TO NET ZERO A PATHWAY

An Australian first is paving the road to meaningful carbon reduction and greater sustainability outcomes across the sector

IMPORTANT LEARNINGS

The third rendition of what is now an annual survey paints a positive outlook for the sectors future AHEAD

OF THE GAME

Inside the newest form of traffic management

AUSTRALIA’S ONLY SPECIALIST ROAD MANAGEMENT, CONSTRUCTION AND CIVIL WORKS MAGAZINE AUGUST 2023 Official media partners of

CLOSE TO OUR CUSTOMERS www.wirtgen-group.com/road Pole Position. ROAD TECHNOLOGIES. The WIRTGEN GROUP owes its strength in the Road Technologies business segment to the excellence of our product brands – WIRTGEN, VÖGELE and HAMM – with their unique wealth of experience. Take advantage of innovative technologies from the market leader. WIRTGEN AUSTRALIA Pty Ltd · Lot 2 Great Eastern Highway (Off Ivy St) · South Guildford WA 6055 T: +61 8 / 62 79 22 00 www.wirtgen-group.com/australia

COVER STORY

14 A pathway to the future

The next innovation in the sustainable binder space.

DIVERSITY

19 A diverse supply chain

Two companies are helping to remove typical barriers to employment.

ROADS REVIEW

22 How can construction companies encourage more diversity in the workplace?

TECHNOLOGY

25 An insightful outlook

An annual review of the sector’s shortcomings and achievements.

33 Technology update

A wrap up of the latest technological developments from across the sector.

COMPANY PROFILE

36 A fresh perspective

An overview of the recent changes to UAA’s senior leadership.

39 Young guns

Exciting plans are in development for a Victorian infrastructure provider.

42 Tonne up

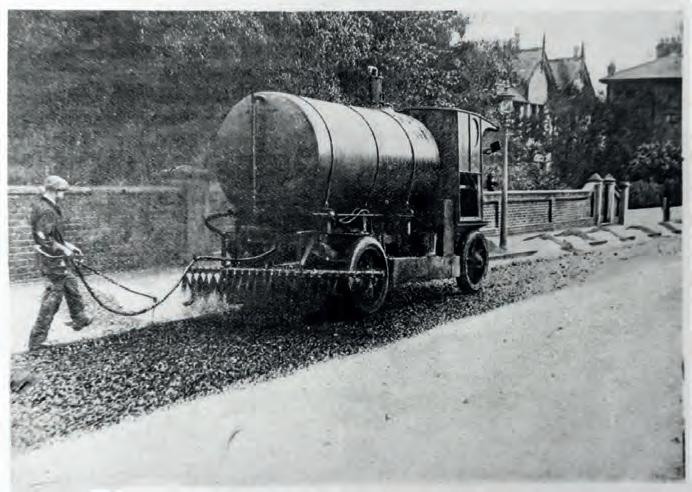

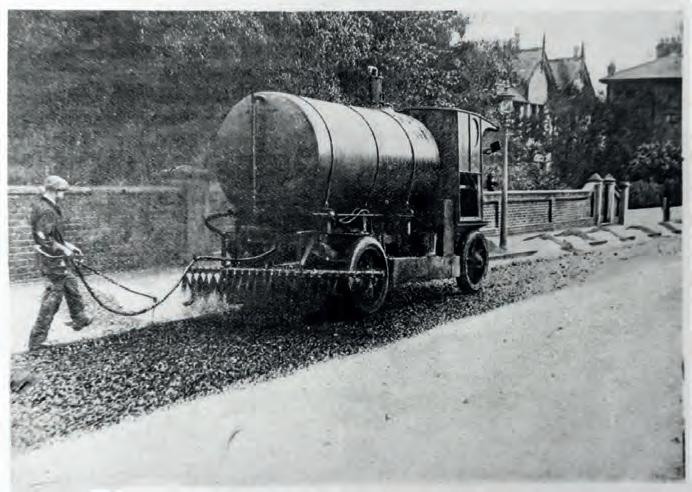

Behind more than 100 years of bitumen emulsion.

MACHINERY AND EQUIPMENT

46 Being an employer of choice

What separates Komatsu’s approach to human relations.

49 Zero emissions take centre stage

A new zero-emissions load-handling solution.

51 New tech trims roadsides nationwide

A range of machinery for well-maintained roadsides.

EVENTS

53 Victorian Major Infrastructure Conference

54 No-Dig Down Under

55 2023 Ecologiq Conference

57 Inside Construction Expo

AFPA SECTION

58 Innovations and opportunities

A wrap up of AfPA recent 2023 the Industry Technical Panel Event.

NATIONAL PRECAST SECTION

61 Benefits for WA infrastructure

How pre-casters are contributing to the Bunbury Outer Ring Road project.

CONTRACTS & TENDERS

62 A summary of the contracts awarded for major infrastructure projects across Australia and New Zealand.

REGULARS

4 Editor’s note

6 News

AUGUST 2023 CONTENTS

In the August edition of Roads & Infrastructure Magazine, we’ll preview a variety of upcoming conferences and events.

BRIDGING THE GAP

FOR THE AUGUST EDITION, Roads & Infrastructure Magazine celebrates the work being done by inspirational figures across the sector to encourage and support greater diversity, in what remains a male-dominated industry.

In this month’s Roads Review column, we hear from some of the industry’s key decision makers on how construction companies can greater support the level of diversity across the sector.

Some leaders say diversity training could help accelerate cultural change. This includes promoting flexible working arrangements, gender pay gap analyses, as well as sponsorship and mentoring programs. Others outline the importance of recruiting based on skills and qualifications, rather than demographics, to attract talent from more diverse talent pools.

Three Victorian companies, who have worked closely with Major Road Projects Victoria over the past few years, are demonstrating the use of their platform to provide unique employment opportunities for a diverse range of talent pools. One such example if LEV (Latrobe Valley Enterprises), which is giving people with disabilities the opportunity to contribute to not only major infrastructure projects, but also the local community.

For this month’s cover story, we speak with Puma Bitumen to learn more about the company’s use of biogenic materials to produce the latest development in asphalt binders. Described as a “carbon sink” by Erik Denneman, Global Technical Manager – Puma Bitumen, local research and development has pioneered a product for both Australian and international use.

We also provide previews of three upcoming conferences in 2023, with plenty of opportunities on show for both government and industry.

Happy reading!

Tom O’Keane Roads & Infrastructure Magazine

COO

Christine Clancy christine.clancy@primecreative.com.au

GROUP MANAGING EDITOR

Sarah Baker sarah.baker@primecreative.com.au

MANAGING EDITOR

Mike Wheeler mike.wheeler@primecreative.com.au

EDITOR

Tom O’Keane tom.okeane@primecreative.com.au

JOURNALIST

Chris Edwards chris.edwards@primecreative.com.au

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR

Blake Storey

DESIGN

Bea Barthelson

BUSINESS DEVELOPMENT MANAGER

Brad Marshall brad.marshall@primecreative.com.au

CLIENT SUCCESS MANAGER

Salma Kennedy salma.kennedy@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive, Docklands VIC 3008 Australia

p: +61 3 9690 8766 f: +61 3 9682 0044 enquiries@primecreative.com.au www.roadsonline.com.au

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au

Roads & Infrastructure Australia is available by subscription from the publisher. The rights of refusal are reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Roads & Infrastructure Australia is owned and published by Prime Creative Media. All material in Roads & Infrastructure Australia is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without the written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Roads & Infrastructure Australia are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

4 ROADS AUGUST 2023

$32.1B

INVESTMENT ANNOUNCED FOR QLD ROAD AND TRANSPORT PROJECTS

The Queensland Government has announced a four-year, $32.1 billion investment program for new and on-going road and transport projects.

The Queensland Transport and Roads Investment Program encompasses a range of infrastructure investments including road, rail, marine, passenger transport, and active transport projects, which will all contribute to enhancing connectivity, improving safety, and supporting economic

growth across Queensland.

The program includes $1.815 billion for road safety initiatives, that complements other investment in behavioural change initiatives that aim to reduce lives lost and serious injuries on Queensland roads. This includes over $500 million for the Road Safety Program in partnership with the Federal Government.

Significant investments have also been allocated for rail, including $4.869

DOWNER COMPLETES SALE OF AUS PROJECTS BUSINESS

billion towards the Queensland Train Manufacturing Program. The program also includes allocations of $2.598 billion towards the Logan to Gold Coast Faster Rail project, and the $550.8 million Beerburrum to Nambour Rail Upgrade (Stage One).

The $1.219 billion Gold Coast Light Rail (Stage Three), Broadbeach South to Burleigh Heads is also continuing construction as part of the Queensland Transport and Roads Investment Program.

Downer has announced its completed the sale of its $212 million Australian Transport Projects business to DT Infrastructure Pty Ltd.

DT Infrastructure’s Australian Transport Projects business is responsible for delivering major construction services to mainly government, including design and construction of roads, rail, signalling, station works, bridges and more.

The sale will see Downer’s business, people and capabilities transferred, including around 1000 staff and a forecast work in hand of approximately $2 billion nationally.

Downer CEO Peter Tompkins said the sale was an important milestone in the company’s “portfolio simplification strategy”.

“Going forward in the transport sector, Downer will concentrate on enhancing its market leading positions in rollingstock, road maintenance and New Zealand infrastructure delivery,” Tompkins said.

6 ROADS AUGUST 2023

NEWS

The sale sees Downer’s Australian projects assets transferred to DT Infrastructure.

The infrastructure pipeline includes a considerable commitment to increasing efficiency and safety. Image courtesy of the New South Wales Government.

Call us today on 1300 074 249 komatsu.com.au Unleash the power of precision and efficiency with the Komatsu PC138US-11 Excavator with 3D machine guidance and payload *Terms and conditions apply visit: https://komatsuweb.link/rfk-pc138us-11. Image is for illustration purposes only. *Applies to Komatsu PC138US_11 range only. Scan to learn more For a limited time, offer includes: � Factory Fit Retrofit Kit (RFK) � 3 Year Smart Construction Support Subscription giving you expert guidance and support � 3 Year Access to Smart Construction Pilot for advanced project management � Komplimentary Maintenance � 4-year/8000-hour premium warranty Our comprehensive package is designed to empower your team with cutting-edge features and in-house support.

