Major project experts

RATP Group has completed a number of brownfield and greenfield projects across Paris and is bringing this experience to the global market.

CELEBRATING 15 YEARS IN AUSTRALIA

At MTR, our vision is to “Keep Cities Moving”. We believe that world class metros enable thriving sustainable cities. We are proud and remain committed to our mission of connecting communities across Australia through close partnerships with Governments, the rail industry and the customers we have been serving over the last 15 years.

From the Editor

ISSUE 9 - OCT 2024

Published by:

379 Docklands Drive

Dockalnds, VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

Publisher John Murphy

E: john.murphy@primecreative.com.au

Chief Operating Officer

Christine Clancy

E: christine.clancy@primecreative.com.au

Managing Editor

Lisa Korycki

E: lisa.korycki@primecreative.com.au

Editor Josh Farrell

E: joshua.farrell@primecreative.com.au

Business Development Manager

Alex Cowdery

M: 0422 657 148

E: alex.cowdery@primecreative.com.au

Client Success Manager

Salma Kennedy

E: salma.kennedy@primecreative.com.au

Head of Design

Blake Storey

E: blake.storey@primecreative.com.au

Design

Daniel Truong

Subscriptions subscriptions@primecreative.com.au

www.RailExpress.com.au

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published.

© Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the Publisher.

Josh Farrell Editor - Rail Express

Welcome to the October edition of Rail Express

It feels like the year is rattling along at an alarming rate and as my first year as editor of Rail Express nears its completion, I am regularly impressed by what the future holds for this sector.

It has been a month full of major news for the industry. Every day it seems exciting announcements are coming across my desk all over the country. I am looking forward to seeing what the rest of the year has in store for the sector ahead of an exciting 2025.

As Inland Rail edges closer to completion I am interested to see what milestones we hit in 2025.

This groundbreaking project will transform the way freight is moved in Australia and we are already beginning to see businesses look to take advantage of it.

Aware Real Estate, in partnership with Barings, recently expanded its industrial footprint with the acquisition of Austrak Business Park, a 99 hectare high-quality industrial estate in Melbourne’s north.

The site is located in the core infill suburb of Somerton, 20 kilometres (km) north of the Melbourne CBD, 10km north east of Tullamarine Airport and 22 km north of the Port of Melbourne.

This area will take advantage of Australia’s largest intermodal freight terminal which is set to be complete in 2025.

It was interesting to see Aware Real Estate Chief Executive Officer Michelle McNally note the platform is committed to acquiring well located assets with strong tenants and the ability to add value through development. The organisation expects an uptick in demand for the park once the Somerton Intermodal Terminal becomes fully operational next year and able to accommodate up to one million Twenty Foot Units (TEUs).

The Somerton Intermodal Terminal’s capacity will allow the rail freight market to flourish while also benefiting the wider community, enabling more freight to move on rail, thereby helping to reduce traffic congestion, road accidents and damage,

and transport emissions. This project out at Somerton that is set to capitalise on the growth of Inland Rail and connect into the Port of Melbourne shows the benefit of rail to the freight market.

It is yet another example of just how much rail grows industry around it. It is imperative we continue the hard work the government has been putting in expanding the rail network to truly revolutionise the way we move freight in Australia.

It really was a pleasure putting together this month’s Rail Express. The team got the opportunity to have interesting conversations and dive into some exciting projects including one by RATP Group, which was working to get Paris ready for the Olympics and how it will support Australia.

We spoke with Nick McLoughney from Allworks to learn more about the company in its 25th year and how it is supporting the rail sector across Australia. We also delved deeper into its Hitachi range of equipment to better understand the relationship.

The distinct flavour of plant and equipment continued with an exploration into how to transition to net-zero on construction sites. We look at different technologies and how we can lean in on international experience to achieve this in Australia.

We looked at station design and how stations can now be designed to better support the local communities they serve and what each state across the country is doing to achieve this.

Further on we dove into the ARI Awards, regional train lines and heard from the National Transport Commission.

This month also includes comments from the ARA, RISSB, and the PWI.

Happy reading!

joshua.farrell@primecreative.com.au

Connecting Australasia.

We’re the leading provider of end-to-end rail and transport solutions in Australia and New Zealand. From designing and constructing transport networks to operating them, we’re transforming the way people travel and providing better connections across the country.

Every day, more than one million passengers journey are taken on our networks. Our longstanding experience in mass transport means we know how to put together the right solution - from start to finish. Focused on the future of transport, we innovate today for the best outcomes tomorrow. From digital engineering to digital asset management, to targeting zeroemission transport modes; we’re in it for the long haul.

Another Victorian station opens

A brand-new Parkdale Station has opened and another two sets of boom gates removed, marking three quarters of the way to removing 110 level crossings by 2030 in Victoria.

Mentone and Mordialloc stations until the lifts open.

During a two-week closure of the Frankston Line, a crew of 450 worked around the clock to get the new station ready for passengers and connect the elevated rail bridge to the existing line.

Parkdale Station’s modern facilities feature a forecourt, gathering places for locals, more lighting, station precinct parking and better CCTV.

Crews will continue to work throughout spring to finish the station’s lifts. For passengers who are unable to use the stairs, shuttle service will continue between

Crews will also continue working on open space – about the size of two Melbourne Cricket Grounds – and recreational facilities including a basketball half court, open-air gym, village green, a community garden and a nature-based play area.

By 2025, a new shared use path will connect Parkdale to Cheltenham via Mentone and set the groundwork for a future connection to Mordialloc. More than 100,000 trees, shrubs and grasses will be planted as part of the project, increasing vegetation and greenery in the area.

The level crossing removal will improve journeys for more than 20,000 vehicles

travelling through the former level crossings each weekday, where the boom gates were down for up to 44 minutes during the morning peak.

The Frankston Line will be level crossing free by 2029.

Since 2015, the Level Crossing Removal Project has built more than 50 new and upgraded stations, created the equivalent of 21 MCGs of open space for communities to enjoy and built 60 kilometres of walking and cycling paths across the city.

Across Melbourne, 84 level crossings are gone for good – saving more than 50 hours of boom gate down time during the morning peak every day and avoiding 100 crashes and near misses every year.

Have your say – National Rail Safety Law regulation amendments

Australia’s rail system is currently made up of 18 separate rail networks, 11 different signalling systems, and various operating rules and processes.

According to the National Transport Commission these differences drive up the costs of running trains. They create an added burden for people who work across more than one network and affect rail’s ability to move people and goods safely and seamlessly across the country.

Creating a more consistent, interoperable rail system is a priority for all Australian governments.

Currently under the Rail Safety National Law (RSNL), rail transport operators have not needed to consider the national interoperability impacts of their individual network decisions. However, a recent Rail Safety National

Law (RSNL) review has recommended that interoperability provisions be included in the law.

As a first step, transport ministers have asked the National Transport Commission (NTC) to develop changes to regulations to require rail transport operators on freight and passenger lines between major cities and ports, to include an Interoperability Management Plan as part of their Safety Management System.

The Plan will ensure all matters of national interoperability are recorded and considered before making any changes to the operator’s railway operations.

Consultation on this draft amendment regulation closes on 4 October 2024.

To learn more or have your say, visit the NTC website.

The new station will provide modern facilities for passengers.

The NTC wants the industry to provide feedback on changes to regulations to improve interoperability.

You’re in control

OF YOUR SAFETY, COMFORT, FLEET & PROFIT.

Zaxis-7

Create your vision

Hitachi

Keeping Your Project on the Right Track

• Australia’s Most Skilled and Experienced Operators

• Cutting-Edge Equipment for Superior Performance

• Nationwide Service

• Customer Satisfaction is our Priority

• Reliable 24/7 Support

For services and equipment you can count on in your next rail project. Call 0437 402 673

First test train on track

The first train to Ellenbrook has taken to the tracks, with testing now underway on the METRONET Morley-Ellenbrook Line.

