Jason leads Comdain’s experienced team of water and wastewater treatment professionals. With over 20 years project management experience and an impressive portfolio of treatment plant projects, he understands the challenges of working within complex brownfield environments. Collaborative and responsive by nature, Jason works with our clients to deliver quality, fit-for-purpose treatment solutions.

INTELLIGENT DOERS, DEPENDABLE DELIVERY

comdaininfrastructure.com.au

Jason is just one of our 90+ multidisciplinary engineering experts from across the country. With our ability to selfperform, our in-house design and specialised electrical, mechanical and instrumentation teams, we challenge convention and drive exceptional outcomes for our clients.

Jason Dennis Treatment Program Manager - QLD

e’re predicting 2018 will be a big year, not only for us, but across the entire utility sector. Water utilities are continuing to look for solutions to population growth, climate change and increasing customer expectations, while energy uncertainty has power utilities turning to battery storage and improvements in solar and microgrids for practical measures to safeguard against a constantly evolving sector.

At the centre of these issues, are utilities that are ‘going digital’ and figuring out exactly what this means for their organisation.

Instead of worrying about how to collect data and what technologies to use, utilities are delving deeper into how this fits into their core values and looking at the best ways to utilise the data and technologies that are already in place. This is just the utilities that have embraced digital, for some there is still a long way to go. There are however many utilities that have already successfully implemented digital technologies and processes, and learning from their experiences and mistakes could be valuable for others. It was this idea of collaborative knowledge sharing that sparked the concept of the Digital Utilities Conference.

Digital Utilities is a two-day conference running from 19-20 April in Melbourne that will feature an expert lineup of utility leaders talking about their digital transformations, the challenges they have faced, and what you can learn from their experiences.

The first round of speakers has already been announced and includes key players such as Ausgrid CEO Richard Gross, Horizon Power Managing Director Frank Tudor, Queensland Urban Utilities Chief Information Officer Susan Heath, Sydney Water CIO George Hunt, and many more. You can view our industry experts on page 44, with more speakers to be announced shortly.

While there is still a long way to go before everyone becomes a full ‘digital utility’, there have been major steps forward for utilities across Australia in the implementation of digital technologies and processes. We’ll be celebrating the organisations that are leading the way at the Digital Utility Awards. There are four awards up for grabs: Digital Utility of the Year, Utility Innovator of the Year, Best Use of New Technology, and Best Customer Innovation, with winners announced at the Gala Dinner on 19 April. You can nominate your organisation at www.utilityawards.com.au.

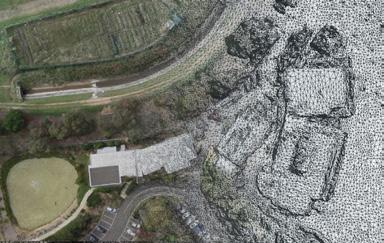

In the lead up to Digital Utilities and throughout this issue, we’re looking at all things digital, from big data, distributed generation and virtual power plants, to the use of satellite technology in the mapping, GIS and surveying sector, and impact of data on utility locating.

Being able to effectively use data in the decision-making process is a key skill that utilities will look to possess in order to increase efficiencies and reduce costs, and it will continue to be sought after in 2018. Given the importance of accurate utility locating in regards to safety and minimising risk, new technologies, digital processes and the use of data is also set to revolutionise this field.

In addition to the Digital Utilities event, Utility will also be attending other key industry events, including Locate 18, Power Australia, Smart Energy and WIOA NSW, where this issue will be distributed. I’m excited to talk further with a lot of you at these events about how your utility is tackling the current changes in the sector, and I can’t wait to see what other developments this year brings.

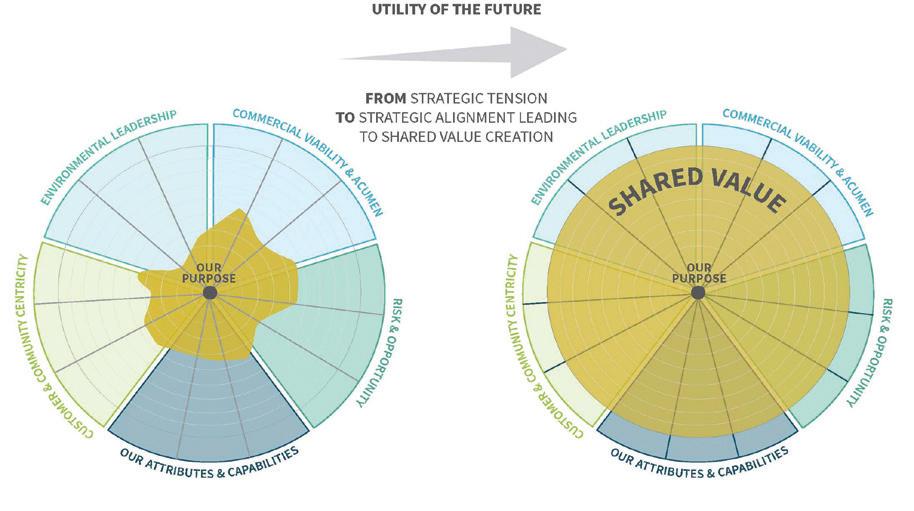

Anyone familiar with Lewis Carroll’s Wonderland will recall it is an unsteady, shifting geography, where linear thinking, rules and stability don’t apply. Through the Looking-Glass is meant as an instruction of how to negotiate this gravity-defying world – peer very closely at this reflection and make strategic decisions to successfully pass through this new world.

The biggest challenge for Alice is the rapidity with which things change without warning. Elements meant to be measured and paced, like the growth of her body, occur so quickly that the unmitigated knock-on effects are disastrous.

The modern day world of energy is, without doubt, a wonderland.

The industry’s transformation is driven by many things: smarter energy solutions, affordability for customers, security and stability.

These key points can’t be considered in isolation, but rather each is a cornerstone on which solutions are balanced.

At the recent 2017 Energy Networks Australia Gala Dinner I presented the Innovation Award to SA Power Networks for the Salisbury Trial, an Adelaide-based project in which 100 customers received battery storage systems. This trial resulted in a myriad of benefits for individuals, communities and enterprise. Reduced bills for customers, increased backup power for communities, and deferment of a $2.9 million network upgrade.

