® AUSTRALASIA’S TRAILER INDUSTRY RESOURCE SEPTEMBER 2023 SHOWCASING THE VERY BEST AUSTRALASIAN TRAILER AND BODY TECHNOLOGY ISSN 1838-2312 9 771838231003 08 SEPTEMBER 2023 $10.00 INFRASTRUCTURE SPOTLIGHT NEWS SPECIAL REPORT WORLD MAP ECONOMY TRAILER BUILDER World class manufacturing World class manufacturing

GROWTH

GROWTH Rigid Bodies

EXPONENTIAL

EXPONENTIAL

PUBLISHER

John Murphy john.murphy@primecreative.com.au

MANAGING EDITOR

Luke Applebee luke.applebee@primecreative.com.au

ASSISTANT EDITOR

Peter White peter.white@primecreative.com.au

JOURNALISTS

William Craske william.craske@primecreative.com.au

Louise Surette louise.surette@primecreative.com.au

ADVERTISING

Con Zarocostas: 0422 222 822 conzarocostas@primecreative.com.au

Ashley Blachford: 0425 699 819 ashley.blachford@primecreative.com.au

DESIGN

Daz Woolley/Tom Anderson

ART DIRECTOR

Blake Storey

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

CLIENT SUCCESS MANAGER

Salma Kennedy salma.kennedy@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive Docklands VIC 3008 Australia

SUBSCRIPTIONS

03 9690 8766 subscriptions@primecreative.com.au

Trailer Magazine is available by subscription from the publisher.

Annual rates: AUS $99.00 (inc GST). For overseas subscriptions, airmail postage should be added to the subscription rate. The right of refusal is reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Trailer Magazine is owned by Prime Creative and published by John Murphy.

All material in Trailer Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material.

While every effort has been made to ensure the accuracy of information Prime Creative will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Trailer Magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Country and Western

Award-winning singer-songwriter

James Blundell of Stanthorpe, Queensland, knows his way around trucks and heavy machinery having had his heavy rigid licence since he was 19. Touring over the past 35 years the hemp farmer has spent many hours at a time on the road and confesses to witnessing a few close calls on his travels through major cities and remote areas. James agrees that when a motorist is unaware of their surroundings, or simply doesn’t know how to share the road, things can go devastatingly wrong.

James lends his voice to the chorus of reason that is the National Heavy Vehicle Regulator’s We All Need Space road safety campaign and says it is crucial to keep your cool and give truck drivers space and urges drivers

to be safer around heavy vehicles. Ultimately, we all set out to get to our destination safely – that’s his take for all motorists to heed.

James’ banger ‘Way Out West’ is more than 30 years old and has been refreshed with a new spin with alternate lyrics and a catchy tune to emphasise the importance of giving trucks the space they need.

It is unfortunate that such a simple and logical message needs to be reinforced again and again. The Regulator confirms the number of fatal crashes involving heavy vehicles was significantly higher in regional areas (approx. 53 at the time of writing) compared to metropolitan areas (approx. 20). As a result, more must clearly be done to amplify road safety messages to all parts of Australia to save lives.

From

the Editor’s desk

Officially endorsed by the VTA www.trailermag.com.au

4 Trailer Magazine SEPTEMBER 23

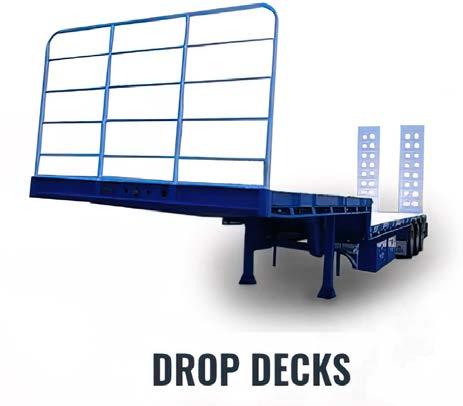

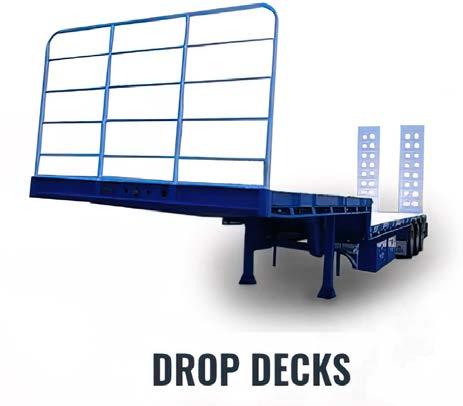

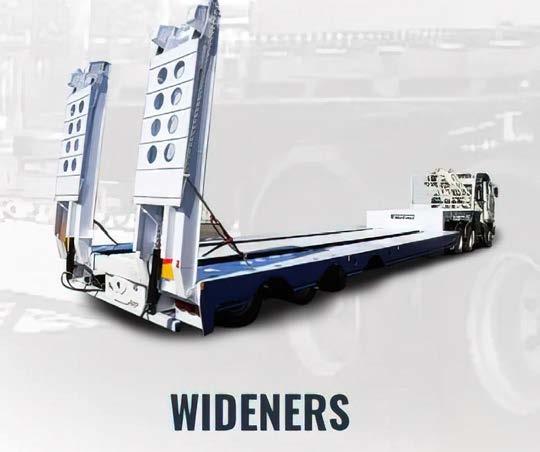

AAA Ian (General Manager) 0477 000 011 - ian@aaatrailers.com.au www.aaatrailers.com.au - 02 9188 3222 - 159 Walker St, Helensburgh, NSW 2508 Dan 0429 160 094 – Dan@aaatrailers.com.au – Perth WA TOP QUALITY AND FIT FOR PURPOSE WITH A FOCUS ON SAFETY AND RELIABILITY. DROP DECK CURTAIN SIDE STRAIGHT SIDE TIPPER

8 Industry news

The latest news and industry developments.

24 Economy

A look at the latest Government assistance review.

26 Rigid Bodies

Scully RSV is tripling its manufacturing capability

28 Trailer builder

Australia’s trailer manufacturing industry is as strong as ever.

32 Trailer building materials/components

A showcase of the products and services that keep trailers on the move.

48 Special report: Linfox

Senator Glenn Sterle recently experienced a day in the life of a Linfox truck driver.

50 Rigid Body Builder Showcase

The only published list of all leading manufacturers in the country that specialise in the production of rigid bodies.

58 Infrastructure Spotlight What you need to know about Australia’s biggest road projects this month.

60 World map Transport Logistic in review.

62 Fleet of the month

Direct Freight Express reinforces its national footprint with modern trucks from Isuzu.

64 Industry Innovators

Adam Woltanski has made several noteworthy contributions to the international transport industry.

66 What’s on

Upcoming shows and field days.

6 Trailer Magazine SEPTEMBER 23

26 42 32 34 38 48

September 2023

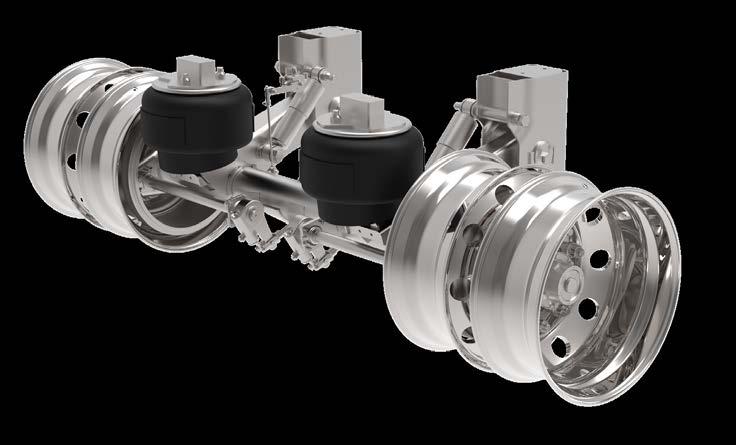

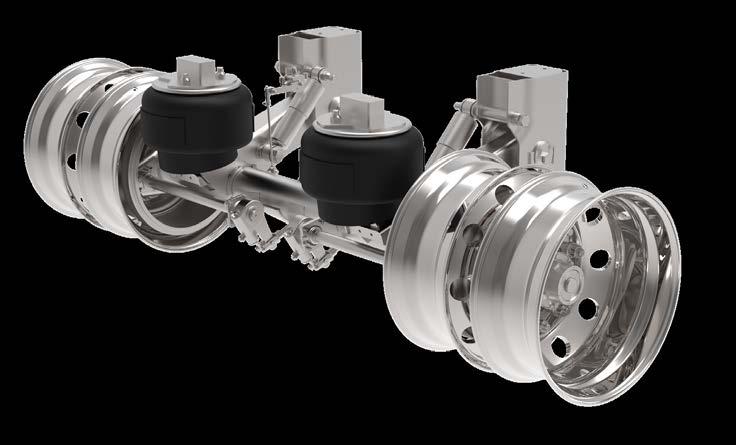

SAF-HOLLAND (Aust.) Pty. Ltd

ABN: 79004371215 | Sales: 1300 131 613 Email: sales@safholland.com.au

www.safholland.com.au SAF-HOLLAND (Aust.) Pty. Ltd Ph: (61-3) 9971 7900 Fax: (61-3) 9743 6763 SAF-HOLLAND (Aust.) QLD Ph: (61-7) 3375 7033 Fax: (61-7) 3375 7044 SAF-HOLLAND (Aust.) WA Ph: (61-8) 9353 1720 Fax: (61-8) 9353 1730 SAF-HOLLAND (Aust.) NSW Ph: (61-2) 9672 1950 Fax: (61-2) 9672 1994 Specify SAF- HOLLAND INTRADISC & INTRADRUM.

+

anchor

SAF INTRA

6

warranty on

absorber & pivot bushes *WHICH EVER OCCURS FIRST OFF-ROAD WARRANTY 3 YEARS / 500,000KM*

+ Frame bracket symmetry – no shocker bracing needed

SAF drum brake with quick release spherical

+ No Ubolts + More uptime + Low maintenance + Patented composite rotor + Long life disc brake technology

1 MILLION KM OR

YEARS* On-road

bearings, shock

www.safholland.com.au

New survey finds female drivers feel unsafe at rest areas

A new study has found that women driving heavy vehicles on Australian roads will not stop at rest areas if they don’t feel safe.

Female drivers surveyed for the study said poor lighting, unenclosed shower facilities, a lack of security, and the risk of vandalism to vehicles prevents them from stopping at or using existing rest stops.