The new line will be the largest public transport project delivered in Perth since the Mandurah Line was opened by the West Australian Government more than 16 years ago.

Twenty-one kilometres of new rail line, including 150,000 sleepers and 96,000 tonnes of ballast, and new stations in Morley, Noranda, Ballajura, Whiteman Park and Ellenbrook have been constructed as part of the project.

The new line spurs from the existing Midland and Airport lines at Bayswater Station and will connect tens of thousands of people in the city’s north-eastern suburbs to the metropolitan rail network for the first time.

Western Australian Premier Roger Cook spoke about the major milestone.

“The tracks are laid, the stations are almost complete, and now trains are on the METRONET line to Ellenbrook – the finish line is well and truly in sight,” he said. “This will be a game changer for Perth’s north-east

Once the line opens, commuters in the north-east will be able ride to the city for as little as $4.16 with a SmartRider.

The first train on the tracks marks the start of an extensive testing and commissioning program, which will ensure all infrastructure and systems are operating effectively and trains are running safely, efficiently and smoothly.

Testing will take place for about four weeks, with a gradual increase to operational speeds. Following the testing phase, training of Transperth’s drivers will commence.

station to be completed, alongside Ellenbrook and Ballajura.

Works on Morley and Noranda stations continues, with completion scheduled in the coming months.

Construction of the METRONET MorleyEllenbrook Line has supported an estimated 6,500 jobs to date.

When passenger services begin later in 2024, the line will provide an estimated 30-minute journey from Ellenbrook to Perth, halving the commuting time for passengers.

Public Transport records tumble with 50-cent fares

A six-month trial of 50-cent public transport fares in Queensland started successfully as records tumbled across the first week.

Patronage increased across all modes during the first week of the trial with public transport use in southeast Queensland returning to 98.5 per cent of pre-COVID levels for the week.

It was the first week to exceed one million journeys on southeast Queensland trains since the week ending March 15, 2020.

More than four million passenger trips were taken, with total trips up 11.1 per cent from the previous week and up 11.6 per cent from a comparable week in 2023-24. Tuesday, Wednesday and Thursdays were the busiest days in the week.

Premier Steven Miles said the results were encouraging and a sign the trial was delivering real savings for commuters.

“We put the call out for Queenslanders to make the most of this trial and they are doing just that,” he said.

The weekend was a standout, with Saturday and Sunday both recording their busiest days ever on the network.

There were more than $7 million in savings from the first week of the trial, based

on the same number of trips being taken under the previous fare structure.

Trips were up 11.1 per cent across all four modes in southeast Queensland compared to the week before the trial started.

Minister for Transport and Main Roads, Bart Mellish said in the first week of 50-cent fares, the government had seen patronage almost returned to pre-COVID levels which was a great result.

“How fantastic to see southeast Queenslanders getting out and about on public transport while keeping money in their pockets,” he said.

“This is a cost-of-living initiative first and foremost and on average, southeast Queenslanders saved more than $1 million per day last week.

“It’s not just commuters who are benefiting – we said before the trial that 50-cent fares would provide a great opportunity for residents and tourists to explore some of the great locations across our region and the data shows people did exactly that over the weekend.

“We saw busy days across all modes of the public transport, including the busiest weekends ever in the southeast, but still

Passenger numbers have increased up to 98.5 per cent on pre-COVID numbers during the trial.

exactly what we hoped for.”

While weekend figures were boosted by busy crowds at Suncorp Stadium where the Wallabies took on South Africa and Dolphins versed Warriors, and at the Gabba for the Brisbane Lions – GWS Giants AFL game, free travel arrangements were in place for these games and patrons did not need to tap on.

Airtrain passengers are also making the most of half price fares with an 18 per cent increase in passenger numbers in the first week, as well as a 69 per cent increase in airport staff tickets.

Testing is the start of an extensive period of preparation ahead of the line opening later this year.

Iconic station gets name change

Park Road rail station is being renamed to Boggo Road rail station in a move to make navigating the network easier for Queenslanders. The rail station has now combined with the Boggo Road busway to

create a major public transport interchange, Boggo Road station, offering transfers between the Beenleigh, Gold Coast and Cleveland rail lines and busway services at the one station.

High speed rail accelerates

Nearly 30 boreholes being drilled in New South Wales will support critical geotechnical investigations to determine the locations for the Federal Government’s High Speed Rail between Sydney and Newcastle.

The geotechnical investigations are being undertaken by the High Speed Rail Authority (HSRA) as part of the business case being developed for the first stage linking Sydney and Newcastle.

High-speed rail will connect Australian regions, cities and communities –delivering more job and lifestyle choices, greater housing options and new economic opportunities.

Infrastructure, Transport, Regional Development and Local Government Minister Catherine King spoke about the early works.

“High-speed rail means generations of new opportunities for regional Australia, creating more jobs in more locations and giving people greater choices in where they live, work, study and play,” she said.

“It is a nation-shaping investment to support a growing population, which will better link workers with opportunities while delivering a sustainable low emissions form of transport.

“High-speed rail will help shape Australia for decades to come.”

The Federal Government is planning for a high-speed rail network that will connect

The Cross River Rail project will also deliver two new below-ground rail platforms at Boggo Road, further increasing the importance of this interchange location.

Minister for Transport and Main Roads, Bart Mellish said the government is making the network better and more user-friendly to ensure those using the network can easily get to where they want to go.

“Customers wanted a common name at this location, and we have listened.

“Boggo Road is an iconic landmark, and this is all about making the network easy to navigate for Queenslanders.”

Customer feedback to Translink demonstrated a preference for a common name at this location.

Translink, Queensland Rail and the Cross River Rail Delivery Authority have worked together on the change, while the feedback from key stakeholder groups has been supportive.

Brisbane, Sydney, Canberra, Melbourne and regional communities across the east coast of Australia.

The first stage will connect Newcastle to Sydney – a nationally significant corridor – to create a fast, reliable and regular link between the two largest cities in New South Wales.

High Speed Rail Authority Chief Executive Officer Tim Parker said journeys will be quick, convenient and comfortable.

“Right now, we’re working on how to build a new railway in complex areas and the engineering challenges we would face,” he said.

Work has started on drilling 27 boreholes in key areas between Newcastle and Sydney

The information from this work will help determine the proposed depths of new rail tunnels, assess geological and geotechnical conditions to cross the Hawkesbury River and understand the geological complexities of traversing the escarpment into the Central Coast and on to Newcastle.

The government has committed $500 million for the planning and corridor protection of the Sydney to Newcastle section and established the HSRA to conduct the work.

The business case for the Newcastle to Sydney stage is due to be delivered to the government by the end of 2024.

The station will be combined with the busy Boggo Road busway to create a major transport interchange.

The beginning of preliminary works on the project is an exciting milestone.

Contract awarded for level crossing removals in Melton

The Victorian Government has announced four crossings in Melbourne’s west are one step closer to being gone for good, with contracts awarded for crossing removals at Coburns and Exford roads in Melton, and Ferris and Hopkins roads in Truganina.

A $560 million contract has been awarded to John Holland, Kellogg Brown and Root (KBR), Metro Trains Melbourne, V/Line, and the Level Crossing Removal Project. This alliance will deliver the new Melton Station and remove the level crossings at Coburns and Exford roads by constructing a rail bridge.

Additionally, a $229 million contract has been awarded to an alliance comprising Fulton Hogan, Metro Trains Melbourne, V/Line, and the Level Crossing Removal Project. This team will deliver new road bridges to remove crossings at Ferris Road, Melton, and Hopkins Road, Truganina.

The removal of the Melton level crossings will make way for the introduction of larger nine-car V/Locity trains as part of the $650 million Melton Line Upgrade, boosting passenger capacity by 50 per cent. The new Melton Station will feature two additional platforms to accommodate Ballarat train services and the short-starter services that begin and terminate at Melton.