CONSTRUCTION UNDERWAY ON FIRST ROAD UPGRADE OF $850M PACKAGE

Works are underway on the first intersection and road upgrade works being delivered as part of the River Torrens to Darlington Project in South Australia.

The construction of the first intersection and road upgrade consists of works to Selgar Avenue link road. Once complete, the upgrade will provide new entry points into the area of Tonsley. These works are being completed by Bardavcol and are expected to wrap up by December 2023

The upgrade aims to reduce travel times, create a route for commercial freight and provide greater connections. This package will also construct the remaining 10.5

The NSC will create 78 kilometres of nonstop, traffic light-free motorway between Gawler and Old Noarlunga in Adelaide’s south. The T2D Project is expected to support 5500 jobs annually during construction.

TUNNELLING BEGINS ON WESTERN SYDNEY AIRPORT

TBMs moving through the first 5.5-kilometre sections of the twin metro tunnels.

The 23-kilometre new railway will link residential areas with job hubs including the new Aerotropolis and connect travellers from the new airport to the rest of Sydney’s public transport system.

The line will be operational when Western Sydney International Airport

opens for passenger services, with an expected travel time of 15 minutes from St Marys metro station to Airport Terminal Station and a further five minutes to the Aerotropolis Station.

The tunnelling contract was awarded in December 2021 to CPB Contractors and Ghella Joint Venture to build the new twin metro rail tunnels.

The TBMs will excavate around 120 metres of tunnels per week, the first step in delivering the six new metro stations along

the line from St Marys to the centre of the new Aerotropolis.

The two 1066-tonne TBMs Eileen and Peggy are named after two historic figures for the region. TBM Eileen pays tribute to the first female Mayor of Penrith, Eileen Cammack OBE, who also established the first pathology laboratory at Nepean District Hospital. TBM Peggy honours pioneer aviator Peggy Kelman OBE, who was instrumental in promoting female aviation and was a flying companion of Nancy-Bird Walton.

8 ROADS AUGUST 2023

NEWS

The upgrade forms part of a $850 million package for the River Torrens to Darlington Project (T2D).

kilometre section of the state’s North-South Corridor (NSC).

Two 1066-tonne tunnel boring machines have begun their journey on the new 23 kilometre line. Image courtesy of the New South Wales Government.

Artists impression of the T2D Motorway (Richmond Road). Image courtesy of the South Australian Government.

LEVEL UP

NEVER IDLE

In this game, there’s no substitute for experience. But finding expert Motor Grader operators can be tougher than the terrain they’ll be tackling. That’s why John Deere is the only player in Australia to be offering Motor Grader automation upgrades to all machines from 2019 onwards. Spec’d out with the latest tech including Machine-Damage Avoidance, Auto-Articulation, Auto-Pass, Auto-Shift Plus, and Blade Stow, less experienced operators can get to grips with the machine double quick, and takes the pressure off your more experienced hands. Take your operation to a whole new level. Check your serial number with your local dealer, today.

DEERE.COM.AU/SMARTGRADEMOTORGRADERS SCAN TO LEARN MORE

MOTOR GRADER JOB SITE AUTOMATION

Next

Extract

Puma Energy Bitumen bitumen.au@pumaenergy.com pumaenergy.com/en/web/bitumen/

biogenic components Roads become perpetual CO2 vaults Integrated with our global supply network

capture atmospheric CO2 Puma CarbonBind

Trees

generation,

road binders Your journey to net zero starts on a road paved with Puma CarbonBind

carbon sinking

PREPARATIONS CONTINUING ON $983 MILLION FITZROY TO GLADSTONE PIPELINE

The first pipes have arrived on site for the Fitzroy to Gladstone Pipeline in Queensland, as preparations continue ahead of the start of construction.

The project is a new 115-kilometre pipeline that will support the transfer of

30,000 megalitres of water annually, from the Fitzroy River to Gladstone.

A joint venture between McConnell Dowell and BMD has been appointed as the construction contractor. The proponent Gladstone Area Water

Board will own and manage the pipeline following construction. The pipes on the project are being manufactured by Steel Mains.

The project is expected to be completed in late 2026.

Construction is now underway on the second grid-scale battery storage system in Western Australia.

The $625 million Kwinana Battery Stage Two project will deliver 200 megawatts of energy capacity with 800 megawatt hours of energy storage – four times that of Kwinana Battery Stage One.

The project will play a key role in closing coal-fired power stations, as part of the Western Australian Government’s 2030 emissions reduction targets.

Construction on the second big battery will include 288 shipping containersized battery modules and will feature 72 inverter units. These inverters use new-generation technology to support

grid stability by storing electricity when demand is lowest and delivering it back into the grid during peak times.

Construction of the big battery is situated close to the old Kwinana Power Station site, adjacent to the first gridscale battery.

The second big battery is expected to open by late 2024.

roadsonline.com.au 11

NEWS

The project will deliver a new 115-kilometre pipeline. Image courtesy of McConnell Dowell.

The ‘big battery’ is one of the largest in Australia. Image courtesy of Kwinana Industries Council.

WORKS PROGRESSING ON VIC’S LONGEST ROAD TUNNELS

Construction on the North East Link tunnels in Victoria is powering ahead, with works underway for on and off ramps at a new interchange.

The North East Link signifies the largest ever investment in Melbourne’s northeast and once complete will remove 15,000 trucks from local traffic and reduce travel times by up to 35 minutes.

The new interchange at Manningham will help to divert 14,700 vehicles off Bulleen Road daily, with this traffic to instead travel through the new 6.5 kilometre road tunnels.

Works on this section are focused on building structural walls to allow for the excavation of the ramps, as well as the tunnel boring machine retrieval box.

The tunnel boring machines for these works are expected to arrive in late 2023. The machines will be assembled before major tunnelling works begin next year.

Development has started on surrounding infrastructure, including the TBM launch area which will consist of two large storage sheds.

Additional works are also underway to move Bulleen Road further west, to make space to build the new Yarra Link green bridge over Bulleen Road, linking Koonung Creek Trail to Bulleen Park.

SA GOV TO INTRODUCE $98M ROAD SAFETY PROGRAM

The South Australian State Government has announced plans to invest $98 million in a new road safety program to address the state’s high road death toll.

Under the $98 million program, half of the funding will be allocated to improve the safety of road infrastructure.

This includes $40 million for connections surrounding the Mount Barker roundabout in Adelaide. The scope of works for this project involves upgrading the intersection to increase capacity from all roads, provision of shared use paths, stormwater drainage improvements and installation of streetlights. These works are expected to be completed by June 2026.

The $98 million funding package includes $17.8 million for approximately 15 new mobile speed cameras and the replacement of an anticipated 16 fixed

speed and red light cameras with newer technology. A further $13.4 million will be spent on an anticipated 10 additional mobile phone detection cameras to deter dangerous behaviour.

591 people have died on South Australian roads so far this year, 17 higher than the five year average.

31 per cent of lives lost have been attributed to excessive speed and 27 per cent attributed to dangerous driving so far this year. The State Government says Mobile speed cameras will assist in enforcing speed limits in regional areas, where as of 14 June 2023, the majority of fatal crashes occur—including 60 per cent of all lives lost this year.

The cameras are expected to be operational in 2024. The initiative is projected to increase expiation revenue

by $17.1 million per annum (indexed) from 2024/25.

A further $10 million will be spent over four years on rural road targeted initiatives including audio tactile line marking, safety barriers and rural junction activated warning system signage.

12 ROADS AUGUST 2023

NEWS

The safety improvements include upgrades to both equipment and infrastructure.

The North East Link project will be complete in 2028. Image courtesy of the Victorian Government.

Introducing the first and only skid steer with a telescopic boom the JCB Teleskid; a truly unique, versatile skid steer with endless possibilities. Now you can lift higher, reach further, dig deeper.

This revolutionary product is designed to suit all types of job sites meeting the need of multiple machines wrapped nicely into one. Combining the strength and safety of our single side boom with side door entry and extendable boom JCB has increased the versatility of the SSL-CTL world.

To find out more contact your local JCB CEA dealer today. Ph: 1300 522 232 www.jcbcea.com.au

A PATHWAY TO F

THE FUTURE

PUMA BITUMEN IS IMPLEMENTING BIOGENIC MATERIALS TO FURTHER INCREASE THE SUSTAINABILITY OF ITS ENVIRONMENTALLY FRIENDLY SOLUTIONS. PUMA AND CUSTOMER BORAL EXPLAIN HOW THIS AUSTRALIAN-FIRST PRODUCT COULD HELP TO ACCELERATE CHANGE ACROSS THE INDUSTRY.

or years, Puma Bitumen has been heavily involved in the research and development of bitumen solutions across the globe. This has led to the procurement of products that are now considered standard across the roads and infrastructure sectors.

The company continues to innovate, with an even greater focus on sustainable sourcing and supply. This expertise is what led to the development of Puma bitumen’s newest sustainable binder.

Erik Denneman, Global Technical Manager – Puma Bitumen, says CARBONBIND bituminous binders contain biogenic materials (plant grown components), some grades can also

14 ROADS AUGUST 2023

include waste tyre-derived rubber.

“Three years ago, we decided that all our future research and development had to be focused on ‘what do our binders look like in 2030? What do they look like in 2050? And how do we get on the path towards net zero emissions?’

“With CARBONBIND I’m very excited because it’s the first time that we, as an industry, can see a clear path to get [to net zero],” he says.

Puma Bitumen’s CARBONBIND is the first bio-based asphalt and sprayed seal binder in Australia.

The product has been specifically designed to reduce the overall carbon footprint of bitumen, as well as asphalt products that

contain it. So much so, that Denneman refers to CARBONBIND as a “carbon sink”.

Incorporating biogenic materials means carbon can be captured and stored in road pavements. This is achieved by extracting biogenic materials from plants that capture carbon dioxide. These materials are also sustainably and ethically sourced.

“Only about 15 per cent biogenic material is required to make bitumen carbon neutral and about 25 per cent for polymer modified binder,” Denneman says. “This is already technically feasible, and the industry can follow the path opened by CARBONBIND to develop and demonstrate next generation technology that makes net zero a commercial reality.”

Products such as CARBONBIND, combined with Puma Bitumen’s sustainable processes, help to minimise carbon emissions throughout the entire supply chain.

