THE ROAD TO A BRIGHTER FUTURE

The next steps towards achieving a more efficient and sustainable national road network

A POSITIVE LEGACY

The 2032 Brisbane Olympic and Paralympic Games present a unique opportunity to shape the nations infrastructure for generations to come

CELEBRATING EXCELLENCE

A wrap up of the big winners from the 2023 Women in Industry Awards

ONLY SPECIALIST ROAD MANAGEMENT, CONSTRUCTION AND CIVIL WORKS MAGAZINE JULY 2023 Official media partners of

AUSTRALIA’S

A WIRTGEN GROUP COMPANY Sustainable solutions. www.wirtgen.com/recycling WR 250: The WR model generation from WIRTGEN epitomizes premium quality in soil stabilization and cold recycling – whatever the job. The most powerful machine in the range, the WR 250 even stabilizes heavy, muddy ground efficiently and with the greatest ease. Its high engine performance and extremely robust milling and mixing rotor enable the WR 250 to produce an excellent mix quality even at high advance rates. Take advantage of innovative solutions from the market leader. WIRTGEN Australia Pty Ltd Lot 2, Great Eastern Highway South Guildford WA 6055 T: +61 8 6279 2200 sales.australia@wirtgen-group.com www.wirtgen-group.com/australia

COVER STORY

12 The road to a brighter future Industry is moving to increase the resiliency, quality and sustainability of Australia’s road network.

RENTAL/USED EQUIPMENT

19 Specialised by name

New Zealand’s SIRE is making a splash across the pond in Australia.

22 Growth and commitment

The story of a company driven by quality and family culture.

26 The choice for all needs

How SIXT has expanded its offerings for the infrastructure market.

ROADS REVIEW

29 We asked the industry’s decisionmakers, ‘Do specifications need to be relaxed to support innovation?’

THOUGHT LEADERSHIP

30 A balancing act

A discussion on the Warrnambool Line Upgrade, as well as VIC’s current contract distribution model.

TECHNOLOGY

33 A process of evolution

The role of tunnel monitoring in maintaining some of the world’s busiest connections.

36 The names Bond, SAMIbond

There’s more than meets the eye with SAMI Bitumen Technologies’ SAMIbond 007.

39 The cleaner subset

The newest addition to a renowned plantbased, bitumen performance fluid.

42 Building on global infrastructure investment

How to leverage growth to maximise your operational outcomes.

MACHINERY AND EQUIPMENT

45 Constant evolution

MBE is embracing new technologies, while further developing its patented Tack Coater.

48 A new era

One of the world’s largest machinery manufacturers has opened its first HQ in Australia.

51 Taking on the challenge

Flocon has been at the forefront of machinery manufacturing for more than four decades.

54 No limits

Equipment is helping to reach previously inaccessible areas during road construction works.

58 Going beyond the point of call

Expanding on the professional relationship between Newpave Asphalt and WesTrac.

60 Flexihire fires up for all

Why CEA machinery is the equipment of choice for Flexihire.

62 Forest fears

Exploring SANY Australia’s new range of forestry excavators.

EVENTS

64 Women in Industry Awards

A look over the big winners from the 2023 Women in Industry Awards.

66 No Dig Down Under

A preview of the upcoming No-Dig Down Under Conference.

67 Inside Construction

A peak inside the first ever Inside Construction Expo.

ISC SECTION

68 Sustainability key to positive legacy

How the Brisbane Olympic and Paralympic Games could leave a generational impact on the development of sustainable infrastructure.

AFPA SECTION

70 Resiliency in Roads

Inside the New South Wales Government’s efforts to increase road resiliency across impacted communities.

NATIONAL PRECAST SECTION

72 A milestone has been reached on Perth’s first major elevated rail project.

CONTRACTS AND TENDERS

74 Contracts in brief Roads & Infrastructure provides an update on some of the contracts and tenders recently awarded or put to market across the Australian infrastructure sector.

REGULARS

4 Editor’s letter

6 News

17 People on the move

roadsonline.com.au 3

JULY 2023 CONTENTS

In this edition we address the need for greater road resiliency and recycling for the long-term benefit of Australia’s national road network.

AN EXCITING PRESENT AND FUTURE

INNOVATION IS NOW MORE THAN JUST A BUZZWORD for the sector. It now represents a committed investment into the future of construction machinery, services, maintenance and more for the industry.

The Federal Government’s national rollout of its 10-year infrastructure investment pipeline will increase from $110 billion to close to more than $120 million, a new record for the sector.

The results of such investment are already making in-roads on a sector, which generates $367.2 billion in revenue, producing around nine per cent of the nation’s total GDP (Australian Industry and Skills Committee).

Such a pipeline has also resulted in an influx of new opportunities and projects concerning road construction. In this month’s cover story, we hear from four key stakeholders around the industry’s current push towards increasing the sustainability and resiliency of Australia’s road network. The future is bright, but there’s still a few key steps for us to take in order to develop a higher quality road network.

For this month’s feature topic, we take a look at the current offerings and state of the equipment hire and rental industry. With the boon of infrastructure projects in the pipeline, many across the hire and rental sectors are experiencing significant growth.

Roads & Infrastructure Magazine also hears from Peter Gill and Leslie Chung of Donald Cant Watts Corke, to hear how the company currently views the contract distribution model employed by the Victorian Government. This discussion produced a range of potential solutions to what is a controversial model for some.

A record 158 nominations were received for the 2023 rendition of the Women in Industry Awards. We take a look at the big winners from the night which recognised outstanding women from various industrial sectors, such as mining, transport, manufacturing, engineering, logistics, bulk handling, waste management, rail and construction and infrastructure.

We also shine a spotlight on two of the industries most anticipated events, the 2023 Inside Construction Expo and the 2023 No-Dig Down Under Conference. Both events will provide opportunities for key decision makers in the construction industry to brainstorm, explore and innovate.

Finally, in this month’s Roads Review column, we hear from some of the industry’s leading decision makers on how relaxed specifications could make way for greater innovation across the sector.

Happy reading!

Tom O’Keane Roads & Infrastructure Magazine

COO

Christine Clancy christine.clancy@primecreative.com.au

GROUP MANAGING EDITOR

Sarah Baker sarah.baker@primecreative.com.au

MANAGING EDITOR

Mike Wheeler mike.wheeler@primecreative.com.au

EDITOR

Tom O’Keane tom.okeane@primecreative.com.au

JOURNALIST

Chris Edwards chris.edwards@primecreative.com.au

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR Blake Storey DESIGN

Bea Barthelson

BUSINESS DEVELOPMENT MANAGER

Brad Marshall brad.marshall@primecreative.com.au

CLIENT SUCCESS MANAGER

Glenn Delaney glenn.delaney@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd 379 Docklands Drive, Docklands VIC 3008 Australia p: +61 3 9690 8766 f: +61 3 9682 0044 enquiries@primecreative.com.au www.roadsonline.com.au

SUBSCRIPTIONS +61 3 9690 8766 subscriptions@primecreative.com.au Roads & Infrastructure Australia is available by subscription from the publisher. The rights of refusal are reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Roads & Infrastructure Australia is owned and published by Prime Creative Media. All material in Roads & Infrastructure Australia is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without the written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Roads & Infrastructure Australia are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

4 ROADS JULY 2023

PREPARATIONS PROGRESSING ON $2.2B COFFS HARBOUR BYPASS

Staff, equipment and contracts are moving into place ahead of more major works on the Coffs Harbour Bypass in New South Wales.

The 14 kilometre bypass project seeks to improve connectivity, transport efficiency and safety for motorists.

The project is expected to save motorists about 12 minutes in travel time, avoid up to 12 sets of traffic lights and reduce the number of vehicles through the city centre by about 12,000 a day. Works on vegetation removal are already underway and will continue until late this year. More works will start in the coming weeks, including excavation for some of the cuttings.

Additional works will also start to establish access points to the corridor, as well as drainage and bridge works, the

development of compound sites and the installation of project boundary fencing. Construction will also begin on new road connections between Campbell

Close and the Pacific Highway and between Russ Hammond Close and Korora School Road. The Coffs Harbour Bypass will be completed by late 2027.

PILING COMPLETE ON $1B GYMPIE BYPASS

The last of 575 concrete piles are now in place for the $1 billion Gympie Bypass project in Queensland.

With the piles now in place, works on all 42 bridge structures on the Bruce Highway Upgrade – Cooroy to Curra, Section D (Gympie bypass) are now

underway or complete.

The $1 billion section of the project is a new 26 kilometre, four lane divided highway between the current Bruce Highway interchange at Woondum, south of Gympie and Curra.

The project aims to improve and

increase the safety, flood resilience, and capacity of the connection.

The project is expected to be competed in late 2024 and is being jointly funded by the Federal ($800 million) and Queensland ($200 million) governments.

6 ROADS JULY 2023

NEWS

The project will aim to increase the safety and reliability of the bypass. Image courtesy of the Queensland Government.

The project will be completed by late 2027. Image courtesy of the New South Wales Government.

Introducing the first and only skid steer with a telescopic boom the JCB Teleskid; a truly unique, versatile skid steer with endless possibilities. Now you can lift higher, reach further, dig deeper.

This revolutionary product is designed to suit all types of job sites meeting the need of multiple machines wrapped nicely into one. Combining the strength and safety of our single side boom with side door entry and extendable boom JCB has increased the versatility of the SSL-CTL world.

To find out more contact your local JCB CEA dealer today. Ph: 1300 522 232 www.jcbcea.com.au

CHAIR, BOARD APPOINTED FOR NEWLY FORMED HIGH SPEED RAIL AUTHORITY

The Federal Government has announced its appointments for the newly formed High Speed Rail Authority.

Jill Rossouw has been appointed as the Chair of the Authority Board with the four other board members to include Gillian Brown, Dyan Crowther, Ian Hunt and Neil Scales.

This authority will oversee the development of the high-speed rail network along the east coast.

It will aim to provide a faster alternative for commuters between cities and regional centres across Australia.

This network could allow passengers to travel between major cities and regional centres at speeds exceeding 250 kilometres per hour.

According to the Federal Government, the first priority for the High Speed Rail Authority will be planning and corridor works for the Sydney to

FIRST TWO TBMS BEGIN MAJOR SYDNEY METRO WEST TUNNELLING WORKS

The first two tunnel boring machines have begun tunnelling out the next section of the 24-kilometre Sydney Metro West line.

The Sydney Metro West project will double rail capacity between the two CBDs, linking new communities to rail services and supporting employment growth and housing supply.

The new 24-kilometre metro line will include stations at Westmead, Parramatta, Sydney Olympic Park, North Strathfield,

Burwood North, Five Dock, The Bays, Pyrmont and Hunter Street in the Sydney CBD.

Tunnel boring machine Daphne is already 150 metres into its 11 kilometre journey to Sydney Olympic Park. Tunnel boring machine Beatrice is 45 metres into its journey on the parallel tunnel.

TBM Daphne has been named in honour of pioneer for Paralympic sport Daphne Hilton, while TBM Beatrice’s namesake is iconic local

newspaper seller Beatrice Bush who sold newspapers for over 25 years in Sydney.

