A FLEXIBLE APPROACH

TAKING A FRESH SPIN ON CONVENTIONAL CRUMB RUBBER

SAFETY ON THE BIG SCREEN

A short film competition is giving young filmmakers the opportunity to produce the next big road safety campaign

ROAD TO IMPROVEMENT

Behind the scenes of one of Melbourne’s largest road infrastructure projects

AUSTRALIA’S ONLY SPECIALIST ROAD MANAGEMENT, CONSTRUCTION AND CIVIL WORKS MAGAZINE MAY 2023 Official media partners of

COVER STORY

16 Fulton Hogan

A look inside Fulton Hogan’s innovative spin on traditional crumbed rubber asphalt.

ROADS REVIEW

20 This month, we asked industry decisionmakers, ‘What more can the industry be doing to ensure the safety of workers on infrastructure projects?’

SAFETY

22 Putting road safety on the big screen TAC’s short film competition is targeting road safety amongst young drivers.

24 Keeping a keen eye with AI New AI-enabled cameras are keeping drivers and other motorists on the road safe.

27 The median of excellence

Ingal Civil’s new innovation in back-to-back central road barriers.

30 Constant improvement

Coffey Testing has established national

PROJECT REPORT

33 The road to improvement

A look inside the Epping Road Upgrade in Melbourne’s north-east.

MACHINERY & EQUIPMENT

36 Keeping it mobile

How Topcoat Asphalt’s mobile asphalt plant is transforming the company’s capabilities and services.

39 Rolling out the upgrades

An insight into the versatile and growing popularity of CAT’s CB2.7 GC roller.

41 Empowering teams on the go Revizto’s new phone app is giving users access to BIM on the go.

42 Power for all sizes

Toshiba International Corporation’s SCiB rechargeable battery is built for infrastructure applications.

45 Rolling with innovation SANY continues to innovate, with its SW305K and SW405K wheeled loaders.

SUSTAINABILITY

46 Crushing for good Rokon’s rock crushing plant is delivering sustainable outcomes for projects across Victoria.

48 A hybrid of innovations

John Deere is achieving sustainable business outcomes by hybridising some of its traditional machines.

INSIDE CONSTRUCTION

50 A preview of the 2023 Inside Construction Expo.

AFPA SECTION

53 Transforming road safety

An overview of a new pilot program aimed at reducing speeding amongst motorists.

ISC SECTION

56 Supporting the next generation of leaders

The ISCouncil has developed a new program to develop the next generation of sustainable leaders.

CONTRACTS & TENDERS

58 A summary of the contracts awarded for major infrastructure projects across Australia.

REGULARS

4 Editor’s note

6 News

14 People on the move

The back-to-back guardrail, designed to absorb the energy and impact of cars hitting the barrier surface.

MAY 2023 CONTENTS

THE BRIGHT SIDE

WHETHER IT BE THROUGH changing risk-taking behaviour or embedding a safety culture, companies are doing their bit to ensure their workers can return home safely. Increasing risk mitigation and fostering a supportive environment for mental health are among the many strategies that companies now consider a priority. Which is why we are aiming to highlight the progress being made. In the May edition of Roads & Infrastructure , we take a look at how the industry is avoiding hazardous situations and environments through the use of technology and best practice.

The Transport Accident Commission (TAC) has become a pioneer of road safety awareness, thanks in part due to its iconic advertising campaigns dating back to the 80s. We put TAC’s Split Second Competition under the spotlight to learn how the program is helping increase road safety, while also launching the careers of young filmmakers. The competition allows young filmmakers between the ages of 1825 to produce a short-film highlighting the dangers surrounding drink driving and driving while fatigued. Roads & Infrastructure Magazine sits down with TAC’s senior management, the Victorian State Government and past winners to learn more. This month we also learn more about Coffey Testing’s services when it comes to low-level radiation detection. Coffey Testing has established programs that are being used nationwide to train personnel in the treatment and detection of radiative materials and surfaces. Brooke Scott, Coffey Testing Safety and Wellbeing Manager, says these risk assessment services are essential for ensuring the safety of s taff on site.

For this month’s cover story, we shine a light on Fulton Hogan’s national approach to sustainable road project delivery, through innovations in crumb rubber asphalt. The company’s desire for sustainable outcomes has helped to produce a new spin on the crumb rubber concept. Successful trials of the product have shown its potential for future use, with the development of ‘TyrePhalt’ likely to be used as a template for future innovation in the road construction space.

Finally, in the May edition of Roads & Infrastructure Magazine , we had the pleasure of talking to the Infrastructure Sustainability Council’s CEO to hear how the council is aiming to attract the next generation of industry leaders, through its ‘Rise’ Mentoring Program. The mentoring program has already attracted keen interest from some of the sector’s most renowned sustainable representatives.

Happy reading!

Tom O’Keane Roads & Infrastructure Magazine

COO

Christine Clancy christine.clancy@primecreative.com.au

GROUP MANAGING EDITOR

Sarah Baker sarah.baker@primecreative.com.au

MANAGING EDITOR

Mike Wheeler mike.wheeler@primecreative.com.au

EDITOR

Tom O’Keane tom.okeane@primecreative.com.au

JOURNALIST

Shannon Paten shannon.paten@primecreative.com.au

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR

Blake Storey

DESIGN

Bea Barthelson

BUSINESS DEVELOPMENT MANAGER

Brad Marshall brad.marshall@primecreative.com.au

CLIENT SUCCESS MANAGER

Glenn Delaney glenn.delaney@primecreative.com.au

HEAD OFFICE Prime Creative Pty Ltd 379 Docklands Drive, Docklands VIC 3008 Australia p: +61 3 9690 8766 f: +61 3 9682 0044 enquiries@primecreative.com.au www.roadsonline.com.au

SUBSCRIPTIONS +61 3 9690 8766 subscriptions@primecreative.com.au

Roads & Infrastructure Australia is available by subscription from the publisher. The rights of refusal are reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Roads & Infrastructure Australia is owned and published by Prime Creative Media. All material in Roads & Infrastructure Australia is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without the written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Roads & Infrastructure Australia are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

4 ROADS MAY 2023

EXPERTS IN MOBILE PLANT INSURANCE For more information on UAA’s Industrial Special Plant and Procon products, please contact your Insurance Broker or visit www.uaa.com Industrial Special Plant and ProCon underwritten by QBE Insurance (Australia) Limited. ABN 78 003 191 035, AFSL 239545. Underwriting Agencies of Australia Pty Ltd. ABN 86 003 565 302 AFS Licence 238517. Underwriting Agencies of New Zealand Limited (UAA). 4758199, NZBN: 9429040999678. J6663 Our insurance products are tailored to produce a hand crafted solution to meet your business needs The UAA Group has the knowledge, ability and capacity to insure a wide variety of plant and machinery spanning numerous industries. Our experienced claims team has access to a network of the very best expert industry repairers, assessors and suppliers. With over 30 years’ experience, UAA is the largest and most reputable specialist mobile plant and machinery insurer in Australia, New Zealand and globally.

CONSTRUCTION NOW UNDERWAY ON $2B COOMERA CONNECTOR

Construction works have now kicked off on the $2.16 billion Coomera Connector (Second M1), Queensland’s largest single road project. The works will see the development of the first stage of the 16-kilometre Coomera Connector, creating a ‘second M1’ to remove up to 60,000 local trips a day from the M1 Pacific Motorway.

The new road will be an alternative to the M1, providing more transport capacity to support the growing residential and business communities in the northern Gold Coast and neighbouring Logan areas. It will also mean more reliable travel times between Brisbane and the Gold Coast by alleviating congestion on the M1.

Early works to prepare for construction, between Shipper Drive, The final tracks have now been laid on the Metro Tunnel Project in Melbourne.

Coomera and Helensvale Road, have been ongoing since November 2021. The first stage of the project will be delivered in three construction packages: Stage One North: Shipper Drive, Coomera to Helensvale Road, Helensvale (now underway), Stage One Central: Helensvale Road, Helensvale to Smith Street Motorway, Molendinar (expected to start later this year) and Stage One South: Smith Street Motorway, Molendinar to Nerang-Broadbeach Road,

Nerang (in design).

A new, one-kilometre-long, Coomera River bridge crossing is a key feature of the first package, along with a fourmetre-wide shared active transport path. The Australian and Queensland governments have each committed $1.08 billion to the $2.16 billion to plan and build Coomera Connector Stage One between Coomera and Nerang. The Second M1 will open progressively from 2025.

FINAL TRACKS LAID ON METRO TUNNEL

The Metro Tunnel will create a new end-to-end rail line from Sunbury in the west to Cranbourne/Pakenham in the southeast, with bigger and better trains, next generation signalling technology

and five new stations in Arden Station, Parkville Station, State Library Station, Town Hall Station and Anzac Station.

Once complete, the Metro Tunnel Project will create capacity for more than half a million extra passengers each week during peak times and save

passengers in the suburbs up to 50 minutes a day on a return trip.

The final tracks being laid represents the culmination of nine months of work along the twin nine-kilometre tunnels and stations. These works began in mid-2022 with crews installing 4000 high-performance concrete panels to create an even base for the rail. The panels were cast in 300 different shapes to match the curvature and elevation of the tunnels.

Following the laying of the final tracks, crews are preparing for test trains which will begin running in the second half of 2023.

Additional works are still on-going to fit out the new five stations. This includes the installation of lifts, escalators, security systems, CCTV, passenger information displays and emergency phones.

The Metro Tunnel is expected to open in 2025.

6 ROADS MAY 2023

NEWS

Artist’s impression of Coomera Connector. Image courtesy of TMR Queensland.

The final tracks have been laid on the Metro Tunnel Project. Image courtesy of the Victoria’s Big Build.

NEW VIC ELECTRIC VEHICLE LAB UNVEILED

The Victorian Government has unveiled a new purpose-built electric vehicle laboratory, which will aim to increase the skills and provide accreditation for emerging specialised technicians across the state.

The new laboratory, at the Kangan Institute’s Automotive Centre of Excellence at Docklands, will be home to new technology in electronic training boards and simulators, new computers and software programs and sophisticated teaching aids.

This equipment can simulate almost all variants of EVs, making it flexible and

adaptable to current and future markets. These facilities will improve the learning opportunities of new students and apprentices, while also upskilling existing industry technicians.

Kangan Institute will deliver a wide range of EV-specific accredited courses and skills to give those in the automotive industry the chance to upskill, including a new apprenticeship program specialising in EVs.

The new facility is set to support the Victorian Government’s target for EVs to make up 50 per cent of all new lightvehicle sales by 2030.

CONSTRUCTION BARGES IN PLACE FOR $786M BRIDGEWATER BRIDGE

The Bridgewater Bridge Project has reached a new milestone with the first construction barges now in place for the Tasmanian project.

The $786 million project is Tasmania’s largest ever transport infrastructure project and will aim to improve efficiency and safety, connect local communities and create more open space between the north and south of the state.

The new four-lane, one-kilometre-long

bridge will address the perceived missing link in Tasmania’s National Highway, improving connections at Bridgewater and Granton, as well as catering for cyclists and pedestrians with a safe shared path.