What is striking about this particular project, and all three recipients of awards presented on the night, was how instrumental to success both collaboration and innovation proved to be. Innovative concepts require collaboration and partnership in order for ideas to reach fruition.

There’s a second way in which collaboration and innovation has transformed our energy landscape - we’ve become part of the shared economy. Transport didn’t take Uber seriously. Hotels didn’t hear Airbnb sneak up from behind. Retail has been forced back to the drawing board to find ways to compete with online shopping. Traditional business models in our sector are taking note from these lessons.

Our own landscape is being entirely transformed. Advancing technology has created a shared energy economy. Customers are selling energy back to the grid and power is a shared asset, with transmission and distribution no longer being one-way activities. Every part of our sector needs to respond; legislation and regulation, pricing models and system design.

Several of the initiatives shortlisted for awards in 2017 were powering communities independently of traditional poles and wires. Advances in technology are redefining the way in which energy services can be provided. Continuing improvements in distributed energy resources provide new

opportunities for increasing the efficiency of electricity supply through microgrids and stand-alone power systems.

For some customers there may be significant benefits in deploying lower cost, off-grid solutions in regional and remote communities. Analysis undertaken by Energeia for Energy Networks Australia and CSIRO found that microgrids are most likely to be cost-effective in areas that are the highest cost to serve. With a flexible regulatory framework, lower cost off-grid solutions like microgrids and stand-alone power systems could be employed by networks to reduce the total costs for all customers.

The transformation of the energy sector is a given. For networks, the challenge is to innovate and evolve quickly enough to ensure they don’t miss the wave of change.

Further, we must ensure that all our innovative work, regardless of where it sits within a business, is aimed squarely at improving consumers’ experience, and that the environment in which we operate can support and drive an innovative mindset.

These challenges are likely to require just as much fresh thinking from regulatory policy and rule makers, as from energy network businesses themselves.

This should be based on the real outcomes for all customers in our energy markets. It should be led by market evidence. During a time of rapid technological change, Australia’s regulatory policy is yet to fully realise the benefits of innovation activities undertaken by network businesses.

This means that Australian electricity customers may miss out on the opportunities for integrating new technologies into the grid in ways that can not only make them money, but can lead to reduced costs for all consumers. Our current pricing structures are at the top of the to-do list, the status quo is fundamentally unfair and in desperate need of reform.

Considering recent trends in the energy sector, innovation in the delivery of network services may have substantial social benefit. Conversely, the absence of innovation will come at a cost.

We are living in the most momentous period of innovation the energy sector has seen since the days of Tesla and Edison. Redesigning regulatory frameworks that match the pace of technology; modernised infrastructure; exceptional customer experiences; value for money; and stable yet responsive business models are challenges we must meet to service the needs of tomorrow and well into the future.

Our collective success requires a multi-faceted approach. Two keys in particular will help to unlock the future, and if we look at the successes showcased at Energy Networks Australia’s Annual Awards, both components are required to reveal the prize behind the door. Innovation and collaboration.

The Water Services Association of Australia (WSAA) has released its latest paper: Workforce Skills of the Future. WSAA and the Water Environment & Reuse Foundation (WE&RF) commissioned KPMG to help their members understand and prepare for future trends affecting the urban water industry and its workforces.

Clean water and sanitation are precious. The water sector has its own specific challenges in terms of reuse, recovery and regulation, but the sector is also affected by the global megatrends disrupting industries across the world. In this time of unprecedented change, it is difficult yet increasingly important to understand the potential impacts on the workforce and the skills required in the workforce of the future.

If unaddressed, the water sector may be left with significant skill gaps. By understanding trends and planning for the future, water utilities can create more engaging customer experiences, enhance the liveability of urban areas and provide greater development opportunities for their people.

The paper includes results across three continents, and provides insights on where the urban water industry is headed and the key enablers for success. A survey was conducted among water utilities in Australia, the United States and the United Kingdom to collect information on five key facets of the workforce: cost, capability, capacity, connectivity and compliance.

Key insights and themes were explored further during a two-day industry workshop, which focused on the

development of plausible future water scenarios. These scenarios were based on the potential impact and interaction between four key drivers for change of workforce skills in the water sector, being the customer, technology change, regulation and government, and climate change.

Its recommendations are essential for the industry as we undergo the transition to the digital future. Our workforce must develop and change, and strategic workforce planning is crucial in our ability to attract, retain and develop people in an increasingly competitive labour market. To be successful in an uncertain future, urban water utilities will need to proactively understand, influence and react to change.

The research results have identified two key foundation programs, which should be viewed as the priority next steps. The first is an Employee Value Proposition - a tailored and unique framework which encompasses employees’ intrinsic and extrinsic motivators in order to engage the desired level of time, effort and loyalty from the workforce.

The second is the development of a sector wide Strategic Workforce Plan - a sector wide plan will help the water sector and its workforce position itself to adapt and thrive in an uncertain future.

The Workforce Skills of the Future Paper is a great example of international collaboration that enables informed strategic planning for future opportunities, challenges and risks up to the year 2040, with an emphasis on customer focused outcomes.

Expertise in Plumbing Equipment, Tools, Materials and Safety Supplies

• Delivered on time & on spec

The Australian Government will provide $3 million in funding to the Cooperative Research Centre’s project stream to fund research and innovation into the Smart Lining for Pipes Project.

Executive Director of the Water Services Association of Australia (WSAA), Adam Lovell, said the funding was vital for water utilities to manage water and sewerage infrastructure.

“Many water and sewer pipes in our cities and towns are approaching the end of their life, and to completely replace them can cost thousands of dollars per metre. Water

utilities can potentially keep customer bills down by using new materials or new smart robotics and sensors in repairing pipes instead of replacing them,” Mr Lovell said.

The project is valued at a total of over $24 million and is expected to position Australia as a global leader in smart water infrastructure design, engineering, testing and management.

The project will see collaboration across the globe with 31 project partners focusing on new materials and technologies to increase the lifespan of these assets.