On top of tunnelling, works on the tunnels will also include the construction of cross passages and crossover caverns. Construction of the twin metro tunnels is being led by the Acciona Ferrovial Joint Venture, which was awarded the construction contract in July 2021. Passenger services are expected to commence in 2030.

8 ROADS JULY 2023

NEWS

Newcastle section of the high-speed rail network, backed by a $500 million Federal commitment.

The senior leadership team has been finalised for the brand new authority which has already begun operations.

The progress of the machines is a major milestone for the project. Image courtesy of the New South Wales Government.

WORLD FIRST RECYCLED GLASS TRIAL A SUCCESS

mix can be replaced with recycled crushed glass, reducing reliance on virgin sand and diverting waste glass from landfill.

These mixes were used in the construction of temporary suspended concrete slabs, successfully producing a concrete mix of equal strength and quality.

Similar mixes have only previously been used in the construction of footpaths and local roads, hence the world-first milestone.

The Metro Tunnel will create a new end-to-end rail line from Sunbury in the west to Cranbourne/Pakenham in the south east, with bigger and better trains, next generation signalling technology and five new stations.

Researchers from the University of Melbourne, as well as industry have demonstrated the world’s first use of a recycled glass concrete mix in a structural application on a major infrastructure project.

The trial formed part of works on the Metro Tunnel Project in Victoria, specifically construction on the new State Library Station.

The trial demonstrated that 25 per cent of virgin sand used in concrete

Following the success of the trial, the Victorian Government is considering further trials with the University of Melbourne to increase the virgin sand replacement from 25 per cent to 80 per cent crushed glass.

NEW MILESTONE FOR $280M TOWNSVILLE RING ROAD – STAGE FIVE

Ramps have reopened on the Townsville Ring Road in Queensland, with traffic now travelling in each direction.

The Townsville Ring Road Stage Five project aims to deliver improved road safety, efficiency and travel time reliability for freight and passenger vehicles on the Bruce Highway in Townsville.

The Townsville Ring Road’s southbound entry and exit ramps at Hervey Range Developmental Road have reopened, with the southbound ramp at Shaw Road also expected to reopen. Works began on these sections in August 2022.

Traffic will remain single lane in each direction for several more months while final works are completed on the project, which includes construction at Beck Drive to install a new, signalised intersection at Gouldian Avenue.

All four lanes of the newly duplicated

roadsonline.com.au 11

NEWS

motorway will open to traffic when the Townsville Ring Road – Stage 5 project is completed later this year. The Federal Government has

committed $224 million and the Queensland Government $56 million toward the $280 million Townsville Ring Road Stage Five project.

The trial saw the use of recycled glass in a major infrastructure component. Image courtesy of the Victorian Government.

Traffic is now flowing on the section, with additional works also set to get underway. Image courtesy of the Queensland Government.

THE ROAD TO A

BRIGHTER FUTURE

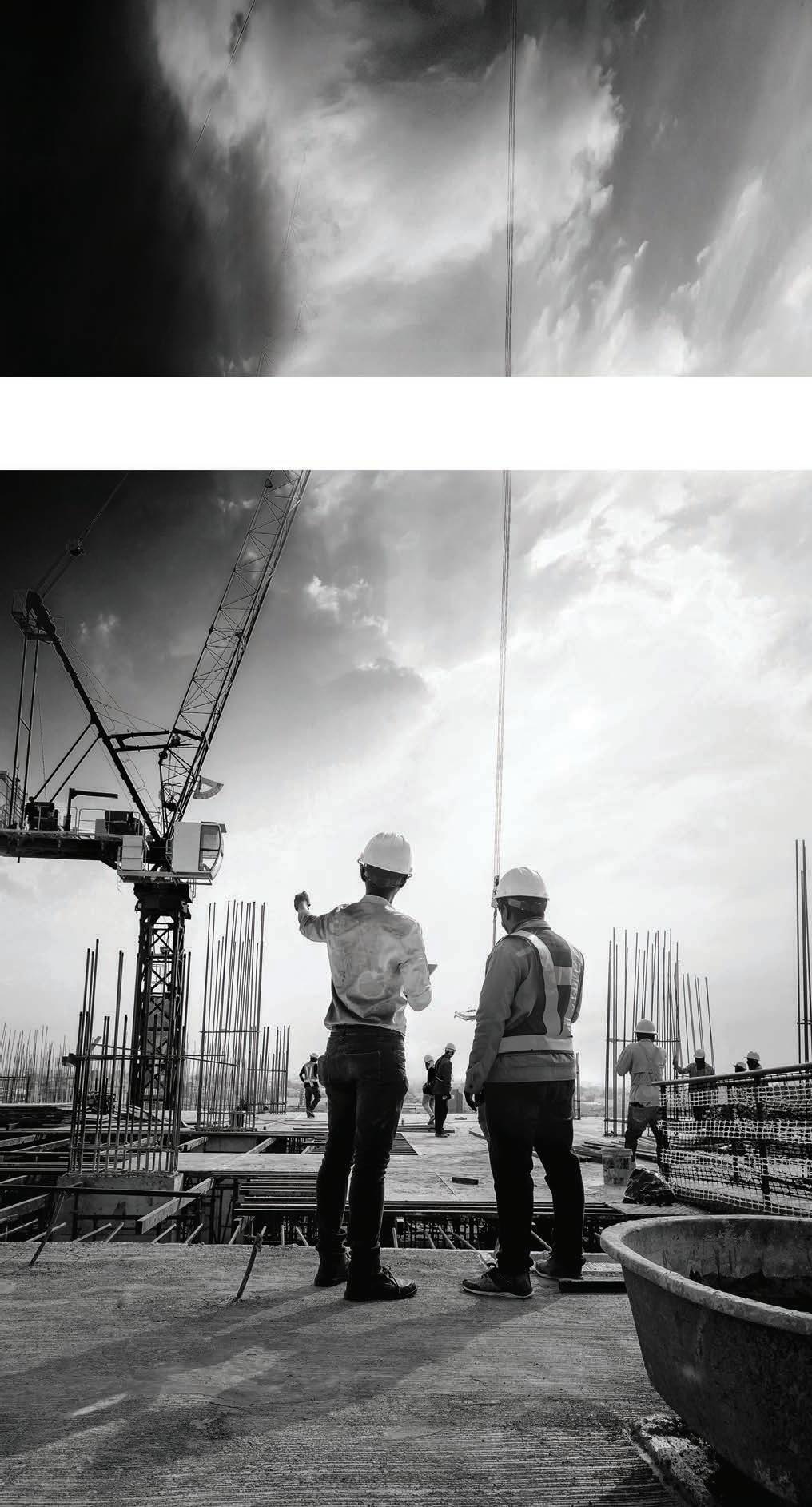

THE ROADS AND INFRASTRUCTURE SECTORS ARE TAKING STRIDES IN ROAD RESILIENCE, RECYCLING AND REHABILITATION. DESPITE THESE DEVELOPMENTS, THERE’S STILL A LONG PATH TO IMPROVEMENT AHEAD. ROADS & INFRASTRUCTURE MAGAZINE HEARS FROM FOUR KEY DECISION MAKERS ON THE IMPORTANCE OF THE NEXT STEPS AHEAD.

Australia’s road network is one of the largest in the world, estimated to be larger than 877,000 kilometres (Roads Australia).

The size of the existing road network, paired with rapid expansion caused by Federal and state government investment, means Australia’s road network will face even greater expansion.

Roads Australia predicts that to 2024-25, the estimated spend on road construction activity will be equal to $106 billion. And yet annual maintenance budgets are in the order of $7 billion.

While such a large focus has been placed on future development, maintaining existing road infrastructure cannot be overlooked, Jim Appleby, Chief Operating Officer – Hiway Group says.

“Particularly in a country as geographically

spread as Australia. If you don’t have a well maintained and resilient road network you have disconnection and disruption” he says.

“That disconnection has not just an economic cost, but a social cost as well. As soon as you lose your road network, then commerce and community are directly affected. Having those connections are critical to the success of the nation.”

One of the core components of maintaining the existing network is road resiliency. This relates to suitable infrastructure that can endure current and future hazards, such as severe weather events, high traffic volumes and changing infrastructure environments.

Dr. Michael Moffatt, Chief Technology Leader and Discipline Leader: Pavements, Safer Smarter Infrastructure – NTRO (formally ARRB), says Australia’s reliance on road travel places an even greater need

on road resilience.

“In terms of surfacing, the vast majority or two-thirds of Australia’s roads are unsealed, and road travel is the most popular mode of transport,” he says.

“Roads are also responsible for carrying around 65 per cent of all freight. Essentially our communities are linked by the existence of the road network. If the road network isn’t resilient, then communities are not connected. People don’t have the same access to family, social groups, food, medical services and more.”

Daniel Orriss, Executive General Manager, Stabilised Pavements of Australia, says the opportunity to provide better performing assets is in the interests of both the public and asset owners.

He says the floods in Queensland are an important example of evaluating the resiliency of an infrastructure network.

“Queensland experienced significant rainfall events around 10 years ago and the Queensland Government has subsequently taken time to really learn what had been the biggest impacts to those assets,” Orriss says. “The end damage bill was above $5 billion to repair and rehabilitate the network after those events.

“Rather than just accept that outcome, the QLD State Government looked and evaluated ‘how we could prevent this outcome from occurring again in the future?”

“These learnings weren’t only in designing for asset life, or traffic loads on the road network, but they also incorporated the

12 ROADS JULY

2023

Road recycling and resilience helps to establish sustainable options for future and current road production.

impacts, not only just for roads, but also other components of the state’s infrastructure, helped to give an indication of what needs to be incorporated to limit any network failures from occurring in the future.

“It requires asset owners to be more aware of what options they have, as well as the benefits of each option. For example, utilising pavement materials that are less susceptible to moisture is a really good option,” he says. He says this includes considerations such as moisture ingress and materials that have reduced moisture sensitivity properties.

GREENER AND GREATER

On top of future-proofing and creating a more reliable road network, increased road resiliency can also provide a suit of benefits in terms of sustainability, says Appleby.

“I can only applaud that sustainability is now a primary consideration,” he says. “Now more than ever there’s a big push towards sustainability and reducing our carbon impact, and rightfully so.”

Appleby adds that increased sustainability doesn’t come at a cost to quality.

“I’m sure we all want to leave a positive legacy for our children. Sustainability should be at the forefront, but it doesn’t mean it has to come with a technical compromise. The technology is already available, such as in-situ stabilising, where we are reusing what

were previously raw materials. We reuse and recycle, to bring these materials back to their former glory,” he says.

“Confidence in recycled materials has definitely grown. With the technical depth and engineering capabilities available in Australia, we’re now talking about achieving the same pavement quality, but in a different way,” Appleby says.

Recycling and re-use doesn’t only help to reduce carbon emissions as well as the reliance on virgin materials, but can also reduce pressures surrounding the financial aspects of infrastructure development.

