4 minute read

Future roads

ROADS OF THE FUTURE

SWINBURNE UNIVERSITY RESEARCHERS HAVE REPURPOSED A WELL-KNOWN MANUFACTURING TECHNOLOGY TO CREATE NEW MATERIALS WITH SPECIAL PROPERTIES CAPABLE OF ABSORBING SOUND AND SEISMIC WAVES. ROADS AND INFRASTRUCTURE MAGAZINE SPEAKS TO PROFESSOR XIAODONG HUANG ABOUT THE RESEARCH.

When looking to create metamaterials capable of traffic sound absorption and earthquake proofing, the Swinburne University engineering research team started with a design method called Bi-directional Evolutionary Structural Optimisation (BESO) and advanced manufacturing techniques.

The BESO method, an intelligent design approach to create building structures, is a computer software that enables engineers to input conditions, such as loading or boundary restrictions. Professor Xiaodong Huang, Leader of the Swinburne research project says the software presents the best structural option for infrastructure projects.

The method was created 10 years ago and has gradually been developed, starting with designs for mechanical or civil infrastructure, which aids projects to hold more volume efficiently.

In recent years, the research team extended the BESO method to include the design of material used for infrastructure projects.

By integrating physics with the BESO method, researchers have found they can create materials with scientific properties, which help with other design problems, such as noise attenuation or stabilisation.

Professor Huang is a Professor of Mechanical Engineering, who joined Swinburne in 2017 after nearly 13 years at the Royal Melbourne Institute of Technology. He created the gradient BESO method and is an expert in topology optimisation.

“The generalised BESO method, called

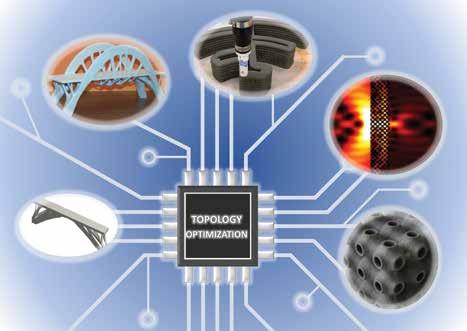

Topological optimisation has the potential to help engineer architected materials.

‘topological optimisation’, can be used to determine the spatial distribution of materials needed to achieve the best performance while satisfying multiple objectives and constraints,” Professor Huang says.

He says multi-discipline topological optimisation is a popular topic in academia and industry because of its potential to help engineer architected materials and metamaterials with desired properties.

The BESO method, integrated with physics, allows researchers to design a metamaterial structure with properties capable of controlling electromagnetic, acoustic and mechanical waves, making the structure capable of finding certain solutions such as energy absorption or vibration isolation.

Metamaterials can be any size and be customised to have many different properties, including those to reflect and absorb sound or seismic waves.

The size of the metamaterial structure depends on the frequency range of waves the structure needs to reflect and absorb. The design of each metamaterial, all with different properties, is aimed at specific industrial applications.

“We use the concept of metamaterials because the metamaterials create a band gap. A band gap allows the structure to reflect or absorb the waves that hit the material. The design structure of a metamaterial can manipulate the structure to reflect the sound that usually goes through it,” Professor Huang says.

An example he gives is a structure that could block low-frequency noise from a busy highway.

“We can design a structure, say a row of columns beside a freeway. The columns would have an internal structure that enables the absorption of sound waves. Essentially, this blocks the sound waves from coming through the row of columns, eliminating the low-frequency noise from surrounding buildings,” Professor Huang says.

This concept of property-enhanced metamaterials uses the BESO method to determine what shape the structure should be to achieve best performance, combined with topological optimisation and 3D printing.

In 2017, Swinburne researchers coauthored a paper on the design of a 3D acoustic metamaterial that could block low frequencies for sound cloaking in spaces such as road tunnels.

They found that using metamaterials can not only help projects structurally, but the method could have health benefits too.

“Low-frequency noise especially, is not healthy for people to hear. Building a wall, low-frequency noise cannot be blocked or reflected, but this technology enables that,” Professor Huang says.

The same idea applies to seismic waves and could have major benefits for infrastructure such as buildings or bridges.

“This method will enable structures to be built to surround an important building so when a seismic wave approaches the structure, the wave can be reflected back into the earth to increase the stability of the building,” Professor Huang says.

While Professor Huang says the metamaterial structure won’t completely protect a building during an earthquake, it has the potential to lessen the damage. These metamaterial structures can be built around the building, or if it is a new building, the structure can be built underneath.

The idea to create a metamaterial capable of reflecting seismic waves was developed in 2018 when Swinburne’s research team created an algorithm that optimises the understanding of damping and natural resonant frequency in macrostructures. That algorithm could improve earthquake resistance through the design of the microstructure of building materials.

The team has also found they can create metamaterials to affect ‘superlenses’, which take microscopes beyond the natural diffraction limit.

“The research method to create metamaterial structures involves some trial and error.

“After inputting all of the conditions into the optimisation program, the computer then produces the structure that should be able to reflect the wave,” Professor Huang says.

Once the correct property is found that can reflect or absorb the wave, the team is then able to derive the structure.

The project is still in the research stage. Swinburne’s engineering research team have built structures in the lab and are currently undergoing testing.

Once commercialised, Professor Huang says this multi-discipline topological optimisation technology is expected to usher a new era of engineering.