ISSUE 202 | March 2024 Sealing success in PNG first 32 A welding master on wheels 48 ENHANCING WATER SECURITY WITH FITZROY TO GLADSTONE PIPELINE – page 16 CO2 pipeline testing triumph 24 Powering AHEAD

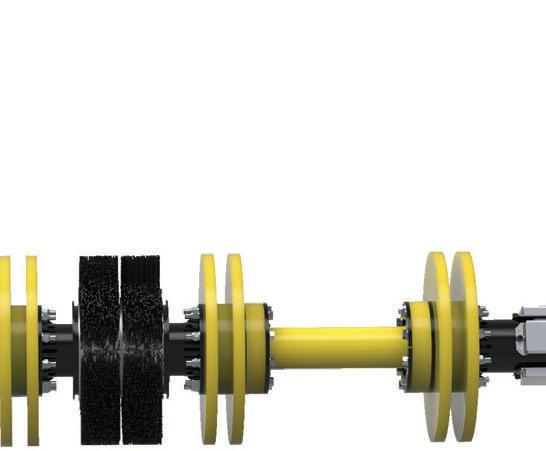

ALL ABOARD THE PIG TRAIN › Line cleaning and scraping › Batching › Hydrostatic fill › 360 degree coverage › Magnetic ferrous material removal Our Exclusive Global Partner www.pipetek.com.au Taddam: 0432 666 917 taddam@pipetek.com.au Myles: 0417 707 729 myles@pipetek.com.au CLEAN YOUR PIPELINE WITH FEWER PIG RUNS Achieve optimal cleaning results while saving time and money by running multiple cleaning elements at the one time.

CONTENTS 4 FrontcoverimagecourtesyofGladstoneAreaWaterBoard. The Australian Pipeliner | March 2024 16 EXECUTIVE REPORTS CEO's Message 8 POLICY AEMO urged to consider gas supply chains 10 FUTURE FUELS Understanding the techno-economics of hydrogen energy 12 WOMEN IN PIPELINE FORUM Plugging the leak: how pipeliners can take action 14 WATER PIPELINES Fitzroy to Gladstone powers ahead 16 Stormwater drainage solution shaking up industry 18 Hitting the benchmark with Riteline 20 New pipeline for Coles Bay 22 PIPELINE CONSTRUCTION CO2 pipeline testing success 24 e essence of customer satisfaction 26 e 007 of padding machines 28 From A to Z with kwik-ZIP 30 Sealing success in PNG rst 32 REHAB AND REPAIR A novel approach to pipeline valve replacement 34 INTEGRITY AND MAINTENANCE A long legacy of success 36 Maintaining pipelines with ACC Corporate 38 Safeguard assets with Pack Tu 40 VACCUUM LIFTERS La crème of vacuum lifting equipment 42 A diversi ed range for safety 44 HDD Reclaiming HDD project sustainability 46 WELDING A welding master on wheels 48 A stand-out pipeline solution 50 ENERGY TRANSITION Developing opportunities to improve the energy transition 52 Pragmatism is of essence 54 APGA CONVENTION e crucial role of submitting papers to industry 55 REGULARS APGA members 56 People On e Move 58

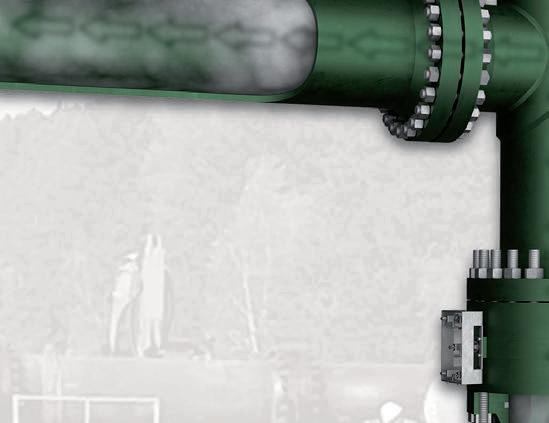

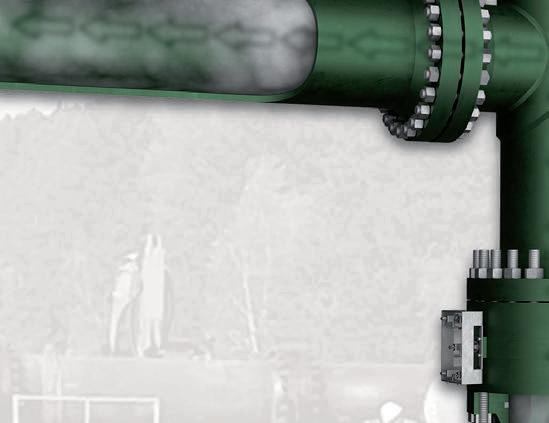

integrated bypass maintains production during isolation

Dual Leak-Tight Seals

Double Block & Bleed Isolation

Isolated Pipeline

Monitored Zero-EnergyZone

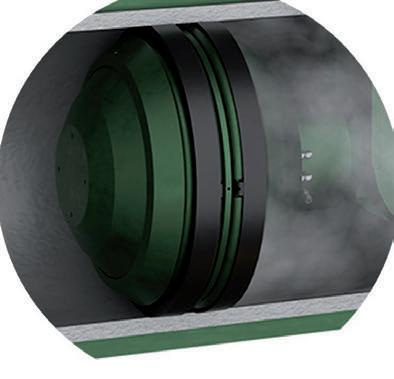

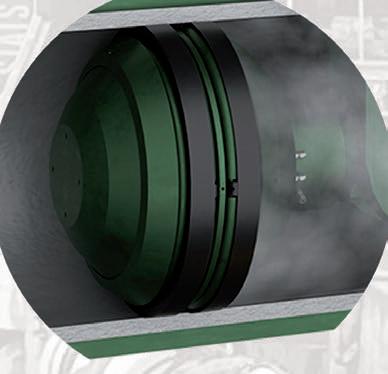

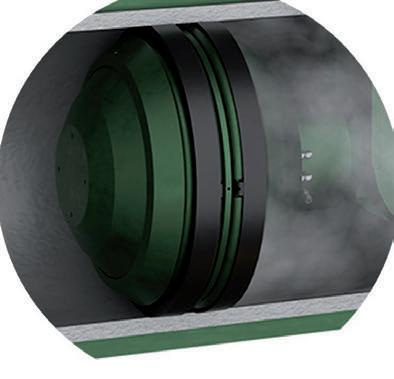

The BISEP® has an extensive track record and provides pioneering double block and bleed isolation while

dual seals provide tested, proven and fully monitored leak-tight isolation, every time, any pressure.

CEO

John Murphy COO

Christine Clancy christine.clancy@primecreative.com.au

MANAGING EDITOR

Molly Hancock molly.hancock@primecreative.com.au

EDITOR

Clemence Carayol clemence.carayol@primecreative.com.au

JOURNALIST

Vivien Topalovic vivien.topalovic@primecreative.com.au

BUSINESS DEVELOPMENT MANAGER

Jake Niehus jacob.niehus@primecreative.com.au

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR

Blake Storey blake.storey@primecreative.com.au

DESIGNERS

Kerry Pert

COPYRIGHT

The Australian Pipeliner is owned by Prime Creative Media and published by John Murphy. All material in The Australian Pipeliner is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in The Australian Pipeliner are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated. © Copyright Prime Creative Media, 2021

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Printed by: The Precision Group

83-89 Freight Drive, Somerton VIC 3062

Ph: (03) 9490 1500

The Australian Pipeliner brand comprises: a quarterly magazine, a news website, a fortnightly e-newsletter, multiple social media platforms, an annual industry directory and an annual pipelines wallchart. Book an advertising and editorial package to gain access to our exclusive audience.

3,300+

20,000+ website views each month

13,700+ social media followers magazine subscribers

16,500+ e-newsletter subscribers

Want to find out more?

Contact our business development team to discuss how you can grow your business with The Australian Pipeliner. Call 0466 929 675 or email jacob.niehus@primecreative.com.au

Head Office 379 Docklands Drive, Docklands VIC 3008 Ph: (03) 9690 8766

Sydney Office Suite 303, 1-9 Chandos Street, Saint Leonards NSW 2065 Ph: (02) 9439 7227

enquiries@primecreative.com.au www.primecreative.com.au

The Australian Pipelines and Gas Association’s (APGA) vision is to lead the sustainable growth in pipeline infrastructure for Australasia’s energy. APGA is a non-profit organisation formed to represent the interests of its members involved in: the ownership, operation, maintenance, design, engineering, supply and construction of pipelines, platforms and all other structures used in or in connection with the drilling for, extraction and transmission of hydrocarbons, solids, slurries and similar substances both onshore and offshore. As a single voice representing the collective interests of its members, APGA is dedicated to encouraging the extension and development of the industry.

The Australian Pipeliner is the official journal of the Australian Pipelines and Gas Association (APGA) and is distributed to members without charge and circulated to interested organisations throughout Australia and overseas. It is also available on subscription. The publishers welcome editorial contributions from interested parties. However, neither the publishers nor APGA accept responsibility for the content of these contributions and the views contained therein are not necessarily the views of the publishers or APGA. Neither the publishers nor APGA accept responsibility for any claims made by advertisers. All communications should be directed to the publishers.

6 PUBLISHER Maximise brand awareness by connecting

with thousands of industry professionals

The Australian Pipeliner | March 2024

The Reliable Solution

BlackMAX® Drainage Pipes & Fittings

The original Australian manufacturer Lightweight and easy to install Water-tight protection iplex.com.au Iplex Pipelines Civil 13 10 86 Contact us to learn more about Iplex’s BlackMAX® drainage solutions.

Chief Executive O cer’s report

Welcome to the March edition of e Australian Pipeliner. 2024 is well underway and I have high hopes this is going to be a great year for our industry. is month’s theme is water, and it is really good to see a number of signi cant projects progressing well.

While we tend to focus on the implications of the energy transition for gaseous infrastructure (not just natural gas but hydrogen and carbon dioxide amongst others), there are equally large consequences for water pipelines.

We’ve enjoyed a few years of above average rainfall across most of the country, but we shouldn’t lose sight of the likelihood that climate change will lead to changing weather patterns and a growing demand for bulk water transport.

Water is a fundamental input into green hydrogen and, whatever the ultimate size of this industry, large quantities of water will be being transported to industrial-scale electrolysers wherever there is hard-to-abate industry.

e Federal Government’s Hydrogen Headstart program has shortlisted applicants for the rst tranche of signi cant funding and the list provides some insight into the types of applications we can expect of see large-scale deployment of hydrogen in the years ahead, so I encourage you to go and have a look.

As we contemplate the size of the infrastructure task in the decades ahead (I think it is a lot bigger than most of us are anticipating) the fundamental issues of land access and stakeholder engagement need to be given the highest priority. e pipeline industry has an outstanding track record in this space, and it is critical that we do not become complacent.

In early February, the Australian Energy Infrastructure Commissioner released its rst Community Engagement Review. It did not get a lot of attention, but it has some very concerning data that all infrastructure sectors should be mindful of as we try to build the next generation of infrastructure across the county. Noting that review focussed speci cally on electricity projects:

• 90 per cent of survey respondents disagreed that they received relevant information in response to a concern raised.