It will replace the existing 1940s era bridge, cutting travel times for the 22,000 motorists that use the route daily, and improving freight routes around Hobart.

Floated into place, linked together and rested on the riverbed, a total of 12 barges will provide a safe and sturdy temporary platform from which McConnell Dowell will construct the one-kilometre-long bridge.

This method aims to reduce costs and the environmental impact of constructing temporary work platforms. The new bridge will be open by the end of 2024.

8 ROADS MAY 2023

NEWS

An early impression of the Bridgewater Bridge Project in Tasmania. Image courtesy of the Tasmanian Government.

Photo by Waldemar Brandt on Unsplash.

Low carbon emissions polymer modified binders (PMBs) Puma Energy Bitumen 1800 24 88 66 bitumen.au@pumaenergy.com pumaenergy.com/en/web/bitumen/ Your journey towards net zero starts NOW with our next generation PMBs with biogenic component. Extract biogenic components Roads become perpetual CO2 vaults Integrated with our global supply network Trees capture atmospheric CO2 Puma CarbonBind

Introducing the first and only skid steer with a telescopic boom the JCB Teleskid; a truly unique, versatile skid steer with endless possibilities. Now you can lift higher, reach further, dig deeper.

This revolutionary product is designed to suit all types of job sites meeting the need of multiple machines wrapped nicely into one. Combining the strength and safety of our single side boom with side door entry and extendable boom JCB has increased the versatility of the SSL-CTL world.

To find out more contact your local JCB CEA dealer today. Ph: 1300 522 232 www.jcbcea.com.au

AUSTRALIAN FIRST FOR BURNLEY TUNNEL

An Australian-first pacemaker lighting system has been switched on for drivers in Melbourne’s Burnley Tunnel. Drivers in the tunnel will now see a green band of moving light along the

walls, which is expected to help keep pace through to the tunnel exit. These green bands will move at a speed safe and appropriate to traffic conditions in the tunnel with hopes

to encourage drivers to maintain a consistent speed, while never exceeding the tunnel’s speed limit of 80 kilometres per hour.

Due to the nature of the tunnel, drivers tend to slow down as they travel uphill to exit the tunnel.

The pacemaker lights are expected to prevent backlogs of traffic that can lead to congestion across the wider road network.

The installation of the new system was funded by Transurban. It included repainting the tunnel walls and installing new LEDs in an attempt to make the tunnel look brighter, more spacious and ultimately, safer.

A comprehensive road safety audit, which included closely examining the effect of pacemaker lighting on drivers, was completed as part of the project.

PLANS RELEASED FOR CANBERRA LIGHT RAIL

The final stages of planning for the Canberra Light Rail Project Stage 2A have been released with works approval and development application for the network now open for public comment. Stage 2A of the light rail is the first step in extending the network south to Woden. It is set to feature an additional 1.7 kilometres of wire-free track including three new stops at Edinburgh Avenue, City South and Commonwealth Park.

The final plans reveal details about the project design. These include a landscape developed with the National Capital Authority (NCA) to retain the historic character of Commonwealth Avenue, two new signalised intersections on London Circuit at West Row and University Avenue also providing pedestrian and cyclist crossings, and cycle ways on newly designed intersections at London Circuit and Northbourne Avenue.

Extra features of the plans also include in-ground pedestrian lights, a cobbled median on London Circuit West to

differentiate the light rail corridor from the roadway, grass track sections on parts of Northbourne Avenue, London Circuit and Commonwealth Avenue and a new inset bridge for the light rail constructed over Parkes Way, in between the two Commonwealth Avenue bridges.

Work is also currently underway to raise London Circuit, which will enable the construction of light rail stage 2A. Pending planning approvals and procurement processes, construction on the Stage 2A extension is expected to start soon after the raising of London Circuit is complete.

roadsonline.com.au 11

NEWS

Australian first technology is now being used on the Burnley Tunnel. Image courtesy of Roads Australia.

Final plans have been released for the Canberra Light Rail 2A Project. Image Courtesy of the ACT Government.

MAJOR MILESTONE FOR PERTH RAIL NETWORK

The biggest expansion of Perth’s rail network since the Mandurah line has hit a major milestone, with the first tracks being laid on the Metronet MorleyEllenbrook line.

The first section of rail will see approximately 1.5 kilometres of ballast and sleepers installed north of Whiteman Park Station through to the Gnangara Underpass and along Drumpellier Drive.

The project includes new stations at Morley, Noranda, Malaga, Whiteman Park and Ellenbrook, with patronage expected to reach 18,000 people boarding per day by 2031.

Specialised equipment has been used to undertake the 21 kilometre upgrade, including a ballast box spreader which positions the ballast and an excavator with an ‘octopus’ attachment to position the sleepers.

The $1.1 billion Metronet project is

the longest the company has seen and is jointly funded by the Federal and State governments.

The upgrade is expected to support the area’s growth as a major activity centre, while making the most of

development opportunities nearby, including new housing.

Set to be completed by late 2024, the project is expected to give locals greater transport choice, reduced travel times and new modern stations.

UGL COMPLETES MAJOR STAGE OF HUNTER POWER PROJECT

CIMIC’s UGL has completed concrete pours for a 3700-tonne concrete foundation, which forms part of the first gas turbine for the Hunter Power Project in New South Wales.

UGL is the principal contractor for the construction of the 660-megawatt power generation plant at the project in Kurri Kurri, commissioned by Snowy Hydro Limited.

The proposed Hunter Power Project at Kurri Kurri will fill the gap in electricity demand and ensure security of supply following the retirement of the Liddell Power Station in Muswellbrook.

The closure of Liddell Power Station will reduce NSW’s electricity supply by around 13 per cent and without replacement dispatch-able capacity, this risks prices rising by around 30 per cent over two years.

The Hunter Power Project comprises two open cycle gas turbines which will operate on natural gas and can also support hydrogen streams. Diesel is available on-site as a backup to support NSW’s power grid.

UGL’s concrete pour consisted of 1480 metres3 of concrete for the foundation of the first gas turbine. The final foundational

concrete block is over 3.5m high, 11m wide, and 36m long, and weighs approximately 3700 tonnes.

UGL’s entire scope of works includes procurement and supply of all the supporting components and auxiliary systems of a power plant needed to deliver the energy, all civil and foundation works, site installation of equipment supplied by both MHI and UGL, and testing and pre-commissioning.

By providing firmed energy the Hunter Power Project will facilitate an estimated 1.5 to 2GW of renewables, or the equivalent of 160,000 household solar installations.

12 ROADS MAY 2023 NEWS

Works continue on the Hunter Power Project.

Image courtesy of CIMIC ’s UGL.

First tracks have been laid on the Metronet MorleyEllenbrook line. Image Courtesy of Metronet Western Australia.

rokon.com.au MELBOURNE'S PREMIER CIVIL AND ROAD CONSTRUCTION COMPANY Residential Sub-Divisions Industrial Sub-Divisions Infrastructure & Structural works Medium Density / Retirement Developments Wetland Developments Rokon is certified for ISO 45001:2018; 14001:2015; 9001:2015 & OFSC Accredited

PEOPLE ON THE MOVE

ROADS & INFRASTRUCTURE HELPS YOU KEEP UP WITH THE LATEST MOVEMENTS ACROSS THE ROADS AND INFRASTRUCTURE SECTORS.

DOWNER APPOINTS NEW CHIEF FINANCIAL OFFICER

Downer has announced that Malcolm Ashcroft has been appointed as Chief Financial Officer, commencing in July 2023. Ashcroft is a leader with financial and senior executive experience in the infrastructure services, construction, health, and education sectors. Prior to becoming Chief Operating Officer (CEO) at G8 Education Limited (his current role), Ashcroft has held senior executive roles including as Chief Financial Officer at Healius Limited, Deputy Chief Financial Officer and Group Executive Transformation at CIMIC Group Limited, Acting Head of Finance and Risk at Sydney Metro and Senior Audit Partner at KPMG. He will take over from Michael Ferguson, who has held the position of CFO since October 2016.

Image courtesy of Financial Executives Institute.

LAING O’ROURKE APPOINTS NEW GROUP CHIEF OPERATING OFFICER

Laing O’Rourke has appointed Cathal O’Rourke to the newly created role of Group Chief Operating Officer (COO). The creation of the COO role will assist the Group and Europe executive teams to work closely together and share learning across the company’s international operations. He will begin his new role in April. During his time in Australia, he transitioned the business from an oil and gas resources focus to secure a broad pipeline of public infrastructure and defence work for the State and Federal Governments. As the Australian Managing Director and President of the Australian Constructors’ Association (ACA), he was important in the sector’s transition to more collaborative contracting, including early engagement models and incentives for high performance. Prior to leading the business in Australia, he had operational business unit leader roles in both Hubs, in main contracting and the specialist businesses. Cathal O’Rourke will support the recently updated business unit leadership team in Europe and be responsible for maximising the return of the company’s investments in strategic initiatives. He stepped down as Managing Director of the Australian business last year, after eight and a half years leading the hub and as a member of the Group Executive.

Image courtesy of Laing O’Rourke.

NEW CEO APPOINTED TO QRA

Major General Jake Ellwood (Rtd) has been appointed Chief Executive Officer (CEO) of the Queensland Reconstruction Authority (QRA). The QRA was established in 2010-2011 in response to the Queensland floods and Tropical Cyclone Yasi. It was made a permanent part of the Queensland Government in June 2015. Ellwood was originally State Recovery Coordinator for the 2022 South East Queensland flooding disaster, one of the biggest disasters to impact the state. He was national coordinator for the Australian Defence Force’s response to the Black Summer bushfires in 2019-20 and has served in Kosovo, Iraq, Afghanistan, and on two tours in East Timor. He served as Commander of the First Division, based in Brisbane, and as Deputy Chief of Army. Ellwood’s appointment comes after former QRA CEO Brendan Moon took on the role of Coordinator General of the National Emergency Management Agency (NEMA) in 2022. Major General Ellwood was appointed QRA CEO by an independent panel.

Image courtesy of the Queensland Government QRA.

14 ROADS MAY 2023

Introducing Ezy-Guard High Containment, a member of the next-generation Ezy-Guard barrier family, providing superior motorist safety. Ezy-Guard HC is proven and crash tested to the latest MASH Test Level 4 standard, distinguishing it from all existing public domain guardrail barrier systems in Australia.

