WHEN WASTE ISN’T WASTED TIME TO JOIN TEAM

THE PSYCHOLOGY OF CONSUMER CHOICE TRENCHLESS

WHO HAS THE

BEST TASTING WATER?

Engineering, Construction & Maintenance WATER | SEWER | ELECTRICITY | GAS | NBN www.utilitymagazine.com.au Issue #7, August 2015

Andrew Gaston Project Manager

On site at the Cranbourne Racecourse Recycled Water Tank Project (LD&C Joint Venture)

Intelligent Doers, Dependable Delivery

www.comdaininfrastructure.com.au/media/videos

Andrew is one of Comdain’s 70 full time, qualified and experienced Project Managers / Engineers and is indicative of the innovative, dynamic and passionate sector specialists delivering projects for our clients.

Comdain’s 50 years experience provides an in depth understanding of what it takes to be industry leaders in project delivery. Our project management professionals are supported by highly functional delivery teams, systems, project controls and governance - a high performance environment driving high performance results.

Watch Andrew’s 10ML tank being constructed here:

Will your plant and operations survive a cyber attack?

E

ver ywhere it ma t ters , we de liver

RISK MANAGEMENT

Discover and remediate security gaps in your critical systems before an attack occurs

COST- EFFECTIVE SOLUTIONS

Practical, cost-effective treatment of cyber threats benchmarked against your industry

OPERATIONAL RESILIENCE

Strengthen organisational security and resilience so you can maintain availability

PROTECT REPUTATION

Protect your organisation’s reputation and compliance by managing your security risks

PLAN FOR THE FUTURE

Get actionable intelligence on the state of your organisation’s security so you can plan for the future

Will your plant and operations survive a cyber-attack?

With the cost of cybercrime now exceeding AUD 2 billion and affecting over 50% of Australian organisations, traditional IT defences will not protect your operations from a cyber-attack. Avoid becoming part of the statistic. Thales’s vulnerability assessment service is helping utility providers understand the real risk of cyber-attack and how to position themselves to handle the added security challenges of merging operational and information technology environments. Supported by over 40 years experience, Thales delivers cyber security solutions used by 90% of the world’s largest global banks to give you a solution the world already trusts. With security in our DNA, Thales products, services and solutions provide you with the information, services, equipment and control needed to understand the threats your business faces so that we can commit to delivering the results you need, whatever it takes. Call us. Get started 1800 ALL CYBER or by email cybersecurity@thalesgroup.com.au

BUSINESS CONTINUITY

Identify single points of failure to ensure your business continuity

thalesgroup.com.au

TFROM THE EDITOR

his edition has a strong focus on treating both water and wastewater. It ties in with the upcoming Water Industry Operators Association (WIOA) Bendigo conference, and we have been proud to be the official media partner of all WIOA events this year.

The work done by Australia’s water industry operators is often not glamorous, but is essential to the lifestyle that all Australians enjoy. We take our clean drinking water for granted, and this edition we look at some of the work that goes on behind the scenes to make this happen.

At the other end of the process, we look at what happens to the waste. The increasing repurposing of waste, whether as recycled water, or energy, will be a growing feature of the industry in the future. It is testament to the ingenuity of our engineers that when waste was once simply a problem to be disposed of, it has now been turned into an opportunity.

I have always been excited by the innovative industry of trenchless technology, an industry where Australia has often been a world-leader in devising new and better methods to install and repair underground infrastructure with minimal surface disruption. In 2004 I was involved in the launch of Australia’s first trenchless magazine and I’m pleased to see it is still going strongly to this day.

The next challenge for the trenchless industry is to maximise awareness and buy-in from the utility decision makers. To

that end, in this issue we talk to some of the utility leaders who are already proud to declare themselves members of Team Trenchless, and we hope their example will be followed by many more.

We have also worked with IT industry leader CSC to create some new crossplatform content with this issue, please turn to pages 38-39 to read the first of our interviews about key utility issues. From there you can also find the links to go online to watch further video content on these issues. We will be progressively rolling out more of this content in the months to come. To ensure you don’t miss it, make sure you are subscribed to our free online newsletter by visiting the website and clicking subscribe.

We are pleased to note that our audited circulation has once again increased for the past half, and thank the utility industry for their ongoing support and interest in our magazine.

Finally this issue, we look more closely at retail and billing issues, reflecting on the importance of the customer relationship. This leads in well to our next edition, where we look more closely at how the information gathered from the customer can be used more broadly to benefit the whole network.

Chris Bland Publisher and Editor

Publisher and Editor Chris Bland Managing Editor Laura Harvey Associate Editor Michelle Goldsmith Journalist Emily Thomas Marketing Director Amanda Kennedy Marketing Consultants Aaron White Cynthia Lim Creative Director Sandy Noke Graphic Designer Alejandro Molano Monkey Media Enterprises ABN: 36 426 734 954 PO Box 3121 Ivanhoe North VIC 3079 P: (03) 9440 5721

(03)

ISSN: 2203-2797 Published by Cover image highlights our feature on water and wastewater treatment in this issue.

F:

8456 6720 monkeymedia.com.au info@monkeymedia.com.au utilitymagazine.com.au info@utilitymagazine.com.au