The study, which included surveying men and women drivers, also found there are not enough fit-for-purpose rest areas for heavy vehicle drivers, which is impacting driver safety and mental and physical health.

Most survey respondents said they stop at rest areas due to fatigue and to use the bathroom.

Commenting on the findings, a Healthy Heads in Trucks & Sheds spokesperson

highlighted the importance of mental wellbeing in drivers.

“It is critical that heavy vehicles drivers are as mentally healthy as they can be so that they can maintain concentration and deal with the stresses of the road,” the spokesperson said.

“To achieve this, it is critical that we provide the support they need while on the road: suitable rest areas are an important part of this support.”

Following the results, the report is recommending the establishment of a National Heavy Vehicle Rest Area Strategy, ongoing consultation of an industry action group, adding clean toilets and adequate parking, and the designing and implementation of a Heavy Vehicle Rest Area pilot stop.

New ADR mandates reversing technology for heavy vehicles

The Australian Government is mandating reversing technologies for all new vehicles.

The new standard, Australian Design Rule 108/00 – Reversing Technologies, will apply to all types of light, medium and heavy vehicles.

The new legislation for the technologies, including reversing cameras and motion sensors, will aim to increase driver awareness of road users behind a vehicle.

“We know that reversing aids will improve visibility for drivers to

minimise black spots while reversing,” said Federal Assistant Minister for Infrastructure and Transport, Carol Brown.

“ This new standard supports our unwavering commitment to achieving Vision Zero: zero deaths and serious injuries on our roads by 2050.”

Reversing technologies that meet the new standard must be installed in all new vehicle models from 1 November 2025. For new vehicles made from existing models, the technology will be required to be installed from 1 November 2027.

8 Trailer Magazine SEPTEMBER 23

XXX News

Leading the way in vehicle safety and performance

Scully RSV is on a mission to have the safest vehicles on the road. Every day.

Scully RSV and SafetyCulture have partnered to develop an industry leading initiative for transport safety. The digital safety inspection captures the performance of Scully RSV vehicles each and every time they are used on our roads.

The SafetyCulture platform enables a more efficient and optimised inspection capture and reporting system for vehicle compliance and safety. Delivered via a QR code scan, users can launch and complete the vehicle inspection in less than 30 seconds.

Scully RSV is proud to be bringing this initiative to market with Safety Culture and leading the way in keeping our communities and their families safe. It’s another great example of delivering on the customer promise, that Scully RSV fleet is managed to the highest levels of quality, safety and reliability.

FLEXIBILITY TECHNOLOGY RELIABILITY SERVICE QUALITY 1800 728 559 info@scullyrsv.com.auwww.scullyrsv.com.au

Lactalis to pay Dairy Code penalties

Milk supply company and dairy product provider, Lactalis Australia, has contravened the Dairy Code of Conduct.

Lactalis Australia failed to meet some of its obligations in relation to the 202121 milk season and was ordered by the Federal Court on 25 July 2023 to pay $950,000 in penalties.

Following proceedings brought by the Australian Competition & Consumer Commission (ACCC), the Court found in September 2022 that Lactalis had breached the Dairy Code by publishing and entering into agreements that allowed Lactalis to unilaterally terminate an agreement in circumstances that didn’t involve a material breach by farmers.

In particular, under the agreement, Lactalis was permitted to unilaterally terminate the agreement when, in Lactalis’ opinion, the farmer had engaged in ‘public denigration’ of processors, key customers or other stakeholders.

Lactalis had also breached the Code by failing to publish its milk supply agreements on its website, and instead required farmers to sign up to receive their milk supply agreements by email.

“The Code was introduced to help dairy farmers make informed choices about where they sell their milk by ensuring there is transparency in pricing agreements and by allowing them to compare agreements from different processors in a timely

fashion,” said ACCC Deputy Chair, Mick Keogh.

“These were the first contested proceedings under the Dairy Code and the outcome is an ongoing reminder that processors who fail to comply with the Code may face significant penalties.

“Ensuring that small businesses receive the protections they are entitled to under industry codes continues to be one of the ACCC’s enduring compliance and enforcement priorities.”

Lactalis is one of Australia’s largest dairy processors and purchases milk from more than 400 dairy farmers across all Australian states. The company produces a wide range of dairy products across a number of brands including Pauls, Oak, Vaalia and Ice Break.

The Dairy Code (the Competition and Consumer (Industry Codes—Dairy) Regulations 2019) is a mandatory industry code regulating the conduct of dairy farmers and milk processors in their dealings with one another that came into effect on 1 January 2020.

Under the Dairy Code, a processor must, by 2pm on 1 June each year, publish its standard form milk supply agreements on its website.

For every exclusive milk supply agreement, a processor publishes, a processor must also offer a non-exclusive supply option to farmers.

The Dairy Code requires processors to only purchase milk under a milk supply agreement. All agreements must comply with the code by meeting a number of key requirements, including:

• specifying a minimum price paid for the milk,

• consisting of a single document,

• specifying quality and quantity requirements, including testing procedures, and

• specifying the circumstances in which parties may unilaterally terminate the milk supply agreement – for processors to unilaterally terminate, the circumstances outlined must involve a ‘material breach’ by the farmer.

The publication obligations of the Dairy Code apply to all processors with an annual aggregated turnover of $10 million or more in the previous financial year.

Lactalis Group, based in France, claims to be the world’s leading dairy group.

Last year it acquired Jalna in Australia, positioning the business as number two in the Australia’s yogurt market.

The dairy products market is expected to continue to grow due to an increase in global population by an estimated 11 per cent by 2033. This would be approx. 873 million additional people, 35 per cent of which will be in Asia.

Each year, Lactalis collects more than 22 billion litres of milk from some 460,000 partnering farmers in 49 countries.

Generally, in Australia, Lactalis uses thirdparty transportation companies.

The group is mindful about optimising truck loading, reducing distances travelled and encouraging the use of alternative fuels.

In 2022, Lactalis as a group generated €28.3 billion (approx. $46.3 billion AUD) in revenue, an increase of 28.4 per cent compared to 2021. By geographical area, 50 per cent of that consolidated revenue is from Europe, 33 per cent via the Americas and 17 per cent across Africa and Asia and Pacific.

XXX News 10 Trailer Magazine SEPTEMBER 23

RUNNING GEAR FOR ALL APPLICATIONS AND ENVIRONMENTS FUWA K-HITCH www.khitch.com.au MELBOURNE 13-21 Bliss Court Derrimut VIC 3030 p: 03 9369 0000 f: 03 9369 0100 melb@khitch.com.au PERTH 5 Freight Road Kenwick WA 6107 p: 08 9350 6470 f: 08 9350 6570 perth@khitch.com.au BRISBANE Unit 1/15 Seeana Place Heathwood QLD 4110 p: 07 3372 2223 f: 07 3372 1022 qld@khitch.com.au FOR ALL YOUR EQUIPMENT AND OE SPARE PART REQUIREMENTS, YOU CAN TRUST KHITCH

Smedley’s Engineers announces Underrun Protection services

Smedley’s Engineers is now offering Front Underrun Protection (FUP) and Rear Underrun Protection (RUP) validation services for manufacturers.

As an approved testing facility, Smedley’s Engineers provides complete support commencing from the design of the products through to the issuance of a Component Type Approval, based on the manufacturer’s requirements.

The new addition to its capabilities, Smedley’s Engineers said, is a curation of the combined efforts within the Design, Testing and Simulation department.

“This is a lot more complex than a typical FE stress analysis,” said Design, Testing and Simulation Engineering

Manager, Dion Simms.

“When validating underrun devices by simulation, we track the slippage and breakage of bolted and pinned joints, the permanent and temporary deformation of components and the contact interaction between parts as damage is incurred.

“We can also build out from here to simulate complex failure behaviour in broader aspects of engineering design, backed up by the physical testing we use to close the loop.”

According to Smedley’s Engineers, simulating these tests saves logistical challenges and costs of physically testing a prototype while allowing for fast design iterations to be evolved in an agile design

development environment.

Eliminating the dependency of fabricators and test engineers with a single simulation engineer, it said, enables design teams to move rapidly without compromising on OH&S or outcomes.

“Testing by simulation allows us to provide manufacturers of modular bull bar designs with validations across a range of vehicles, just by changing the brackets, loadings and positioning in a model,” said Project Engineer, Simon Burston.

“This is an exercise that happens within a matter of hours, whereas to physically test the same thing would require producing and then destroying a bull bar for every truck model which requires validating.”

12 Trailer Magazine SEPTEMBER 23

XXX News

B dynamic Logistics announces leadership appointment

Third-party logistics provider, B dynamic Logistics, has appointed Adam Quinn as its new Head of Growth.

The appointment will supercharge the company’s growth as it continues to broaden its national footprint.

“We are absolutely delighted to welcome Adam Quinn to our business,” said B dynamic Logistics founder and CEO, Mal Siriwardhane.

“Adam brings with him many years of senior experience in supply chain management, third-party logistics and key account management, and of course a stellar family history of creating industryfirsts in retail.”

“Adam’s expertise and industry knowledge will be invaluable as we implement our aggressive growth strategy over the near term.”

Quinn was pleased to join the team at B dynamic Logistics.

“It is exhilarating to be part of such a dynamic organisation that is growing and

expanding across the country and the world and I am looking forward to playing a key role in helping the business to further strengthen its market leadership and expand its market share through customised excellence,” he said.

“Every person in the organisation is appreciated and valued and this ethos carries through to the way the business

operates, engages and supports its clients.

“It is a business that continually innovates and elevates its thinking, its actions and its services to do better faster and in a more cost effective way day in and day out.”

Quinn will be located in B dynamic Logistics’ headquarters in Sydney, New South Wales.