• 89 per cent disagreed that their concern was managed in a timely manner.

• 93 per cent disagreed that they received a satisfactory resolution to concerns raised.

Whatever processes were followed by project developers, at a minimum these numbers re ect very high expectations from land holders and communities impacted by projects.

It is heartening to me that pipeline projects have been both delivered and surveyed across Australia in the last few years without this kind of negative sentiment, it shows we are taking the necessary steps to satisfy most people.

Well done to everyone in our industry involved in this key activity! Keep up the good work and be mindful of the level of expectation out there in the community.

All the best.

STEVE DAVIES CHIEF EXECUTIVE OFFICER

ABN: 29 098 754 324

APGA Secretariat Registered O ce:

7 National Circuit, Barton ACT 2600 (PO Box 5416, Kingston ACT 2604)

T: +61 2 6273 0577

E: apga@apga.org.au

W: www.apga.org.au

Chief Executive O cer

Steve Davies

Corporate Services Manager

Michelle Wickson

National Policy Manager

Jordan McCollum

Communications Manager

Lawrence Shelton

Engagement Manager

Gayle Burns

Membership O cer

Katy Spence

Events Coordinator

Matthew Freeborough

Policy Manager

Catriona Rafael

Government Relations Manager

Paul Purcell

EXECUTIVE REPORTS 8 The Australian Pipeliner | March 2024

Unlock the Power of Data

Elevate your asset integrity with unmatched data accuracy and unparalleled expertise. Our unique synergy of advanced inspection systems, cutting-edge analytics and human expertise allows us to transform data into knowledge. Knowledge enables smarter decisionmaking and delivers a comprehensive understanding of asset safety, lifetime, and performance. www.rosen-group.com

AEMO urged to consider gas supply chains

The 2024 Draft Integrated Systems Plan continues Australian Energy Market Operator’s history of unrealistic gas supply chain and utilisation modelling. But simultaneous consultation on CSIRO’s 2024 GenCost report shows that it’s not entirely AEMO’s fault.

By APGA National Policy Manager Jordan McCollum

The biennial Draft Integrated Systems Plan (ISP) cycle delivers upon the Australian Energy Market Operator's (AEMO) legislated obligation to plan for no-regrets investments in electricity transmission infrastructure. To do so, AEMO creates scenarios to stress test a model of the transmission grid, helping to identify investments necessary under as many scenarios as possible.

Despite this purpose, the scenarios created by AEMO are being more and more frequently considered predictions of the future of Australia’s energy system. is means that ISP scenario projections have a very real impact on investment choices in the Australian energy market.

For both this reason and the ISP’s intended purpose, it is important that AEMO get it right when forming these projections. Unfortunately, when it comes to gas, they rarely do.

An example of why this is the case can be seen in gas power generation (GPG) projections. GPG should be the simplest gas sector aspect for the ISP to get right. But each ISP continues to project GPG reducing within one to three years of publication before increasing after around a decade.

Conversations with AEMO and associated stakeholders indicates that this has, historically, been at least in part due to the ISP not considering failure cases beyond a single generator failing at one time – the opposite of what was seen during the 2022 energy crisis.

It has also been suggested however that projected low GPG demand over the medium term is also due to assumed government funding for utility scale batteries (such as the Federal Capacity Investment Scheme which includes batteries but excludes GPG), making batteries cheaper than GPG in the immediate term. is, combined with increased GPG demand beyond the 10-year horizon, implies that GPG will regain its cost competitiveness when battery energy storage subsidies cease. But if this is the case then policy makers should be asking themselves whether they should subsidise utility scale batteries at all. Suppressing near term GPG demand also introduces risk in GPG capacity investment. Battery subsidies won’t be around forever, and the ISP shows that when they stop GPG will be needed once more. But it is not reasonable to expect investors to maintain

investment in GPG capacity with close to little expectation of near-term demand (or revenue) for the greater long-term good.

Either AEMO projections of GPG use do not re ect electricity market reality, or utility scale battery subsidies represent a risk to securing investment in the GPG capacity required to rm the variable renewable generation heavy electricity market of the 2040s.

Whether accurately modelled or not, the weight given to AEMO scenarios means that GPG investors will be seriously considering their market position. Without some form of revenue assurance during the 2025–2035 horizon, we may very well see GPG retract from the market at the very point when new capacity needs to be developed.

Looking beyond GPG itself, the dispatchable generation nexus between GPG and deep electricity storage shows where AEMO is missing an important part of the story. AEMO receives most of its ISP cost assumptions from the CSIRO GenCost series of reports. However, GenCost doesn’t project natural and renewable gas transmission and storage costs. is means that AEMO isn’t in the position to model these energy storage options.

AEMO is aware of what it is missing however, having referenced the capacity of the Iona Underground Gas Storage Facility in response to the Victorian Gas Substation Roadmap consultation. Iona alone has three times the energy storage capacity identi ed in the ISP as required new storage investment.

Without considering even existing natural and renewable gas storage and infrastructure options, AEMO may be overestimating the required

investment in electricity storage options. is becomes especially concerning noting that AEMO’s largest projected category of storage investment is in the form of consumer energy resources (CER) i.e. customer purchased energy storage.

is is all without considering assumed progress of electri cation of residential and commercial gas demand, which industry modelling shows is in no way connected to real world energy and appliance cost statistics.

ere is hope for a better future however, where AEMO ISP scenarios and other projections genuinely consider the opportunities of gas supply chains and the impacts on gas customers.

e Federal Government commenced consultation into a “supercharged” ISP in 2023, exploring the opportunity to model electricity and gas supply chains side by side through multi-vector energy modelling. is could inject natural and renewable gas supply chain and storage economics into AEMO’s calculations, and ultimately reduce projected energy costs for all energy customers.

However, initial signs aren’t promising. e Federal Department initially dismissed multivector energy modelling as ‘impossible’ due to resourcing, despite the University of Melbourne having accomplished exactly this through a Future Fuels CRC Project. Impossible without increased investment in modelling capability, sure, but not impossible.

Every two years AEMO updates its ISP, and APGA provides advice demonstrating AEMO’s approach to gas supply chain fails to re ect market realities. Maybe development of a ‘supercharged ISP’ will help get things right, only time will tell.

10

POLICY

The Australian Pipeliner | March 2024

A better future is possible on the condition that AEMO considers the opportunities of gas supply chains and the impacts on gas customers.

Image: Mike Mareen/stock.adobe.com.

• First to move the vacuum reservoir from the excavator stick to the counterweight

• First to use the excavator hydraulics to power the vacuum pump

• First to remove radio remote control

• First to introduce dedicated excavator operator controls

• First to introduce 360˚ rotation

• First to develop an in-trench pipe assembly apparatus

• First to develop an hydraulically assisted multiple o ring jointed pipe assembly tool

• First to develop a remote controlled in pipe inspection tool

• First to develop a VacLift that will only release a pipe when the pipe is on a solid surface

• First to increase the range of diameters able to be handled by each pipe shoe

• First to develop a fully adjustable attachment pickup.

We know the industry better than anyone, talk to us about all your pipeline plant hire needs first.

ONE CALL - PROBLEM SOLVED 1300 367 046 PIPELINEPLANTHIRE.COM.AU

Understanding the techno-economics of hydrogen energy

Our recent research shows how the economics of producing and moving hydrogen are evolving, enabling projects to move towards wider commercialisation based on better economic knowledge.

Producing hydrogen

e Universities of Adelaide, Melbourne and Queensland have worked together on a detailed technical and economic assessment of hydrogen production processes.

ey assessed 22 production methods from water electrolysis and biomass processing, to natural gas and coal with carbon capture and storage (CCS).

ese included processes such as steam methane reforming, autothermal reforming and coal gasi cation all combined with CCS.

Two variations of methane pyrolysis were also examined, where importantly carbon is transformed into a solid byproduct, rather than gaseous carbon dioxide.

ey looked at every opportunity for low emission hydrogen production, modelling how feedstocks, capital and operational costs could be combined into a quantitative economic comparison.

Over half of water electrolysis’s total costs are from the electricity used, so driving cost reductions there would create major improvements in overall cost.

For biomass processing, only electricity prices and the capital cost of the processing plants had a notable impact on the overall cost of hydrogen, which is where proponents need to focus their development work.

For natural gas the modelling showed that autothermal reforming with CCS o ers the current lowest potential costs but was heavily reliant on the cost of the natural gas feedstock.

Production that uses fossil fuel feedstocks requires CCS to reduce emissions, for which energy penalties, capital and operating costs were included. For biomass pathways, the cost of adding CCS to yield negative emissions was

also investigated as a signi cant potential extra bene t.

Purifying the nal hydrogen fuel was an important cost across all technologies, indicating that end-uses with a tolerance for lower-purity hydrogen could access supplies at a lower cost.

e researchers considered hydrogen carriers including ammonia, methanol and liquid hydrogen, to search for the most economic pathways for future development.

e modelling found ammonia was the most cost-e ective carrier on a mass basis. at cost doesn’t include conversion back to hydrogen later.

Moving hydrogen or electricity?

e widespread adoption of hydrogen produced from green electricity raises a fundamental question, is it more cost-e ective to transport “green” hydrogen molecules, or transport “green” electricity around Australia?

e University of Melbourne has delivered a rst-of-its-kind mathematical framework for nding the optimal plan of electricity and hydrogen transmission and storage infrastructure.

e team of researchers have demonstrated the capabilities of this framework with two case studies; a single transmission corridor case study that assesses supply capacity, corridor length and storage requirements and then a larger, more complex proof-of-concept case study that considers all the renewable energy zones proposed in the Australian Energy Market Operator’s 2022 Integrated System Plan. at case study also considers hydrogen export ports and how depleted gas elds for underground hydrogen storage (UHS) could play a crucial role in bu ering the variability of renewable energy sources.

is modelling considers high voltage direct current (HVDC), high voltage alternating current, reactive power plants, battery energy storage systems (BESS), and hydrogen pipelines and compressors, but also incorporates all the essential nonlinearities that in uence

infrastructure decisions. eir ndings suggest for hydrogen volumes modelled at port locations:

For steady-state throughputs, hydrogen pipelines are more cost e ective than their electricity counterparts.

In cases where more than two hours of storage duration are required, hydrogen pipelines are more cost e ective than their electricity counterparts over most distances and capacities.

In cases where only one hour of storage is required, the optimal transmission and storage infrastructure is heavily in uenced by the cost of BESS relative to the cost of electrolysers.

For export projects, linepack storage’s role is very important, as the RES supply is variable and the hydrogen export demand is constant.

Investing in UHS in the form of depleted gas elds in speci c locations in Australia can signi cantly decrease the total investment costs of transport and storage infrastructure as the marginal cost of underground storage is much lower than that of a pipeline.

is research helps to lay the groundwork for Australia’s full-scale hydrogen industry, by understanding how to make the optimum infrastructure investment.

12

For more information, visit futurefuelscrc.com

is creating the depth of new knowledge needed to take hydrogen fuel into the mainstream. FUTURE FUELS CRC

Research

The Australian Pipeliner | March 2024

Future Fuels CRC Chief Executive O cer David Norman. Image supplied by Future Fuels CRC.