“We have to be honest. There isn’t a bottomless pit of available funds for road construction and maintenance,” Appleby says. “We have to be thrifty in the road building

roadsonline.com.au 13 COVER STORY

Education is a valuable asset for implementing greater levels of sustainability and efficiency into road production.

Australia’s road network is estimated to be larger than 877,000 kilometres.

world. We don’t need to have a gold-plated network, we need a network that’s resilient and fit for purpose.

“The reality is that it’s cheaper to recycle a road than dig out and put in a new one. It just makes commercial and environmental sense.

“Australia’s in a position to impress the world if we fully embrace road recycling.”

QUALITY LEADS TO SAFETY

Appleby believes increased road resiliency, and therefore increased road quality, can also play an “essential role” in tackling one of Australia’s biggest safety issues.

The Bureau of Infrastructure and Transport Research Economics says Australia’s annual road death toll in 2022 was 1194, an increase of five per cent on 2021.

“We’re clearly fighting a mounting death toll on Australian roads,” Appleby says. “Investment into the road network can increase the safety of roads. These safety elements should never be forgotten, because ultimately, we’re talking about people’s lives.”

Simon Abrahams, General Manager, National

and the road resiliency that comes with these recycled pavements, is that if you have a bound and stabilised pavement surface, it is far more robust and reduces the likelihood of future pavement failures. Furthermore, recycled pavements often offer a more sustainable and cost effective solution which means more improvement work can be done with limited funding.”

THE TO DO LIST

To support increased road resiliency, as well as a higher adoption of sustainable road construction methods and material use, Downer’s Abrahams says an appropriate and mature procurement process is the first step.

“A lot of times, it is assumed that virgin material will deliver a better result in comparison to recycled and stabilised options because it’s new. This traditional method of road design and specifications is evolving as communities demand a more sustainable approach,” he says.

Abrahams adds that changing this way

“THE ADVANTAGE OF ROAD STABILISATION WORKS, AND ROAD RESILIENCY, IS THAT IF YOU HAVE A BOUND AND STABILISED PAVEMENT SURFACE THERE’S LESS CHANCES OF DEFECTS. IF YOU HAVE A FLOOD EVENT, THE SURFACE IS LESS LIKELY TO BE DAMAGED.”

Wirtgen machinery on site for works on the Inland Rail project.

Major stakeholders in the roads and infrastructure sectors say the technologies and processes are within the sector’s reach to increase the sustainability of Australia’s road network.

and final road quality.

“You get the best results when you have a process that creates collaboration between the asset owner, designers and expert construction contractors with a deep knowledge of pavement recycling,” he says.

“There are three key factors to making the collaboration successful and achieving sustainable, resilient, and optimum project outcomes.

“Firstly, set clear expectations upfront with designers, that input from contractors will be sought on pavement recycling options to allow the designer to consider this in their approach.

“Secondly, allow sufficient time in the procurement process for pavement investigation and testing and providing contractors the geotechnical investigation data early in the process, to consider and recommend genuine alternatives.

“Thirdly and finally, it’s important to ensure that risk is allocated to the parties that can most effectively manage it. Tenderers can then develop better, and more innovative solutions based on reliable information and lower project costs and risks accordingly.”

Stabilised Pavements of Australia’s Orriss says another key driver of a sustainable and resilient road network will be education.

“Education and awareness is one of the biggest challenges. Often what you already

know, or what you have been doing for years becomes the first option. It’s important to be educated and remain aware of other options that are out there,” he says.

“Due to the nature of the industry, people are transient and move around roles. That’s where you can lose that inherent knowledge, as it’s not easily transferred, and it takes time to build up that knowledge.”

Education isn’t the only issue.

“The other challenge is what you could consider risk management. When asset owners utilise third-party designers, there’s often a disconnect between options that are selected based on the risk to the designer, as opposed to engineering fit for purpose solutions that fit in within the asset owners needs,” Orriss says.

“There’s a great opportunity for asset owners where they’re devoid of that internal experience to leverage off what the industry can provide. Particularly organisations like Stabilised Pavements of Australia, which can support them through a documented design process to achieve better outcomes.”

A LIKE-MINDED PARTNER

Despite being competitors, Hiway Group, Stabilised Pavements of Australia and Downer are all united by their vision of a more sustainable, resilient and effective

domestic road network.

These organisations also share another common denominator – the support of Wirtgen Group Machinery for their equipment needs.

Appleby says both Hiway Group and Wirtgen are united by both companies push for continual improvement and technological development for the betterment of the industry.

“It’s great to have a partner that is willing to collaborate with us to drive improvement,” Appleby says. “Just like us, Wirtgen isn’t happy with what we do today, we’re constantly challenging ourselves for tomorrow.”

Orriss believes it’s the manufacturer’s passion and commitment that differentiates Wirtgen from others in the market.

“They’ve partnered with organisations such as ourselves to enable them to use subject matter experts to develop products to be fit for purpose,” he says.

Abrahams says Downer has shared a more than 20 year professional relationship.

“The majority of our frontline specialist recycling equipment is Wirtgen machinery, not just because Wirtgen Australia support the pavement recycling industry, but because they provide some of the most advanced equipment that’s currently available anywhere in the world,” he says.

roadsonline.com.au 15 COVER STORY

PEOPLE ON THE MOVE

ROADS & INFRASTRUCTURE HELPS YOU KEEP UP WITH THE LATEST MOVEMENTS ACROSS THE ROADS AND INFRASTRUCTURE SECTORS.

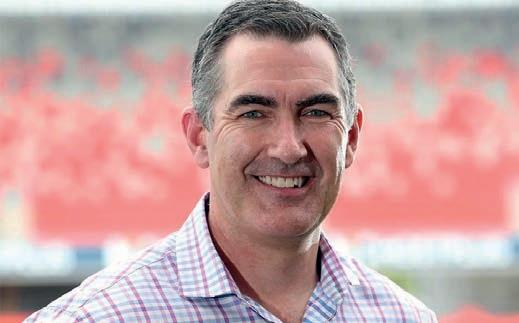

ROADS AUSTRALIA FAREWELLS CEO

Roads Australia has farewelled its Chief Executive Officer Michael Kilgariff, who is leaving the organisation following a five-year tenure. Kilgariff brought major economic, social and government policy experience to the role, as well as a broad understanding of key issues impacting the industry. Kilgariff holds a degree in Economics from the Australian National University and is a Graduate of the Australian Institute of Company Directors’ diploma and advanced diploma courses. He also completed the Cambridge University Judge Business School Advanced Leadership Programme in November 2017.

Image courtesy of Roads Australia.

ARA ANNOUNCES NEW BOARD MEMBER

The Australasian Railway Association (ARA) has announced that Pacific National Managing Director and Chief Executive Officer Paul Scurrah has joined the ARA Board as a General Director. Scurrah’s previous experience includes more than 20 years in transport, logistics, travel, and aviation, working at companies such as Virgin Australia, Queensland Rail and port and supply chain operator DP World Australia. He has also held senior leadership roles at Ansett, AWH and Australia Post and is a director of the Gold Coast Suns AFL team.

Image courtesy of Gold Coast Suns.

NEW TAC CEO APPOINTED

The Victorian Government has appointed Tracy Slatter as the new CEO of the Transport Accident Commission (TAC). Slatter has previously served as CEO of Barwon Water for the past six years and prior to that, as CEO at the City of Port Phillip. Slatter also worked as the Head of Claims at the TAC for four years. She also serves on the boards of the Institute of Public Administration Australia (Victoria) and Water Services Association of Australia and is Deputy Chair of the Barwon Regional Partnership. Slatter will take over from Joe Calafiore, following an eight-year term as CEO.

Image courtesy of Barwon Water.

roadsonline.com.au 17

PLAN B COMMS

SPECIALISED BY NAME

SPECIALISED ROADING EQUIPMENT IS ONE OF NEW ZEALAND’S HIGHEST REGARDED MANUFACTURERS OF BESPOKE ROAD CONSTRUCTION MACHINERY AND EQUIPMENT. NOW THE COMPANY IS LOOKING TO MAKE A SPLASH IN THE AUSTRALIAN MARKET. MANAGING DIRECTOR MARK WANSBROUGH OUTLINES THE COMPANY’S PLANS.

road construction equipment, particularly telescopic bitumen sprayers.

SRE Managing Director Mark Wansbrough says the company has rich roots in product development, in part thanks to the company’s early days more than 20 years ago.

“SRE was founded about 23 years ago by a guy who had his own road construction and sealing business. At the time he became frustrated that the only bitumen sprayers that were available on the market were pretty basic, fixed wing sprayers,” Wansbrough says.

“He couldn’t see a suitable machine available anywhere else in the world. It really depended on what he could create. So, he formed the company and from scratch he designed New Zealand’s first telescopic sprayer.”

“People started coming and knocking on his door saying ‘hey we’d like one of those, too’. It started from that initial innovation and a desire to improve his operations in the industry,” Wansbrough says.

Following the success of the first machine, the roading business was eventually sold, with an emphasis placed on the sprayer manufacturing business. Specialised Roading Equipment is the spiritual successor of this first innovation.

SRE now provides tack coat sprayers, emulsion pumps and trailers, telescopic bitumen sprayers, emulsion sprayers spray bars and more to both New Zealand and Australia.

FROM SMALL BEGINNINGS

Wansbrough identified SRE’s potential in

2019 and set about increasing its capabilities and services, while also making changes to the internal structure of the company.

For the past four years, Wansbrough says SRE has more than tripled its output when it comes to building sprayers for the New Zealand and Australian markets. He says that evaluating the company internally identified opportunities for improvement.

“We changed our outlook as a business and we reiterated our focus on looking after machinery from the time they’re made, until the time they die,” Wansbrough says.

“Another big change was filling some niches with new products. Before 2019, we effectively had one product in our portfolio. But now we’ve got a number of different options, depending on what the customer wants.”

A big part of this continued growth is embracing new markets and opportunities,

roadsonline.com.au 19 RENTAL /USED EQUIPMENT

From its headquarters in New Zealand, Specialised Roading Equipment has established a meaningful presence in Australia’s road construction market.

SRE ABROAD

SRE has always eyed the Australian market as a baseplate for further growth.

The company has now supplied machinery and equipment to Australia for more than 15 years.

Wansbrough says the Australian and New Zealand road construction industries share similar desires and concerns, making the transition towards Australia’s domestic market much easier.

“In New Zealand, and the same things happening in Australia, customers are becoming more aware of how they’re using their machinery and what they’re using it for,” he says.

“Having a fancy sprayer that’s close to a

were using one tool to do everything, but we’ve helped them to find the appropriate tool for each role.”

Wansbrough says one of SRE’s strengths is its control over the manufacturing process, allowing customers to have streamlined contact for after sales support.

“We control the entire build process from the start. We don’t use someone else’s heating control system or someone else’s designs. We control and support all of the parts and systems,” he says.

This applies to the machinery, as well as inbuilt technology like the computer control system and bitumen job tracking.

These systems can provide operators and project managers with real-time job management and productivity data. This is also supported by SRE’s support services, including maintenance and repairs throughout the entirety of a sprayer’s serviceable life.