CONTACT US TODAY TO FIND OUT MORE: 03 8794 6000 www.cargobull.com Australia’s Most Fuel Efficient Reefer Trailers LUKE HARDEMAN 0467 001 515 SIMON HAKVOORT 0478 848 292

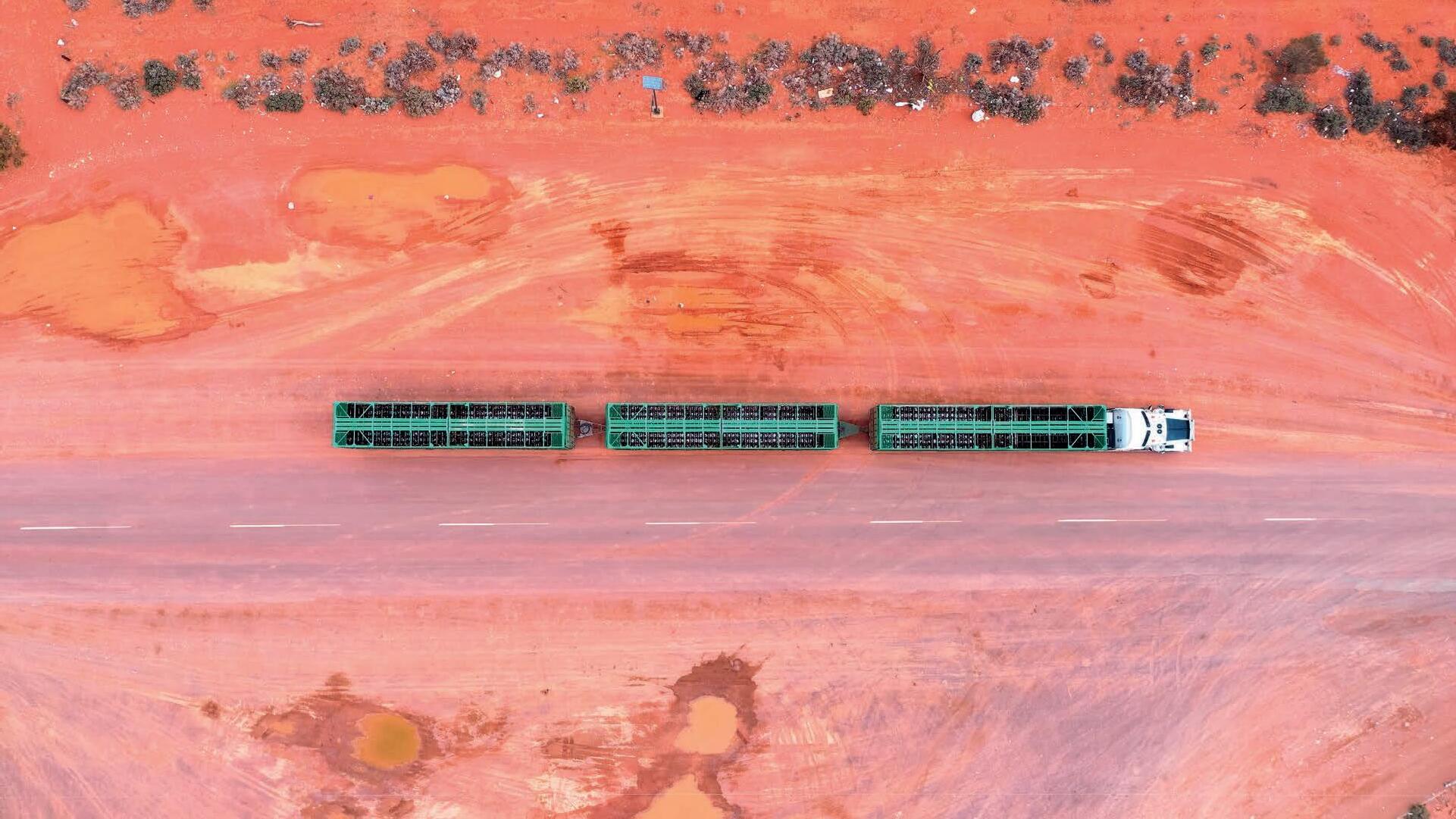

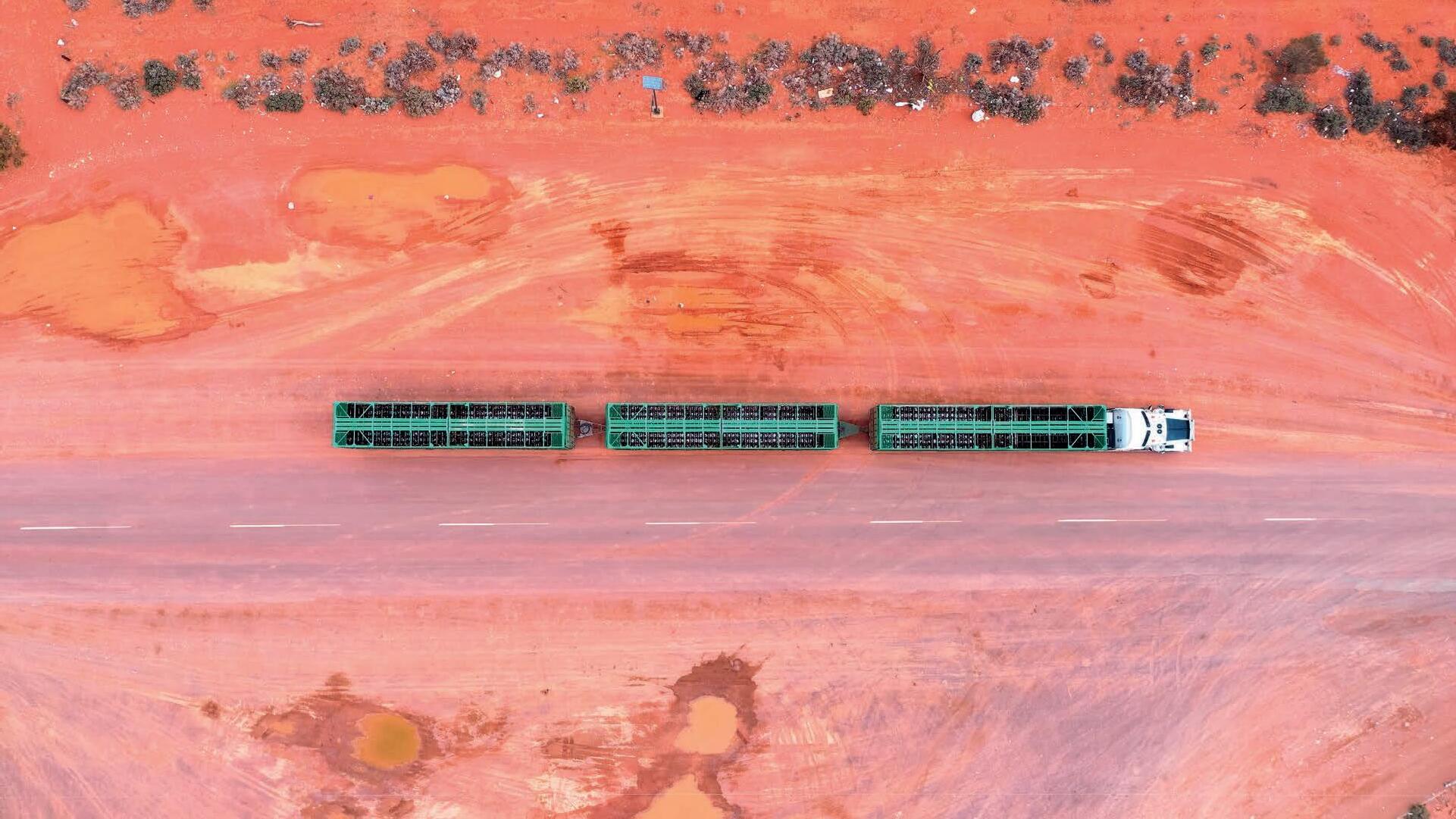

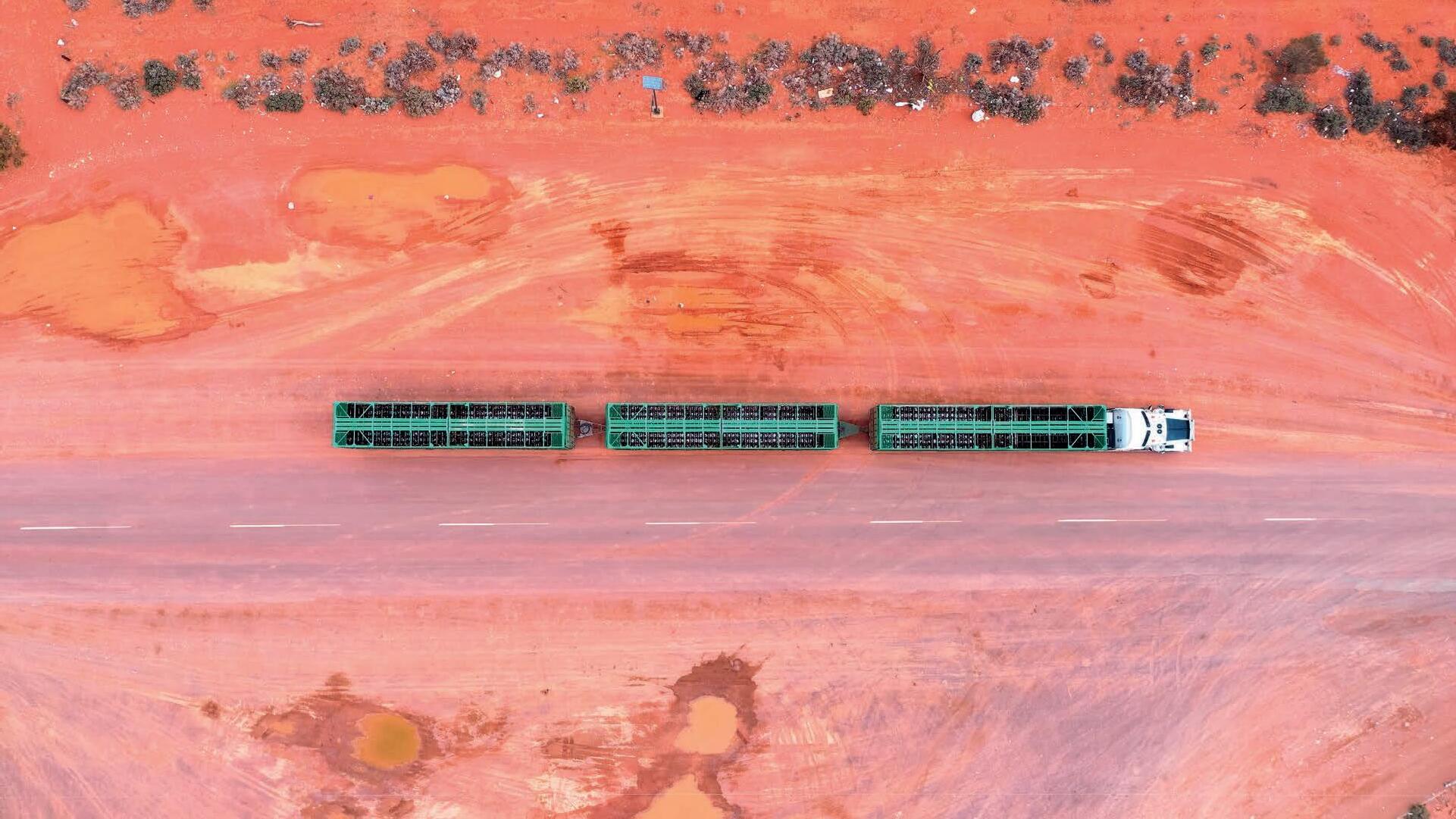

Calls come for joint taskforce to shore up freight networks

Western Roads Federation (WRF) and Northern Territory Road Transport Association (NTRTA) are calling on the Federal Government to establish a joint industry taskforce to build the resilience of major freight networks across Northern and remote Australia.