ISSUE 7

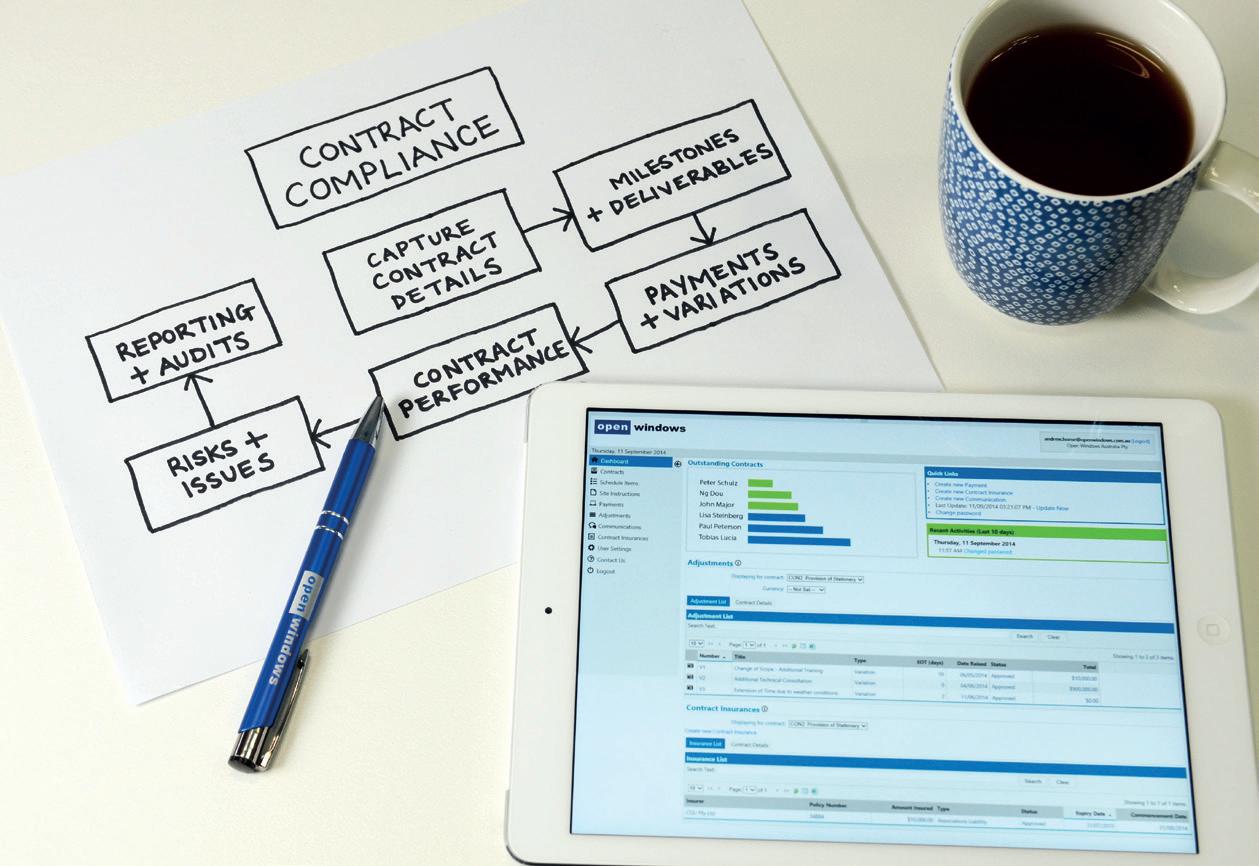

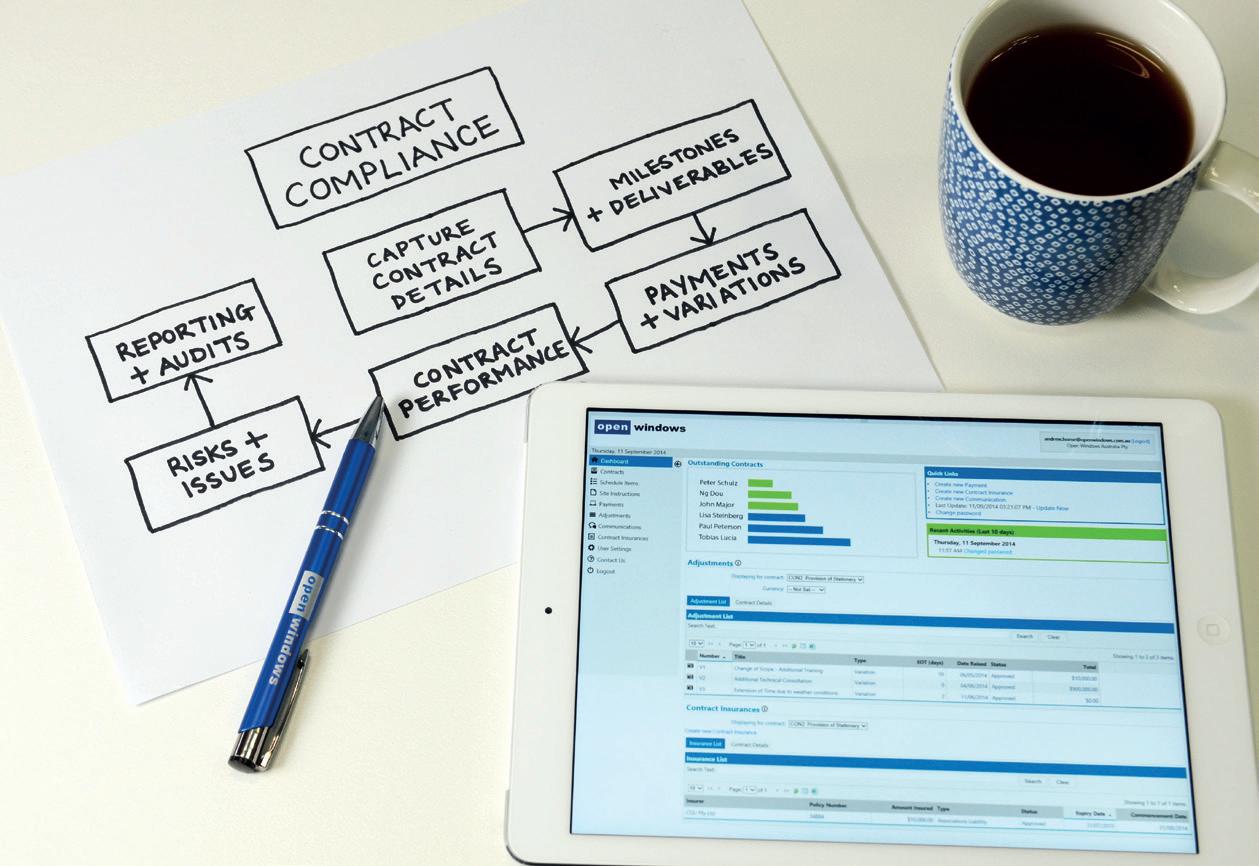

Contract Management Solutions for Utilities

Contracts repository

Strategic sourcing

Contractor management

Business process workflow

Capital program management

Payment management

The preferred choice for many of Australia’s utilities companies, extract more value out of your agreements while reducing risk and increasing compliance. A comprehensive suite of contract and contractor management modules in Open Windows CONTRACTS ensure that the contracts being signed are the contracts being delivered.

Modules include tender management, KPI management, payment and variation management, insurance management, risk determination and mitigation, as well as program management tools and external CONTRACTS Portal. Open Windows CONTRACTS can be integrated with your ERP, document management and financial management systems.

openwindows.com.au

WATER & WASTEWATER TREATMENT

Trenchless technologies play a major role in the installation and rehabilitation of the buried assets that form our water networks. Here, we’ve gathered a group of leaders within the water industry who are proudly ‘team trenchless’ - the people that are championing the benefits of trenchless technologies, and specifying their use on major

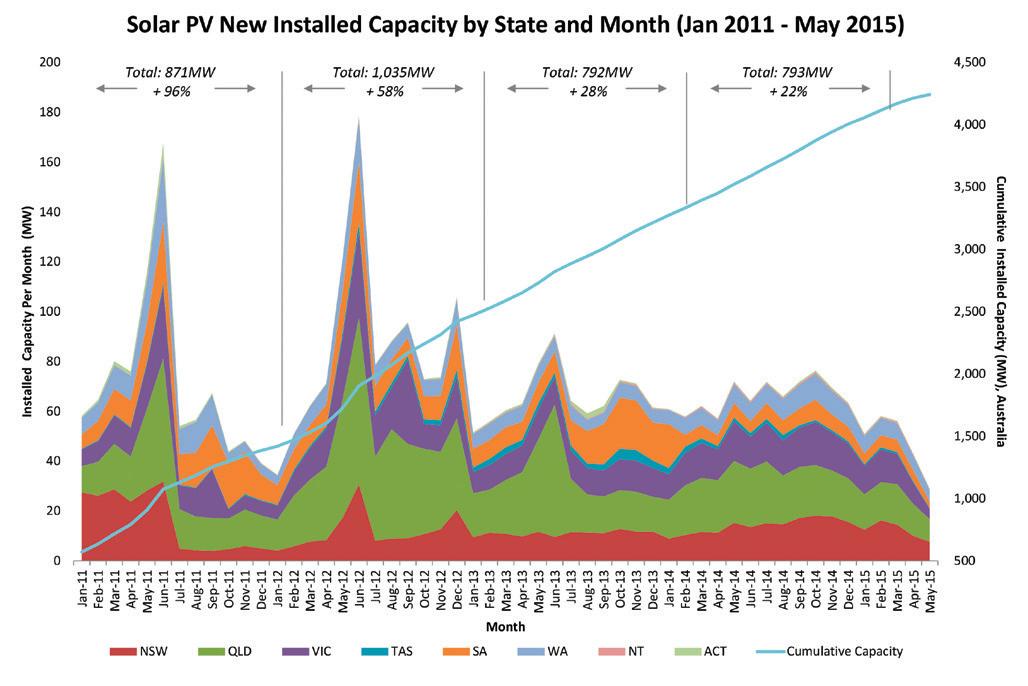

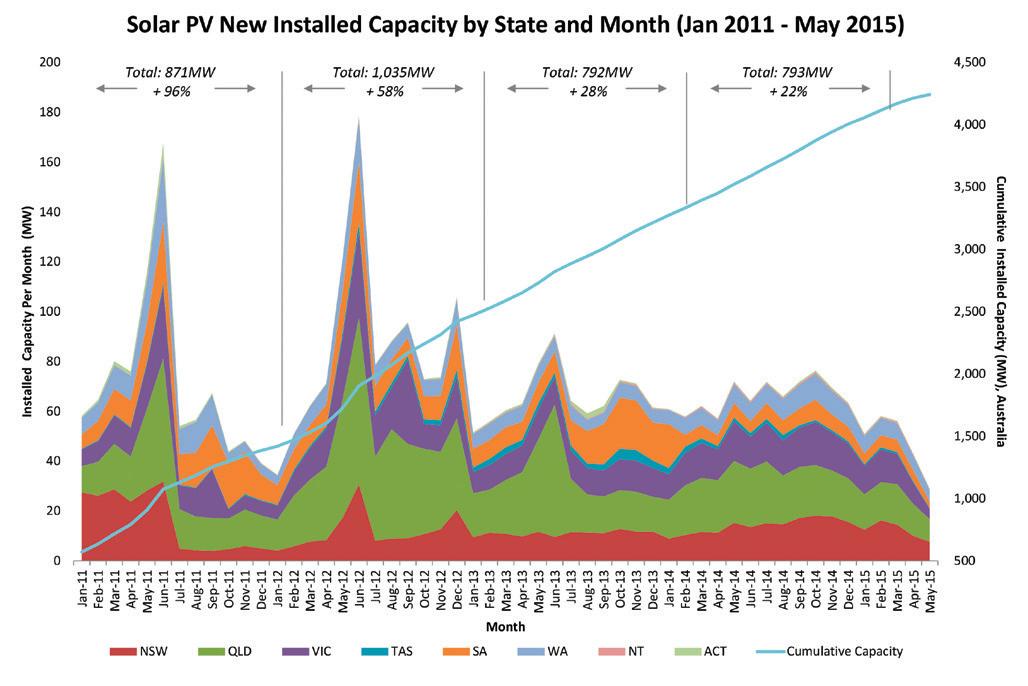

The popularity of renewables with consumers is undeniable, with EY research showing that nearly 90 per cent of Australians would consider switching to solar energy.

CONTENTS 6 16 20 WIOA Operating in a changing environment: the water industry professionals delivering water around the nation ........................ 16 We met with a

of

they face, the

they’re working with

the future for the water industry as they see it.

diverse group

water industry operators to learn about the challenges

new technologies

and

Turning waste into energy ......... 20 Harnessing the power of poo .... 26 Odour control company builds air release valve .......................... 29 Smarter. Safer. Faster. ................ 30 Arsenic removed from drinking water ............................. 31 From prehistoric to artesian gold 32 34 50

outlook for renewables in Australia 50 For more than a decade in Australia, the debate around renewable electricity generation has been simmering, alternating between fever pitch and

Managing fatbergs: taming the monsters that lie beneath ......................................... 34 Rats and Batts inspect Queensland sewers 36 38

What’s holding smart water meters back? 38 It’s our most precious resource,

water utilities

as

metering

as the electricity sector?

RENEWABLES The

benign interest.

DRAIN CLEANING

OPINION

so why haven’t

been

quick to deploy intelligent

systems

WATER

40

projects around the country.

ISSUE 7 7 54 62 RETAIL The psychology of customer choice ........................................... 62 Customer information systems: increased need, decreased cost ............................. 65 SCADA Real-time data powering intelligent networks .................... 66 Managing your connections 69 72 In each issue Editor’s welcome ................................................. 4 A word from the ENA .......................................... 8 News briefs ......................................................... 10 Advertisers’ index .............................................. 88 Editorial schedule .............................................. 88 Utility magazine is bringing together experts on various fields to answer all your questions 86 80 ASSET MANAGEMENT Assessing asset management: improving systems and enhancing outcomes 54 Reaping the benefits of a true mobility solution ......................... 56 The changing face of asset management 58 Connecting Australia .................. 59 Strategic asset management for water utilities 60 84 CABLES Who will be the world’s best cabler? 84 NBN Creating constructive NBN partnerships ....................... 80 UTILITY IN PROFILE Gold Coast Water ........................ 70 WOMEN IN UTILITIES Jenny Gannon ............................. 74 PIPE & CONDUIT We need to talk: a smarter way of managing assets .................... 77 70

A WORD FROM THE ENA

JOHN BRADLEY CHIEF EXECUTIVE OFFICER – ENERGY NETWORKS ASSOCIATION

If you had been starting university 20 years ago, you were probably still photocopying reading materials in the library. Living on campus meant you probably queued to use the college phone and early adopters may have signed up for their own hotmail account. A missed lecture may have come on cassette tape and in some great classes, a forward thinking lecturer may have decided to do some interesting group projects using the world wide web.

Ten short years later, a student may have had their own pre-paid mobile, been able to download lectures and papers from the university’s student website and library database, and the university had apartments to complement the college accommodation.

Today we could ask – do you even need to turn up to a university campus? Your computer is lighter than the reading compendiums of old. With webinars, online learning and journals, do you really need the bricks and mortar of the university to receive the qualifications for your chosen career?

The ‘business model’ of universities has clearly been challenged, their role is changing and their customers have significantly increased control and choice. Yet they remain a fundamental institution for learning which has embraced, rather than resisted, its own disruption. Most universities have changed their service delivery as technology changes, without diminishing their value. There remains a strong acceptance that participating in the sharing of knowledge, learning in a community of others is important. Interaction with people matters, choice matters and service matters – and technology is the facilitator not the substitute.

HOW DOES THIS RELATE TO ENERGY?

In similar ways, technology and empowered consumers are

transforming our interaction with energy and Australia’s ‘great energy disruption’ is clearly in full swing. While it’s possible this revolution will lead us to atomised, self-sufficient energy production and consumption, most expert analysis concludes that it is unlikely to be the optimal outcome for consumers.