Wansbrough says SRE is able to provide after-sales support quicker than some Australian providers in the case of a breakdown or component fault.

“We can support [customers] from a technical perspective remotely. We can hop online, hook into the sprayer and look at the data and see exactly what’s happening with the machine at any time,” he says.

“We’ve also got the ability to get people on the ground. We’re involved all the way through the process.”

relationships in Australia to help customers.

“One of our customers had a slight issue with the bitumen pump on a Thursday, so we were on a plane that night to be onsite first thing Friday morning. We worked through the weekend and on the following Monday they were ready to spray again,” he says.

“I’d question if they’d be able to get support that quick from anyone in Australia, and we did it from Hamilton, New Zealand.”

SRE also has services when it comes to spare parts for its bitumen and emulsion machinery.

EXCITING OPPORTUNITIES

SRE machinery has already been used on Australian projects, with its equipment being used as part of works on the NorthLink Program for Main Roads Western Australia.

The company is looking to expand its portfolio, assessing new machinery developments and new business opportunities throughout Australia. This includes developing new technology for its equipment, as well as equipment that can support the spraying of sustainable materials.

“We could be like other companies that make any equipment in the roading industry. But instead, we’ve chosen to be experts in the niche bitumen equipment market, while having a full product offering for specific jobs,” Wansbrough says.

“We’re living up to our name.”

RENTAL /USED EQUIPMENT

Specialised Roading Equipment Managing Director Mark Wansbrough.

A number of companies are already using Specialised Roading Equipment for projects across Australia.

MOVING TOMORROW, TODAY WWW.SANYAUSTRALIA.COM.AU WWW.SANYAUSTRALIA.COM.AU

A HISTORY OF GROWTH AND

COMMITMENT

KENNARDS HIRE IS DRIVEN BY QUALITY AND A FAMILY CULTURE. GENERAL MANAGER – COMMERCIAL, TONY SYMONS, PAINTS THE COMPANY’S PICTURE

The post-war economic expansion, following the devastating conflict of World War II, can be regarded as one of the most influential periods on modern civilisation.

Rapid economic growth and technological development led to the birth of new opportunities and business.

Shortly after the end of World War II in 1945, a simple gesture by Walter Kennard laid the foundation for what is now one of Australia and New Zealand’s largest family-owned machinery and equipment hire providers.

Walter Kennard was approached by a customer, asking if he could borrow one of Kennard’s concrete mixers. Walter Kennard said he wouldn’t lend the mixer to the customer, instead he would hire it out to him.

And so, in 1948, Kennards Hire was born. The company boomed in the early 1950s, moving from its original storefront in Bathurst, to Sydney.

Kennards Hire continued to expand, adding branches, new machinery and

equipment as the years passed.

In 2023, the company is celebrating its 75th anniversary. General Manager – Commercial, Tony Symons says the milestone has been achieved through reliability and innovation.

“Being a family business has helped to ride the peaks and troughs of the economy, as well as the construction industry and other sectors,” he says.

“There’s been a consistent focus on quality as well. We’re a very customer centric organisation.”

Symons says this notion started with Walter Kennard’s commitment in providing the very best on offer to every customer. In fact, Walter Kennard, and later his sons Neville and Andy Kennard, would often make changes to existing machinery, to increase the efficiency and safety of machinery for customers.

“We’ve gone from a business that was primarily focused on small trades and those keen on DIY, to include much bigger, broader and diverse sectors,” he says.

According to Symons, Kennards Hire is now the largest family-owned equipment hire business across Australia and New Zealand, with almost 200 sites and branches, as well as more than 1800 members of staff.

WHAT’S IN STORE?

Kennards Hire’s equipment range now spans across a vast number of commercial industries.

For the roads and infrastructure sectors, the company provides options for compaction, materials handling, access, rail, safety, concrete, generators, lighting, lifting, portable site equipment and much more.

Symons says Kennards Hire’s network of sites, as well as its reliability, have made it the provider of choice on some of Australia’s largest infrastructure projects, including the West Gate Tunnel project, as well as works on the Monash Freeway.

“We have great equipment brands and a branch network that spans all states,

22 ROADS JULY 2023

Kennards Hire has provided hire equipment and solutions for 75 years.

including regional towns. Geographically, there’s extensive coverage, with a lot of our sites close by for works on large projects,” he says.

“In the last 20 years our range of products and solutions in construction and infrastructure has increased significantly. We expanded our equipment offerings and distribution, which led us to the infrastructure market.”

In the past few years, Kennards Hire has also developed a dedicated internal major projects business.

“This side of the business was developed in the last three to four years to focus specifically on larger projects, with a slightly different offer,” Symons says.

“Our business development team engages the client at an early stage of the project to understand their wants and needs. We then work with them on solutions on a day-to-day basis.

“Our team is highly trained and highly skilled and have a very good

“WE’VE HAD PEOPLE TRAVEL OVERSEAS TO KEEP ABREAST OF INNOVATION. AS A RESULT, WE’RE NOW INVESTING MORE IN SOLA R-POWERED EQUIPMENT, ELECTRIC EQUIPMENT AND HYDROGEN-POWERED EQUIPMENT.”

understanding of specific site requirements, as well as equipment compliance. We work closely with the project manager around equipment, repairs, technical advice as well as numerous other support services.”

Symons says the differentiator is Kennards Hire’s capabilities and service.

“We’ve got high quality and modern equipment, but it’s our ability to respond quickly to a client’s needs. Project managers need to make decisions on the go, so when they contact our branch or business development team, we can provide answers quickly,” he says.

CONTINUED INNOVATION

A common theme throughout the company’s 75-year history is continual

development and investment into its machinery range.

“There’s been a huge investment in environmentally friendly products and greener machinery, primarily when it comes to the burning of diesel fuel,” Symons says.

“We’ve had people travel overseas to keep abreast of innovation. As a result, we’re now investing more in solarpowered equipment, electric equipment and hydrogen-powered equipment.”

Kennards Hire also has electric trucks within its Sydney branch network. The company has received orders for the first hydrogen-powered generators in Australia.

“It’s been in the company’s DNA forever,” Symons says. “We have

roadsonline.com.au 23 RENTAL /USED EQUIPMENT

Kennards Hire can provide hire equipment options for infrastructure and road projects of all sizes.

established a robust framework for addressing and progressing environmental and sustainability initiatives for many years. This commitment is significant not only to us but also resonates with the Kennards family and clients.”

CONTINUED EXPERTISE

Symons adds that the company’s push for new developments is supported by the company’s expertise, “We have a lot of long-term people in the business. There’s team members who’ve been in the company for more than 40 years.”

Symons says that by using their expertise, the team at Kennards Hire can help to improve the smoothness of project delivery, from your weekend warrior, right up to tier one infrastructure developers.

“We can offer one point of contact in a dedicated account manager who is supported by technical experts and others within the business,” he says. “These account managers have a very good understanding of how a project works, site compliance, safety requirements and more. They know the lay of the land.”

He adds that getting ahead of the job at hand can often be key. And for every

project stage, Kennards Hire is there to assist.

“Wherever possible we like to have early engagement to understand the clients’ issues and the sites complexities, to see what they’re looking for,” Symons says.

This model has kept Kennards Hire in great stead, particularly when it comes to establishing meaningful relationships within the industry.

“We’re responsive to the client and always evolving our business. People within the sector may change companies, might be working on different projects or may have changed their roles, but there’s a sense of familiarity,” Symons says.

“They know our brand and our people, so there’s long term established relationships. We’ve grown and expanded our business accordingly.”

CONTINUED IMPROVEMENT

Another aspect that has remained

consistent is continual improvement.

“There’s certainly been investment in the units themselves and replacing of assets to keep them at a young age,” Symons says. “This helps from a reliability point of view and a technological point of view.”

This ethos not only accounts for machinery and equipment performance, but also for the internal functions of the company.

“We run an extensive internal quality audit program, which ensures there’s consistency across the business and that machinery is maintained,” Symons says.

“Company-employed quality auditors visit every branch across Australia and New Zealand – without notice – with a full day of quality auditing across procedures and equipment standards.”

Additionally, Kennards Hire conducts internal training programs to increase the quality of its service, while also providing opportunities for employees to expand their skill set.

This improvement also extends

to assisting clients to improve the efficiency and sustainability of their operations.

“For example, traditionally a lot of sites would have run a diesel generator 24 hours a day,” Symons says. “Now we can turn that generator on during the day to charge a battery that can then run overnight.

“There’s a lot happening in the renewable power source space that’s not only green, but can actually also save time and money. What was fairly pie in the sky sort of stuff is now readily available.”

“Continuous improvement is key.”

Symons says the future is bright for Kennards Hire, with even more products and services currently in development. “Looking towards the future, we’ll be looking to grow, improve and expand our relationships with clients in the construction and infrastructure space. All while keeping those strong family values in place.”

24 ROADS JULY 2023 RENTAL /USED EQUIPMENT ww

“LOOKING TOWARDS THE FUTURE, WE’LL BE LOOKING TO GROW, IMPROVE AND EXPAND OUR RELATIONSHIPS WITH CLIENTS IN THE CONSTRUCTION AND INFRASTRUCTURE SPACE. ALL WHILE KEEPING THOSE STRONG FAMILY VALUES IN PLACE.”

Tony Symons, General Manager Commercial –Kennards Group.

ww.flocon.com.au Phone: (03) 9703 2777 Email: reception@flocon.com.au Flocon Engineer Pty. Ltd. flocon_engineering www.flocon.com.au Phone: (03) 9703 2777 Email: reception@flocon.com.au Flocon Engineering Pty. Ltd. flocon_engineering FLOCON ENGINEERING PTY LTD & FLOCON INDUSTRIES PTY LTD AUSTRALIAN OWNED & OPERATED SPECIALISED ROAD MAINTENANCE EQUIPMENT MANUFACTURERS WITH OVER 40 YEARS IN THE INDUSTRY FLOCON HAS A VAST RANGE OF MANUFACTURED EQUIPMENT FOR THE ROAD REHABILITATION AND CONSTRUCTION INDUSTRY.

FOR ALL NEEDS THE CHOICE

SIXT AUSTRALIA IS WELL EQUIPPED TO CATER FOR A VARIETY OF VEHICLE HIRE NEEDS. ROADS & INFRASTRUCTURE SPEAKS WITH SOME OF SIXT’S L EADERS TO LEARN HOW THE COMPANY HAS EXPANDED ITS OFFERINGS AND CAPABILITIES NATIONALLY.

Agile and flexible. These are the two principles which guide SIXT’s offerings for businesses across the sector.

SIXT Australia is 100 per cent owned by the NRMA and has more than 30 years experience in the Australian car and truck rental industry. The company has one of the largest vehicle fleets nationally, consisting of options for economy, compact, intermediate, standard and fullsize passenger vehicles.

SIXT also offers premium and electric vehicles, SUVs, people movers and other commercial options such as 4WDs, Utes, vans, buses and trucks.

SIXT Australia CEO, Matthew Beattie, says the catalogue of options, mixed with an expansive network, can provide options for the majority of Australia.