The world’s largest lithium ion battery has been fully installed in South Australia and has entered the regulatory testing phase.

Tesla Powerpacks, connected to Neoen’s Hornsdale Wind Farm, have now been fully installed on-site, with the testing phase ensuring the battery is optimised and meets AEMO and South Australian Government requirements.

Throughout this testing period, the battery will be providing system security services to South Australia.

In March 2017, the State Government announced its Energy Plan, with the objective of delivering cleaner, more affordable and more reliable energy to South Australians.

This plan included building the nation’s largest battery to store

“We are especially pleased to be working with an extensive range of national and international partners, including SMEs. This will keep customer bills down and reduce the ‘inconvenience’ cost to the community,” Mr Lovell said.

The global market opportunity for smart lining products is estimated at more than $60 billion over the next ten years, assuming linings defer ten per cent of pipe renewals.

Australia represents five per cent of this market so expanding market opportunities for Australian SMEs offers huge potential.

renewable energy and have backup power for when it is needed.

In July 2017, following a competitive process, French renewable energy company Neoen and US sustainable energy company Tesla were awarded the contract to deliver the project, which would be the world’s largest lithium ion battery and installed near Jamestown.

SA Premier, Jay Weatherill, said an enormous amount of work has gone in to delivering this project in such a short time.

“The world’s largest lithium ion battery will be an important part of our energy mix, and it sends the clearest message that South Australia will be a leader renewable energy with battery storage,” Mr Weatherill said.

For more energy news like this, as well as in-depth feature articles and expert commentary on Australia’s energy industry, visit the newly launched Energy site at www.energymagazine.com.au.

Advanced mobile and spatial solutions to solve complex asset and data management challenges.

Capture & Asset Mapping

Reduce your network risks and maintenance costs

Processing & Analysis

Make sense of your spatial data, whatever the source

Visualisation & Reporting

Deliver timely information to reduce errors and accelerate action

Mobile Workforce Management

Manage your mobile workforce and streamline operations

Data Maintenance

Reduce your costs without compromising service or safety

The ACCC released the second interim report into gas supply markets in Australia, focusing on the operation of the East Coast Gas Market where there are continuing immediate and long-term concerns.

The report found that over the past few months, Queensland LNG producers have diverted significant quantities of gas into the domestic market. LNG producers have contracted 42 petajoules (PJ) of gas under long-term gas supply agreements (GSAs) to domestic buyers for supply in 2018 since the September 2017 report.

Collectively, LNG producers reduced their LNG export contract and LNG feed gas requirements for 2018 by 34PJ and their planned LNG spot sales by 29PJ. LNG projects are still forecasting to sell 34PJ on the international LNG spot markets in 2018.

The bulk of the gas sales by LNG producers were to aggregators and retailers. While a substantial portion of this gas will be used to supply customers that were already contracted, the rest of the gas was used to enter into new GSAs with C&I users and gas powered generators (GPG). In total, aggregators and retailers have sold 32PJ of gas for

supply in 2018 since the September 2017 report.

As a result of additional supply being made available and a reduction in planned exports, there is now a lower likelihood of a supply shortfall in the East Coast Gas Market in 2018. However, the gas supply-demand balance in the market remains tight.

ACCC chairman, Rod Sims, said the gas supply shortage has had “a catastrophic effect on the Australian economy”.

“It’s meant that gas prices have gone up a lot — doubled, tripled, quadrupled for some businesses and some consumers,” Mr Sims said.

“And it meant that some companies just could not get gas, there just wasn’t enough gas.

“What we’ve seen is LNG producers have reduced exports to provide more gas to the domestic market, and that has overcome the shortfall, and that has seen prices for many companies fall from around $16 [per gigajoule] to around $8 to $12.

“It’s certainly a better picture, the market still has some problems, but it’s a much better picture now than we had a couple of months ago.”

For more energy news like this, as well as in-depth feature articles and expert commentary on Australia’s energy industry, visit the newly launched Energy site at www.energymagazine.com.au.

SPEED. PRECISION.

LOCAL PRODUCT SUPPORT.

THE VERMEER PD10

SOLAR PILE DRIVER IS YOUR SPRINGBOARD INTO LARGE SCALE SOLAR.

[ Speed ] Designed from the ground up for solar array installation, the PD10 brings cycle times down to unprecedented lows.

[ Precision ] Laser or optional GPS guidance and an innovative hammer design means outstanding accuracy, less pile damage—and less rework.

[ Local product support ] Get your project underway with the peace of mind that only the backing of a truly nationwide dealer support network can offer.

Contact your local Vermeer product specialist to learn more.

PD10 SOLAR PILE DRIVER. GET EQUIPPED.

Apaper released by Infrastructure Australia called for national urban water reform as utilities are set to come under increasing pressure from growth and climate change.

Reforming Urban Water: A national pathway for change addresses mounting challenges in the urban water industry, aims to provide a case for reform and outlines the potential costs of inaction. The report also establishes national objectives to guide reform and ensure the sector can meet future challenges, as well as identifies a pathway with clear recommendations.

Infrastructure Australia has recommended a three stage approach to reforming urban water:

1. This first stage is for the Australian Government to establish a national reform pathway by the end of 2018, including agreeing to a new national urban water reform plan, establishing an independent national reform body and using incentive payments to drive reforms

2. The second stage is to roll out nationally consistent reforms over the next five years. This includes refinements to regulation and governance in each state and territory, improvements to long-term planning and pricing frameworks, and enhanced collaboration between regulators

3. The final stage is to consider further reforms over time, such as moving to a national regulator and privatising urban water assets

Infrastructure Australia Chief Executive, Philip Davies, said that while reforms of this scale will take time to be rolled out, it is important that governments get on with the task of initiating reforms now.

“Across Australia many of our dams are relatively full, which gives us a rare window of opportunity for clear thinking and long-term planning to meet our future needs.

“Now is the time for governments to get on with the job of bringing urban water policy, regulation and governance up to speed so that it can meet the changing needs of Australians in the twenty-first century,” Mr Davies said.