A ROADMAP FOR THE FUTURE

In this time of unprecedented change for global energy services, the Energy Networks Association is partnering with Australia’s national science agency, CSIRO, to develop an Electricity Network Transformation Roadmap. The project will update and build on the CSIRO Future Grid Forum analysis of Australia’s potential electricity pathways to 2050, which was completed in 2013 after 18 months, involving input from a broad range of stakeholders.

This project recognises there is no crystal ball and no single energy future. However, the actions taken by Australian network businesses, supply chain participants, governments and regulators in the next critical decade (2015-25) are likely to have significant consequences for our ability to support the evolving needs of consumers. The Roadmap seeks to position networks and the supply chain for the future, to innovate and develop new services that customers value and foster the long-term resilience and efficiency of Australia’s energy system. It will inform options for regulation, business models and electricity pricing that are best able to support delivery of the future services which customers want, while ensuring an efficient, competitive and economically-robust value chain.

The Roadmap program will be highly collaborative, recognising that the transformation of the energy system can not be ‘engineered’ by any single player. Stakeholders from service and

technology providers, policy makers, regulators, consumer representatives and academia will be invited to shape and contribute to key elements of the work program.

The Roadmap framework involves five domains each involving a number of work packages:

• Customer Oriented Networks, assessing transformation drivers, the reorientation of network services to customers and potential services of the future

• Revenue and Regulatory Enablers, reviewing potential revenue and business models, along with regulatory frameworks and mechanisms

• Pricing and Behavioural Enablers, addressing tariff reform and support for vulnerable consumers

• Technological Enablers, supporting integration of distributed energy resources; network asset utilisation; grid-side technologies and capabilities

• Next Generation Platform, examining new models for market operation and automation.

During this work program, our focus will be on:

• Creating new customer value through service innovation anticipating customer-oriented energy futures

• Informing Australia’s electricity system evolution including its policy and regulatory frameworks

• Providing network businesses with capacity and resources to support innovation

• Enhancing long-term asset productivity for both traditional and new value-creating applications

• Maximising collaboration and shared learning to focus on key knowledge gaps and barriers impeding network transformation. It is an exciting time to be engaged in the transformation of our energy

Featuring a 26% increase in carriage speed, a 37% increase in ground drive speed, and a narrow profile to get to the most confined job sites, the Series 3 D9x13 Navigator helps you fit more metres into to the working day.

Combined with extendable track width for side-hill stability, a durable one-piece hinged hood, and Vermeer’s legendary build quality and unmatched local dealer support, you’ve got the ideal partner for today’s fibre installation environment.

Same familiar controls More metres in the ground Gets there faster Access all areas Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the United States and / or other countries. © 2014 Vermeer Corporation. All Rights Reserved.

/ VermeerAustralia

| 1300 VERMEER

| 1800 195 558 (WA & NT) VERMEER’S

NAVIGATOR® SERIES 3 THE

D9X13 NAVIGATOR ® S3. GET EQUIPPED.

WWW.VERMEER.COM.AU

WWW.VERMEERWA.COM.AU

D9X13

NEW LEADER IN LEAD-INS GET THROUGH MORE SHOTS EVERY DAY WITH THE NEW VERMEER D9X13 NAVIGATOR® S3.

A WORD FROM THE ENA

Continued from page 8

sector. Australia is at the ‘bleeding edge’ of high-penetration integration of renewables. Our world leading rates of rooftop solar penetration make us a ‘hot zone’ for the emerging battery storage market – indeed, our networks are already deploying both utility scale and residential storage options to benefit communities and customers.

There is significant Australian and international expertise emerging in smart grids and the future potential for ‘transactive’ energy systems. Our long extended networks in rural and remote locations have always been a disadvantage – now we find them providing insights for the rest of the sector in fringe of grid solutions; the emergence of

micro-grids and non-network solutions.

Where electricity networks once connected communities, business and homes through traditional poles and wires, in a one way flow of energy, the network of the future will most likely be a platform of services that enables the technology that customers choose and connecting communities.

The network of the future will rely on its ability to create, and demonstrate, value to customers. The Network Transformation Roadmap will seek to highlight these opportunities to create value in collaboration with stakeholders.

NEW POWER STATIONS FOR WESTERN AUSTRALIA MACQUARIE RIVER-ORANGE PIPELINE COMPLETE

Horizon Power has brought six new power stations online, and relocated a control centre from Karratha to Perth.

The relocation of the control centre from Horizon Power’s Karratha base to Perth is predicted to save approximately $800,000 a year. The delivery of six new power stations in Cue, Meekatharra, Yalgoo, Wiluna, Sandstone and Mount Magnet and more flexible contracting arrangements with the independent power producer Contract Power are together forecast to save millions of dollars over the ten-year life of the contract.

As part of its strategic review in 2013, Horizon Power committed to reducing its operating subsidy to become a low cost and sustainable business. Horizon Power has made strong progress in achieving this reduction, with $203million savings already included over the forward estimates period to 2018/19.

“Projects such as these show that as a business we are delivering on our promise to save taxpayers money, but have not wavered from the commitment to provide our customers with safe and reliable power supply,” said Horizon Power Director Rosie Wheatley.

WA Minister for Energy Mike Nahan officially opened the relocated control centre and acknowledged the steps Horizon Power is taking to become a sustainable business.

“In many ways, Horizon Power is leading the way in an industry that is changing pace at an unprecedented rate and in an environment where customers have higher expectations than ever before,” he said.

Horizon Power will implement further changes to achieve its operational subsidy reduction over the year, including the rollout of new advanced metering infrastructure across its operational area and ongoing collaboration with Western Power to deliver off grid solutions to remote customers.

The 39km Macquarie River to Orange water pipeline in NSW is now complete.

Construction of the $47million pipeline was funded with $20million from the Australian Government’s National Water Security Plan for Cities and Towns, $18.2million from the NSW Government and $8.8million from Orange City Council.

Leed Engineering and Construction began work on the pipeline in October 2013, with Essential Energy undertaking refurbishment of the power, and Poles and Underground completing construction of new electrical infrastructure.

Parliamentary Secretary to the Minister for the Environment, Bob Baldwin, said the pipeline would deliver 1,616 megalitres of water each year from the Macquarie River to the Suma Park Dam.

“This pipeline project reflects the Australian Government’s long-standing commitment to support communities in rural and regional Australia.

“It is another example of how the Australian Government is fulfilling its commitment to meeting the infrastructure needs of regional Australia, promoting sustainable growth and development in this region for many decades to come,” said Mr Baldwin.

Federal Member for Calare, John Cobb, said that Orange had a history of water shortages and in May 2010 the city was on the brink of level 6 water restrictions which would have severely restricted business and industry activity within the city.

“The construction of the new pipeline will help the Orange community achieve its potential, and address a shortfall in the supply of drinking water,” said Mr Cobb.

The Suma Park Dam will be topped-up by pumping during periods of good river flow, so pumping will not be required during drier times.