Increasing disruptions by adverse weather events, poor maintenance and rising demand for road freight services are compromising food and fuel security, strategic defence operations and economic development according to WRF and NTRTA.

The peak bodies cited the impact of climate events on the state of the road networks as a mounting concern given there are usually no alternative roads for trucks to use.

As a result of the impacts on road networks across the North and Northwest, WRF and NTRTA reveal that freight costs have skyrocketed at a time when all Australians are suffering a costof-living crisis.

The WRF and NTRTA’s call for a joint taskforce comes from what they describe as hard-won lessons dealing with major road freight disruptions (road and rail) over recent years, ranging from the pandemic, bushfires, floods and even the on-going loss of a key bridge.

According to the WRF and NTRTA,

multiple Government reports are converging on the same issues.

CSIRO modelling shows critical freight routes to the north of the country as having high or very high vulnerability risks.

The BITRE Road and Rail Resilience Report 2022 identified that “the lack of a single, overarching national approach to address gaps and emerging issues in the transport context presents a risk to supply chain resilience.”

While a Defence Strategic Review outlined that a “central component of deterrence is resilience,” and noted “Australia’s deterrence efforts sit within a whole-of-government framework.”

Much of this relies on harnessing all elements of national power which included “robust national logistics”.

The WRF and NTRTA have outlined a number of actions that could assist in ensuring resilient freight networks.

The increasingly frequent loss of the Perth – Kimberley – Darwin freight route due to flooding, means that roadtrains need to be sent via Port Augusta in South Australia then up to Katherine in the Northern Territory then back into the East Kimberley.

A return distance equivalent of driving one way from the English Channel at Calais to Vladivostok on the Sea of Japan. However, to meet freight volume needs

cost-effectively, the transport industry has to negotiate each time for it to allow triple roadtrains on the detour route.

This requires negotiation with the WA, SA and NT Governments, as well as with the National Heavy Vehicle Regulator in SA on permit and operating conditions for the transport.

Concurrently, approvals then need to be sought from either State or Federal Government’s to cover the additional freight cost, rising by 80 per cent in some cases, so that the costs aren’t unfairly worn by the local communities.

Standing arrangements, as part of a short-term recommendation, need to be made such that both approvals and subsidies can be immediately activated by a delegated authority.

In regard to longer term actions, considerations for re-building warehouse and storage in vulnerable regions needed to be made so they can continue to supply communities and businesses until an adjusted freight supply is implemented and to educate the public not to ‘panic buy’, to alleviate further stress on logistics supply systems.

Agility also needed to be built into the logistics system, such that the loss of a single route doesn’t create up to 6,000km detours.

“Achieving this will require accelerating

14 Trailer Magazine SEPTEMBER 23

XXX News

new identified road freight routes, hardening of vulnerable parts of the network, investigating the role of coast shipping and multi-modal hubs in regions,” the release stated.

Speaking at the Developing Northern Australia Conference 2023 in Darwin, NTRTA Executive Officer Louise Bilato, said a nationally-led joint Industry and Government Taskforce would help deliver a resilient, sustainable freight network across vulnerable parts of WA and the NT.

“The freight industry has learnt the hard lessons through the pandemic and why the nation needs a network of resilient roads which secure supply chains across the nation,” said Bilato.

“As a nation, we need to ensure that essential foods, fuel, medicines and groceries can be transported uninterrupted to communities and businesses in regional and remote parts of the country.”

WRF Chief Executive Cam Dumesny, said the Commonwealth Government’s Defence Strategic Review had brought renewed focus on Northern Australia. However, Northern defence bases and capabilities will require logistics support from the South as he views it.

“Any sustained military defence operation in the North or North West of Australia will depend on civilian road transport and logistics operators to help sustain supply operations, but we question how we’re expected to meet the demands of defence given our challenges supporting civilian communities and businesses now due to increasing freight disruptions?”

Dumesny agrees with the Defence Strategic Report which identified the need for a ‘robust national logistics’ system.

“But support to the North is built on a fragile logistics system.

WRF and the NTRTA are offering to work with the federal Government on a joint Taskforce to contribute the hard learnt lessons of the transport industry.

NHVR extends tipper body design code

The J4 tipper trailer body design code certification has been extended in the National Heavy Vehicle Regulator’s (NHVR) latest version of the Vehicle Standards Bulletin 6 (VSB6).

An initial three-month period was provided for tipper bodies to be certified under the new requirements to provide time for modifications which were already underway and allow industry to adjust to the new standards.

Following further review and consultation, the NHVR has extended the transitional arrangements for the implementation of the new design code to 1 February 2024.

NHVR CEO, Sal Petroccitto, said the extension follows discussions with Heavy Vehicle Industry Australia (HVIA) and Approved Vehicle Examiners (AVEs), with the NHVR considering it appropriate to extend the certification period a further four months.

“The extension to February 2024 will provide additional time for AVEs to become accredited by their jurisdiction’s accreditation scheme, familiarise themselves with the updated code, and allow tipper body manufacturers to make the necessary changes to their designs,” he said.

“It will also allow the NHVR to work with industry to address any queries relating to the new code and VSB6 Version 3.2 in general.”

HVIA CEO, Todd Hacking, said he wanted to recognise the NHVR for its willingness to engage with HVIA, its members and other affected parties to recognise the issues that are at play.

“The intention of these Standards is to ensure that Australia’s heavy vehicle fleet is both safe and productive, and we support their ongoing improvement,” he said.

“We will work closely with the NHVR team and other stakeholders towards ensuring there is adequate capacity and resourcing to allow the updates to succeed when the transition period finishes next February.”

Petroccitto said the NHVR understands that some vehicle modifications are complex changes and require extensive design and work to complete.

“We are asking owners and modifiers that require the extension to February 2024, to apply to the NHVR for the extension so that we can monitor how industry is progressing as well as target any future communications,” he said.

To apply for an extension of the J4 tipper body design code, the NHVR is asking requests including a name, business name and estimated number of tipper body certifications over this period to be sent to vehiclestandards@nhvr.gov.au.

Kings Transport & Logistics ramps up sustainability efforts

Kings Transport & Logistics has demonstrated its commitment to sustainable development by implementing several initiatives.

These include operating a fleet of twelve electric vehicles with plans for future growth and a carbon offset partnership.

Several sustainability initiatives at the new facility in Dandenong South have also been implemented, including long-life LED lighting throughout all areas to significantly reducing electricity consumption and maintenance requirements.

Two 10,000-litre rainwater tanks for toilet flushing, irrigation, and bin washing, will minimise reliance on mains water and preserve water catchment levels according to the logistics and transport operator.

Car parks will have provision for electric vehicle charging infrastructure, actively supporting adopting eco-friendly transportation methods and reducing carbon emissions.

The installation of end-of-trip facilities, including eight bike parks, showers, and lockers, will also encourage, Kings Transport said, alternative commuting options for employees to promote a

greener environment and enhance well-being.

Integration of high-efficiency WELS star-rated water fixtures and fittings will reportedly reduce mains water usage and creating more significant water conservation.

Kings Transport have adopted lowvolume organic compound paints, adhesives, sealants, and carpets to improve indoor air quality and prioritise

the health and well-being of its people.

There has also been installation of a 10,000 kW rooftop solar PV array to utilise solar energy, reducing the fleet’s dependence on the electricity grid.

“Here at Kings we will continue to play our role toward carbon reduction and helping to create a more sustainable future, and we thank all of our partners involved in building this fantastic new facility,” a Kings Transport & Logistics spokesperson said.

16 Trailer Magazine SEPTEMBER 23

XXX News

Centurion partners with key transport initiative

Centurion has come on board to join a national health and safety initiative to assist the road freight sector.

Steering Healthy Minds is an initiative of the Transport Workers Union, the Transport Education Audit Compliance Health Organisation, Kitney, WorkCover Queensland, EML, and TWUSUPER.

Although it was originally established in Queensland, it has now expanded nationally.

In the coming months, Centurion will be training Mental Health First Aiders to learn how to assist people who are developing or experiencing a mental health problem until the person can be seen by an appropriately trained mental health professional.

“Steering Healthy Minds is driven by the industry, for the industry and led by the industry and Centurion will use its growing national presence to advocate the program throughout the industry,” a Centurion spokesperson said.

“Through it, we will be placing as much importance on the mental health of our people as we are on their physical health.”

60 YEARS’ EXPERIENCE Designing and building BORCAT TRAILERS STANDING THE TEST OF TIME sales@borcat.com.au, Jamie Carter 02 9631 9594

Smedley’s Engineers conducts training on MaxiTRANS combinations

Smedley’s Engineers recently conducted hands-on training for its new certification and compliance team members at MaxiTRANS’ Derrimut facility.

Smedley’s Engineers’ Performance-Based Standards (PBS) Specialist and Training Facilitator, Jesse Colagiuri, led the training by walking through various MaxiTRANS trailer combinations.

Along with some tips and tricks being shared, the team had the opportunity to test their knowledge application across the different combinations available.

Smedley’s Engineers Operations Manager, Dean Abram, told Trailer this two-day certification training program is crucial for a better understanding of what is involved in the inspection and how to efficiently meet key criteria for approvals.

“This training covers the basis of services offered through certification and compliance,” he said.

“The autonomous nature of the role demands an equal level of ongoing support to ensure we have provided sufficient knowledge and guidelines to assist our employees during the conduct of inspections, and to ensure accuracy through training in different techniques and scenarios.