WSAA’s Executive Director, Adam Lovell, said, “WSAA supports the calls from Infrastructure Australia for a new national urban water reform plan and an independent national urban water reform body.”

“It is gratifying to see the strong and growing consensus around urban water reform that has developed between governments, water utilities and the private sector. The recommendations from Infrastructure Australia are in line with the reforms WSAA has been championing on behalf of the industry and its customers,” Mr Lovell said.

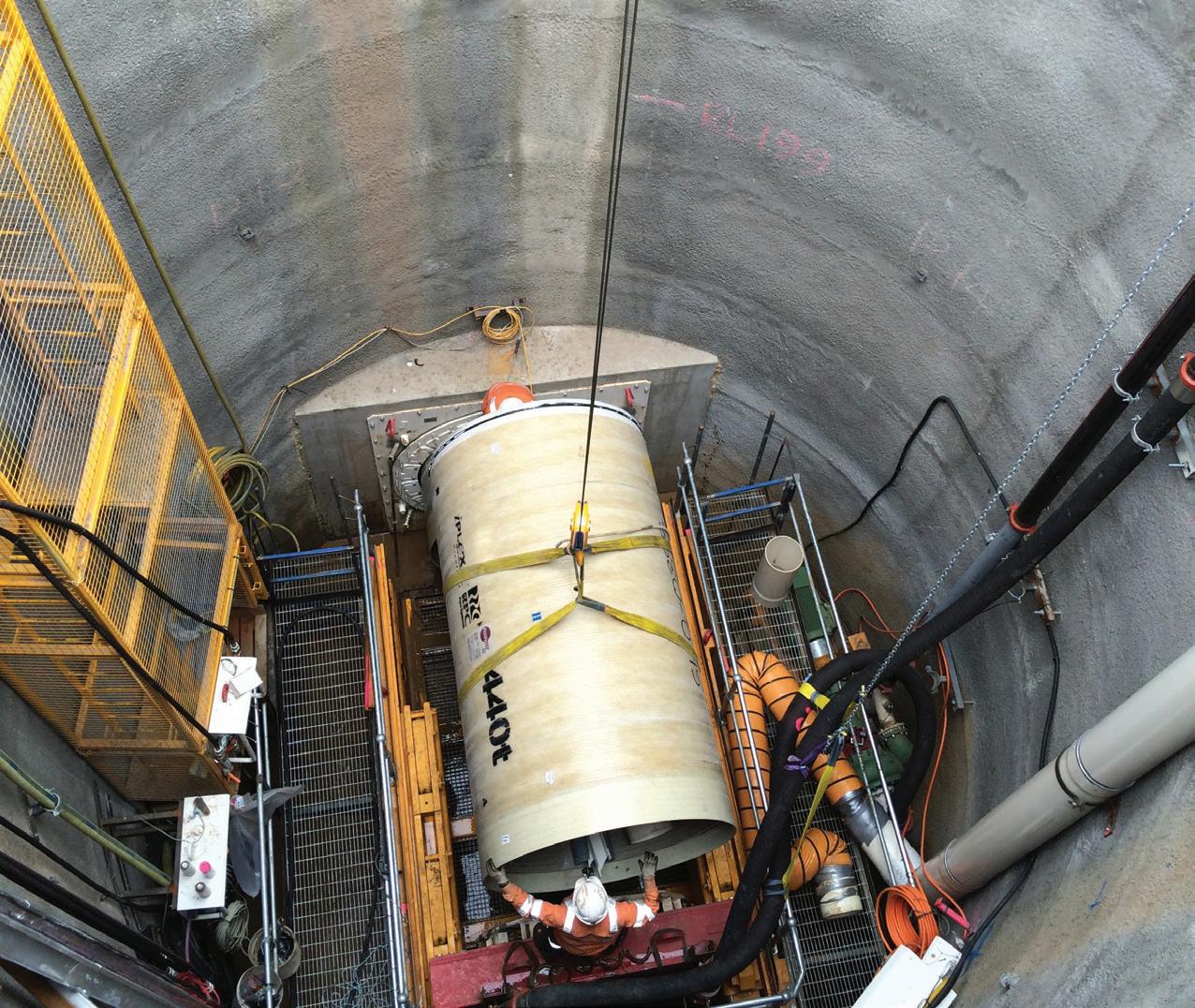

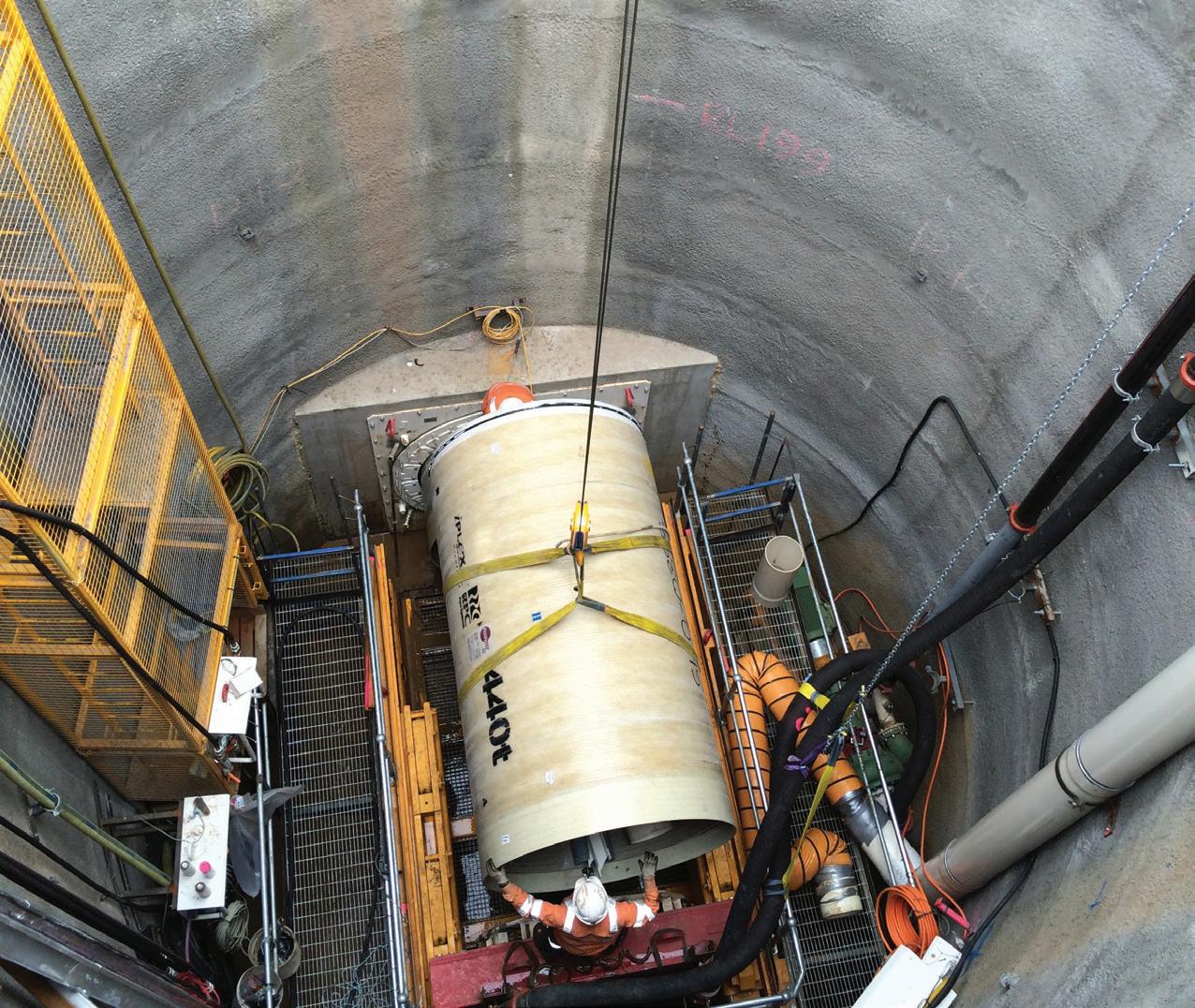

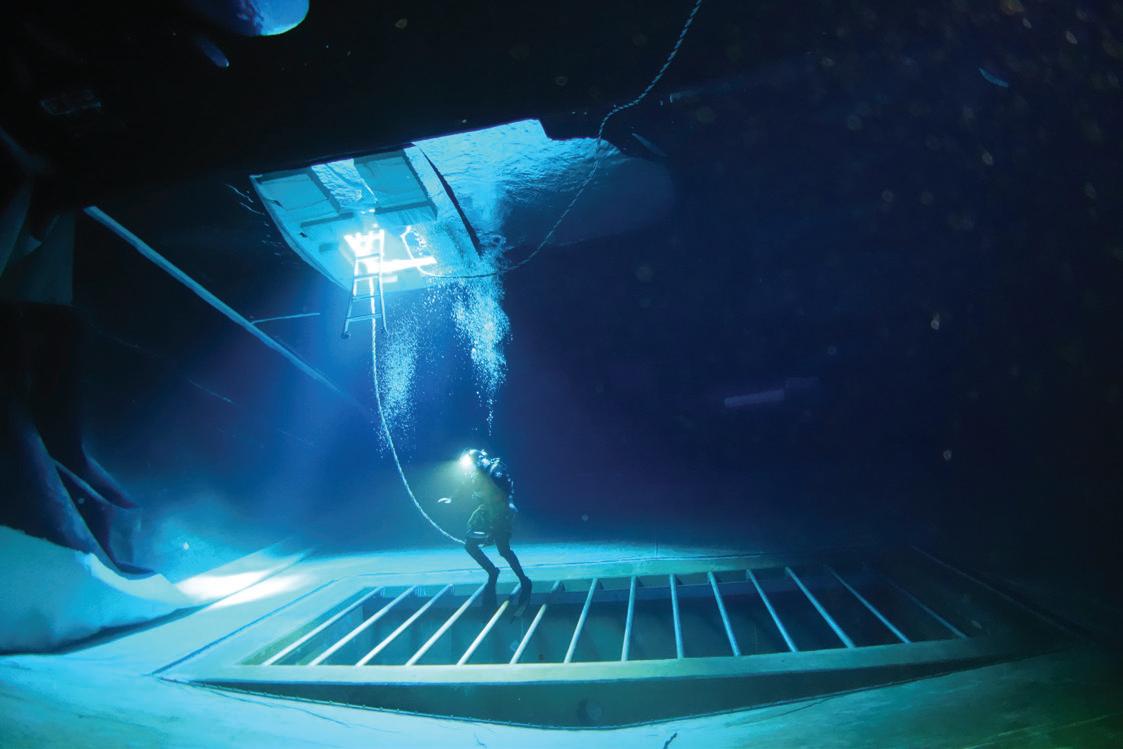

A recycled water plant in Sunbury, a town in Melbourne’s north-west, is using innovative membrane technology to treat wastewater.

As part of a $53 million upgrade to the Sunbury Recycled Water Plant, wastewater will be filtered through hundreds of thousands of tiny strawlike membranes with holes ten times smaller than the smallest bacteria.

The upgrade will increase the plant’s treatment capacity from 6.5 million to 9.2 million litres of sewage per day.

“Thousands of these 2.6mm-wide

membranes, which look a bit like the strands of a mop, are packed into modules,” Western Water’s Managing Director, Neil Brennan, said.

“(In November 2017) we had cranes lifting 24 of the modules into place in the new membrane tank at the plant.”

“The surface area of the membranes combined is 43,200 square metres, which is more than double the size of the MCG.”

The membrane tank will filter wastewater through holes that are just 0.00003 of a millimetre wide, removing particles and bacteria to

produce exceptionally high quality recycled water.

“This is the first time we have used this innovative technology, which also takes up far less space than traditional filtration technology,” Mr Brennan said.

“The space-saving design has meant we can keep the upgraded plant within the same footprint as the original plant. We can also add more modules in future if needed.”

It will enable the plant to keep up with the rapidly growing population of Sunbury and Diggers Rest.