“CARBONBIND is an economically viable and meaningful solution to reduce the carbon footprint of flexible pavements, while maintaining equivalent or better longterm performance,” Denneman says.

DEVELOPING INNOVATION

Development of CARBONBIND was completed in Puma Bitumen’s research and development facility in Melbourne, the Puma Global Bitumen Technology Centre. This facility has supported the development of several products under Puma Bitumen’s sustainable binder range. Denneman says Puma Bitumen is proud to have introduced an Australian-first product that was also developed locally.

“The majority of my career has been focused on taking technology from overseas and implementing it in Australia,” he says. “But here we’re doing this in reverse. It’s fantastic to be in that space where we can share some of the great work that we’re doing with the rest of the world.

“WHEN IT COMES TO RESEARCH AND DEVELOPMENT IN THE BIOGENIC MATERIALS SPACE, WE HAVE IDENTIFIED THIS AS PROBABLY THE MOST EXCITING BRIDGE BETWEEN LEGACY TECHNOLOGY AND THE LOW CARBON, HIGH PERFORMING BINDERS OF THE FUTURE.

“It’s changing the narrative.”

Domestic development has also let to a range of CARBONBIND asphalt and sprayed seal grades satisfying Austroads PMB specifications. These requirements outline standards associated with materials used in sprayed sealing and asphalt applications.

Satisfying these requirements also means that contractors don’t need to make changes to their equipment, processes or designs before using the product.

“Our customers in Australia have been very supportive,” Denneman says. “Customers are willing to invest and understand that this is a journey. If no one is going to support that first step, no company is going to truly invest in a great idea.

roadsonline.com.au 15 COVER STORY

This application of Puma Bitumen’s CARBONBIND contained both biogenic and recycled materials.

“It’s important to understand that this technology isn’t just something that you switch on by 2050. If you want to be net zero, you must have a pathway to get there.”

Phil Chirnside, General Manager for Australia – Puma Bitumen says the company has put significant focus on its research and development into creating a product for the future.

“When it comes to research and development in the biogenic materials space, we have identified this as probably the most exciting bridge between legacy technology and the low carbon, high performing binders of the future. The time and effort we dedicate to this research reflects our belief in its future value to our industry,” Chirnside says.

“For Puma, this encompasses not only safeguarding our position as a preferred supplier of high-quality bitumen well into the future, but doing so to the highest degree of corporate social responsibility with current and future generations in mind.

“These ambitions extend to supporting our customers to achieve their sustainability goals. We believe CARBONBIND is our most exciting development to date, which plays a truly meaningful role in delivering on these objectives.”

EYE-TO-EYE

One company that has been a keen supporter of CARBONBIND is Boral, the largest vertically integrated construction materials provider in Australia.

Just like Puma Bitumen, Boral’s operations are engrained in sustainability. Both companies share ambitious net zero targets and are committed to reducing their carbon footprint wherever possible.

Which is why CARBONBIND’s potential sustainability benefits attracted Boral.

Rob McGuire, National Sales Manager, Asphalt – Boral says the relationship between Boral and Puma has been decades in the making.

“Puma is a key supplier of bitumen to Boral,” he says. “They come with international experience and a global perspective, given their coverage across the world.

“There’s a long history and a deep technical connection. We’ve been key partners for just about as long as Boral’s been in existence.”

Carl Topp, National Technical Manager, Asphalt – Boral says both companies share a similar philosophy, particularly when it comes to quality and sustainability.

“We align very well in terms of our desire to provide not only an innovative product, but also a high quality one,” Topp says.

“We take a lot of pride in the quality of our work, as well as the products that we supply. We also work very closely with their technical team. There are some striking similarities in terms of collaborating to reach a high-quality outcome.”

Chirnside says the strength of the partnership lies in a commitment to serve the industry.

“Boral has been a loyal user of Puma’s binders since we entered the Australian market. They have a strong pedigree and reputation as an organisation that fulfils its craft to the highest standards. Their passion and commitment to innovation, ongoing improvement, and sustainability mirrors that of Puma,” Chirnside says.

McGuire agrees.

“We’ve got a shared vision around collective improvement to both our businesses,” he says. “We’ve got a balanced approach, from technical, health and safety, environmental sustainability, and some innovation along the way.

“That’s why we’ve got such a mutual respect for each other and are aiming for the same outcomes.”

“THERE’S A LOT MORE OPTIONS NOWADAYS TO BRING THESE PRODUCTS TO THE FORE AND HAVE THEM GREEN LIT FOR ROAD USE. PREVIOUSLY THIS WASN’T AS EASY, IT’S CHANGING THE CULTURAL APPROACH TO WHAT WE’RE DOING.”

16 ROADS AUGUST 2023

Dr Erik Denneman believes CARBONBIND will open new doors towards fully sustainable options for the industry.

This is what drove Boral’s initial interest in the CARBONBIND

THE FIRST USE

Boral engaged Puma towards the end of its development cycle of CARBONBIND, inquiring about the potential use of the product.

For Boral one of the standout qualities of the product, on top of its sustainability benefits, was that it had been developed locally. As McGuire explains.

“There’s a lot more options nowadays to bring these products to the fore and have them green lit for road use. Previously this wasn’t as easy, it’s changing the cultural approach to what we’re doing,” he says.

Topp says the CARBONBIND marks the first time that Boral has used a product that combines both recycled components and bio-genic materials. He says that such a product is clearing a pathway for use and development of materials that wasn’t previously possible.

“A lot of that now is a change to approach, there’s more confidence in the people who are developing these products and putting in

the time and effort,” Topp says. “[Puma] are delivering this successfully.”

Topp adds that another standout feature of the CARBONBIND is its ability to be implemented into existing processes and requirements.

“It’s been very well developed by Puma with a mindset of having a product that could fit into current specifications,” he says.

“That’s certainly a big thing, it’s probably viewed as lower risk for stakeholders. Really the biggest benefit is the assistance it gives in terms of sustainability and carbon reduction.”

Boral and their subsidiary company Allen’s Asphalt have utilised CARBONBIND on five sites across Southeast Queensland to date for their main customers. When it comes to performance, Topp says the product performs at least equivalent to conventional materials and products.

“It’s the same but different. It’s a different product, but I think that’s what the beauty of it is. It behaves and is delivered very consistently to that of a conventional treatment,” Topp says.

“There’s nothing significant that we have to change in terms of process or application.

That’s a big tick for us.”

Topp says these works have received positive feedback from clients, as well as the crews using CARBONBIND.

“There can sometimes be a perception around new products, but there’s been no concerns,” he says. “It’s all been positive feedback so far. Everything operationally has been great, and our customers have been very supportive of the reasons why we’re using the product.”

McGuire says he can tell Puma considered a variety of factors when developing CARBONBIND.

“We haven’t had any issues with fuming or smells and those kinds of intangibles,” he says. “Credit to Puma, they’re very much aware and conscious of considerations for a product like this.”

Boral is conducting performance-based testing in field installations for the product. Topp says early indications point towards CARBONBIND potentially becoming a standard application for industry.

“Longer term, I can see this product being the standard selection for all projects where PMB’s are specified. It ticks several boxes,” he says. “The future’s very bright.”

roadsonline.com.au 17 COVER STORY

PMB (Polymer Modified Bitumen) product.

Boral has become a keen supporter of CARBONBIND and other sustainable options.

REALIZE PROJECT CONFIDENCE

TRANSFORMING THE WAY THE WORLD BUILDS

So ware that helps you

Learn more at InEight.com

So ware for Capital Projects

A DIVERSE SUPPLY CHAIN

Anumber of businesses who work with Major Road Projects Victoria (MRPV) are driven by an ethos of providing employment opportunities to communities that would otherwise face significant obstacles in the labour market.

This forms part of MRPV’s vision of a strong, sustainable and diverse infrastructure sector.

Key to achieving these milestones is supporting businesses that are contributing to the betterment of the industry, particularly when it comes to removing barriers to meaningful employment.

LaTrobe Valley Enterprises (LVE) is one such company. Suzanne Lewis, CEO – Latrobe Valley Enterprises says LVE works to remove barriers to employment.

“We provide meaningful and sustainable employment to people living with disabilities,” Lewis says.

“We have approximately 100 people with a

number of those people living with various disabilities, whether they be intellectually or physically disabled.”

Around 85 per cent of LVE’s entire workforce has disabilities. General Manager Operations Mark MacManus says the company’s ethos has remained intact since its inception, with a focus on grasping opportunities and growth.

“We’ve been going for close to 57 years now and since we started the goal was to provide opportunities. As the business has grown and we’ve started to work in a lot of different areas,” he says.

“This growth has meant that we’ve needed to make sure that our business can continue to grow and offer more people opportunities. That’s a big part of our work, we make sure that it’s sustainable so we can continue to do this into the future.”

LVE offers a variety of services for projects

of all sizes, such as sign making, recycling, business support services and grounds & facilities maintenance.

LVE’s variety and quality of services has led to the company winning several contracts for works on infrastructure projects with Major Road Projects Victoria.

This includes works on Princes Highway East, the third and final stage of the upgrade is delivering 43 kilometres of duplicated highway between Traralgon and Sale in the state’s east.

LVE has also delivered signage works for projects that form part of the Regional Rail Revival program.

“We’ve had a great relationship,” says Lewis on the affiliation between MRPV and LVE. “MRPV has been on that whole journey of social enterprise. There’s a lot of organisations that might speak about social enterprise, or about people living with disabilities, but they don’t truly live it.”

roadsonline.com.au 19 DIVERSITY

A NUMBER OF VICTORIAN COMPANIES ARE PROVIDING LIFE-CHANGING OPPORTUNITIES FOR LOCAL EMPLOYMENT, AS PART OF THEIR WORKS ON MAJOR TRANSPORT INFRASTRUCTURE PROJECTS ACROSS THE STATE.

Works are continuing on the Epping Road Upgrade.

ALL IN

Another company that’s opening doors for employment is NLA Logistics.

NLA Logistics is the only 100 per cent Aboriginal Female Owned plant hire business in Victoria, catering for the plant hire needs for major infrastructure works.

With works on projects such as the Monash Freeway Upgrade, Hall Road Upgrade, Glen Huntly Level Crossing Removal Project and Epping Road Upgrade, NLA has grown rapidly since its foundation seven years ago.