• Crash tested to MASH Test Level 4

10,000kg Truck

• Narrow footprint saving road width

• Easy to transport and simple to install

• Consideration for motorcyclists with rounded post corners

• Can be installed as a post-on-baseplate for areas where underground services restrict posts from being driven into the ground

Ref: PP0615 www.ingalcivil.com.au sales@ingalcivil.com.au

• Sydney (02) 9827 3333 • Brisbane (07) 3489 9125 • Melbourne (03) 9358 4100 • Adelaide/NT 0438 153 482 • Perth (08) 9452 9111 • Newcastle 0400 235 883 • Wagga 0427 779 588 • Local call 1300 446 425 INGAL

High-Containment Roadside Safety Barrier

CIVIL PRODUCTS

Consideration for motorcyclists Narrow footprint saving road width Baseplated installation Australian Made MASH TL4 MASH TL3 MASH TL4: 10,000kg Truck + 2,270kg Utility

–

TL4 1.20m TL3 1.16m Ezy-Guard HC Deflections at 2m Post Spacing

A FLEXIBLE APPROACH

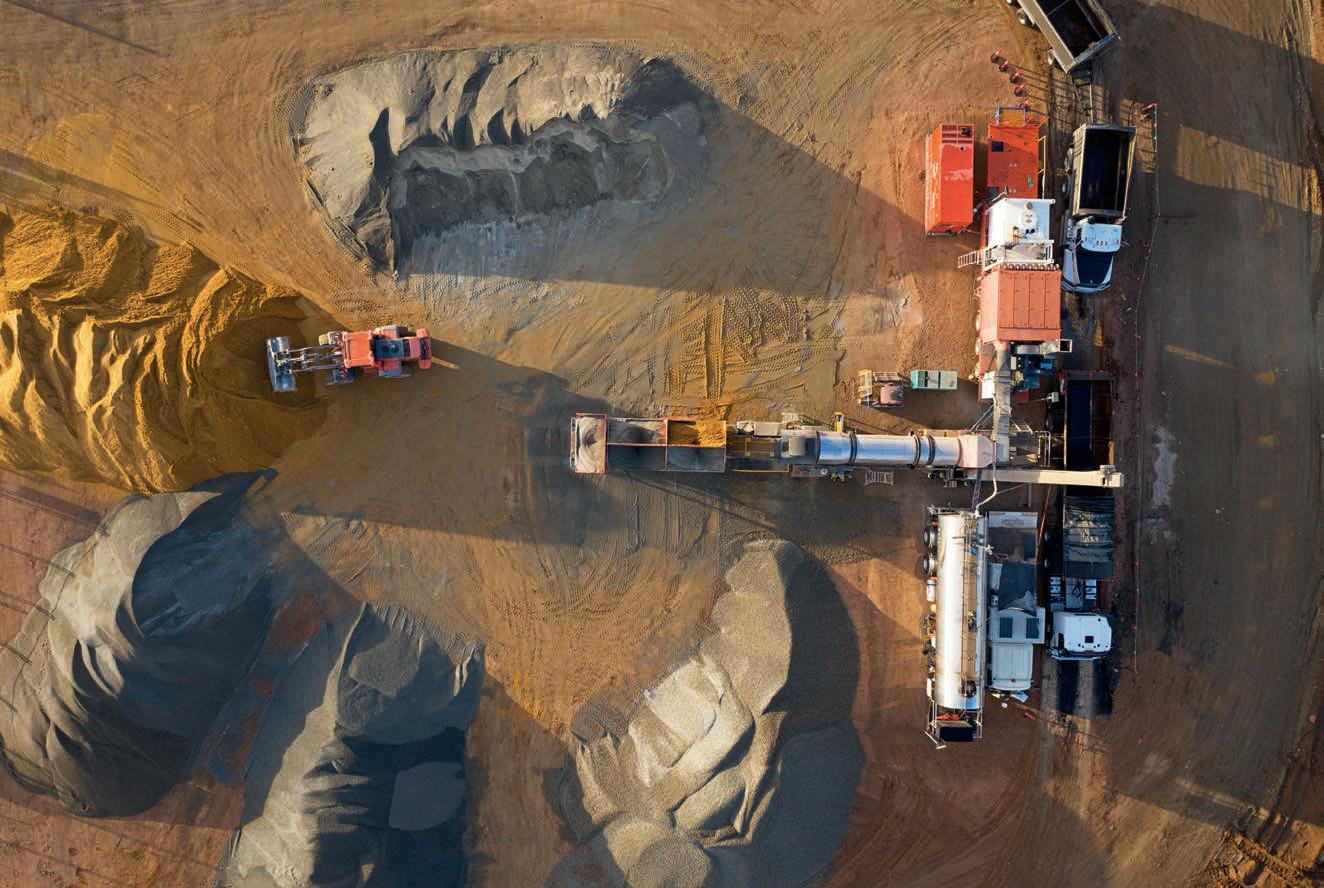

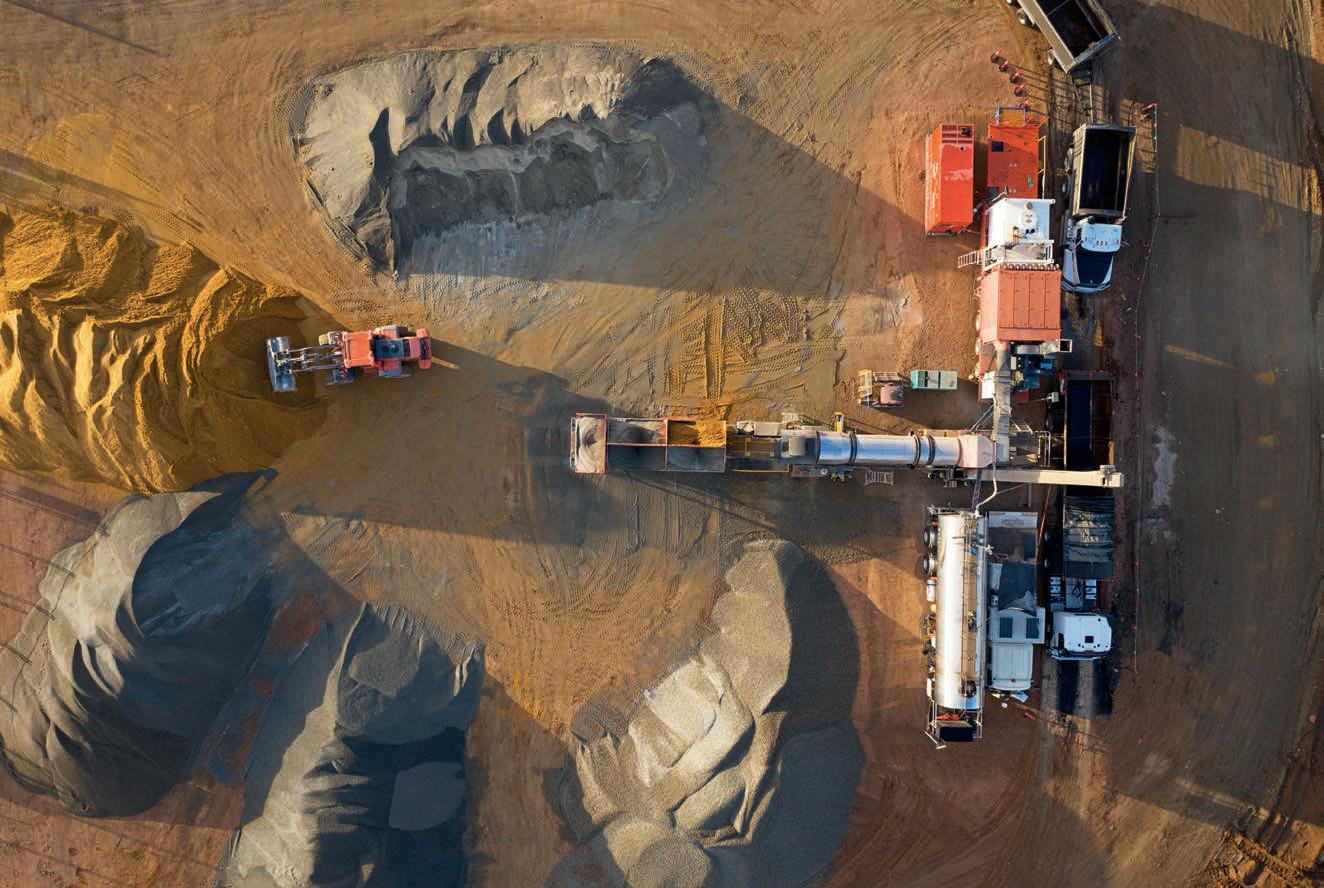

FULTON HOGAN IS PUSHING THE ENVELOPE WHEN IT COMES TO INCLUDING CRUMB RUBBER ASPHALT IN INFRASTRUCTURE PROJECTS OF VARYING SCALES NATIONALLY.

According to Tyre Stewardship Australia, 450,000 tonnes, or 56 million passenger tyres reach their end of life nationally, with some of these tyres often ending up in landfill.

Tyres can take centuries to decompose, meaning waste tyres pose a significant threat to the environment. This growing issue has resulted in tyres being listed as one of three priority waste streams by the Federal Government.

The use of recycled tyres in road construction has been a popular method internationally for decades, through the form of crumbed rubber asphalt and modified binders.

Crumbed rubber asphalt and binders feature varying percentages of tyre components, predominantly gathered from motor vehicles. The uses and variety of options for the market was previously limited. But thanks to collaboration and a push from both government and the private sector, including companies such as Fulton Hogan, has opened the door for a greater volume of crumb rubber asphalt use.

Fulton Hogan has more than three decades worth of experience in crumb rubber binder production, for both spray sealing and asphalt mixes.

Nick Canton, Regional Manager – Fulton Hogan Infrastructure Services - Southern

Region, says the company has vast experience in the development and utilisation of crumb rubber modified binders. He says this knowledge has led to additional research into new blend types.

“We’ve been using crumb rubber to modify spray seal binders for number of years,” he says. “In doing so, we identified the value in the modified properties, and how this could be adopted into asphalt.”

“We are continuing to innovate and explore solutions to our clients and communities’ waste and environmental problems. We are constantly exploring how we can use repurposed materials to increase specific performance characteristics across all our product range.”

Fulton Hogan has invested heavily to develop suitable infrastructure and established markets for the production of sustainable asphalts and spray seals across Australia.

In 2021-22 alone, Fulton Hogan manufactured over 16,000 tonnes of crumb rubber asphalt, helping to divert over 10,000 used tyres away from landfill. These crumb rubber modified asphalt products were used in road projects for most State Road authorities and many Councils including the City of Greater Geelong, Mornington Peninsula Shire, City of Greater Dandenong, City of Stonington, Central Coast, City of Lake Macquarie, Cessnock, City of Gold Coast and Moreton Bay Councils to name a few.

16 ROADS MAY 2023

Fulton Hogan’s wet blended crumb rubber asphalt is set to be used in a variety of road infrastructure projects.

Fulton Hogan has developed crumb rubber products for more than 30 years.

A NEW BLEND

Around 10 years ago, Fulton Hogan identified the opportunity to incorporate wet blended crumb rubber modified bitumen into asphalt.

Over the course of the last two years, development on these products have formed part of Fulton Hogan’s ‘TyrePhalt®’ banner, now a standard product in Fulton Hogan’s vast offerings in the crumb rubber binder and asphalt space.

Chris Lange, Technical Manager – Fulton Hogan Infrastructure Services - Northern Region, says the wet blend method can result in a product with vastly improved fatigue resistance properties.

“In the dry blend process, the crumbed rubber is added into a batch plant or the drum of a continuous mix to partially replace a portion of the fine aggregate. Whereas in the wet blend method the bitumen is modified by blending the crumbed rubber and bitumen in a specialised blending plant,” Lange says.