AGL has outlined plans to repurpose Liddell Power Station beyond its 2022 closure.

The New South Wales Generation Plan proposes a mix of high-efficiency gas peakers, renewables, battery storage and demand response, coupled with an efficiency upgrade at Bayswater Power Station and

conversion of generators at Liddell into synchronous condensers.

The feasibility of a pumped hydro project in the Hunter region is also being explored with the NSW Government.

Graeme Hunt, Chairman of AGL, said the plan demonstrates that old power plants can be replaced with a mixture

of new, cleaner technology, while improving reliability and affordability.

“Decisions for the investments are staged to enable flexibility to respond to the changing needs of the market and improvements in technology over the next five years,” Mr Hunt said.

The AGL Board has approved the commencement of efficiency improvements at Bayswater that will create more capacity without using additional fuel; ordering equipment to convert generators at Liddell to synchronous condensers; and the signing of contracts to purchase 300MW of generation from two new solar power stations to be developed by third parties in NSW.

An assessment of AGL’s plan found the replacement generation is more affordable at $83/MWh, compared with extending Liddell at $106/MWh.

The plan was also found to deliver reliable, dispatchable power for longer, due to a longer asset life of 15-30 years, compared with a Liddell extension of five years.

Independent analysis found an extension until 2027 would cost approximately $920 million.

•

The AGL Board also considered selling Liddell and determined that a sale would not be pursued as Liddell is currently needed to supply energy to its customers and will be repurposed to form part of its alternative generation post 2022.

For more energy news like this, as well as in-depth feature articles and expert commentary on Australia’s energy industry, visit the newly launched Energy site at www.energymagazine.com.au.

With so much change and uncertainty in Australia’s energy sector, it is important for the industry to think critically about what energy producers and retailers should be doing now to ensure a stable future.

Monkey Media, the team behind Utility Magazine, is launching Energy – a thought-leading, technology neutral magazine, developed to help the industry answer some of the critical questions it is currently grappling with.

Energy will be a sister publication to Utility, but will delve deeper into the issues and solutions for the entire energy industry chain in Australia.

Energy will look at the policies and politics affecting the industry but will always place the emphasis on outcomes rather than political point-scoring.

It is committed to helping the industry move forward and solve the so-called energy “trilemma” –establishing new forms of energy that are reliable, affordable and clean – without over-emphasising the role governments will play in finding the solution.

Energy will help to answer questions including:

• What are the energy sources of the future?

• How do we provide energy that is clean, affordable and reliable?

• How do we give customers what they want?

• How to we contend with disruption in the energy sector?

• How do we digitise our networks safely, securely and efficiently? These issues will be discussed through thought-leading editorial contributions from some of the best

and brightest minds in the energy industry.

We believe the future for the energy sector – while it looks considerably different than it has over its first century of existence – has never looked brighter. The opportunities are waiting to be taken advantage of, and Energy will be there, showing you how to best position yourself in energy’s brave new world.

Energy Magazine Issue One will launch in March 2018 and be published quarterly in March, June, September and November. Energy will also include an associated website with news updated daily, as well as a weekly newsletter.

To subscribe to Energy visit www.energymagazine.com.au.

For more energy news like this, as well as in-depth feature articles and expert commentary on Australia’s energy industry, visit the newly launched Energy site at www.energymagazine.com.au.

Australia’s most comprehensive domestic gas market event

The Australian Domestic Gas Outlook (ADGO) conference is the annual meeting place for stakeholders in Australia’s domestic gas industry, attracting over 250 senior managers each year.

It’s your opportunity to hear insights from industry CEOs, politicians, regulators and more.

Attend and discover how the industry is recalibrating itself to the new gas market dynamics, get the latest updates on gas market reform and stay ahead in these uncertain times.

To view the full speaker line up and agenda, visit the website.

Isle Utilities work with the water industry to assess new technologies and assist with their adoption into the workplace. Technologies such as high-res monitoring of pressurised sewer lines, transient event and leak detection, and low power, narrow bandwidth, long-range networks for the IoT are not only important for improving day-to-day business operations but also translate to more efficient IT systems and data management processes.

Isle Utilities first launched its Technology Approval Group (TAG) in the UK in 2005. The innovative platform is now available to utilities all over the world, including Australia. The aim of the TAG forum is to provide a platform to evaluate emerging technologies, share best practice, and collaborate on technology trials and other projects.

The Australian TAG forum is being run in partnership with the Water Services Association of Australia (WSAA), and its members consist of over 30 of Australia’s largest urban water utilities, including Sydney Water, Melbourne Water, SA Water and Western Water.

Managing Director, Tim Day, joined Isle Utilities Australia in 2014 after experience in a number of similar roles, most notably as Managing Director for eMeter APAC, a Silicon Valley clean tech company purchased by Siemens in 2011.

“What attracted me to the company was its focus on the adoption of innovative clean tech in the utility sector and, in doing this, their novel approach being funded by the end users of technology to source and implement technologies. This model means that Isle is independent and can be a trusted advisor as we do not take success fees from technology providers,” Mr Day said.

Mr Day explained that Isle Utilities will only look at a technology if there is, at minimum, a working prototype. This ensures there is something tangible to evaluate and customers find more value in being presented with technologies whose claims have already been validated.

“They must at least have a working prototype which we can evaluate both through getting an understanding of the technology and also validating their claims independently. For example, if a technology claims that they have done a trial with a utility, we have the global contacts in place to approach the utility to understand the scope of the project, the objectives and the outcomes,” Mr Day said.

“Isle’s employees are all highly qualified engineers and scientists with years of domain expertise. We use this technical and domain expertise to evaluate technologies both from a first principles perspective but also to independently validate their claims by checking through their proof points.”

Over the last 12 months, over 200 technologies were assessed through TAG. Around 70 per cent of technologies that present at TAG move forward with either trials, demonstrations or further research.

For the past ten years, Isle Utilities’ major focus has been the water sector, particularly the municipal water sector. They have also done work for the gas, electricity and agricultural sectors, and are looking at expanding into the resources sector as well.