“We ensure our new employees are confident in their abilities to go out and conduct their own remote inspections. This comes with initial theoretical and practical on-site training, followed by

shadowing experienced PBS Certifiers during inspections to cover the standards and safety requirements along with various customer expectations are being satisfied.”

Smedley’s Engineers Managing Director, Robert Smedley, commented on Smedley’s Engineers’ strong emphasis for training and development.

“While the heavy vehicle industry also has an ageing population of drivers and mechanics, this is also apparent in engineering services as well, and bringing fresh talent into the heavy vehicle industry is critical to its ongoing success,” he told Trailer.

“Martin Toomey, my first employer after I graduated university, stated, ‘It is better we train them and they leave, than not train them and they stay’ and that’s stuck with me ever since.”

The training isn’t just limited to PBS certification and inspections, as it also goes through the whole PBS process to ensure consideration is taken from the design approval stage through to access.

“It is necessary to facilitate training with new employees providing them the tools and qualities to ensure they can successfully complete inspections,” Abram said.

“Additionally, Smedley’s Engineers aims to ensure the ongoing consistency in the service we provide our customers in the most effective and efficient manner, to ensure employees perform their tasks to

the highest standards and ascertain quality of the output.”

According to positive feedback from participants such as Graduate Engineer, Renee Koh, the training was very successful.

“The training that Dean and Jesse did was useful with regards to consolidating what we knew about PBS certification and introducing us to a bunch of access basics, regulations, requirements, which was quite interesting – access feels like playing a management simulation game where the game’s artificial intelligence is actually real people at the NHVR deciding if your request is valid,” Koh told Trailer.

“With the training at MaxiTRANS, it was useful to see how Jesse did things, especially with some of the vehicles that I hadn’t previously had experience measuring up, such as single dollies and A-doubles.

“The people there were also friendly and allowed us access to all of their vehicles in the yard to train with. All in all, it was an informative three days of training that I enjoyed very much.”

MaxiTRANS has provided continual support to Smedley’s Engineers by regularly giving access to its dealership for the purposes of training.

“MaxiTRANS offers a large range of products, so we can conduct training on various combinations in the one location,” Abram said.

18 Trailer Magazine SEPTEMBER 23 XXX News

West Gate Tunnel Project looks to relocate heavy vehicles

Work to take thousands of heavy vehicles off local roads and slash congestion in Melbourne’s west is continuing at a rapid pace, with the West Gate Tunnel Project now more than 70 per cent complete.

Important pieces of the West Gate Tunnel Project are coming together, with widening works on the West Gate Freeway nearing completion.

Over 4.5 kilometres of road deck has now been installed across the twin tunnels, with a specialist machine lifting and installing more than 2,000 24-tonne concrete segments to create the future road surface.

Upon completion, they will have the capacity for thousands of vehicles per day across three lanes of traffic.

This is the first Australian tunnel to be constructed with an elevated road surface, providing another tunnel underneath to serve as an important point for maintenance of critical services, ventilation and emergency access.

Jacinta Allan, recently joined workers on the project to travel the drivable length of the tunnel for the very first time – marking a huge milestone for the project.

“This is the biggest tunnel project Australia has ever seen – we thank the thousands of Victorians who have worked around the clock to get us closer to the finish line on a project that will transform our transport network,” she said.

times, take more than 9,000 trucks off local roads, and get families home safer and sooner.”

“We thank the community for their patience and understanding while we get on with this important work to significantly improve Victoria’s transport network.”

Work is also underway to construct the tunnel entries and exits and prepare for the installation of the timber net structures.

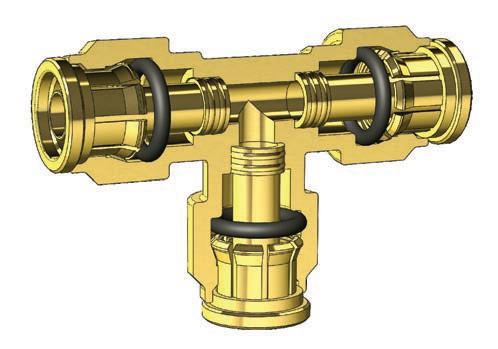

UNCOMPROMISING PERFORMANCE AIR BRAKE FITTINGS Australia’s BIGGEST range and stockist of Metric / Imperial Push to Connect and Compression Style D.O.T Air Brake Fittings D.O.T / S.A.E STANDARDS CONFORMANCE GP TRUCK PRODUCTS available from Truck & Trailer parts outlets Australia wide. Compliant Standards: ADR-38/05 & DOT Lockable Fitting Cabinet Mobile Fitting Stand Emergency Break Down & Glove box kits Brass Fittings Full range of Brass fittings designed to suit North American and European Truck & Trailer Air Brake systems. Phone +61 3 9580 1811 sales@gptruckproducts.com.au www.gptruckproducts.com.au SCAN CODE FIND OUT MORE Huge range available. Approved to meet: Australian Design Rules ADR-38/05 DOT FMVSS 571.106, SAE J2494/3, SAE J1131 blanking plugs.

Victorian Government to modernise truck fleets

The Victorian Government will deliver on its election promise made last year to modernise truck fleets and seal local roads to improve air quality.

As part of a $20 million package, $15 million in grants will target truck operators regularly using inner western roads to support a transition to trucks that produce fewer emissions.

A further $5 million will be made available to local councils to seal local roads, reducing dust pollution.

“We promised we’d make air cleaner in Melbourne’s inner west and that’s what we’re doing – replacing emissions-heavy old trucks and sealing roads to reduce dust pollution,” said Minister for Ports and Freight, Melissa Horne.

Melbourne’s inner west reportedly experiences significantly higher volumes of heavy vehicle traffic than other parts of Melbourne due to its

high concentration of industrial uses.

The Victorian Government will therefore work with community and industry to reduce the environmental impact of heavy vehicles, while making roads safer by lowering speed limits and banning trucks on some roads.

One of these projects includes the Zero Emissions Vehicle Roadmap, which is supported by a $100 million investment to help the adopting of zero emissions vehicles.

The Government is also continuing its Air Quality Strategy with a $2.8 million investment to establish two air quality improvement precincts in the inner and outer west of Melbourne.

“Through this important package and the implementation of our Air Quality Strategy, we’re taking action to improve air quality and tackle pollution in the west,” said Minister for Environment, Ingrid Stitt.

Craig Membrey celebrates 34th anniversary

Membrey’s Transport & Crane Hire Managing Director, Craig Membrey, is celebrating his 34th anniversary of operating the company.

Membrey’s Transport & Crane Hire was established in 1962 with four prime movers and eight pieces of equipment, and has since grown to now operate a fleet of over 100 highly specialised trailers.

Since taking over from his father in 1989, Membrey has been at the forefront of the company.

“Building an empire for the past 34 years has come with its fair share of ups and downs,” he said in a statement online.

According to Membrey, the past few years in particular have personally and professionally been some of the toughest – but he is still living his dream and the company is going from strength to strength.

This, combined with servicing his customers, has been his driving inspiration every day.

“Thank you as always to our wonderful team who make it happen everyday and our loyal customers – we would be nothing without you all,” a Membrey’s spokesperson said.

20 Trailer Magazine SEPTEMBER 23

XXX News

Simon National Carriers recognised with ASP certification

Transport Certification Australia (TCA) has certified Simon National Carriers to be an Application Service Provider (ASP) through the National Telematics Framework (NTF).

Transport operators like Simon National Carriers, who have invested in their own telematics systems, can obtain TCA certification so they can participate in NTF applications and schemes by using technologies already used in their vehicles.

Having obtained certification, Simon National Carriers can provide telematics applications up to Level 2 Assurance, including the Telematics Monitoring Application (TMA) and Road Infrastructure Management (RIM) applications of the NTF, for its own vehicles.

According to Simon National Carriers CEO, David Simon, the move to have the fleet’s telematics system certified by TCA allows the company’s Performance-Based Standard (PBS) drivers to meet TMA and Smart On-Board Mass (OBM) system

requirements on the routes they travel between Brisbane and Melbourne.

“Our fleet comprises PBS combinations, including A-doubles, that require enrolment in TMA and Smart OBM systems to conform with road access conditions,” he said.

“We decided it was time to have our existing telematics system recognised by TCA, rather than fit yet another system in our vehicles.”

TCA General Manager Strategy and Delivery, Gavin Hill, congratulated Simon National Carriers on becoming a certified ASP and for delivering services for its own vehicles through the NTF.

“It highlights how the NTF can accommodate transport operators who have made investments in their technology, which satisfy their specific needs,” he said.

AUSTRALIA’S SMARTEST SMART OBM. Airtec’s AXS Series Available Now! Built to take the pressure off your mass management requirements. Featuring Bluetooth-mesh technology for the strongest wireless connection possible and suitable for all airbag suspension vehicles, the AXS Series is the smartest Truck Scale product available in Australia. Scan the QR code to learn more. 1800 818 884 airteccorporation.com

Results released on impacts of wide tyres

The Truck Industry Council (TIC) and the National Heavy Vehicle Regulator (NHVR) have released the findings of the latest research project investigating the impacts of wide tyres.

Although wide single and ultrawide single tyres have been available for decades internationally, until now, TIC said, there has never been a substantial study focusing on Australian road construction – in particular sprayed seal unbound granular pavements.

According to TIC, this knowledge has always been a barrier to the adoption of next generation wider tyres in Australia.

To address this, a large-scale testing program using the National Transport Research Organisation’s (NTRO) Accelerated Loading Facility was conducted.

Nine identically designed pavements were constructed, with each loaded repeatedly to determine the relative rate of pavement wear for each tyre.

The results showed the pavement deformation rates for both the dual tyres and single tyres were within a similar range, and the 255/70R22.5 dual tyres

caused the highest deformation rate.

The comparative pavement wear of super single tyres was not as sensitive to modest variations in inflation pressure, when compared to duals.

“Taking a real-world perspective on the comparatively small differences in pavement wear found, the pavement damage exhibited by the commonly used 11R22.5 dual tyre configuration was notably influenced by inflation pressure, with the highest damage observed when these tyres were over-inflated – a common occurrence in practice,” said TIC Technical Officer, Paul Caus.

“In addition to the finding, day-to-day use of single tyres make it easier for drivers to check tyre conditions, monitor inflation pressures, and inspect brake components reducing the risk of overheating brakes and wheel end fires.”