“The wet blend method enables quality assurance due to enabling the sampling of the resultant rubber modified binder and testing to ensure compliance to aspects like the softening point, viscosity and torsional recovery.”

In addition to reducing the number of tyres in landfill, wet blended crumb rubber asphalt can increase the fatigue resistance, binder viscosity, film thickness on aggregate and improved elastomeric properties.

Throughout the development of the wet blend asphalt, as well as TyrePhalt® products, Lange adds that Fulton Hogan received a greater level of knowledge on the properties and applicable materials for inclusion in production.

“We learned that the dense grade rubber modified asphalt is a better selection than currently used asphalt with Class or Multi Grade binder – due to its increased film thickness and binder content – resulting in better fatigue and durability properties,” he says.

Nick Canton says Fulton Hogan is always looking to incorporate repurposed materials such as RAP (Reclaimed Asphalt Pavement) and recycled glass sand to reduce the dependency on finite virgin quarried materials.

“We have completed projects where we have incorporated recycled glass, slag, RAP and tyre rubber whilst utilising warm mix technologies which in its own right can reduce our carbon intensity through energy use by up to 30 per cent,” Canton says.

“We have dedicated and accredited technical teams across Australia and New Zealand,

focusing on research and design who are constantly working with our clients to address emerging issues and problems.”

One such expert is Johannes van Heerden Technical Manager, Pavement and Materials Engineering – Fulton Hogan Infrastructure Services - Western Region.

“For the Australian market sustainability is a main focus in this point of time. It’s obviously extremely important. It’s also about performance,” van Heerden says.

“These products are more durable and are highly impermeable, because the more bitumen you put in there, the better the workability. The more impermeable the asset, the longer it’ll last. So these aspects are fantastic.”

van Heerden adds that these factors help to reduce the long-term costs for users.

“If you can actually increase your pavement structural depth, and the distribution of strains and stresses, which would be lower, you can improve the structural capacity as well. You can reduce rehabilitation or pavement

preservation treatment,” he says.

“Ultimately over a period of time this can reduce costs, not only for the cost of the product, but also the cost of the contract.”

PAVEMENT IN PARTNERSHIP

One of the major benefactors of the use and development of wet blended crumb rubber was Tyre Stewardship Australia (TSA), who provided financial support in the form of infrastructure grants.

“These grants have enabled the investment into and development of two Fulton Hogan PMB blending facilities in Australia that would not have gone ahead otherwise,” Canton says.

“Having this infrastructure ensures we are able to produce these products locally and deliver high performing products to the local community. It also helps to ensure an additional avenue for an end-of-life use for recycled tyres in these areas.”

Grants and guidance from Austroads, the Department of State Growth, TSA and the Australian Flexible Pavement Association have

roadsonline.com.au 17 COVER STORY

“WE LEARNED THAT THE DENSE GRADE RUBBER MODIFIED ASPHALT IS A BETTER SELECTION THAN CURRENTLY USED ASPHALT WITH CLASS OR MULTI GRADE BINDER – DUE TO ITS INCREASED FILM THICKNESS AND BINDER CONTENT – RESULTING IN BETTER FATIGUE AND DURABILITY PROPERTIES.”

Community and collaboration were important considerations for Fulton Hogan and the development of its crumb rubber asphalt.

helped to establish product trials in Tasmania to evaluate the performance of the binder against conventional materials.

Chris Lange says these types of trials aimed to provide an insight into the performance of the product in primarily LGA roads, environments with reduced traffic flows and associated pressures than metropolitan highways.

“The main purpose was to give local councils an opportunity to assess the products which are known to provide longer lasting, more durable and fatigue resistant road surfaces,” Lange says.

“These projects will also give the road asset owners experience and knowledge to assist them with developing specifications to utilise this product into the future.”

Lange hails the trials as a success, saying the performance exemplified the wet blend’s ability to extend the life of the pavement layer.

“The increased viscosity enables greater film thicknesses and binder content to be achieved in the various mix types where it is incorporated. This increases the product durability and ability to withstand stressed imposed on the product due traffic and pavement movement,” Lange says.

“It significantly reduces the thickness of the

treatment to avoid reflective cracking – thus providing a substantial cost saving.”

COMMUNITY AND COLLABORATION

On top of significant sustainability and performance benefits, the use and production of Fulton Hogan’s crumb rubber asphalt can also provide a boost for the local economy as well.

Nick Canton says Fulton Hogan carefully considers the wants and desires of the local communities in which we operate. No matter the context or size of the work at hand.

“When we look at things like sustainability, the local component and ensuring we do things right the first time cannot be over looked. Not only working with those local clients individually, but collaborating with local businesses. This is about making sure that we›re using local repurposed waste materials wherever possible and for that specific community, driving real value through sharing our technical support and knowledge,” Canton says. “There’s a heck of lot of work that goes into that.”

“We as contractors have an immense part to play in ensuring the most sustainable future for generations to come. This has to be achieved by people and through collaborative partnerships.”

“It›s going to be a combination of step change and incremental enhancements to get us to where need to be. We also need to enable our clients to realise shared value of these initiatives. We as contractors need to consider ourselves custodians of these assets and endeavour to leave them in a better condition than how we find them whilst extending their life cycles, it›s not just about a win for today, it’s about the longer term. Ensuring we take the right approach and contribute collectively to these environmental challenges”

Canton says the realisation and confirmation of crumb rubber asphalt’s benefits has led to an increased demand.

“The product has been adopted and approved by most State Road Authorities including TMR, DTP, Mainroads, TfNSW and DSG. We’ve also seen wider adoption by Local Government Authorities also,” he says.

He adds that the industry should “watch this space”, with further developments and improvements in discussion for the wet blended crumb rubber asphalt, as well as a slate of upcoming projects which will see the use of the material.

“Our clients have differing needs, our communities have unique environmental issues we need to help in resolving where we can. We understand there is no single product to solve all problems and are continuing to alter and fine tune our products and services,” Canton says.

“We also understand this is just the tip of the iceberg and we’ll keep challenging ourselves to strive for continuous improvement. It’s part and parcel of what we do.”

18 ROADS MAY 2023 COVER STORY

Fulton Hogan’s wet blended crumb rubber asphalt incorporates end of life tyres from a variety of sources, including motor vehicles.

On-going trials are evaluating the performance of wet blended crumb rubber asphalt.

Dedicated national NATA accredited labs, as well as Australasian Technical and Research and Design teams helped to develop wet blended crumb rubber asphalt.

MOVING TOMORROW, TODAY WWW.SANYAUSTRALIA.COM.AU WWW.SANYAUSTRALIA.COM.AU

ROADS REVIEW

THIS MONTH, WE ASKED THE INDUSTRY’S DECISION-MAKERS, ‘WHAT MORE CAN THE INDUSTRY BE DOING TO ENSURE THE SAFETY OF WORKERS ON INFRASTRUCTURE PROJECTS?’

SARAH BACHMANN, CEO – NATIONAL PRECAST

Taking works offsite and into a controlled factory environment is a sure-fire way to improve site safety. When exact, quality tested elements are delivered to site – as opposed to fabricating elements on site – there is less site activity with less construction works and fewer materials’ deliveries, less dust and waste, less disruption to surrounding businesses and site safety for workers is improved. Infrastructure elements manufactured by National Precast Master Precasters deliver all the benefits of offsite manufactured products. Unlike many other delivered structural elements, every precast installation on a civil or infrastructure site is required by Part 3 Civil construction of AS 3850.3:2015 Prefabricated concrete elements to have a written ‘erection design’, that has been approved by a certified engineer.

SHAN RUPRAI, GROUP EXECUTIVE INSTITUTIONAL RELATIONS AND ACCREDITATIONS –COLAS AUSTRALIA

Infrastructure projects fall into a high-risk category for the safety of our workers. It is collective responsibility of the PCBU, employees and other interested parties to work together for safer outcomes. We need to be proactive rather than reactive. Below are some of my key thoughts: Get all interested parties (Customers, Regulators, Policy Makers, Industry stakeholders/ Associations, Employee Representatives, Police etc) under one roof to address breaches, including the speeding vehicles through the road construction sites. Agree on key risks and a publish a guideline to manage and train, as well as media briefings, worker of foot mandatory training via AfPA and mandatory workers health checks.

ANDREW WILLIAM, MAJOR ROAD PROJECTS VICTORIA – ACTING CHIEF EXECUTIVE OFFICER

Workplace health and safety is about so much more than what happens on site. We work in the country’s most male dominated industry – at the same time, more women are entering Victoria’s construction sector than ever before. We’re helping to disrupt this gender imbalance as we implement the state’s Building Equality Policy (BEP) through our projects, and our construction partners to increase female representation from trade roles through to management. A power of work is underway to make women aware that construction is an attractive and viable career option from primary school age to career changers. But workplaces must be adaptive and inclusive to ensure that women stay in our industry. Greater representation of women in construction makes workplaces stronger and will benefit everyone in the construction industry.

JAMES BENNETT, GENERAL MANAGER – TRANSPORT TECHNOLOGY AND RAIL SERVICES

Industry needs to work together to go above the minimum compliant safety standards. Together we’ve identified several initiatives to improve safety and need to work together to make these higher safety measures the norm for our industry. The focus on price during procurement can lead to contractors including the minimum compliant safety solutions, not the optimum one. There is opportunity to reframe major procurement such that investments in safety are separated from other bid costs – and instead evaluated separately. Crucial to this pivot is an understanding that companies will not be penalised for proposing a higher investment in safety.

If you or someone at your organisation is an industry leader and would like to be a part of this monthly column in 2023, please get in touch with Editor, Tom O’Keane: tom.okeane@primecreative.com.au

ROADS REVIEW

20 ROADS MAY 2023

As one of Australia’s largest construction materials testing providers, we’ve been delivering testing services to the transport infrastructure, public utility, residential and commercial development, oil and gas, and mining industries for over 60 years.

We have an extensive network of permanent and site-specific testing facilities located across Australia, including in some of Australia’s most remote locations.

coffeytesting.com 1300 175 531 SOIL CONCRETE AGGREGATE SPECIALITY

PUTTING ROAD SAFETY ON

THE BIG SCREEN

TAC’S SHORT FILM COMPETITION IS GIVING VICTORIA’S YOUTH A CHANCE TO DIRECT THE NEXT ROAD SAFETY CAMPAIGN. R&I SITS DOWN WITH TAC’S MANAGEMENT, AS WELL AS A PAST WINNER TO LEARN MORE.

As of April 5, 87 people have lost their lives on Victorian roads. Out of these 87 lives, 17 were young people aged between 18 and 25 years old.

According to the TAC, young drivers (18-25) continue to be over-represented in road trauma; being involved in more crashes resulting in death and serious injury than any other group of drivers on the road.

Each year, around 50 (five-year average) young people are killed and 1800 are seriously injured in road crashes.

As a pioneer in road safety and support services, the Transport Accident Commission (TAC) helps to establish payment for those injured in transport accidents, while also promoting road safety nation-wide.