“This benefits everyone as there are many technologies that get pigeon-holed into one sector or another and we can use our business model to help them cross over and also allow collaboration between non-competing sectors,” Mr Day commented.

He also said that knowing about the technology is one

thing but getting it adopted into a business, and getting them to realise the benefits, is key.

“Utilities are typically risk averse, with good reason, and find it difficult to engage all the necessary stakeholders early in a process. While they may run many trials they tend not to progress as they come up against barriers within the organisation,” Mr Day said.

“Everyone loses in that money is spent without a return and the technology provider gets burnt in the process. We provide an independent voice to ensure that technology vendors and end users in utilities do not communicate at cross purposes.

“It is typically difficult for a technology or utility company to understand each other's issues. Technology companies become frustrated as the pace of action may not be what they are used to as an agile startup and the utility companies become frustrated as they can’t make sense of the technology or see it as a technology trying to find a problem to solve.

“Isle can sit between the two and make sure the steps in moving the technology through the technology adoption model are done efficiently, with the correct checks and balances.”

Isle Utilities uses cloud-based services for the management of its data and all of the data that it has gathered is held on its TAG platform, which is available to all of its members.

“To date, Isle has evaluated over 4000 technologies so there is quite a list. We are currently upgrading this platform so that it is easier to search for the technologies that are there” Mr Day said.

“The first part of this we have called CATWizard, which is a tool for evaluating Condition Assessment Technologies for potable water pipes. Subscribers can search on multiple criteria to determine which technologies suit their purposes.”

The technologies are also reviewed by utilities from around the world, which keeps the information current and allows for global collaboration. Despite the huge number of technologies evaluated, Mr Day said that Isle Utilities deals with relatively low amounts of data compared to the water utilities they work with.

According to Mr Day, one of the main challenges with data collection is ensuring that it stays current and that there are strategies in place so that it remains relevant and valuable to the business.

“We are redeveloping our technology platform to ensure that a technology that was evaluated ten years ago has the most current information in our portal now, as no doubt there has been lots of changes given the technologies we are looking at are startups and would have been fully commercialised within that period,” Mr Day said.

“As such we are borrowing from areas like social media, and the latest in web design and architecture to present the technologies in a more accessible way and also keep the

information current by getting users of the technology to contribute to the information that keeps it fresh and current.”

As an organisation that comes across innovative and emerging technologies all the time, Isle Utilities are definitely seeing the impact of big data on traditional data management processes.

“What we are seeing more of is technologies that are disruptive to the traditional IT paradigm of holding all data behind a firewall. Operational technologies are being bundled using a software as a service (SaaS) model where data being generated is held in the cloud,” Mr Day said.

“This is obviously a challenge for utilities as the only way to get access to these technologies is to let go of the traditional view which is often supported by regulation. This is not to say that utilities are not adopting this way of managing their data as they are but it's how the paradigm shift is being managed that is important in regards to data access, transparency and security.”

Mr Day said that the biggest lesson for utilities to learn is that is very difficult to test for scale.

“Technology companies can build software with all of the architectural elements needed for scale but until you actually get there no-one really knows how scale will impact a business process or the technology that is coupled with it.

Embracing

“The lesson here is to be prepared for the worst outcome and scale your applications in a controlled manner if you have the opportunity to do so,” Mr Day said.

The need for utilities to go digital is generally understood, but the question of how to best go about digitising current paper based systems, such as incident reporting and safety systems, can present a challenge. One key decision when implementing an online management system is whether you should invest in a customised system, or buy an off-the-shelf solution that is ready to go.

Once a utility has made the decision to transition from manual, paper based forms and processes to fully automated, smart online systems, the next step is finding a management system that fits seamlessly into an organisation’s current structure.

With cost and time often being a key factor, implementing an off-the-shelf system can be seen as the easiest option as they have already been made and are ready to be implemented at any time. Off-the-shelf systems are developed to meet generic business needs and are focused towards a mass-market audience, rather than a specific sector or company.

This means off-the-shelf systems are likely to only meet a percentage of your needs, and have other features that are not needed.

However, highly customised systems, while specific to the needs of a business or utility, can be costly investments and might not be the right system for everyone.

One of the key factors that utilities and contractors must consider in order to determine what online management system will meet all the needs of their organisation, not just some, is whether

the system will fit into your current way of doing things.

More often than not, an off-the-shelf system requires an organisation to change their way of doing things to meet the system’s capabilities, rather than the software fitting in with the business.

There are ways to alter an off-theshelf system but this can be expensive and take more time than it’s worth. Off-the-shelf systems can also be slow to adapt to industry needs and any request submitted for enhancements may get ignored if it doesn't benefit the larger customer base.

This is where a customisable off-the-shelf solution offers the greatest benefits. This process allows organisations to start with a basic system and build it up with their specific customisations, so their management system has all the features they need and nothing that is unnecessary.

FiNAO is a solutions provider that works with businesses to digitise their existing paper based forms and processes, and create an online system offering automatically generated notifications, predetermined automated workflow and real-time reporting.

FiNAO’s point of difference is that it customises off-the-shelf solutions so businesses have a system that is tailored to their specific needs. FiNAO

Director, Terry Down, said FiNAO does this by starting off with its off-the-shelf PRIME system, and then adding features and modules as the business needs them.

“This modular platform, coupled with cloud hosting, provides a very flexible and scalable system that will grow and adapt as your business grows and your needs change.”

FiNAO’s customisable system was used recently by Linbeck Contractors, a construction, repair, maintenance and plumbing business servicing Australia’s water and gas industries.

Linbeck required an online management system that could automate its Mains to Meter (M2M) job acceptance, allocation, scheduling, management and reporting process.

Linbeck needed to be able to receive jobs from Maximo (Sydney Water’s Asset Management system) into a Linbeck system, which would allow a Linbeck administrator to review the job and assign it to a Linbeck crew, as well as view locations of crews and job status on a map in real time and allow the crew to complete job documentation on-site.

The system also had to keep Sydney Water updated with automated real-time status reports, and follow the Linbeck process procedure with regards to safety and business requirements such as SWMS.

Linbeck tried many off-the-shelf products but found it could not get the level of functionality and efficiency it desired, and realised it needed a customisable system.

