STAY

One of the world’s largest construction equipment manufacturers is eyeing further expansion across Australia

A SUSTAINABLE ‘MASTER’ CLASS

A brand-new range includes world-first materials and processes to support sustainable infrastructure development

SAVING LIVES SUSTAINABLY

A greener alternative to traditional road barriers has been found to be more sustainable, while outperforming and outliving conventional designs

COVER STORY

6 Here to stay XCMG is synonymous with its Chinese origins, but in the past few years the company has been knocking louder on the door of the Australian market.

ROADS REVIEW

10 We asked the industry, ‘Despite ongoing industry challenges, what innovations or achievements are giving you optimism for the sector’s future prosperity?’

COMPANY PROFILE

12 Challenges and triumphs

R&S Grating’s story and ongoing success can predominantly be attributed to the company’s commitment to family, and the legacy of its past leaders.

SUSTAINABILITY

16 A masterclass in sustainability

Continual innovation and a commitment to community has led to a brand new, worldfirst development from Hiway.

19 Saving lives sustainably

The ArmorZone temporary barrier is not only more sustainable than conventional road barriers, but it’s also proven to outperform

PROJECT REPORT

24 The future of rollers In striving for optimum sustainability, Transport for NSW has tendered 38 Soil and Asphalt Dynapac double drum rollers.

TECHNOLOGY

26 Data done right

National civil engineering provider Civiltech Solutions has released its latest road data tracking innovation.

29 Optimising infrastructure design Automation and positioning technology provider Aptella has acquired Synergy Pavesmart, a paving services business.

32 Lighting the way

Orca Solar Lighting is distinguishing itself as a premium provider of solar lighting solutions for the road and rail sectors.

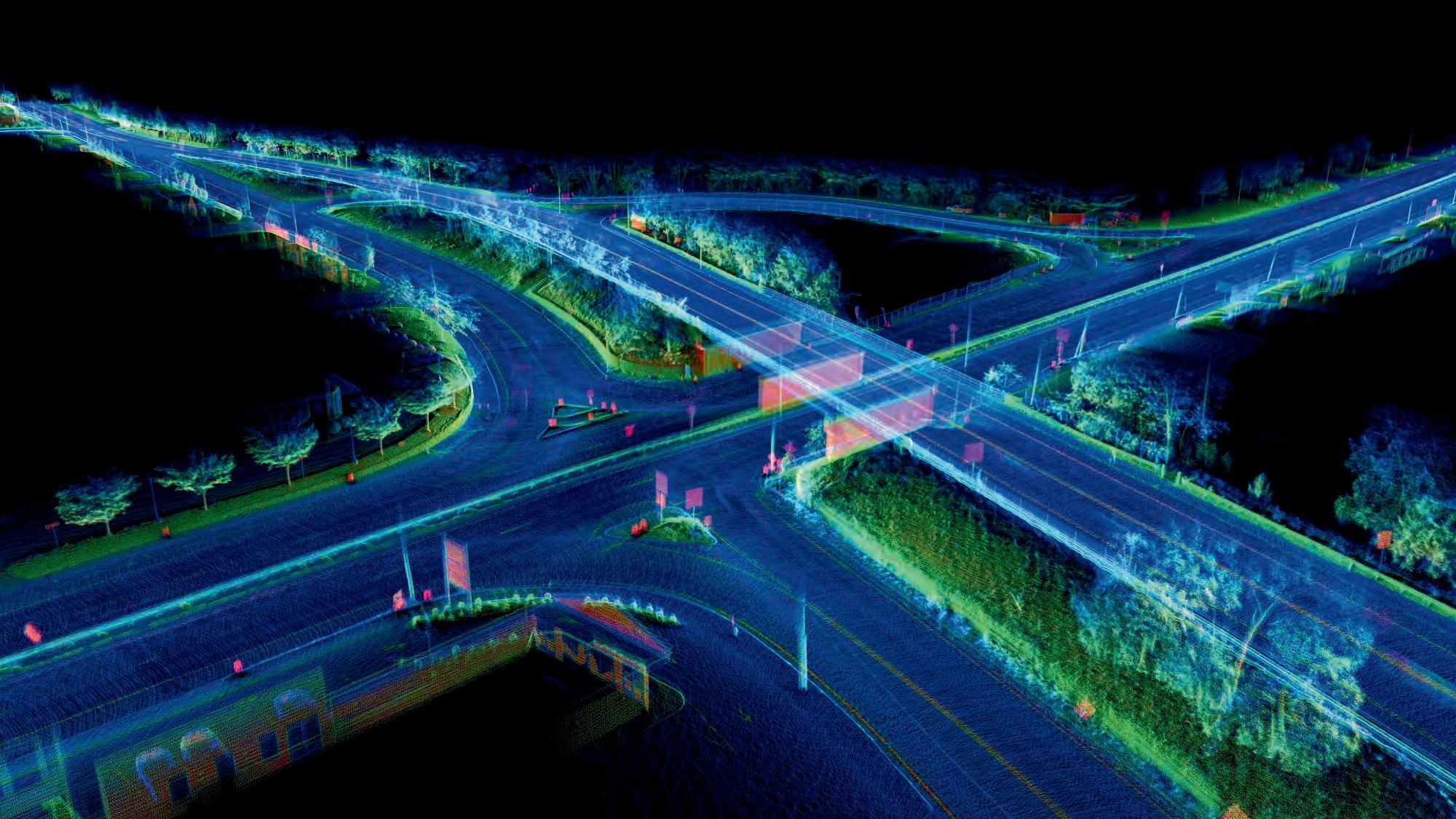

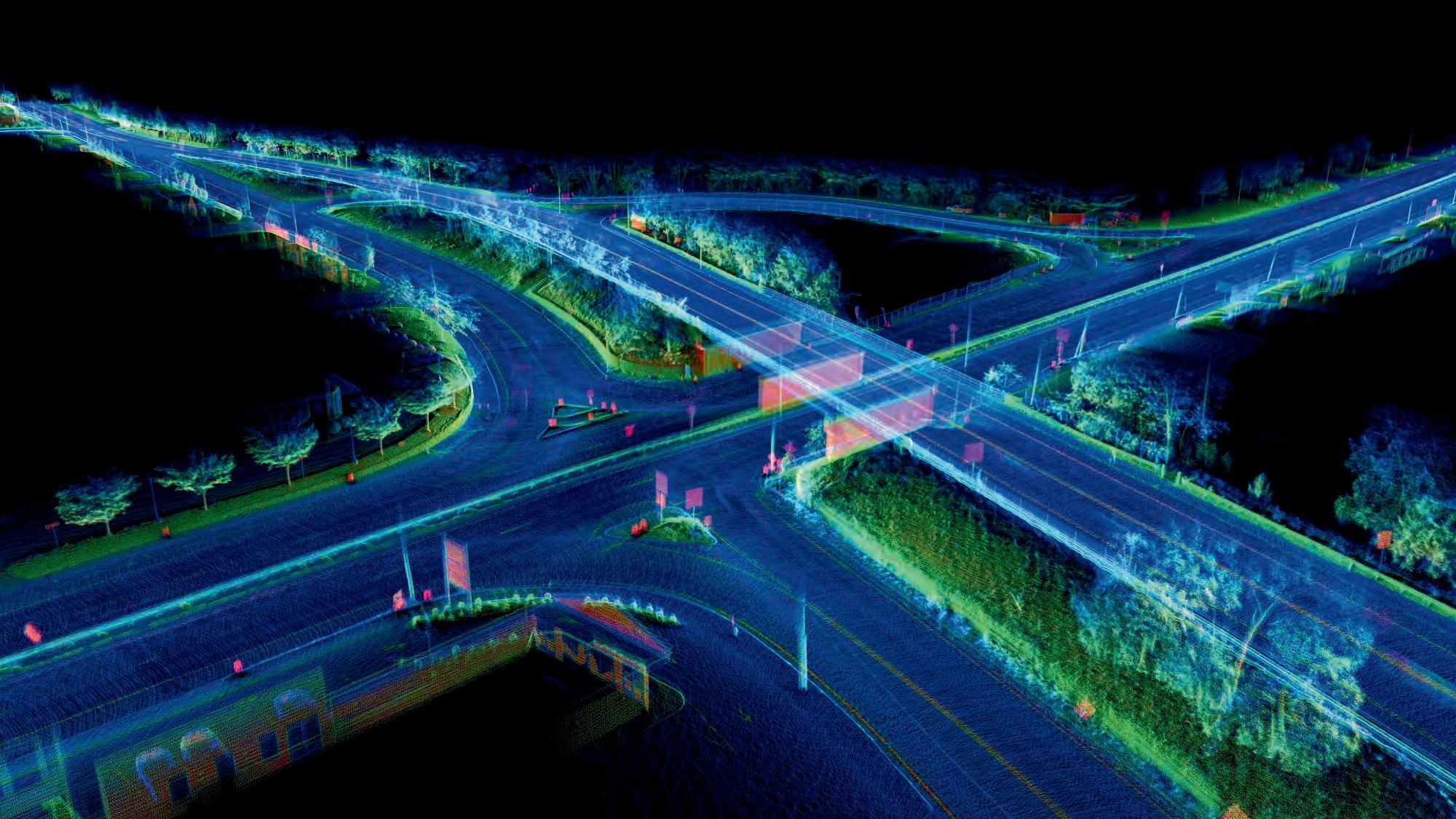

35 Your eye in the sky

Komatsu’s Smart Construction Edge 2 platform is transforming conventional surveying methods, offering a more efficient and safer alternative.

MACHINERY & EQUIPMENT

38 Getting the job done Holz Heavy Haulage has long used TRT trailers as a vital component in delivering its transport services.

41 Years in the making Primal Surfacing continues to benefit from Specialised Roading Equipment’s service.

44 Changing lanes

Hitachi Construction Machinery is expanding its wheel loader range, developing a line suitable for infrastructure and rail works.

