5 minute read

Removing the hazard and increasing safety

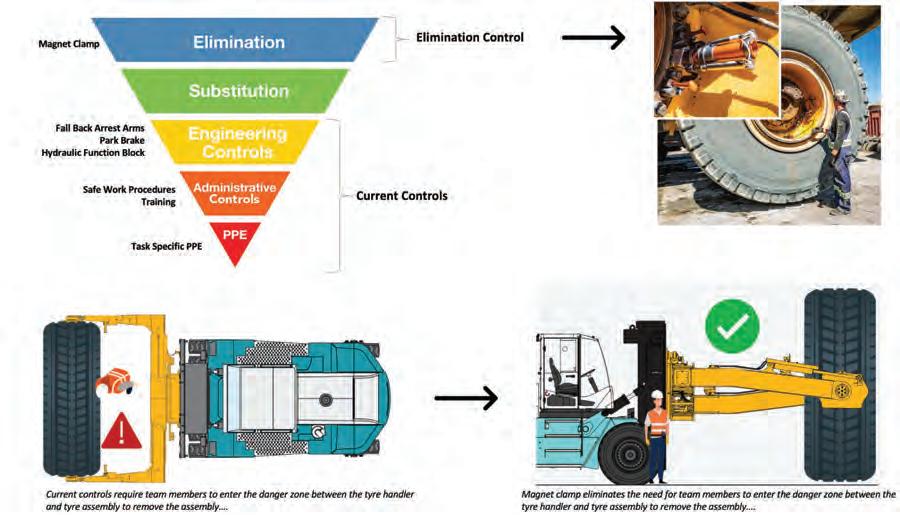

HIGHLIGHTING THE IMPORTANCE OF RISK ELIMINATION, KAL TIRE’S INNOVATION CENTRE HAS RELEASED THE MAGNET CLAMP, A SOLUTION WHICH AIMS TO PROTECT TYRE OPERATORS IN THE WORKPLACE WHILE ALSO IMPROVING EFFICIENCY.

There is an ongoing commitment to improve safety at mining operations when it comes to protecting workers around mobile equipment.

Personal protective equipment gives the worker a degree of safety while administrative controls such as legislative requirements are for companies to follow and change the way people work.

However, the potential for injury is still there despite these measures. The most effective way to improve safety in the workplace is to physically remove the hazard.

Kal Tire Australia operations health and safety manager Scott Laurie says his company uses a guideline called the ‘hierarchy of controls’ in order to identify the best way to keep its team members and customers safe.

“Controlling exposures to occupational hazards is a fundamental method of protecting workers,” Laurie says.

“Traditionally, hierarchy of controls has been used as a means of determining how to implement feasible and effective solutions to control hazards and their associated risks in the workplace.”

Laurie says Kal Tire uses the hierarchy of controls to ensure a continual improvement in safety for its team members when removing wheel assemblies from heavy mobile equipment.

“During the initial stages, Kal Tire implemented procedures which defined for the tyre technician how to conduct the task of safely removing a wheel assembly,” he says.

“That involved procedures for when they got the tyre handler into position, the operator then shuts down the handler, gets out of the machine, and then the tyre technician would then enter the risk zone between the tyre handler and the actual tyre and wheel assembly.

It was through these hierarchy of controls that the company’s Innovation Centre in Canada developed its latest offering, the Magnet Clamp.

Laurie says the key safety benefit from this device is it actually eliminates risk to team members by removing them directly from the risk zone.

“The removal of wheel assemblies is one of the key tasks that Kal Tire technicians carry out within the business, and safety is paramount for those individuals,” he says.

“Part of that process is changing out the tyre and wheel assemblies from heavy mobile equipment and what was normally required in our business was for our tyre service personnel to actually get between the tyre handler and the actual tyre that they are changing.”

Laurie says the original procedure outlined that all the lug nuts are removed except the remaining ones at the three o’clock and nine o’clock positions in order to prevent the wheel from shifting and potentially injuring an team member.

“One of the risks of getting into that zone is obviously the tyre moving and

Kal Tire’s Innovation Centre in Canada developed its latest offering, the Magnet Clamp.

crushing the tyre technician between the handler and the tyre itself,” he says.

“What has now been accomplished through the Kal Tire Innovation Centre is that we have eliminated the risk associated with this task by the introduction of the Magnet Clamp.”

Laurie says the invention of the Magnet Clamp has changed the way this removal process is done.

“Now what we do is we get the technician to actually remove the lug nuts at the three o’clock and nine o’clock position first without the tyre handler being in place,” he says.

“They then attach the Magnet Clamp to the actual wheel assembly.

“Using a remote control, the Magnet Clamp actually secures the tyre in place, they then go around and remove the rest of the lug nuts from the assembly, the technician removes themselves from the risk zone, the tyre handler then comes into position and grabs the tyre, which keeps the operator away from the risk zone.”

Not only does this method work for removing the tyre assembly, but it can also be used to install a new tyre onto the wheel assembly.

Laurie says this is one example of how through innovation Kal Tire is able to make continuous improvement towards safety for its team members and customers, and remove hazards altogether.

At Kal Tire’s Innovation Centre, a team designs and develops tyre management tools and technology that reduce common risks and injuries, while also improving efficiency and productivity.

“We strive to make our work safer in every way possible and it is really part of our journey to zero, which is to ensure our team members go home safely every day,” Laurie says.

“It is all about our culture and our mindset, it is about each team member being able to work in a safe environment, and in turn be responsible for our own safety as well as our customers.”

Laurie says due to the nature of its business, there is always a degree of risk involved in working with the mining and resources sector.

However, he believes the elimination of any risk or hazard in the workplace is the most important part of safety.

“Unfortunately, working with tyre and wheel assemblies is recognised as one of the higher-risk activities that occurs on a mine site,” he says.

“We obviously have procedures in place to prevent workplace accidents from occurring but if we are able to completely eliminate the potential risk to our workers then that is the best form of safety control.”

Laurie says one of the major purposes of the Innovation Centre is to create innovation that makes it safer for the company’s team members and people in the industry in general.

“Our innovation comes from our people on the ground, they are the ones that are dealing with the daily challenges and they are the ones that are seeing new ideas and continue to drive our improvements in terms of safety”, he says.

“That is why I believe it is important that you communicate with your people to make sure you create a culture of supporting these ideas.”