Minister for Transport

Infrastructure Danny Pearson spoke about the announcement.

“We said we’d get it done and we’re not wasting a minute – getting rid of four dangerous and congested level crossings on the Melton line and improving capacity for people in this growing area,” he said.

Final designs for all four level crossing removals and the new Melton Station will be released later this year. The new station will have an expansive pedestrian

walkway, pick-up and drop-off zones, a new relocated bus interchange, and platform accessibility via lifts and stairs. It will also feature an air-conditioned waiting room, a staffed ticket office, and lighting and security cameras throughout.

The level crossings will be gone for good in 2026, along with the completion of the new Melton Station.

ON TRACK, ON TIME

Allworks delivers consistent efficient and quality results owing to a long history of providing reliable plant and personnel for the rail industry throughout Australia. Our end-to-end capabilities enable us to keep your project, On Track, On Time

The contracts will involve four level crossings being removed in Melbourne’s west.

IMAGE: VICTORIA’S BIG BUILD

Port Hedland

Karratha

Wangara

Busselton Kalgoorlie

Burramine

Narrabri

Eumundi

Morayfield

New spur line officially opens

Train services have begun on the new spur rail line into Port Dock following a $51 million rebuild.

The newly established spur line, which runs from the existing Outer Harbor line at Grand Junction Road, will provide rail services for those who already call the area home and the many more set to live, work and visit Port Adelaide into the future.

As part of the project, a new Port Dock Railway Station and plaza at Baker Street, and bus interchange at the existing Lipson Street car park have been established.

Testing of the rail signalling system has been underway since June 2024 and has been a vital part of the project to return trains along the reestablished line to Port Dock Railway Station. Minister for Infrastructure and Transport Tom

Koutsantonis spoke about the importance of the train line reopening.

“The new Port Dock Railway Station and bus interchange will provide a dedicated rail and bus service for the many people who live and work in the heart of Port Adelaide, as well as visitors to the area,” he said.

Outer Harbor services will be changing to accommodate these new services.

Works complete in major regional centre

Trains have returned to the Geelong and Warrnambool lines, with the Federal and Victorian governments’ 72-day construction blitz on the South Geelong to Waurn Ponds Duplication now complete.

Trains returned following intensive works that duplicated eight kilometres of track, upgraded Marshall and South Geelong stations and removed two level crossings.

Trains will now travel over new rail bridges at Fyans Street and Surf Coast Highway, with the removal of the two-level crossings reducing congestion for the tens of thousands of drivers that use these roads each day.

Fyans Street will feature a new streamlined road alignment, along with picnic facilities and rest areas available in the new open space around the rail bridge.

Deputy Prime Minister and Federal Member for Corio Richard Marles said the project is delivering the improvements needed to support the growth of Geelong, now and into the future.

The duplication of more than eight kilometres of track between South Geelong Station and Breakwater Road, and from Marshalltown Road to Waurn Ponds Station, will improve reliability for services, making it easier for trains to pass each other and reducing unexpected delays.

The project’s upgrades have also increased capacity on the line to allow for future additional services between Marshall and Waurn Pond stations, which both feature improved shelter and CCTV to improve safety.

Victorian Premier Jacinta Allan spoke about the major milestone.

“Our massive investment in rail upgrades in Geelong and Warrnambool is delivering huge benefits for local motorists and train passengers,” she said.

Crews will continue minor works at the stations including finishing the Yarra Street car park entrance and lifts at South Geelong Station, and the forecourt and lifts at Marshall Station, with work on landscaping and walking and cycling paths to continue in spring.

Upgrades to train detection technology have also been completed on the remaining public level crossings between Waurn Ponds and Warrnambool as part of Stage 2 of the Warrnambool Line Upgrade, which will enable the introduction of VLocity trains by the end of the year.

Victorian Minister for Transport Infrastructure Danny Pearson noted the importance of this work to the community.

“The Geelong community has said a big goodbye to two congested level crossings, with thousands of drivers to enjoy smoother and safer journeys on the Surf Coast Highway and Fyans Street every day,” he said.

The South Geelong to Waurn Ponds Duplication total project cost is $933.6 million with the Federal Government committing $784.1 million.

The new spur line will better connect the city to Port Adelaide.

Trains are now travelling over the brand new bridge.

IMAGE: VICTORIA’S BIG BUILD

Minister inspects new regional rail fleet in Dubbo

The first two trains of New South Wales’ new regional rail fleet have been inspected by Minister for Regional Transport and Roads Jenny Aitchison at the recently completed purposebuilt rail maintenance centre in Dubbo.

These new trains, that will eventually replace the XPT, Endeavour and Xplorer fleets, are bi-mode diesel-electric hybrids, allowing them to run on overhead power when operating on electrified sections of the network.

The trains will provide new safety features, accessibility, facilities, and reliability for passengers who travel from many New South Wales regional centres to Sydney, as well as Canberra, Melbourne and Brisbane.

While in Dubbo, Aitchison also announced that the current XPT train service between Dubbo and Sydney would be the focus of a roll-on bikes trial. “It was great to inspect the new trains in Dubbo, with two of the 29 new

trains now in Australia,” Aitchison said. “The bimode technology of the new regional rail fleet will significantly reduce carbon emissions and diesel particulates, compared to the current regional fleet.

“I am also looking forward to seeing the results of the Dubbo XPT trial of roll-on bikes, which will inform the feasibility of such an option for our regional transport network.

“I am a passionate advocate for ensuring regional rail passengers can more easily get their bikes onto trains and I want to thank NSW TrainLink, our front-line rail workers, the Rail Tram and Bus Union (RTBU) and bicycle advocate groups for their co-operation and consultation in the lead up to and during the trial.”

NSW TrainLink’s limited proof of concept trial is designed to provide insights into the operational feasibility of transporting bikes onboard long-distance regional trains.

The new fleet will eventually replace the XPT, Endeavour and Xplorer fleets.

IMAGE: TRANSPORT FOR NSW

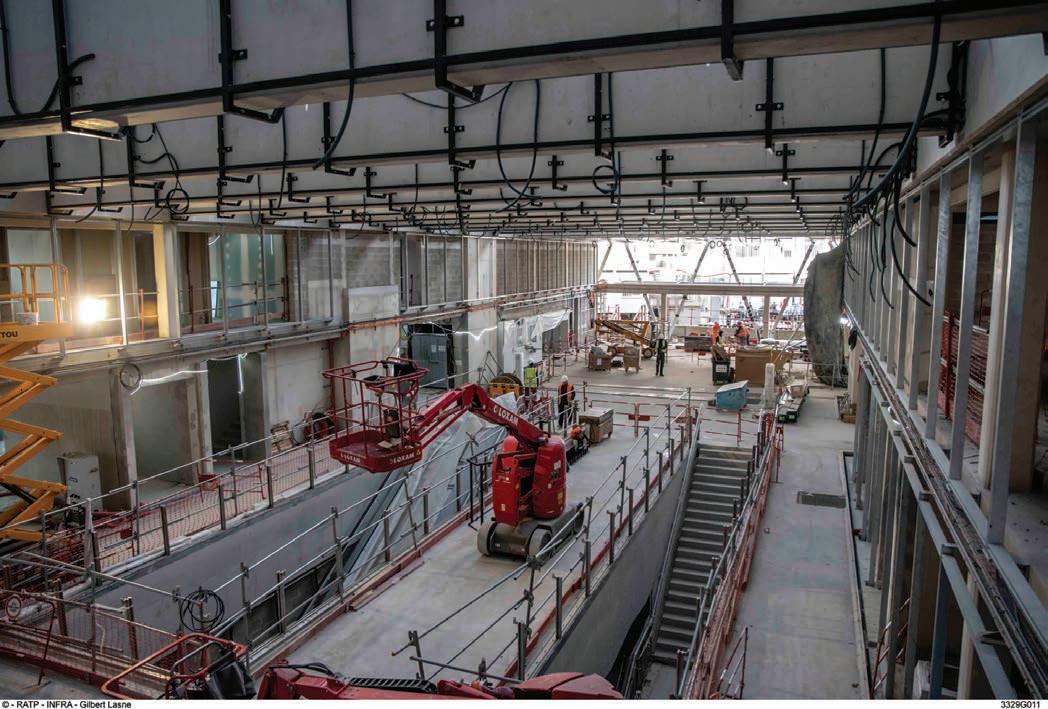

Experts in delivering major projects

RATP Group has completed a number of brownfield and greenfield projects across Paris and is bringing this experience to the global market.