Director Nicole. A says NLA has grown its fleet to more than 150 contractors, with more than 15 units of its own.

In the beginning, she owned and operated the one truck business, before expanding the company’s capabilities for works across Melbourne.

“We try and engage as many members of the Aboriginal community as we can,” she says. “We try and engage contractors to help them to get work. It doesn’t have to be for us, it doesn’t have to benefit us. It’s just to help them.”

NLA contains a diverse workforce, with many contractors from a variety of backgrounds, as Nicole. A explains.

“A lot of our [staff] are refugees, asylum seekers, former defence personnel and more,” she says.

She adds that this generosity and commitment to providing opportunities stemmed from her own personal experiences during the early days of NLA.

“I didn’t have that support from anybody

with my business. It’s not easy, so if we can help someone when we can, we try to,” she says.

“A lot of the contractors come to me and say that if it wasn’t for NLA they wouldn’t be in the industry, or they would be in a poor financial situation. They’re very thankful.”

She’s also recognised higher quality outcomes during projects, thanks in part to the commitment and thankfulness of NLA’s contractors.

“I think it’s very rewarding. I find that they actually care about what they’re doing, they care about their own business, and they care about NLA. It makes them happy to

come to work and this shows in their work ethic,” she says.

This has been prevalent on the company’s recent works on the Hall Road, Carrum Downs Upgrade. Beginning early last year, NLA was tasked with a variety of cartage responsibilities on the works, including the transportation of quarry products and exporting clean fill.

These works will wrap up in 2024, but the impact of providing employment and industry opportunities will last a lifetime, she says.

“Some other plant hire businesses treat contractors like a number. But I like to find out what our contractors need and if we can help them,” she says. “That’s how I choose to run the business.”

20 ROADS AUGUST 2023 C M Y CM MY CY CMY K

NLA, Victoria’s only 100 per cent Aboriginal female-owned plant hire business, is currently contributing to the Hall Road Upgrade.

Construction works on the Princes Highway East project.

WORK ANYWHERE. BUILD EVERYWHERE. Learn more at bluebeam.com.au Try Revu 21 and Bluebeam Cloud today. @ 2023 Bluebeam, Inc. Bluebeam and Revu are trademarks of Bluebeam, Inc. registered in US and other countries.

ROADS REVIEW

THIS MONTH, WE ASKED THE INDUSTRY’S DECISION-MAKERS, ‘HOW CAN CONSTRUCTION COMPANIES ENCOURAGE MORE DIVERSITY IN THE WORKPLACE?’

CAROLINE WILKIE, CEO – AUSTRALASIAN RAILWAY ASSOCIATION

Having a diversity and inclusion focus is important in supporting the long-term sustainability of the rail industry, particularly with a 70,000 skills gap in the face of an unprecedented $154 billion pipeline of infrastructure projects over the next 15 years. The ARA urges all organisations in the industry to champion greater diversity and inclusion by making their workplaces welcoming and safe to all. This could include diversity training to address cultural challenges, providing flexible workplace practices, undertaking gender pay gap analysis, mentoring and sponsorship programs, as well as developing and implementing inclusive workplace policies and practices. The ARA’s Women in Rail strategy supports businesses to build gender diversity. Attracting females into rail apprenticeships or rail training and attracting skilled or qualified female candidates are key challenges and promoting more women will be a crucial part of growing our workforce.

KATRIINA TÄHKÄ, CEO – A HUMAN AGENCY (A-HA!)/ AFPA D&I COMMITTEE MEMBER

People want to work in an environment where they feel valued, respected and heard. When you ask groups of people why they don’t work in a particular company or industry it’s usually because they don’t feel welcome or like they ‘fit in’. Construction companies that consciously build a workplace culture which is inclusive of all people; and actively identify and overcomes any barriers to participation, will reap the rewards in terms of seeing a more diverse workforce wanting to work there. Not sure what your current culture is like? A culture audit will make your action plan clear.

JAY KATTEL, GROUP MANAGER, WORKFORCE DEVELOPMENT AND DIVERSITY –COATES

Coates supports greater diversity in the construction sector through policies and plans that explicitly promote equal opportunities and representation. Implementing clear diversity and inclusion measures also helps progress workplace diversity, as does driving ownership and sponsorship from senior and middle management and the provision of company-wide inclusion training. Recruitment processes that focus on skills and qualifications rather than demographic factors and creating targeted partnerships with community organisations and underrepresented groups, is also an excellent way of identifying more diverse talent pools. Ultimately, creating a supportive and inclusive work culture that values different perspectives fosters and retains a diverse workforce.

If you or someone at your organisation is an industry leader and would like to be a part of this monthly column in 2023, please get in touch with Editor, Tom O’Keane: tom.okeane@primecreative.com.au

ROADS REVIEW

22 ROADS AUGUST 2023

1300 278 322 enquiries.australia@astecindustries.com astecindustries.com BUILT TO CONNECT

REVEAL

ARE AUSTRALASIA’S INNOVATIVE SUBSURFACE EXPERTS.

With Reveal, you can eliminate subsurface risks, deliver infrastructure projects faster and minimise cost blow-outs and variations.

If you need to understand your underground, get in touch with the world’s leading subsurface experts.

WWW.REVEAL.NZ

AN INSIGHTFUL OUTLOOK

INEIGHT’S 2023 GLOBAL CAPITAL PROJECTS OUTLOOK MARKS THE THIRD

Despite on-going pressures, the roads and infrastructure sectors continue to push on.

The confidence and resilience of the sector is supported by a $17.9 billion commitment to major infrastructure projects over the next 10 years, as part of the 2022-23 Federal Budget.

According to the Federal Government, total investment in major infrastructure is expected to reach more than $218 billion. As such, gauging potential areas of growth and improvement will be essential in ensuring that the sector can successfully deliver this pipeline. It’s a key reason for the development of InEight’s Global Capital Projects Outlook.

The outlook is now an annual survey; a study of digital transformation across the sector, as well as a source of insights on important issues such as sustainability, innovation and more.

Now in its third year, it provides valuable insights on trends and behaviours that are likely to shape the industry in its near- and long-term future.

The survey has often communicated the industry’s uncertainty due to lingering effects of the COVID-19 pandemic such as impacts on global supply chains, high demand for skilled personnel and price escalation for both products and services.

Despite these factors still having an impact on project delivery and development, Rob Bryant, Executive Vice President, Asia-Pacific & Japan for InEight, says the 2023 Outlook paints a positive picture for the sector’s future.

“Last year, I think, there was a bit of a pause and a restart off the back of COVID-19,” Bryant says. “There’s still a lot of contractors that are facing challenges around familiar issues of labour and material costs.”

The Global Capital Projects Outlook survey includes 26 questions.

InEight received 300 responses from a variety of industries including manufacturing, construction, mining, utilities and more.

Of the 300 respondents, 100 each were drawn from the regions of Asia-Pacific (APAC), Europe, and North America. Sixty-seven per cent of these were project owners, with the

remaining 33 per cent being contractors.

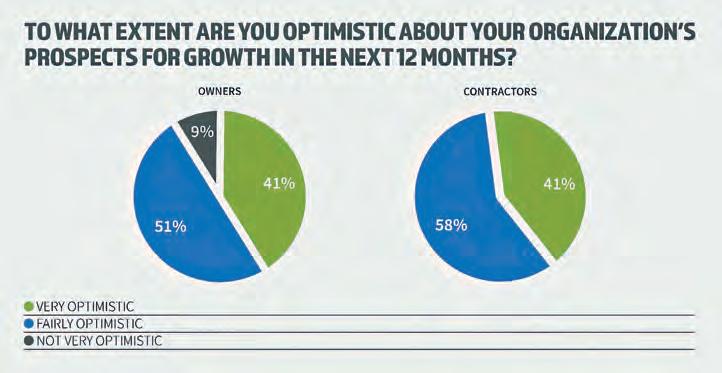

OPPORTUNITIES FOR GROWTH

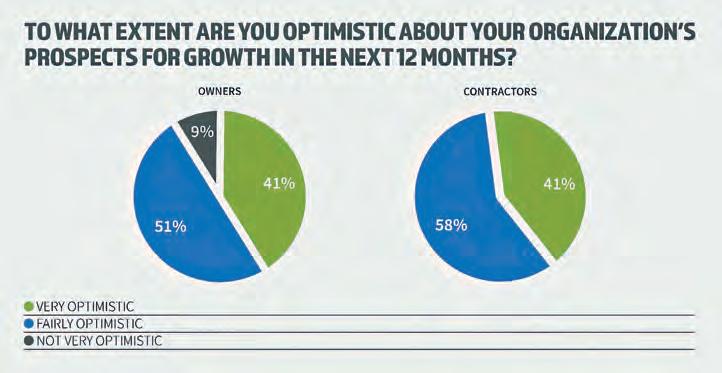

A common theme, since the first Global Capital Projects Outlook in 2021, has been the sector’s positivity towards growth and new opportunities.

According to the survey, 41 per cent of project owners are very optimistic for the future, while 51 per cent are fairly optimistic. Similarly for contractors, 41 per cent say they’re very optimistic, with 58 per cent saying they’re fairly optimistic towards their organisation’s prospects for further growth over the next year.

One of the core themes addressed in this year’s Global Capital Projects Outlook is the depth of new opportunities provided by technology.

“There seems to be a lot of recognition by those in the APAC region that they can be doing a better job of optimising their use of technologies. Whether it be for managing their materials, tracking labour on site, or how they can improve productivity in general,” Bryant says.

This could be attributed to the lack of financial resources available for companies to adopt these new technologies, due to ongoing economic stresses.

Despite this, Bryant says Australia’s

enthusiasm towards adopting new technologies remains strong, particularly when compared to the rest of the world.

“We’ve seen Australia and the APAC region be a leader and perhaps even more progressive than some other areas of the world. That’s a strong sign that we’re seeing this as a continued trend.”

This is reflected in the survey findings – 71 per cent of respondents from the APAC region consider digital technologies to be a significant opportunity, compared to 49 per cent of respondents from Europe.

Such interest in new technologies is already making an impact on project delivery domestically.

Bryant says that the increase in alliance contracts, to decrease the risks associated with project delivery, has called for new collaborative systems.