Future Fuels CRC Chief Executive O cer David Norman

Plugging the leak: How pipeliners can act

The Women in Pipeline Forum discusses this year’s United Nations International Women’s Day theme: ‘Count her In: Invest in women. Accelerate progress’.

By Gretyl Lunn

Iwent to my rst International Women’s Day event two years ago and couldn’t quite describe why I thought it missed the mark. e gender pay gap, a rmative action, even menstrual leave, were some of the topics mentioned. Important topics, but all I could think was, “wow, the presenters are trying so hard to be edgy with these topics.”

Pretty soon I realised what was missing: action. International Women’s Day was rst celebrated in 1911 and was recognised by the United Nations (UN) in 1975. Today, this date is a reminder that gender equality is still a human rights challenge across the globe.

is year’s theme from the UN is ‘Count her in: Invest in Women. Accelerate Progress.’ As the industry undergoes change, how we embrace diversity of people and thought will remain pivotal for our role in steering Australia to a greener economy and sustainable energy systems. ere are two components to building a gender diverse workforce attraction and retention. e rst involves encouraging more women into science, technology, engineering and mathematics quali cations, trades and the industry, which remains a permanent priority. e second involves supporting and developing the women already in the industry, so that they can thrive. However, despite massive strides in women’s representation over time, there is still a noticed attrition of women over 30 from the industry. is phenomenon is referred to as the ‘leaky pipeline’.

During the APGA Convention last year, the WPF asked, ‘what can you do to empower women in the industry?’ and ‘what do women in

the industry need?’ e responses covered ve common themes: trust, opportunity, mentorship, support, and safe spaces.

Support and safe space made up 34 per cent of the responses regarding the needs of women in the pipeline industry. It’s critical, and yet importantly, can be remedied with the actions of individuals.

To me, a safe space looks like my rst commissioning manager sitting me down and telling me, “if you have any problem with anyone on site, you tell me, and we’ll handle it”. It was my General Manager terminating the contract of a contractor who had sexually harassed me. It was my friend, also a rst-year graduate at the time, saying after I con ded in him about the harassment: “I thought I should have said something because you looked uncomfortable and next time I will”.

You can’t write a procedure on how to be a safe space. It is a choice that is made by individuals and hopefully fostered by a site or company.

Ultimately it comes down to individuals treating women with the same respect as their male colleagues, bestowing trust, and being trustworthy providing encouragement.

It also comes down to recognising women’s achievements, actively ensuring a safe work environment – physically, socially and emotionally, checking their unconscious bias and ensuring women on site or in their team are included in social events.

Mentorship also empowers women, not just professionally, but by actively providing that safe space, particularly for young people who may have never been in a professional or site-based

role before.

There are other, broader goals, which aim to empower women. Opportunity was featured in 27 per cent of responses on how to empower women in the industry. Many missed opportunities stem from the fact that women are still assumed the primary care giver in our society. To change this requires a greater social change, but we could start with encouraging exible work for men to share home duties more equally as well as changing construction rosters to make them family friendly.

Encouraging exibility for everyone allows both men and women to have real choices about care giving and gives women opportunity in the workforce.

Finally, there are procedural initiatives which can be implemented within companies:

• Gender neutral parental leave

• Flexibility in working hours - without conditions that impact career development

• Availability of development training

• Awareness of harassment and reporting policies

• E ective diversity, equity, inclusion and unconscious bias training

• Industry and company mentorship programs

So with International Women’s Day this month, are you going to inspire action to truly make women feel like they count, or is it just going to be a day for a nice morning tea (organised by women)?

How are you counting the women around you in? Would your graduates or apprentices feel safe sharing with you something that’s made them uncomfortable? Do they have the opportunity to?

To truly count women in and plug the leaky pipeline is a choice all can make every day.

14 The Australian Pipeliner | March 2024

WOMEN’S PIPELINE FORUM

Empowering women can’t happen without taking concrete actions.

Image: AFotostock/stock.adobe.com.

Trenchless Infrastructure Solutions

Horizontal Directional Drilling

· Completed record breaking 4.7km long HDD

· Hundreds of intersect and long-length crossings

· Rigs available with push/pull capacity up to 815 tonne

· Pipe Installations up to 1.5m

Direct Pipe

· Foremost Direct Pipe Contractor

· Outfalls and shore approaches

· Pipe Installations up to 1.5m

Australia-based operations with permanent local resources

Fully integrated with our global team at international headquarters

Multiple NASTT Project of the Year awards

MichelsTrenchless.com.au

1300 464 243 Level 1 | 98 Murphy St | Wangaratta, VIC 3677 SCAN ME 8,000 people strong founded in 18,000 pieces of equipment

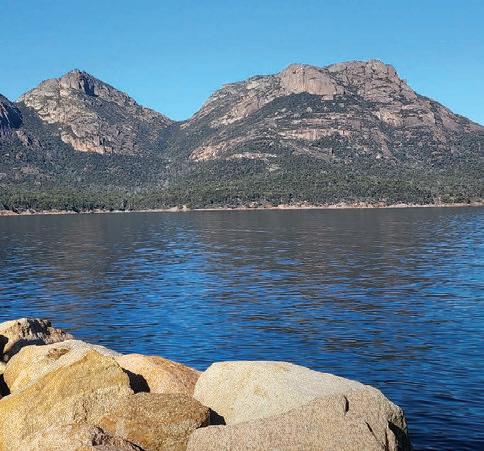

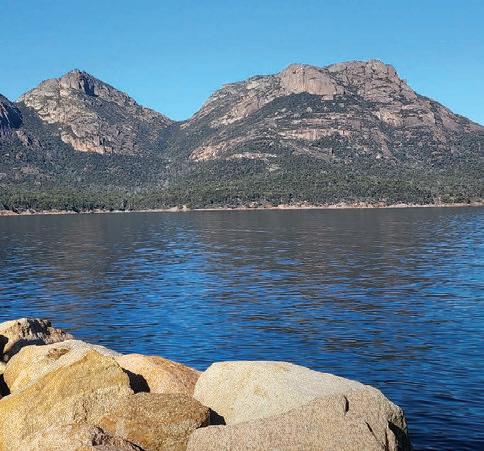

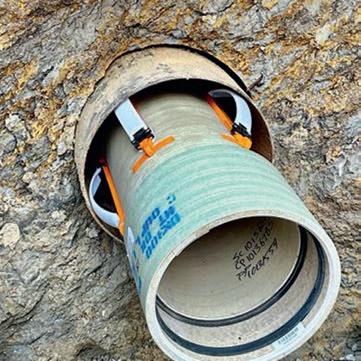

Fitzroy to Gladstone powers ahead

Since starting construction in October 2023, the Fitzroy to Gladstone Pipeline continues to make progress.

As of December 2023, a total of 26km of pipe had been laid through the northern pipeline corridor, making up more than 22 per cent of the 117km of pipe required.

is includes two of the seven total water pipe adaptors within the pipeline corridor. e remaining ones will be completed during the dry season of May to September this year.

roughout the period, pipe laying from Ski Gardens Road to the Alton Downs water treatment plant was also completed, as well as two trenchless crossings at Nine Mile Road and Ridgelands Road in in Alton Downs.

Meanwhile, in November 2023, pipe laying through the northern area of the Stanwell to Gladstone Infrastructure Corridor State Development Area commenced. Pipe laying works of the southern area of the pipeline corridor is expected to commence early this year. is will follow the completion of preparative works such as geotechnical investigations and cultural heritage clearances, which have been ongoing since mid-2023.

Other upcoming activities include the Ridgelands Road and Laurel Bank Road intersection upgrade, site establishment at Alton Downs water treatment plant and Fitzroy River and continued local procurement and engagement of subcontractors.

In October 2023, Fitzroy to Gladstone Pipeline (FGP) Chief Operating O cer Hugh Barbour and Project Delivery Director Graham Stacey also visited the Steel Mains facility, which is providing 106km of mild steel cement lined pipes to transport the high-pressure water in the pipeline.

e $983 million FGP will have the capacity to transport 30 gigalitres per annum from the FPG in Queensland.

e new pipeline will address Gladstone’s

single source water supply risk from Awoonga Dam and will enable long-term security for customers.

Construction began in October 2023 which saw former QLD Premier Annastacia Palaszczuk and Minister for Water and Member for Gladstone Glenn Butcher attend the sodturning ceremony.

“ is critical project is more evidence that Queensland’s Big Build is delivering for Queenslanders, no matter where they live,” Palaszczuk said at the time.

“Its construction will also lead to new industries like hydrogen establishing themselves in Gladstone knowing they have water security, delivering the clean energy jobs of the future.”

e pipeline comprises of a water treatment plant, reservoirs and pumping stations along its alignment.”

Butcher said following recommendations from

experts at Brad eld Panel, the best use of water resources is using water closer to where it falls and developing regional water grids.

“ at is exactly what we are doing through delivering Rookwood Weir and the Fitzroy to Gladstone Pipeline,” he said.

McConnell Dowell BMD Group has been contracted to construct the pipeline, and once constructed, the FGP will be owned and managed by the Gladstone Area Water Board.

“We’re eager to see the lasting positive legacy that the Fitzroy to Gladstone Pipeline will have on our region, creating economic prosperity and resilience for both Gladstone and Queensland for generations to come,”

Gladstone Area Water Board Chief Executive O cer Darren Barlow said.

e project is expected to be completed in late 2026, weather and construction conditions permitting.

16 The Australian Pipeliner | March 2024

WATER PIPELINES

Images: Gladstone Area Water Board.

Two of the seven total water pipe adaptors have been installed.

The new pipeline will enable long-term security for Gladstone.

EXCELLENCE

IN UTILITES

Abletech Underground is recognised as a trusted leader in providing industry solutions for a wide range of sectors and industry projects.

Abletech Underground brings a wealth of experience and capabilities to the energy sector, approaching each pipeline project with the utmost e ciency. We have the ability to mobilise Australia-wide, understanding individual site requirements. We ensure our clients’ needs are met while establishing long-term professional relationships founded on personalised service, reliability, and e ciency.

Abletech Underground has unmatched expertise gained from our extensive involvement with a multitude of challenging large-scale projects. Our highly skilled team, up-to-date industry accreditations, state-of-the-art equipment, industry leadership, ISO certifications, and attention to detail.

WWW.ABLETECHUNDERGROUND.COM.AU admin@abletechunderground.com.au Road and Rail Water Authorities Construction Oil & Gas Surveyors Solar Tunnelling & Drilling Engineers, Consultants, Designers Environmental Residential Owners Mining Councils & Government INDUSTRIES WE WORK WITH:

Stormwater drainage solution shaking up industry

Iplex’s product portfolio is a testament to its dedication of advanced solutions that enhance performance, durability, and e ciency. One of these innovations is BlackMAX® stormwater drainage pipes and ttings.

When it comes to stormwater drainage systems, steel-reinforced concrete has previously been the chosen material.

However, in recent years heavy duty corrugated plastic drainage pipes have been recognised as a viable alternative.

As the original plastic large bore structured wall pipe manufacturer in Australia, Iplex takes pride in providing councils, asset owners and developers an alternative solution for stormwater drainage.

Having been in the water industry for over 30 years, Iplex National Technical Sales Engineer Don Tasevski attests to the quality and reliability of BlackMAX as a competitive alternative to the conventional concrete pipe.

