9 minute read

Trailer Building Materials/Components

by Prime Group

Connectivity is key

BULK LIQUID AND CHEMICAL TRANSPORT CARRIER, UNANDERRA TANKER HIRE, HAS INVESTED IN WABCO TELEMATICS TO IMPROVE THE SAFETY AND EFFICIENCY OF ITS OPERATIONS.

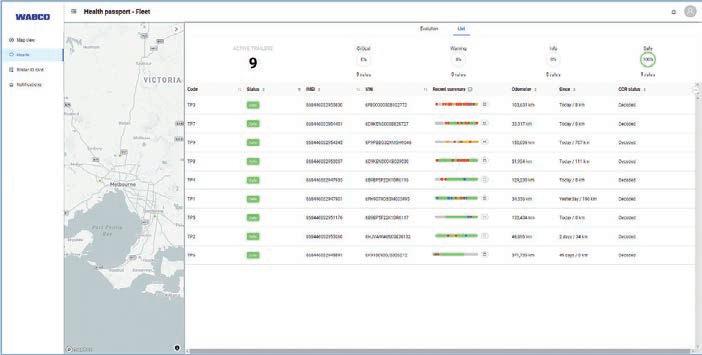

Unanderra Tanker Hire (UTH) has been servicing the liquid transport needs of specialised freight companies along Australia’s eastern seaboard for more than 40 years. Managing Director, Jeremiah Wiedl, says the business is committed to providing environmentally sound and efficient transportation of various liquid products, specialising in chemicals and corrosive 8 Dangerous Goods (DG). The company utilises a diverse fleet of modern vehicles including small rigid tankers, semi-trailers and B-double configurations. There are currently 47 trucks and rigids (a mix of Kenworth, Western Star, Mercedes-Benz, DAF and Volvo) and 66 trailers – aluminium, stainless steel, fibreglass and high-density polyethylene (HDPE). UTH provides metro, short-haul and linehaul cartage within New South Wales as well as linehaul cartage that covers Queensland, Victoria, South Australia and Northern Territory. “Our primary operation is in Port Kembla, as well as a secondary depot in Minto, New South Wales, with a sub-depot in country Victoria, and a presence in south-east Queensland,” Jeremiah says. “UTH staff are trained in the handling of DG and are licensed by the Environmental Protection Authority.” UTH has arranged for the fitment of WABCO telematics on its heavy vehicles to keep track of its assets. “Tracking our fleet is of upmost importance,” Jeremiah says. “We need to know where UTH trucks and trailers are at all times. This helps us manage the fatigue of our drivers, provide accurate ETAs for our clients and is also critical in our trip planning.” The main product that UTH uses is TXTRAILERFIT tracking portal and the WABCO diagnostic software. WABCO Product Support Manager, Blair Rundle, says TX-TRAILERFIT provides a basis to estimate and evaluate the technical health of each trailer. “It processes the diagnostics code history as logged by the Operating Data Recorder (ODR) and specifically features events such as diagnostic trouble codes, warning lamps, tilt alerts, insufficient tyre pressure, RSS events, supply pressure warnings, wheelspeed, demand pressure and axle load sensor data,” he says. “The solution includes up-to-date digital trailer ID cards, describing various technical trailer details, such as trailer brand, model, EBS type and axle configuration. “Daily monitoring and follow-up of the

Workshops use WABCO telematics for diagnostic purposes.

Fast Fact

Unanderra Tanker Hire has its own National Heavy Vehicle Regulator (NHVR) regulated workshop with full-time mechanics and 24/7 emergency breakdown service to minimise equipment downtime while meeting all regulatory and industry standards. The fleet’s use of WABCO telematics ensures efficient and timely operations.

evolution of technical health based on diagnostics trouble codes, EBS warning lamps and other contextual information such as location, result in the attribution of a health score per trailer, which is constantly updated according to any new event that may have occurred.” TX-TRAILERFIT, according to Blair, reduces

the chance of vehicle breakdowns, eliminates unnecessary maintenance and optimises maintenance scheduling, parts replacement sessions, ensuring faster response times in the workshop. “ The ability to live track assets and view events and alerts is the main reason why UTH has invested in WABCO telematics,”

Jeremiah says. “ Tracking driver behaviour is good to coach and change driver behaviour to reduce incidents.” To maintain its WABCO telematics systems and to stay up to date with the latest technologies, UTH has partnered with Air Brake Systems. “The aftersales for the WABCO product is great,” Jeremiah says. UTH recently purchased two new trailers and has retrofitted four units with plans to fit the WABCO system to the entire fleet. Jeremiah has seen immediate benefits with the use of WABCO telematics. “Tracking is live,” he says. “We can prove locations, times, events and weights, air pressures and so on. It’s great to be able to have this data now and look back at history to learn.”