The TAC’s campaigns have aimed to have an impact on viewers while highlighting the dangers and importance of preventing factors such as speed, drink

driving, fatigue, protective equipment for motorcyclists and more. In fact, the TAC’s first television advertisement went to air in 1987.

Now the TAC is granting young filmmakers the opportunity to share their perspectives to share road safety messages to the wider community.

THE REAL PRIZE

The TAC’s Split-Second Competition encourages young filmmakers between the ages of 18-25 to submit a short film with the messaging being around the importance of road safety, as well as the potential dangers associated.

TAC CEO Joe Calafiore says the competition gives young filmmakers a platform to make a meaningful impact on society.

“The Split-Second Competition provides a unique opportunity for young Victorians to use their creative skills to help save

lives. By producing impactful short films that raise awareness of important road safety issues, young people can be a powerful force for change on our roads,” Calafiore says.

“The TAC is proud of the growing impact of the Split-Second Competition and is excited to be expanding to produce two winning concepts in 2023.”

The two competition briefs were released by the TAC for participants, outlining the key messages, guidelines and relevant facts and statistics for each short film.

The first brief focused on driver fatigue, with the key message of ‘you snooze, you lose’. The second brief highlighted vehicle safety, with the key message of ‘safer vehicles save lives’. Young filmmakers are able to choose one or submit projects for both briefs.

TAC Head of Road Safety Samantha Cockfield says the two briefs directly

22 ROADS MAY 2023

A still of Felix Barnett’s winning short film ‘To Die For’, which took out the 2021 Split-Second film competition.

target prevalent causes of road trauma.

“Reducing the prevalence of drowsy driving, and promoting vehicle safety, are critical in improving road safety outcomes for young Victorians, and by engaging young creatives in the process we’re ensuring that messages are delivered in a relatable way,” Cockfield says.

“The Split-Second competition prides itself on giving young Victorians the opportunity to use their story and filmmaking skills to directly communicate with peers on important road safety issues.”

Fatigue is a major cause of crashes, with TAC data showing fatigue contributes to 16-20 per cent of all road crashes in Victoria, and around 30 people die each year and up to 200 people suffer serious injuries due to these types of crashes (five-year average).

When it comes to vehicle safety, a focus has been placed on the increased safety capabilities of newer vehicles compared to older vehicles. According to the TAC, in 2020 64 per cent of vehicle fatalities occurred in vehicles aged 10 years or older.

A WINNING CAUSE

The winner of the short film competition receives a $70,000 production budget, with second place also receiving a $30,000 budget to produce an advertisement promoting road safety.

In 2022, the competition received 307 entries, a 50 per cent increase year on year.

First place also receives $5000 in prize money. The prize money aims to encourage the future development and endeavours of the participants and give them a platform to launch their careers as filmmakers, content creators and more.

But Felix Barnett believes the potential for the short film to save someone’s life is the real prize.

Barnett was the 2021 winner of the SplitSecond film competition, with his short film ‘To Die For’, highlighting the risks associated with drink driving.

His film highlighted the dangers associated with drink driving, depicting a bartender describing and mixing the ingredients of a ‘car crash’.

He says the original idea for his short film originated during the COVID-19 pandemic.

‘It was during lockdown, so I had some time to think through the brief. I went on a few walks and was chatting with people when I came across the phrase ‘to die for’. The idea grew from there, and I thought it

could depict a party situation,” he says.

“But I thought ‘what if I could refine it down to its simplest form?’ What if it was just the making of the drink itself?”

Barnett says finding out that he had won the competition was “amazing”. Shortly after production began. A production company which partners with the competition provided the production crew and equipment, as well as guidance for the project.

Barnett believes the short films are effective as they are made by young people, for young people.

“I think it’ really important to get young Victorians involved in the conversation, because they’re obviously the least experienced drivers on the roads. We’re over-represented in road trauma,” he says.

“Who better to talk to young people, than the young people themselves.”

And for those who are thinking of having a go, Barnett says “why not”?

“There’s no downside to entering, so you might as well give it a try. You can come at this from any angle really,” he says.

“I came from a design background, going into advertising and previous winners have been from TV, film and other backgrounds.”

These past winners include ‘A Trial Before The King’ by Alex Lowe (2020), ‘The Afterlife Bar’ by Alyssa De Leo (2019) and ‘Gates of Heaven’ by Callum Borthwick (2018).

Barnett adds that the competition can help to further expand the knowledge and portfolio of participants.

“[Since winning the competition] I’ve been able to write more ads and get more time on set to direct more films, which I really love doing,” he says.

Entries for the Split-Second Film Competition closed on May 4, but young filmmakers can still learn more about the competition: www.tac.vic.gov.au

roadsonline.com.au 23

“I THINK IT’S REALLY IMPORTANT TO GET YOUNG VICTORIANS INVOLVED IN THE CONVERSATION, BECAUSE THEY’RE OBVIOUSLY THE LEAST EXPERIENCED DRIVERS ON THE ROADS. WE ARE OVERREPRESENTED IN ROAD TRAUMA.”

Minister for Roads and Road Safety, Melissa Horne – 2021 Split Second Competition Winner, Felix Barnett – TAC Head of Road Safety, Samantha Cockfield.

KEEPING A KEEN EYE WITH AI

According to the Bureau of Infrastructure and Transport Research Economics, 1187 people died on Australian roads in 2022, the highest number since 2017.

Statistics suggest a trend of increasingly frequent road incidents nationwide.

James French, Construction Solution Specialist at Teletrac Navman, says technology has a major role to play in reducing risk and improving road conditions.

“We usually make an assumption that the vehicles performance is a fair reflection of the driver’s performance,” French says.

“Modern technology can provide an auditable trail which can show what the driver has seen. Everybody might jump up and down and blame the driver, but when you review the data alongside video footage, it may not be the driver, but instead someone else pulled out in front of them.”

The development of Artificial Intelligence (AI) enabled smart cameras, or ‘dashcams’,

are among the latest in safety technology for fleet managers.

Teletrac Navman launched its ‘Smart Dashcam’ in February 2022, a driver-facing camera that combines telematics and sensors to detect and alert in real-time.

French says the journey to the Smart Dashcam has been years in the making.

“Teletrac Navman has been working on a camera concept for quite some time. In a saturated market we aimed to have a point of difference in the solution,” he says.

“We wanted to take this technology a step further. It’s in line with our view as a company, of trying to push the industry and technology innovations forward.

“Over these years we’ve been working on a solution that gives fleet managers and others in the industry the ability to keep a track and view events as they unfold, from the comfort of their own office.”

IMPROVING BEHAVIOURS

A large focus during the development of

Teletrac Navman’s Smart Dashcam was the capacity to improve the behaviours and performance of drivers.

But how can such technology be used to influence change?

For French, the first step is providing actionable objectives, as well as analytics to review performance.

“This push towards AI-enabled cameras is to see what the driver is doing, to give you a greater indication of the driver’s performance,” French says.

“The Smart Dashcam can provide a personalised coaching programme for drivers based on mistakes, direct from the camera itself, rather than stats and tables of information that you need to dissect and analyse yourself.

“This system is designed to tell you where things are lacking from a habit and behaviour perspective and transform these habits into positive behaviours.”

The Smart Dashcam’s dashboard contains a scorecard, as well as an alerts and recognition system.

24 ROADS MAY 2023

TELETRAC NAVMAN’S ARTIFICIAL INTELLIGENCE (AI) ENABLED CAMERAS ARE HELPING TO INCREASE THE SAFETY, PERFORMANCE AND PRODUCTIVITY OF COMMERCIAL DRIVERS AND VEHICLES.

The scorecard is a means to reward positive behaviours from drivers, to encourage improvement while increasing productivity and performance. Using a mixture of performance and safety metrics, these scores can help fleet managers to benchmark where the optimal yet safe scores should be and help them coach their drivers.

The alerts and recognition system can prevent incidents from occurring in real time thanks to in-built audio alerts for the driver.

“These alerts are all about safety,” French says. “You’ll get alerts if the system detects speeding, aggressive braking, if the driver’s showing signs of distraction, or if the driver reaches for his/her mobile phone.”

The system can also detect lane

departure, forward collision warnings, tailgating and other driver distractions.

These incidents can then be backed up with video footage, recorded on the dual 1080p, 30 frames-per-second highdefinition camera.

Video telematics help to send these alerts, which directs the camera to record and keep the footage leading up to, during and after the incident.

“If an event is triggered you have the visual data to back it up,” French says. “If there’s a speed event or fatigue related incident, fleet managers can see the footage to justify what’s happened to figure out exactly what did or didn’t go wrong.”

On top of being able to view incidents in real time, fleet managers can also access and download footage remotely.

ALWAYS LEARNING

Just like the drivers themselves, the AI technology used by the Smart Dashcam is constantly gathering additional data on performance patterns.

French says that for an example of a business where a crash may occur every 400 days, patterned learning provided by AI can help to predict and better mitigate these future incidents.

“The AI technology can start to see trends and this information becomes part of a predictive analysis,” French says. “We’re constantly working on improvements to the AI engine build, to ensure that it can continue to learn from people on the road.”

French says the real strength of the Smart Dashcam is its ability to provide a variety of services from a single source.

“There’s isn’t much out there in the form of a single system that can do everything for fleet managers from the get-go. All they need to do is jump on board, then the system can help to make these changes, while also providing better coaching, training and safety outcomes,” French says.

“Having a single entity means the users don’t need to use different software packages. It’s a complete solution.”

Teletrac Navman is looking to make further enhancements to the Smart Dashcam model to advance its capabilities as a predictive analysis tool, through improvements to its AI engine, as well as the range of in-built alert metrics.

roadsonline.com.au 25 SAFETY

“THIS PUSH TOWARDS AI-ENABLED CAMERAS IS TO SEE WHAT THE DRIVER IS DOING, TO GIVE YOU A GREATER INDICATION OF THE DRIVER’S PERFORMANCE.”

Teletrac Navman’s AI camera technology can detect and alert when road incidents and accidents occur.

James French, Construction Solution Specialist at Teletrac Navman.

LEVEL UP

NEVER IDLE

In this game, there’s no substitute for experience. But finding expert Motor Grader operators can be tougher than the terrain they’ll be tackling. That’s why John Deere is the only player in Australia to be offering Motor Grader automation upgrades to all machines from 2019 onwards. Spec’d out with the latest tech including Machine-Damage Avoidance, Auto-Articulation, Auto-Pass, Auto-Shift Plus, and Blade Stow, less experienced operators can get to grips with the machine double quick, and takes the pressure off your more experienced hands. Take your operation to a whole new level. Check your serial number with your local dealer, today.

DEERE.COM.AU/SMARTGRADEMOTORGRADERS SCAN TO LEARN MORE

MOTOR GRADER JOB SITE AUTOMATION

EXCELLENCE THE MEDIAN OF

Chave long been a preferred tool in increasing the safety and reducing the likelihood of road trauma on Australian roads.

As stated in VicRoads’ 2018 Road Design Note, central barriers are “presently one of the most effective treatments for reducing the likelihood and severity of head-on crashes and align towards providing safe systems for road users”.