“We wanted to provide an alternative solution to concrete drainage pipes, o ering a durable and lightweight system which is resistant to corrosion

and root intrusion,” Tasevski said.

With a high sti ness rating of SN8, the e cient design of the BlackMAX pro le wall features a smooth inner bore and corrugated outer wall, optimising hydraulic performance while maintaining structural integrity.

Poor joint performance can lead to leakage and tree root intrusion causing pipe blockages and ground water in ltration. For this reason, the quality of the joint is critical to the performance of any pipe system.

BlackMAX pipes and ttings are manufactured with a high-quality spigot and socket rubber ring jointing system.

“For pipe diameters up to DN525 the joint is made with a corrugated socket, and for our larger sizes the socket is a double wall cu ,” Tasevski said. is feature provides peace of mind by adding strength and security at the pipe joint.

BlackMAX pipes are resistant to corrosive and

aggressive ground conditions, such as acid sulphate soils and saline ground waters, enabling years of corrosion free service and minimal maintenance.

Water Services Association of Australia (WSAA) undertook a comprehensive appraisal of BlackMAX and SewerMAX and concluded polypropylene pipes have an anticipated service life greater than 100 years, if designed and installed in accordance with industry standards.

A key bene t of Iplex’s BlackMAX is its ease of installation compared with other conventional drainage pipes.

Lightweight BlackMAX pipes can be easily manoeuvred in con ned areas by hand or with light lifting equipment.

BlackMAX pipes are one of the safest pipes to install. “With the recent spotlight on the health implications of silica dust exposure, the advantage of not cutting concrete pipes is

18 The Australian Pipeliner | March 2024

WATER PIPELINES

BlackMAX optimises hydraulic performance while maintaining structural integrity.

Images: Iplex.

becoming an important point in the discussion,” Tasevski said.

“BlackMAX pipes can be cut without risks of silica dust exposure; pipe can be cut anywhere along the pipe length with a hand saw to make length adjustments on site without the need to suppress dust.”

To stay at the forefront of pipeline innovation, Iplex is extending its current BlackMAX size range.

e BlackMAX range will be extended to provide larger sizes with a complete package of ttings for large infrastructure projects.

“As councils continue to support new products and innovations, the potential for alternatives will continue to grow,” Tasevski said.

“Our larger diameter pipes provide enormous opportunities for our customers and the communities they serve.”

With over 85 years of experience, Iplex has established itself as a leading provider of water solutions in Australia.

Iplex’s commitment to collaboration, expertise and innovation have made them a trusted partner with water authorities and within civil, irrigation and plumbing markets.

» Quality and collaborative HDD design and construct services

» Expertise to advise at the right time in the project delivery cycle

» Maxi-rigs capable of long and wide diameter bores in hard rock and difficult conditions

» Building a future we all look forward to

» Gas, water and sewer, rail, road, power, telecommunications, mining, residential development, renewables and hydrogen

For more information, visit iplex.com.au WATER PIPELINES

19 The Australian Pipeliner | March 2024

LEADING HDD SPECIALIST 02 4966 5583 www.maxibor.com.au admin@maxibor.com.au Follow us on LinkedIn, Facebook &Twitter

BlackMAX is an unparalleled solution when it comes to stormwater drainage.

AUSTRALIA’S

Maxibor is using its design and construct expertise to deliver better project outcomes to asset owners and principal contractors alike

Hitting the benchmark with Riteline

The water and pipeline industries are set to bene t following Riteline spacers being successfully appraised by the Water Services Association of Australia.

Riteline Centralisers represent an innovative solution designed to revolutionise the accuracy of trenchless installations by providing unparalleled support to the carrier pipe, ensuring its xed position relative to the bored hole or encasement pipe.

So, it is no surprise that the Water Services Association of Australia (WSAA) has given Riteline Centralisers the coveted product appraisal certi cate.

Late last year, the cutting-edge technology was approved by WSAA for use in the water and wastewater industry.

Under the leadership of Chief Executive O cer Stuart Harrison, OptionX Group –the parent company of Riteline Centralisers –is making waves.

“Riteline was developed to overcome several limitations of traditional spacers,” Harrison said.

“I’m excited to see that the industry has o cially recognised the spacers.”

e successful appraisal of Riteline by WSAA provides a new option for pipeline installations that complies with WSA PS-324 for casing spacers.

"Contractors and operators can con dently use Riteline Centralisers on their projects, knowing they have been through the necessary tests and thirdparty analysis,” Harrison said.

“ e WSAA appraisal serves as a benchmark for quality within the industry. It signi es that Riteline

Centralisers have met the highest strength, reliability, and quality assurance standards.”

How Riteline Centralisers came to be Riteline Centralisers have been engineered to cater speci cally to the horizontal drilling sector, where precision and adaptability are paramount.

Unlike traditional casing spacers, Riteline Centralisers o er remarkable adaptability, accommodating pipes ranging from 100mm in diameter, with no upper limit.

e ability to make incremental adjustments on-site eliminates the need to purchase speci c sizes, reducing time, cost, and stock wastage.

It also features adjustable heights spanning from 30mm to 125mm. is versatility addresses the diverse needs of trenchless drilling projects, allowing for seamless adaptation to varying conditions.

“One of the limitations of traditional casing spacers was that they needed to be purchased in speci c sizes and couldn’t be adapted on-site to meet changing needs,” Harrison said.

“ is resulted in time, money, and stock wastage. With Riteline Centralisers, there is no need to buy multiple centralisers of di erent sizes.”

e journey of Riteline Centralisers was fueled by industry feedback and real-world eld data.

e collaborative nature of OptionX allowed Riteline to address industry frustrations innovatively, resulting in a product that aligns with the demands of horizontal drilling projects.

Innovative design of features

A distinctive feature of Riteline Centralisers is its individually attached design, minimising the risk of catastrophic failure. is innovative approach enhances safety and reliability, crucial factors in the success of trenchless drilling projects.

Unlike traditional centralisers that surround the pipe and are prone to failure when snagged on obstacles, Riteline's design ensures a more secure and resilient installation.

e low-pro le design of Riteline Centralisers further sets them apart. is thoughtful engineering facilitates seamless grouting, preventing failures and ensuring secure and accurate installations in trenchless drilling operations. Reducing the risk of grouting issues contributes to trenchless drilling projects' overall e ciency and success.

Typically, centralisers are made to either slot together to fully surround the pipe or must be designed in a size that surrounds the pipe. Regardless of the weight or load requirements, the maximum number of centralisers is called for.

Riteline overcomes this limitation as they can be attached to the pipe as needed, with the number of spacers required based solely on the load, providing a tailored and e cient solution. is unique feature lowers excess product use, reducing costs and environmental impact.

“As each centraliser is individually attached to

20 The Australian Pipeliner | March 2024

Images: OptionX Group. WATER PIPELINES

Riteline spacers have been successfully appraised by WSAA.

Riteline centralisers have been engineered to cater to the horizontal drilling sector.

the pipe, the risk of catastrophic failure is reduced. Traditional centralisers that surround the pipe can fail when they snag on an obstacle in the bore, which can cause an entire ring of centralisers to move, compromising the installation,” Harrison said.

Flexibility and adaptability

e system can be used for all pipe materials, including steel, ductile iron, GRP, FRP, concrete, PVC and PE for pressure and nonpressure pipelines. e Flex Series can only be installed in grouted applications, whereas the Rigid Series suits both grouted and ungrouted installations.

e Flex Series is designed to ex around bore imperfections with its unique spring-like design. is not only allows for tension adjustment but also enables elastic deformation around obstacles, preventing jamming and ensuring a smooth work ow in horizontal drilling applications.

At the same time, the Rigid Series incorporates supports that provide a high loadbearing capacity and is recommended for most installations.

Industry recognition

It’s not just the WSAA that has recognised the range of Riteline Centralisers. e product range was acknowledged as a nalist in the New Technology category at the 2023 ASTT Awards, attesting to its innovation

and game-changing capabilities.

“Riteline Centralisers are Australian-owned and manufactured, developed over almost ten years,” Harrison said.

“It is fantastic to see them recognised as an innovative and game-changing product.”

For more information, visit riteline.com.au

WATER PIPELINES

What makes Riteline stand out is the adaptability of the product range.

New pipeline for Coles Bay

TasWater’s latest water main renewal project is all about providing additional water surety to the township by installing an additional pipeline from the existing water main on Coles Bay.

According to TasWater General Manager Project Delivery Tony Willmott, this new pipeline will change Coles Bay’s watermains for the best.

e Coles Bay township is currently supplied by a single pipeline from the reservoir to the north of the town.

e last 750m of this existing main has approximately 80 properties connected with ttings that will need replacing in coming years.

If a fault occurs to any of these connections, a complete water supply interruption is required to make repairs.

e new pipeline will be added to the existing water main on Coles Bay Road to the corner of Reserve Road.

Willmott said this additional pipeline will minimise the number of water supply interruptions for the community of Coles Bay.

“Installing a second section of water main will allow repairs to the existing pipeline to be made

without interrupting water supply to the entire Coles Bay community,” he said.

e Coles Bay township is supplied with water from the recently upgraded reservoir located north of the town.

With the current water main con guration, if a fault occurs to any part of the network, a complete shutdown is required to make repairs, which produces a supply interruption to the approximately 300 water connections that form the Coles Bay water supply network.

“As part of our commitment to the responsible delivery of safe and reliable drinking water to homes and businesses across Tasmania, this new project alleviates potential shutdowns while repairs are undertaken in future,” Willmott said.

Works are scheduled to commence in March 2024 and to take approximately eight weeks to complete once construction starts.

Weather permitting, TasWater anticipate this project to be completed by mid-2024.

Coles Bay is on the east Coast of Tasmania 192km north-east of Hobart and is the main entrance point for visitors to the Freycinet National Park.

It has a population of 515 people including the surrounding area but attracts thousands of tourists for its scenery and outdoor activities.

Each Easter the town is one of the three locations for the Australian ree Peaks Race, a continuous sailing and running event starting at Beauty Point just north of Launceston and ending at Hobart with runners scaling three mountains including Mount Freycinet. is project, besides guaranteeing water security to the communities, will also reinforce the region’s touristic hub status by avoiding any water supply interruptions.

“ e additional pipeline will minimise disruptions to residents and businesses,” Willmott said, “it will improve compliance, and provide water security for the community.”

22 The Australian Pipeliner | March 2024

WATER PIPELINES

Images: TasWater.

The Hazards mountain range looking from the Coles Bay foreshore.

Coles Bay is a destination beloved by tourists, and the new pipeline will improve water security in the area.

GripTight ® Test & Isolation Plugs

Safe and Effective Solutions for Rapid Pipe Testing & Repairs

Confidently test open-end pipe, pipelines & pressure vessels without welding, and isolate & test flange-to-pipe weld connections with GripTight Test & Isolation plugs from Curtiss-Wright.

• Patented gripper design for increased safety in high-pressure applications

• Eliminates welded end cap procedures for testing pipe spools & piping systems

• Test flange-to-pipe welds without pressurizing entire systems

• Isolate & monitor upstream pressure and vapors during hot work

• Standard pressure ratings up to 15,000 PsiG (1034 BarG)

• ASME PCC-2 Type I, III & IV testing devices

Call, click or scan to learn more about our full line of Test & Isolation equipment +1.800.355.7044 l est-sales@curtisswright.com l cw-estgroup.com/tap-24

SAFE.

