5 minute read

Proficiency Testing

AAPA releases the results of its 2019/20 laboratory proficiency testing program.

2019/20 AAPA PROFICIENCY PROGRAM OUTCOMES

NORBERT MICHEL FROM THE AUSTRALIAN ASPHALT PAVEMENT ASSOCIATION DETAILS THE OUTCOMES OF THE 2019/20 ROUND OF ITS LABORATORY PROFICIENCY TESTING PROGRAM.

The annual AAPA proficiency testing program, which has been administered since 2004, represents a national undertaking with a good representation from laboratories from all states, territories and New Zealand.

One of the main objectives of the program is to pursue harmonisation of test methods, to improve and ensure consistent material testing processes are applied across the industry.

HOW DOES THE PROGRAM WORK? The proficiency testing program is undertaken on a homogenised batch of pre-prepared material, from which samples are taken and sent to participating laboratories. The participating laboratories report the results of the tests they undertake on these samples.

The AAPA proficiency testing program, and analysis of the data, follows the process outlined in the Guide to Proficiency Testing Australia (PTA, 2016) and EN ISO/IEC 17043:2010.

Several tests are included in every proficiency testing round for comparison with previous years. This ensures consistency and an ability to assess the efficiency of process control across the industry. Detailed instructions are provided to each participating laboratory outlining the approach to be undertaken.

OVERVIEW OF THE 2019/20 ROUND For the 2019/20 round, AAPA included a new test stream within the program. This test stream (Stream 7 – PMB testing) was introduced to broaden the scope of testing on materials used across the flexible pavements industry. For this stream, samples of A15E binder in 2 litre tins were provided to all registered participants.

The full range of tests undertaken as part of the program include: 1. Asphalt testing (tests related to asphalt product acceptance) 2. Binder recovery 3. Aggregate and filler tests 4. Resilient modulus 5. Wheel tracking test 6. Moisture sensitivity: Tensile strength ratio (TSR) 7. Polymer Modified Binder (PMB) tests

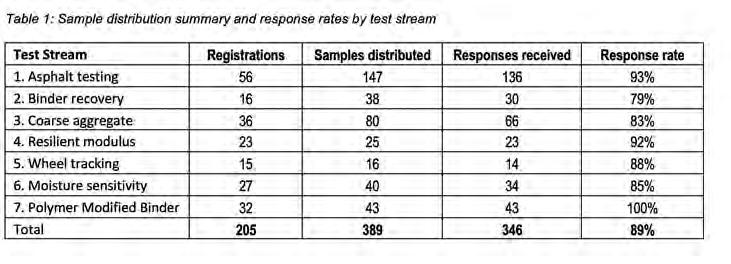

Samples were distributed to all participating laboratories from across Australia and New Zealand based on the range of tests that they registered to participate in. Table 1 provides an overview of the sample distribution for the different streams and the response rates achieved for each of the streams based on the number of result entries received. Each participating laboratory was issued a unique identification number for the purpose of reporting the results anonymously.

RESULTS FOR 2019/20 ROUND The results obtained are reported by the laboratory for each of the specified material properties and compared to the median value of the material property as reported by the collective of participants.

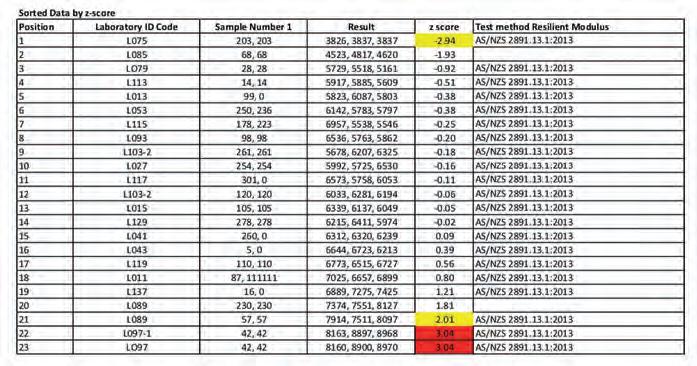

An example of the individual results provided to participants for one of the parameters, Stream 6 – Resilient Modulus, is shown in Figure 1.

This report outlines the following for each of the participating laboratories: • LAB ID • Sample numbers used to undertake the test • Results obtained for that test • Calculated z-score for the results submitted • Test method applied in the determination of that result

These results are then ranked in accordance with their assigned z-score to generate the graph of the positions assigned. This outlines the relative position of each participating laboratory to the median value. The summary statistics for all the submitted results are shown in the summary table beneath the chart.

Finally, the comparison of sample testing is based on the ‘robust statistical approach’ using z-scores to assess the distance of the given sample result from the median. Z-scores close to zero approach the median with increasing values indicating increasing divergence from the median. Sample results with values of z-score >= to 3 (highlighted in Red) are considered to be outliers and should be rejected while z-score >2 (highlighted in yellow) should be investigated for their high divergence from the median. Shown in Figure 1 above.

COMPARISON BETWEEN THE 2018/19 AND 2019/20 ROUND The program has grown in the last two years, both in terms of the number of streams offered and in the number of participating laboratories.

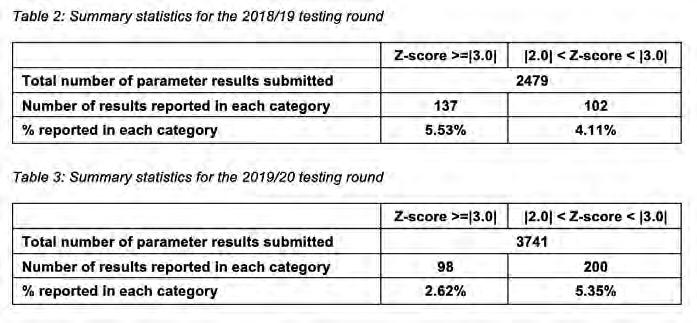

A review of the results submitted and their classification in terms of z-score is provided below in Table 2, which indicates an improvement overall by participating organisations in terms of the number of outliers (z-score > 3). This is a pleasing result as it indicates an increased conversion on reporting accurately (i.e. less erroneous data entry occurrences).

Figure 1: Example summary report for Stream 6 – Resilient Modulus

Of concern, however, is the increase in the number of reported results in the investigation range, where these represent a z-score greater than 2 and less than 3. Over the last 2 years, the number of result entries in this category have doubled in number but only marginally increased in terms of the percentage of the overall result entries submitted (as the size of the program has grown).

WHAT’S NEXT AAPA will start planning for the 2020/21 testing program and information will be made available to the industry regarding the process for registration, sample delivery, test instructions and results submissions.

Furthermore, based on some of the learnings from this latest testing round and active engagement with AAPA National Technology and Leadership Committee, several improvements to the results submission process will be made to improve the data entry process and therefore ensure that entry of erroneous data is minimised. Finally, AAPA is also looking to broaden the offering of the program in terms of the materials being to assist with determination of precision statements for testing of different materials.

Performance with special mixes and fuel efficiency delivering higher results

CIBER iNOVA SERIES

THE MOST ADVANCED TECHNOLOGY WITH HIGH PRODUCTION CAPACITY AND MOBILITY. With production capacity of up to 100t/h , 150 t/h or 200 t/h in 1 or 2 mobilities, the CIBER iNOVA Series line of asphalt plants are perfect for all types of works. When high production, best performance with special mixes and greater efficiency in fuel consumption are required, Ciber iNOVA plants deliver excellent results to your business.