“Alliances are a way that contractors are finding to deliver projects out of necessity, because they recognise that they don’t have the capacity to deliver on these major projects,” he says.

“If you look at the Level Crossing Removal Project [in Melbourne] for example, there’s some good case studies where alliances are coming together to provide their own expertise. Whether these strengths be in rail laying or signalling, tunnels or bridges.

roadsonline.com.au 25 TECHNOLOGY

SUBMISSION OF WHAT IS NOW AN ANNUAL REPORT, DEPICTING AREAS OF POTENTIAL GROWTH AND IMPROVEMENT, AS WELL AS HIGHLIGHTING THE PROGRESS AND ACHIEVEMENTS OF THE CONSTRUCTION INDUSTRY.

The 2023 Global Capital Projects Outlook demonstrates the sectors confidence, despite on-going impacts such as supply chain issues.

“Then you need to collaborate and share information across those different disciplines. They’re doing that increasingly in a digital environment.”

Bryant adds that he’s seen greater acknowledgment of the role digital technologies can play in allowing construction teams from any discipline to collaborate remotely.

This has also increased the need for ‘interoperability,’ the capacity for digital technologies to interact with each other. An increasingly important component for contractors using different programs and systems.

“A lot of conversations are now centred around what the desirable outcome is and why contractors and project owners are employing digital technologies, rather than just deploying it because they feel as though they should,” Bryant says.

The survey outcomes indicate that companies already implementing digital solutions are seeing improved results in project delivery. Of the organisations that deliver projects ahead or on schedule, 69 per cent use project controls software.

GREENER AND GREATER

Bryant says this focus on technology has also produced benefits in achieving sustainable project development.

“From a road and rail perspective, there’s a strong path of delivery for projects over the next 12 to 24 months. What we’ve observed in parallel to the survey has been a shift in focus for companies to spread their portfolio of projects into renewables and the renewable energy sector,” Bryant says.

“That’s definitely a topic that’s come up for our APAC respondents, as well as globally. They’re starting to consider how they can deliver projects from a sustainability perspective. It’s not a new component, but it’s

a more prevalent component now.”

This notion is also supported by the Federal Government’s record funding of close to $25 billion for clean energy spending, including funding for new infrastructure in clean energy and renewables.

“An interesting part of the renewable energy sector is that it still requires a component of road and rail infrastructure a lot of the time,” Bryant says.

“If there’s a wind farm project or a solar project, that doesn’t mean that you’re only delivering the energy generation asset. You’ve still got the access and transportation components of these projects that need to be considered as well.

“Alliances are coming together to deliver renewable energy projects that require disciplines in transport infrastructure, for example.”

This is also reflected in data from the Global Capital Projects Outlook which suggests that 54 per cent of contractors, as well as 48 per cent of project owners, see sustainable building projects and practices as the biggest opportunity for their organisations over the next 12 months.

DATA AND RISK

Addressed in the Global Capital Projects Outlook is the concept of data “haves and have nots.” As Bryant explains, this concept refers to the importance of using historical data to provide more accurate insights to contribute to project delivery, granting more operational awareness.

Importantly, this also centres around gathering a solid foundation of data to compare and to contrast.

“It’s important that if you’re using data for benchmarking, you’ve obviously got to have the data to start with,” Bryant says. “If this has only started to be collected in a meaningful and consistent way over the past couple of years, then you’re only now starting to be in a position where you can use it and actually say ‘how do we compare?’

“Those that haven’t started to gather this data could be four or five years behind. That gap becomes more exaggerated because you’ve got organisations and project groups that are much more invested in their application of data and how it helps them to assess and plan effectively, versus those organisations that haven’t started that process.”

Not using such a data set can have detrimental impacts on project delivery. The results could include communication barriers, unforeseen risks, and a lack of data sharing,

leading to a poor project outcome.

Bryant says that while Artificial Intelligence (AI) will likely contribute to clarifying these data points, it’s still essential that contractors and project owners understand how to use AI effectively.

“Some organisations have a perception that AI technology in general can look at a vast set of unstructured data and make sense of it,” he says. “That isn’t true.

“Data needs to be well organised for these technologies to be leveraged. If you keep your data unorganised, it will find invalidated trends, because it assumes that you’re telling the truth. The better organised your data is, the better quality of the insights that you will achieve.”

FUTURE CONTRACTING MODELS

Bryant says further adoption of new technologies may also require a shift of focus when it comes to traditional project contract models.

“With the traditional model, one of the issues has been trust, as there hasn’t been transparency during progress,” he says.

“What’s happening now is a shift. In recent years there’s been an acknowledgement that contracting models like NEC (New Engineering Contract) allows and encourages greater transparency.

“It’s an environment where stakeholders can share information. This can create a greater level of trust. They can share what they’re learning and can make decisions collaboratively around scheduling and budgeting.”

Bryant says this can create an environment that deviates from a fixed-cost model.

“Why should a contractor absorb the cost change over the course of a four- or five-year project, when material chain costs and labour costs change, and issues are revealed that weren’t foreseen?” Bryant asks.

Bryant adds that projects such as the West Gate Tunnel in Melbourne or the George Street Light Rail in Sydney can act as benchmarks for these future models.

“Then you can say, ‘all right, next time something like that comes up, let’s make sufficient allowance in our budgets for [risks] that we don’t know about yet.’ Suddenly there are fewer surprises, and it becomes easier to reduce surprises over time.

“We have a good chance over the next few years for this to shift quite dramatically. But it will require a change in attitude from project owners.”

To download InEight’s Global Capital Projects Outlook, visit: ineight.com

26 ROADS AUGUST 2023 TECHNOLOGY

The industry’s support of sustainable procurement has led to new opportunities in renewable projects.

Greener Infrastructure Conference 2023

18–20 September 2023

Registration is now open.

Victoria’s infrastructure industry is joining forces to create a greener future and deliver purposely greener projects. Be part of the change.

The three-day conference will feature industryleading speakers, expert panels, networking events and a trade hall that’s bigger and better than ever. Scan

6754

Melbourne Convention & Exhibition Centre

code to register ecologiq.vic.gov.au/conference-2023

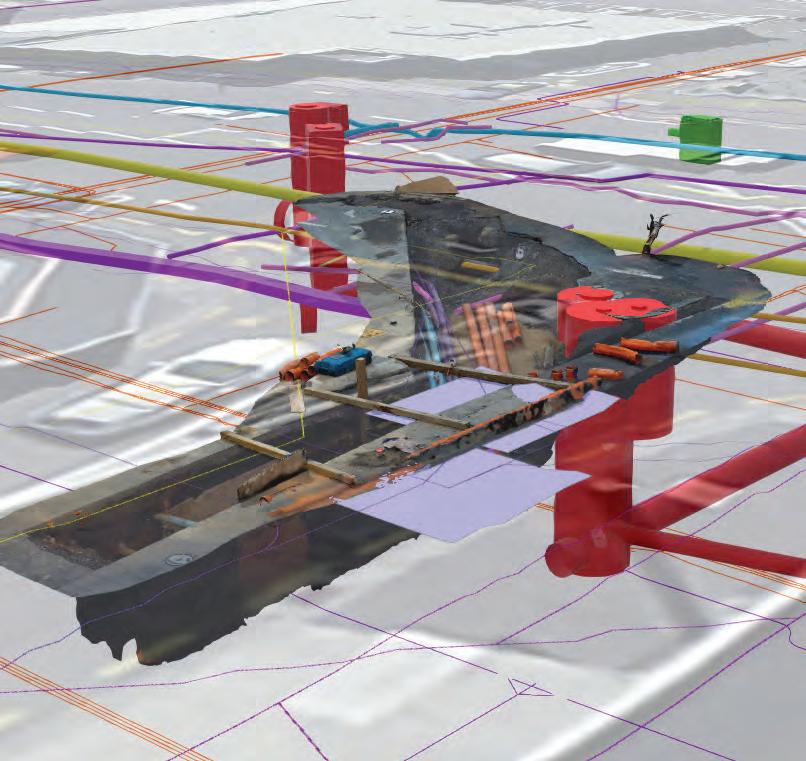

TECHNOLOGY GROUND-BREAKING

DEVELOPMENT HAS LED TO A NEW, SINGLE SOURCE OF TRUTH FOR UNDERSTANDING RISK WITH UNDERGROUND UTILITIES.

CEO AND FOUNDER

SAM WIFFEN EXPLAINS THE STORY AND BENEFITS BEHIND REVEAL.

Striking underground utilities can result in lengthy and even lethal consequences during works on minor and major infrastructure projects.

According to Reveal, utility strikes cost New Zealand $89 million annually in direct costs and, in New Zealand is estimated to be up to $2.5 billion per year in indirect costs – a staggering 1.17 per cent of GDP.

As the CEO and Founder Sam Wiffen explains, Reveal provides a solution to what had been a legacy issue across the construction and infrastructure sectors.

“I have an engineering background and used to work on large upgrades of buildings and electrical substations across the civil construction and heavy electrical sectors. We kept on hitting objects, primarily because we didn’t have accurate information and records on what was underground,” he says.

For Wiffen, along with Co-Founders Luke Herlihy and Oliver Kirk, these personal frustrations sparked the development of a concept. One that would lead to the eventual formation of Reveal.

But the first step was to develop a deeper understanding of the problem.

As Wiffen explains, by combining their expertise and personal experiences, the team quickly set out building a services business with a foundation of technology and innovation.

As Wiffen adds, the aim was never to deliver a “silver bullet”. Instead, it was to ensure that contractors and project owners could accurately and easily implement subsurface data.

“That was the key driver for us. Accuracy is so important when it comes to underground utilities, and this is where information is king. Information and knowledge are also the crux of the problem; some of these bad records have degraded from time and technology,” he says.

“Locating underground utilities is really hard. Our thinking was, ‘How do we make that job easier?’ When you think about Superman, having x-ray vision, that would be amazing. But what if everyone was Superman or Superwoman?

“It’s a simple notion, to be able to make sure that major infrastructure providers and smaller providers know what’s underneath them when they’re building.”