47 One direction for safety

Quality Fabrication & Engineering’s Road Ant is helping to inspire the development of safer and more sustainable road construction machinery.

51 New names, same quality

Caterpillar is renaming several machines in its vibratory soil compactor range as part of a renewed approach to its nomenclature.

INNOVATION

55 Innovation for all Madison Express continues to innovate in the infrastructure space for the betterment of the entire sector.

EVENTS

57-58 A rundown of a number of upcoming events worth keeping an eye on.

ASSOCIATION SECTION

59-61 Hear from leading industry associations on the matters affecting the sector right now.

CONTRACTS

62 Roads & Infrastructure Magazine provides an update on some of the contracts and tenders recently awarded or put to market across the sector.

Material innovation, technology and safety are all focal points for Roads & Infrastructure Magazine’s October edition.

Elevate your worksite efficiency with Komatsu Excavators. Engineered for strength and precision, these machines redefine durability in every dig, conquering any terrain effortlessly.

WHAT’S NEXT?

COVERING TRAFFIC MANAGEMENT, materials innovation and the rental market as part of the October edition of Roads & Infrastructure Magazine has filled me with hope and anticipation for the sector’s growth in the remaining months of 2024.

While 2024 has undoubtedly presented its challenges, from ‘lulls’ in the construction equipment market, to those provided by a lack of funding and legislative flexibility at a government level, I can sense the sector is ramping up momentum to face these trials head on.

In this month’s cover story, we sat down with XCMG General Manager Roy Rossini, one of the key leaders behind the construction equipment manufacturer’s push into the Australian market. Already one of the world’s oldest and largest equipment manufacturers, XCMG is aiming to build upon its existing presence in Australia to tackle new markets, while offering what Rossini believes to be “best-in-class machinery.”

Road worker safety is another topical subject at the moment, with tragic and untimely deaths and injuries providing a big wakeup call across the roads sector. To learn more about what’s happening in the space, as well as what more can be done, we hear from the Traffic Management Association Australia (TMAA). The TMAA recently conducted its annual National Traffic Controller Safety Survey, a comprehensive study shedding light on the experiences and concerns of workers across the country. These unique insights will help to better cater for the immediate and long-term needs of these (at times) at-risk workers.

Products such as Ingal Civil’s ArmorZone are the types of solutions that are helping to improve workplace safety for the better. The updated ArmorZone introduces recycled plastic into its design, enabling this innovative road barrier to not only be a safer option for infrastructure projects, but also a sustainable one.

Also in the October edition, we touch base with our key association partners to learn more about pressing issues in the sector.

The Australian Flexible Pavement Association, a long-time partner of the magazine, provides more insight into its proposed National Worker on Foot Awareness Online Course, which aims to encourage member organisations to invest in the safety and wellbeing of their workforce.

We also sit down with AustStab’s new Chief Executive Officer, Tanja Conners. Leading the Pavement Recycling and Stabilisation Association, Conners is hoping to bring in an exciting future for the organisation and its members.

This and so much more, in the October edition of Roads & Infrastructure Magazine

Happy reading!

Tom O’Keane Roads & Infrastructure Magazine

COO

Christine Clancy christine.clancy@primecreative.com.au

PUBLISHER

Sarah Baker sarah.baker@primecreative.com.au

MANAGING EDITOR

Lisa Korycki lisa.korycki@primecreative.com.au

EDITOR

Tom O’Keane tom.okeane@primecreative.com.au

JOURNALIST

Jennifer Pittorino jennifer.pittorino@primecreative.com.au

HEAD OF DESIGN

Blake Storey

ART DIRECTOR

Bea Barthelson

BUSINESS DEVELOPMENT MANAGER

Brad Marshall brad.marshall@primecreative.com.au

CLIENT SUCCESS MANAGER

Salma Kennedy salma.kennedy@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive, Docklands VIC 3008 Australia p: +61 3 9690 8766 enquiries@primecreative.com.au www.roadsonline.com.au

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au

Roads & Infrastructure Australia is available by subscription from the publisher. The rights of refusal are reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COVER IMAGE XCMG

COPYRIGHT

Roads & Infrastructure Australia is owned and published by Prime Creative Media. All material in Roads & Infrastructure Australia is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without the written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Roads & Infrastructure Australia are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

TO STAY HERE

XCMG IS SYNONYMOUS WITH ITS CHINESE ORIGINS, BUT IN THE PAST FEW YEARS THE COMPANY HAS BEEN KNOCKING LOUDER ON THE DOOR OF THE AUSTRALIAN MARKET. WE SPEAK WITH THE MAN BEHIND THE RE-LAUNCH AND ESTABLISHMENT OF XCMG IN AUSTRALIA.

XCMG is well known for its Chinese heritage, being one of the world’s three largest manufacturers of construction and heavy equipment.

But what some might not know is that XCMG has been operating in Australia for close to two decades. Today, XCMG has an extensive dealer and part network throughout the country, with capability to provide services nationwide.

The company’s status in Australia certainly didn’t come by chance, as General Manager Roy Rossini – XCMG Mining Equipment Australia can attest.

Just prior to 2020, XCMG finalised plans for further expansion into the Australian market. All it needed was a key figure that could help deliver this transition. When XCMG came knocking, Rossini says it was a tough opportunity to refuse.

“I’ve been in the construction and mining sector for over 40 years, working for several OEMs and working in my own business. COVID hit, and XCMG were communicating with me openly for a period, I’d seen them at a few trade shows,” he says.

“XCMG itself is a company that’s been successful overseas since the 1940s, in the very top tier of companies in the world in the construction and mining sectors.

“They offered me the opportunity to come and assist the building of their presence in Australia. They’ve already been here previously for about 17 years, but only in a small and modest way. Their previous approach was to bring a few machines over, sell them, then return to China. They didn’t have plans to establish a support network in Australia. That’s where I came in.”

From humble beginnings, Rossini made his mark and influenced the direction of the machinery manufacturer’s early years in Australia. A challenging, but enjoyable part of his role, as he explains.

“We started off with just one container with a bunch of products. After we unloaded them on site in Melbourne, we put the first machines out and started making modifications to improve the product. After that, I set up a dealer network from contacts that I already had in the industry, some of which I’ve known for many years,” Rossini says.

“We had more products coming in and we had a bit of instant success. In three years, we sold around 3000 units.”

THE AUSTRALIAN CRITERIA

Rossini says tailoring the existing product and service offering to best suit the Australian market was one of the first key steps to establishing XCMG’s presence domestically.

“The support and service network that you need to give to any market to make it successful is quite unique in Australia,” he says. “The number one priority was the need to set up a reputable dealer network, with dealers who had service

XCMG’s grader and roller portfolios continue to expand, as does its presence across Australia.

XCMG’s roller range has been configured to specifically suit Australian applications and projects.

and technical experience, support networks themselves with people on the ground and most importantly, people who understood the industry.”

The second step was establishing a headquarters for the planned expansion, a central site to support the national network.

“To have that base, which could have a million dollars’ worth of spare parts on the shelves, and technical people on the ground was imperative,” Rossini says. “Now we have long-term staff, a lot of whom have 20-30 years’ experience.

“They come with a unique set of qualifications and life experiences that helps to form the backbone of our business. Now we’ve got the equivalent of hundreds of years of experience injected into the organisation. Without that, we wouldn’t succeed.”

For its headquarters in Hallam, Melbourne, XCMG’s next phase is focused on having the systems in place to support additional growth and development, an aspect the XCMG team is still working on today.

Rossini adds that while all these steps have been crucial for establishing a sturdy foundation for future success, the most basic requirement is also the most important –having a decent product.

“You can’t go anywhere if you don’t have equipment that’s got great quality and is value for money for your customers,” he says.

“We’re not afraid to change as required within the industry. A key factor of our success has been listening and considering customer feedback, which has helped to

shape product modifications and changes to our support network.

“From my point of view, XCMG has been, and still is, second to none in this area. I’ve never worked for an organisation that makes changes this quickly if there’s improvements to be had. It’s a unique operation here and we’ll continue to do that.”

MACHINERY RANGE

A core component of XCMG’s product range for the construction sector is its motor graders and rollers. These machines could be considered XCMG’s ‘bread and butter’ and as Rossini explains, are setting the standard for versatility and performance.

“Our graders have benefitted greatly from a joint venture with Rio Tinto, who have helped us to better develop and adjust the product to suit,” he says. “That includes our GR2605, which has a 14-foot blade, along with 260 horsepower.”

The GR2605 has been designed to suit motor grading projects of any scale, thanks to its blade pitch and grading precision, which make it an ideal candidate for several applications including surface levelling, not just road grading in isolation.

“We’re moving on to our stage two cabin design, which gives the operator greater visibility, while being more ergonomic. It’s an extremely viable product for the market, the price point is reasonable, and the quality is very good. There’s some in the industry that have been ‘inspired’ by our designs,” Rossini says.

XCMG has made a name for itself internationally thanks to the robustness and performance of its machinery.

Another exciting aspect of XCMG’s grader range has been its ventures into the battery technology space, with the company developing a variety of prototype, batterypowered graders.

“We will have the first grader in the world to run on battery energy and those concepts have already been realised through our prototype models,” Rossini says.

“We already have joint ventures and partnerships in place, along with a dedicated team in China. We’ve committed a lot of resources, it can be a challenge to implement that technology into massive machines, but we’re making progress right across the board in the battery space.”

When it comes to rollers, XCMG manufactures a variety of both single and double drum models, ideal for both paving roads and compacting soils.

Whether it’s a smooth drum roller, dirt packer, or a ride-on vibratory roller, Rossini says the XS123 is just one in a suite of rolling options for the Australian market.

“The 12 tonne is among the most popular in the marketplace at the moment,” he says. “Feedback has been really positive around that model and it’s a product that continues to progress with each of our factories dedicated to getting it right.”

