5 minute read

3D design

3D DESIGN DYNAMIC

ROADS AND INFRASTRUCTURE EXPLORES HOW SEEQUENT’S LEAPFROG WORKS SOFTWARE HELPED JACOBS AUSTRALIA VISUALISE AND COMMUNICATE THEIR EMU SWAMP DAM BUSINESS CASE.

The Emu Swamp Dam project, a proposed 12,100 megalitre urban and irrigation supply dam on the Severn River in Stanthorpe Queensland, aims to increase security and agricultural proficiency in the state. It specifically caters to the Southern Downs Region, known for drought and subsequent water supply issues.

The project has been ongoing since 2006, when the initial advice application was submitted. Since then, private farmers and developers have committed to funding 29 per cent of the project, with the Federal Government announcing it will look into co-funding earlier this year.

The project is designed to provide a surety of additional water supplies, enabling increased cultivation and benefit to the local economy.

Additionally, the project is estimated to secure 700 local jobs, while increasing production for Queensland fruit farmers and viticulturists, who have been previously forced to truck water in from New South Wales.

Jacobs Australia, an engineering and technical services firm, was engaged by the Granite Belt Chamber of Commerce to develop the Emu Swamp Dam business case and reference design.

Jacobs Technical Director Engineering Geology, Graeme Jardine, says developing the business case involved providing engineering expertise, stakeholder communication, environmental works to offset harm, baseline

economics and provisional water sales assessment.

“The project faced many challenges including determining an economic and safe design, securing water resources without affecting downstream flows, and incorporating the project into state water plans,” says Mr. Jardine.

“Jacobs was also required to liaise and communicate with a variety of stakeholders, from local councils, chambers of commerce and government to private farmers, developers and the local community.”

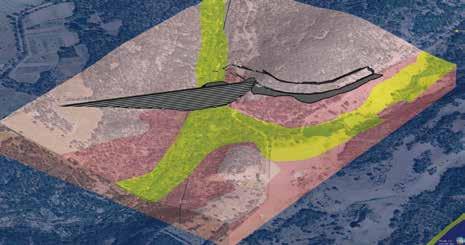

To assess project risk and communicate that risk effectively to stakeholders, Jacobs used Seequent’s 3D subsurface modelling solution Leapfrog Works.

Leapfrog Works is a 3D subsurface modelling solution, specifically designed for the civil engineering and environmental industries.

The software produces highly visual 3D subsurface models to help users understand the geological risks of a project, which can then be accurately communicated to all stakeholders through a range of collaborative sharing tools.

Mr. Jardine says the risks associated with any dam project are considerable, not least due to the risk of valley bulging and associated permeability.

“By using Leapfrog Works to create a subsurface model, Jacobs were able to gain a clear understanding of the geology and mitigate the risks they faced,” Mr. Jardine says.

“This included proposing a grout curtain to stop seepage and piping failure. The subsurface model also identified weathered decomposed granite in the south-east abutment, which meant the dam footprint could require widening

Leapfrog Works produces subsurface models to help users understand the geographical risks of a project.

and/or the use of anchors.”

According to Mr. Jardine, the model also allowed Jacobs to plan for the use of spillway rock in construction work and helped determine clay for the embankment dam would need to be hauled from outside the local area.

“Other identified environmental considerations included use of the rock from the spillway excavation in construction work, and efficient management of the significant surplus.”

Mr. Jardine says identifying all of these sources quickly and accurately is essential, as they have an impact on the overall project cost and delivery.

“We’re delighted Leapfrog Works helped deliver the business case for what could be a landmark project in Queensland,” Seequent’s Civil & Environmental Product Manager Pat McLarin says.

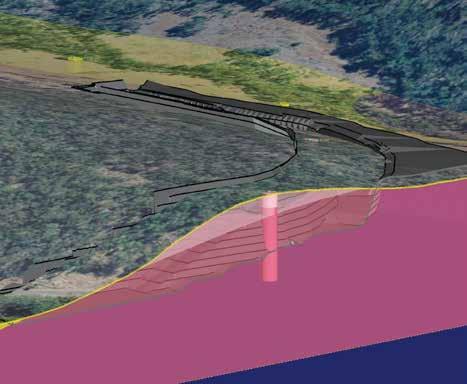

Mr. Jardine says 3D visualisation gave the project clarity and meaning by allowing Jacobs to effectively communicate to all stakeholders. He adds that 3D visualisation was particularly beneficial when dealing with people with no technical background.

“We used Leapfrog Works specifically as a communication tool at the community and non-technical forums to show them what we’d discovered through our drilling programme. Communicating in 3D really helped people understand and visualise the project,” Mr. Jardine says.

“We were also able to use Leapfrog Works’ movie feature to create fly throughs, which we could easily pause during consultations to explain key aspects. These impressive visualisations really helped to bring the project to life.”

The Leapfrog movie function has a high frame rate of up to 60 frames per second and works by dragging 3D scenes into a storyboard inside the modelling software, with the ability to add transitions automatically.

“The real benefit is you don’t need to be a graphic designer – the geologist themselves can produce a quality fly through tour of the project without any specialist movie making training required,” Mr. McLarin says.

According to Mr. Jardine, the software is versatile and enabled his team to interact with building information model designs and ground investigation databases, such as gINT and Holebase.

“This meant we could bring all information into Leapfrog Works’ highly visual environment, giving us a holistic view of the whole project and further helping reduce risk in decision making,” Mr. Jardine says.

“It is likely the decision regarding the Emu Swamp Dam’s go ahead will be made in 2019 and could result in more borehole drilling to fully understand ground permeability – the Leapfrog model will help inform this work, when the project progresses to the detailed design phase.”

If required, new drilling data can be easily incorporated into the subsurface model using Leapfrog Works’ dynamic updating feature.

“Dynamic updating means new data, gained from the field, can be loaded into Leapfrog Works and will automatically flow through to the end model and rapidly update it, with associated time saving and efficiency gains,” Mr. Jardine says.

Jacobs are now using Leapfrog Works as their preferred geological modelling tool for other projects in the Asia-Pacific region, and are looking to expand its application into the UK and North America.

“Leapfrog Works had a very positive impact on our understanding and communication of geology challenges involved in this project,” Mr. Jardine says.

“The software was able to save us considerable time as it’s designed to meet the specific needs of the industry. We don’t need to switch between software packages, we can carry out all of the modelling in one place,” Mr. Jardine says.