PRO-ACTIVE DETECTION

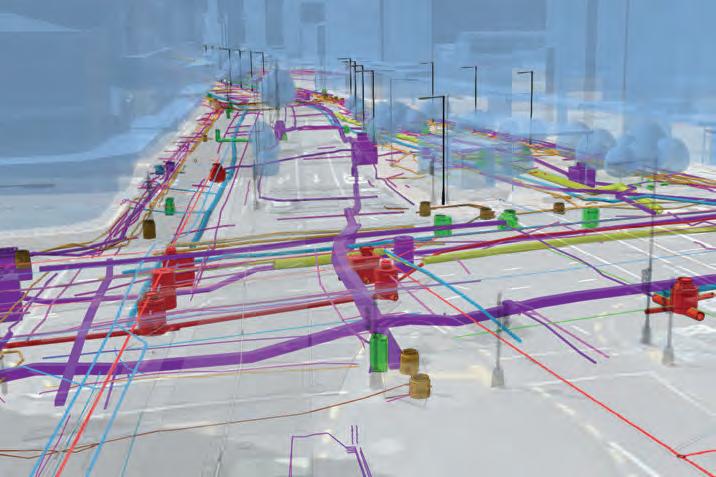

Reveal is a New Zealand technology company that provides a platform for understanding subsurface infrastructure environments. From its headquarters in Wellington, the company now serves the entirety of its home country, as well as the Australasian region.

The Reveal platform consists of a variety of technologies and services, each designed to increase awareness and visibility for potential sub-surface risks.

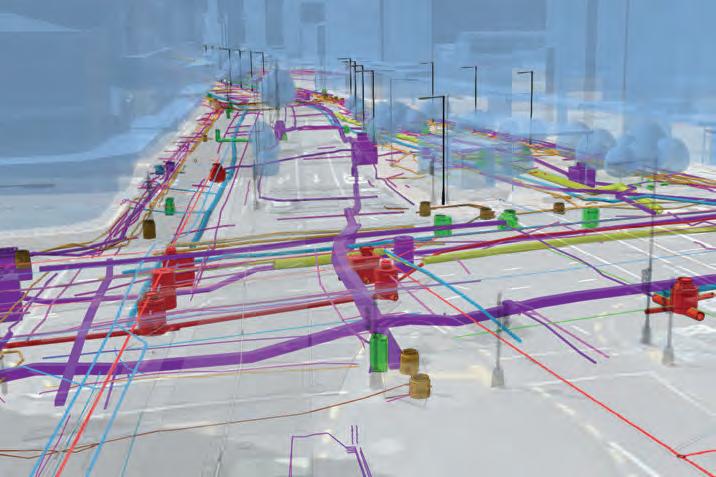

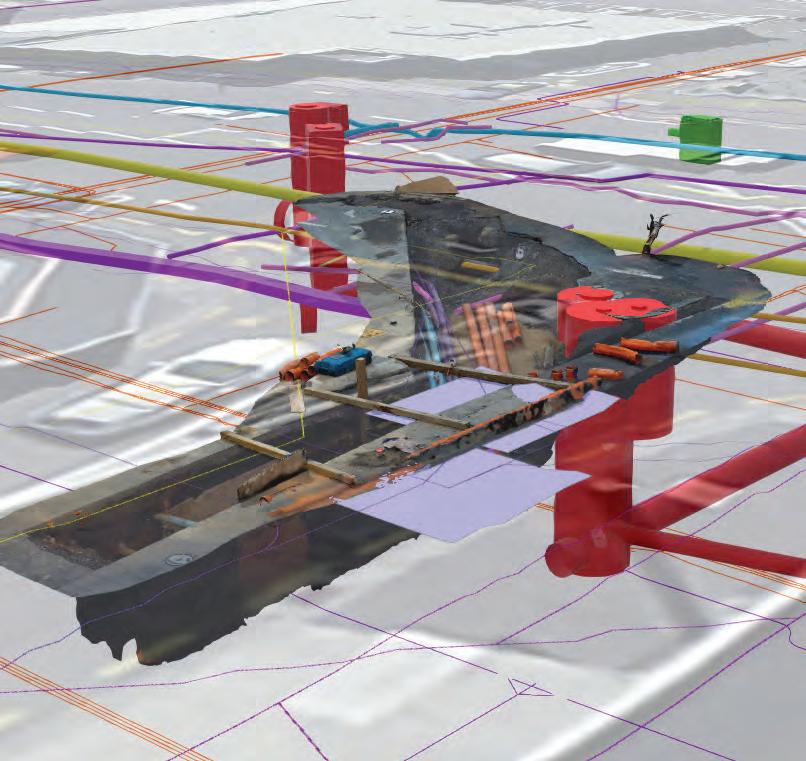

The platform is centred around the creation of a spatial digital twin which contractors and project owners can view in real time.

“The long-term vision was set around how we could collect this data, democratise this data and make it available to as many people as possible,” he says.

Reveal can quickly and accurately paint a picture of any potential geophysical and

28 ROADS AUGUST 2023

Reveal provides a new way of understanding the risks and proximity of underground utilities.

utility risks, in part due to its ability to provide reliable data around subsurface assets.

Technologies such as ground-penetrating radar are used to capture data to form the digital twin. This twin then forms part of a ‘map’ of underground assets, which engineers, contractors, asset owners and government can view from a single source.

“We create accurate utilities models. We can help people do that, or we can provide an environment where users can do that themselves,” Wiffen says.

“We’re helping people to not just take the existing records of utilities and combine those before making a design. It’s providing an understanding through a subsurface utility engineering process to identify where these risks lie.

“It’s also an understanding of the legacy that we’re leaving behind at the end of a project. How do we make sure that we’ve improved our understanding about the underground? What’s the digital legacy we’re leaving behind?”

Reveal’s platform has already been utilised on crucial works during the Christchurch earthquake rebuild, as well as infrastructure works such as the Let’s Get Wellington Moving project.

The company’s work on the latter also included the world’s largest subsurface utility model (as of August 2022).

Reveal expect the platform to also be used in more infrastructure projects across Australia in the near future.

GRATIFYING GROWTH

Wiffen says the benefits of the platform have been substantiated through positive feedback from users and project stakeholders.

“I’ve had customers say that ‘if I didn’t have

the information that was provided to us through the platform, we would have had a massive utility strike’. They say that would’ve had a huge project delay or even a death,” he says.

“By having this information available to them during the planning stage, asset owners and contractors have been able to create a safe project through design. It’s allowed their teams to work faster and safer.

Wiffen believes that the real world and professional experiences of the Reveal team have contributed to what is now a “pioneer” in the subsurface space.

He says Reveal’s development and services are backed by a diverse staff, originating from a range of industries. He says this diversity has greater supported both idea generation and innovation throughout the company.

“We’ve got people who are masters of their craft, people that are geophysicists,

geologists, engineers, technologists, project managers, accountants, economists, you name it.”

“Everyone is treated as an equal and this culture has been huge for us. What’s been really special to me is that as the company has grown, it’s given us more resources to invest back into our staff through different training and development programs.”

Reveal recently celebrated its 11th anniversary. A milestone that reflects not only the growth of the company, but also the moving world of subsurface detection technology.

The company is also now pushing further into the international markets.

“The biggest challenge is that these markets are huge, so we’ve been learning as much as we can,” Wiffen says.

“One of the biggest differences across some markets is where risk potentially lies. In New Zealand, there’s differences of where the control or change can happen on a project, particularly on the governance side of the project.

“In other areas, such as Southeast Asia, everything is on the contractor. So those motivations can be quite different.”

Wiffen says this learning has been invaluable.

“As a business we’ve been getting lots of validation that this is a phenomenal way to approach this systemic problem. That we can meet that challenge and grow the company globally is incredibly exciting,” Wiffen says.

“Of huge importance to us is, the value set that we have as a business and imbuing these values into our products and technologies –creating that positive change.”

roadsonline.com.au 29 TECHNOLOGY

Reveal CEO and Founder Sam Wiffen.

The platform has already been used on some of New Zealand’s largest infrastructure works.

ACCELERATING CHANGE

WAMARRA AND SYMAL ARE AIMING TO CREATE MORE OPPORTUNITIES AND REMOVE BARRIERS TO THE EMPLOYMENT OF ABORIGINAL PEOPLE WHILE USING

throughout the sector. This led to the foundation of Wamarra.

Heta himself is a proud Aboriginal man of the Wiradjuri Nation in central New South Wales. He says the creation of Wamarra has ignited a change throughout the construction industry.

“I started the company around three and a half years ago with a clear intention of providing career opportunities to Aboriginal people. Currently Aboriginal participation is a criterion under the social procurement framework which is relevant to all government funded works,” he says.

“Historically, Aboriginal participation has been met through transient outcomes. These outcomes don’t have a focus on building sustainable employment and career opportunities.

“Starting this company was really about providing a genuine solution to social

provides job security and all of the benefits associated. My business partners and I share the same values and same vision,” Heta says.

“It’s something that we’re really proud of because an investment in your people can ultimately lead to a successful business.”

Heta believes implanting systemic change begins with supporting new habits.

“We have a tier of management and leaders that can guide new entrants into the industry and start creating change. That’s really where we’ll see change, if we talk about breaking the cycle of disadvantage, it really starts with mum and dad,” he says.

“Having their parents getting up to go to work every day in some ways can create this subconscious view on what the new norm is. It can help to create role models within families and within the community.

“The feedback is really positive. We’ve

meaning ‘to build’. And build it has.

Since its inception, Wamarra has steadily grown and increased its capabilities to suit both private industry and government works.

The company has now contributed to major infrastructure works such as the Monash Freeway upgrade, North East Link and a number of Level Crossing Removal projects in Melbourne.

Wamarra already has plans in place to support further growth, with objectives such as a retention rate of more than 95 per cent across its staff and supporting a minimum of 55 Aboriginal people with employment over the next 12 months.

