR, FIXED – COULD ONE PLANT DO IT ALL?

Wash plants have traditionally been static or modular, with limited mobility around the quarry. Jim Hankins explains how recent iterations of the wash plant have evolved to become more portable and flexible – and may one day be capable of covering all facets of operation.

Portable plants have been utilised in the quarrying industry for decades. In the US, portable wash plants became popular in the 1960s and generally consisted of a vibrating screen mounted over a sand screw. The various configurations were typically used for projects with short to medium term contracts, requiring screening and washing on-site, and the ultimate removal of equipment at the end of the project. With developments leading to more flexibility, portable plants are now found in a broad range of applications.

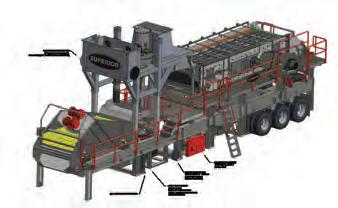

In the past decade, Superior Industries acquired washing, crushing and screening, as well as portable equipment, manufacturing firms. With these acquisitions, its range of portable processing plants – dry or wet, crushing, screening and integrated washing plants – has grown immensely.

PORTABLE AGGREDRY The first Superior Industries Aggredry portable wash plant was imported into Australia in late 2017. This was a standard configuration, with Australian requested modifications to suit local conditions, described as a 2m x 6m (6’ x 20’) Aggredry. It combines a Guardian horizontal triple-deck 6m x 2m (20’ x 6’) screen, with a pan feeding a 91cm (36”) twin Aggredry dewatering washer makes a powerful and flexible plant. Two reversing and roll-out cross conveyors, made from the Superior Industries product

The original Australian portable Aggredry wash plant in operation.

range, accommodate the product of the screen decks on either side of the plant, with the third screen discharge to a chute at the end. An arrangement of stackers, appropriate to the site requirements, will stockpile the various products.

This unit has been in operation for close to two years, processing a sand with minimal bottom end with some organics. The washing process is cleaning the organics out, while producing sand in grade at a high production rate.

The second portable Aggredry wash plant to come to Australia had considerable Aussie input to modifications to make the plant more versatile. Both technical and operational modifications were involved. For the first time, Superior Industries built a twin 112cm (44”) Aggredry with removal flared sides, for travel, again making use of the Guardian 6m x 2m horizontal triple deck screen. The water manifold was reconfigured, valve changes, electrical components were altered for road travel within Australia.

With the changes, what can the newly configured portable plant do? The Guardian screen can process in excess of 500 tonnes, depending on feed and aperture sizes. The twin 112cm Aggredry can produce a nominal 275 tonnes per hour, depending on the raw feed grading of the –4.75 mm material. 1

Based on river rock (or pebble) and sand in a typical alluvial deposit, the Aussie Aggredry wash plant could take a 45:55 ratio of rock to sand, of the material fed to this plant. 1 If a feed hopper is used with a grizzly, the plant can produce one oversize, threescreen washed rock or pebble size ranges, depending on preferred screening apertures,

in addition to a washed sand.

Washing pebbles for the landscaping market is an art or science in itself. Removal of difficult surface coatings may require further processing. If the river rocks are crushed to make aggregates, and require washing after crushing, the same processes could be followed, while the crusher dust could be blended with the natural sand, if blending ratios were acceptable. 2 If a hard rock site was looking at washing aggregates, three washed aggregate ranges could be produced, while washing crusher dust to make a local manufactured sand. The versatility of this plant is only limited by the site-specific products and required feed rates.

ALL-ROUND OPERATION While portable and easy to move within a site and from location to location, the plant can be set up in position for permanent operation. With regards to modularity, plants can be set up to operate in tandem, once a second one is added (or more, as required). Is it possible for

The versatility of the “Aussie” Aggredry portable wash plant is only limited by site-specific products and feed.

one plant to cover all facets of portable, mobile, modular and fixed operations? Within reason, yes. With experience in operation and expertise in sizing plants it is possible to base an initial operation around the use of the Aggredry wash plant, with expansion in multiples of these added to the process, with some materials handling additions or modifications, as well as inputs such as water and power.

With level assist technology, to efficiently utilise hydraulic levelling of the plant, the Superior Industries portable range can be brought on site and set up in a matter of days, with supply of electricity and water (if required). With Superior Industries’ foundation in conveying and stacking, needless to say, there is a vast range of options for conveyors and stackers, ranging from fixed, to radials, to the Telestacker

telescopic radial with automated controls.

Superior Industries continues to innovate in the portable field, recently unveiling the latest development in portable washing – the Portable Spirit Wash Plant, which was on show at CONEXPO-CON/AGG Las Vegas in March 2020. •

Jim Hankins is the principal of Rivergum Industries.

FOOTNOTES: 1. The basic operation of an Aggredry washer is determined by the water requirements and the speed of the shafts, which are directly related to the raw material feed grading. The throughput will depend on sitespecific parameters. 2. Ratios for blending of natural sand and manufactured sand are dependent on a number of issues related to the ultimate end product.

PORTABLE CAPTURES STATIC COUSIN’S ‘SPIRIT’

Superior Industries, the US-based manufacturer and global supplier of bulk material processing and handling systems, showcased its newly configured portable wash plant at CONEXPO-CON/AGG 2020 in Las Vegas in March.

Based on the company’s successful brand of static Spirit sand plants, the Portable Spirit Wash Plant is capable of producing as many as five products. It carries a 6m x 2m (20’ x 6’) Guardian Horizontal Screen, plus a sand production module and ultrafines recovery module.

As part of the sand washing process, material is fed to a slurry box, which liquifies it to improve the screening and stratification processes. The three-deck horizontal screen washes and sizes three products from a top, middle or bottom deck. Leftover sand is then processed through one of two Spirit wash modules, which comprise of one or more Helix cyclones followed by a dewatering screen.

The first wash module uses a cyclone to size and separate material for a traditional sand product. A dewatering screen ensures it is instantly saleable off the discharge chute.

The Portable Spirit Washer Plant.

Depending on the deposit, an optional ultrafines recovery module washes out -100 to -400 fines for microfine material, which is saved from being lost to a waste pond.

“It’s the first time such a configuration has been created for the portable market in North America,” Matt Voigt, Superior’s manager of portable plants, said. “We incorporated our low profile dewatering screens and a series of hydraulically-powered components to ensure the plant is road permissible and quick to deploy.”

Applications for the new portable plant include operations with settling ponds, crushed aggregate, sand and gravel, dredging and frac sand.

The Portable Spirit Wash Plant was one of a dozen new products for crushing, screening, washing and conveying applications that Superior Industries launched at CONEXPOCON/AGG 2020. The new equipment included the brand new Sentry Horizontal Shaft Impact (HSI) crusher, the Fusion Modular Platform, the Valor Vertical Shaft Impact (VSI) crusher, the bolted model Liberty Jaw Crusher, and the Alliance Low Water Washer. Additional equipment with new features included the Anthem Inclined Screen, the Valor Vertical Shaft Impact (VSI) crusher, the P500 Patriot Cone Crusher, the Aggredry Dewatering Washer and the TeleStacker conveyor.

Superior also displayed aftermarket solutions for new conveyor idlers, pulleys and accessories, plus crushing rotors, cone bushings, cone heads and jaw dies, alongside a multimedia experience showcasing several turnkey projects completed by the company’s construction management division. •

Source: Superior Industries

PLANT . EQUIPMENT . PARTS . SERVICE & SUPPORT