XCMG is also aiming to implement brand new technology into its future roller units, this time in the form of autonomous operation. Operators should keep their eyes out, with the autonomous options set for a wider rollout soon.

These products and much more are backed up by XCMG’s support and servicing networks across the globe, an aspect that’s been instrumental in the growth of XCMG in Australia.

“We always keep the line of communication open between sites, so whether it’s a customer or a matter for us, we can speak directly with an engineer in the factory,” Rossini says. “Whenever we have any issues or suggestions, we can have those conversations quickly.

“I might be standing with a customer in front of a unit, and they might say the seat needs to move, or they’re used to the armrest being in this position, or they might need better visibility in a certain situation. Usually, a big manufacturer would just say ‘too bad, that’s how we make them’, but we don’t.”

FUTURE PLANS

Reflecting on the progress made, Rossini says he’s “extremely proud” of how XCMG’s

venture into the Australian market is progressing, from an initial foray, to now an established and growing international brand.

He says the collective minds of XCMG domestically, as well as the company’s vast international experience is ensuring that the manufacturer is rising in the ranks of Australia’s premier construction machinery brands.

“It has not been a small task by any means, it’s been a huge challenge. To see what we’ve done, building from nothing to where we are now in such a short time, that’s a massive achievement,” Rossini says.

“At the end of the day we’d be nowhere if it wasn’t for the team’s effort. They’ve all dedicated so much to reach the position that we’re in today. That’s the benefit of having people with so much experience in the sector and having established relationships. I trust what they’re saying and the direction they want to go and likewise, it’s a strong collective.”

And while it won’t happen overnight, XCMG has its sights firmly set on the top step of the podium.

“We don’t shy away from the fact that we’re gunning to be number one in the world. That’s what we’re aiming and growing towards. On top of our customer’s needs, that’s what pushes us every day.”

FREO GROUP INVEST IN INNOVATION

Freo Group’s Principal Assessor, Chris Everleigh, conducted a comprehensive two-day inspection of the TIDD Crane, evaluating its drivability, manoeuvrability, comfort, and operational lifting capability. Chris rated the crane a perfect 10/10 across all categories, stating:

“The TIDD Crane is very comfortable with the latest technology advancements, all coupled with TRT’s team of great knowledge. The TIDD is a very well-refined crane, 10/10.”

PETER ALI, CEO – MUNICIPAL WORKS

AUSTRALIA

The adaptability and commitment demonstrated by the next generation of municipal works practitioners gives me the most optimism. They are incredibly talented and use social media and other emerging technologies to create professional networks and share ideas. Their openness to new ideas and approaches reassures us that non-traditional solutions to long-held problems will continue to emerge. For example, we now see increased use of recycled materials in traditional pavement designs. The type of materials used is growing, and approval processes from regulatory authorities to use these products are faster. Image: Municipal Works Australia.

TANJA CONNERS, CEO – AUSTSTAB

Despite the ongoing challenges facing broader industry, AustStab’s outlook is with significant optimism driven by innovations and achievements in sustainable pavement recycling and stabilisation practices. These advancements are steering the sector toward net zero emissions, particularly through the development and adoption of cutting-edge recycling technologies that reduce the need for virgin materials and the generation of construction waste. Techniques like insitu stabilisation and cold recycling are not only extending the lifespan of existing infrastructure through resilience but are also minimising the carbon footprint associated with road rehabilitation. Additionally, the decarbonisation of our material inputs through increased use of renewable energy and recycled materials in stabilisation processes is helping to lower greenhouse gas emissions. These sustainable practices are proving that with the right strategies, our industry can play a pivotal role in the global push toward environmental stewardship while ensuring the longevity and quality of our roads. Image: AustStab.

MICHAEL CALTABIANO, CEO – NATIONAL TRANSPORT RESEARCH ORGANISATION (NTRO)

From adversity comes innovation because doing the same thing results in the same outcomes. The infrastructure industry has been rocked by cost escalation and must now deliver on a culture of being “innovation driven”. This requires a genuine partnership with government and entities like NTRO that provide the bridge to certify the development of new standards for new products. Image: NTRO.

If you or someone at your organisation is an industry leader and would like to be a part of this monthly column in 2024, please get in touch with Editor, Tom O’Keane: tom.okeane@primecreative.com.au

COMPACT SIZE CAN MEAN

A HUGE ADVANTAGE

CAT® AP400 ASPHALT PAVER

The Cat® AP400 is the perfect machine for those asphalt paving jobs where space is at a premium.

It’s got the compact size, flexibility and versatility you need, especially in built-up urban areas.

Plus, when you purchase a new Cat AP400, you’ll also have the option of:

• access to locally supported parts via the national dealer network

• a comprehensive warranty package

• a Cat Customer Value Agreement (CVA).

To find out more contact your local Cat dealer or visit cat.com/AP400-au

CHALLENGES AND TRIUMPHS: THE R&S STORY

R&S GRATING’S STORY AND ONGOING SUCCESS CAN PREDOMINANTLY BE ATTRIBUTED TO THE COMPANY’S COMMITMENT TO FAMILY, AND THE LEGACY OF ITS PAST LEADERS. TIM HOCKHAM AND STEVE SKINNER REFLECT ON THE PAST AND SHED SOME LIGHT ON THE FUTURE.

Not many businesses across the roads and infrastructure sectors began their journey in a backyard stable. But then again, Road Safety Grating (R&S Grating) has always succeeded in doing things a little differently.

Back in 1974, a small backyard stable in Mentone, Melbourne was the backdrop for what would become one of Victoria’s oldest and leading supplier of high quality grates into Melbourne’s major road projects, and eventually a leading civil drainage supplier.

All of this kicked off when the late Stephen “Stevo” Hockham and his brother sought to establish a modest business, focused on the manufacture of welded steel grates.

As Steve Skinner, National Sales and Business Development Manager – R&S Grating explains, Stevo’s desire for success was a key factor in the company becoming a

favoured grate supplier across Victoria for decades.

“To give you an idea of how things got started, someone came to Stevo one day and said ‘you should make grates’. That’s honestly where the business came from,” he says. “As Stevo would tell it, the story goes that he made the grate, the customer said it was the best he’d ever seen, and he asked if he could have another.

“I’m not sure if they even had a horse in the stable,” Skinner jokes. “It all started with Stevo. He was very passionate about grates. You think ‘how can you be passionate about grates?’ But he found a way, and that shone through in everything that he did.”

Skinner first joined the company over ten years ago, when R&S Grating was already an established and wellregarded manufacturer.

“I think the word got out that I wasn’t

working for my old company, so Stevo approached me to come and work for him,” he says. “His pitch was as simple as ‘I want you to come and work for me’. It started with a phone call, I came into the office to see him, we had a great chat and he gave me two bottles of wine.

“I thought ‘that’s the first job interview I’ve ever done where I’ve walked away with two bottles of wine’. That was Stevo, he’d bend over backwards for anybody.”

Stevo was much more than just the Founder and patriarch of R&S Grating. He’s a life member of Municipal Works Australia, an organisation that he was heavily involved and committed to. He’s also highly regarded in the local community.

Skinner says there are plenty of stories when it comes to Stevo, with most providing some insight into his selfless and considerate nature. Hence his wellknown nickname, the “Grate Man”.

“Years back, Stevo took a trip to the United States. He stayed up in a room that overlooked Niagara Falls. He thought it was one of the best things he’d ever seen. There were a few people at the business who were thinking of going on a holiday, so he said, ‘if you go over there, I’ll pay for your room to overlook the Niagara Falls, you have to see it’. He did

that for a couple of people and the offer was there for everyone,” he says.

“He’d take generosity to another level, and he always looked up to other people in the business, not down. You had to do something seriously wrong to get on his bad side, I’m not even sure if he had one.”

Widely known for his humour, humility and generosity towards R&S Grating’s customers – as well as the wider community – Stevo’s passion and determination endure through his three sons, all now working in the business, including his eldest son, Tim.

For Tim Hockham, R&S Grating was always a part of his life growing up.

“My earliest memories of the company are coming to work with Dad in the 1990s, I would’ve been about 12 at the time,” he says. “In those days, Dad would bring Pop along as well to help out. The company was much smaller then.

“There’s a lot of things that have changed since those days.”

A constant theme throughout the years has been a strong connection to family, as well as the past. As Hockham explains, he’s one of many employees who have a strong family connection to the business.

“It’s not just about my family and I think that’s what sets us apart. All our employees and their families really care. Everyone wants the business to do well, everyone wants each other to succeed. We really care about each other and that generational factor plays a big part in that,” he says.

Taking over the mantle from his father, Hockham is among the company’s leaders who are helping to settle the ship, with enduring market challenges not making life easy for the R&S Grating team.

The most important thing is that the team has each other, he says.

“The family element has been in this business since it started. It’s not just our family, there are many multi-generational family relationships across the business.”

Malifa Taeleipu, Production – R&S Grating, started coming to R&S Grating in 2006, helping his father Sam.

Taeleipu says the strong family values of R&S Grating are reflected in his family’s close ties to the business, with his father working at the grate manufacturer for more than 20 years. Taeleipu himself is coming up on 18 years of service.

“I was originally a labourer, cutting steel for my father to fabricate. I didn’t know

R&S Grating’s early days have laid the foundation for what the company is today.

it at the time, but he took me under his wing and taught me about the real world. He’s taught me everything that I know today, and I grew to appreciate those opportunities to have lunch with Dad and spend time with him,” he says.

These experiences have been instrumental throughout his journey at R&S Grating. He adds that the support of Stevo, Hockham and Skinner, helps to create a positive workspace where integrity and honesty help to drive

“PLENTY

the year has also marked a year of celebration for R&S Grating. The company is celebrating 50 years of manufacturing in Australia.