“SIXT’s commercial rental vehicle fleet is one of the largest in the country and through our national footprint we supply vehicles to the most remote parts of regional and rural Australia,” Beattie says.

“This means we can deliver purposebuilt mining and construction specialty vehicles to get the job done, wherever and whenever needed, making us an ideal partner on major infrastructure projects.”

SIXT now has over 160 locations nationally, including all major airports across Australia.

A SMOOTH RIDE

Rob Jaffer, Regional Sales Manager for New South Wales, the ACT and Western Australia, says SIXT’s focus on the customer has resulted in the company being recognised on a national level.

“We focus heavily on our service delivery and have won various national and international awards that demonstrate SIXT’s customers value the unique service experience. Regular surveys help [us to] know more about the customer’s opinion which enables constant improvement,” Jaffer says.

“Our commercial fleet is new, clean and safe, and our ‘floating fleet’ model enables us to relocate vehicles quickly and efficiently to meet demand.”

On top of providing for the construction and infrastructure sectors, SIXT has also forged a market for vehicle options suited to mining applications.

As Jaffer adds, the company has built its portfolio in these industries over a number of years.

“We have a history working with some

of the largest mining and construction companies in Australia. We continue to partner with companies of all sizes in providing commercial vehicles, specifically mine spec light vehicles, trucks and buses for short and long-term projects,” Jaffer says.

SIXT can work with each client to ensure that their vehicle needs can be met. This is thanks to a collaborative approach, which can deliver specific customer requests and requirements.

This also extends to SIXT’s on-going customer support for clients, which includes a damage service. All SIXT Australia vehicles are supported by 24/7 roadside assistance.

SIXT also uses a unique method to formulate its vehicle fleet. The company uses analysis from existing and projected customers to maintain a modernised range of options. This includes benefits to performance, safety and the environment, with features such as enhanced fuel economy and vehicle reliability.

TAKING ON THE CHALLENGE

SIXT also has experience in catering for major infrastructure projects. Pacific Complete – a joint venture between

26 ROADS JULY 2023

two major infrastructure providers – was tasked with delivering a 129 kilometre section of the Pacific Highway in partnership with Transport for New South Wales.

The project required the use of 120 dual cab Utes over a five-year period.

Ian Moore, Commercial Fleet Manager at SIXT Australia says the company worked to ensure that project requirements were met for each vehicle.

“The fleet needed to be customised with driver telematics installed. As we were all working towards a clear enddate, it was an easier and more attractive proposition for our client to hire vehicles and have us take responsibility for arranging all maintenance on the fleet throughout the five-year project,” Moore says.

service and capabilities enabled the company to overcome these issues.

“There were challenges with the driver telematics due to network black spots and functionality, so we needed to change all systems to get better range and functionality across the board. We did this by working closely with the client at all times to achieve the desired outcome,” Moore says.

EYEING EXPANSION

Despite its foothold in New South Wales, Victoria and Queensland, SIXT has recently shifted its focus towards

metro expansion, and we have recently opened new locations in Kewdale and Fremantle with more locations being identified,” Jaffer says.

Jaffer says SIXT is also working to further develop its range of sustainable offerings for the market, including electric vehicles.

“[We’re] continuing our journey to become a ‘premium mobility provider’, leading the way in sustainable mobility as we increase our EV offering, which will extend to commercial vehicles,” he says.

“We’ll also be partnering with and supporting companies that have strong sustainability goals.”

roadsonline.com.au 27 RENTAL /USED EQUIPMENT

“WE FOCUS HEAVILY ON OUR SERVICE DELIVERY AND HAVE WON VARIOUS NATIONAL AND INTERNATIONAL AWARDS THAT DEMONSTRATE SIXT’S CUSTOMERS VALUE THE UNIQUE SERVICE EXPERIENCE.”

SIXT can mobilise vehicles to support your location and site requirements.

SIXT’s commercial fleet caters to both civil and mining projects.

SIXT is seeing high demand of buses for mining and infrastructure projects.

REVIEW

THIS MONTH, WE ASKED THE INDUSTRY’S DECISION-MAKERS, ‘DO SPECIFICATIONS NEED TO BE RELAXED TO SUPPORT INNOVATION?’

JAMES FRENCH, AUSTRALASIAN SOLUTIONS SPECIALIST – CONSTRUCTION –

The relationship between specifications and innovation varies depending on the context. Specifications can provide necessary guidelines and standards for ensuring quality and safety, but overly strict or inflexible specifications can sometimes hinder innovation. We need to support and encourage innovation and experimentation in the correct channels without compromising these specifications. By providing more flexibility, organisations can enable the exploration of unconventional ideas and solutions, facilitate the integration of emerging technologies, and create opportunities for new businesses. Thoughtful consideration of the context, risk assessment, and stakeholder involvement is necessary to strike the right balance and harness the benefits of both innovation and necessary standards.

ROMILLY MADEW, CEO – ENGINEERS AUSTRALIA

Australia’s engineering sector is at the forefront of innovation globally, but we would never seek to compromise the safety of our infrastructure. A balance needs to be struck between fostering innovation and ensuring that it does not risk the structural stability and/or design life of assets. Specifications and standards are critical to ensure the integrity and safety of roads, but they must also be regularly reviewed to deliver the best outcomes for the community. Overall, we believe greater collaboration is needed between government and industry to be agile and enable both innovation and safety.

SARAH BACHMANN, CEO – NATIONAL PRECAST

We have always argued that overly-prescriptive specifications stifle innovation. It is overly-prescriptive specifications that stagnate productivity and increase costs. In the case of supplying authorities with infrastructure, this can be detrimental to all parties and those increased costs are ultimately borne by the Australian taxpayer. Outcomes-based specifications however, provide inherently more freedom and allow manufacturing suppliers to explore creativity and innovate. It is innovation that will benefit clients, asset owners, suppliers and end-users. What differentiates one product manufacturer from another is their ability to deliver a unique product for a fair price, and to do that, they innovate. After all, it is they who are the subject matter experts; it is they who tweak the manufacturing process down to a fine art. What is the risk for authorities, when those manufacturers are generally long-standing, highly regarded operators – such as audited National Precast Master Precasters – who will manufacture in accordance with required design outcomes and stand by their products. It is in their interests to do so for their own future prosperity. Specifications should not be prescriptive and rather, should largely point to outcomes-focused Australian Standards. Nationally developed, they are inclusive with all parties – including authorities –contributing to their development. They are transparent and subject to public comment.

If you or someone at your organisation is an industry leader and would like to be a part of this monthly column in 2023, please get in

ROADS REVIEW

roadsonline.com.au 29

A BALANCING ACT

ROADS & INFRASTRUCTURE MAGAZINE SITS DOWN WITH DONALD CANT WATTS CORKE’S MANAGEMENT TEAM TO HEAR ABOUT THE COMPANY’S INSTRUMENTAL CONSULTATION WORKS ON THE WARRNAMBOOL LINE UPGRADE, AS WELL AS WHY THE CURRENT CONTRACT DISTRIBUTION MODEL IS LEAVING MUCH TO BE DESIRED.

The Victorian Government is committed to increasing the capacity, safety, accessibility and efficiency of the state’s public transport network, which has resulted in an infrastructure boom.

Under the umbrella of Victoria’s Big Build infrastructure pipeline, the State Government is delivering 165 major road and rail projects across Victoria.

This $90 billion investment into the public transport network has also provided new opportunities for tier one, two and three infrastructure contractors.

Leslie Chung, Director – Infrastructure –Donald Cant Watts Corke (DCWC) says this investment has helped to establish programs aimed at improving the transport capabilities of regional communities.

“Victorian and Federal governments have committed more than $4 billion to the Regional Rail Revival Program, which will

upgrade 10 regional rail lines,” Chung says.

As part of the Regional Rail Revival Program, DCWC – one of Australia’s largest providers of project management services – was awarded a contract in 2021 for works on the Warrnambool Line Upgrade in Victoria.

This upgrade aims to provide additional services and improved rail infrastructure for one of the State’s fastest growing regions.

“The Warrnambool Line Upgrade has been identified as a high priority project under this program, with Warrnambool’s population expected to expand by 20 per cent over the next 20 years,” Chung says.

On top of delivering suitable infrastructure to support the rollout and use of modern VLocity trains, the Warrnambool Line Upgrade also includes upgrades to surrounding infrastructure.

“All 57 level crossings around Warrnambool Station must be updated to fully activated

axel counting-enabled crossings to allow more frequent patronage,” Chung says.

“For our organisation to play such a pivotal role in a growing area and rail line makes us very satisfied.”

DCWC’s services for these works includes providing detailed constructability lines in cost budgetary, as well as a robust estimating service, which is fully risk adjusted to P50 and P90 risk adjusted prices.

These risk adjusted prices represent the probability that the project will be delivered within that cost estimate (P90 represents a 90 per cent probability and so forth).

Chung says DCWC is well placed to provide such guidance, even for a project of such a large technical scope.

“One of the reasons why we were selected to be a part of this project is our ability to produce budgets and a service that’s risk managed to the absolutely highest level.

30 ROADS JULY 2023

One of Donald Cant Watts Corke’s most recent ventures is cost estimation and consultation works on the Warrnambool Line Upgrade in Victoria.

That’s usually between one to five per cent of the contracting market prices,” Chung says.

“Our accuracy and our confidence are commodities that our clients really value. We’re trusted cost and strategic advisors and we leverage off these skills while walking our clients through their journey.

“We’re able to mitigate risks on the spot and estimate to a very highly accurate number, even at the early stages of a project.”

DCWC’s success in both government and private industry-led projects has resulted in the company being selected to provide services on other infrastructure projects, such as the North East Link Project and Metro Tunnel Project.

“The reason why we love working on these projects is that we can actually see the value of our efforts come to fruition on works that are contributing to the wider society and making it a better place,” Chung says.

“We don’t treat [projects like the Warrnambool Line Upgrade] as a mere transaction, but a partnership in realising our ambitions as a state and as Victorians. That’s what really excites me.”

THE CURRENT CONTRACT MODEL

Throughout his 35-year career, Peter Gill, Managing Director Infrastructure – DCWC, has seen the ebbs and flows of infrastructure delivery, both in Australia and overseas.

Gill says that the current distribution model for infrastructure contracts in Victoria, while effective, could implement changes in order to “share the load” between tier one and other infrastructure service providers.

Particularly for projects such as the Warrnambool Line Upgrade.

He says the early signs of this pattern could be traced back to the mining sectors growth in the late 2000s.

“If we go back to the mining boom between 2008 and 2013, the size of the projects that were coming out at the time were worth billions of dollars,” he says.

“The tier two and three contractors couldn’t compete with the big tier one companies. These contractors lost out on a lot of work. Then there was obviously a slowdown in the economy in 2014-15.”

Gill says these similarities can be drawn between this economic environment and the environment that the sector faces today.

“There were discussions around encouraging tier one contractors to provide more opportunities to tier twos and tier threes,” Gill says.

“We’re in a similar situation now, where

there’s been a slowdown. Projects are being put on hold due the tight economy and escalations. One of the ways that [State and Federal] governments can add value and make the process more competitive is to recognise the tier two or tier three contractors.