RATP Group, along with its international subsidiary RATP Dev, has been using its experience in operations, maintenance, and project management to deliver and support projects across the globe.

RATP Dev was recently awarded the contract for Sydney Metro – Western Sydney Airport Line as a part of the Parklife Metro Consortium in which RATP Dev is the operations and maintenance partner.

RATP Group will be leaning on its experience operating 24 metro lines globally, 11 of which are fully automated

either in operation or under construction.

The company believes mobilising its in-house experts and a constant drive for innovation is what ensures success working across major projects.

INTEGRATION

General Manager Australia New Zealand for RATP Dev, Denis Masure said that thorough knowledge of project life cycles, equipment and infrastructure, combined with operational agility across transport modes and demanding projects, as well

as a socially responsible culture, are all qualities that ensures RATP Group can meet any challenge.

“RATP Group’s key strength lies in integrating its areas of expertise required for the design, construction, operation, and maintenance of transport systems, which guarantees project consistency and sustainability,” Masure said.

“We have the capability to issue project requirements before the design stage to ensure enhanced reliability, availability, maintainability and safety levels.

RATP has worked to bring its expertise to projects across its global networks.

IMAGES:

RATP

“RATP Group boasts the full range of skills and expertise required in its multiple roles as designer, project owner, project manager, transport and maintenance operator.”

The group has extensive multimodal experience across commuter rail, metros, trams and buses, all of which the organisation leans on when working on new major projects.

“Project managers have proven field knowledge in operating and maintaining public transport systems, and in the essential professions involved in infrastructure construction,” Masure said.

“Their expertise is also fine-tuned through the internal career evolution offered by the group so engineering teams can build a track record in operations and maintenance.”

Masure said this allows project managers to anticipate future requirements, and to factor them into specifications and program schedules.

RATP Group understands that the majority of major projects across the globe operate with a range of stakeholders. Masure said this understanding is pivotal to its success. The group consolidates projects by coordinating stakeholders operating in the same scopes. This was exemplified in recent work completed in Paris.

MAJOR CONSTRUCTION IN PARIS

Work began in 2016 to automate metro line 4 and was completed at the end of 2023 with no disruptions to the line or the work itself.

Other major projects RATP Group contributed to include line extensions on the north and south metro line 14, on metro line 11 and on tram line T3b, all before the Olympic Games began.

Masure said that RATP Group completed the work by adhering to four driving principles.

Ensuring service continuity during ongoing works was its first priority. Twelve million passengers use the service daily. Masure said RATP Group understands that continual service needs to be a priority so that a line upgrade does not penalise hundreds of thousands of passengers.

Works are conducted at night and major track possessions are not implemented unless compulsory. Alternative itineraries or replacement bus services are provided and communicated beforehand.

The next principle is leveraging inhouse and partner engineering expertise to adapt to the specific conditions of projects. The organisation looks to support companies working in and around it with

its own expertise. The third principle is complying with schedules and budgets. RATP has honed its commitment to this principle by completing projects in the agreed time frames, while keeping within a fixed budget.

The line 14 South extension to Orly Airport was delivered in six years as opposed to the initial eight proposed, to ensure it was ready in time for the 2024 Paris Olympic Games.

The final and critical principle is guaranteeing safety in all daily activities. To ensure business as usual during works, meticulous adaptation is required across safety systems and a safety compliance demonstration is compulsory at the end of each night shift.

UNIQUE CHALLENGES

RATP operates a long-serving network in Paris and extending these networks poses unique challenges. This experience running complex systems at various points of the life cycle is the key to success when working on major projects, according to Masure.

The century-old metro line 4 was extended and automated in 2022. Running from north to south, it serves as a major

long-distance line with train stations and strategic hubs, while carrying 700,000 passengers daily.

Alongside the line’s extension, automation works were launched in 2016 with the goal of improving service quality and transport capacity. This decision was made following the successful automation of metro line 1.

The transformation was completed as planned in December 2023, with the operations control centre also renovated in preparation for the line’s automation.

On metro line 14, RATP Group contributed to the doubling in length of the line.

Masure said this work demonstrated the company’s ability to not only work on brownfield projects but also contribute to greenfield projects.

As part of metro line 14 extensions, the new segments and the existing line had to match to ensure operations were smooth. It required the automation system (CBTC) to be fully renewed and improved by a nextgeneration system. Masure described it as an unprecedented technical feat.

Adding more than 14 kilometres to the line, eight new stations and a new maintenance centre and depot, were all completed in record time to ensure the line

RATP has experience working on networks at varying stages of its life cycle.

Cover story

was operational for the Olympic Games.

Masure said the key to success was the way the organisation carried out trials.

“Transport operators and maintenance operators were mobilised, thereby raising standards and efficiency to ensure the line could get underway far quicker,” he said.

“Among its multiple challenges, the project had to meet a tight schedule, simultaneously operate three tunnel boring machines, accommodate new rolling stock, and integrate a new automated driving system.”

The project had to be co-ordinated with the region’s industrial players and stakeholders including construction company Société des Grands Projets, international airport operator Aéroports de Paris, and government organisation Île-deFrance Mobilités.

Another challenge was the integration of metro line 14 close to Orly Airport infrastructure, and its connection to tram line T7.

The line now offers direct connection to the Stade de France in Saint-Denis-Pleyel north of Paris, and the Paris-Orly airport in the south, with a headway of 85 seconds between trains.

Masure said the success of the project was showcased during the Olympic Games, with no service failures reported during the event.

The group’s extensive expertise in metro operations was also instrumental in extending metro line 11, showcasing its ability to design and execute highly complex projects.

Six new stations were delivered for this six-kilometre extension, as well as modernising 10 of the 13 existing stations to accommodate the new rolling stock with increased capacity from four to five cars. It also called for the construction of a new operations control centre.

Civil engineering, railway systems, energy, and public transport systems, as well as station design, equipment, lift pumps and ventilation systems formed various components of the group’s project management.

Leveraging its metro operations expertise, the group effectively co-ordinated various industrial contributors to meet project deadlines.

Another challenge was ensuring seamless integration between rolling stock upgrades and the connection and construction of a new maintenance centre at Rosny-sous-Bois.

A UNIQUE SET OF SKILLS

The organisation understands the

of rolling stock as a way of supporting major projects. This equipment durability contributes to the group’s efficiency.

The life cycle is optimised across France’s regional network by transferring rolling stock from one line to another, Masure said. RATP Group will also repair and retrofit older equipment to optimise its life cycle and help to curb the environmental impact.

With new MP 14 trains deployed on metro line 14, the group seized the opportunity to repurpose the rolling stock to metro line 1. The automated MP 89 trains previously on metro line 1 were redeployed to metro line 4, which at the time was undergoing automation. MP 89 trains with a driver’s cabin, which had been running on metro line 4 until its full automation, were subsequently reassigned to metro line 6.

Henri Pottier, Chief Executive Officer of RATP Dev APAC region said that what made the redeployment exceptional was the successful switch while ensuring the compatibility of the rolling stock in question with each infrastructure and systems.

“The goal was to centralise the command and control of trains, shuttles, stations, terminuses, and in the case of metro line 14, maintenance,” he said.