TRUSTED.

RELIABLE.

CO2 pipeline testing success

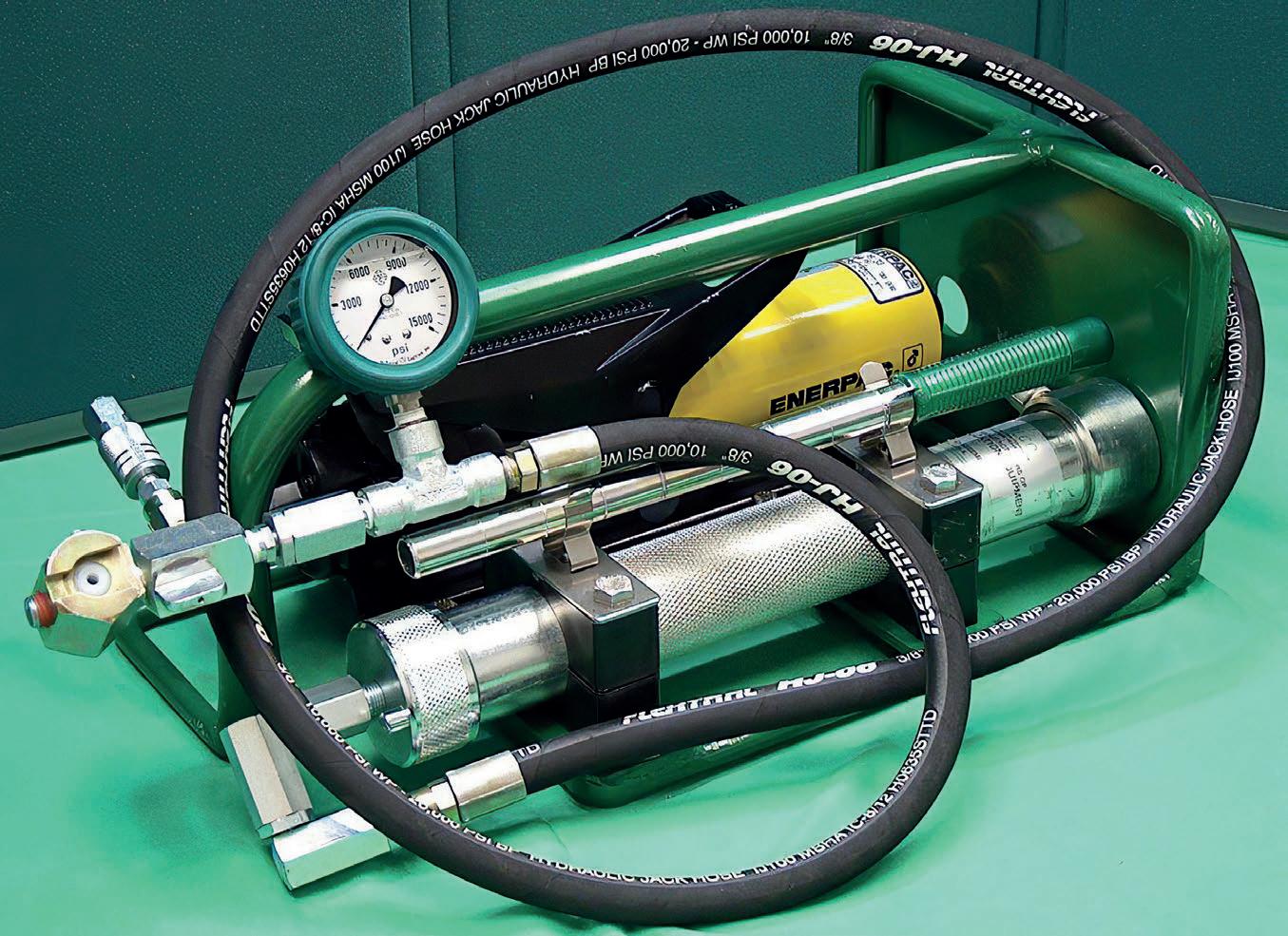

As Australia moves towards a cleaner energy future, more CO2 pipelines for carbon sequestration will be required. The Australian Pipeliner spoke with Pipe Tek Chief Operating O cer Taddam Farrant about the company’s successful pipeline and facility testing for contractor MPC Kinetic on Santos’ Moomba Carbon Capture and Storage Project and overcoming the challenges of working in the remote Cooper Basin.

Santos’ Moomba Carbon Capture and Storage (CCS) Project will deliver a largescale CCS hub centred around the Moomba Gas Plant, targeting capture of up to 1.7 million metric tonnes (MMt)/a of CO2 for injection into depleted gas reservoirs in South Australia’s Cooper Basin. e monumental project is an important component of Santos’

industry-leading emission reduction target of net-zero by 2040.

e project includes a 53km, 10-inch diameter carbon steel pipeline to transport compressed, dehydrated CO2 from the Moomba CCS facility east to injection wells at depleted reservoirs in the Marabooka and Strzelecki elds. e heavy and standard wall pipeline is designed

a bidirectional

to transport the dense-phase CO2 at pressures between 10-15MPa.

MPC Kinetic (MPK) was contracted to construct the pipeline, who then engaged Pipe Tek to test the pipeline and ve aboveground facilities before commissioning.

Why is this project so interesting?

Although the process of injecting into depleted reservoirs has been used for many years, CCS is a relatively new technology that has the potential to help Australia achieve a decarbonised energy future, with pipelines playing an important part in transporting the CO2 emissions.

Once completed, the Moomba CCS Project Pipeline will be the longest CO2 transmission pipeline in Australia, and its successful development will likely see more gas companies plan to sequester their emissions in Australia’s remote depleted reservoirs.

CO2 pipelines have some unique design and operational requirements:

• Maintaining a supercritical ow of CO2 through the pipeline: Pure CO2 reaches supercritical form when in an environment with pressures above 7400kPag and temperature above 31C.

• Dehydration: e CO2 needs to be dehydrated before entering the pipeline to avoid the formation of free water which could lead to pipeline corrosion or the formation of CO2 hydrates across throttling valves at pipeline de-pressuring vents and the injection wells.

MPK included rigorous testing requirements for both of the above elements as part of the Pipe Tek’s pipeline and above-ground facility testing brief.

e testing process

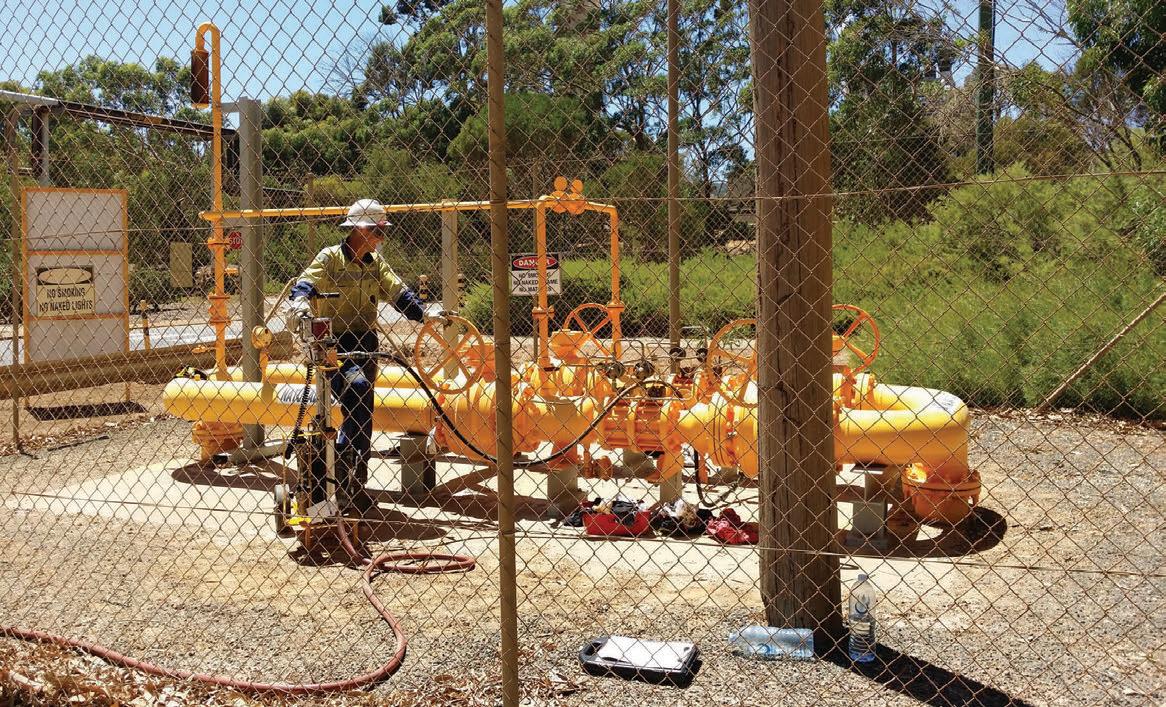

Pipe Tek’s Chief Operating O cer Taddam Farrant managed the pipeline and above-ground facilities testing.

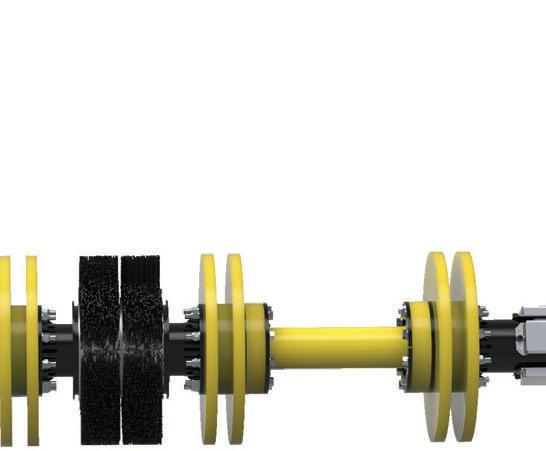

Before testing could occur, a rigorous precleaning process was required. Several cleaning runs were performed with an Enduro pig train to ensure the pipeline internal surfaces were burnished and substantially free of residual dust.

“We chose to use an Enduro bidirectional pig train and pig links. It included cups, brushes, gauge plates and magnets with bypass sealing

24 The Australian Pipeliner | March 2024

PIPELINE CONSTRUCTION

Installing

brush magnet pig for cleaning inside the 53km, DN250 CCS pipeline. The tool is propelled with compressed air.

Images: Pipe Tek.

bidirectional pig with high-wear discs before being strength and leak tested to 21,000kPa and AS2885.5 requirements. e ve aboveground facilities were leak tested as per ASME B31.3.

Dewatering

Once the pressure tests were completed and approved, Farrant and his team began the dewatering and cleaning process, taking into consideration the stringent requirements to ensure no free water remained in the CO2 pipeline.

“We ran a desiccant dryer with a stage of cleaning and drying pigs to ensure no further water, debris or particles were pushed in front of the pigs as they exited the pipeline,” he said.

discs to allow for optimal cleaning and reduce ferrous material left behind from the construction process,” Farrant said.