In real world conditions, Caus said, it can be expected that the wider adoption of wide tyres would not cause a discernible increase in road pavement wear.

“TIC’s view is that there is no justification in limiting axle masses when using appropriate wide single tyres given the

improved vehicle stability and efficiency they bring,” he said.

“They should be permitted to operate at the same mass as equivalent dual tyred axles.”

The project, led by TIC, was funded by the NHVR’s Heavy Vehicle Safety Initiative and supported by the Australian Government.

NHVR Chief Safety and Productivity Officer, David Hourigan, welcomed the report’s findings.

“The findings of this report will be of great importance to equip road managers and the NHVR with the knowledge needed during consideration of vehicle load limits and the benefits provided by super single tyres,” he said.

According to Smedley’s Engineers Managing Director, Robert Smedley, this will become a cornerstone piece of research.

“It will lead to industry wide improvements in safety and environmental impacts of transport,” he said.

“I’m proud to have been a contributor to this body of work that will have a positive impact for generations to come.”

22 Trailer Magazine SEPTEMBER 23

XXX News

Toll Group executive bids farewell

Toll Group General Manager –Equipment & Fleet, Nathan Perrott, has resigned.

Following a 23-year career at Toll Group, Perrott announced his departure from the company in a statement online.

“After an incredible 23-year journey with Toll Group, I bid farewell to this chapter of my life,” he said.

“Last Friday marked the end of an era, and I am filled with gratitude as I reflect on the wonderful opportunities and experiences that Toll has given me.”

Throughout his time at Toll, Perrott has had over 10 different roles across Australia and the Asia Pacific region.

Over this time, Perrot said he has had the privilege to work alongside incredible people.

“A special shout-out to my exceptional leadership team, who tackled challenges head-on, standing together in the face

of every obstacle,” he said.

“As I step into this new phase of my life, I want to extend my best wishes to Toll Group for the future.

“The company has not only been a significant part of my past but has also played an instrumental role in shaping the person I am today. For that, I am truly grateful.”

Perrott will recharge and refocus

before moving on to his next role.

“The future is brimming with possibilities, and I am eagerly waiting to see what it has in store,” he said.

“Thank you, Toll Group, and to everyone who has been a part of this remarkable journey.

“Here’s to the memories, the lessons, and the exciting adventures that lie ahead.”

Find t he s hock s w i t h t he golden st icke r & w in $ 500 !

To celeb r a t e o ur 40t h Anni v e rs a ry Po w e r do w n w ill be gi v ing a w a y 10 x $ 500 gif t v o u che rs, t o t he l u ck y w inne rs w ho find t he 40t h Anni v e rs a ry golden st icke rs on a Po w e r do w n S up e rs hock .

o ut mo r

www.p o

a u Call 02 4949 0000 Vis it p o w e r do w n . com . a u Follo w @ Po w e r do w nA ustr alia

The Tha t 's Gold pr omo tion w ill ru n A ustr alia w ide fr om 01 / 06 / 2023 to 1 / 01 / 2024. Te r m s and Condition s a pp ly, to find

e v is it

w e r do w n com

Government assistance review exposes rising industry expenses

Money spent by governments to support Australian businesses rose to $13.8 billion in 2021-22, according to the Productivity Commission’s annual Trade and Assistance Review (TAR).

The Productivity Commission is the Australian Government’s independent research and advisory body on a range of economic, social and environmental issues affecting the welfare of Australians. The TAR, its annual report series, aims to provide a transparent and consistent estimate of the value of budgetary

assistance to industry, and which industries benefit.

The 49th TAR examined government subsidies and concessions, which increased by $460 million over the previous year. The rise in industry assistance comes amid a global return to overt industry policy, as fears about

supply chain disruptions continue.

“The TAR is an important transparency document and is a vital resource for understanding how governments are using taxpayers’ money to support private businesses,” said Productivity Commission Deputy Chair, Dr Alex Robson. “The world’s largest economies are increasingly

Economy

engaged in policies to favour selected domestic industries through subsidies, local content rules and trade barriers. In many cases this is simply a form of oldfashioned protectionism.

“As a small open economy, our future prosperity depends on global economic integration and low trade barriers. It is unlikely to be in Australia’s interests to try and compete in a protectionist contest via large scale industry assistance.”

Whereas past industry assistance mainly took the form of tariffs, this year’s TAR showed that most assistance now comes from ‘behind the border’ measures such as tax concessions and government appending.

The Productivity Commission said the main effect of Australia’s tariff system is to impose ‘nuisance’ compliance costs

Australian Consumer Confidence

on importers. The TAR estimates these costs were between $1.2 and $3.6 billion in 2021-22, compared to tariff revenue of $1.8 billion.

“For every $1 in revenue raised by tariffs, between $0.67 and $2.00 is lost in economic activity,” Dr Robson said. “Our tariff system imposes unnecessary costs and hurts consumers and does not protect domestic industry.”

The 2021-22 TAR also explores two growing sources of industry assistance – concessional finance from governmentowned entities and climate change measures that are not achieving emissions reduction objectives at lowest cost.

According to the Productivity Commission, concessional finance – where governments provide finance at favourable interest rates to industry – is particularly challenging to

evaluate, given that not all governmentowned financing entities report the value of their concessional loan charges.

“This year’s TAR establishes a framework to estimate the cost of these arrangements to taxpayers,” Dr Robson said. “Better estimates could be made if all entities published the credit rating of their loan portfolio and their concessional loan discount expenses.”

The TAR also analyses Australia’s complex structure of carbon abatement policies to assess whether they are reducing emissions at least cost.

“Grants and concessions can play a role in supporting emissions reductions,” Dr Robson said. “But they also deploy taxpayers’ money to support private businesses, so transparency is important.”

GDP growth rate March 2023 Unemployment rate June 2023 Interest rate July 2023 0.2% 3.5% 4.1%

0 5 -5 -10 -20 10 15 20 25 9 5 0 0 1 1 -1 -4 -3 -1 6 6 Jul 2022 Oct 2022 Jan 2023 Apr 2023 -3

Triple threat

With a new 12,000-square-metre rigid body building facility in Brisbane, Scully RSV will triple its manufacturing capability.

Scully RSV is once again entering a new era of growth. CEO, Andrew McKenzie, reveals a new Queensland facility is underway, which upon completion will further grow the Scully RSV network.

“It will be state-of-the-art for rigid body manufacturing in this country,” he says. “It will be a full production line taking into account all of the modern OH&S requirements and equipment that we’ve been able to obtain from our exposure and relationships with the biggest trailer manufacturers in Australia and Europe.”

The site itself is around 12,000 square metres with a 1,500-square-metre shed, which Andrew says will enable Scully RSV to manufacture up to 60 rigid bodies a month.

“It’s really exciting for us,” he says. “It sets us up for the future. With all of our corporate head office facilities and manufacturing on that site, it also gives

us the ability to offer trailer rentals here in Queensland with a trailer fleet on site.”

In hindsight, unprecedented demand for the product as well as refrigerated transport equipment across the board is what fundamentally led to the development of Scully RSV’s new site.

“We’ve seen exponential growth in our rental business,” Andrew says. “Balancing growing our rental fleet while still maintaining the expectations of our loyal customer base has meant that we’ve reached a point where we need to move into this new facility.”

Taking the lead in investing in safety and efficiency is ultimately what Scully RSV is doing – and it’s leaving no stone unturned.

“There are no expenses being spared,” Andrew says. “It’s a blank canvas and we’ll be setting that up for us long into the future. The industry has really been calling out for someone to take the lead in

refrigerated rigid body manufacturing – it is a fragmented segment in the market from a manufacturing standpoint. We know the trailer manufacturers don’t want to make rigid bodies, so there needs to be someone at the table to provide that national offering.”

Scully RSV, Andrew believes, is perfectly positioned to do just that.

“We’ve got our main factory here in Brisbane, but we’ve got Scully RSV sites in all of the main capital cities all over Australia with extensive coverage up and down the eastern seaboard and also in the west,” he says. “Buyers of our rigid bodies will be able to leverage that rental network along with the rental and repair service facilities already at our disposal.”

The future for Scully RSV customers will be a reality where they can buy rigid bodies and get service and support in any corner of the country. With rental

26 XXX Trailer Magazine SEPTEMBER 23 Rigid bodies

and repair service facilities already at its disposal, and a growing national footprint with no end in sight, Andrew says it will become possible sooner rather than later.

“We have that national footprint of sites that enables us to be able to help, support and manage customers regardless of their size or location,” he says. “So, this new facility will bring in a new era for Scully RSV and its customers. Meanwhile, we will retain the Archerfield site here, which will be our dedicated service and repair, truck sales and rental facility. All of the factory operations will move to Rocklea.”

As part of this new venture, Scully RSV will also pursue its strategic alliance with Queensland University Technology (QUT). This will see graduate engineers continue

to help Scully RSV design, engineer and market its products.

“We’ve got graduate engineers here working in the business today as part of their development and their education doing industrial work experience,” Andrew says. “They come and form part of the team, so continuing to grow and build that manufacturing footprint means we will be able to continue to build and grow those alliances with universities like QUT and provide pathways for the next generation of young Australians.”

With the help of partnerships and alliances like QUT, the Rocklea site will represent a world class rigid body manufacturing facility completely dedicated to Scully RSV’s customers.

“At this stage we’re looking to produce our first trucks out of the new facility by September,” Andrew says. “That is our timeline, so work is actively underway now at the facility.

“We’re driven by our customers – we’re here to serve them. So, like our expansion in other markets, we’re really focused on following our customers to wherever they want to go. We’re a customer-central organisation and our customers lead us, so the demand for our product has necessitated the need to expand our facilities.”

Contact Scully RSV

Ph: 1800 728 559

Web: www.scullyrsv.com.au

www.trailermag.com.au 27

Hub Link Transport presses on with Schmitz Cargobull orders

Hub Link Transport , a rapidly growing company established in 2017 as part of Hub Link Group, has taken delivery of 10 new Schmitz Cargobull 24-pallet SKO semi-trailers to assist with its freight tasks for Americold Logistics.

While Hub Link Transport has only been around for six years, it’s already made a significant mark in the transport industry. The company is now the service provider for Americold Logistics’ general freight and contracted transport requirements in Australia, seeing it operate throughout Tasmania, Victoria, New South Wales, Queensland and Western Australia.