From its beginnings in the backyard stable, R&S Grating has grown to be successful and competitive on major government contracts, helping to maintain the safety and structural integrity of grates on Melbourne’s major connections, such as the Bolte Bridge, Tullamarine Freeway (Citylink), the M80

OF OUR WEAVE GRATES ARE STILL IN MANY PLACES IN MELBOURNE, SOME HAVE BEEN THERE FOR 25-30 YEARS. AND THESE ARE CONNECTIONS THAT ARE TRAFFICKED BY UP TO 100,000 MOTORISTS DAILY.”

further product improvements.

“Stevo was always so supportive of my father and myself, he was a big part of not only work, but also my upbringing and the life lessons I learned along the way,” Taeleipu says. “The apple doesn’t fall far from the tree with Tim. His understanding and care for everyone here speaks volumes of where he and the company are heading.”

PUSHING FORWARD

While 2024 has come with its challenges,

Ring Road and the new West Gate Tunnel Project, to name just a few.

A key part of the company’s growth was the innovative Weaved Sump Grates, regarded as its signature product.

Such was the innovation and popularity of the Weaved Sump Grate that R&S Grating’s initial concept was subsequently re-created by competitors in the market.

“At the time we weren’t getting a lot of freeway work, even though we had the best product for freeways. We had one of our weave grates tested and we

discovered that the grate had exceptional load sharing capabilities. After a report was conducted, we learnt that the uplift was greater than the downforce,” Skinner says.

“Effectively we were building a bridge, so we needed to have bridge-inspired technology in our grates if we wanted them to last. That’s where the extra bolt down came from. Plenty of our weave grates are still in many places in Melbourne, some have been there for 25-30 years. And these are connections that are trafficked by up to 100,000 motorists daily.”

R&S Grating’s weaved grates continue to be a popular solution. Hockham says it’s the versatility that’s added to the design’s longevity.

“We introduced the weaved grate in 1992, which coincided with the introduction of Australian Standards for access covers and grates,” he says. “Councils might’ve had their own requirements and standards, but there was nothing on a national level.”

The weave grate was among the first to provide a bike safe grate, with most

grate manufacturers at the time going for a traditional design. The way it’s welded makes it a very strong grate and more efficient by enabling the load bars to be at larger gaps, meaning less steel is involved in manufacture.

“Suddenly you had a very strong grate that was efficient, lighter and cheaper to produce, while also being bike safe. It was a big innovation that a lot of councils jumped on,” Hockham says.

“We look to continually innovate. We have an unwritten policy not to stagnate anywhere. We’re always looking at improving our products and optimising them to keep us competitive. That happens right across the board.”

This spirit of innovation lead to another success story for the company, with the development of its SMC Ecolite range of light-weight composite pit lids.

“We introduced a composite lid range around 15 years ago now,” Hockham says. “There were options available in the market, but these were made from a timber core, coated in fibreglass and were prone to damage and structural collapse. We introduced the

first full-depth composite pit lid into the market and worked hard to engineer it to be the lightest and strongest available. The hard work paid off and we’re now the leading supplier of composite pit lids in Victoria.”

For Skinner, it’s product consistency that continues to put R&S Grating in the box seat for upcoming contracts and opportunities.

“It’s extremely rare that one of our products fails. Occasionally we might lose a contract, then six to 12 months later, the contractor will come knocking at our doors asking if we can replace it,” he says.

“There’s been some horror stories where cheaper grates have been installed that don’t meet specifications and aren’t as safe as products made in Australia. R&S Grating has always had a reputation for quality, but it can be challenging when cheaper imports enter the market.

“At the end of the day, our grates work, and they’ve worked for years. The quality of our grates is the statement that we make to the sector. You put our product down, then you don’t need to worry about it again for years to come.”

LEAVING A LEGACY

When it comes to the future, Hockham says maintaining and improving R&S Grating’s product range is at the top of the priority list. So is continuing the strong platform for success that his father built.

“Dad was very proud to see one of his products in the ground. I just want to keep seeing our grates on important infrastructure. Seeing the R&S Grating name around Melbourne, as well as the growth of our team, is what fills me with the most pride,” Hockham says.

“Just the fact that we can have such a presence is amazing and it’s something that my family and many other families have been working on for five decades.”

He says, R&S Grating isn’t perfect, sure, but the drive of its team to eradicate imperfections is what’s helping to elevate its products and services from others in a competitive market.

“We don’t want anyone to remember R&S from our mistakes. We want to be remembered for what we did about those mistakes,” Skinner says.

“Even if it’s not our mistake, we approach each case in the same way. That’s who we are as a business.”

A MASTER-CLASS IN SUSTAINABILITY

CONTINUAL INNOVATION AND A COMMITMENT TO COMMUNITY HAS LED TO A BRAND NEW, WORLD-FIRST DEVELOPMENT FROM HIWAY. JIM APPLEBY AND ALLEN BROWNE EXPLAIN WHAT THE NEW MASTERS RANGE MEANS FOR SUSTAINABILITY IN INFRASTRUCTURE AND SOCIETY, AS A WHOLE.

Sustainability is a concept that many companies claim is close to home. However, for a few, sustainability isn’t an additional focus area, but an aspect that guides every operational decision.

Hiway is one such company that’s constantly looking through a sustainable lens, assessing every opportunity in the hope to optimise the decarbonisation and long-term sustainability of its products and services while meeting performance requirements.

Sustainability is also an aspect that hits close to home on a personal level, especially for Hiway Chief Operating Officer Jim Appleby.

“We’re in an age now where carbon reduction is front and centre. Sustainability is rightfully getting the attention it deserves. At Hiway we have been working for some time on a range of sustainable outcomes that gives exactly what our clients need, all framed around carbon reduction and without technical compromise.” Appleby says.

“It’s exciting because I promised my daughters that we’d reach a sustainable future, and to be part of something that’s driving a better world makes me very proud.”

Allen Browne, Executive General Manager, Technical and Innovation – Hiway, says the company has a rich history in the sustainability space, helping the sector Australia-wide to achieve lower carbon outcomes.

“The company’s been recycling via the use of conventional or innovative binders for 38 years,” he says. “The market has come to us and recognised the importance of recycling and sustainability.”

Over the past 38 years, Hiway has worked closely with its customers to understand their needs and many of the issues surrounding traditional infrastructure products and service offerings. This understanding, combined with the company’s extensive research and development capabilities (and partners), has led to what Appleby and Browne refer to as the “global standard in sustainability and performance”.

As part of the company’s strong history

of adaption, Hiway is making changes to its internal structure to better cater for the needs of the market.

“We have a significant presence across Australia. We have operated under some incredible brands in different locations including SAT Civil in Queensland, W.A Stabilising in Western Australia and Hiway Stabilizers in all other states,” Appleby says.

“As part of our journey, we’re bringing all our brands under the one umbrella – a consistent brand under a consistent message. This will help to create a uniform approach to meet and drive our value for clients across all geographies.

“It’s giving commonality with no technical compromise, with no change to how we operate and even more belief in what we’re trying to achieve as a business.”

This rebrand echoes Hiway’s original DNA of being road recycling and stabilising practitioners, increasing its design and materials capability over time. Sustainability has been a constant, with the Masters Range set to further support its notion that ‘Our

communities deserve it. Our environment depends on it’.

THE MASTERS RANGE

Hiway’s Masters Range is a collection of products and solutions with innovation at its core, focused on sustainability, durability and unsurpassed performance.

The Masters Range is ultimately designed to improve the quality of life and create a better future for the customers, communities and multiple sectors that Hiway services.

On top of its sustainability benefits and potential, the Masters Range will also help to provide unprecedented transparency to ensure that contractors and engineers are using the best and most suited option for their projects. As Browne explains.

“I see the Masters Range as a platform for clear, unambiguous messaging of the different applications and best utilisation,” he says.

“Broad terminology can create issues for engineers and the industry, that’s why we feel that the Masters Range allows us to better pigeonhole where some of the conventional and non-conventional binders sit.

“The amount of material you put in will determine the strength, durability, ability to handle deflection and related performance measures. The Masters Range will help designers cut through that uncertainty by showing what’s required to provide a different outcome.”

Just one of the highlights within the Masters Range is the recently developed MasterCarb A, carbon negative pavement, which has been developed in conjunction with research partner C-Twelve.

A world-first pavement solution, MasterCarb A delivers a cold in-situ recycled asphalt with superior load capacity, durability, and moisture resilience. Setting a new standard for basecourse layers, it’s both time and costeffective while, critically, achieving a carbon negative outcome for the entire process. With high modulus, fatigue capability, rut resistance and reduced construction times, MasterCarb A, along with the wider Masters Range, will help to reduce quarrying and cartage of virgin materials, therefore reducing the strain on Australia’s transport network and precious aggregate resources.

When discussing MasterCarb A, Appleby says: “To say it’s catching people’s attention would be an understatement. When you talk about the performance levels that are being achieved and the carbon negative outcome that’s associated with it, it’s groundbreaking.”

Hiway’s MasterCarb A represents an exciting

advancement in pavement technology with decarbonisation at its core. By blending a proprietary modified binder with a laboratory-designed carbon sequestration medium, this solution delivers a robust, high performing pavement that surpasses conventional solutions and plant-produced dense asphalt. The innovative approach behind MasterCarb A lies in its utilisation of recycled materials to produce a pavement that exhibits asphalt-like characteristics, yet outperforms hot-mix asphalt, while delivering maximum environmental benefits.

Findings from a recent large-scale project in Watheroo achieved a carbon negative outcome of minus 54,200 kilograms in

“The Masters Range will incorporate materials, services and processes, all formulated to give a client a different outcome to what they might’ve been able to achieve in a traditional format. It’s not just about materials, it’s about solutions” he says.

“There’s a dozen Masters Range processes or materials that give a whole spectrum of coverage to the transport and wider infrastructure sector to decarbonise, be more efficient and reduce costs, while providing a greater technical outcome.”

“I SEE THE MASTERS RANGE AS A PLATFORM FOR CLEAR, UNAMBIGUOUS MESSAGING OF THE DIFFERENT APPLICATIONS AND BEST UTILISATION.”