A view of the digital portal.

Contact WABCO Australia Unit 3, 8 Anzed Court Mulgrave VIC 3170 Ph: 03 8541 7000 Web: www.wabco-auto.com

Making the switch

ELECTRONICS COMPANY, REDARC, IS RELEASING ITS LATEST BATTERY MASTER ISOLATION SWITCH THAT FULFILS THE REQUIREMENTS OF THE NEW AUSTRALIAN DANGEROUS GOODS STANDARD.

Since its launch in 2016, the Australian Made BMIS (Battery Master Isolation Switch) has been trusted by commercial vehicle manufacturers like Kenworth to safely isolate vehicle batteries when required and ensure a reliable performance while the vehicle is operating. During the development of the BMIS, it underwent extensive independent testing and validation including rugged field trials to ensure the unit could be fitted as OE equipment. This, according to REDARC, is a prime example of collaboration and cooperation with an OEM to ensure a world best product outcome. Now with the recent release of the new Australian Dangerous Goods Standard AS2809:2020, REDARC is proud to release the next generation BMIS (V2) fulfilling the requirement for a Master Isolation Switch under that standard. The new Australian standard is referred to within the Australian Code for the

Battery Master Isolation Switch.

Owners and operators of Road Tank vehicles rely upon the manufacturers of the safety components like REDARC to assure compliance and reliable safety.

Transport of Dangerous Goods by Road and Rail (ADG Code) which sets out the requirements for transporting dangerous goods by road or rail. The Heavy Vehicle Industry Association affirms that compliance to the Australian standard is required to make road tank vehicles conformant to the legislated standards. Owners and operators of Road Tank

vehicles rely upon the manufacturers of the safety components like REDARC to assure compliance and reliable safety. REDARC Managing Director, Anthony Kittel, explained that isolation switches are assessed as part of the full vehicle safety system under these standards, and this is why REDARC have ensured that the BMIS meets the criteria and enables the vehicles to operate safely in those conditions. “We have been working for over 30 years (since 1989) with the truck original equipment manufacturers, supplying products they can rely upon,” he said. “We continue to work closely with our customers to provide products that meet their needs as well as industry standards. “The upgraded compliance of the BMIS is another example of how our design engineers strive to set the industry benchmark for innovation in electronic vehicle technology.”

REDARC’s head office in Lonsdale, South Australia Contact REDARC Electronics 23 Brodie Road North Lonsdale 5160 South Australia Ph: 08 8322 4848 Web: www.redarc.com.au

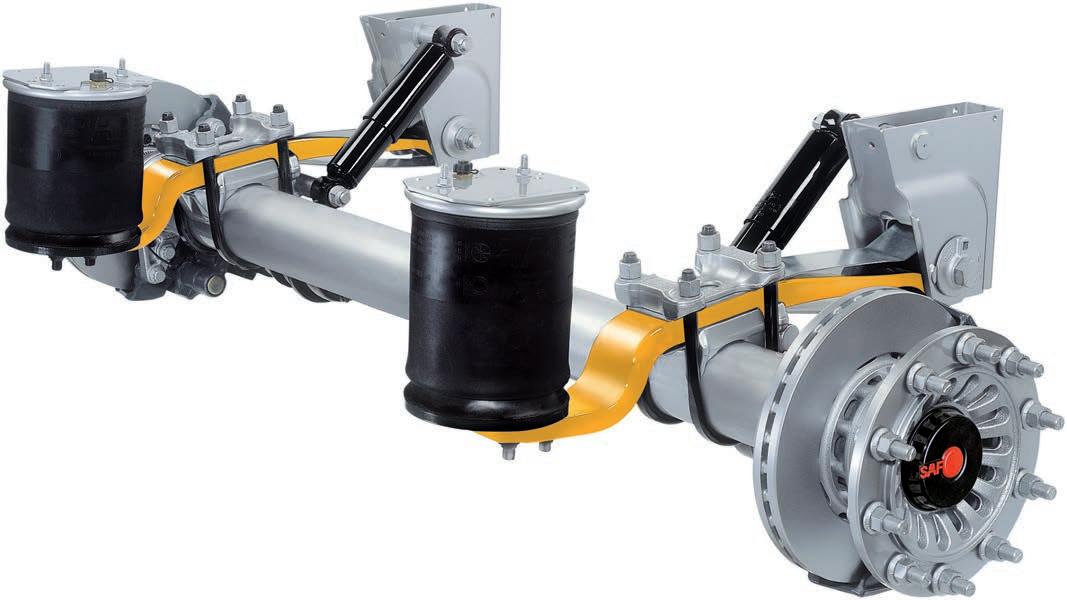

Most Air spring suspension rely on the shock absorbers to limit extension travel and maintain firm tyre to road surface contact. Image Courtesy of SAF-Holland (Aust) - Modul suspension