NEWS 10

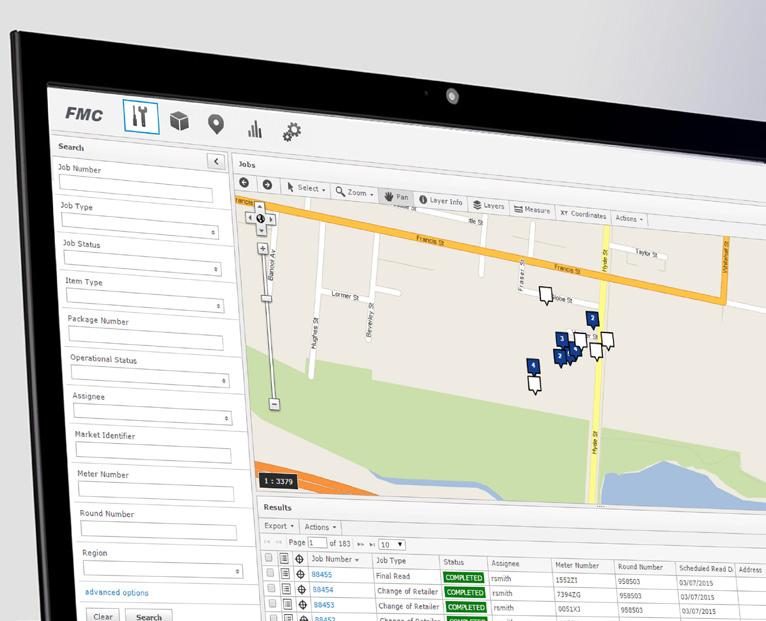

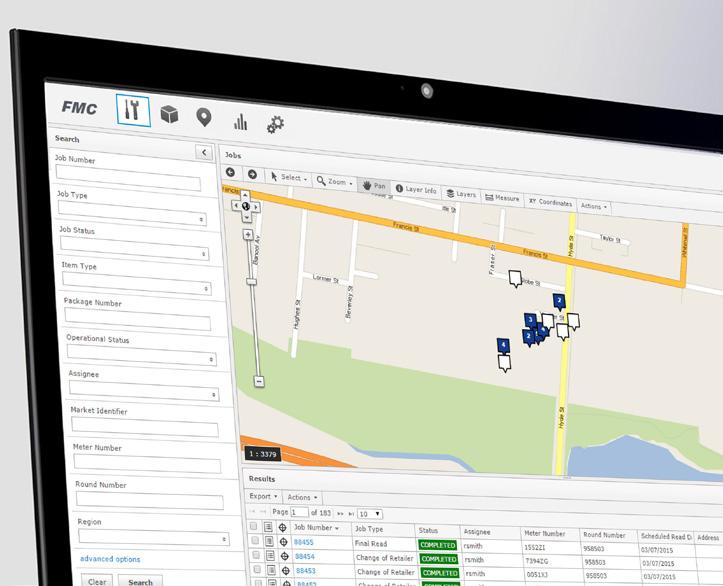

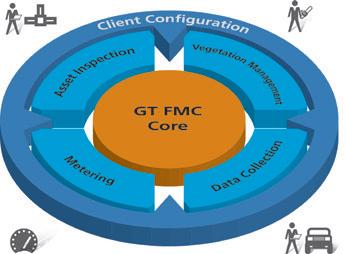

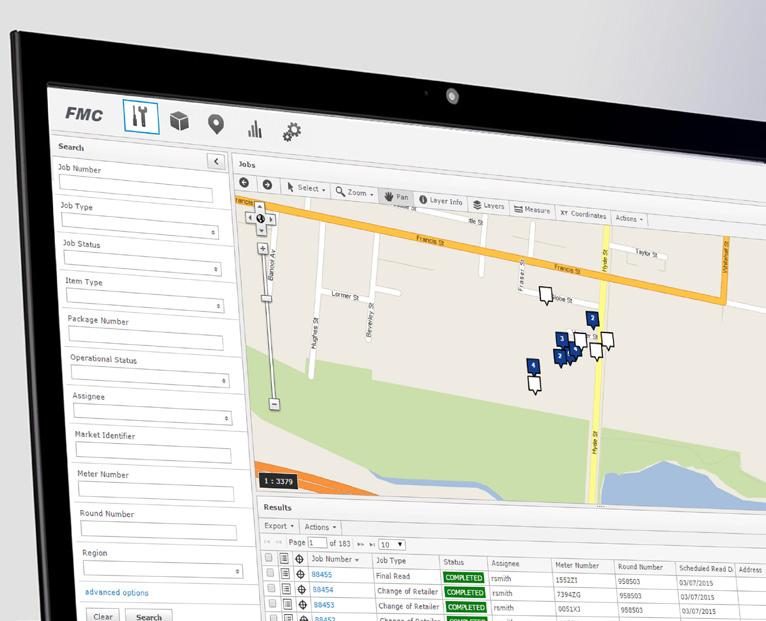

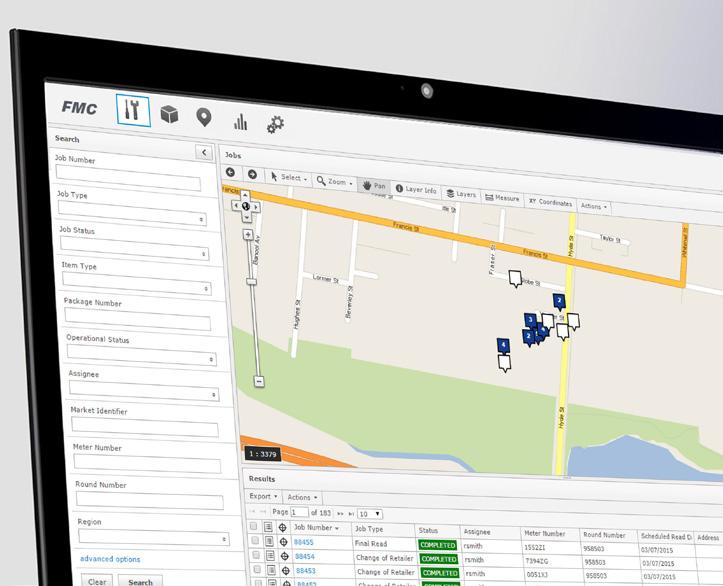

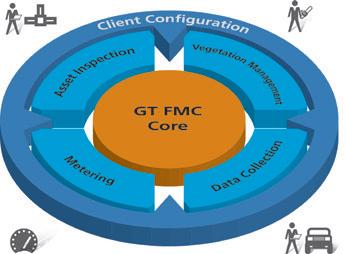

Manage meters and metering activities easily with FMC

Select Solutions is an innovative, adaptable and experienced provider of infrastructure asset management services.

Using our field mobility solution (FMC), Select Solutions has provided smart ways to manage field-based activities for more than fifteen years.

One of the many applications of FMC for the utility sector is managing the end-to-end lifecycle of meters and metering activities through:

> Easy and visual Scheduling

> Inventory management

> Customer information

> Contractor management

> Invoicing and KPI reports

> Customer dashboard reporting

> Stock tracking

> Customer notifications and workflows

> Robust workflow and auditability to ensure consistency and compliance

> Photo capture to minimise customer disputes

> Optimised routing for a more efficient workforce

> Multi-service requests per property

> Sequential workflows to encourage right and safe behaviours

Visit our website to find out more about our work with Australian utilities.

www.select-solutions.com.au

An AusNet Services Business

$100M FOR SOLAR ROOFTOP DEVELOPMENT

Origin has secured a 12-year $100million finance commitment from the Clean Energy Finance Corporation (CEFC) to further develop rooftop solar offerings for Australian consumers.

The finance will be utilised by Origin to support its Solar as a Service offering where customers can access the benefits of solar without purchasing the solar system. This sort of offering is also known as a power purchase agreement (PPA).

Through Solar as a Service, the customer buys solar energy produced by a solar installation on their roof, which is owned, operated and maintained by Origin. The initial solar contract rate for eligible customers will be lower than what they would pay for energy from the grid.

The CEFC finance also provides flexibility to support Origin’s future rollout of battery storage solutions. Origin is currently trialling a battery solution in the market and expects to have a battery offering available to customers later in 2015.

Origin General Manager Solar and Emerging Businesses, Phil Mackey said, “Origin is already one of Australia’s longest-standing and largest solar retailers and we aspire to be number one, driving long-term growth in the solar market.

“Solar as a Service is already proving an attractive proposition to customers since it was launched earlier this year, and the CEFC finance will be used in expanding the offering, so more Australians can enjoy the benefits of solar,”

said Mr Mackey.

The CEFC provides competitive finance that meets the needs of clean energy business developers.

CEFC CEO, Oliver Yates said, “PPAs offer a clear benefit for residential and business consumers, who can have increased confidence about their long-term electricity costs, while at the same time enjoying the benefits of solar.”

Origin’s Solar as a Service offering was launched in May 2015 and is currently available to residential and business consumers within a 100km radius of the central business districts of Adelaide, Brisbane, Gold Coast, Sydney and within a 50km radius of Townsville.

NYNGAN PLANT RAMPED TO FULL POWER

AGL’s Nyngan solar photovoltaic (PV) plant in NSW has been ramped up to full generation, and is now feeding 102MW of renewable energy into the National Electricity Market.

As the biggest solar PV plant in Australia, this is enough to power 33,000 homes annually.

The plant is part of the $440million AGL solar project, which is supported by $166.7million ARENA funding and $64.9million NSW Government funding.

ARENA CEO, Ivor Frischknecht, said the achievement was another critical step forward for large scale solar PV in Australia.

“This new Australian record sends a strong signal to the energy industry that utility-scale solar PV plants can be

constructed on time and on budget,” Mr Frischknecht said.

“ARENA is pleased to support this landmark project, which will greatly increase market confidence in future solar PV projects, bringing down the cost of planning, construction and finance.”

The Nyngan project has provided economic benefits for the community including employment, which during the peak of construction reached more than 250 people on site.

Businesses in Nyngan, and the wider Orana region, have also benefited from local procurement and contracts associated with the project’s construction.

AGL is now conducting final commissioning and testing ahead of the plant being fully operational later this year.

12

NEWS

Pipe Bending Machines

Pipe Cu ng & Bevelling Equipment

Clamps - Cage, Chain & Rachet Pigs

Bol ng & Tensioning Tools

End Caps, Chocks & Timber Skids

Pipe Li ing / Lowering

Internal Lineup Clamps / Mandrels

Bending Sets

Roller Cradles

Inspec on & Quality Control Instrumenta on HDPE Welders

Pipe Cu ng & Beveling Machines

Flange Facing Machines

Tracked Tack, Welding & Blast Rigs

Email: michael@psssa.com.au Or call John Wilton on 0400 794 097

For more information please call: PSSS on 07 3200 4999 or Email: sales@psssa.com.au Call Michael Lee on 0418 695 779

of our

To’ status

attitude.

Pipeline

Email: john@psssa.com.au Proud

‘Go

and ‘Can Do’

www.psssa.com.au Your “Go To” Supplier for all things

Proudly representing

URBAN GARDENS – THE WASTEWATER PLANTS OF THE FUTURE

Did you know that by 2050 more than two thirds of the world’s population is expected to be living in urban areas?

As our cities grow, traditional sanitation methods with centralised sewage treatment systems may not cope with growing sludge disposal restrictions, the need to reduce and retrieve nutrients and concerns about contaminants.

This led to new wastewater treatment solutions including Organica – a system that relies on a natural plant ecosystem to treat wastewater and makes a treatment plant look more like a greenhouse or a garden.

Organica uses plant roots that grow into the effluent encouraging bacteria and living organisms to develop. This creates a completely natural form of treatment and reduced energy and operating costs. Its bio-film-based treatment technology suits modern society with a small footprint, lower excess sludge production and integration into an urban environment.

With 50 operating references around the world, Organica plants are successfully and easily installed into urban environments where typically it would be difficult to place a traditional wastewater treatment plant.

HOW DOES IT WORK?

The Organica Food Chain Reactor incorporates wastewater treatment into a single structure and includes solids removal, biological treatment/ nutrient removal, phase separation and final treatment at a quality for re-use (if required).

This is done in a multi-stage cascade approach that uses Integrated Fixed Film Activated Sludge technology. It combines natural plant and engineered media to provide a habitat supporting a diverse range of bacterial culture.

The plant roots grow in water and their high specific surface area provides an especially good habitat for microbes to form biofilm on the roots. Additional artificial carriers imitating plant root structure are installed into the deeper zone of the reactors where natural roots do not reach.

Due to the biofilm-based process, a lower footprint and lower excess sludge production can be achieved compared to conventional treatment technologies, decreasing capital and operational costs.

DOMESTIC GAS FROM BROWSE

The Western Australian Government has signed a Key Principles Agreement with the proponents of the Browse floating liquefied natural gas project (FLNG). The agreement obliges the provision of gas for domestic purposes and will also aim to locate a supply chain in Western Australia.

WA Premier and State Development Minister, Colin Barnett, said this was the first time the state’s domestic gas policy would be applied to an FLNG project. “While the State Government would still prefer this project to be developed onshore, this agreement ensures that the project will deliver benefits to the state in terms of domestic gas and opportunities for

local businesses and workers,” said Mr Barnett. “It also clears the way for the extension of the retention leases covering the project fields, and provides the Browse Joint Venture with certainty as it heads towards the frontend engineering and design phase.”

Under the agreement, the joint venture has committed to reserve gas equivalent to 15 per cent of production from the state’s share of the Torosa reservoir, one of three gas fields that make up the project.

“The domestic gas obligation will coincide with first production from Torosa and amount to around 800 petajoules over the life of the project, helping to secure the state’s energy future,” Mr Barnett said.

JOHN KOUMOUKELIS.

JOHN KOUMOUKELIS.

ABOUT THE AUTHOR

John Koumoukelis is a Board Member of the Hydroflux Group whose subsidiaries include Hydroflux HUBER, an equipment supplier of the world’s best wastewater technology. Organica Water recently appointed Hydroflux as its exclusive agent for Australia. More information can be found at www.hydroflux.com.au.

PEL BUY-BACK SCHEME EXTENDED

The Petroleum Exploration License (PEL) buy-back scheme under the NSW Gas Plan has been extended.

Minister for Industry, Resources and Energy, Anthony Roberts, said the buy-back scheme has so far seen 12 PELs cancelled that covered more than 2,941,081 hectares of NSW.