Scope 1 to 3 total carbon emissions, underscoring MasterCarb A’s significant contribution to sustainable infrastructure.

Further testing has been completed and will continue to provide greater confidence in the design and durability of MasterCarb A, as Browne adds.

“We are getting a huge amount of interest from all different sectors. We’ve done some large-scale field trials and now we’re looking to implement project level contracts both in the private and public sectors,” he says.

“The high-level research that we’re doing to support the process and provide context around performance has been important because it’s so different and so unique to conventional products. We’ve got research partners and great relationships with laboratories, it’s really exciting to see the development path from proof of concept to Masters Range roll-out.”

Appleby says the MasterCarb A is just a taste of what the overall Masters Range

Hiway is always looking to improve its products and services to stay ahead of industry requirements and demands, as the company’s history of pioneering reflects.

“To be able to alter your approach for the specific needs of the sector is a really important facet, to provide the right solution for the right circumstance. We’re very outcome and performance driven in the low emission pavement construction and rehabilitation space,” Appleby says.

With solutions such as the upcoming Masters Range, as well as the company’s rich history of developing and catering for infrastructure projects of all sizes, Hiway looks set to maintain its reputation as one of the industry’s leading innovators in the space.

But the company never rests on its laurels.

“I’m so proud of the progress we’ve made so far in the space. We genuinely want to see the best outcome for all our partners and that’s a philosophy that’s endured to this day,” Appleby says. “That’s the reason why people have been wanting to work with us again and again for 38 years. We’re still going strong and there’s no signs of slowing down.”

SUSTAINABLY SAVING LIVES,

THE ARMORZONE TEMPORARY BARRIER IS NOT ONLY MORE SUSTAINABLE THAN CONVENTIONAL ROAD BARRIERS, BUT IT’S PROVEN TO OUTPERFORM AND OUTLIVE CONVENTIONAL DESIGNS. ROADS & INFRASTRUCTURE SITS DOWN WITH THE CONGLOMERATE RESPONSIBLE FOR THE PRODUCT’S MANUFACTURE AND DISTRIBUTION TO LEARN MORE ABOUT ITS GROUNDBREAKING DESIGN.

Distracted, speeding or inexperienced drivers can pose a number of risks on local roads, not only to other motorists, but also pedestrians and nearby workers.

Protecting roadside workers has been, and is very much today, a topical subject, with many near-misses and too many fatalities still occurring.

The Traffic Management Association of Australia’s 2024 National Traffic Controller Safety Survey highlights this issue, with 49 per cent of respondents reporting that they’ve nearly been struck by a distracted driver, and 44 per cent saying they’ve had near misses due to speeding vehicles. These are just some of the reasons why road barriers – temporary or permanent – are a standard requirement for most roadside, commercial and residential projects.

In a market that’s saturated, one roadside barrier has long been a successful option for road and infrastructure projects.

A plastic unit joined together using steel pins and filled with water, ArmorZone is a temporary work zone barrier, able to be

In the past 18 months, Ingal Civil Products and its manufacturing partners have managed to build upon what was already a popular design. The aim was to make the barrier more sustainable, as John Annison, Operations Manager – Ingal Civil Products explains.

“About four or five years ago, the International Crash Rating System was upgraded because cars and trucks around the world were getting heavier,” he says. “Crash barriers had to be improved as a result and that’s when development began on the MASH version (Manual for Assessing Safety Hardware).

“A lot of our customers were upgrading their road barrier fleet to the new MASH versions, and they were looking for a way to dispose of their older barriers. We started to look into how we could recycle the older versions of the ArmorZone, as it’s a

ArmorZone barriers. One of the first steps was partnering with organisations that could facilitate material testing and application.

This led Ingal Civil to the New Zealandbased roto-moulding experts in Vision Plastics and AR Moulding.

A TEAM EFFORT

The ArmorZone barrier is manufactured using a process called rotational moulding, a process by which a plastic material in powdered form is placed into a hollow mould, before being rotated and heated, making it a cost-effective process to manufacture large hollow plastic components.

Vision Plastics (VPLAS) is a rotational moulding material specialist. Steve Lewis, Sales and Marketing Manager, New Zealand – VPLAS says the unique formula used for

the ArmorZone is what gives the product its premium performance characteristics.

“It’s a formulation that’s got a very good balance of stiffness and impact that’s required for such a product,” he says. “It’s a huge physical demand that’s placed on the plastic, which is part of the reason why we’ve got very tight specifications with our suppliers and the production process.

“We can’t substitute materials, it’s this material or nothing and it took years to develop it, which is why there’s been a number of unsuccessful replications of this product from other providers.”

To manufacture the ArmorZone barriers, Ingal Civil Products works closely with AR Moulding, who (as the name suggest) help to mould the plastic and finish the final product to ensure that it fits industry requirements and expectations.

As Jason Walker, General Manager – AR Moulding recalls, ArmorZone had long been a successful product, but the recycling aspect added fuel to the fire.

“Ingal Civil Products’ client’s desire to be different in the market is really what initially drove the recycling aspect. They were making a push to contribute more to the circular economy, hoping to have an outcome that wasn’t just sending these products to landfill,” he says.

“We all said ‘yep, we can make that happen’. The focus then was to find a percentage/mix that would work, to see exactly how much recycled and virgin material we’d require to produce a stable product that would meet industry requirements.”

As a fellow New Zealand-based business, both VPLAS and AR Moulding share a close relationship. Lewis says this professional partnership, as well as VPLAS’ strict focus around quality, ensure that Ingal Civil Products can distribute the best product possible.

“AR Moulding is about a kilometre away from our site and I’m down there nearly weekly for a catch-up, which enables us to have our raw materials supply in line with their demands,” he says.

“It takes a group effort to make sure that Ingal Civil Products is adequately supplied. There’s a lot of requirements around recycled feedstock, which we’re sourcing from New Zealand and Australia. It’s important that the recycled feedstock is controlled and we put a lot of effort into ensuring that.”

It’s a relationship that’s strengthened by a commitment to helping both companies achieve quality outcomes for their customers, as Lewis adds.

“Because we’re just around the corner, I have an intimate knowledge of their processes, to the point that I can run their machinery,” he says. “We spend a lot of time at AR Moulding, ensuring that both ours and their processes are consistent. That includes testing, which there is a lot of before all boxes can be ticked and the barrier can

“The communication and relationship between AR Moulding and VPLAS is a hugely important part of this product’s success.”

Walker says this trust between the two companies has helped to make what was

“There’s no secrets between us,” he says. “Our common goal with VPLAS and Ingal Civil Products was to make a greener plastic product. Plastic is often considered a dirty word, because most associate it with soft plastics.

Contractors can satisfy both specification and sustainability requirements for their projects by using ArmorZone road barriers.

“With ArmorZone, we’ve shown that the final recycled product can perform as good, if not better than virgin materials. We’ve demonstrated that it’s feasible to reuse plastic to give it a second life, and even maybe a third or fourth life and so on.”

PATH AHEAD

Despite only being released for a number of months, the ArmorZone – which satisfies both MASH TL-1 and TL-2 specifications – has already seen a high level of interest.

Annison attributes the majority of such interest to the changing needs of the market, where the depth of sustainable practices can make or break a tender submission.

“Both private and public sector projects across the country are adding sustainability clauses into their contracts, insisting that contractors and suppliers provide a product that’s sustainable and can be recycled,” Annison says.

“From a commercial point of view, having a barrier that ticks all of these boxes, that can give a commercial advantage, is a no-brainer. That’s being driven by our customers, as they’re the ones wanting to have sustainable products to offer in their hire fleets. The whole supply chain is on board as well.”

And Ingal Civil Products isn’t stopping there.

“It’ll take more testing and approvals, but we are looking at ways to increase the recycled content in the barrier. That’s the main driver at the moment, first and foremost to increase the recycled content. We’re fairly confident we’ll be able to,” Annison says. “It’s a great story and we’re just getting started.”

Owners of ArmorZone barriers in Australia and New Zealand can contact Ingal Civil Products for instructions on where to send their units for recycling into new ArmorZone barriers.

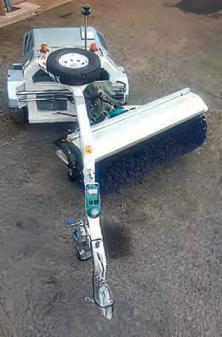

PICK THE RIGHT TOOL

Proud Suppliers of Telescopic Bitumen Sprayers to the Australasian Roading Construction market for over 20 years

Over the last 20+ years, we’ve listened to our customers’ feedback and continuously evolved our range of sprayers, meeting the specific and unique demands of the Australasian roading market.

From our brand new 4.0m emulsion only telescopic sprayer, through to our highly manoeuvrable 4.5m telescopic urban sprayers right up to our 6.0m reseal sprayers we have the right sprayer for the job – all offering the ease of use and efficiency of our telescopic spray bar.

Find out today why operators across Australia and New Zealand are ditching fixed wing sprayers and demanding SRE’s range of telescopic bitumen sprayers.

www.specialisedroadingequipment.com

Email info@specialisedroadingequipment.com

Ph +64 7 848 1197

AS PURE AS IT GETS

IN A WORLD WHERE SUSTAINABILITY IS AT THE FOREFRONT OF CORPORATE CONCERN, INDUSTRIES ARE PROACTIVELY EXPLORING THE POTENTIAL TO SUBSTITUTE A PORTION OF THEIR PRODUCTS WITH SUSTAINABLE ALTERNATIVES. AS HAMIDREZA SAHEBZAMANI, PHD, MIEAUST, TECHNICAL SERVICES MANAGER – SAMI BITUMEN TECHNOLOGIES WRITES.

Often, alternative materials are derived from waste or by-products. The primary objective of using these alternatives is to meet one or more of the following targets: enhancing technical properties, reducing carbon emissions, supporting the circular economy, improving sustainability targets, and cutting costs.