“By co-ordinating teams and stateof-the-art technologies more efficiently, the network is able to broadcast more responsive passenger information and improve incident management.”

benefit from its approach to continuous innovation, especially in the maintenance area. Anticipating breakdowns, and limiting their impact, are some of the key goals of predictive maintenance.

Data gathered from sensors that are embedded on trains and tracks allow the group to continuously monitor the operational status of its assets. By analysing such data, breakdowns can be anticipated, indicating exactly how and when to conduct repairs.

Efficiency in maintenance is also enhanced by virtual reality. RATP Group uses this cutting-edge technology to simulate maintenance operations through digital representations of trains and maintenance centres.

In the future, maintenance operators will be equipped with augmented reality glasses, which will provide them with instructions from a remotely connected expert guiding them through their operations.

WORKING WITH LOCAL PARTNERS

As part of a global network, RATP understands its role will differ in major projects and understands the importance of effective communication with various stakeholders to benefit from industry-wide vision and experience across the entire value chain.

This experience has proven to be invaluable. The metro line 14 extension

RATP understands its role will be different on every network and project.

RATP Group completed a number of projects in Paris.

to Orly Airport was one example of this stakeholder management.

Connecting metro line 14 to metro line 15 on the future Grand Paris Express network, by tunnelling under the airport’s runways, required close co-operation between teams from construction company Société des Grands Projets, international airport operator Aéroports de Paris, and government organisation Île-de-France Mobilités.

Partnering with construction partners is important, but Pottier said RATP Group understands it is critical to foster relationships with transport authorities as well.

Most often, these groups are funding the work RATP Group is completing. By regularly monitoring cost and schedules, the group provides these bodies with accurate reporting that eases their decisionmaking process.

“Co-ordinating these assets is a feat in itself, involving the evaluation and integration of various parties into complex schedules,” Pottier said.

“When the opening date of the metro line 14 extension was brought forward, the

group mobilised its project owner partners and rescheduled operations, while keeping to agreed budgets and time frames.”

On metro line 11 and line 14 extensions, RATP Group relied on its in-house project management division to build the transport system which included railways, signalling, and power supply, while outsourcing miscellaneous works on roads and networks.

This experience has been pivotal to the company’s success but the long-term relationships it has formed are invaluable.

“We worked closely with Siemens Mobility and Alstom to leverage their experience and expertise as transport operators and maintainers to perfect their rolling stock,” Pottier said.

Major works also serve as a platform for integrating local workforces into the project.

“Workforce integration clauses are systematically included in all project management contracts,” Pottier said.

“For instance, the recent southward extension of metro line 14 generated 460,000 workforce integration hours. RATP Group relies on regional facilitators,

who mobilise local employment stakeholders. The group works together with these facilitators to encourage contracting companies to promote longterm employment, upskilling, training and the development of workforce integration programs.”

SUSTAINABILITY

RATP Group has long been committed to a strict approach to corporate social and environmental responsibility, in which its major projects are seen as opportunities for change and to create more resilient cities.

This commitment is evident in the large-scale initiative to introduce greenery across the group’s properties, which not only introduces nature back into the city, but, crucially, uses plant species that consume less water, such as the grass on tram line T3b platforms.

Given the increasing frequency of droughts, the group has acted on various fronts to conserve water including optimising consumption, and recovering and reusing non-potable water.

MTR Australia and MTS colleagues, together with representatives of the business partners, joined MTR Chief Executive Officer Dr

Integration experts

MTR Corporation brought its international experience to the Sydney Metro City project to ensure the opening got off without an issue.

A cloudy and cold day in the middle of August may not have seemed like a particularly memorable day for Sydney residents. But the 19th of August will go down as a historic date for the city – the day the doors officially opened for the City section of Sydney Metro.

Metro Trains Sydney (MTS), a subsidiary of MTR Corporation, successfully launched the much-anticipated Sydney Metro extension that connects the city’s Northwest to the Central Business District (CBD) through new twin railway tunnels beneath Sydney Harbour.

MTR was entrusted with the task of delivering the trains and systems, plus system integration, of what is Australia’s first fully automated metro passenger service.

MTR delivered 23 new metro trains and all core rail systems, Operations Control Centre (OCC) expansion, systems integration, and testing and commissioning.

FROM SCRATCH TO SEAMLESS INTEGRATION

From the initial stages of design to the final stages of construction, the Sydney Metro City and Southwest (SMCSW) Project Delivery Team of MTR worked closely with partners to ensure that respective deliverables under each contract blended together in accordance with the project outline, while meeting all quality and safety standards.

The team co-ordinated with all contractors for the six new stations, the new metro platforms at Central and Sydenham stations, as well as an additional maintenance facility at Sydenham and expansion of the existing maintenance facility at Tallawong.

The integration and migration of the new City section into the existing operational Northwest section was a key challenge for the team, requiring rigorous configuration management processes involving software updates, possession

management of a brownfield metro, over and back and migration testing, and final safety case certification.

Expanding the system into an operational brownfield GOA4 driverless metro involved a much greater degree of testing and safety assurance process compared to a greenfield situation or a railway with drivers, MTR Corporation chief executive officer Dr Jacob Kam said.

Prior to the opening, the team undertook multiple system performance and capacity testing to ensure it met stringent requirements.

MTS also conducted extensive trial runs of the new trains from Chatswood into the city to identify any teething issues prior to opening.

Throughout the project, MTR kept Sydney Metro Authority (SMA) up to date with its whole-of-project approach and contingency planning. This culminated in the new safe

Jacob Kam.

and swift journey experience for passengers across different landscapes in Sydney.

Kam welcomed the smooth and successful launch of the new metro extension into the heart of Sydney’s CBD, stating it delivers significant time savings for passengers on their daily journeys and will play an important part in the growth and development of the city.

“Working closely with the New South Wales Government and our partners, MTR is proud to have contributed its Hong Kong and global expertise to this railway line including project works, such as the integration of the new extension with the existing North West Metro Line, through to testing, commissioning and the commencement of passenger service,” he said.

IMPORTANT FOR THE CITY

The Sydney Metro City section will revolutionise the way in which Sydneysiders will come and go to the city.

New South Wales Premier, Chris Minns congratulated everybody who worked to bring the major project to fruition.

“It’ll be a huge change for Sydney and a big step forward,” he said.

“Obviously, this will see hundreds of thousands of people get to work in a different way. It needed to fully integrate with the rest of the public transport system.

“It will genuinely transform the way people get to and from work, and it’ll be fantastic, so Sydney, enjoy the experience.”

New metro services launched to a weekday timetable, which means a service every four minutes during the peak and every 10 minutes during the off peak. For Opal fare consistency, peak times are the

minute frequency for trains travelling from Tallawong Station between 6.08am-9.24am and 2.54pm-6.46pm. Sydenham Station will see a four-minute frequency from 6.54am9.46am and 3.16pm-7.32pm.

Interpeak trains will run every seven minutes, increasing to a train every five minutes after the first month.

A total of 445 new metro services will run through the heart of the city each weekday. The 45 new metro trains can each carry more than 1150 people and will alleviate pressure on existing transport and road networks.

This transformative new section of railway is the next stage of the M1 Northwest & Bankstown Line, which now extends

and Sydenham.

Sydney Metro Chief Executive Peter Regan said the opening is a great moment for public transport in the city.

“I want to thank our teams, who have been at work since 2017; I know each and every one of them is so proud to welcome you all today,” he said.

“We know people will have a lot of questions, so we’ve bolstered our teams on the ground to help commuters familiarise themselves with the new network and get where they need to go.

“A reminder that metro trains can travel at speeds of up to 100 kilometres per hour, so please hang on when taking off.”

GO SOUTHWEST AND BEYOND

While the opening of the City section marks a new milestone for Sydney’s public transportation, MTR now focuses on the passenger services for the extended M1 Line and the transformation of the future southwest section, between Sydenham and Bankstown.