“We have extended the scheme due to the ongoing interest of titleholders. We understand a buy-back is a significant decision for titleholders, which is why we have extended the scheme,” said Mr Roberts.

The NSW Gas Plan has reduced the footprint of CSG across the state from more than 60 per cent to 11 per cent.

14

NEWS

committed

Leaders in quality, value and trust.

ACTEW Water has been supplying Canberra with top quality water and wastewater services for 100 years – and this year we’ve changed our name to Icon Water.

As the largest inland water supplier in Australia, we know our responsibilities flow beyond our own community. In maintaining and surpassing national compliance standards, our commitment is to both our customers and for the generations to come.

talktous@iconwater.com.au | (02) 6248 3111 | @iconwater | iconwater.com.au

Operating in a changing environment: THE WATER INDUSTRY PROFESSIONALS DELIVERING WATER AROUND THE NATION

Sometimes overlooked, it’s the water industry operators who are at the coalface every day, ensuring the quality of water supply, managing assets and ensuring access to our most precious resource. We met with a diverse group of water industry operators to learn about the challenges they face, the new technologies they’re working with and the future for the water industry as they see it.

The Water Industry Operators Association of Australia (WIOA) is the leading body representing people in operational roles in the water industry. It is a rapidly growing, not-for-profit national association with a primary role of facilitating the collection, development and exchange of quality information between people undertaking operational roles in the water, wastewater and recycled water industries.

With key objectives including promoting standards of education and training to ensure efficiency and competency of members; and preservation of clean waterways and protection of public health and the environment, WIOA has an important and ongoing role to play right across Australia.

With a national membership base approaching 2,300 members are represented by an elected committee of twelve. Utility met with four of the general committee members - Anthony Evans, Assets & Projects Coordinator at Wannon Water; Neil Crossing, Process Optimisation Engineer at Allwater; Lindsay Walsh, Process ControllerSewer at MidCoast Water and Darren Lord, Technical Officer/ Senior Operator Operation & Maintenance at TasWaterto gain an insight into their roles within the industry and their involvement with WIOA.

A DAY IN THE LIFE

Daily life for our WIOA committee members is diverse, reflective of the different positions each member holds. While Anthony Evans is busy managing Wannon Water’s latest water and wastewater treatment projects, Lindsay Walsh is up early each morning undertaking operational checks at the Old Bar Sewage Treatment Plant on the New South Wales Mid North Coast.

Darren Lord at TasWater can often be found at reservoir or pump station sites, looking after operational and

maintenance projects, while Neil Crossing from Allwater works at actively seeking new ways to deliver water treatment process optimisation.

“Here at Wannon Water, I manage the Water Plan 3 (WP3) CapEx program for the Treatment Services division,” said Mr Evans. “The projects were identified in the lead up to WP3 and submitted to the State Government for final approval prior to commencing in July 2013. There were around 250 small projects identified in our area ranging in budget from $5,000-$150,000. In total around $6,000,000 has been allocated. The majority of the projects are undertaken in our water and wastewater treatment plants and include new and replacement infrastructure, as well as general amenities improvements.”

“My role at TasWater is rather varied, and there are times when my day turns out very differently than initially expected,” said Mr Lord. “At the moment, TasWater is cleaning out and refurbishing a WTP clarifier consisting of a wide range of projects spanning pump station upgrades, updating of lab equipment to operational fault finding missions and producing risk assessments.”

For Mr Walsh, the day starts early when he arrives on site. “My day starts at around 6am when I arrive at the Old Bar Sewerage Treatment Plant on the Mid North Coast of NSW. I begin by checking plant flows from the previous day as well as pump starts and runtimes from Old Bar and Manning Point plants. I then check our SCADA system for any overnight faults or failures which need attention.

“At 6.30am I call our Process Coordinator, Pat Welsh, and discuss any outstanding issues. I then begin nutrient tests on effluent produced, and measure the biomass from our bioreactors. Once complete, I jump into the ute for a tour of the remote plants and attend to routine maintenance

WIOA

16

throughout the area where required. We are always busy, as there are four operators and one coordinator for the eight sewage treatment plants under our control,” said Mr Walsh.

For Mr Crossing, the main priority throughout the day is managing and monitoring water treatment projects that are aimed at improving water quality for health and contractual compliance, as well as reducing cost. “I also coordinate technical review visits by experts from one of Allwater’s parent companies, Suez Environment,” he added.

THE NEXT FRONTIER

Improvements and upgrades are the current buzzwords for our WIOA committee members. Optimisation of processes and upgrading of infrastructure across a range of sites is high on the agenda for all of the operators we spoke to.

Mr Evans noted that Wannon Water is currently working on improving maintenance activities to ensure assets are capable of operating at the optimum level of service for their maximum life expectancy, and beyond.

For Mr Lord, the upgrading of TasWater’s water and sewerage infrastructure is currently the number one focus. “Since the reforms of 2009, $472million has been spent improving infrastructure around the state. If TasWater’s proposed forecasts are met, the expenditure will total $1billion by 2019. It’s an exciting time to be at TasWater,” he said.

Mr Walsh’s work is also focused on upgrades and process optimisation, with MidCoast Water always looking to improve the way they operate. Reflecting this the utility has recently upgraded its assets to the new, ClearSCADA system.

At Allwater, Mr Crossing speaks of improvements to the water treatment filtration performance at wastewater treatment plants, energy reductions, nitrogen reductions in treatment plant effluent and the increase in site cogeneration, with improved biogas production and optimisation of membrane bioreactors.

EMBRACING THE CHALLENGES

Adapting to changes in management, guidelines and the industry as a whole is an ongoing challenge for water industry operators. Restructuring within businesses can

result in time and job losses, and the introduction of new systems can slow processes down until they are mastered.

According to Mr Evans, “Awareness of the Australian Drinking Water Guidelines when planning improvements is crucial in ensuring that we aren’t throwing money in the wrong direction on instrumentation and plant operational changes, if we then have to upgrade in a couple of years to achieve the required results.

“As the area we cover has increased since the formation of Wannon Water with two other water businesses in south west Victoria ten years ago, long days travelling to and from jobs or training has also been a challenge for our team,” he added.

“The biggest challenge we have faced as operators would be the overarching changes in the water and wastewater industry in the state over the last six years,” said Mr Lord. “We transferred from our local councils into three separate organisations which lasted for four years. The companies then transferred into one organisation across the state, which meant another major restructure and a lot of role changes and job losses in the early days.”

For Mr Walsh, the introduction of new technology has been the biggest challenge. “The introduction of new SCADA and IT systems are always challenging, especially for an old bloke like me, but that’s what keeps me going.

“Keeping a quality process operating within a limited budget is also a challenge,” he added.

Managing water quality during drought has been a major challenge for Mr Crossing. Allwater is now dealing with algae blooms and associated elevated pH in raw water at water treatment plants and one of Adelaide’s largest water reuse plant. “Keeping up consistency of operating processes during major upgrades to infrastructure at both water and wastewater treatment plants is also a key challenge faced by our team,” he added.

LOOKING IN THE CRYSTAL BALL

Implementation of projects currently in the pipeline will be the most exciting prospect for each of our WIOA committee members in the future.

“Our Wannon Water maintenance strategy that is

17

NEIL CROSSING, PROCESS OPTIMISATION ENGINEER AT ALLWATER

LINDSAY WALSH, PROCESS CONTROLLER - SEWER AT MIDCOAST WATER

DARREN LORD, TECHNICAL OFFICER ENGINEERING SERVICES AT TASWATER

WIOA

ANTHONY EVANS, ASSETS & PROJECTS COORDINATOR AT WANNON WATER

currently in the planning and building stage will hopefully be implemented in the near future, as well as construction of major infrastructure at a number of our plants,” says Mr Evans.

Over at TasWater, the focus has been on a new, three-year price and service plan that has been handed down by the Economic Regulator and came into effect on July 1.

“This plan sets our prices and service standards for our customers,” said Mr Lord. “The successful implementation of this plan is critical for the ongoing sustainability of TasWater.”

Midcoast Water has plans to upgrade its Gloucester water treatment plant as well as to build a new facility at Nabiac to ensure a quality water supply to the Manning Valley and Great Lakes areas into the future; and at Allwater, trials will be carried out in partnership with SA Water involving granular sludge tested at a high salinity wastewater

treatment plant, as well as works to improve pressure management in the Adelaide distribution system to reduce pipe bursts.

EMERGING TECHNOLOGIES

From trenchless to SCADA, the emergence of new technologies is impacting the water industry in a number of positive ways.

According to Mr Evans, portable water treatment plants and portable sludge dewatering plants are revolutionising the water and wastewater industries.

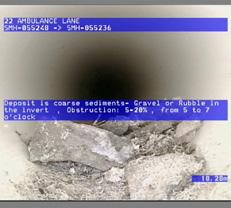

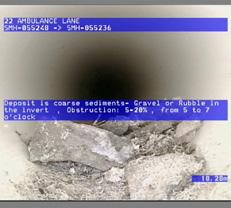

“Trenchless technology has also taken off in a big way, as well as CCTV used for condition assessment and SCADA monitoring. Drones to check above-ground assets and recycling of our wastewater are also technologies that are having an impact, and that’s only just scratching the surface,” he added.

According to Mr Lord, “One of the technologies that we are seeing

Civil Infrastructure Solutions

With a wealth of experience in the design of civil infrastructure, Taylors offers solutions focused urban development consulting and project management, from project inception to design, approvals, construction and delivery.

more here in Tasmania is the use of membrane filtration plants. We have a lot of small towns that don’t currently have water treatment, just disinfection. With these towns requiring only small flows, it only takes a small footprint to fit a plant to suit. Some can even be package built off-site and simply dropped into place.

“Further improvements to our SCADA network and our new Network Operations Centre will be key to TasWater getting better visibility of our asset performance in real-time and improving our asset management,” said Mr Lord.

Allwater and SA Water are trialling the use of trade waste to improve digestion and consequently improve co-digestion at wastewater treatment plants. “Allwater in conjunction with SA Water has also successfully run a pilot plant study for the Anammox process and trialling of granular sludge at a high salinity wastewater treatment plant,” said Mr Crossing.

At the forefront of ‘big data’ technology, Taylors can deliver fast, accurate and cost effective customised solutions for a broad range of projects and market sectors including water and sewer, waste management, local government, transport (road and rail), pipeline, resources and telecommunications.

18

taylorsds.com.au

Taylors offer a unique integrated and seamless approach to consulting across four core businesses in Urban Development, Built Environments, Infrastructure and Engineering and Project Management.