Some of these alternatives can be utilised directly without any modifications, while others necessitate additional processing to ensure safety, or to enhance their properties.

As the global drive to reduce carbon emissions and non-renewable resource usage gains momentum, it can create potential doubts. This transition may open the way for the usage of materials that have yet to be proven safe and of effective performance.

Regarding the road industry, we must bear in mind that the most sustainable road is the one that lasts the longest. There is no advantage in constructing a road with a lower initial carbon footprint but a reduced lifespan when compared to traditional ones. The carbon cost of maintaining or prematurely reconstructing pavements may negate the initial gain of low carbon footprint if the pavement doesn’t have the same longevity.

Consequently, the whole of life carbon footprint would be higher. It is also necessary to consider the rolling resistance of roads. Notably, a road that is not smooth can generate additional emissions from cars and trucks that may exceed the carbon footprint of the road’s entire construction.

WEO AND REOB

Lubricating oils derived from petroleum are used in a variety of applications, ranging from the lubrication and protection of engine parts to heat and power transfers. Over time, depending on their application and operating environment, these oils become contaminated or otherwise degraded, resulting in what is known as Waste Engine Oil (WEO).

Despite its contamination and apparent dirtiness, WEO never becomes entirely unusable. In fact, WEO is recyclable and can be re-refined back into lubricating oils. The re-refining process employs distillation and

hydrotreating. WEO is dehydrated under atmospheric pressure to remove water and light hydrocarbons.

Atmospheric distillation then separates the reusable lubricating oil from the heavy oil. Vacuum distillation further separates the reusable lubricating oil into re-refinable base oil and a non-distillable residue, known as REOB or Vacuum Tower Asphalt Extender (VTAE).

The re-refinable base oil is further processed into re-refined base oil stocks, ready to be used in the production of new lubricating oil. Re-refined Engine Oil Bottom (REOB) or Vacuum Tower Asphalt Extender (VTAE), are the non-distillable residue from the WEO refining process.

Any re-refined products derived from used oil that do not meet this definition should not be referred to as REOB/VTAE, and the degree of their usage in asphalt production remains uncertain.

REOB comprises approximately 12 per cent of the total WEO composition.

It consists of higher boiling components, typically containing paraffinic lubrication oil, residual additives, and engine wear metals.

REOB can contain as much as 60 per cent residual lubricating oil, about four per cent polymer, and various soluble metals, which account for about five per cent of the total REOB composition1. Figure 1 shows the process of re-refining used oil and where the REOB/ VTAE is produced.

SAFETY

Used oils (WEO) can contain Polycyclic Aromatic Compounds (PACs), with some of these compounds classified as carcinogenic. During the processing of used oil in a vacuum tower refining system, PACs are typically removed from the residuum (bottoms). REOB/VTAE materials have been found to contain only trace levels of PACs.

Concerns have been raised about the PAC content in REOB/VTAE due to potentially carcinogenic levels in used oil. To investigate this concern, the Asphalt Institute conducted research, collecting seven samples at different stages of the re-refining process and testing

them for mutagenicity index (MI) and PAC levels which are measures of carcinogenicity of a chemical substance.

Samples taken before vacuum distillation exhibited high levels of MI and PACs, indicating a higher risk of carcinogenicity; however, these levels were significantly reduced in samples taken after the vacuum distillation process2

Currently, REOB/VTAE is not recognised as a carcinogen, although ongoing research is exploring more on this.

This highlights the importance of suppliers clearly declaring the contents of bitumen when they use any stream of re-refined used oils.

TECHNICAL PERFORMANCE

In the United States, some State Departments of Transportation (State DOTs) have raised concerns about pavement durability and may restrict the use of REOB. A review of State DOT specifications conducted in 2022 revealed that five State DOTs permit the usage or limited use of REOB. Among these, there was no consistent maximum usage limit; one State DOT allows up to 5.0 percent, while another permits a maximum of 8.0 percent.

The remaining three State DOTs impose no limits. Additionally, thirty-one State DOTs have no stated restrictions, with two requiring prior approval for potential use, and fourteen State DOTs do not allow the use of REOB1

Research on pavement performance impacts has yielded conflicting conclusions. There is

limited information regarding the comparative field performance of mixtures made with binders containing REOB/VTAE versus those without.

Some studies suggest that REOB/VTAE adversely affects the aging characteristics of bituminous binders, consequently reducing the cracking resistance of in-service pavements. In contrast, other researches indicate that asphalt mixtures blended with REOB/VTAE perform equally well or better than those made with neat bitumen of comparable stiffness.

The literature is inconsistent, with some authors asserting that REOB/VTAE is innocuous, while others warn of potential detrimental effects on performance. Furthermore, data indicate that the performance of binders and mixtures containing REOB/VTAE depends on the dosage, the source of REOB/VTAE, and the source of the bitumen. [1, 2, 3, 4, 5, 6, 7, 8]

Numerous studies suggest that current binder specifications require improvement to accommodate REOB use, such as extending Pressure Aging vessel (PAV) aging to better characterize all types of modified binders.

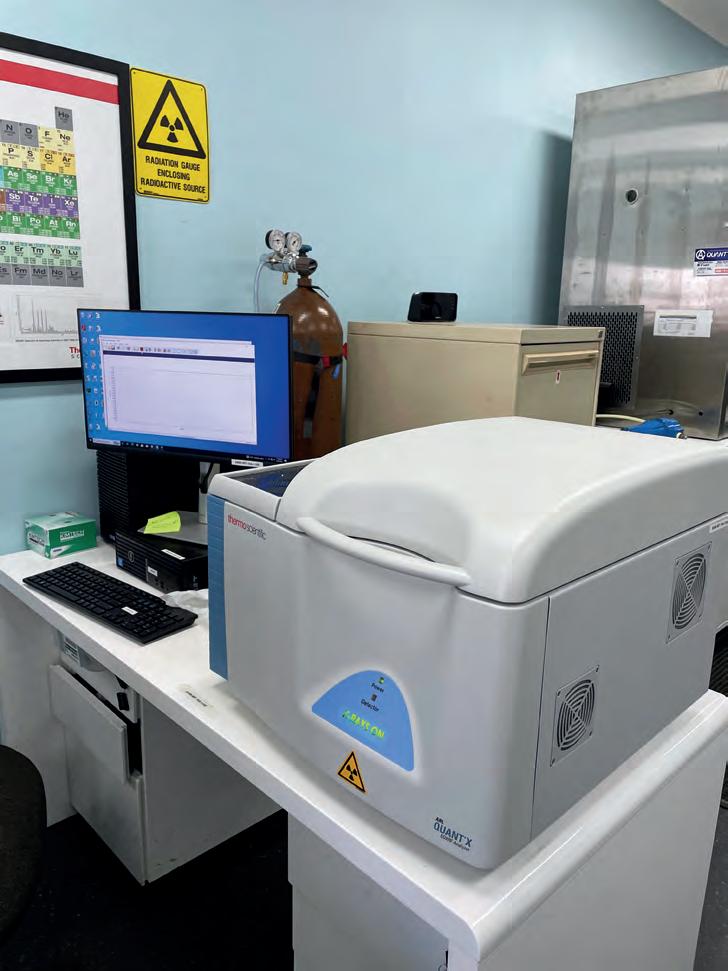

X-Ray Fluorescence (XRF) technology has been identified as a qualitative tool for detecting the presence of REOB/VTAE in bitumen.

A recurring theme in the research highlights the significant impact of aging on the relaxation properties of mixtures and binders. Extended PAV aging (greater than 20 hours) may be necessary to distinguish performance differences in binders that age variably.

The addition of recycled asphalt pavement (RAP) tends to make ΔTC more negative, as these materials are significantly aged in the field. Additives containing paraffinic base oils, when combined with REOB/VTAE, have been shown to accelerate the rate and extent of m-control in a binder (leading to a more negative ΔTC). The presence of REOB/ VTAE can adversely affect binder relaxation properties as it ages.

The Asphalt Institute has recommended further exploration of the binder parameter

ΔTC after 40 hours of PAV as a more effective method for characterizing long-term binder durability and performance (over five years)2 However, recent research suggests that this parameter may not be a reliable indicator for polymer-modified binders.

Studies have also shown that even trace amounts of REOB in bitumen can render it unsuitable for producing emulsion. Over the past two years, some incidents have occurred regarding the quality of bitumen emulsion in the Australian pavement industry.

Internal research by SAMI indicated that the base binder used for these emulsions contained trace metal elements typically found in REOB products, underscoring the importance of responsible usage of these additives and transparent declarations.

DETECTION

It is not possible to directly identify or quantify the exact content of REOB in bitumen. However, because bitumen does not naturally contain certain elements found in REOB, one can reasonably infer that the presence of these elements in bitumen suggests the potential inclusion of REOB. Several instrumental analytical techniques are available for determining and quantifying these elements. These methods include graphite furnace atomic absorption (AA) spectroscopy, inductively coupled plasma spectroscopy (ICP), energy dispersive X-ray fluorescence spectroscopy (EDXRF), and wavelength dispersive X-ray fluorescence spectrometry (WDXRF)1

The EDXRF method is versatile, capable of analysing various matrices, including solids, liquids, and powders. It typically covers an elemental range from sodium to uranium on the periodic table, with concentrations ranging from sub-parts per million (ppm) to 100 percent.

Elements with higher atomic numbers generally have better detection limits than lighter elements with lower atomic numbers. In EDXRF, X-rays produced by a source, such as

an X-ray tube, irradiate the sample.

The elements in the sample emit fluorescent X-ray radiation with discrete energies characteristic of those elements. By measuring the energies of the emitted radiation, one can identify which elements are present (qualitative analysis). Additionally, by measuring the intensities of these emitted energies, it is possible to quantify the amount of each element present in the sample (quantitative analysis)1

RESPONSIBLE USE

REOB/VTAE has been utilised in the bitumen industry for several years and is currently gaining increased attention due to sustainability targets and the push for cost optimization within corporations.