“These companies have lower overheads, not only onsite overheads, but also offset overheads.”

Chung says that tier two and three companies can be supported by different contract models such as collaborative approaches.

“The traditional method of thinking is that

transformations particularly in the last six months,” he says.

“We’re starting to see some of those results being tracked and reported back to the government. One example is Major Road Projects Victoria on the Roads Upgrade Program have been using a PPP model. I’d like to see more of a collaborative model.”

bigger is better. That’s not necessarily the case,” Chung says.

“Multibillion dollar projects where the ultimate risk is passed on to a particular contractor, which is usually an international company, isn’t necessarily the best idea.

“Breaking down the projects into collaborative contracts allows local contracting firms to contribute funds back into the local economy. Changing the narrative will be pivotal for the next stage.”

Chung adds that these new models could potentially provide solutions to current economic, supply chain and skilled personnel constraints. He says that while these models have seen limited use in Australia, the results are so far pleasing.

“I think that the State Government is starting to realise that due to budget

Gill says he expects these models to face further review within the next year, with hopes that changes can reinvigorate competitiveness in infrastructure project contracting.

“I think in the next six to 12 months they’ll be forced to look their procurement model, purely due to the current economic situation, the interest rate rise and their current budgets,” he says.

“The Federal and State governments need to provide a pipeline of work to make sure that we retain those resources in our country.”

“These models can help to break down these works into smaller packages, sharing around the world with shadow alliance and collaborative contracting to provide confidence to the market that there’s going to be works in the future.”

roadsonline.com.au 31 THOUGHT LEADERSHIP

“THE REASON WHY WE LOVE WORKING ON THESE PROJECTS IS THAT WE CAN ACTUALLY SEE THE VALUE OF OUR EFFORTS COME TO FRUITION ON WORKS THAT ARE CONTRIBUTING TO THE WIDER SOCIETY AND MAKING IT A BETTER PLACE.”

Peter Gill, Managing Director Infrastructure – DCWC.

Leslie Chung, Director –Infrastructure – DCWC.

EFFICIENCY Widener SEE HOW WITH 844-494-3363 www.roadwidenerllc.com David (Homer Dale) Wix, Superintendent , Q&D Construction-Energy Division We CUT A 4-STEP PROCESS TO 2 with the FH-R material placement attachment. READ THE FULL TESTIMONIAL

A PROCESS OF EVOLUTION –OVER 60 YEARS OF TUNNEL

SAFETY SOLUTIONS

SICK SENSOR INTELLIGENCE’S RANGE OF TUNNEL MONITORING DEVICES PLAY A MUCH MORE IMPORTANT ROLE THAN YOU MAY THINK.

LINTU MATHAI, SENIOR MARKET PRODUCT MANAGER – ANALYSER, FLOW AND SYSTEM SOLUTIONS, EXPLAINS HOW THESE DEVICES ARE HELPING TO MAKE A DIFFERENCE.