Major planning and works are underway to convert the T3 Bankstown Line to metro standards. All ten existing stations will be upgraded and fitted with lifts and platform screen doors, providing enhanced passenger accessibility and security.

On completion, when the southwest section is integrated with the city and northwest, the M1 Metro Northwest & Bankstown Line will be a network of 31 metro stations along a 66 kilometre dedicated metro railway system.

Railway fans and passengers were excited to take their first ride on the new Sydney Metro extension.

The line offers faster journey times and more frequent departures to and from the city’s CBD.

Plant and equipment

Hitachi works for Allworks

Allworks has undergone an impressive expansion over its 25 years, in its corner throughout the journey has been Hitachi Machinery Australia.

Family-owned equipment hire business

Allworks operates across the rail, civil, mining and infrastructure industries throughout Australia. The company has more than 300 pieces of equipment with a large selection of Hitachi Machinery in its national fleet.

Allworks has been in operation since 1999, starting with a couple of small machines on a project in South Australia and has grown to its impressive size today in which it operates in all mainland states.

General manager Nick McLoughney said the company turned to Hitachi machines due to the great price point, reliability, aftermarket backup service and parts availability.

The company operates a range of hi-rail excavators, standard excavators, and loaders across its sites.

The 30 Hitachi Hi-rail excavators are used across Australia in a variety of rail

construction and ongoing maintenance projects. The smaller ZX75, ZX85, ZX135 and ZX140W are narrow, standard and broad-gauge rail compatible, with the larger ZX170W being dedicated to standard and broad gauge.

The fleet includes 20 Hitachi wheel loaders and excavators and are deployed across projects in rail, civil and mining industries.

McLoughney said the diversity of Hitachi’s range has been a benefit to the company and its expansion across the country.

“We can send those smaller machines up onto narrow sites in Queensland on projects like Cross River Rail for example,” he said.

“Then the 17 tonne or 21 tonne machines can go into the Pilbara to do work there. We were one of the first to develop the 7.5 and 8.5 tonne hi-rail excavators in conjunction with Harrybilt Engineering and Hitachi

Construction Machinery and we would have a couple dozen running around now.”

The relationship between Hitachi and Allworks has been mutually beneficial. It has allowed development of these smaller machines to be used on Australia’s diverse rail networks.

WHY HITACHI?

McLoughney said the organisation was originally drawn to Hitachi machinery due to the price point, but the appreciation for the machines has grown to be much more.

“The Hitachi is laid out like a standard excavator allowing it to be simple to use and train team members on,” he said.

“When it comes to training our team members or those on site for dry hire, it is far simpler to show them the additional functionality of the hi-rail component as

The relationship between Hitachi and Allworks has been beneficial for both organisations.

opposed to showing them a completely different machine than what they are used to.

“What also became apparent very quickly was that the support Allworks would receive from Hitachi would help us in our growth and our work.”

McLoughney said the relationship with Dale Smulders, the sales manager working out of the Forrestdale branch for the past 10 years, and Tom Price from Port Hedland, has provided the support the company was looking for from its OEMs.

“As you expect when you work on the sites like the ones our machines go out on, issues are inevitable,” he said.

“Dale and Tom will move heaven and earth to support us with any issues. Hitachi Machinery Australia keeps us up to date on the availability of new equipment as well as changes to models and new technology.”

He noted an example where some machines had been damaged during transport to Australia. Hitachi flew replacement parts from Japan to Australia and the OEM lost no time in the delivery schedule, getting the machines out and working when needed.

“All our Hitachi machinery fleet has been exceptionally reliable,” McLoughney said.

“Any small issues have been rectified by the Hitachi team promptly and professionally. They understand the demands placed on our equipment and our clients, especially in rail where on-track time is often restricted, and windows of work are limited. Reliable machines are critical to project success.

“A majority of those machines also have an extended warranty when we purchase them so we have even more confidence from the OEM that the machines are going to be working around the clock in some harsh environments.”

SAFETY

McLoughney said that safety is always the focus for Allworks, and is something that is considered when investing in new machinery.

“Our hi-rail excavator fleet has a key safety lockout system to prevent unauthorised actions and ensure the machines remain within designated safe work zones,” he said.

“These additions are especially critical when operating around personnel, other equipment and high voltage overhead electrical power lines in the rail corridor.”

McLoughney said that the familiarity operators get with the Hitachi excavators ensures highest levels of safety are achieved.

SUPPORTING THE HI-RAIL EQUIPMENT

Australian manufacturer Harrybilt Engineering installs the hi-rail equipment for Hitachi and then will provide the backup support in conjunction with the OEM.

McLoughney noted the streamlined process of acquiring hi-rail excavators from Hitachi after the partnership between Harrybilt Engineering and the OEM began.

“If operators can jump from an excavator into a tipper and any other machine and use similar controls across each, they can usually maximise the safety features installed,” he said.

“In the past our machine would arrive from Hitachi, and we would advise Harrybilt it is in transit and then we would see it six months down the track,” he said.

“We now just have to work with Hitachi. They will organise the machine and can be the point of contact for all issues on both

the excavator and the hi-rail equipment.”

McLoughney said the reason Allworks goes back to Hitachi again and again is the strength of the relationship between the two organisations.

“I think it is similar to what our customers get with us, we have the confidence and trust to deal with Hitachi,” he said.

“This was obvious when we developed those smaller hi-rail machines. We were able to collaborate with Hitachi and work through any teething issues we had in the early stages.

“We have the confidence to know they are always there to support us and ensure that we always succeed.”

Allworks has been impressed by the diversity of Hitachi’s range.

Both Allworks and Hitachi ensure the machines have all the safety features needed for safe working conditions.

Plant and equipment

Quarter century of success

In its 25 years, Allworks has undergone rapid expansion onto the east coast of Australia after servicing South Australia and Western Australia.

Allworks has 25 years’ experience supporting the rail industry with wet and dry hire of plant and equipment. The company’s recent growth onto the eastern seaboard during the past five years has people lauding its success. General Manager Nick McLoughney said it is the classic story of a 25-year overnight success.

“I think the success of the business is down to the fact our team has an in-depth knowledge of the rail industry that extends beyond their specific roles,” he said.

McLoughney said each of the management team can operate across a broad range of areas within the business, and deal well

with competing priorities and sometimes ambiguous project demands.

“This expertise ensures we remain nimble,” he said.

“If a customer rings and needs plant or equipment on site immediately, we can often meet that need. If we do not have the equipment on hand, we will move heaven and earth to make it happen.

“A lot of Tier One companies have been customers over the past 20 years and their key personnel, even if they move companies, have strong ongoing relationships with us. Customers know when they call Allworks, we will make it happen.”

Owners Angelo and Robin Sarich began Allworks in 1999, but the opening of the business was a culmination of years of experience serving the railway sector.

Angelo Sarich was only 19 when he started working with Western Australian Government Railways, the operator of the state’s railway services before being privatised in 2003.

After being retrenched at age 35, Angelo joined John Holland for a four-year stint, after which he bit the bullet and decided to start his own company. McLoughney said the success of the company 25 years later can be attributed to a deep understanding of the rail sector stemming from Angelo’s experience.

Allworks has made the expansion onto the east coast of Australia.

“We understand what our service offering is, and we back it 100 per cent,” he said.

“Not everything goes to plan all of the time, but we are very good at responding to that. We build contingency into our plans and have spare resources on standby if a job requires it.

“We have a large transport fleet and can redeploy our assets very quickly if need be, and understand what is required across a diverse range of rail projects.”

SUPPORTING RAIL

McLoughney said understanding customers projects and leaning on the organisation’s experience to support the local team is critical to the success of a project.

“With the current demand for rail-specific expertise across Australia, some projects may not pre-empt problems we see regularly. We can advise of what plant and equipment is best suited to each application to avoid some of these issues,” he said.

