5 minute read

Bicycle swept path analysis

ENGINEERING LIVEABLE CITIES

ENGINEERS CAN NOW USE THE LATEST GENERATION OF TRANSOFT SOLUTIONS’ SWEPT PATH ANALYSIS SOFTWARE, AUTOTURN PRO 11, TO PREDICT CYCLIST PATHS WHEN DESIGNING BIKE-FRIENDLY LANES ON KEY ROUTES.

Over the past few years, the movement to design lowemissions cities has been gaining traction across the globe.

While there are a range of measures city planners have taken to reduce emissions, one popular initiative is to return roadways to pedestrians and cyclists.

In 2018, Paris began car-free Sundays once a month, with some exceptions, in the heart of its city centre. Transport Victoria has even highlighted the importance of planning for cyclists in its 2018 Victorian Cycling Strategy.

These changes encourage commuters to switch their cars for other, low-emissions transport modes, whether that be public transport, walking or cycling.

With this movement in mind, urban designers are increasingly having to incorporate bike lanes into road design.

To keep up with this growing trend, Transoft Solutions’ upcoming release of AutoTURN Pro, a leading application for vehicle swept path analysis, includes the ability to simulate the paths of a variety of bicycles.

Steven Chan, Vice President of Simulation at Transoft, says the company had requests from cities in the US and other transport agencies worldwide for the introduction of different bicycle types to their AutoTURN Pro system.

Transoft’s AutoTURN solution was first introduced in 1991 and has since developed and grown to incorporate many guidelines for different vehicle and pedestrian scenarios from around the world.

AutoTURN Pro 11 is Transoft’s latest generation of vehicle swept path analysis, including bicycle measurements for the first time. This allows asset managers to consider accurately measured bicycle movements when planning roads and intersections.

“The core idea behind AutoTURN was to calculate the space a vehicle would need as it makes a turn in specific environments to inform the design of roads and intersections,” Mr. Chan says.

The system helps engineers to reduce guesswork and design errors while visualising a transportation network with all types of vehicles to reduce a range of accidents.

When creating the AutoTURN Pro simulation for bicycles, the team modelled 13 different types of bicycles including cargo bikes, which carry trailers at the rear.

Transoft looked at existing design guidelines and field tests to create and calibrate algorithms that replicate bicycle behaviors during development of the new AutoTURN cycle analysis features.

In Australia, the cycle feature adheres to

the Austroads guidelines set out in its 2017 report, Cycling Aspects of Austroads Guides.

“We maintain our guidelines based on changes worldwide periodically so any guideline that has been updated will be reflected in the software,” Mr. Chan says.

“We also worked with a body in the United Kingdom called Sustrans (Sustainable Transport) and they actually helped with the field testing. We gave them a specific trajectory so that we could take in the data.”

In field tests, volunteer riders followed marked paths of 90-degree turns with fiveand 10-metre turning radii. For each ride, speed and lean angle data were collected.

The data helped to define vital parameters such as the maximum lean angle for a bicycle when turning a corner. Additionally it defined transition duration, which is the time it takes to steer in from a straight line path to a steady state turn.

AutoTURN Pro will automatically lay out the swept paths of specified bicycles, in the same way it does for other vehicles. This provides engineers and planners with trusted simulation results based on speed and turning transitions.

“The newest release of AutoTURN Pro also features other capabilities. The simulations can now be inspected so the user can view what speeds were used, when the simulation was first placed in the drawing, what parameter the steering angle is at and so on,” Mr. Chan says.

“This provides users with a better understanding of how the simulation was created and helps make sure the results meet the design criteria of the project.”

Transoft has also developed the ability to set and display clearances to key elements of the various bicycle classes included, such as handle bars, pedals and the rider’s head.

These envelopes can be displayed on the go, to add extra safety when checking

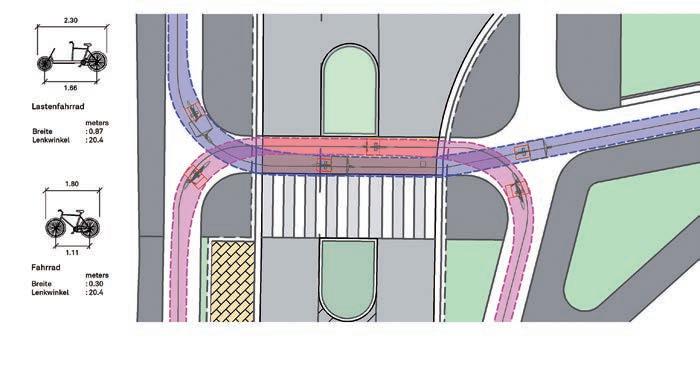

An example of an AutoTURN Pro bicycle simulation.

bicycle simulations against various elements of road infrastructure.

Mr. Chan says AutoTURN also includes a comprehensive database of vehicles based on manufacturer’s specifications. This covers cranes and garbage collection vehicles right through to oversized or overweight vehicles. The end result ensures roads are engineered to accommodate all forms of transport. Whether used for new development projects, rehabilitation schemes or temporary traffic management plans, the accuracy and reliability of the AutoTURN software has made it a standard tool for sweptpath analysis.

“In general, Transoft is a company that looks for these niche issues in the industry and we try to identify gaps that can be solved with our technology,” Mr. Chan says.

He says Transoft has many technologies expected to be released this year and the company is constantly working with industry bodies, experts and government agencies to find solutions to industry concerns.

Seismic Shaking up compaction

About Transoft Solutions Transoft Solutions develops innovative and highly specialised software for aviation, civil infrastructure and transportation professionals. Since 1991, Transoft has remained focused on safety-oriented solutions that enable transportation professionals to work effectively and confidently. For more information on Transoft’s range of aviation, civil design, and vehicle simulation solutions visit www.transoftsolutions.com or contact Transoft directly at salesAPAC@transoftsolutions.com Access promo code: R&IPROMO and save on your first purchase (conditions may apply).

Scan following QR code to keep up with all the news about the latest version.

THE BEAT OF A DIFFERENT DRUM Dynapacs Seismic system recognises all drum and soil combinations and automatically detects the frequency of the soil characteristics. Working together with it, and applying the correct amount of energy when required. Ensuring optimal compaction everytime.