“We’ve been working with Enduro as part of an exclusive partnership deal since 2019 – we choose their tools because we believe they perform above their competitors and provide more e cient and reliable data to our clients.”

e pig train and a series of magnets were run through the pipeline until visual inspection showed the internal surfaces to be clean, bright and free from particulate rust and scale, and air exiting the pipeline ahead of the pig was clear and practically free of dust.

e pipeline was then lled using a

“We were working to an acceptance criterion of less than 15mm for the depth of discoloration of the foam pigs after being cut, but we managed to achieve less than 5mm penetration on the handover acceptance pig – which is an incredible achievement for a 53km pipeline.”

e dew point at the end of the drying process was -20°C.

Following the drying process, a commissioning batch treatment was carried out to establish the pipeline corrosion inhibitor consisting of 1:1 mixture of Diesel and Corrosion inhibitor.

After the successful completion of the aboveground leak tests, the pipeline was then N2 purged with less than 5 per cent residual O2 content left in the pipeline with a blanket pressure of 350kPag.

Remote location

Working in the Cooper Basin poses a large challenge in terms of transport and logistics for most companies.

“ e Cooper Basin has always been

di cult to navigate,” Farrant said.

“It’s remote, dry, hot, and dusty. is posed a particular challenge for our works because it was important, we had clean equipment and a good source of water to complete the testing.”

Pipe Tek set up mobile wash down bays for the Enduro pigs on trailers specially designed to transport the gear in and out. Located at either end of the pipeline during the cleaning and testing runs, the trailers were also set up with satellite communication so the team could receive up-to-date, live information on how the pigs were running.

MPK supplied four 750,000 litre water bladders to push the pigs and ll the pipeline for hydrotesting. e water was then disposed of into a man-made settling dam.

“ e extreme heat was also a concern. Our team worked 24 hours a day on split shifts to complete the work on time,” Farrant said.

“To ensure everyone’s safety, we made sure that our trailers were set up with shade, air conditioning, fridges to store food and plenty of water.”

CO2 pipelines represent a critical component in enabling the e cient and safe transportation and storage of CO2, supporting Australia’s e orts in reducing greenhouse gas emissions.

MPK and Pipe Tek’s involvement in successfully commissioning Santos’ Moomba CCS Project Pipeline puts them at the forefront of CO2 pipeline expertise in Australia.

“We’re so proud to have been involved in this project, and met the high expectations of the testing scope,” Farrant said.

“Now, we’re looking forward to getting started on our next challenging project.”

Pipe Tek is a pipeline cleaning, inspection, and testing company with strong attention to detail and a direct approach to safety.

25 The Australian Pipeliner | March 2024

visit

For more information,

pipetek.com.au

PIPELINE CONSTRUCTION

The dusty, hot, and dry Cooper Basin poses a challenge for pipeline cleaning and hydrotesting works where equipment needs to be kept clean and a good source of water is required.

The Enduro tools used to clean and test the Moomba CCS pipeline.

e essence of customer satisfaction

Austrack Equipment’s key focus, alongside the quality of its machinery, is making sure its customers will come back for more.

The Austrack Equipment yard can only be described as a hive of activity. With the main yard close to where the Brisbane River meets the Paci c Ocean, the Brisbane International Cruise Terminal is only walking distance away.

But at the 12,000 square metre facility, cruising is the last thing on anyone’s mind with heavy equipment is arriving and departing the yard at all hours of the day and night.

e number one customer receiving its equipment are Australia’s premier pipeline contracting companies.

It is from here that Austrack services its customers with specialised equipment that keeps Australia’s premier pipeline contractors productive.

e array of machinery on show is impressive and includes excavators up to 90 tonnes. But it doesn’t stop there with graders, loaders, dozers, telehandlers, tractors, backhoes, dumpers, Moxy’s, padders, crawler carriers, and vacuum pipe lifts also available.

ere is also an array of attachments capable of performing almost any work task that anyone installing a pipeline has ever even considered.

Austrack Plant Manager Matt Jones is in charge of looking after all operations as well as working out the complicated logistics of getting equipment to and from the facility.

“It can look a little chaotic here at times, but we like to think the chaos is organised and controlled,” Jones said.

“Our absolute priority is to ensure that our customers get the very best service possible.”

Part of the reason behind Austrack’s ability to make and keep delivery promises is the strategic partnerships the company has forged across its supply chain.

is ensures delivery promises are met and means that the equipment provided is in top class condition.

“It also means that we assist our customers with informed advice on the equipment they require to get their job done,” Jones said.

“It means getting machines to where they are needed, on time and ready to work, and it means when machines break down as they sometimes will that Austrack organises having them attended to and put back in service as soon as possible.”

Jones’ heightened understanding of customers’ needs in pipelining doesn’t just come from what he has learned at Austrack. But from his unique set of quali cations and skills.

Before Austrack, he spent more than 30 years on the front-end of pipelining.

“I spent a good deal of my work life in pipelining before I joined Austrack,” he said. “I started o in Queensland on the Cheapie to Gilmore section of the gas pipeline which eventually nished in Barcaldine.”

For the past 20-odd years Jones has been at the pointy end of water and gas pipelines in most of the mainland states.

“I have worked and ran crews at Moomba in South Australia and the Surat and Cooper Basins in Queensland, worked on the Sydney to Longford, Victoria gas pipeline and onto major Victorian water pipelines like the Sugarloaf,” he said.

His passion? Concentrating on the now with one eye always on the future.

“I know what it is to be a customer and that knowledge gives me a clear vision to deliver the considered advice and the quality service that pipeline contractors need,” Jones said.

Austrack is big on planning and reacting at speed and problem solving, positioning itself as a ‘can do’ supplier.

“What we are not big on is excuses. e words ‘can’t’, ‘won’t’ and ‘maybe’ are not much in use around here,” he said.

Jones has seen Austrack grow exponentially in his time with them.

e company has outgrown two yards already and the two-person-start-up operation has matured into a highly e cient equipment hire operation that can service its customers in any corner of this big country.

“Dealing with Austrack is not just about hiring machinery,” Jones said.

Austrack’s machinery comes backed by an expert team to support customers in every step with responsive intelligent and informed advice to tackle any challenge.

e company supplies only name brand reliable equipment, ensuring its well-maintained equipment meets the highest safety standards.

“We also pride ourselves on staying ahead of the

26 The Australian Pipeliner | March 2024

PIPELINE CONSTRUCTION

Images: Austrack Equipment.

Massey Ferguson 7724 tractor dragging heavy pipes up steep inclines on a water pipeline in Kuri Kurri, NSW.

Selection of Austrack excavators waiting for their next assignment.

curve with machinery technology. Whether it’s happening here in Australia or overseas, and the boss Mick Benson makes sure we keep our nger on the pulse,” he said.

e recent introduction of the SafeVac Lifting Systems Vacuum pipe lifter has added an extra string to Austrack’s bow and completed the range of equipment it can supply to pipeline contractors.

“ e successful introduction of our SafeVac system which sports the Australian made logo is a great sense of pride to us here at Austrack,” Jones said.

“We have supplied SafeVac systems for two signi cant water pipelines in Queensland currently under construction one being the Fitzroy River to Gladstone, the other the Haughton pipeline Stage 2 servicing Townsville.”

Jones said Austrack has already custom-built sand hoppers in service on the Haughton pipeline project, leading to the clinet wanting a second one.

“A client will come to us and tell us what they want, and if we don’t have it we go out and source it,” Jones said.

“And if it requires to be adapted or retro tted or customised, well that’s just part of the service.”

For more information, visit austrackequipment.com.au

www.sawdust.com.au 130YanYeanRoad,Plenty,Victoria3090 (03)94356167 Standingupunderpressuresince1968 DELIVERAUSTRALIAWIDE Contactusformoreinformationaboutour products, requestafreesample forevaluation, orplaceanorder. Lightweight–upto80%lighterthanequivalentsandbags Eco-friendlyfromsustainablesources Chemicalfree 3sizestosuitallpipediameters Won’texplodeorballoonunderpressure Pollard’sSawdustSupplieshasbeenatrustednationalsupplierofgraded andbaggedsawdustandwoodshavingsproductsforover50years. Thepipelineconstructionindustryhasbeenentrustingourbusinessto providesupportfortheirpipeassetsformanydecades. OurpipelinebeddingPackTuffbagsare: PIPELINE CONSTRUCTION

JCB Telehandlers reaching skywards.

e 007 of padding machines

Worldwide Machinery’s extensive inventory of equipment would not be complete without the aptly named Superior SP-350 padding machine.

This machine is the Rolls-Royce of the padding machinery, and there’s a million reasons why.

According to Worldwide Executive Vice President Padding Operations Mike Layh, the newest 350 heavy duty (HD) padding machine was built with the contractor in mind.

It is Superior’s most popular padding machine, and it is no wonder that Worldwide Machinery can count it in its eet.

e machine has quickly become the padder of choice in the pipeline and renewable energy industries.

“ is machine is operated from a comfortable chair with all the operating controls within hands reach,” Layh said.

“Four cameras bring into view key areas allowing the operator to monitor all functions while operating this machine.”

What’s more, the cab now lowers down for easy transportation without having to disassemble the machine with a maximum height of 12 foot.

Worldwide is a global leader in machinery with a proven track record of supplying quality, heavy earthmoving, and pipeline equipment across the globe, o ering new and used equipment for sale, lease, and long-term rental.

Having been constantly improved upon to quickly become the padder of choice in the padding industry, the Superior SP-350 ticks every box.

Safety rst

e machine’s roll-overprotective structure (ROPS) ensures for a safe use of the Superior SP-350.

e machine is equipped with a 10-foot by 6-foot screen allowing for 60 square feet of screening area with an enhanced vibration system.

Versatility and e ciency

“Worldwide has the best operators in the industry with many that have been operating padding machines for more than 10 years,” Layh said.

“Our service team preparing the machines before they are shipped is one of the reasons we are the premier padding operation in the US,” he said.

Worldwide doesn’t just retail and lease

machinery, it also accompanies the user all throughout the padding process, making it a one-of-a-kind customer-centred service.

Lastly, Worldwide takes pride in providing exceptional protection of the pipe or cable by meeting all necessary job requirements and speci cations.

Worldwide also counts in its eet smaller padders, the SP-150 and SP-160, which are both remote-controlled. In addition, the SP-250 is part of the smaller padders eets whichis a smaller version of the SP-350.

Worldwide o ers machine rentals with and without trained operators, if the client chooses, along with the logistical support and onsite services.

28 The Australian Pipeliner | March 2024 For more information, visit worldwidemachinery.com

PIPELINE CONSTRUCTION

Images: Worldwide

Choosing Worldwide is choosing a company that will stay by the users’ side all throughout the process.

Machinery.

The machine has been designed to quickly become the padder of choice in the padding industry.

Meet the Superior SP-350, one of the most prized padding machines on the market.

The most e ective method to maintain and improve safety and reliability of pipeline ball valves is routine lubrication using a proven valve lubricant along with a preventative maintenance scheme will ensure optimum valve operation.

The DSI range of lubricants, sealant and flush are being used throughout the Pipeline industry in all states within Australia.

All ACC’s DSI products are supplied by a company that is a leader in the manufacture of lubricant since 1968.

