5 minute read

Pushing mining to next safety level

from STW Jul 2021

by Prime Group

Technology Fibre optics take mining to next safety level

REAL-TIME MONITORING ALLOWS MINING COMPANIES TO NOT ONLY DETECT FIRES BUT PREVENT THEM IN ALIGNMENT WITH 2021 TRENDS OF ZERO HARM.

Fires and explosions continue to be one of the biggest threats to mining industry personnel, operations and the environment.

A report from the Western Australia Government reveals that fires were the biggest cause of mining incidents, accounting for more than one third of accidents (34 per cent) from September until December of 2020.

Fibre optics technology has emerged to offer a more comprehensive and safer solution to the mining industry’s safety needs, aligning with the latest mining trends as stated in Deloitte’s 2021 Tracking the Trends report.

“Safety, always central to mining, can be enhanced by new technologies and data…An integrated approach to their use is needed. Safety analytics can predict potential harm and offer the means to prevent it,” the report stated.

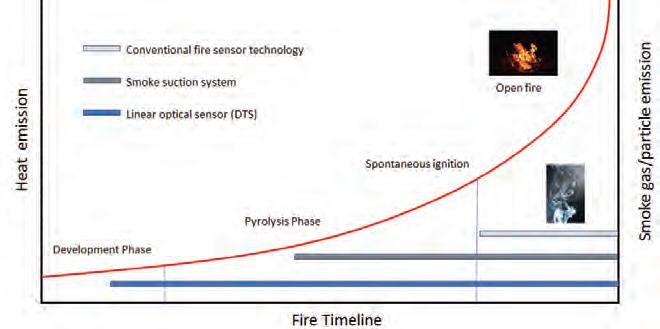

The conventional solutions for fire safety send alarms and activate fire suppression systems only after a fire has started, becoming hard to control once it is already happening.

A better outcome would be to detect an emerging fire event before it takes hold to minimise the risk to life, damage to equipment, production loss, heavy fines, loss of operating license or even the shutdown of the whole operation.

The technology has evolved and is now available to prevent all these risks with higher accuracy, real-time monitoring and no other field devices required rather than the fibre cable.

Latest research reveals that fibreoptic technology detects a smouldering event ahead of any conventional gas or infrared detectors with a single cable, offering the lowest total cost of ownership in the long run with no maintenance needed.

In the diagram below there is a comparison of the timing involved to detect a fire among different fire safety systems.

Timing involved to detect a fire in different fire safety systems.

FIBRE OPTICS TECHNOLOGY TO DETECT AND PREVENT ACCIDENTS

Distributed Temperature Sensing (DTS) technology uses a laser source through a single fibre optic core measuring four millimetres in diameter and has been successfully tested and deployed in both surface and underground mines.

The ruggedised stainless steel fibre optic-based system has the capacity to detect heat build-up quickly and localise the source to within 0.5 metres of accuracy.

This precision is unaffected by wind and other environmental effects, because not only convective (air), but also conductive (surfaces) and radiant (infrared flame) heat is detected by the cable.

The system sets early warning of potential fires which allows mining companies to prevent and detect accidents.

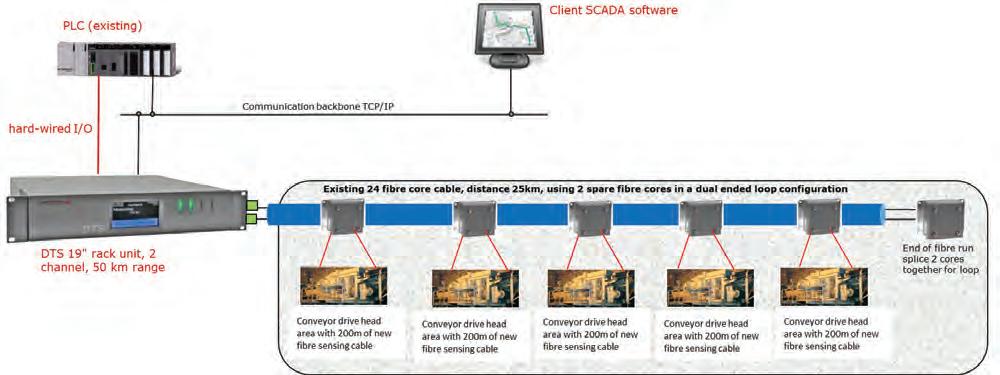

The system can also be fully integrated into the mine site PLC (programmable logic controller), SCADA (supervisory control and data acquisition) or DCS (distributed control systems), providing a complete set of real-time data for analysis for a reliable, safe and practical solution.

The system can utilise new fibre cable or existing fibre optic cables already installed on mining sites.

Temperature readings with precise location are transmitted to the site’s system which provides a full temperature profile along the entire

length of the fibre cable.

This assists in identifying abnormal hot spots along the route through its SCADA operator displays.

Alarms and historical trends are also available and are an insightful source of information to report or even prevent future incidents.

A typical overall system layout diagram is shown below.

The fibre optics-based system performs all of that with a single cable that has a long-life span and the highest levels of accuracy in the industry.

All of these aspects, when compared, reveal that the total cost of ownership is significantly lower for the fibre optics system in the long run as it does not require multiple devices, intrusive installation or regular maintenance.

As a result of a safer system, mining companies may also achieve a lower insurance premium resulting in significant savings over time.

The system is totally integrated to the plant SCADA system for a faster decision-making process and better user experience.

The system goes in line with 2021 mining industry trends of zero harm, risk management and integrated operations as detailed below.

MINING INDUSTRY TRENDS

According to the Deloitte Mining Insights Report, the industry is experiencing an increase in deployment of new technologies adapted to tackle safety, data integration and environmental challenges.

Among the overall trends, there are three that align with fibre optics technology: • On the road to zero harm: Creating the next generation of integrated predictive safety systems

Miners are on the path to zero harm so that the workplace can be safer for their employees, nearby communities and the environment. Adopting new systems and technologies can prevent incidents and increase overall safety standards.

• Corporate governance adding to

competitive advantage: Emerging risks mandate greater oversight

Corporate governance is emerging as a powerful way to manage risks: cyber security, environmental and technological compliance are on the agenda. Companies are stepping up to comply with higher levels of safety not only on site but also on data and information, minimising any potential risks. • The path towards integrated operations: Positioning miners to

DTS technology uses a laser source through a fibre optic core.

pivot in the face of change

The rapid pace of technological advancement has provided an increase in the amount of information available to support decision-making in the mining industry. This trend is expected to accelerate over time and companies are going towards integrated operations and systems, like the fibre optics fully integrated system, rather than isolated systems.

For all these reasons fibre optics technology is emerging as one the best technical and cost-effective solutions to ensure safer level of operations. The total mine coverage with a single cable and early warning of abnormal heat build-up in real time are a taking the industry to the next safety level, protecting lives and safeguarding operations.

Ruggedised stainless steel fibre optic-based system layout.