Shock value

SHOCK ABSORBERS ARE CRITICAL SAFETY COMPONENTS THAT CAN AFFECT TYRE WEAR, STABILITY, VIBRATION, DRIVER COMFORT AND THE LIFE OF OTHER STEERING AND SUSPENSION COMPONENTS. PACCAR PARTS AUSTRALIA PROVIDES OPERATORS WITH THE GEAR AND THE SERVICE THEY NEED TO MAXIMISE TRAILER AND HEAVY VEHICLE UPTIME.

One of the main cause of tyre wear on air suspended trailers, according to PACCAR Parts Australia, is due to worn shock absorbers. A good understanding of how shocks function, and maintaining heavy vehicle equipment with quality parts, can help keep heavy vehicles on the job. Shock absorbers are expected to perform a range of vital functions including: 1.Transforming movement to heat.

Velocity sensitive dampers transform the kinetic energy produced by suspension movement into thermal energy, which is dissipated via hydraulic fluid. 2. Reducing cost per kilometre. Properly functioning shock absorbers can help reduce operating expenses by extending tyre life, reducing wear and tear to other components and protecting the trailer investment. 3. Preventing damage to the air spring suspension. Most shock absorbers are

designed with a hydraulic limiting lockout feature which prevents over extension of the shock under extreme conditions, which in turn limits extension of the air spring. 4. Maintaining road to tyre surface contact. Maintaining firm tyre-to-road contact is critical for safe steering, handling and load control. PACCAR Parts Australia emphasises that preventative maintenance is the key to maximising truck and trailer uptime. “Routine inspection as part of a scheduled maintenance program can help to identify signs of problems in these critical components early on,” says Rekha Mohan, Senior Product Manager at PACCAR Parts Australia. Below are some of the simple visual inspection techniques that can help get the maximum life out of shock absorbers and related suspension parts. 1. Understanding the difference between

Light Misting

misting and leakage is important. Misting is normal for the function of a shock absorber whereas fluid leakage from the upper seal, which could drip over the shock body, is a clear indication for replacement. 2. Mounting bolts have to be tight, loose bolts can cause damage to mounting holes, which can in turn loosen the fitment of a new shock absorber. 3. Upper and lower mounts have to be intact and not broken. Incorrect ride height or shock absorber can damage the mounts.

Heavy Misting

4. Look out for any accumulated debris on the air springs/hub seals/shock absorbers.

They need to be cleaned if present as heavy dust/debris can act as an abrasive that can potentially cause wear and tear. “When replacing worn air bags, remember to replace worn shock absorbers,” Mohan says. “As for choosing the right shock, the application in which the truck-trailer combination operates or will operate is the deciding factor.” All vehicles accredited with Higher Mass limits (HML) under NHVAS must be fitted

with Road friendly suspension (RFS), which

Leakage

will reduce the impact of laden axles on roads and related infrastructure according to the National Heavy Vehicle Regulator. In addition, when replacing shocks on road-friendly suspensions, it is important to replace only with a shock absorber part number that is listed on the Vehicle Standards Bulletin 11 (VSB 11) certificate against the particular model of suspension in question, to ensure ongoing compliance to HML accreditation. Relevant VSB 11 certificate numbers are required to be displayed on the vehicle under the scheme so that they can be easily referenced. All VSB 11 certificates can be found on the Department of Infrastructure website for easy cross reference with the certificate label on the vehicle. “We always recommend a like-for-like replacement where possible,” Mohan says. “And if you are in the market for an aftermarket shock absorber, please choose established brands with proven product quality, service, warranty and technical support.” “We carry a huge range of both OEM and aftermarket trailer shock absorbers such as BPW Transpec, Hendrickson, Koni, Monroe, Powerdown and our own brand TRP to name a few,” Mohan says. “Our dedicated parts specialists at our dealerships can help with your technical and sales queries.” PACCAR Parts Australia helps fleet operators to maximise uptime on the road and allows for peace-of-mind with a firm commitment to delivering on parts availability that is reinforced by technical expertise and nationwide dealer support. With more than 250,000 available truck and trailer parts and accessories, an efficient inventory management system complemented by innovative warehousing technologies and a large dealer network, PACCAR Parts Australia has the trucking industry covered.

PACCAR Parts Australia would like to thank Hendrickson, Monroe and SAF-Holland for their technical inputs to this article.

Contact PACCAR Parts Australia 20 Canterbury Road Bayswater VIC 3153 Ph: 1800 772 787 Web: www.paccarparts.com.au