Hub Link Transport began purchasing Schmitz Cargobull refrigerated semitrailers just one year ago, which COO, Rohan Dwyer, says may have just been a blessing in disguise as it has been a major contribution to the company’s success.

“We wouldn’t have to be able to win this last Primary Connect contract without Schmitz Cargobull because they can supply in such a short timeframe and to your specification,” he says. “Their delivery timeframe has been excellent.

From order to delivery it’s been six weeks, which is incredible in this industry – you’re talking about two years to order a trailer in Australia from anyone else at the moment. It’s enabled us to engage with contracts and supply services well in advance of our competition.”

Hub Link Transport’s new units are fitted out with all of Schmitz Cargobull’s safety features including Roll Stability Control, an Electronic Braking System (EBS), Anti-lock braking system (ABS) and an emergency park brake.

Rohan’s favourite feature though, is Schmitz Cargobull’s renowned double loader system.

“The double loader system is brilliant,” he says. “The bars are fixed into the trailer and they sit up near the roof – you just hit a switch and they come down into place. There’s no more manual handling for

drivers, loading bars in and out, or putting them away into a toolbox. It’s just massive time saving, and also from an OH&S point of view, it’s really the only way to go.”

With 18 Schmitz Cargobull trailers already present in the fleet, and six more in the delivery process, Rohan is confident these new units will outperform the standard in their operations.

“The safety in the technology is cuttingedge, and that’s obviously because of their presence in Europe,” he says. “Their thermal qualities are absolutely out there with anyone. To me, I can’t see any disadvantage with the Schmitz Cargobull range.”

Contact Schmitz Cargobull Australia Unit 2, 221 Browns Road Noble Park North 3174 VIC Ph: +61 434 743 144 28 XXX Trailer Magazine SEPTEMBER 23 Trailer builder

Hardox® In My Body equipment is light, strong and cost-effective to operate, with high load capacity and long service life. Smart design and the latest grades of Hardox® wear steel makes it all possible. Hardox® steel is constantly developed to deliver unmatched combinations of wear resistance and structural performance. hardoxinmybody.com

Contact SSAB Brisbane. Melbourne. Perth G1, 28 Balacalva Street Woolloongabba, QLD 4102 australia@ssab.com hardox.com Taking quality to the next level

LEVEL UP YOUR DUMP BODIES

Moits makes the most of Borcat

Moits, a New South Wales-based earthmoving company, has benefitted in the long run of using combinations for over 20 years.

Deciding to stick with a manufacturer for years on end says a lot about the product. Moits has done this for 20 and counting, and Workshop Manager, George Saliba, says it’s been worth it.

“Siding with Borcat has definitely contributed to our success over these years”, he says, “because the maintenance is very low on their products. The craftsmanship on their bins is excellent. I very rarely have any issues with their stuff – they are a very well-built trailer.”

Moits has accumulated 35 truck and dog combinations from Borcat as well as several 10-wheeler combinations with three-axle dog trailers. But Moits isn’t stopping there, as there are another five truck and four-axle dog combinations on order expected to arrive this year.

“We’ve just recently gone to the aluminium bins with the steel floors,” George says. “I’ve got two of them so far which are working brilliantly, and I’ve still got another five to come.”

Having quality equipment that you can rely on is essential to Moits, George explains, especially due to the fleet’s demanding operating conditions.

“We do a lot of demolitions and excavations, and we drop brick, concrete, boulders and sandstone, so these bins have got to be able to carry anything,” he says. “We find that they hold up to our

coming back for more.

“We started with Angelo Borg, the original owner, and we continued our business with Paul,” George says. “With Borcat, there is never an issue. They look after us, and if

XXX 30 Trailer Magazine SEPTEMBER 23 Trailer builder Contact Borcat Ph: 02 9631 9594 Web: www.borcat.com.au

RENTCO TO BRING AUSTRALIA’S FIRST FLEET OF TERBERG YT200-EV ELECTRIC TERMINAL TRACTORS TO AUSTRALIA

Rentco is proud to announce the long awaited arrival of the first of 12 electric terminal tractors being delivered this year.

Our Journey, is the culmination of 12 months’ work with Terberg in Europe and Asia and we are very excited to deliver the first fit for purpose R/H rental terminal tractor into Australia.

The first 4 Terberg EV units are scheduled to start arriving in June 2023, the remaining 8 units all to be delivered in 2023 and will boost Rentco’s already impressive portfolio of Terminal Tractors. In an ever-changing world, the transport industry of Australia is starting to recognise and even incentivise green choices in an effort to help shape a more sustainable future. Rentco takes this very seriously and will lead the way with this order of 12x 100% EV Terminal Tractors into Australia this year.

For Terberg Rental enquiries, contact Paul Scott: Tel: 0407 456 463 Email: paul.scott@rentco.com.au Web: www.rentco.com.au

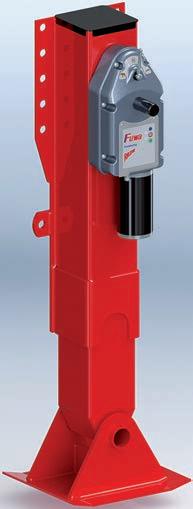

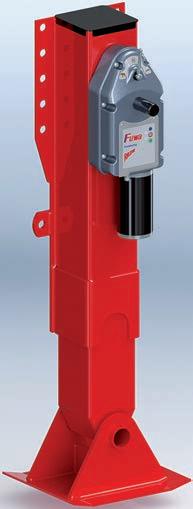

JOST is the way

Ausway Transport was introduced to JOST through its first truck and trailer combination in 2003.

Since its establishment in 2003, the structure of Ausway Transport’s entire fleet has transformed to revolve around relationships with its suppliers. Now, Ausway Transport has a dedicated OEM for each individual product which carries over with every truck and trailer combination.

“Around 2006, we decided to have a set supplier for everything,” says General Manager, Bobby Sooch. “The fleet has grown significantly, to over 50 prime movers, mostly Kenworths and Volvos, and over 100 trailers, mostly Vawdrey and FTE.”

As well as with the prime movers and trailers, this principle applies to the fleet’s lighting, suspension, axles, fifth wheels and landing legs. A leading example of this structure is JOST.

Since 2003, Ausway Transport has specified JOST products as standard wherever possible. It began, as Bobby recalls, thanks to the family’s first truck and trailer combination which was fitted with a JOST fifth wheel. The product

outperformed in every possible way, and after experiencing nothing but success for several years, the Sooch family knew they had struck gold.

“We had no trouble with the turntable whatsoever, and that’s what grew the relationship,” Bobby says. “JOST’s heavy duty Modul landing legs and JSK37C turntables are now standard across the entire fleet. We’ve got their Rockinger R0500 coupling as well in a road train setup, which we’re just starting to deploy.

“JOST is a recommended brand by most dealerships as well, because most trucks come with JOST as a factory option. But if a truck does not have a JOST product fitted to it, and it’s a brand-new purchase for us, we will change it to JOST.”

Regular orders all year round with JOST since then has familiarised its quality with Ausway Transport’s operations.

With the fleet growing at such a rapid pace, and Bobby wanting to provide drivers with the best equipment, it was essential for him to delve into the

of mind,” he says. “There are a lot of accidents can happen. We’re pretty skilled when it comes to the sensor wheels, but if someone forgets to check a trailer or something, at least there’s a vital piece of technology available to prevent you from damaging the trailer. It’s really good safetywise, you know the turntable is locked all of the time.”

Although the fleet was unaware of it at the time, this first purchase would solidify a relationship between both companies for years to come.

32 XXX Trailer Magazine SEPTEMBER 23 Trailer building materials/components

Drivers are warned when the fifth wheel is unlocked.

The running gear has been reliable when it comes to using the JOST product – I’ve had trucks that have passed one million kilometres and they’ve just gone through minor adjustments.”

Ausway Transport’s fleet runs mainly on the east coast, but it has just introduced trips to Western Australian and back.

exclusive supplier is its unparalleled aftersales service, led by Area Sales Manager, Colin Himmerman.

“The beauty is that they come and visit you,” he says. “Every couple of months Colin will come in just to check on everything. He’s always available, and if he misses our call, we know that he will

These factors give Bobby confidence to go towards JOST time and time again.

“My father and grandfather always told me that it’s not about sales,” he says. “When you come to buy a product, every single salesman is the best – they will sell you the product. You can buy a Mercedes or any other brand, and you will find that every single salesman is confident to sell that product. What you have to look at is the after-sale effect and if there are people looking to support that product.

“That’s why we choose JOST, because they’re always there when you need them. It’s not about the sale for them, it’s about the quality and support they are providing. That’s what you want to target when you go to a supplier, and that’s the reason we have set suppliers.”

Contact JOST Australia Ph: 1800 811 487 Web: www.jostaustralia.com.au

www.trailermag.com.au 33

A green display means the fifth wheel is locked and good to go.

Hardox knocks

Hardox 500 Tuf is a unique 500 Brinell product which offers a high Brinell QT steel with the impact of toughness and workshop properties close to that of Hardox 450.

SSAB spent many years developing this unique product, as Regional Sales Manager (WA), Graham McClelland, says, so that the transport industry can benefit from weight savings and increased longevity of the products it manufactures.

Hardox 500 Tuf is available as sheet in thicknesses of between 3.0 to 25.4mm, making it a very convenient and flexible choice for trailer builders. It’s also very workshop friendly and, according to Graham, allows the work shop process to basically remain unchanged due to its clean properties.

Roadwest Transport Equipment & Sales is one of the many trailer manufacturers and suppliers that can attest to this. Since joining the transport race in 1970, it has specialised in the manufacturing of

tipping trailers and transport equipment.

Director, Peter Lombardi, has been dealing with SSAB himself for 25 years and he’s seen everything it has to offer. A quarter of a century down the road, Roadwest still specifies Hardox for its trailers.

“We’ve been dealing with SSAB even prior to them coming into Australia in their own right, when they were using agents,” he says. “We only use their materials in the chassis and the body, we don’t use any mild steels in our trailers at all. We only use their high strength and quenched and tempered steels.”

Using Hardox 500 Tuf enables Roadwest to deliver the best product for fleet owners and operators.

“It allows us to improve our designs and also reduce some of the thicknesses in the materials that we use to offer a better tare weight for essentially the same structure as the previous thicker material that we used,” Peter says. “With 500 Tuf,

34 XXX Trailer Magazine SEPTEMBER 23 Trailer building materials/components

SSAB’s 500 Tuf wear plate is the latest upgrade in the Hardox range, and it delivers high strength, guaranteed toughness and ultimate durability all in one product.