A COMPANY WIDE ETHOS

Wamarra forms part of the Symal Group which includes Symal Infrastructure, one of the largest providers in Victoria, with an annual

30 ROADS AUGUST 2023

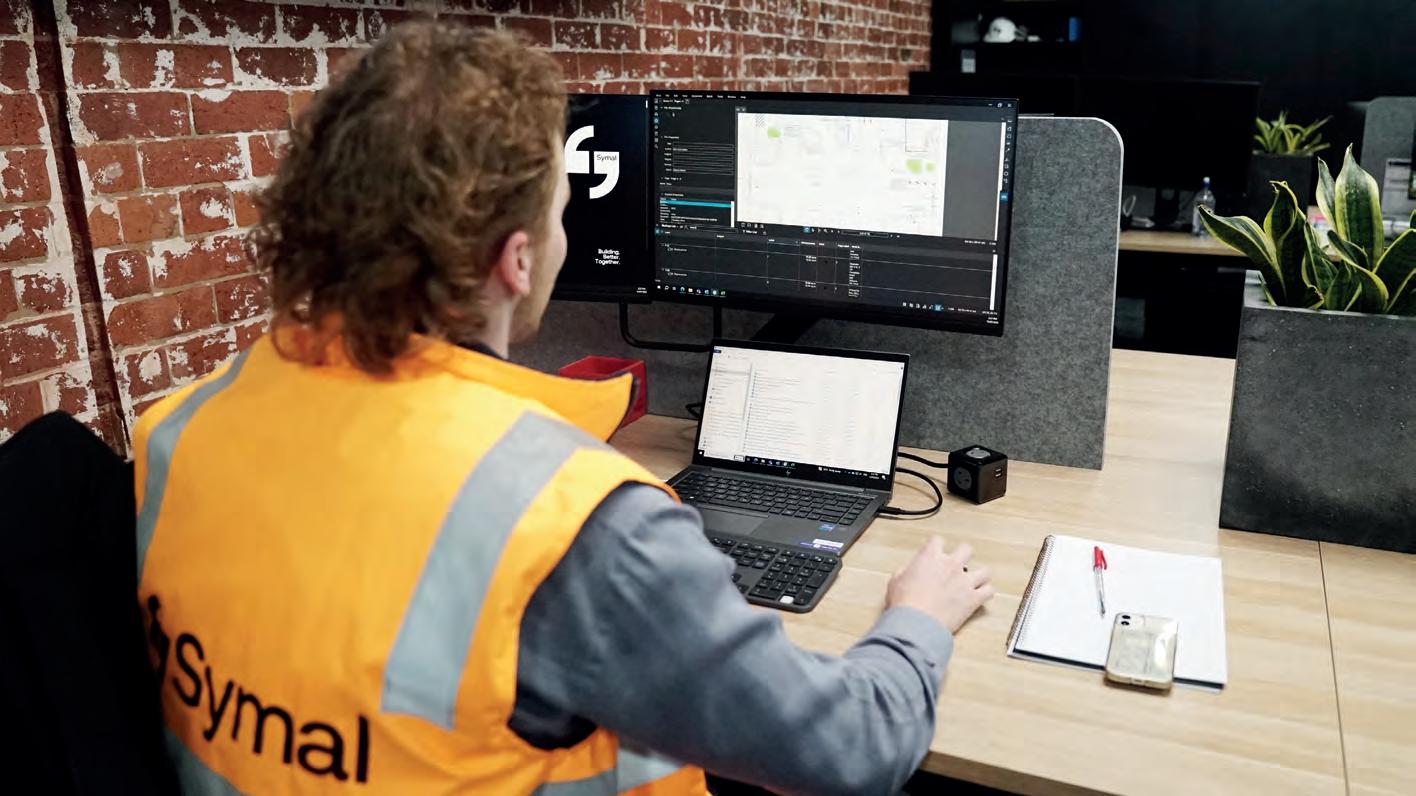

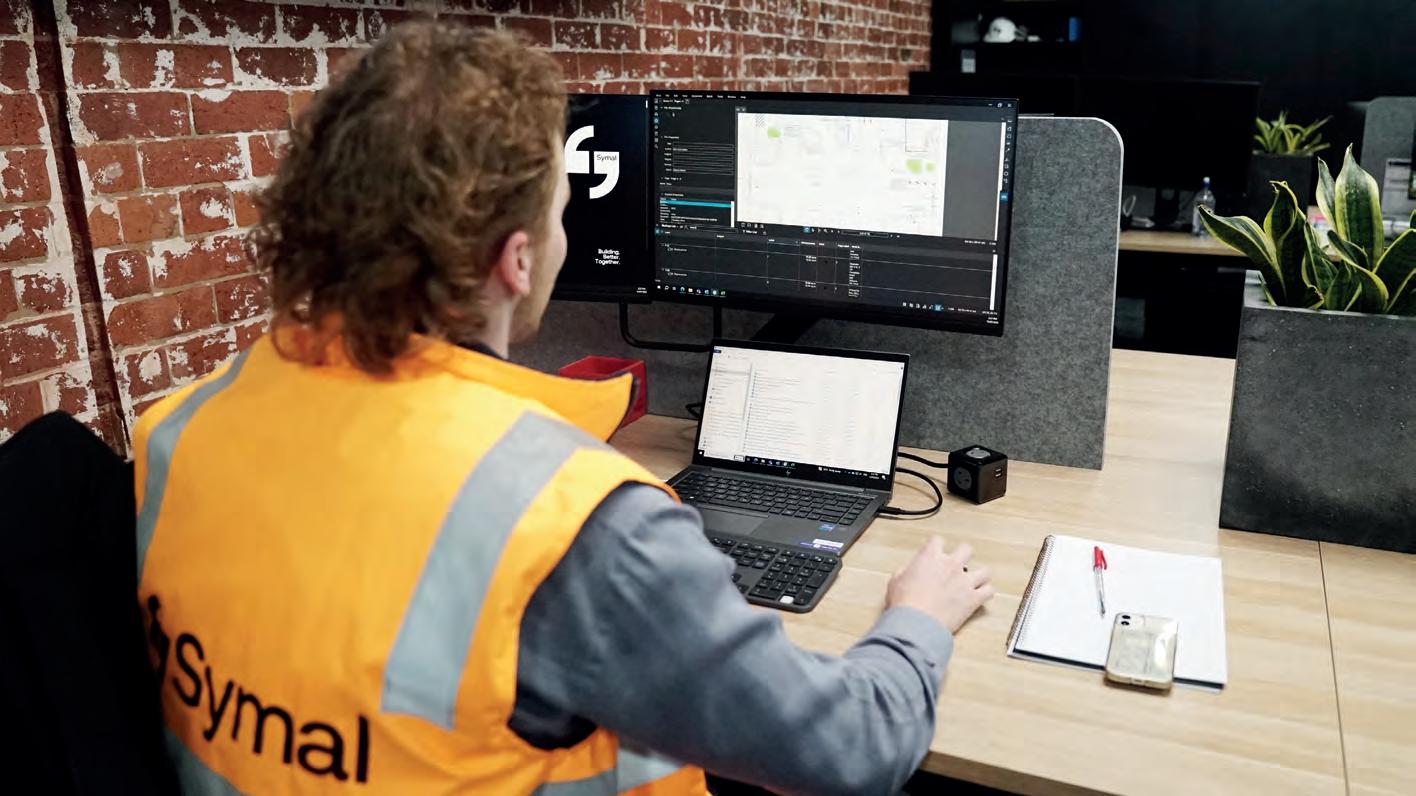

Symal uses Bluebeam software as part of its works on major infrastructure projects.

turnover of more than $750 million.

Matthew Gurney, General Manager, Symal Infrastructure says the establishment of Wamarra has helped to create internal change.

“We saw some real long term benefits that required some short and long term investment. As one of the largest civil employers in Victoria we’ve always valued our own internal skills. This is an extension of that,” he says.

Gurney says Heta has made a “massive impact” on both Symal and the wider industry, helping to accelerate a cultural shift.

“The number one goal of Wamarra is to provide long term upskilling employment for Aboriginal people above all else. Hayden has been instrumental in that. He’s always prioritised this as the number one priority from a board level, all the way down to the construction site.

“He’s made a huge impact and he’s been a great educator in this space.

Gurney says these impacts can be seen firsthand throughout the business.

“Wamarra is something that our people are truly proud of. For some, it’s part of the reason why people come and work at Symal,” he says.

UNITED BY TECH

Beyond their commitment to changing the culture towards employment across the construction and infrastructure sectors,

Symal and Wamarra also share a vision when it comes to their use of construction software.

Both companies utilise Bluebeam software for virtually their entire infrastructure pipeline, across multiple disciplines.

Symal and Wamarra’s engineering teams use the software across a variety of functions, as Gurney explains.

“From a pre-contract phase at the beginning of a job, [our engineers] use it for a lot of the quantification of jobs. Then as we enter the delivery phase, in a similar way, they use it for

their cost forecasting. They’re able to measure up the plans and then use that information to manage drawing revisions,” he says.

“It has the unique ability when they import a new set of drawings, they can overlay the old set and see what’s changed. The other way that they use is delivering messages to the field.

“They also do their vehicle movement plans on site as well as their environmental management plans. They use it in a lot of ways.”

Gurney says Bluebeam software is used across the whole business, contributing to works such as the widening of the Monash Freeway for client Major Road Projects Victoria.

Similarly, Wamarra has used Bluebeam software on works that form part of Melbourne’s Level Crossing Removal Project. Hotak Akran, Site Engineer says he almost uses the software daily. The software provides greater flexibility during the planning process.

“I use Bluebeam for a variety of things. The main one is plan take-offs, so I can use drawings to give us a better idea around quantities of certain materials, I can estimate the meterage of concrete, garden beds and more,” he says.

“I also use it to create sketches for anything that’s on site that might be different to what’s in the site drawings, or even for any ideas that might come up on site. Thanks to the software, we can cater to these as best as possible.

“I’m not sure how I’d go without it,” he jokes.

roadsonline.com.au 31 TECHNOLOGY

“I USE BLUEBEAM FOR A VARIETY OF THINGS. THE MAIN ONE IS PLAN TAKE-OFFS, SO I CAN USE DRAWINGS TO GIVE US A BETTER IDEA AROUND QUANTITIES OF CERTAIN MATERIALS, I CAN ESTIMATE THE METERAGE OF CONCRETE, GARDEN BEDS AND MORE.”

Both Symal and Wamarra are united by their commitment to removing barriers to Aboriginal employment.

Hayden Heta, Managing Director – Wamarra.