“I think customers appreciate us being open and clear with what our service offering is and what we can provide.

“What we have learnt over the past few years is that we sometimes need to say no. If we cannot deliver on customer’s expectations we will let them know early so they can explore other avenues.”

McLoughney said the company has the modern fleet needed to work across a number of large projects. It works across greenfield, brownfield, ongoing maintenance and derailment works using its diverse equipment.

The company’s expansion onto the east coast was an exciting move for McLoughney and the team but it was not without new and exciting challenges.

“It has certainly been something that was been a challenge for us over the first couple of years,” he said.

“I think before that, a lot of our machines were dedicated to Western Australia. We had a lot of our equipment on metro and regional WA projects, as well as out in the Pilbara.

“We now have equipment working across the east coast on multiple rail networks.”

Allworks Asset and Compliance Manager Tom Butcher is responsible for managing equipment approvals across Australia’s diverse rail networks.

McLoughney said this full-time role ensures the machinery is readily compliant across Australian Rail Track Corporation, Arc, Queensland Rail, the Pilbara rail networks and Public Transport Association in Western Australia.

“Tom has been an integral part of our team for over 10 years and he has a great understanding of the requirements of each network to ensure the machinery is up to standard,” McLoughney said.

BACKUP SUPPORT

After its expansion onto the east coast, Allworks understood it needed strong backup support systems across the country.

The company has a robust equipment replacement program and works with brands it knows and understands. This ensures a

Allworks has a strong range of excavators.

operators and maintenance staff.

“Our fleet is predominantly Hitachi, Volvo, Isuzu and John Deere. Across the more than 300 assets they are our main equipment suppliers,” McLoughney said.

“Majority of those machines have an extended warranty at purchase. We have even more confidence from the OEM that the machines are going to be reliable while working around the clock in some harsh environments.

“We generally turn over our machines over quicker than others in the industry. This ensures our machines have the latest technology, with the highest level of quality and reliability when out on site.”

Allworks often deploy equipment to work on critical projects that are completed in short shutdown periods and emergency works such as derailments.

McLoughney said keeping the fleet updated reduces the risk of plant and equipment breakdown while working on time-sensitive projects.

“We know customers are often working in a short work window with limited network or track time, so we ensure we are prepared for any challenge that might come our way.”

He said the key to this industry support is the company’s understanding of the rail industry.

“Organisations know we are more than just a hire company; we bring great experience and knowledge to challenging circumstances.

“We are set up for things like derailments and that is why we are so good at deploying resources quickly and efficiently,” he said.

McLoughney said the company understands that challenges are part and parcel of working with machinery, especially when things don’t go to plan.

“It is all about understanding what each project needs, the customers’ requirements, anticipating potential issues and working through them together.

“Ensuring customers projects are On Track, On Time is what we do.”

The organisation has a deep understanding of the rail sector and uses this to support the industry.

IMAGES: HITACHI

Plant and equipment

Turning to Harrybilt

Harrybilt Engineering has leant on its close to 40 years’ experience to develop turnkey capabilities to deliver high quality hi-rail equipment.

Entering its 40th year in 2025, Harrybilt Engineering remains focused on developing Australian made products designed and built to support the Australian rail sector.

Based out of its modern manufacturing facility in Ballarat and still family owned, the company specialises in the design, development and manufacturing of specialist rail plant.

The original factory, constructed in 2008, was expanded in 2011 to incorporate a large spare parts store. In 2019, the factory floor was doubled to meet growing demands in the rail market and to tackle complex projects.

The company has been honing its skills in delivering Hi Rail, Hi Brid or Rail Guidance Systems to support the rapidly growing

rail sector. This development has delivered the company to the point where it has full turnkey capabilities providing Hitachi and Komatsu machines.

Engineering finance and marketing manager

Beth Martino said Harrybilt has grown over the past few years and partnerships with the two original equipment manufacturers (OEM) have allowed the company to go from strength to strength.

“That relationship has gone really well, and we have seen a lot of growth since that relationship began.”

Martino said the decision by Harrybilt Engineering to provide more turnkey solutions a few years ago has been revolutionary for the business.

“We are managing the purchase of the machine and installation of the Hi Rail, Hi Brid or Rail Guidance System,” she said.

“This also includes supporting registration for required networks around Australia, so the machine is rail ready when it leaves the workshop.

“The team also handles the purchase and installation of a tiltrotator, along with Harrybilt Engineering’s own wide range of rail maintenance attachments.”

These turnkey capabilities allow Harrybilt Engineering to simplify the language it uses for its machines. The S Series machine has different models based on the tare weight with the rail equipment attached. This is exemplified by the H21 S series machine which

The language used for naming of the machines has been simplified as shown by the H21 S Series.

is a 21-tonne rail machine with the Hitachi ZX170W as the base excavator.

The K18 S Series is an 18-tonne rail machine using the Komatsu PC138US-11 as the base excavator. These excavators leave the Harrybilt Engineering workshop ‘rail ready’.

Martino said these turnkey capabilities signify a moment when Harrybilt Engineering has arrived as one of the foremost hi-rail manufacturers in Australia.

“Over the years we have developed our fabrication, machining, hydraulics and painting capabilities, along with larger overhead cranes in all workshops and a testing facility that includes a triple gauge test track to conduct compliance testing for network registration,” she said.

“This careful and considered updating of our facilities is what allows us to provide an endto-end solution for all project needs.”

These enhanced capabilities, coupled with the strong relationships the company has formed with excavator OEMs, is what has set it up for success.

“We also have a close working relationship with top level tiltrotator brands and compliance and design specialists,” Martino said.

Over the past few years, Harrybilt Engineering has expanded with two new factories and an increased labour force. This has had an immediate impact on its output, resulting in improved lead times and building of stock of its popular attachments and machines for short turnaround for customers.

All of this allows Harrybilt Engineering to deliver turnkey excavators for the rail sector that are safe, versatile and efficient, Martino said.

“Our machines can withstand the most severe working conditions while remaining simple to operate across Australia’s diverse rail network,” she said.

Harrybilt Engineering is often challenged by specialist rail problems allowing the team to design and manufacture a customised product to suit an organisation’s needs.

FINDING THE RIGHT MACHINE FOR THE RIGHT CHALLENGE

One of the challenges faced by Australia’s rail sector is the sheer diversity of gauges and networks. Martino said Harrybilt Engineering understands the challenges the industry faces are complex and the turnkey capabilities it has developed better supports the rail sector.

“We work closely with customers at the beginning, and then throughout the process, to build and provide an end product that suits their individual needs,” she said. “We can do this as we have in-house specialists, including

engineer department. The team also listens to customer feedback, frequently discusses with those in the rail industry and attends rail shows around Australia and internationally to get a true insight into the industry and what it is looking for from its hi-rail equipment.”

Martino said Harrybilt Engineering consists of fully qualified and experienced tradesmen and apprentices.

“We have a wealth of knowledge and experience to help keep our customers on track.”

Martino said the company likes to keep it simple when it comes to sourcing the right machines for a company’s specific needs. Early communication allows the company to establish the requirements.

The basic questions the organisation often asks include:

• What tasks the machine needs to do? operate?

• What safety system option will be mandatory?

• What attachments and trailers will suit the machine and application?

• What are the required timeframes?

Harrybilt Engineering’s design caters for the products to suit at least two, if not all three main gauges, meaning they can be adjusted from one gauge to another and back again throughout its life.

Harrybilt Engineering frequently engages Independent Certifying Parties (ICP) who are accredited with the rail networks that its customers hope to operate on.

The ICP reviews design, inspects and tests the machines and where applicable prepares and or submits the application for each of the networks.

Harrybilt Engineering has developed strong relationships with OEM’s Hitachi and Komatsu.

The company can deliver diverse excavators to suit any company’s needs.