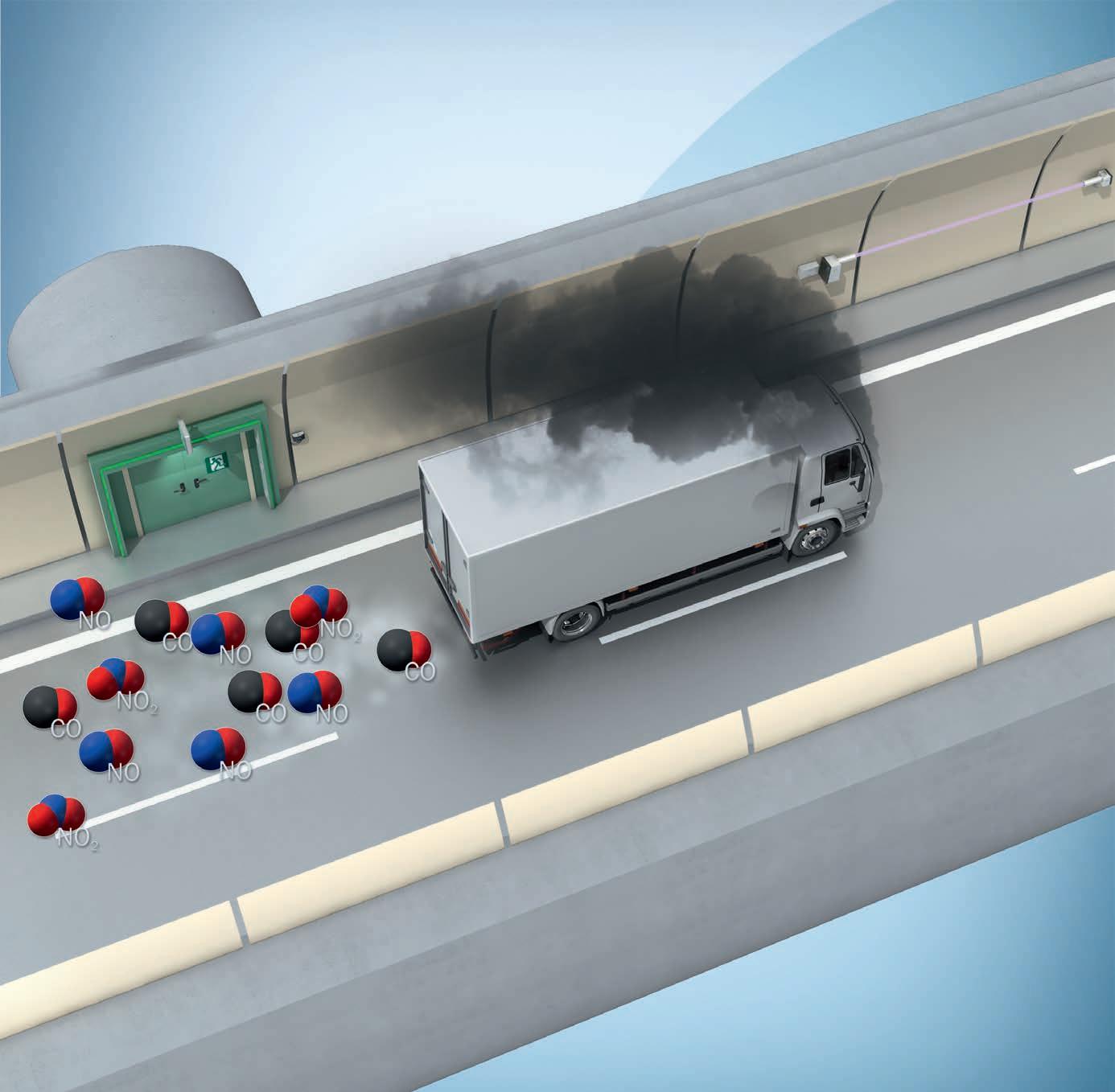

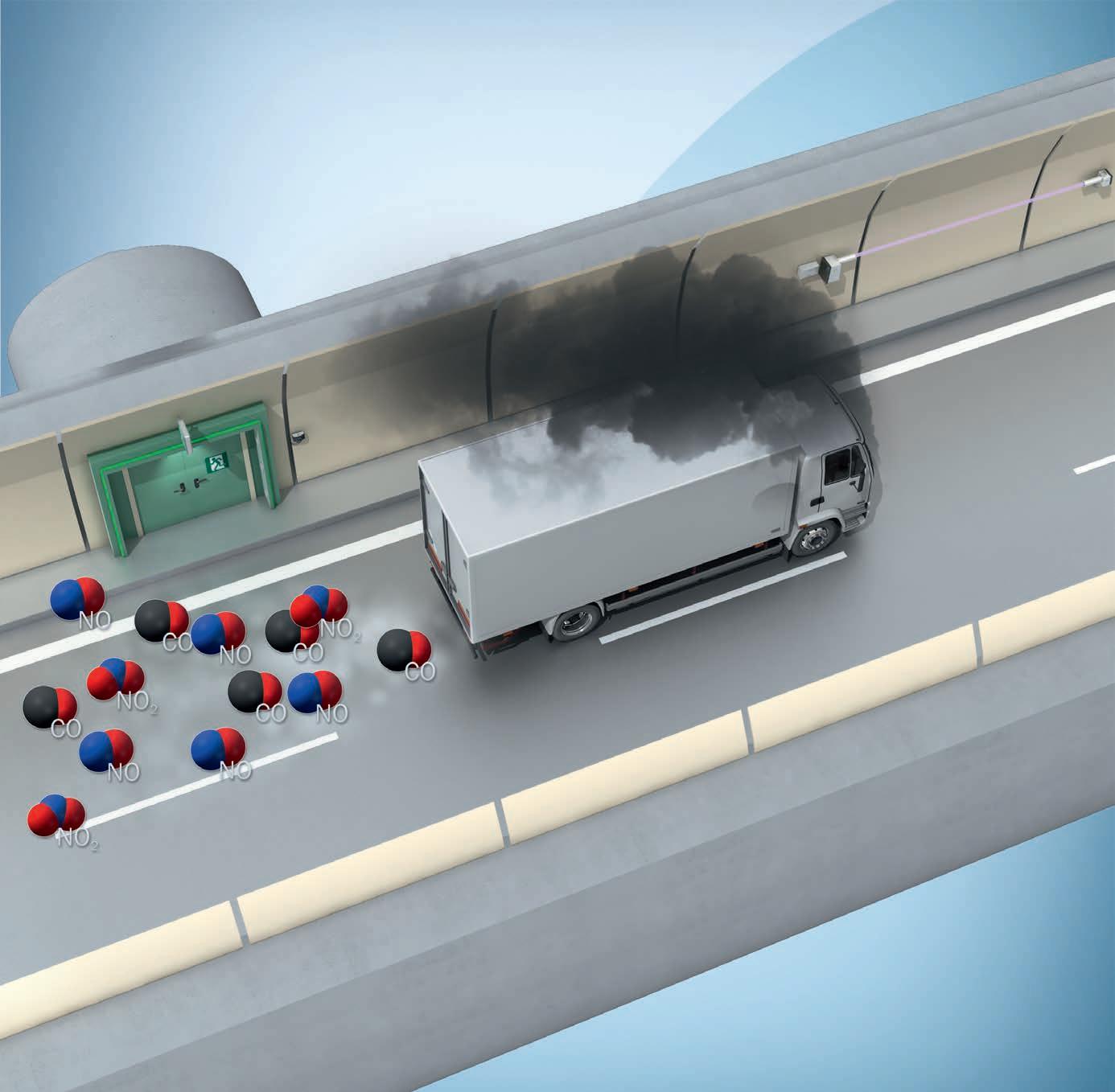

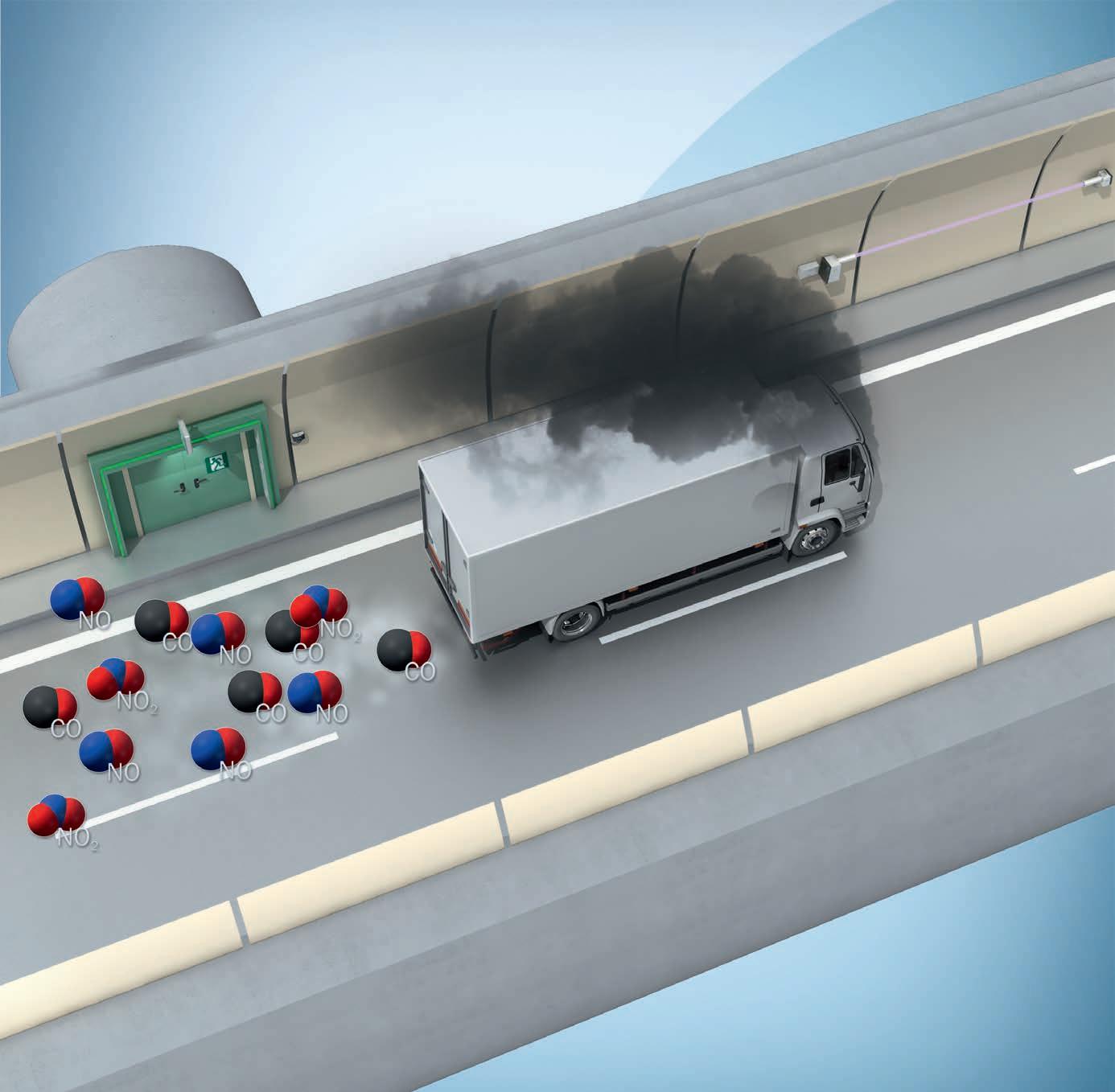

Air quality can at times be an overlooked, but crucial aspect to tunnel users.

Hazardous gases pose a serious potential risk to the health of both contractors and civilians using the road.

Lintu Mathai, SICK Senior Market Product Manager – Analyser, Flow and System Solutions, says these environments have called for a suitable monitoring solution.

“Most road tunnels, depending on the length and complexity, need to be monitored for emissions, such as nitrogen monoxide (NO), nitrogen dioxide (NO2) and carbon monoxide (CO),” Mathai says.

“They also need to be monitored for smoke. These gases and fumes can have serious health risks not only for just motorists, but also the people who are conducting maintenance and work inside these tunnels These devices are important to make sure that tunnels are sufficiently ventilated.

He says that as the density of traffic on roads increases, the future will be about finding ways to increase the availability of tunnels, while at the same time improving safety for road and tunnel users.

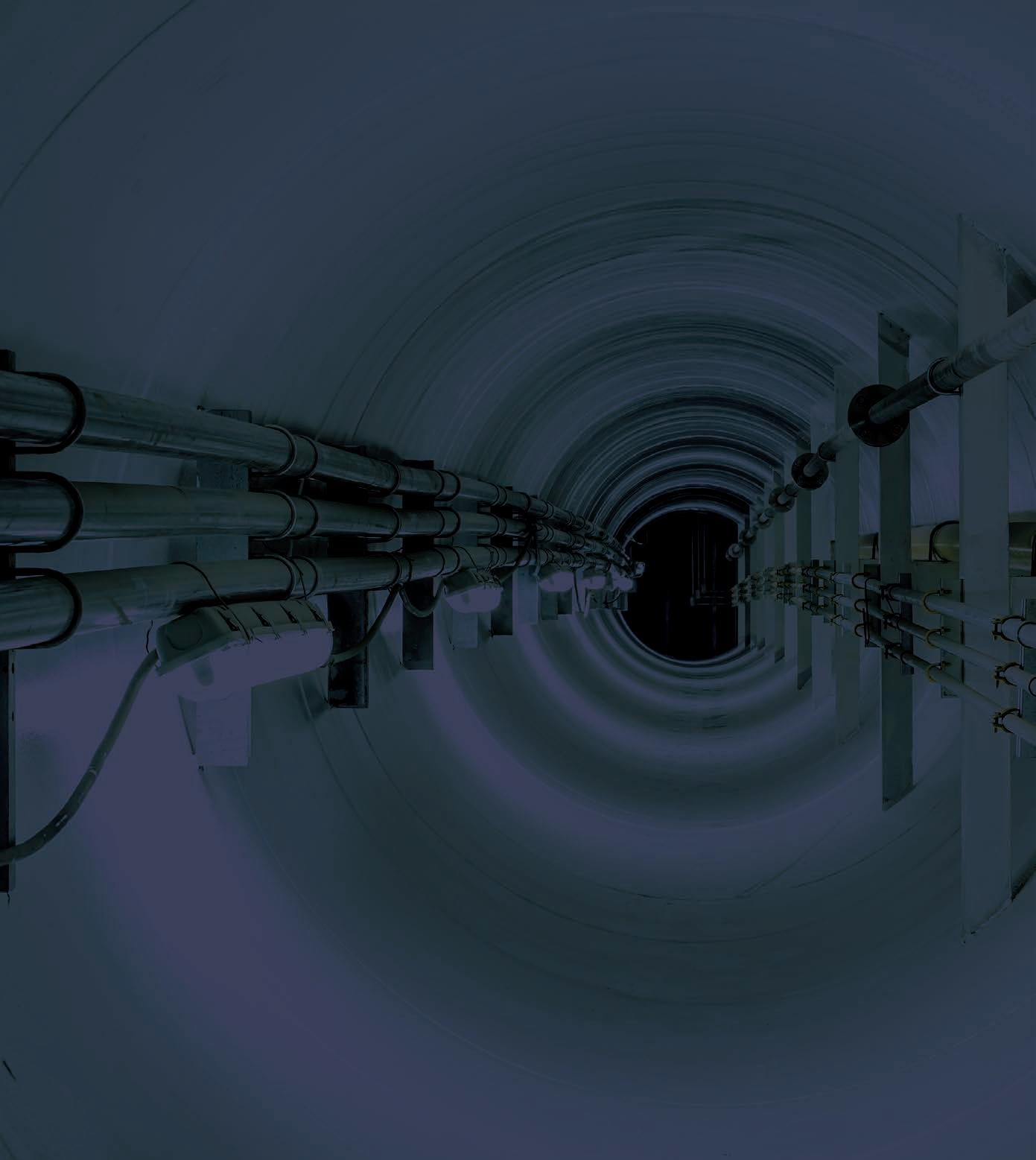

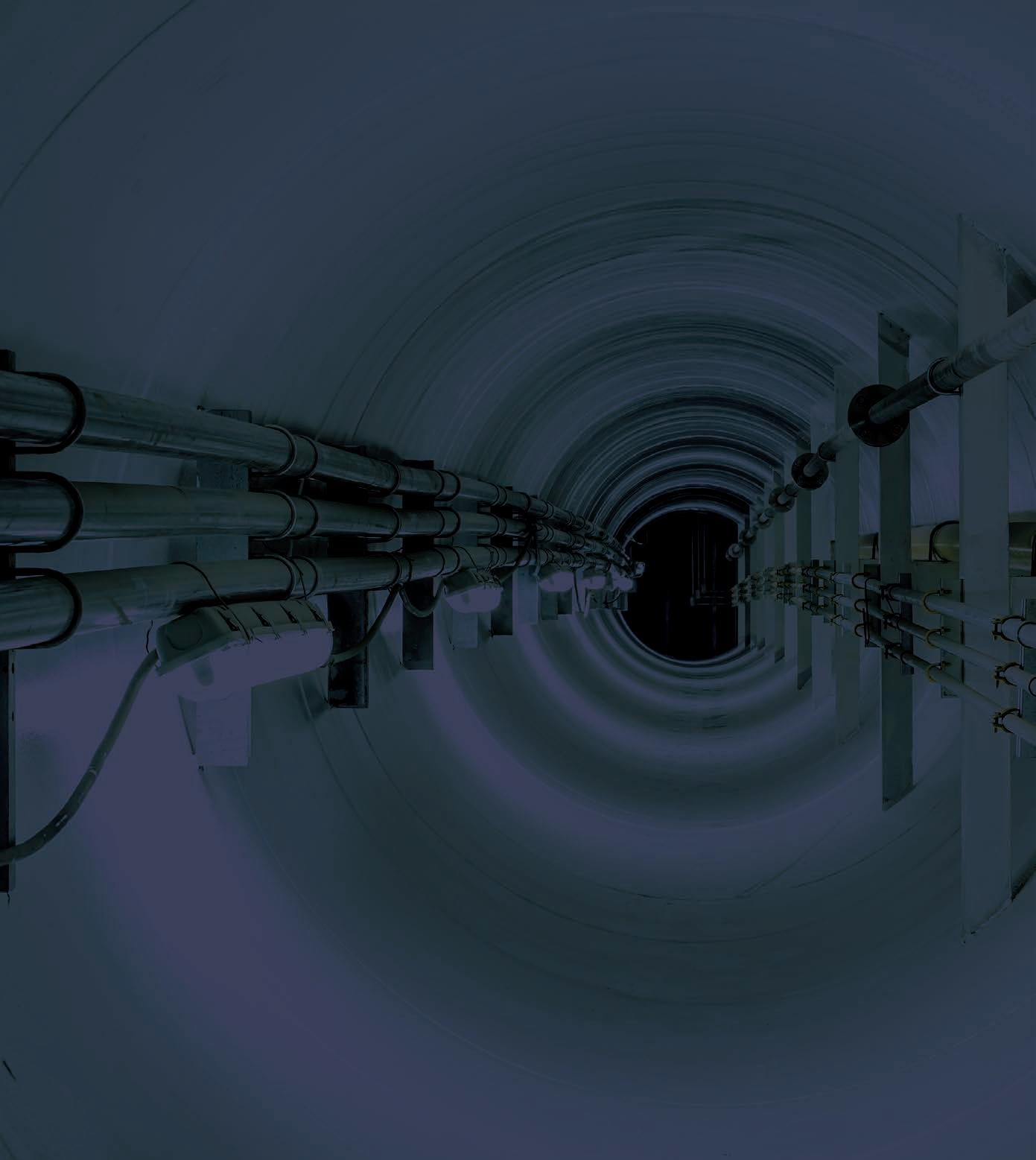

“This is where we come in. For over 60

years, SICK has been helping road and tunnel operators to take on this challenge by offering innovative products, not only for measuring visibility and air quality, but also for air flow measurement and smoke detection in emergency situations,” he says.