A study into the barriers has revealed that they can provide an 87 per cent reduction in fatal median related incidents, including head on crashes, over a six-year data collection period before and after installation (‘Digesting the safety effectiveness of cable barrier systems by numbers’ – D. Chimba, E. Ruhazwe, S. Allen, J. Waters).

Ingal Civil is a pioneer in the manufacture and distribution of highway safety barrier systems, making meaningful impacts on

roads nationwide.

This also includes investment into the development and research of new products which aim to increase the safety of road connections for motorists.

The Austroads Safety Barrier Assessment Panel has recently recommended for acceptance the TREND Median terminal, a new and improved addition to Ingal Civil’s central barrier product line-up.

According to Ingal Civil Product Manager Luke Gallagher, the TREND Median guardrail terminal is helping to modernise the catalogue of available road safety systems on the market.

“Wire Rope Safety Barriers have long been a preferred barrier type in medians, due to their costs and installation time,” he says.

“They’re great for expressways or roads that have long runs and plenty of room for

focus is moving to barriers closer to urban and built-up areas, where speeds are reduced and the horizontal curvature is reduced.”

As a result, manufacturers have had to make adjustments to increase the adaptability and flexibility of road safety barriers for varying installation environments.

The TREND Median guardrail terminal is a double sided, gating re-directive and impact absorbing end terminal. This terminal is used with longitudinal road safety barriers and can be applied to a number of applications, such as roadside shoulders, as well as unidirectional and bidirectional traffic.

Trialled and tested according to Test Level three of the MASH (Manual for Assessing Safety Hardware) testing regulations, the TREND Median guardrail terminal can absorb the kinetic energy of a vehicle, bringing it to a controlled stop from 100km/h.

roadsonline.com.au 27 SAFETY

INGAL CIVIL HAS ALWAYS BEEN A KEEN SUPPORTER OF HIGHWAY SAFETY BARRIER

The TREND Median guardrail terminal installed on a local road in Western Australia.

This is thanks to the barrier’s unique slotted rail and shaper-fin design. This concept allows a cutter-bolt to sheer through the barrier slots, with the shaper-fin deforming the rail upon impact.

BENEFITS OVER OTHER BARRIERS

The TREND Median terminal offers a variety of benefits over other road safety barrier options currently available in the market, as Gallagher explains.

“Concrete barriers can be five or six times more expensive than a median guardrail barrier,” he says. “So they’re cost prohibitive most of the time.”

When compared to conventional wire rope safety barriers, the TREND Median terminal can hold its own.

“With wire rope, a single impact can cause a lot of damage to the barrier. With a back-toback guardrail, even if you clip or scratch the barrier with your car, it typically doesn’t need immediate maintenance to repair its integrity,” Gallagher says.

“Most wire rope barriers can also require concrete footings and anchor blocks as part of the installation. The TREND Median terminal can be fully commissioned and installed in just one day, with the installer driving the posts into the ground, instead of waiting for concrete to set.”

The VicRoads’ 2018 Road Design Note also states that back-to-back road barriers can sustain secondary hits, whereas wire road barriers can be disabled after a significant incident. An important consideration for regional roads, where the response time for maintenance may be delayed.

“Having space for deflection as well as a lower life cycle cost are big differentiators,” Gallagher says. “Some wire rope barriers might be cheaper to install, but more expensive to maintain in the long run.”

Back to back guardrail systems also provide significant drainage when compared to other road safety systems, such as concrete barriers which can have an effect on the surface flow of metropolitan and regional roads.

INSIDE THE INSTALLATION

Safety Barriers WA is one company who has already installed the Median Ezy-Guard barrier as part of it services.

Glackin has received additional positive feedback from other installers, who say the process helps to save both time and money.

“Our installers commented on the ease of which they can layout materials in preparation for installation. They noted a significant weight difference in the post and slider assemblies and how much more materials they could carry from the laydown area to the worksite,” Glackin says.

Etienne Fourie, Senior Associate at BG&E says the TREND Median guardrail terminal’s simplicity for installation, as well as the support of Ingal Civil were major benefits.

“We selected the ezy-guard median barrier

Patrick Glackin, Project Manager, says the installation of the median guardrail is comparably easier than other systems on the market.

“The installation process for MASH systems such as Ezy-Guard is in general is much more efficient than standard conventional systems. Due to the reduced length and smaller footprint, the posts seem to penetrate through the ground much faster than their conventional counterparts,” Glackin says.

“The slider block system used in Ezy-Guard is also much faster to attach to the post and secure the rail than that of the old plastic block method, especially when the task is doubled on median systems.

based on its ease of construction and a suitable barrier within a median based on location, available verge width and space for deflection. We also selected it because we were able to install the barrier only on one carriageway saving installation time and material,” Fourie says.

“I personally liked the simplicity of the system and installation seemed fairly easy and quick. I also appreciated the support we received form James and the team.”

The Ezy-Guard 4 Median system, which is available now, has already been deployed at sites in Western Australia, with expectations that the product will have a wider rollout across Australia.

28 ROADS MAY 2023 SAFETY

“WITH WIRE ROPE IN NARROW MEDIANS, NUISANCE IMPACTS CAN BE A BIG PROBLEM FOR ASSET OWNERS. BACK-TO-BACK GUARDRAIL IS MUCH MORE TOLERABLE OF THESE IMPACTS AS THE POSTS ARE MORE ROBUST, MEANING LESS MAINTENANCE AND LOWER LIFE CYCLE COST.”

The TREND Median guardrail terminal has

a comparatively easier installing process when compared to other road safety barriers in the market.

A back-to-back guardrail is designed to protect motorists from lane departures across the median into oncoming traffic.