The use of this type of additive should be approached with caution and responsibility, ensuring clear communication with customers. There are several inconsistencies regarding the performance of asphalt and bitumen, particularly with emulsions made using these additives.

Additionally, certain streams in the rerefining process of waste engine oil have been shown to pose safety risks. It is essential for governmental regulations to be established to ensure transparency in these practices.

It is also crucial for users of bitumen to have a full understanding of the materials they are working with. At SAMI, we are committed to this principle and have recently set up an EDXRF device in our central laboratory in Camellia, NSW.

This device can detect trace elements in bitumen samples, enabling us to identify any unknown materials.

This technology and process are available to serve all stakeholders in the pavement industry, ensuring that binder users and producers can be confident that the product they are using is genuine and meets their specifications. This will decrease the risk of reduced quality and problems in production, especially with emulsions.

REFERENCE:

1. Responsible use of re-refined engine oil bottoms (REOB) in asphalt binder, 2023, FHWA

2. State of the knowledge – The use of REOB/VTAE in asphalt – IS-235, 2016, Asphalt Institute

3. Evaluation of rejuvenator’s effectiveness with conventional mix testing for 100% RAP mixtures, Martins Zaumanis, Rajib B. Mallick, Robert Frank, TRB 2013

4. The performance of aged asphalt materials rejuvenated with waste engine oil, Christopher D DeDene, Zhanping You, IJPE 2014

5. Five year performance review of a northern Ontario pavement trial: Validation of Ontario’s double-edge-notched tension test (DENT) and extended bending beam rheometer (BBR), S.A.M. Hesp, S.N. Genin, D. Scafe, H.F. Shurvell, S. Subramani, CTAA, 2009

6. Asphalt cement loss tangent as surrogate performance indicator for control of thermal cracking, Abdolrasoul Soleimani, Shanon Walsh, Simon A. M. Hesp, TRR, 2009

7. Effect of waste engine oil residue on quality and durability of SHRP Materials Reference Library Binders, Kelli-Anne N. Johnson, Simon A. M. Hesp, TRR, 2014

8. Cold winter and early asphalt pavement cracking observed in Ontario, Ludomir Uzarowski, Gary McDonald, John Rizoo, Gary Moore, Vimy Henderson, CTAA, 2015

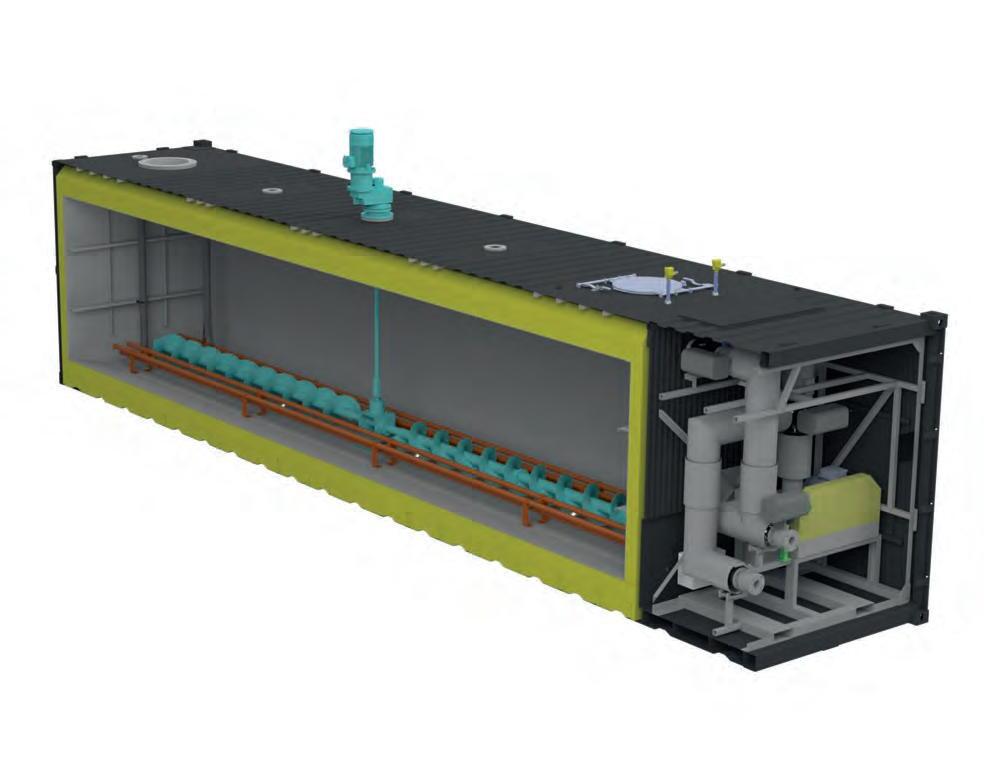

THE FUTURE OF ROLLERS

IN STRIVING FOR OPTIMUM SUSTAINABILITY, TRANSPORT NSW HAS PURCHASED 38 SOIL AND ASPHALT DOUBLE DRUM ROLLERS FROM DYNAPAC CEA. SO WHY AND HOW DID DYNAPAC FIT THE BILL? ROADS & INFRASTRUCTURE FINDS OUT.

Dynapac’s long history of delivering high-quality products and services that contribute to customers’ sustainable productivity remains at the forefront of its brand promises.

Dynapac, much like its partners in the public and private sectors, shares an ambition towards greener and greater outcomes for construction projects. One such partner is Transport NSW.

Through its Transport Sustainability Plan, annual reporting and Transport Net Zero and Climate Change Policy, Transport NSW upholds its mission to remain eco-friendly.

Following federal guidelines to use clean energy on construction sites, Transport NSW follows the highest emission control standards.

Dynapac CEA is currently delivering 38 new soil and double drum rollers, all with Stage V engines, to Transport NSW, in line with the

authority’s mission to lead the development of safe, efficient and sustainable transport systems for New South Wales citizens.

Kerry McCauley, Dynapac CEA Brand Leader, says it was an important component of the tender for Transport NSW to have rollers equipped with Stage V engines.

“In Australia the legislation requires a minimum of tier three engines, that is the standard engine and the type most companies choose to go with,” she says.

“However, Transport NSW opted to buy all Stage V engines so they can meet the highest environmental criteria possible. They wanted the cleanest energy we could give them.”

GETTING STARTED

This time last year Dynapac CEA, along with a collection of other manufacturers, gathered to meet with Transport NSW to

undergo a product demonstration. Present at this demonstration were a selection of Dynapac’s Soil and Double Drum Rollers.

As McCauley explains, Dynapac was a front runner from the beginning, for multiple reasons.

“To win the tender you had to score well not only from an operators’ perspective, but also on all service points,” McCauley says.

“Transport NSW found our operator assessments to be best in class in terms of ergonomics, operator platform, visibility, and comfortability,” she says.

Daniel Axiak, Regional Manager Oceania, Dynapac says Transport NSW required 42 new Soil and Double Drum Rollers, 38 of which were chosen from Dynapac.

“The 38 rollers will be used for Transport NSW’s replacement program, which involves mostly rehabilitation and maintenance programs working on existing roads across regional road networks,” he says.

“While Transport NSW might use the rollers to build some new roads, the rollers will mostly be used for the rehabilitation of current existing road infrastructure.”

Soil Rollers included in the tender were a mix of smooth drum rollers, which provide pressure to the soil by compacting it to produce an even and uniform surface, as well as versatile Padfoot rollers, which cater for a range of applications on cohesive materials such as clay, silt and disintegrated rock.

The order included a mix of CA1300PDB – five tonne, CA4000D 13 tonne Smooth Drums, CA5000D 16 tonne Smooth Drums and CA6000D 19 tonne Smooth Drums.

The Dynapac CA6000PD front

roller will keep the team confident and healthy when working on the job site.

Padfoot rollers listed in the order include CA4000PD 13 tonne Padfoot’s, CA5000PD 16 tonne Padfoot’s, CA6000PD 19 tonne Padfoot’s, CP1200W – Pneumatic Tyre Rollers and D.ONE – Trench rollers.

SOIL ROLLERS

Dynapac’s current soil roller range is the fifth generation of Dynapac CA single drum vibratory rollers.

With unique features such as crossmounted engines to provide optimal serviceability access and 180-degree rotating operator station, Dynapac’s single drum vibratory rollers provide comfort when working on the toughest compaction applications.

McCauley says this tender has reinforced the strong working relationship Dynapac CEA has had with Transport NSW, as well as Dynapac’s innovation in the roller market.

“From the operator’s perspective the rollers ticked every box, from the ergonomics to the comfort, the design and more. One of the standout features which Dynapac has is its crossed-mounted engine,” she says. “All filters, oils and fluids can be checked and changed from the ground level, making it convenient and easy for operators.

“That being operators’ and application efficiency, service efficiency and compaction control efficiency,” he says.

“Plus, the position of the combustion air intake has the advantage of keeping the inlet air as clean as possible, while giving optimal weight distribution.”

DOUBLE DRUM

Transport NSW selected two types of Double Drum Rollers, which Axiak says have been designed with efficiency in mind.

Across the range the machines are manufactured with unique designs to provide excellent visibility and increased serviceability.

Axiak says the Dynapac double drum rollers provide a range of machines from 1655 kilograms, up to 12,400 kilograms and with combination options available across the entire range.

“Double drums are used after the soil rollers, for the finishing process and preparation for spray seal, and

paving large sections of the road maintenance,” he says.

“The rollers are designed to meet the construction industry’s tough conditions with the operator in mind, resulting in a robust, comfortable and modern machine with the best compaction results.”

Axiak adds that the rollers will be spread around different sites as far north as Ballina, south to Bega and as far west as Broken Hill.