IT’S IN THE AIR

SICK Sensor Intelligence is a global organisation, responsible for developments in technologies branching into factory automation to logistics automation and process automation.

The company’s focus on providing technologies that increase safety, while also preventing impacts on the environment has forged a path towards increased automation for tunnel and condition monitoring.

“It’s just a process of evolution,” Mathai says. “Back in the day there weren’t ways to make sure that motorists were safe. I think one of the driving factors would have been the level of pollution.

“If you go back 60 or 70 years, vehicles were

polluting a lot more as they were spewing out smoke and gases that weren’t safe for other motorists. Back in the day there were no emission standards and vehicles had powerful motors but no exhaust gas cleaning mechanism.

“This led to road tunnels with low visibility. Visibility then was used as a general indication of pollution inside the tunnel. Scenarios like this drove SICK to come up with a device that makes it safer for motorists to drive with information on visibility.”

As the first manufacturer, SICK offers standard product families for both routine operation and emergency situations in tunnels.

“Data is captured on aspects like air velocity, visibility, air quality and even if a vehicle has caught fire. Once detected, the traffic is then managed accordingly inside the tunnel, and the tunnel exhaust system is controlled automatically,” he says.

“All of this happens in real time.”

The VISIC100SF and Vicotec32X series

roadsonline.com.au 33 TECHNOLOGY

SICK Sensor Intelligence’s monitoring systems provide conditioning monitoring to boost safety, efficiency and maintenance.

are all-in-one solutions for measuring visibility, carbon monoxide (CO) as well as nitrogen monoxide (NO) or nitrogen dioxide (NO2) in tunnels. The VISIC50SF and Vicotec450 smoke detector is SICK’s reliable and extremely fast solution for early fire detection.

Apart from in-tunnel monitoring, SICK also has devices that are used to make the tunnel safe from unsafe vehicles.

The HISIC450 is used to reliably detect vehicles that are too high before they enter the tunnel, thereby helping the operator to redirect those vehicles and prevent them from entering the tunnel.

This helps in protecting the tunnel infrastructure from potential damage that can be caused by such vehicles.

“We also have VHD Systems for detection of overheated vehicles. So basically, if a vehicle is really overheated, it obviously has the potential to catch fire inside the tunnel. We can detect such vehicles before they

enter the tunnel and give that information to the tunnel operator so that those vehicles can be redirected. This again helps in keeping the tunnel safe for users.”

“In an emergency situation, in case a vehicle does catch fire, our solutions are designed to give information to the tunnel operator in terms of the direction in which the smoke is travelling so that tunnel staff can take corrective actions.”

With over 1000 installations, these devices have already been deployed across the globe, in some of the world’s busiest tunnels and motorways.

REAL TIME CONDITION MONITORING

AI Based Real-Time condition-based monitoring of tunnel equipment is another service that is offered by SICK. SICK’s condition monitoring solutions aim to improve the reliability, efficiency, and safety of tunnels by enabling predictive maintenance and early fault detection.

By continuously monitoring the condition of equipment, potential issues can be identified and addressed before they lead to significant failures or potential operational disruptions.

While also providing the safety benefits of tunnel monitoring, condition monitoring goes a step further to increase the efficiency and cost effectiveness of tunnel maintenance.

“There can be a lot of learning from our installations,” Mathai says. “Condition monitoring contributes significantly to the utilisation of tunnels. Intelligent remote diagnostic features can improve the planning and maintenance or scheduling of service tasks.”

Condition monitoring from SICK provides an effective solution for monitoring and maintaining devices and sensors in tunnels. Device and sensor states can be monitored in real time, and undesired operational states predicted ahead of time.

If required, every significant change to the device states is visualized concisely and clearly in a browser-based dashboard, thereby enabling the operating staff to intervene in a timely manner.

This ensures the availability of critical device components.

“It reduces the number of service interventions and allows for better and more efficient preparation for necessary service deployments,” Mathai says.

“For a tunnel in the Netherlands, our condition monitoring has enabled them to reduce their unplanned service intervention by as much as 70 per cent. For maintenance and the operating cost of a tunnel – that’s a huge cost saving.”

All this data is also kept secured, thanks to SICK’s Data Security Policy.

“We take Cyber Security very seriously and we prefer to be safe than sorry when it comes to Cyber Security,” Mathai says.

“We have commissioned SICK Product and Security Incident Response Team (SICK PSIRT), who manage all cyber security threats for SICK products and services. The SICK PSIRT manages the inspection, internal coordination and disclosure of Cyber Security vulnerabilities.”

“Before commissioning a project, we sit with the PSIRT team, and go through all aspects of Cyber Security Vulnerabilities and implement safeguards.

“We make sure that both parties are more than comfortable.”

SICK’s sensor intelligence devices are available now.

34 ROADS JULY 2023 TECHNOLOGY

SICK Sensor Intelligence’s monitoring systems can analyse information in real time.

SICK Sensor Intelligence provides internal and external tunnel monitoring for some of the world’s largest road connections.

PICK THE RIGHT TOOL

Proud Suppliers of Telescopic Bitumen Sprayers to the Australasian Roading Construction market for over 20 years

Over the last 20+ years, we’ve listened to our customers’ feedback and continuously evolved our range of sprayers, meeting the specific and unique demands of the Australasian roading market.

From our highly manoeuvrable 4.5m telescopic urban sprayers right up to our 6.0m reseal sprayers we have the right sprayer for the job – all offering the ease of use and efficiency of our telescopic spray bar.

Find out today why operators across Australia and New Zealand are ditching fixed wing sprayers and demanding SRE’s range of telescopic bitumen sprayers.

www.specialisedroadingequipment.com

Email info@specialisedroadingequipment.com

Ph +64 7 848 1197

THE NAMES BOND, SAMIBOND

SAMI BITUMEN TECHNOLOGIES’ SAMIBOND 007 TRACKLESS TACK COAT EMULSION HAS BEEN DESIGNED FOR HIGH STRESS IMPACTS AND APPLICATIONS. ROADS & INFRASTRUCTURE SPEAKS WITH SAMI TO LEARN MORE.

Tough, effective and calm in high stress environments. These are words commonly associated with the title of 007.

SAMI Bitumen Technologies’ take on the 007 label maintains the sophistication while removing the cheesy one liners. But what does it take to earn double 00 status?

Kanjana Yindee, Laboratory and R&D Manager – SAMI Bitumen Technologies, says the company’s development of non-tracking tack coat emulsions began in 2019. Ultimately leading to the production of the SAMIbond 007 trackless tack coat emulsion.

“To ensure a sufficient bond between layers, a tack material should remain intact after application. However, a conventional tack coat is likely to track under paving equipment and asphalt delivery vehicles,” Yindee says. “Even if the tack coat is appropriately sprayed, the tack coat binder can be removed in a wheel path due to its pickup by the construction vehicle tyres.

“This is why our customers frequently ask if we have trackless tack coat emulsion, the

main reason why we’ve developed such a product.”

A tack coat refers to a thin layer of bitumen that is applied between the layers of a multilayer asphalt pavement, to bond them together, improving the overall strength and durability of the pavement and surface. One of the many reasons it achieved 00 status.

This is usually applied in the form of an emulsion that is sprayed prior to the application of the next layer of asphalt being laid.

This special emulsion allows delivery trucks and pavers to drive over the new surface without leaving markings or wheel tracks on the adjacent surfaces.

Once applied, the SAMIbond 007 renders a shiny black and hard surface.

As Yindee explains, SAMIbond 007 is a cationic bitumen trackless tack emulsion that has been modified with a polymer.

“The addition of polymer helps to improve the emulsion’s performance and durability, making it better able to withstand high horizontal stresses from traffic during the life of the pavement. This makes the emulsion

ideal for use in pavements associated with heavy traffic and high stresses,” she says.

BEHIND THE SCENES

Development of SAMIbond 007 focused not only on the trackless component, but also overall durability.

Brad Richards, State Manager Southern Region – SAMI Bitumen Technologies, says this development has also caught the eye of Victoria Department of Transport (VDoT).

“The concept really started with VDoT who were looking to tack coating products that weren’t going to be picked up by the tyres of machinery that were laying the asphalt on top of it,” he says.

“Their thinking was ‘what’s the point of putting down a tack coat if it’s just going to be picked up by the wheels of the equipment?’ It’s just messy.”

He adds that the product has already been used in projects with high-stresses, such as highways and airports.

“Sometimes, like on an airport, there are only short windows of time that the crew is allowed to be on site so careful planning and

36 ROADS JULY 2023

SAMI Bitumen Technologies’ SAMIbond 007 trackless tack coat emulsion is highly suitable for high stress surface applications, like airports and highways.

specialty products are key to productivity,” Richards says.

“SAMIbond 007 has been used successfully in several applications to date, including cold environments and at night. Paving equipment can drive on the sprayed surface with no pickup on the paving equipment wheels.

“Time is money and the faster the asphalting equipment can get onto the job, the better.”

Richards says SAMI Bitumen Technologies’ direction from both industry and government were large influencers during development.

“Our technical experts have refined the product over recent years balancing the ease of handling, speed of curing and trackless behaviour, to now have a product that is being used successfully in calibrated sprayers and through pressurised crew trucks,” Richards says.

Yindee concedes that one of the biggest challenges during the product’s development was establishing an emulsion product that catered for Australia’s variety of spraying machinery.

“There is a wide variety of sprayers on the market and it is difficult to anticipate how the product will react with each one,” Yindee says.

“Over a long development period we worked hard to achieve the final formulation with all of the properties that we were aiming for. SAMIbond 007 can now be applied without heating with some sprayers. It’s also energy-efficient, making it a sustainable product.”

FIRSTHAND EXPERIENCE

One company that has already benefitted from using SAMIbond 007 is Centre State Asphalting.

The Victoria-based contracting business carries out works across the state for clients of all sizes, from private works, to leading contracting on resurfacing works for the Victorian Department of Transport.

Scott Bowley, Project Engineer – Centre State Asphalting, says delivering quality outcomes is the company’s number one priority.