FAE MTH MAXIMIZE YOUR POTENTIAL Be more productive with the FAE MTH multitask head for 300-500 hp tractors. Rock grinder, stone crusher, asphalt shredder, and stabilizer all in one. Experience top performance, made possible with the innovative variable geometry mixing and grinding chamber that allows you to work the soil with extreme precision and efficiency. Contact us to find the right FAE product for you: Ph. +61.3.9706.4088 - Toll free 1300.981.337 - info@fae-ap.com.au fae-group.com

TRIALS UNDERWAY FOR AUSTRALIAN-FIRST SAFETY TECHNOLOGY

Heavy vehicles working on the first stage of the Mickleham Road Upgrade in Victoria will be the first in Australia to benefit from new safety technology.

The new MAX-SAFE technology has been installed in some heavy vehicles being used on the road project – with trials of the audible and flashing light alert system to help reduce the likelihood of injuries and deaths associated with heavy vehicle movements.

The Side View technology, as part of the MAX-SAFE system, uses an artificial intelligence smart camera to detect specific vulnerable road users and not other objects or obstructions.

Items in vicinity could include a pedestrian, cyclist or scooter rider, in particular during left-hand turning manoeuvres.

The automatic detection system sends an alert to the operator within the cabin. Electronic flashing lights and alarms will initiate inside and outside the vehicle,

providing the crews who are operating heavy vehicles and machinery the advanced warning they need to assist with avoiding an unexpected collision. It also acts to alert those outside of the vehicle.

Without intervention, pedestrians, cyclists, and scooter riders could be at a heightened risk of entering a heavy vehicle operator’s blind spot. Instead, this system aims to negate the risk and maintain a form of visibility.

The trial is the result of a collaboration between Major Road Projects Victoria, construction partner BMD, and SGESCO-MAX, to find new ways to reduce the likelihood of safety incidents with members of the public during construction and around heavy equipment on site. Success of the new technology will be closely monitored and evaluated.

“Through close collaboration with our construction partner BMD, we’ve developed this trial of the MaxSafe

technology – providing the critical audio and visual warnings to not only the operator within the cabin, but also those vulnerable road users outside of the heavy vehicle,” says Major Road Projects Victoria Area Safety Manager Kelvin Doyle.

The safety trial is part of the Mickleham Road Upgrade, which is building extra lanes in each direction on Mickleham Road between Somerton Road and Dellamore Boulevard, along with new traffic lights, intersection upgrades, and better walking and cycling connections

According to the Victorian Government, the Mickleham Road between Somerton Road and Dellamore Boulevard is used by more than 25,000 vehicles each day and is a key arterial route for Melbourne’s growing north-west.

The Victorian and Australian governments have invested $222 million for the Mickleham Road Upgrade. Stage One of the project is expected to be complete in mid-2025.

roadsonline.com.au 33 NEWS

The technology will help to increase the safety of road users near heavy vehicles. Image courtesy of the Victorian Government.

The first test trains have entered the Metro Tunnel, a landmark moment for the biggest rail project in Victoria since the City Loop.

Two next-generation High Capacity Metro Trains entered the twin nine kilometre tunnels at the South Yarra tunnel entrance and travelled 1.7km to Anzac Station, directly under St Kilda Road.

The journey was years in the making and marks the start of the project’s next major testing phase inside the new tunnels and stations, which will stretch into 2024.

Over the coming months, crews will run trains back and forth between the five stations. The basics, such as lining the trains

FRESH TRIALS FOR NEXTGENERATION TRAINS CONTRACT AWARDED FOR 219-MEGAWATT BATTERY CONSTRUCTION

CIMIC Group’s UGL has been selected for the design and construction of the Collie Battery and associated energy infrastructure in Western Australia.

The Collie Battery is a 219MW/877MWh battery energy storage system (BESS) to be stored in the Western Australian town of Collie.

Neoen’s Collie Battery will provide up to four hours of energy storage and will connect to Western Power’s substation, part of the South-West Interconnected System (SWIS).

Neoen, which awarded the contract to UGL, is a specialist, independent producer of renewable energy.

The Collie Battery aims to provide short duration storage in the peak times to ease pressure on the grid.

The battery will provide grid stability and other grid services, which will also encourage more integration of more renewable energy

up with the platforms, will be tested first. Operators will then gradually increase the complexity, from one train at low speed using minimal power through to multiple trains at greater speeds.

Various equipment and systems will be tested to make sure the Metro Tunnel is safe and ready to open to passengers in 2025 – a

year ahead of schedule.

The Metro Tunnel is said to enhance the way Victorians travel around the suburbs, city and state by freeing up space in the City Loop, slashing travel times and allowing for more than a half a million more passengers a week during peak times across Melbourne’s train network.

into the network.

UGL will be responsible for the design, construction, testing and commissioning of the 33/330kV substation, the installation of the Tesla2 XL Megapacks and the associated balance of plant infrastructure.

UGL’s scope also includes the replacement of an existing bridge and construction of an access track to the site.

CIMIC Executive Chairman Juan Santamaria says UGL is pleased to be able to apply its knowledge on a project such as the Collie Battery.

“Reliable energy supply that helps to contribute to Australia’s net-zero aspirations is essential, with battery energy storage systems

playing a key role. As a leading designer and constructor of electricity generation and storage assets, UGL has delivered 17 major renewables generation and storage projects,” Santamaria says.

UGL has commenced work on the project, which is expected to be completed in late 2024.

Neoen Australia Chief Executive Officer Louis de Sambucy commended UGL for its hard work.

“This is our third big battery with Tesla and UGL, and we appreciate being able to leverage the experience and trust built across a number of years for our first major project in Western Australia,” de Sambucy says.

34 ROADS AUGUST 2023 NEWS

The next generation trains are being used as part of ongoing tests for the Metro Tunnel in Melbourne.

The Collie Battery will provide short duration storage in peak times to ease pressure on the local electricity grid.

MOVING TOMORROW, TODAY WWW.SANYAUSTRALIA.COM.AU WWW.SANYAUSTRALIA.COM.AU

A FRESH PERSPECTIVE

CHANGES IN UNDERWRITING AGENCIES OF AUSTRALIA’S SENIOR LEADERSHIP ARE SET TO PRESENT NEW OPPORTUNITIES FOR THE ORGANISATION AND ITS CLIENTS, AS WELL AS THE WIDER INDUSTRY.

Underwriting Agencies of Australia (UAA) has recently undergone a period of change.

Throughout its 30-year history, the company has withstood global impacts, such as the Global Financial Crisis and lasting impacts of the COVID-19 pandemic.

Now the company is strengthening its position as one of Australia’s largest providers of specialist plant and machinery insurance solutions, in part due to changes across some of its executive and senior leadership positions.

The most notable change is the announcement of Stan Alexandropoulos as UAA’s new Chief Executive Officer.

Alexandropoulos, formerly the Chief Operating Officer, says multiple factors influenced the leadership changes.

“Firstly, our previous CEO retired, creating an opportunity for transitions within the company,” he says.

A core component of this has been maximising new opportunities from across the sector.

“The timing of these changes also aligns with our merger with MECON, which has brought together two strong brands, each excelling in their respective fields,” Alexandropoulos says.

“The merger of UAA and MECON presents an opportunity for synergy, as the two brands complement each other to a degree. By making these leadership changes now, we can focus on increasing the efficiencies of both organisations and enhancing their abilities to effectively serve our customers.”

The merger combines two of the leading providers of insurance solutions for their chosen industries (plant and machinery and construction insurance respectively).

Throughout the merger process, emphasis was placed on providing continuity and stability in leadership, with Glenn Ross staying put as MECON Insurance CEO.

To further support the cohesion between both organisations, George Grasso will

Ross says the cultural change driven by the executive team offers an exciting future for both companies.

“[It’s created] a stronger and more cohesive management group with fresh initiatives, one of which is an expansion of the claims area with a heightened focus on service and expedient settlement times,” she says.

She says the leadership changes will also aid with an alignment of company values between UAA and MECON Insurance.

“Establishing a clear path of alignment for the direction of the company will see service standards enhanced, to both company and client – this is a ‘win-win’ opportunity,” she says.

AN EXCITING OPPORTUNITY

Another significant change is the appointment of Marc Crossman as the Group Strategy and Distribution Manager.

Crossman will oversee the sales and market strategy of both UAA and MECON Insurance. He’ll also manage strategic relationships and oversee the global marketing and branding work for the group.

He’s excited for the new opportunity, and says the changes will open new doors for growth and expansion into new markets.

“The goal is to enhance our offerings

36 ROADS AUGUST 2023

Stan Alexandropoulos, UAA’s new Chief Executive Officer.

to the industries we insure, drive future innovation, and continually improve our services,” Crossman says. “The infusion of new leadership perspectives sets the stage for innovation, enabling UAA to embrace emerging technologies and pioneer new approaches to insurance services.

“Ultimately, these opportunities ensure that UAA remains at the forefront of the industry, delivering exceptional value to its clients and stakeholders.”

Crossman is not shy of change and growth. He played a key role in UAA’s expansion into the Asian market in 2019. He says that changes, such as those to the UAA and MECON Insurance’s executive team, can help gain a competitive edge in the market, due in part to potentially improving productivity.

“The leadership changes are expected to increase operational efficiencies across the organisation,” Crossman says. “With a more focused distribution strategy, streamlined underwriting processes, and improved claims management, the UAA Group will be better positioned to optimise resources and deliver a higher level of service to our customers.”

He adds that he expects the leadership changes to help further improve the experiences of clients and partners across both UAA and MECON Insurance.

“While it’s still early days, I’m confident that with the support of the UAA and MECON teams, we will make significant strides in achieving our objectives,” Crossman says.

“Together, we can shape the future of the organisation and make a lasting difference in the industry. The possibilities are endless, and I am eager to embark on this exciting journey ahead.”

While only months into his new role as UAA CEO, Alexandropoulos says he’s already seeing an impact.

“Through improved experiences, enhanced offerings, innovative solutions, and a continued commitment to excellence, we aim to solidify our position as a trusted partner and provide the best possible service to our clients,” Alexandropoulos says.

“There seems to be a real buzz around the business at the moment and a renewed vibrancy and enthusiasm which is really encouraging.

“I am really excited about what the future holds.”

“WITH A MORE FOCUSED DISTRIBUTION STRATEGY, STREAMLINED UNDERWRITING PROCESSES, AND IMPROVED CLAIMS M ANAGEMENT, THE UAA GROUP WILL BE BETTER POSITIONED TO OPTIMISE RESOURCES AND DELIVER A HIGHER LEVEL OF SERVICE TO OUR CUSTOMERS.”