“Roads and Maritime Services (RMS) will be doing base course material compaction, which can be done with a multitude of different materials, whether that be rock fill or soil,” he says.

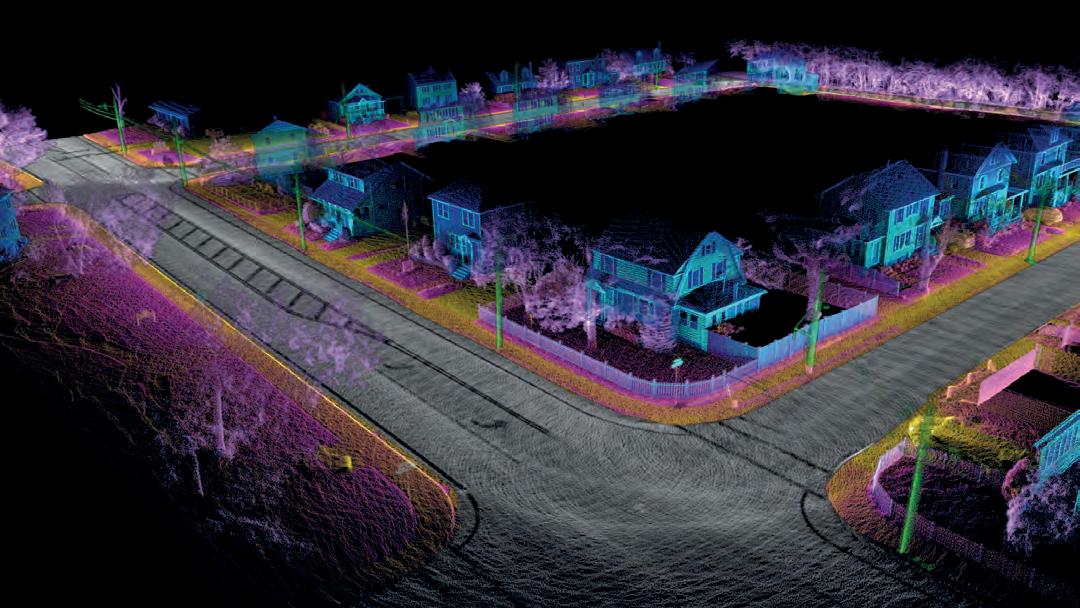

DATA DONE RIGHT

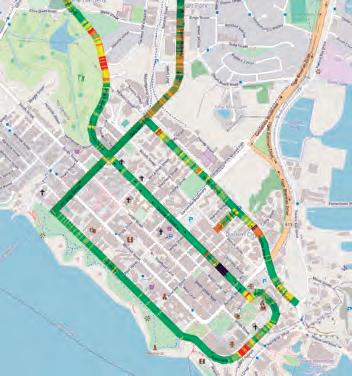

NATIONAL CIVIL ENGINEERING PROVIDER CIVILTECH SOLUTIONS HAS RELEASED ITS LATEST ROAD DATA TRACKING INNOVATION.

Civil engineering firm Civiltech Solutions delivers innovative and high-quality civil engineering and project delivery services across various industries.

Its mission, to provide project delivery solutions that cater to the unique needs of clients, is made possible through its newest road data sensors.

Leigh Carnall, Founder and Chief Executive Officer, Civiltech Solutions, says the sensors, operated with the help of Cyvl.ai, can improve the reuse of data to make better decisions about local roads.

“Local governments have a very big need for improving the way they look at their roads and understand their roads,” he says.

Carnall says councils can collect the data they need, when they need it, quickly, accurately and efficiently, to make better decisions to improve their road network.

To access this data, the council will attach the sensor, provided by Civiltech free of charge, to their vehicle. At their own pace, the council will drive around their road network to map out the municipality.

Once the data has been broken down, the council will meet with Civiltech to

discuss which aspects of the data they need from the collection, with the rest remaining on file with the possibility of later reuse.

The data will show a score of the road network, displaying cracks and inconsistencies in the roads.

Carnall says local governments do more than just look after roads. Councils also assess and maintain signs, pipes, potholes, guideposts and more.

With the road data gathered from Civiltech, councils will be able to plan future works, devise engineering plans and undergo major capital works such as resealing and asphalt patching.

“This level of infrastructure all has a value to it, and typically that level of information wouldn’t have been collected previously,” he says.

“Typical methods of collecting that information would be someone driving around in a car with a digital camera or even an iPad.”

The Civiltech sensor collects information on varying road data, including the condition of roads, signs and line marking.

Civiltech partners with United States company Cyvl.ai to ‘Australianise’ models of the road network and to develop more products specifically for Australia.

Carnall says there are two main uses for collecting this level of road data – daily maintenance and for asset evaluation.

“The data can be used for day-to-day maintenance on assessing where all the bins are, how many security cameras there are, how many trees are on the road, assessing if a sign needs to be replaced or if there’s any safety hazards,” says Carnall.

“This level of information can then go towards planning daily operations to upkeep the municipality.”

Carnall says the second reason falls on councils’ legal responsibility to undergo asset revaluation.

“There are checks and balances in place for councils who are obliged to spend money on infrastructure to continuously improve their assets,” he says.

“In order to get an evaluation, you need good information. If the value of the asset is being maintained and not going backwards, then that council will be seen to be doing the right thing,” he says.

Councils who access their road data through Civiltech sensors also have the option to reuse their data later.

Carnall says having the option to reuse data provides the council with flexibility on which information they want to access at which time.

“COUNCILS HAVE THE ABILITY TO PICK DATA TO SUIT THEIR ASSET MANAGEMENT NEEDS. IF A COUNCIL LATER NEEDS A CERTAIN PIECE OF ASSET INFORMATION, WE CAN REPROCESS THE EXTENSIVE ROADWAY DATA OUR SENSOR COLLECTS WITHOUT DOING ANOTHER PICKUP”

“If a council doesn’t want to access one piece of information at a certain time, but later needs that piece of information, we can reprocess the data and give it to them at a later stage,” he says.

“They might not want to know about the light poles now, but in six to 12 months they may want it to be reprocessed, without having to do much in the way of driving around the network again.”

CATERING FOR COUNCILS

The extent to which Civiltech can assist in reading the data varies from council to council. As Carnall says, there are some who understand asset management better than others.

“We cater for a wide range of councils, and there are some that have very little experience with asset management systems and want a very simple breakdown,” he says.

For these councils, Carnall says Civiltech works on a web GIS (Geographic Information System) platform where the council can assess the information they desire.

“We talk it over with them and we create something that is nice and easy to use, because most councils do not have GIS asset managers to use this information.

“It is very important to help where we can, because the majority of Australia’s

537 councils are small, regional and rural councils.”

QUALITY OF PCI

The Pavement Conditions Index (PCI) has been in operation for many decades, providing a snapshot of the pavement health of a road.

Civiltech’s road data is unique in the level of detail it can display on the PCI scale, right down to minor distresses.

Carnall says the unique data is displayed on a highly detailed road map which shows different defects highlighted in varying colours.

“The council is able to zoom in and around their road network, click on a particular defect, view the image and zoom in, displaying the evidence which can then be used to send someone to go fix the defect,” he says.

“For example, an engineer could assess the image and decide reconstruction or resealing the payment is necessary.

“We have gone from solely providing an evaluation to providing answers on how to remedy these areas.”

GUIDING INFRASTRUCTURE DEVELOPMENT

Carnall believes up to date street level imagery is crucial in guiding infrastructure development for local councils, understanding the value in both planning and operations.

“Having street level imagery that is up

to date and collected within one year of the works is important,” he says.

“Councils can collect certain pieces of information in alternating years, and then use the updated information for their works.

“Civiltech is flexible in allowing councils to collect this information one year, so it can be re-evaluated at a later time.”

OPTIMISING INFRASTRUCTURE DESIGN

AUTOMATION AND POSITIONING TECHNOLOGY PROVIDER APTELLA HAS ACQUIRED SYNERGY PAVESMART, A PAVING SERVICES BUSINESS. ROADS & INFRASTRUCTURE

SPEAKS TO SENIOR LEADERS, AS WELL AS MEMBERS OF THE NEW PAVING SERVICES DIVISION, TO LEARN HOW THE ACQUISITION WILL BENEFIT THE SECTOR.

With more than 15 years’ experience on major projects that include airport runways and infrastructure, motorways, bridges, and sports tracks, Jason Carroll comes close to seeing it all.

As the Business Development Manager for Aptella’s new Paving Services division, Carroll says the company’s adaptation has been the result of a shift in demand for services, based on the accuracy he and his team can deliver.

“Two years ago, I would say our work was 80 per cent road infrastructure and 20 per cent airports, but nowadays it’s a more even split between the two,” he says.

Simon Chamberlain, General Manager, says the team’s specialist skills and ability to work collaboratively with clients to provide optimised paving outcomes through a proven methodology has been the foundation for success.

“I think that shift is due to our proven track record with our customers of achieving the higher accuracy that airports require, where you’re looking at vertical tolerances of plus/ minus five to seven millimetres – compared with roads where it’s ten,” he says.

As a provider of automation and positioning technologies, Aptella has made a name for

itself for its ability to implement worldleading technology, supported by its team of experienced professionals.

“We have a tried-and-tested workflow and process that is rigorously accurate, and NATA (National Association of Testing Authorities) accredited, so our clients can trust in its validity,” Carroll says.

THE ‘SOURCE OF TRUTH’

On any project, whether resurfacing or a new build, the Aptella team always begins with a survey of the existing surface. This is used to compare against any previous surveys for the job, as well as allow for pre-works volume calculations, cut and fill and so forth.

For road projects, the team performs a pretest using a high accuracy laser profileograph fitted to the body of a car. This scans the existing surface to calculate a bump count, or International Roughness Index (IRI) count.

In some cases, the original survey could have been done years before the project is ready to start, so there is potential for significant variations to the original design. In other scenarios, the team has picked up on errors in the original survey due to the use of different methods.