Technology Hydrographic Technology Terrestrial Scanning INFRASTRUCTURE Vehicle Mounted LIDAR Drone-Tech Mapping

Innovative Spatial

Stakeholder Consultation

ENGINEERING

WIOA

Design

of Roads & Reticulation Feasibility and Servicing Strategy Contract Administration

& PROJECT MANAGEMENT

THE WATER INDUSTRY IN TEN YEARS

According to our committee members, the future of the water industry appears overall positive, and constantly evolving.

“I think we will be doing a lot more remote monitoring of our plants with the installation of online analysers,” said Mr Evans. “A quality reference should only need verifying weekly to maintain the integrity of the instrument...at least that’s what the salespeople tell us!

“I would like to think that operators will still be looking after their plants not just from the treatment perspective but managing the maintenance as well. I also think we will begin to see operators employed with an electrical background as we move into the era of remote monitoring equipment and automation,” he added.

For Mr Lord, the future of the water industry in Tasmania will rely heavily on young people getting involved within the business. “Here in Tasmania, I couldn’t say where the industry will be in ten years if we don’t start to get young people on board,” said Mr Lord.

Mr Walsh believes that the water industry is destined to look very different in the next ten years, with advances in technology being the catalyst for change. “I don’t know what the industry will look like in ten years, but you can guarantee it will bear little resemblance to what it is now. Technology will continue to play a greater part in process control,” he said.

Mr Crossing envisages the future of the water industry to be focused upon optimised management across the board. There will be more centralised operations with higher qualified operators, each operating more than one or two plants.

WIOA Executive Officer Mr George Wall notes that there has been a great deal of change occurring in the industry and the level and range of responsibility assigned to operators is constantly evolving.

“The introduction and use of new technology, the desire to increase operational efficiency from an aging asset base, coupled with community pressure to control costs means

operators need to be better trained and have a much broader set of skills than just a few years ago,” said Mr Wall.

To ensure ongoing skill development, WIOA has increased the range of services and opportunities it provides for the operational employees. WIOA has been instrumental in the development and introduction of a certification scheme for water treatment operators, which includes ongoing professional development opportunities.

Mr Wall stated “There are a number

of certified water treatment operators around the country and we are now moving our attention to the introduction of a scheme for wastewater operators as well. At the moment these are voluntary schemes but we see them as vitally important for our industry and will continue to lobby for them to be universally adopted”.

It’s clear that the water industry is destined for change, and with exciting, yet challenging times ahead, we can only imagine what the future will hold for Australia’s most precious drop.

Know whats going on underground because ...it Happens

UNIQUE FEATURES

• Satellite Communications provide extremely high reliability

• Communicates from anywhere on earth

• Attaches to existing manhole cover or hatch

• No confined space entry to install or maintain

• Traffic Rated Antenna

• No Nuisance alarms

APPLICATIONS

• Pump stations

• Wastewater maintenance optimisation

• Inflow and infiltration

• Underground utility vault monitoring

• Odour monitoring

19

Scan here to find out more WIOA

INTO TURNING

Sydney Water has been utilising biogas to operate cogeneration assets, which produce electricity and heat, since 1999. The renewable energy program has expanded over the last 15 years, and the cogeneration plants now produce around 15 per cent of the organisation’s energy needs, providing significant financial benefits from reduced electricity costs, a hedge against future power cost increases, as well as a green commodity value.

BEN

iogas is produced in anaerobic digesters at wastewater treatment plants across Sydney and contains between 55-65 per cent methane.

Sydney Water now has cogeneration units at eight wastewater treatment plants with an installed capacity of 9.8MW following the installation of new cogeneration assets in 2009 and 2014.

THE PROCESS

Sydney Water has followed a staged approach in implementing cogeneration. The technology was first implemented at Sydney Water in 1999 and in 2007 a renewable energy program commenced. Several sites were identified where cogeneration was calculated to be financially feasible and facilities were installed at these sites during 2009 and 2010.

Optimisation programs were undertaken between 2010 and 2012, aiming to realise the full potential of the new and existing cogeneration fleet.

20

WASTEWATER TREATMENT

ERGY

IS THERE VALUE IN COGENERATION?

A second program examined sites with excess biogas or sites with anaerobic digestion and no cogeneration unit. This resulted in further expansion of cogeneration in 2014 at Cronulla and North Head wastewater treatment plants.

Some sites currently remain unviable and will be reviewed again as key success factors change. Sydney Water will continue to investigate ways to get more value from cogeneration in the future. This includes gaining a better understanding of co-digestion and other technologies including the Organic Rankine Cycle.

Sydney Water has gained significant value from cogeneration and continues to invest in it. While the primary benefit of cogeneration is the financial returns achieved, ongoing value from cogeneration also extends to the

environment and plant performance.

The installed cogeneration plants have a capacity to generate over 60,000MWh of electricity per year, reducing over 60,000 tonnes of greenhouse gas emissions, which is the equivalent saving of removing 15,000 cars from the road.

LESSONS LEARNED - INSTALLATION

Fifteen years of planning, installation, maintenance and operation in the cogeneration space has provided Sydney Water with significant insights. These insights have been amplified due to the technical expertise provided by Sydney Water contractors.

Alex Sanbrook, Renewable Energy Generation Manager at

NEW ENGINE AT CRONULLA WASTEWATER TREATMENT PLANT.

21 WASTEWATER TREATMENT

Sydney Water said “Prior to installation it is important for utilities to have a full understanding of all capital investment requirements to ensure value from cogeneration.

“Consideration must be given to ensure appropriate engine sizing, plant type, biogas supply/optimisation and measurement, biogas pre-treatment requirements and to the high voltage connections for large engines.

“We learned pretty quickly that engines below 200kW, are generally not financially viable for Sydney Water.

“Allowance must also be made for site factors such as corrosion, emission requirements, access and maintainability of engines.

“Understanding maintenance costs and developing maintenance strategies compared to those recommended by the manufacturers, as well as any auxiliary equipment costs required and the complexity of the operation are also key considerations.

”Correct assumptions during the evaluation process around costs, onsite power utilisation, minimisation of energy export, electricity price, green commodity value forecasting, as well as accurate prediction of engine downtime and the timing for implementation are keys to success.

“Identifying additional value from cogeneration assets beyond financial

benefits from electricity production is a valid approach. A focus on optimising gas production can lead to better biosolids management”, said Ms Sanbrook.

LESSONS LEARNED - OPERATION

According to Ms Sanbrook, during an optimisation program between 2010 and 2012, Sydney Water increased generation from cogeneration by 10 per cent in the first year and a further 5 per cent in the second year.

“We have continued to incorporate improvement planning into our management of renewable energy assets,” said Ms Sanbrook.

“Root cause analysis showed that downtime is the greatest cause of lost generation. Without standby units, any downtime represents lost revenue.

“Maintenance planning remains the biggest challenge in reducing downtime. A high level of unplanned maintenance is required on biogas engines and coordinating these maintenance needs across ten sites with a small team is very challenging.

“Technical expertise of the maintenance provider is essential. The provision of fast diagnosis and innovative solutions are important elements in reducing downtime. Coupled with this, parts management is crucial because waiting for delivery of engine parts can cause significant delays.

“Good performance monitoring provided us with the foundation for identifying and monitoring improvements. Performance was constantly challenged. We soon discovered that cogeneration units running on biogas do not all respond equally. This created differences in maintenance requirements depending on engine model and biogas composition.

“Biogas pre-treatment for removal of hydrogen sulphides and siloxanes needs to be considered on a site-bysite basis to determine whether the cost of biogas cleaning is offset by reduced engine maintenance.

“Optimisation of digester gas production and accurate gas flow measurement is important and can be done before cogeneration is installed to ensure appropriate sizing of engines and that the full potential of the asset is realised.

“Stakeholder engagement can improve performance. Operator training and sharing of lessons can assist in identifying causes of lower biogas production”, said Ms Sanbrook.

As electricity exported to the grid receives a much lower return than the savings generated by offsetting imported grid electricity, there is significant benefit in maximising the onsite usage of electricity produced from cogeneration.

22 WASTEWATER TREATMENT

EXISTING ENGINE AT THE NORTH HEAD WASTEWATER TREATMENT PLANT.

The TRILITY advantage

TRILITY operates as a water utility. This means we have an intimate understanding of every issue encountered by water authorities, government agencies, local councils and industry. The depth of expertise at TRILITY means we create options for our clients and outline likely outcomes based on our experience as a long term water infrastructure owner-operator. TRILITY operates plants across Australia treating over 1.8 GL/d and servicing millions of Australian’s everyday.

www.trility.com.au For more information visit us at Mundaring Water Treatment Project (WA) 29 Macarthur Water Treatment Plant (NSW) Agnes Water and Seventeen Seventy Integrated Water Project (QLD) Yan Yean Water Treatment Plant (VIC) Adelaide Desalination Plant (SA) Grampians Region Water Treatment Plants Operations and Maintenance (VIC) Brisbane office Adelaide office Perth office Barwon Biosolids (VIC) Townsville City Council Water Supply Upgrade Project (QLD) Northern Peninsula Area Operations and Maintenance (QLD) ealand nt (VIC la Mangawhai Water Reclamation Scheme (NTL Australia Administration offices Asset Management and Operations and Maintenance Design and Construction Design and Construction and Operations and Maintenance Operations and Maintenance Services * Reference site

Electrical load studies have provided data to allow Sydney Water to reduce export over the last few years.

Practical limitations on operating and maintaining cogeneration units are now well understood, including operator capability, realistic downtime and major periodic maintenance requirements. These limitations can now be built into business cases for future investment in cogeneration units, which gives business owners greater confidence in achieving a positive financial return.

UTILISING EXCESS BIOGASA CASE STUDY

In 2012, Sydney Water carried out an investigation into the feasibility of new or additional cogeneration capacity at four wastewater treatment plantsShellharbour, West Hornsby, Cronulla and North Head.

Installation of cogeneration at West Hornsby was not considered feasible as the plant had low gas production and Shellharbour is not currently cost-effective as the result of low biogas production (<200kW) and low electricity rates. However, a future business case may be submitted if a more cost-effective solution or a method to increase biogas production can be implemented.

A $6million project was approved to

utilise excess biogas at Cronulla and North Head. The project upgraded the existing cogeneration unit at Cronulla from 475kW to 835kW and installed an additional 1MW cogeneration unit at the North Head Wastewater Treatment Plant. The project was aligned with Sydney Water’s Energy and Greenhouse Gas Mitigation Strategy to provide cost effective reduction of greenhouse gas emissions by on-site generation of renewable energy. The project’s business case provided a net present value of $3.5million.