Plant and equipment

Jack is on track

Just trying to catch Jack Divall for a phone call is no easy task. The owner of Jack Divall Earthmoving was out on site when he spoke with Rail Express about his Liebherr A 922 Rail Litronic that he has been operating for close to a year.

Operating excavators runs in Jack Divall’s blood, a third-generation operator, he left school at 17 to work for his dad. After five years, Divall made the decision to go it alone and purchased his first 14 tonne civil machine.

Divall’s ability behind the excavator has always been evident but he received an impressive honour by being named New South Wales best operator in the Global Operator Challenge. This achievement led him to Japan in 2024, where he competed against some of the best operators in the world.

Back in 2017, Jack Divall won the Civil Contractors Federation ‘Plant Operator of the Year’ award at just 18 years old, a milestone that filled the Divall family with immense pride. Fast forward to 2024, and Jack continues to impress, demonstrating a strong commitment to the sector and showing no signs of slowing down.

“I got into the rail sector by working on the civil aspect of level crossing removals and then I just went from there,” Divall said.

Spot tamping on a rerail in the Hunter Valley.

including rerails in the Hunter Valley, track reconditioning works up and down the East Coast and even spent six weeks working in South Australia.

rail space was a no-brainer for him and that is why he has brought the Liebherr A 922 Rail Litronic into the fold.

noticed a shortage of operators and machines in the hi rail space,” Divall said. “I decided to take a stab at it and bought myself the Liebherr.”

WHY THE LIEBHERR A 922

RAIL LITRONIC?

Divall is using the A 922 Rail Litronic for rerailing, vegetation clearing work and the civil aspect of rail work.

“We really use the machine any time that we need some grunt,” Divall said.

“When you are doing re-railing, you need a big machine, and not many are capable of it.

In addition to standard ballasting, a revised heavy ballast weight with a reduced rear swivel radius of 2,000 millimetres is now also available. The maximum payloads can also be increased by a Power Lift mode and an optional four-point support.

The design concept of the A 922 Rail Litronic was developed to deliver maximum performance and flexibility. The new 120 kilowatt / 163 horsepower construction machinery engine and the hydraulic system enables the machine to achieve even higher

Completing local council works while not working on the rail.

IMAGES: JACK DIVALL

working speeds with the familiar fluid equipment movements.

using attachments, the flow volume of the double variable-displacement pump (with i increased to 2x220l l/min. Furthermore, the capacity can also be used as the sum of both hydraulic circuits (for example for piledriving) as in the past. A second high pressure circuit means that three hydraulic functions can be controlled directly on special attachments such as on tamping devices.

“The machine is just extremely versatile and capable of tackling any challenge,” Divall said.

“The versatility of the A 922 allows us to do local council work when we are not working on rail projects.”

The A 922 Rail Litronic has been designed with operator comfort in mind. The large Liebherr double cab with standard rollover protection system (ROPS) provides comfort, which enhances concentration and productivity.

Thanks to the double seat layout, the cab supports two-man operation required in many countries. Access to the cab is made easy for both seats by entry lighting. This avoids often time-consuming re-familiarisation phases and allows the operator to work efficiently in the machine straight away.

ON RAIL CAPACITY

The A 922 Rail Litronic is available with a range of undercarriage versions with different gauges, rail wheels and suspension systems enabling it to be used on tracks anywhere in Australia.

An independent variable-displacement pump for the rail chassis always delivers outstanding traction and reliable drive power. The permanent level regulation of

networks, but we have worked across most in New South Wales, and it has been pretty straight forward, thanks to Meg and the team in our office,” Divall said.

SAFETY

Besides the performance and efficiency of a railroad excavator, the safety of the operator and the machine must always be paramount.

Numerous equipment features such as the standard pipe fracture safety valves on the lifting and stick cylinders, electronic lift limitation, electronic swivel limitation, load moment limitation, smash-resistant laminated safety glass, ROPS and an emergency exit through the rear window provide maximum safety in all operations.

LED lights illuminate the working area to deliver excellent visibility and a high level of safety for both man and machine. To comply with the appropriate standards, the machine can be fitted with additional railway-specific lighting at the factory.

All the steel components are designed and manufactured by Liebherr. High strength steel sheets designed to withstand the harshest requirements guarantee high torsion resistance and absorption of forces to ensure a long service life.

BACKUP SUPPORT

Divall has had his A 922 Rail Litronic for almost a year and has been impressed by

is great as we often work strange hours.”

Liebherr has strived to ensure maintenance is simple on the A 922 Rail Litronic. The service-based machine design guarantees short servicing times, minimising maintenance costs due to less downtime. All the maintenance points are easily accessible from the ground and easy to reach due to the large, wide-opening service doors.

With the new generation, the accessibility to important components is even further improved. Air, oil and fuel filters, the main battery switch, the lubricating nipple for the oscillating axle and the pilot valves for emergency actuation are much easier to access. This means that service work can be completed even more quickly and efficiently.

Hydraulic oils with added value Liebherr hydraulic oils achieve a service life of 6,000 operating hours plus, adding increased value to customers. Instead of having defined change intervals, the results of the oil analysis determine when the oil needs to be changed.

Divall said the team has been “stoked” with the new machine.

“They always love the new gear, and they know it is up for any task and can do any of the work they need it to,” he said.

“The Liebherr machine provides peace of mind when accepting new work. We believe the Liebherr A 922 has set the industry standard for hi rail machines.

“It is a good quality machine, and we are really happy with it.”

Jack Divall, pictured next to his all new Liebherr A 922 Rail Litronic.

Events ARI Awards a chance to celebrate

The rail industry has announced the 16 winners across Australia and New Zealand of the Australasian Rail Industry Awards.

Held at the Hilton Hotel in Sydney, the Australian Rail Industry (ARI) Awards were an opportunity to come together to celebrate the year that was.

Australasian Railway Association (ARA) Chief Executive Officer and ARI Awards judging chair Caroline Wilkie said almost 600 people gathered in Sydney at the Hilton Hotel in August to congratulate the winners of the highly anticipated awards.

“The degree of talent and innovation in the rail sector is incredibly impressive and the individuals and projects highlighted tonight are testament to the hard work and dedication at every level of the industry,” Wilkie said.

“The extraordinary contribution of this year’s nominees illustrates a very bright future for the rail industry as it delivers a once-in-a-generation $155 billion pipeline of construction to expand rail across our passenger and freight networks.”

The 2024 awards featured 16 categories recognising individuals, organisations and rail projects in the areas of diversity and inclusion, sustainability, passenger, infrastructure, innovation, supply, customer experience, freight, signalling and systems engineering and safety.

Metro Trains Melbourne won the Customer Service Excellence Award for its transport management for the Taylor Swift concert series, with an additional 145 train services and more than 200 additional staff deployed to get attendees to and from concerts over three nights.

Taylor Swift played to 96,000 people each night at the MCG over three nights in February a statement from Metro Trains said.

“Our commitment to excellence in customer service shone during these concerts, thanks to our meticulous planning, robust execution, and enthusiastic participation.

“The initiative not only navigated the logistical challenges of a large-scale event, but also elevated the overall customer experience, establishing a new benchmark for future events.”

Phil Ellingworth, Chief Engineer at Metro Trains Melbourne, won the Career Achievement Award in recognition of his significant contribution to the industry.

“With over 42 years of dedicated service in the rail industry, Phil’s leadership, technical

expertise, innovation, mentorship and unwavering focus on safety has contributed significantly to the rail sector,” Wilkie said.

speaks of Phil’s excellence.

“Phil sees the railway holistically – a set of integrated systems rather than isolated disciplines,” he says. “His deep understanding of how engineering, technology, operations and maintenance intertwine sets him apart from many others.

“His leadership has left an indelible mark on the wider rail industry, shaping its direction in the region for generations to come.”

“Despite Phil’s significant technical skills and knowledge, what makes him truly worthy of this award is his demeanour, his incomparable ethics, and his gentlemanly approach to all things professional and personal.”