Fast fact

and even with the cutting and processing of the plate, we’ve had next to no issues with at all.”

used to use. We definitely do well using it,

By utilising the latest equipment and software available, Roadwest holds the ability to custom build products in a range of sizes and specifications in accordance with the varying needs of its customers. However, SSAB’s prevalent dedication to quality and availability makes this commitment hassle-free for Peter and the team.

“There are always constant improvements going on,” he says. “The support to they give to their customers is the same – there are no problems. I make a phone call and they come back to me. There are very few issues at all when you deal with SSAB.”

Contact SSAB

Email: australia@ssab.com

Web: www.ssab.com

SSAB claims that with Hardox 500 Tuf, customers can expect twice the service life compared to a 400 HBW AR steel and up to 50 per cent longer service life relative to a 450 HBW steel.

www.trailermag.com.au 35

RoadWest Transport Equipment & Sales Managing Director, Peter Lombardi, and SSAB Regional Sales Manager (WA), Graham McClelland.

The more things change, the more they stay the same

Earlier this year, it was announced that global infrastructure investment manager, I Squared Capital, signed a definitive agreement to acquire a majority stake in Rentco. The deal, which is now in place, saw the ownership of 80 per cent of the business be handed over to I Squared Capital. The remaining 20 per cent belongs to original Rentco Owners, John and Bob Shier, who have successfully taken the business to where it is today over the last 29 years.

Despite this proportional ownership change, National Business Manager, Paul Scott, assures that Rentco will still be the same leasing company the transport industry has come to love.

“From a customer experience, they will be dealing with the same people,” he says. “The Shiers are staying in their roles as CEO and Director and the management team has been secured in its entirety.

We’re pushing on harder than we ever have. We’re now affiliated with the world’s largest truck and trailer rental companies,

and that’s going to mean some added clout when it comes to scaling up with new equipment.”

Accoridng to Paul, Rentco will also share and draw on the experiences the new affiliation will provide as part of “world leaders in global equipment solutions”.

“We’re going to do that via organic growth with a large future equipment order bank and by looking at certain strategic fleet acquisitions,” he says. “There’s a huge desire and a huge amount of support from our current ownership group to push forward with that. It’s their exclusive desire to do so.”

The investment has given Rentco the funding to progress at a rate which Paul says was most likely previously prohibitive for a family business. Thus, the biggest

compliance and serving,” Paul says. “In the long term, you’ll see a more prominent and much larger-scale Rentco business, which we’re looking at particularly growing in the purchase and lease back of larger fleets. Nothing is off the table.”

The arrival of Rentco’s first four fully electric terminal tractors is a clear indication of this expansion. A further eight will be delivered to Rentco by the end of 2023, and they will all be available to operate within large and medium-sized warehousing and port facilities to give customers a fully electric option. This new offering, Paul says, is very important. Rentco has put considerable effort into evaluating the terminal tractor including designing tailored charging solutions to give clients complete piece of mind. While

36 XXX Trailer Magazine SEPTEMBER 23 Trailer building materials/components

While Rentco has new equity partners following its majority acquisition earlier this year, the company has kept its management structure to preserve its well-known reputation and commitment to reliable rental solutions.

only way to grow or swing into another area or pick up a new contract is to have a reliable equipment partner, and that’s where a rental fleet with backup of nearly four thousand vehicles is imperative.”

This, Paul predicts, is where Rentco will thrive.

“I would assume that companies that are going to require equipment quicker than 12 months are going to source it from a

flexible equipment partner with compliant late model stock,” he says. “The rental or leasing opportunities with Rentco are endless, and you can structure a deal with us in any way that works for you”.

Contact Rentco Ph: 08 9353 9999 Web: www.rentco.com.au

www.trailermag.com.au 37

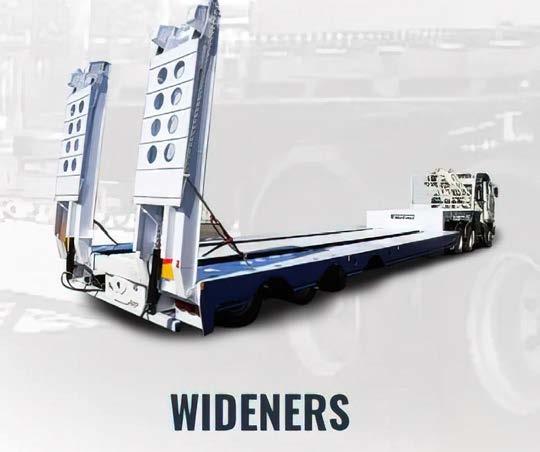

Hungry for more

Haulmore Trailer Sales & Rentals was founded in a small factory in Bayswater, Western Australia, by Alan Moody to offer quality heavy duty equipment to the Australian transport industry. As Alan recalls, the company started as a very small business building tippers and trays and cutting chassis. But overtime, alongside Fuwa K Hitch, it developed to become a much larger presence in the industry.

“We’re celebrating our 50th anniversary of operations,” he says.

Alan’s motto of ‘Challenges accepted’ is ultimately what has allowed Haulmore Trailer Sales & Rentals to thrive in various circumstances.

“I like coming to work, I like what I do, and I’m proud of what we do,” he says. “We have had good communication with our customers over 50 years, and I don’t think it gets any better than that. That’s why I like to be in business – because of the quality of the people I do business with. And the same can be said for our business with K Hitch.”

Haulmore Trailer Sales & Rentals’ alliance with Fuwa K Hitch goes back to its arrival in the market. Alan had even chosen the OEM, known as ‘K Hitch’ at the time as his main supplier for trailer builds before FUWA came into the picture.

“If I wasn’t their first customer, I would have been their second or third one,” he

says. “So, our association with K Hitch is very longstanding. There hasn’t been a month where we haven’t done business with them.”

As Alan recalls, when K Hitch first began it was only building turntables. But, once it was purchased by FUWA, it grew rapidly and globally. So, as Fuwa K Hitch’s product offering increased, so did its presence in Haulmore’s trailer builds.

Today, Haulmore specifies Fuwa K Hitch on its trailers as standard. From the ground up, its combinations feature Fuwa K Hitch’s axles, suspensions, low loader suspensions, landing legs and kingpins.

“We buy the full range of their equipment,” Alan says. “Our basic quotes

38 XXX Trailer Magazine SEPTEMBER 23 Trailer building materials/components

In celebrating 50 years of business, Haulmore Trailer Sales & Rentals is commemorating its persisting relationship with Fuwa K Hitch since becoming one of its very first customers.

include K Hitch – we use anything they have to sell in our industry here. We are very strong supporters of them, and they provide a good level of service for us.”

In addition, Haulmore also owns and operates a rental fleet of 100 units, including semi-trailers, road train dollies,

trailers, water tankers and flat top trailers. Like all of its trailer combinations, its rental units are also fitted with Fuwa K Hitch equipment. This, to Alan, is a clear case in point of the quality and reliability Fuwa K Hitch has to offer.

“The product is of a good standard, the

we continue to do business with them,” he says. “I would like to think we’re a five-star customer. We always pay our bills and we’ve always had good service with Fuwa, which is why we always use their product on a regular basis.”

Furthermore, Alan believes the relationship between two companies is one of the most important factors in business. With Fuwa K Hitch, it’s something both parties have mastered.

“It all comes down to good business relationship,” he says. “Business is about competitive price, good service and a good relationship, so that everyone can work together and make a profit – and that has always been the case with K Hitch over many years.”

Contact Fuwa K Hitch Ph: (08) 9350 6470 Web: www.khitch.com.au Haulmore Trailer Sales & Rentals Ph: (08) 9274 6355 Web: www.haulmore.com.au

www.trailermag.com.au 39

Haulmore Trailer Sales & Rentals Managing Director, Alan Moody, and Fuwa K Hitch State Manager WA, Ryan Ussher.

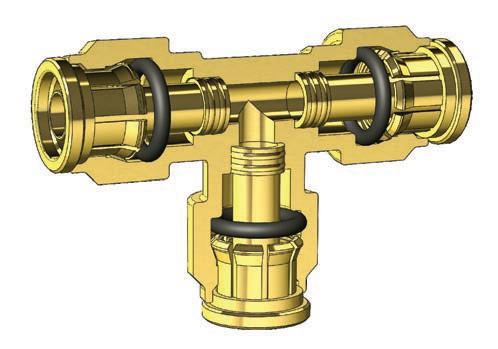

Airtec’s AXS SmartOBM just keeps getting better

Before the AXS SmartOBM System’s debut in the transport industry, syncing up trailer combinations to Smart On-Board Mass (OBM) systems was much more bothersome. Previously, for example, operators would need to push a button on the master truck unit to engage scan mode and then go down to the combination and push the side button on every trailer to sync the data to the master unit. However, Airtec Electronic Engineer, David Morton, also the man behind the innovation, has made these requirements disappear.

“Now with the new AXS series, that’s all done automatically behind the scenes in the firmware of the unit,” he says. “On power-up it sends messages out to all of the trailer units to find out which ones aren’t connected up to a system, and then based on signal strength and other indicators, we use that to calculate which truck and trailers are in your combination and which order they are in as well.”

The AXS SmartOBM System has been in development for the past 18 months and the auto-scan function is just one of many new features David and the highly skilled team at Airtec were able to bring in with the new product – due to its transition

away from old radio protocol to Bluetooth Mesh.

“By having all of our units now running on the BlueTooth mesh, we can connect all of them using our TruckOBM app that runs on Android and iOS,” David says. “This means our operators can now update and configure their devices using the app on all of their assets, and also have more updates.”

The benefit of this, David explains, means anyone using these new systems will be able to stay up to date with the latest firmware and features.

“If we make a change to this autoscanning feature down the line, they will actually be able to update their units so that they are all running to the best algorithms and using the best technology,” he says. “That’s something pretty unique with our system – we’ve got the over the air connection with all of our assets, and we can do few more updates.”

Airtec has also increased the speed in which the data transitions between all trailer units, which, on top of all of AXS SmartOBM’s other features, makes OBM monitoring a much more seamless process.

Contact Airtec Corporation Ph: 1800 818 884 Web: www.airteccorporation.com

Scan to view the AXS SmartOBM Series 40 XXX Trailer Magazine SEPTEMBER 23 Trailer building materials/components