Sydney Water’s lessons from installing and operating cogeneration were incorporated into these business cases along with an understanding of electricity and green certificate forecast rates, government policy, current price trends and electricity demand forecasts. Minimising export at North Head was an important consideration as the site had two existing renewable energy assets; a 1.4MW cogeneration unit and a 2.1MW mini-hydro plant. The cost of an 11kV ring main unit to enable more versatile utilisation of power from the new engine to the site was incorporated into the business case to help minimise the export of renewable power.

The North Head project was delivered under a Design and Construct contract during 2014. This method

of project delivery and preparing an advanced concept design prior to tendering helped manage capital costs.

THE FUTURE

Treatment process improvements are being implemented as a result of digester audit recommendations. Studies are underway to improve gas production, storage and distribution at some sites.

Sydney Water is trialling the codigestion of trucked organic waste with sewage sludge. This involves receiving trucked organic waste for a fee and adding it to a sludge digester to increase biogas production. Glycerol is currently being trialled at Bondi. Other waste materials including beverage waste, pulped food waste, dairy, bakery and fats, oils and grease will be trialled at other sites over the next three years. Co-digestion has the potential to double biogas generation, which could see some wastewater treatment plants become energy neutral and make cogeneration cost-effective at plants that were previously not viable.

The Organic Rankine Cycle technology makes use of waste heat from the cogeneration units to produce additional electricity. This process requires higher temperatures and is more suitable from exhaust heat recovery rather than the lower temperature engine jacket water. Sydney Water is currently investigating the technology. One study showed that an additional 100kW could be generated using heat from the new 1,000kW cogeneration unit at North Head.

While the primary benefit of cogeneration is the financial returns achieved, ongoing value from cogeneration also extends to the environment, plant performance as well as contributing to a liveable city.

Any current limiting factors such as achievable production rates and the market value of energy are constantly changing. Decisions on sites where cogeneration implementation or expansion is not currently feasible should be regularly reviewed.

For further details contact Alex Sanbrook, Renewable Energy Generation Manager at Sydney Water via email at alex.sanbrook@sydneywater.com.au.

24

WASTEWATER TREATMENT

NEW ENGINE AT THE NORTH HEAD WASTEWATER TREATMENT PLANT.

Pipe

& Construc tion Water R ail Road Sewer M ining & Power Pipe Bursting, Slip lining and Pressurelining Tunneline and man entr y pipe refurbishment Berolina UV Cured pipe lining system p 02 8603 2000 e enquiries@itspipetech.com.au w www.itspipetech.com.au 1/13 Stanton Rd, Seven Hills NSW 2147 BEFORE Tunneline – struc tural concrete lining for rail culver ts Head O ce f 02 8603 2001

ITS PipeTech

Rehabilitation

THE FUTURE OF SE WAGE

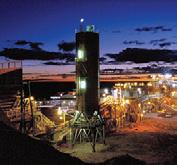

THE COGENERATION MACHINES AT LUGGAGE POINT SEWAGE TREATMENT PLANT. QUEENSLAND URBAN UTILITIES HAS DUBBED THE UNITS THEIR BIG, GREEN MONSTERS.

WASTEWATER TREATMENT 26

WAGE TREATMENT: HARNESSING THE POWER OF

Around 100 years ago, Brisbane’s Municipal Council began removing human waste through an underground network of sewers. It was a revolution for public health and a big mark of progress for modern society. As awareness for environmental stewardship grew, local authorities moved onto both removing and treating that waste. Now, modern utility companies have embarked on a new frontier, not only removing and treating human waste, but turning that waste into a useful product. In effect - they’re taking the waste out of wastewater.

Queensland Urban Utilities (QUU) is embracing this innovative new approach; from the latest cogeneration machines - supercharged by beverage by-product - to floating wetlands and solar panels.

Utility spoke to QUU Executive Leader of Planning, Paul Belz, about how its sewage treatment plants are becoming more like resource recovery centres, harnessing the power of poo.

SUPERCHARGING COGENERATION

“Cogeneration is an exciting technology, that’s why we’ve just installed three new state-of-the-art units at our two biggest sewage treatment plants – Luggage Point and Oxley Creek,” Mr Belz said.

“They work by capturing the biogas produced from sewage sludge to drive an engine and generate electricity. We’re producing enough energy to provide up to 40 per cent of the plants’ electricity needs, which is the equivalent of powering 1,250 homes each year.

“It’s a win-win for the environment and the business, as we’re not only reducing our carbon footprint but keeping operating costs down. In fact, we’ve estimated we’ll save up to $1.45million a year.”

These cogeneration units are getting an extra supercharge, with QUU experimenting with by-products from soft drink, juice, honey and even alcohol.

“We recognise the potential for this high-sugar waste to

WASTEWATER TREATMENT 27

be used productively in our treatment process,” Mr Belz said.

“By pumping the sugary by-product straight into the digesters we increase the amount of biogas produced, which in turn bumps up energy yields from the cogeneration units even further.

“After a successful trial, we’re planning to take in more than 100,000 litres of beverage waste every week from our commercial customers. It’s a successful partnership – they’re happy to have a low cost, environmentally friendly alternative for their trade waste, and we’re happy to give our cogeneration units an effective sugar hit!”

FLOATING WETLANDS

Another way QUU is reducing its reliance on the electricity grid is by making the sewage treatment process less energy intensive. A new trial has been launched at a small treatment plant at Forest Hill in the Lockyer Valley, where floating wetlands are being used to purify the wastewater. The Queensland-first project involves growing wetlands on specially

engineered plastic mattresses, which are then floated on purpose-built lagoons.

“It’s a natural, cost-effective and energy efficient solution to purifying wastewater,” Mr Belz said.

“The roots of the plants dangle beneath the mattress drawing out unwanted nutrients such as carbon, nitrogen and phosphorus.

“The floating wetland is like nature’s kidney, cleansing the water by trapping sediment and removing toxins. It’s a great example of green engineering and also has the potential to reduce operational costs at the plant.”

SOLAR PANELS

It’s not only the treatment process or the wastewater itself which offers utility companies an opportunity to operate smarter. The physical land on which sewage treatment plants lie offers another area of potential to unlock a value stream, while adopting more sustainable sewage treatment practices.

“Harnessing the power of poo is one thing, but in Queensland it makes

sense to also harness our abundance of sunshine,” Mr Belz said. “We’ve done this by installing more than 500 solar panels at the Laidley, Gatton, Forest Hill, Kalbar, Boonah, Kooralbyn, Beaudesert and Kilcoy sewage treatment plants, cutting power use at the facilities by more than 20 per cent.

“The solar systems will deliver operational savings of around $45,000 a year and reduce the annual carbon dioxide emissions to the equivalent of taking 57 cars of the road for a year.”

The initiatives are part of QUU’s Renewable Energy Plan which aims to make its sewage treatment plants cleaner and greener.

“QUU is always exploring innovative ways to become more sustainable, both environmentally and economically,” Mr Belz said.

“In fact, as the population increases, our reliance on the electricity grid is decreasing. Despite this great outcome, we recognise there is more work to be done on the journey of turning waste streams into value streams and fulfill our vision to be a utility of the future.”

28

QUEENSLAND URBAN UTILITIES’ MICHELLE CULL AND MIKE OAKEY WITH THE FLOATING MATTRESS INNOVATION AT FOREST HILL SEWAGE TREATMENT PLANT.

WASTEWATER TREATMENT

QUEENSLAND URBAN UTILITIES’ MICHELLE CULL AND TRENT WATKINS WITH THE NEW SOLAR PANELS AT GATTON SEWAGE TREATMENT PLANT.

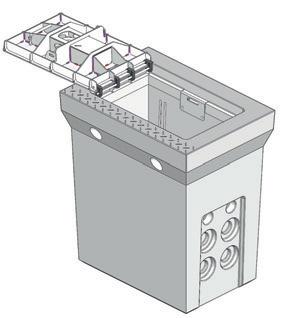

The

answer is simple: due to industry demand for reliability.

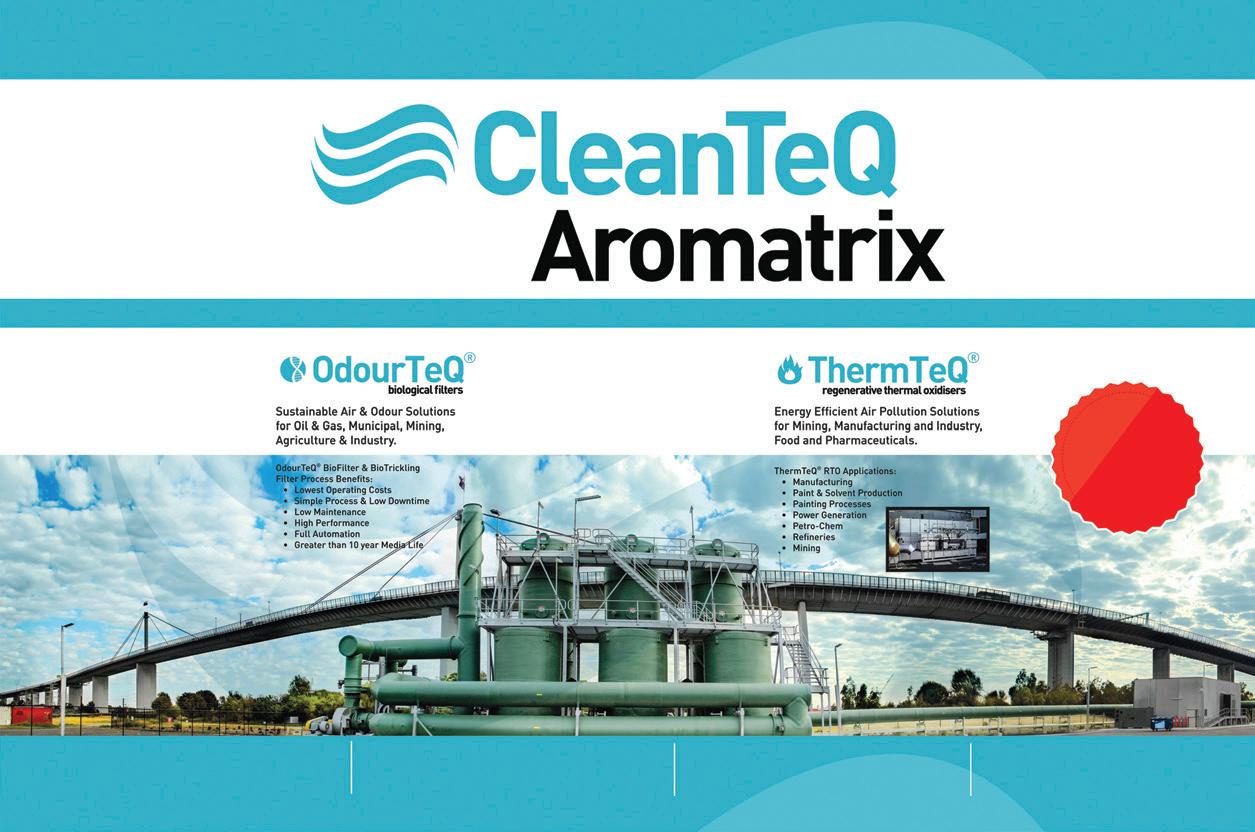

ABrisbane-based company has developed a sewage air release valve which has successfully eliminated issues found in singlechamber air release valves.