ENHANCE SAFETY AND COMPLIANCE OF YOUR PIPELINE VALVES WITH ACC

EQUIPMENT

SERVICES TECHNICAL ASSISTANCE | EQUIPMENT | LUBRICANTS | SEALANTS | GREASE FITTINGS

PRODUCTS,

AND

+61 8 9470 5070

Hours) sales@acc-corporate.com ACC Corporate 4 Roy Street Welshpool, 6106 Perth, Western Australia Call today for more information

(24

From A to Z with kwik-ZIP

The Australian Pipeliner sat down with General Manager Paul Je reys to recap kwik-ZIP’s successes over almost 25 years.

kwik-ZIP spacers shown on corrugated pipe.

The centraliser and spacer system manufacturer and supplier has been servicing the drilling and pipeline industry for just under 25 years, making an unparalleled impact on the industry.

What is the genesis of kwik-ZIP?

e company was established in 2000 by current Managing Director Jason Linaker.

kwik-Zip is an Australian owned company certi ed under ISO 9001 for production, supply, sales and distribution of inert centralisers and spacers.

Where does kwik-ZIP operate and in which industries?

kwik-ZIP has established distributors in Australia, New Zealand, United States and Great Britain and operates from its head o ce in Bayswater and maintains warehouse facilities in Perth, Sydney, Dallas (Texas, USA), and Leicester (UK).

kwik-ZIP supports many key industry sectors such as trenchless, pipeline, mining, oil and gas, ground engineering, waterwell drilling, civil engineering, and construction.

What is kwik-Zip's mission?

To provide expertise, responsive customer service, cost-e ective solutions, and an innovative range of products to meet our customers’ needs that are applicable across multiple local, state, national and international industries.

kwik-ZIP’s innovative range of products and applicability across multiple industries are a testimony to its capabilities in design and manufacturing. is is evidenced by our ongoing certi cation under ISO 9001 for production, supply, sales and distribution of inert centralisers and spacers.

What models are available and what certi cations do they hold?

kwik-ZIP centralisers and spacers are sold under ve speci c product series (HDXT, HDX, HD, GT, and 155) all with varying models within each series. Each is more applicable to speci c business sectors ensuring solutions can be found by potential customers easily.

kwik-ZIP products (HDX/HDXT) are certi ed against the Water Services Association of Australia (WSAA) Product Speci cation 324 and all kwik-ZIP products certi ed by the Australian Water Quality Centre (AWQC) against AS/NZS 4020:2018 Testing of Products.

kwik-ZIP products are also approved for use

30 The Australian Pipeliner | March 2024

PIPELINE CONSTRUCTION

Images: kwik-ZIP.

kwik-ZIP HDXT-43 on a 4-pipe HDPE bundle for a project in the UK.

within many utilities infrastructure including Melbourne Retail Water Association (MRWA), South East Queensland’s (SEQ) Infrastructure and Materials (IPAM) list, Sydney Water, and the Water Corporation of Western Australia.

What makes kwik-ZIP’s products unique on the market?

kwik-ZIP’s spacers and centralisers have a segmented design, meaning they can be used on an extensive range of pipe diameters with the addition of multiple segments. Furthermore, they can be used on all manner of pipe materials pipe materials including steel, ductile, MSCL, GRE, PVC, HDPE amongst others.

ey represent the latest in centraliser and spacer innovation and provide many advantages, such as corrosion protection, low co-e cient of friction, high exural strength as well as reduced insertion forces among others.

kwik-ZIP products have numerous key di erentials. e use of kwik-ZIP products will prevent corrosion and voids that can a ect the integrity of installation. e low coe cient of

friction makes it easier for the pipe to be inserted. e spacers and centralisers are lightweight and simple to install. Finally, their segmented design and e cient packaging results in low inventory and transportation costs

What's the outlook for kwik-ZIP over the next 12 months?

kwik-ZIP is focussed on continuing to support our customers with cost e ective and appropriate solutions for their spacer and centraliser requirements. A signi cant amount of time is invested on interactions with current and prospective customers.

is time invested in our clients’ successes provides a fantastic feedback opportunity to look for improvements in our products for future iterations, as well as having a constant pulse on the challenges our customers are facing on their projects.

e information gleaned is used to determine opportunities for where our current product range can assist and the potential for development of additional products to meet the needs of customers.

For more information, visit kwikzip.com

PIPELINE CONSTRUCTION Safer, more e cient material handling solutions. 22 Huntington Street, Clontarf, QLD 4019 Australia P: 0498 101 888 E: sales@vacuworx.com.au www.vacuworx.com

kwik-ZIP HDXT on 508mm OD high-strength steel line pipe with an external epoxy coating.

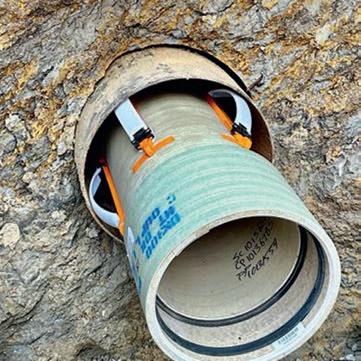

Sealing success in PNG rst

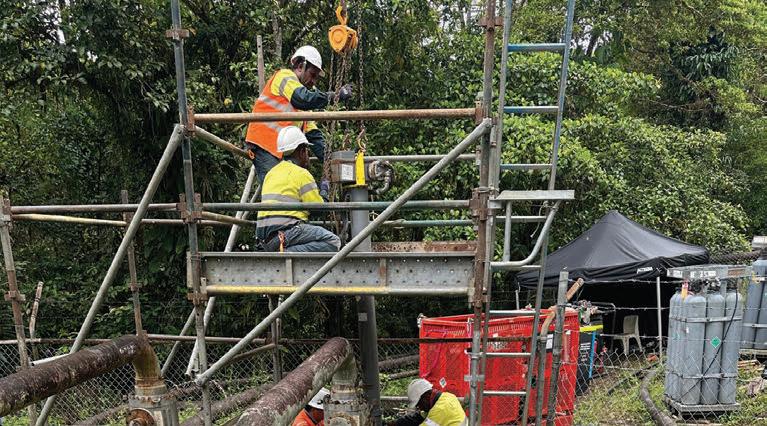

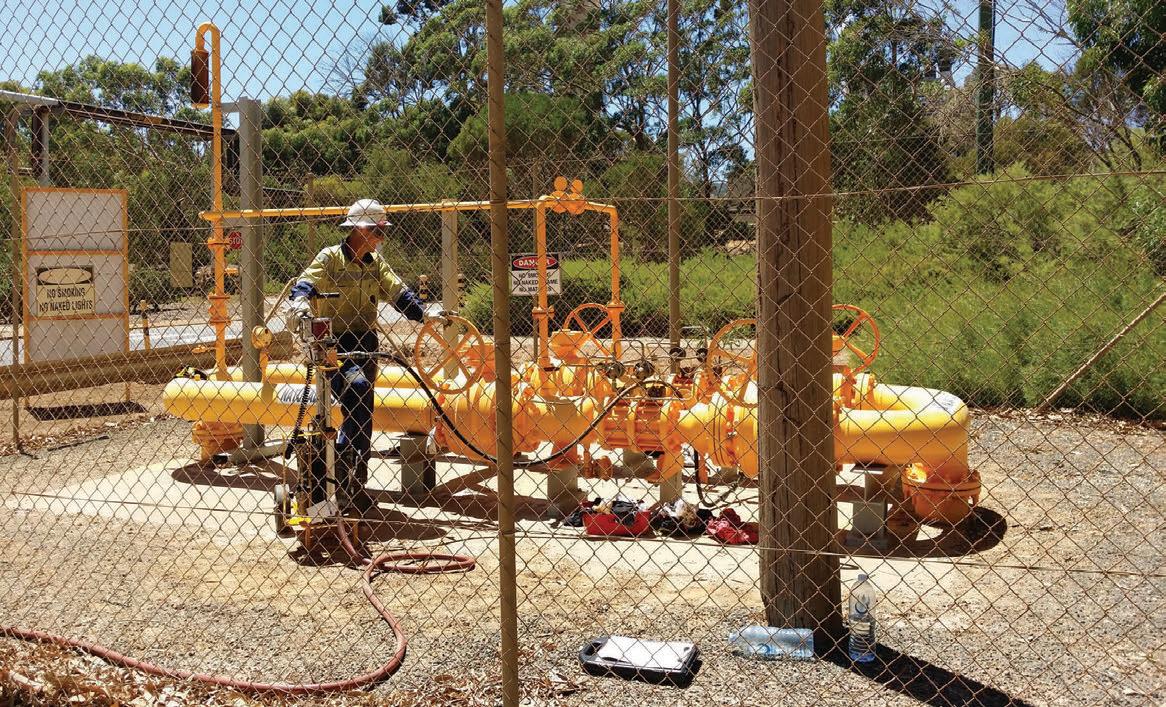

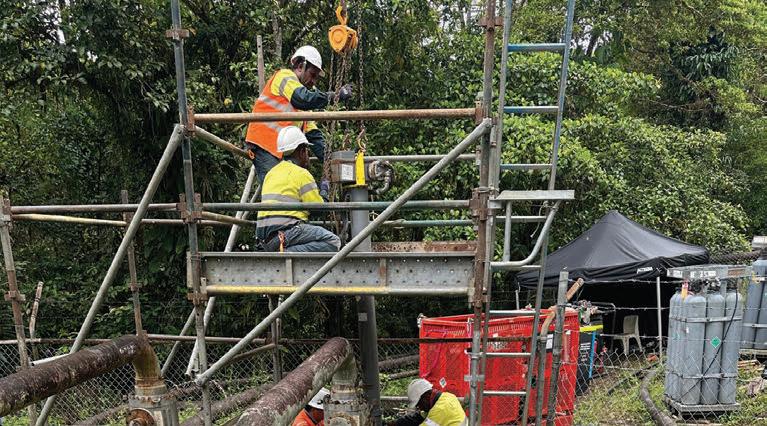

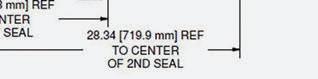

A challenging remote location at high altitude was the destination for STATS Group’s rst hot tap and line stopping project in Papua New Guinea.

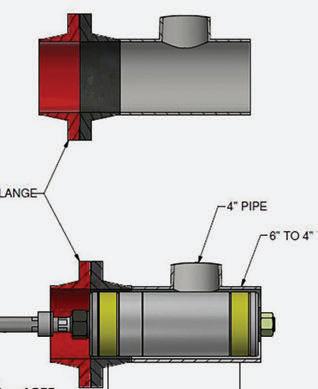

STATS Group was contracted to provide hot tapping and line stopping services on a redundant 4-inch oil owline that needed to be recommissioned to bring it back into service.

STATS Group Field Technician Rab Milligan saluted the company’s milestone and success in Papua New Guinea (PNG).

“ is was our rst project carried out in PNG and the high altitude – at 4200ft - made conditions challenging at times, however the BISEP performed awlessly,” Milligan said.

“ e project was completed safely and ve days ahead of schedule which provided signi cant savings for the client.”

e BISEP line stopping tool was utilised to provide safe worksite conditions and avoid any discharge to the environment during breaking of containment activities.