TO IMPROVEMENT COMMITTED

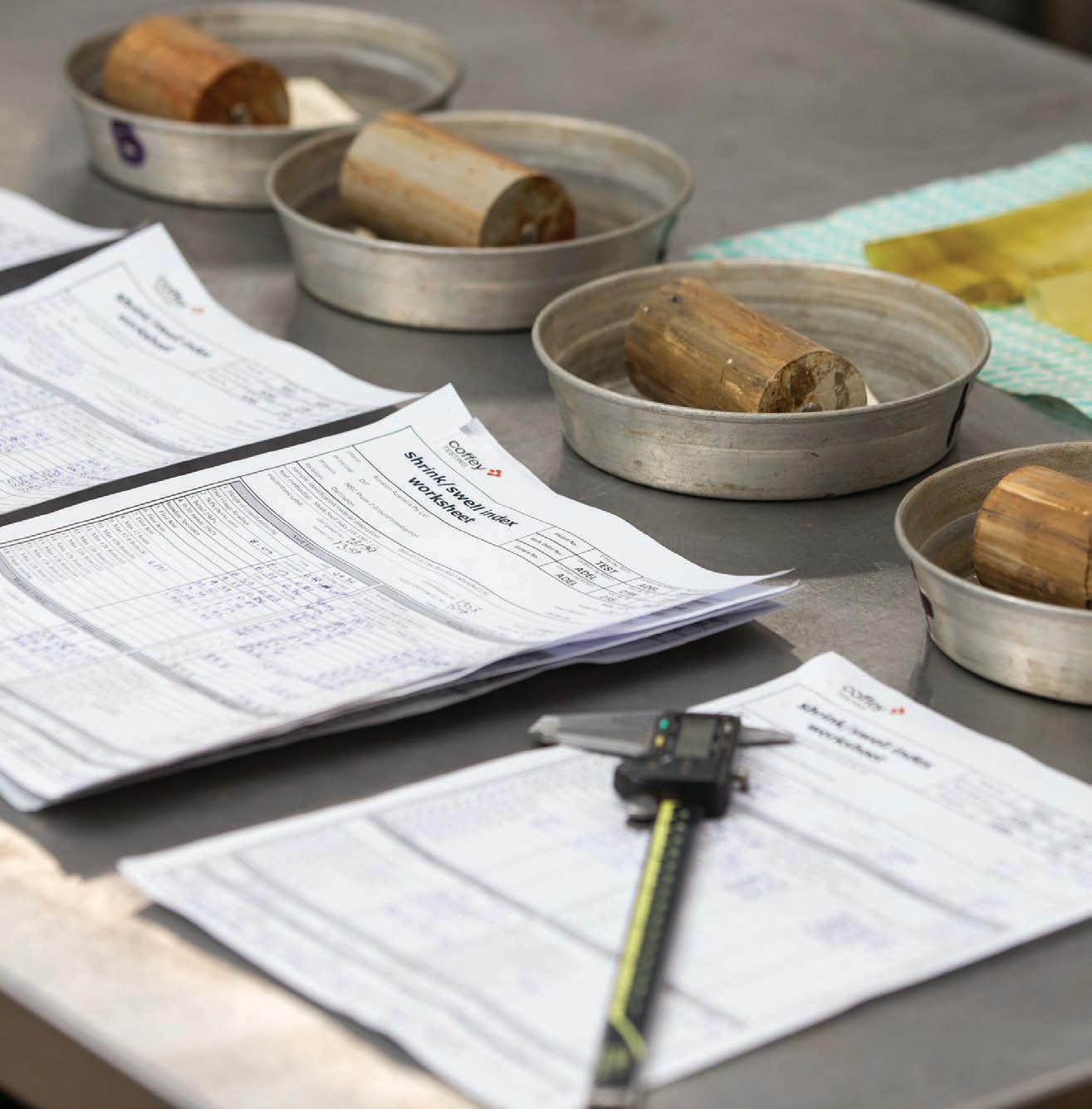

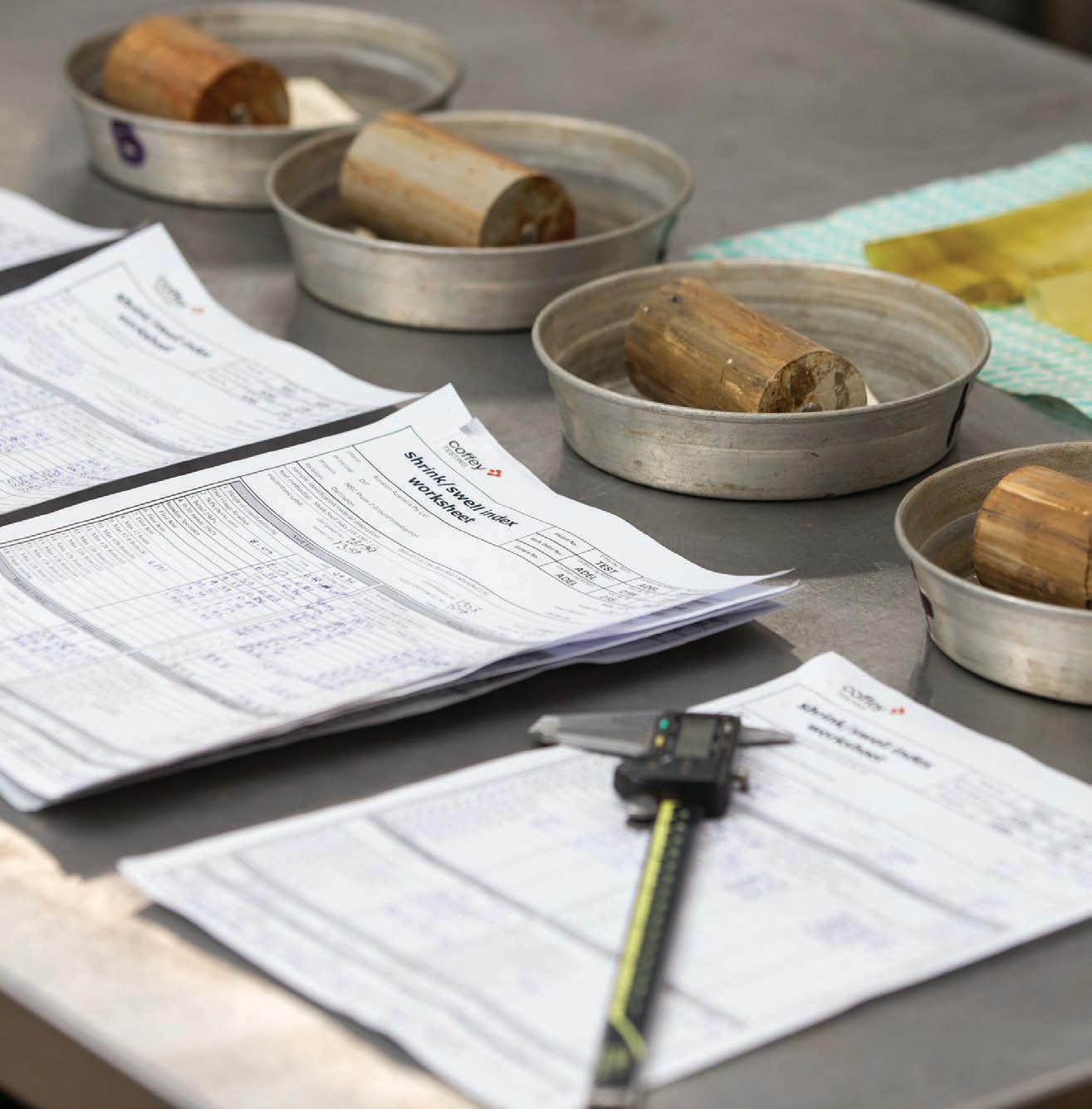

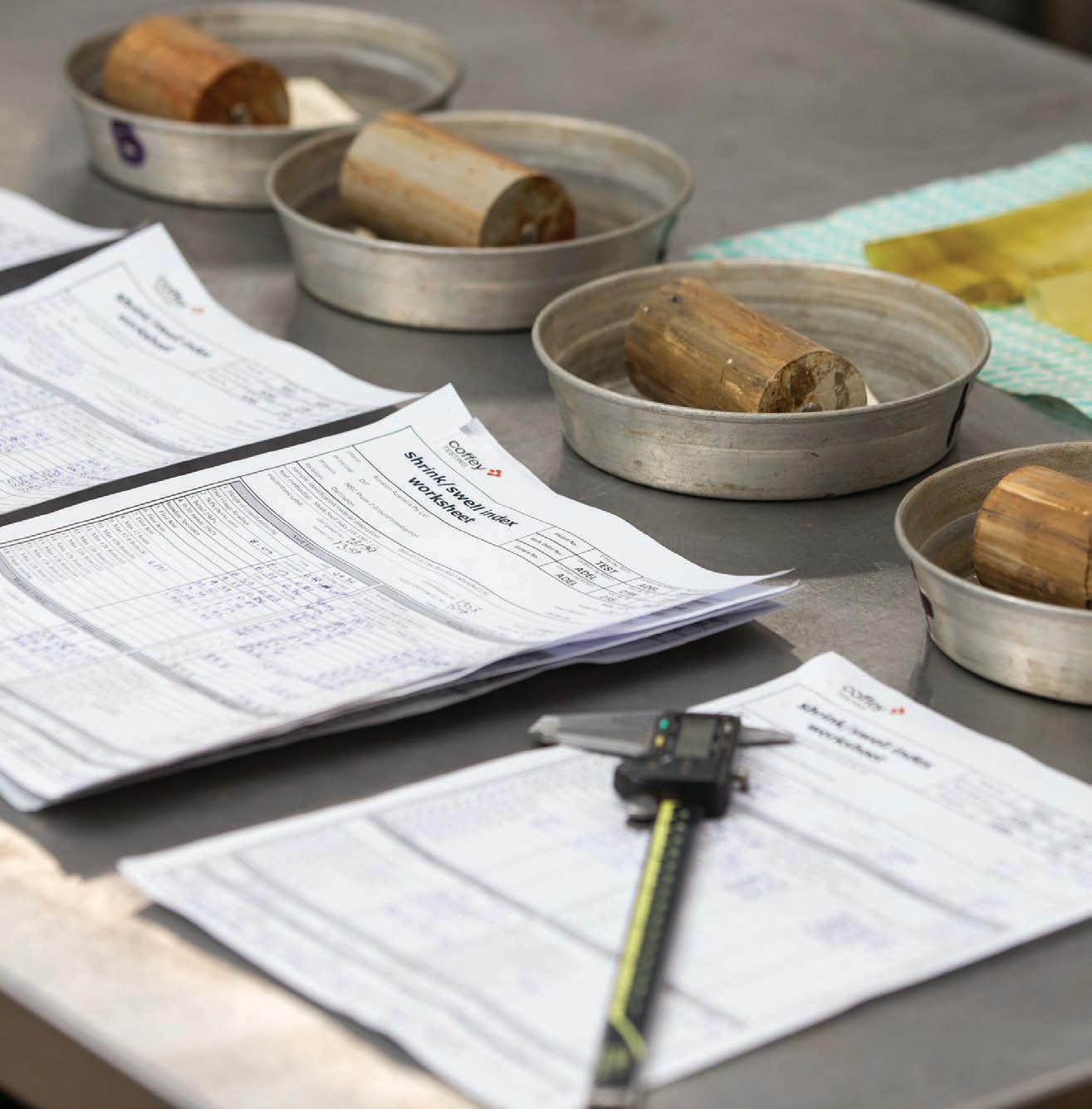

COFFEY TESTING IS CONTINUALLY IMPROVING ITS RADIATION MANAGEMENT PROCESSES AND TRAINING TO ENSURE THE SAFETY AND WELLBEING OF ITS STAFF.

For more than 60 years, Coffey Testing has become synonymous with geotechnical testing for infrastructure projects of all sizes.

Providing testing for aggregates, soft soils, rock, grout and concrete, the company has provided geotechnical services as part of the development of some of Australia’s largest road projects, such as M1 Pacific Highway project, as well as the Bruce Highway Upgrade.

As part of its materials testing services, Coffey Testing utilises equipment that contains a radioactive source to determine the insitu density of soil.

Brooke Scott, Coffey Testing Safety and Wellbeing Manager, says the company, which is considered one of the largest providers of material testing, has robust procedures and training programs in place to ensure the health and safety of its staff and compliance to regulatory requirements.

“It’s important to make sure that the appropriate controls are in place when our staff are using, storing, and transporting soil moisture density

gauges, therefore we’ve got the systems, processes and training in place meet each of these requirements,” Scott says.

Coffey Testing can utilise its ISO/ IEC 17025 NATA accredited testing laboratories in multiple sites across Australia, reducing the call out time and increasing the accuracy of timely results.

Some of Coffey Testing’s staff of 200 technicians nationwide are also local to their respective regions, providing more knowledge around ground conditions unique to each area. The company’s local capabilities are also backed by international best practice when it comes to both equipment and conformance standards.

LEADING THE WAY

In order to operate and transport soil moisture density gauges, individuals must be a licensed operator with the relevant regulatory body, such as the Department of Health Victoria or New South Wales Environment Protection Authority.

As part of Coffey Testing’s

commitment to the safety of its people, the company is aiming to go above and beyond just an accreditation. This has led to the development of in-house and external training services.

Coffey Testing is currently certified to deliver an accredited Radiation

Coffey Testing offers its Radiation Safety Training Course across New South Wales, the Northern Territory and Western Australia.

Safety Training Course across New South Wales, Northern Territory and Western Australia. Not only for its own staff across the company’s 25 locations nationwide, but also for external participants, with an aim to expand into other states in the near future.

“As one of only a few companies to have an accredited Radiation Safety Training Course, it allows us to train our own people to enable them to gain the appropriate skills and knowledge to obtain their radiation licence, plus also deliver the training externally to anybody in the industry in NSW, NT and WA,” Scott says.

Out of the total number of the Radiation Safety Training Course participants in 2022, 22 per cent were external to Coffey Testing.

Scott says Coffey Testing is always looking to support the industries it serves. Whether it be through the training programs, or utilising the company’s five decades worth of experience in materials testing.

“Prior to starting a project, we always consult with the client to conduct risk assessments and ensure appropriate controls relevant to the environment in which we are working are put in place,” Scott says.

“It’s an interactive process too. It’s important to work together with the client to ensure their requirements are met and all the appropriate controls are implemented.”

Coffey Testing will be conducting further updates to its radiation management plans for each state and territory, while also adopting new equipment and technologies.

“We’ve implemented GPS tracking devices on all of our soil moisture density gauges, to better track and secure radioactive sources,” Scott says.

More employees will also have a chance to undertake the radiation refresher course over the coming months, further cementing Coffey Testing’s geotechnical expertise in radiation.

roadsonline.com.au 31 SAFETY

“WE’VE IMPLEMENTED GPS TRACKING DEVICES ON ALL OF OUR SOIL MOISTURE DENSITY GAUGES, TO BETTER TRACK AND SECURE RADIOACTIVE SOURCES.”

Coffey Testing uses established programs and equipment.

YOUR TOTAL SOLUTION FOR ASPHALT AND CONCRETE

Lintec & Linnhoff is a global manufacturer and distributor of leading-edge solutions for the asphalt and concrete industries. Under the Lintec, Linnhoff and Eurotec brands, our products include asphalt mixing plants, concrete batching plants, pavement related technologies and specialist concrete cooling solutions. The Lintec containerised asphalt and concrete batching plant series, built in 100% certified ISO sea containers is one of our key technologies.

www.lintec-linnhoff.com • info@lintec-linnhoff.ccom

Lintec CDP mobile continuous asphalt mixing plant

Linnhoff TSD MobileMix asphalt mixing plant Lintec CSM containerised asphalt mixing plant Eurotec Eco concrete batching plant

Lintec CDP mobile continuous asphalt mixing plant

Linnhoff TSD MobileMix asphalt mixing plant Lintec CSM containerised asphalt mixing plant Eurotec Eco concrete batching plant

IMPROVEMENT THE ROAD TO

MAJOR CONSTRUCTION IS UNDERWAY ON THE EPPING ROAD UPGRADE IN MELBOURNE’S NORTH-EAST. MRPV PROGRAM DIRECTOR, ADRIAN FURNER, EXPLAINS THE STAGES OF DEVELOPMENT, PROGRESS, AND GOALS POST-UPGRADE.