During discussions with council engineers and operators it was found that a secondary major problem existed, which was the failure rate and maintenance cost of single chamber air valves, resulting from their inability to prevent contained solids from causing blocking and leaking. This research also identified an additional eight design faults contributing to early failure of single chamber valves.

Odour Technologies took up the challenge and over many years of prototypes and testing produced their revolutionary twin-chamber, VS-4 Smartvalve air release and inlet valve,

which is now standard purchase for more than 30 Australian and New Zealand councils, and has also gained entry into the US market.

Odour Technologies claim to have overcome all single chamber valve deficiencies and point out the results of one major Queensland council which deferred purchasing until conducting a twelve-month trial.

Twelve VS-4s were installed at highly contaminated sites, at which many makes of air release valves had previously been used, all requiring fortnightly and in many cases weekly servicing. The VS-4s were initially checked at three months and found to be working perfectly and therefore their service intervals extended out to twelve months. At no time during this period were any of the VS-4s blocked or

found to be inoperable.

Because of the considerable cost savings, many VS-4s have since been purchased, plus they have been officially specified for sewage in-line air release and inlet operation.

With the significant quantity of VS-4 Smartvalves now in use, in conjunction with Odour Technologies’ target of 100 per cent reliability and their standing offer of a no obligation trial, it would appear the future of this revolutionary designed valve is assured.

WHY

AN AIR RELEASE VALVE? THE AMAZING VS-4 SMARTVALVE Australian designed and manufactured from 316 stainless steel • Simple on-site servicing • Rated 18 Bar • Seals at atmospheric pressure • Guaranteed anti-hammer at all times • Auto throttled against premature closing • References and testimonials available • Selling Aus, NZ and USA. Export opportunities available. USE THIS AD FOR A FREE TRIAL For more information: and click on the video Odour Technologies Pty Ltd enquiries@odourtechnologies.com.au Tel 61-7-3287 7020 Mob 0414 861 000 International Patents and Patents Pending www.vs-4.com The key benefits of the VS-4 can be found at www.vs-4.com and www.odourtechnologies. com. Contact the company directly by emailing enquiries@ odourtechnologies.com.au. 29 Utility Partner Solutions WASTEWATER TREATMENT

WOULD AN ODOUR CONTROL COMPANY BUILD

The

THE BATTERY POWERED CHLORINE ANALYSER THAT KEEPS YOU CONNECTED TO YOUR NETWORK

SMARTER. SAFER. FASTER.

The need for innovation in the Australian drinking water industry has been heavily influenced by changes to the Public Health Act 2010 and the Public Health Regulation 2012. These Acts require drinking water suppliers to develop and adhere to a ‘quality assurance program’ (or drinking water management system) and from 1 September 2014, this requirement applies to water suppliers defined in the Act, including water utilities, private water suppliers and water carters.

The requirements of the Act can be met in different ways including manual sampling or analysers housed in roadside cabinets or service pits, which require external power supplies. The manual sampling process can however be time consuming and power supplies are not always available or reliable. As a result of this, on-site manual water sampling and laboratory testing must be undertaken before problems within the network can be identified.

Reducing risk and streamlining the process of chlorine analysis is the newest product offering from Wallace & Tiernan® an Evoqua brand. The Chloroclam® and Hydraclam® technologies allow for the deployment of analysers simultaneously across the network, providing a multi-measured approach. The process includes the measurement of total or free chlorine and temperature (Chloroclam) while turbidity, electrical conductivity and pressure (Hydraclam) can be monitored throughout the network simultaneously.

Transmitting measurements at preset time intervals, the analysers function automatically and do not require interaction from an operator. Powered by lithium batteries, these analysers allow samples to be taken directly from fire hydrants or from any point in the potable water reticulation system. Once a sample is taken, vital data is transmitted to the utilities provider via the mobile phone network. This enables utilities to receive their chlorination readings in near real-time allowing for quicker responses to any deviations from safe levels.

The technology, which is leading the way in automated water sampling, assists utilities to rectify water quality issues in a time frame far shorter than manual sampling could provide and offers the assurance that the analysers will work, even in the event of a power failure.

30 WATER TREATMENT

CHLOROCLAM ® by Utility Partner Solutions

ARSENIC REMOVED FROM DRINKING WATER

Mareeba Shire Council recently engaged Amiad Water Systems to design, construct and commission a 6-10L/s arsenic filtration plant for the township of Chillagoe in Far North Queensland.

The town sources its water from a local bore field which suffers from arsenic levels in the range of 0.010-0.020mg/L, exceeding the Australian Drinking Water Guidelines.

The contract specified that the plant must achieve a target level of arsenic of less than 0.005mg/L in the product water. To achieve the target Amiad proposed a system of chlorination, ferric chloride dosing, DMI-65 catalytic media filtration and cartridge filter polishing. The supplied plant is fully automatic and controlled by an Allen Bradley PLC with a Schneider PC/touch screen loaded with Citect software, for local and remote operation.

TREATMENT PROCESS

Chlorination: in groundwater, arsenic

occurs predominantly as arsenite As (III), and requires conversion to arsenate As (V) by chlorination to enhance the effectiveness of the filtration process.

Chlorine also acts as a catalyst for the DMI-65 media, and is required for its regeneration to re-establish the oxidizing environment on the surface of the media.

Ferric chloride dosing: arsenic can bond with iron salts in the water and with metal based coagulants such as ferric chloride. Ferric chloride is dosed such that there is a sufficient reservoir of iron for arsenic to form complexes and precipitants with the iron salts via the chemical processes of precipitation, co-precipitation and adsorption, which can then be filtered.

DMI-65 catalytic media filtration:

DMI-65 is a manganese dioxide (MnO2) infused media whose surface acts as a good oxidant and is effective in removing both arsenite and arsenate, as well as iron/arsenic complexes and precipitants. The DMI-65 media filters are periodically backwashed and rinsed based on either pressure differential across the media filters, or on time, whichever occurs first.

Cartridge filters: 1 micron cartridge filters were installed to polish the product water and provide a final barrier to the precipitated arsenic.

The arsenic filtration plant, designed and constructed by Amiad utilising DMI-65 media, was commissioned in March, 2015, and has been successfully reducing the arsenic to 0.001 mg/L, making it suitable for consumption by the community of Chillagoe, Queensland.

31

WATER TREATMENT Utility Partner Solutions

FROM PREHISTORIC TO ARTESIAN GOLD

However the small town of Richmond in western Queensland, famous for its paleontological discoveries that include the fossils of prehistoric marine creatures, did just that, and has reinvented their town’s drinking supply to win the ‘best tasting water’ award at the 2014 IPWEA Queensland conference.

This year, following the Queensland state win, Richmond’s water ran to compete with NSW at the WIOA Operations Conference and Exhibition for the title of ‘best tasting water’ between the two states. A competition referred to as the ‘Water of Origin’ of water taste tests. The competition is held annually and coincides with the Rugby League State of Origin series.

Although Queensland lost game two of the rugby series, they did take home the honour of having the best tasting water between NSW and QLD. For a small town like Richmond to win such an award against Orange NSW, a larger,

It’s not so often that one hears of a rags to riches water story, let alone one that sees a town’s entire water source transformed into an award-winning drop.

better resourced council from south of the border, demonstrates that it can be done, and all communities regardless of size or location have the opportunity and capacity to deliver the highest quality in essential services.

John Wharton, Mayor of Richmond Shire Council, is proud of the town’s achievements. “It has been a great result winning the awards in western Queensland, let alone winning the state title against all the large councils that were finalists,” he said.

“Topping it off with the water of origin win is testament to the Aeramix design team’s process development methods, expertise and their capacity to deliver outcomes at full scale.”

Further to the taste test wins, Richmond Shire Council also took home another accolade. Geoffrey Johnson, the town’s head plumber and now water treatment plant operator won the Queensland Water Directorate - Young Operator of the Year.

Beyond the honour of receiving

the award, Geoffrey also pocketed a trip to attend the New Zealand WIOG Conference and spend a week touring water and wastewater treatment plants expanding his knowledge and further honing his skills.

Geoffrey also presented a paper at the conference detailing his experiences and involvement with the water treatment plant construction, and his learning curve throughout the commissioning and early days operating the plant - for which he took home third prize in the best operator papers category.

The transformation of the town’s water began when high levels of manganese and iron were found to be present in the Shire’s bore water, combined with sulphide, causing strong odours and rusting of pipes.

“People will not invest in a community that has bad water,” said Mr Wharton. “Continual maintenance and renewal of taps and water infrastructure due to the water’s highly

32

WATER TREATMENT

corrosive properties was costly to the council.”

Not only were residents complaining of the water’s unpleasant odour and the discolouration of building facades from outdoor sprinklers, the poor water quality meant that water meters could not be installed as they were continually becoming blocked from precipitates of iron and manganese.

In 2014, the council stepped into action, contracting Aeramix Water & Wastewater Solutions to construct a new water treatment plant to solve the township’s contamination issue.

Design and installation of the plant was part of the contract, as well as installation of related pumps, pipework, filters, tanks, chemical dosing and connection to the township. The project was a $4million water investment for the Shire and was completed by December 2014. Since the plant’s construction the community of Richmond have benefited greatly from the new water system in multiple ways.

“Since the opening of the new treatment plant, we can now install water meters in the knowledge that they will actually work, and not block up,” said Mr Wharton. “In the past, council had never been able to meter and charge for water, which led to excessive water usage by some ratepayers and extra pumping charges for council.

“Now the people living in Richmond can drink straight from the tap, and good water means a very positive future for Richmond.”

HOW THE NEW TREATMENT PROCESS WORKS

The new water treatment process uses physical and chemical oxidation to aid removal of the iron and manganese. The aeration stage also removes the sulphide smell and softens the water.

The water is then dosed with a coagulant, which attracts the iron and manganese, forming larger particles which are filtered out of the water

leaving nearly no traces of iron and manganese while the filter media also absorbs organics.

A small scale pilot plant was developed before the project began, to simulate the treatment process and demonstrate its effectiveness.