For STATS Group Regional Manager for Asia Paci c Gareth Campbell, the project was a real turning point for the company.

“ is project is another signi cant milestone for STATS as we expand our presence to support pipeline operators in PNG and the wider Asia Paci c region,” Campbell said.

e BISEP provided fail-safe, double block and bleed isolation through a single hot tap, increasing safety while also reducing the number of ttings and associated welding and hot tapping activities.

“We are delighted to demonstrate our market leading line stop technology in the PNG market and look forward to future projects as we expand our presence in the region,” Campbell said.

e leak-tight isolation allowed the pipe to be

cut and a valve manifold welded into the pressurised owline to allow a 128bar hydrotest to be conducted prior to reinstatement to con rm that the line could operate safely at its maximum allowable operating pressure.

In addition to the provision of the BISEP line stop tool, STATS Group also manufactured and supplied the tting and completion plug, slab valve and hot tap machine, along with the company’s trained and competent eld technicians.

All STATS Group’s supplied equipment was tested and certi ed prior to mobilisation to site and in line with the project parameters to con rm full functionality.

e worksite was situated next to a road which allowed access for the crane to deliver the equipment to the site location. Once at the worksite the tting was welded onto the line and tested.

STATS Group then conducted the hot tapping, recovering the coupon and installing the BISEP ready for deployment. To remove the metal cutting chips, the BISEP head was deployed into the line to sweep the line and displace the swarf prior to redeploying the BISEP and hydraulically setting the plugging head.

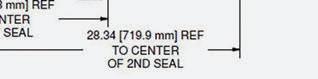

Setting the BISEP causes the plugging head

32 The Australian Pipeliner | March 2024

PIPELINE CONSTRUCTION Images: STATS Group.

A successful completion plug and blind ange installation.

Hot tap machine installation using BISEP.

to contract squeezing the dual seals and causing them to radially expand and contact against the pipe wall. Hydraulic activation allows for high integrity sealing, especially in ageing pipelines which may have internal issues, such as pitting or pipelines with ovality issues.

During the setting process, the pressure within the annulus (space between the primary and secondary seals) rises as the annular space is compressed by the expanding seals. is pressure was then monitored to prove no pressure loss and provide an initial indication that the seals are isolating, allowing the client to depressurise and drain the line. Once the line was depressurised, the di erential pressure across

the BISEP plugging head maintains isolation independent of the hydraulic pressure providing a fail-safe isolation.

Once the isolated section of line was drained, the BISEP secondary seal was tested above the pipeline pressure to prove the integrity of the secondary seal.

e seal annulus was then vented to a safe area and locked-in. is allowed the primary seal to be tested and monitored for sealing performance.

Once the secondary and primary seal tests were conducted STATS issued an isolation certi cate to con rm leak-tight double block and bleed isolation allowing breaking of

containment activities to commence safely.

e BISEP is the only hot tap installed isolation tool in the market that satis es the design criteria for DNV Type Approval for Pipeline Isolation Plugs.

On completing the successful welding of the anges and installation of the valve, a hydrostatic test of the 4-inch owline was conducted at 128bar.

With the client work scope completed, the line pressure was equalised and the BISEP was hydraulically unset and recovered from the line.

STATS Group then redeployed the hot tap machine to install a completion plug marking the end of a successful project.

33 The Australian Pipeliner | March 2024 For more information, visit statsgroup.com

PIPELINE CONSTRUCTION

This is the rst project STATS Group has conducted in PNG.

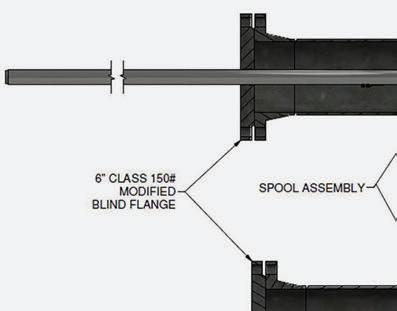

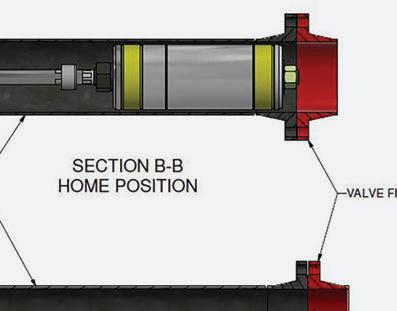

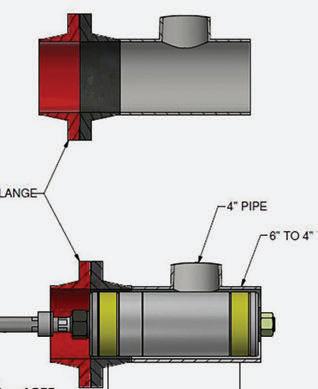

A novel approach to pipeline valve replacement

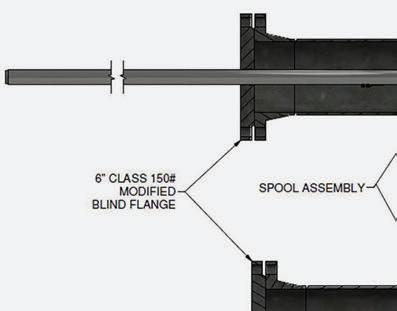

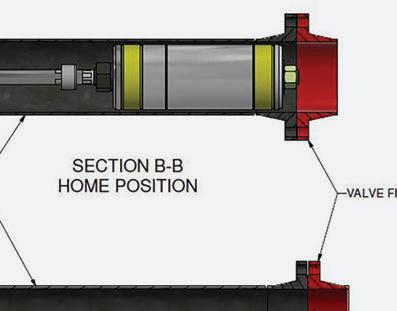

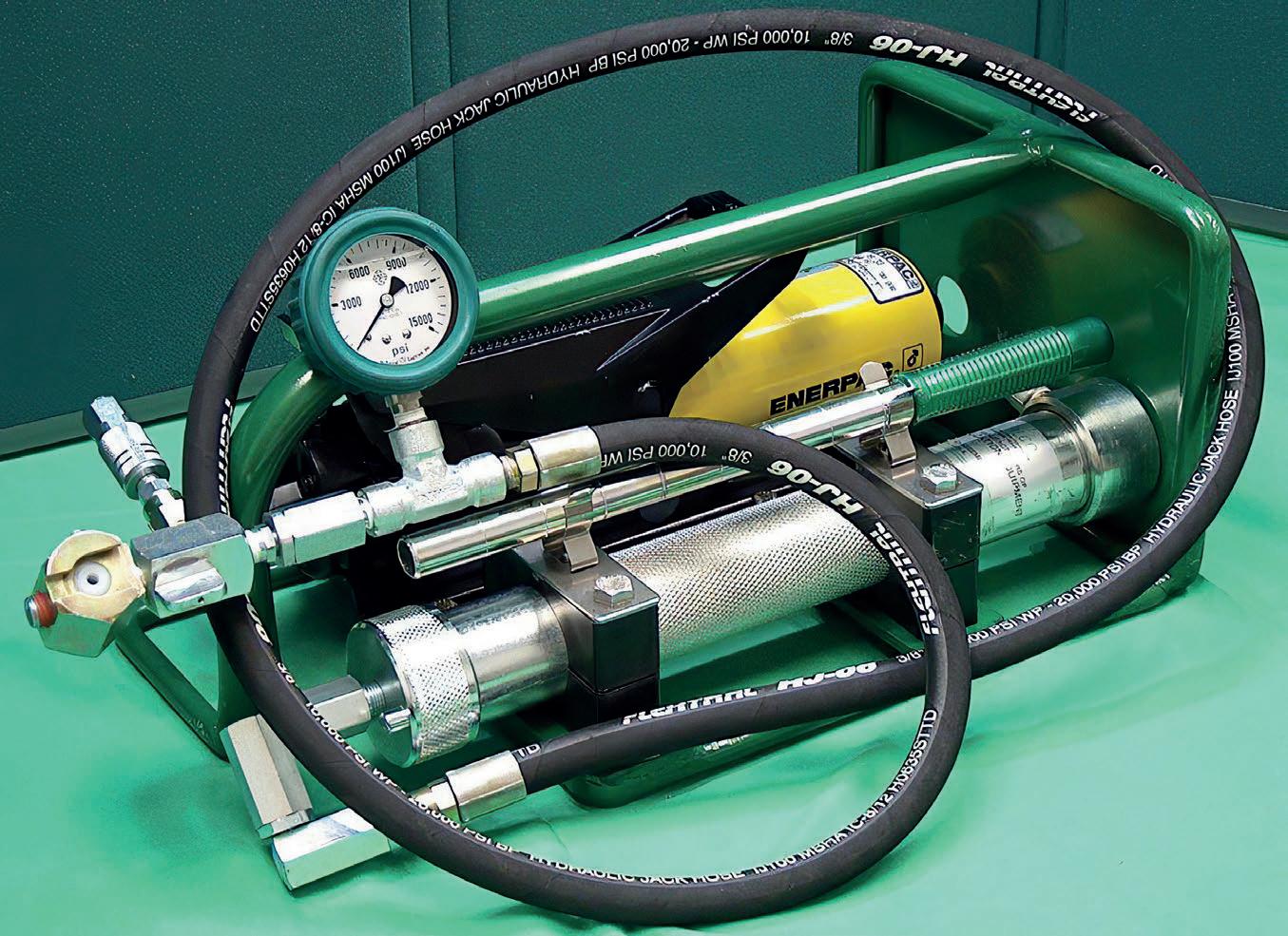

When an oil and gas operator needed a pipeline valve replacement with key considerations, Curtiss-Wright EST Group proposed a solution.

Safety and speed are key considerations when a pipeline valve needs to be replaced. However, when the pipeline cannot be fully drained of its contents and depressurised, these considerations take on a whole new sense of urgency.

For an oil and gas operator working o the coast of Australia, this was the case. e operator needed to replace a blowdown valve on a spool lled with hydrocarbons on one of its o shore platforms.

ey wanted to avoid the conventional process that requires ushing, purging, and then drying the entire spool volume prior to performing the changeout, all of which would add a great deal of time and money to the project.

Further complicating the process, the valve changeout had to be done while ensuring that the spool was completely isolated at all times. ere could be no oxygen ingress to the line and no release of hydrocarbons into the atmosphere.

Field-proven solution

Curtiss-Wright EST Group proposed a solution that previously proved successful for the operator in other “tie-in” applications, such as installing new anges into existing pipework: the Double Block and Bleed (DBB) Test and Isolation Plug.

e DBB is widely used to isolate and monitor potentially explosive vapors from upstream gases or hydrocarbon uids in a vessel or pipeline during modi cations or repairs requiring hot work.

e plug’s dual-cavity port creates a completely air-free, positive pressure barrier between its seals, allowing isolation for welding activities and hydrotesting of new weld connections to be performed with the same isolation tool.

Traditionally, this plug is used to increase the safety for welding activities and gives the operator the ability to hydrotest the new weld between the seals with less than 3.785L of water. is reduces ll times, wastewater, and treatment expenses while facilitating testing in remote areas of the facility.

e dual port system also allows water to be circulated between the seals for improved cooling during pre-and post-weld procedures.