Since the early stages of development in 2018, works on the Epping Road upgrade have had a strong focus on safety for commuters in and around the community, as well as increasing liveability and commercial development opportunities for the Wollert area.

Major Road Projects Victoria is delivering the project as part of the $3 billion Suburban Roads Upgrade package for improvements across suburban Melbourne.

Program Director Adrian Furner says the ongoing works involve a suite of up to 21 priority roads in the north, southeast and western outer suburbs.

“The Epping region is considered a fastgrowing suburb in Melbourne, so demand was growing to increase the area’s road capacity,” he says.

“This meant the Department of Transport and Planning, who are responsible for identifying these roads, decided Epping Road would be its next priority.”

As part of the Epping Road upgrade, extra lanes will be added between Craigieburn Road East and Memorial Avenue, and six key intersections will be improved.

Furner says safety was a big focus due to the increasing population.

“With more people and local schools in the vicinity, one of the main features of this project is how it will improve safety for all road users travelling through the area,” he says.

“The major priorities focus on right turn intersections being made safe, barriers to protect shared walking and cycling paths and making routes more efficient.”

Furner explains that benefits for traffic will come as the project continues.

“The intersection of Park Street and Epping Road will be signalised to increase the safety for motorists and pedestrians on Epping Road. The project hopes to improve traffic reliability - and safety - and get people where they need to be sooner.”

The upgrades include extra lanes in each direction between Craigieburn Road East and Memorial Avenue, new traffic lights at Park Street, the improvement of existing intersections at Craigieburn Road East, De Rossi Boulevard, Baltrum Drive, Harvest Home Road and Lyndarum Drive and the upgrade of the pedestrian traffic lights at Taggerty Grove.

The area is also expected to receive a new shared walking and cycling path from Lyndarum Drive to Craigieburn Road East, on-road bicycle lanes from Memorial Avenue to Lyndarum Drive and the installation of road safety barriers along Epping Road.

With early works underway since mid-2022 and major construction now beginning, Furner says he is proud of the major milestones hit so far.

“We’ve established our main construction site for the site compound and offices to build the road on the Craigieburn Road

East section. We’ve also installed safety barriers along Epping Road to allow access for works associated with service and utility relocations, including power, gas, water, and telecommunications that need to be protected,” he says.

“We are also working on temporary pavement along High Street so we can build the new southbound lanes in that area. Later this year, we’ll be looking forward to the beginning of the key intersections around Memorial Avenue and Craigieburn Road.”

Furner hopes travel benefits for the community will continue to be prioritised.

“Travel times and improved connectivity are key priorities for everyone, even those extending past your typical road user,” he says.

“We hope the project continues to provide easier access to jobs and services and allows easier travel for people navigating from the local residential community to their activity centres, schools, and

roadsonline.com.au 33 PROJECT REPORT

Preparing to build the new southbound lanes on Epping Road.

commercial businesses in the area.

“We also want to make it easy for people to walk and cycle safely around their local community and lower the risk and severity of any crashes that may occur along the alignment.”

With these milestones comes challenges, but Furner says these challenges are being looked at as opportunities rather than roadblocks. He says one example of this was the Wollert Church relocation.

The Methodist Church served as a place of worship for over 120 years and holds both historic and social value in the community.

In May 2022, the church was relocated to Carome Homestead in Mernda to make room for the upgraded intersection at Lehmanns and Epping roads.

Furner says this relocation represented a

MRPV and the community.

“The relocation was adopted by the project team, in consultation with community representatives and Working Heritage, to identify and relocate the historic building to a location nearby,” he says.

“It has now been reconstructed and commissioned so that the community can continue to benefit from this structure for many years to come.”

UNDER THE PDA

The upgrade is being delivered under MRPV’s Program Delivery Approach (PDA), which awards road upgrades to contractors based on capability, capacity, past performance, and ability to deliver value-for-money solutions to the industry.

The construction and upgrades underway on the Epping Road project have been operating under the PDA since the contract was awarded in 2022.

The approach helps with an increasing demand for large road projects and, according to Furner, brings a greater volume of work to market quicker.

“The PDA is intended to provide greater value for money and transparency for Victorian taxpayers.” Furner says.

“We’re now able to stage our projects

all tiers of the market, whilst also working collaboratively with our contractors.

“This means better outcomes and greater efficiency is achieved over time.”

Furner says contractors have been able to break through barriers to entry for growth in the market, something he is excited to see.

“Smaller contractors continue to have a great sustainable workload to provide continuity for their growing teams. They can now grow into greater roles as the project is delivered and benefit from social procurement initiatives, skills and guarantees,” he says.

“After working with multiple forms of contractual models, the PDA stands out in achieving a collaborative, positive working environment while recognising that value is far greater than the dollars we spend.”

Furner says his goal with the completion of the project is to continue seeing the upgrade of roads in outer suburban areas as a critical priority.

“We want to thank the whole community as guests of their neighbourhood while we are under construction. In continuing to work with us, we will get people where they need to be safer and quicker as a result.”

The upgrade is expected to be complete in 2025.

34 ROADS MAY 2023 PROJECT REPORT

Crews get ready for construction to begin on Epping Road.

The Wollert Methodist Church’s new home at Carome Homestead in Mernda.

A new approach to understanding sustainability across your fleet

Understanding the term sustainability and safety is the first step toward having a measurable impact. Where artificial intelligence turns data into insight, it empowers meaningful insights into sustainable practices.

Health & Safety

Analtyics to curb poor behaviour and improve on safety through coaching.

Sites of cultural significance

Tech to protect & promote sustainabile innovative projects.

Preserve natural ecosystems

Ensure the protection of the environment for the future generations.

NetZero

Data to reduce carbon emissions to contribute toward Net Zero.

1300 111 477 TeletracNavman.com.au TN360

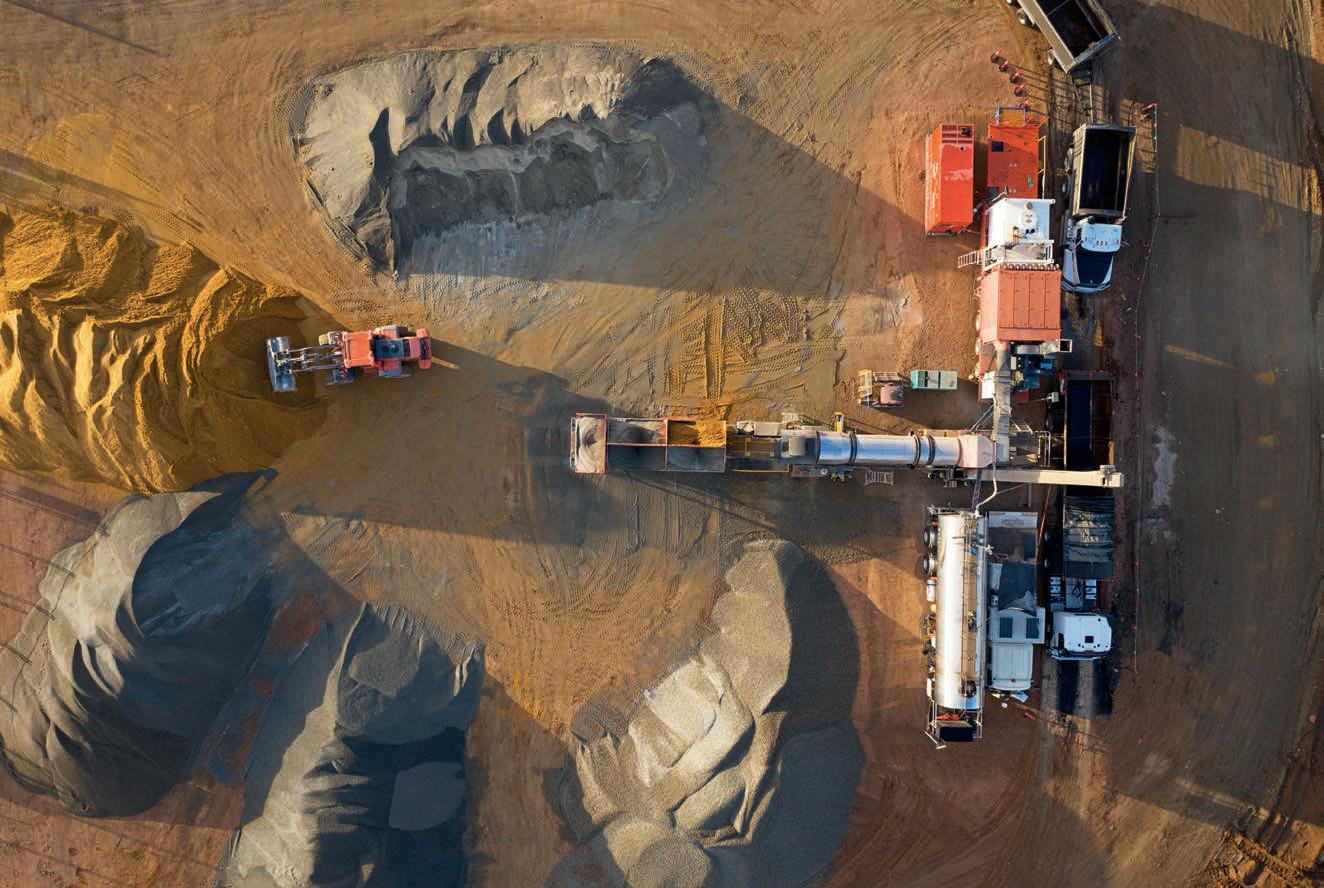

KEEPING IT MOBILE

TOPCOAT ASPHALT CONTRACTORS’ MOBILE ASPHALT PRODUCTION PLANT IS PROVIDING FLEXIBILITY TO THE COMPANY’S EXPANDING NATIONAL SERVICE OFFERINGS. DANIEL RENSBURG-PHILLIPS, BUSINESS DEVELOPMENT MANAGER SHEDS LIGHT ON THE SYSTEMS CAPABILITIES.

Topcoat Asphalt is one of the fastest growing asphalt manufacturers in South Australia. Essential to the company’s growth was the quality and quantity of asphalt produced from its fixed asphalt plants.

Daniel Rensburg-Phillips, Business Development Manager says that Topcoat identified an opportunity to expand its operations by embracing mobile asphalt production methods and procured its mobile asphalt plant.

Differentiating itself from the competition, Topcoat’s mobile asphalt plant can be established quickly and cost effectively for both large- and smallscale projects.

“In 2019 we underwent a large refurbishment [of the mobile asphalt plant]. At the time we already had two fixed asphalt production facilities,” Rensburg-Phillips says.

“We started to see more opportunities in regional South Australia, as well as places such as Alice Springs. With

our fixed facilities, we were limited somewhat by the travelling capacity, time frames and workability of asphalt for longer distances.”

Since its refurbishment, Topcoat’s mobile asphalt plant has been mobilised as far as Alice Springs for only 900 tonnes, and as close as the SA Riverland for more than 25,000 tonnes.

A quick and cost-effective establishment brings Topcoat’s customers value by mitigating the time lag between asphalt production and placement, reducing haulage trucks on the road and increasing serviceability of regions once “too small” for “traditional” mobile plant offerings.