“After some extensive trials and research we came across FiNAO and immediately we liked the functionality available from the base modules, but mostly we were interested in how the system could be tailored to suit our business and key projects,” said Joseph Lynch from Linbeck. Customised solutions can provide a competitive advantage and potentially the least disruption to your business model.

As a result, Linbeck were provided with a fully automated job workflow system that met its specific business requirements, complied with Sydney Water requirements, and provided a range of real-time reports for job progress, outcomes and billing. Using this system, Linbeck successfully processed over 1,000 jobs in the first few weeks.

Linbeck found the system easy to navigate and has been able to integrate it with key internal and external systems, which eliminated a number of paper forms and site packs, and provided a low cost mobility solution with all its data being available in real time on basically any device.

“The FiNAO team have helped to make the implementation and development process as painless as possible, we are pleased with the results and can see our system is clearly on the way to being what we require, one that is flexible and scalable enough to manage and integrate our WHSE, Quality, HR, Job and Project Management functions.”

– Joseph Lynch, Linbeck

Organisations need to consider that there might not be a system that exists in the market that meets all their specific business needs, so a bespoke system may be the only option. While there are pro’s and con’s to both options, the main thing to remember is to do your homework before you commit.

Organisations need to think about how they currently operate, from larger processes down to the terminology that employees use. The software solution that they choose must fit their particular business needs, otherwise it’s not the right solution.

Although a custom solution may have a high upfront cost, it has the potential to provide a greater return on investment and cause the least interruption to a business.

If an organisation finds an off-the-shelf system that fulfils all their needs, then this can be implemented. However, it’s essential that the long-term and future needs of a business are also considered.

If you want to partner with a stable, knowledgeable, experienced company to maximise your success and minimise your business risk, partner with FiNAO. For more information on how FiNAO can develop a customisable off-the-shelf solution for your business, head to finaomanagementsystems.com.au or contact Terry Down direct (terry@finao.com.au or 0413 481070).

How ‘making data work’ is central to unlocking the opportunities that come with digital disruption and technology innovation.

by Igor Sadimenko EY Asia –Pacific EAM Regional Lead

by Igor Sadimenko EY Asia –Pacific EAM Regional Lead

The way electricity is generated and consumed is changing irreversibly toward a more distributed model. The future of our system is decarbonised, decentralised, digitised and democratised. The way we manage energy assets and asset data is also having to fundamentally change –and it’s happening faster than we think.

This distributed model requires a significant level of digitisation in order to work efficiently and effectively, as it relies much more on ‘many-to-many’ transactions between a growing variety of service delivery assets – from solar array and storage to smart meters and sensors.

Across the power and utilities sector, the shared digital architecture is being reconfigured and businesses will need to transition to a more inclusive and far reaching digital infrastructure, capable of far deeper levels of asset inclusion.

The Internet of Things (IoT), the proliferation of distributed energy resources, behind-the-meter connected devices and electric vehicles (EVs) are generating vast quantities of unstructured data. At the same time analytics and artificial intelligence (AI) – machine learning, image recognition and deep learning in particular – are transforming how asset data is collected, collated, analysed and leveraged.

AI can remove the need to start from a hypothesis – a common requirement in traditional analytics that has constrained thinking, making evolution an incremental and slow process – and instead look for and find new insights in well-worn data sets.

Image recognition, for example, can help identify anomalies, manage and predict the performance of grid assets. Whereas machine learning and deep learning can synthesize and model the impacts of numerous new technologies (EVs, batteries, drones, advanced metering systems to mention just a few) deploying in a far shorter timeframe than before.

Data informs every management decision throughout the asset lifecycle and supply chain. It needs to flow effectively and lead to actionable insight. The more an organisation values data and information as a strategic asset and a differentiator in its own right, the greater the efficacy of its asset management and the likelihood of maximising ROI.

Today, utility incumbents are often data rich but intelligence poor, collating vast amounts of asset data in asset registers, without necessarily linking it back to an asset strategy designed to support long-term business goals. This takes its toll on utility asset decision-making, often resulting in lackluster return on (asset) investment and value leakage.

Exercising tight planning and controls to manage data quality makes organisations far better equipped for timely, cost-effective interventions. But collecting and managing the right data throughout the asset lifecycle requires robust organisational discipline, particularly where large asset fleets are concerned, as these demands increase with the exponential growth in data volumes.

To turn asset management into asset excellence, leading organisations need to incorporate the following three considerations into their asset strategy:

1. Treat data as an asset class. Data and data culture need to be key priorities for the organisation. Data has strategic significance, can be leveraged and monetised, and requires appropriate management — so it should be valued as an asset in its own right. This means identifying, collecting and standardising asset data critical to decision-making; establishing governance and processes to manage information — how it is acquired, cleansed, stored, secured and evaluated; creating a data-driven culture with accountability around data; and taking a commercial view of data that prioritises investment and balances short and long-term costs and benefits.

2. Seek out opportunities to exploit data across the whole organisation. Data should be integrated across platforms — such as operational technology, finance and asset systems — to unlock additional insight and promote truly joined-up thinking. Where appropriate, organisations should partner with specialists to gain cost-effective access to new data and analytical capabilities

3. Pursue insight through enabling technologies and analytical capabilities.

Organisations need to commit to consistent investment and development of enabling technologies (such as analytic, AI, augmented reality, blockchain, etc.) across the P&U value chain.

Digital disruption and technology innovation provides not only the motivation but also the means for utilities to make the data work for them and reinvent the way energy assets perform in a sector undergoing rapid transformation.

Those that embrace digital asset management as a gateway to better decision-making and a fundamental driver of utility value will gain competitive advantage and outperform their peers. Those that don’t face a widening capability and stakeholder expectation gap on performance, service and cost, because with disruption also come new entrants – often from other sectors – that are tech savvy, agile, aggressive and cash rich.

For that reason, asset excellence must be prioritised on the board agenda to enable the appropriate cultural, strategy and policy changes across the business. For asset intensive P&U businesses, harnessing the power of data and asset management has never been more important to reinvent themselves as a disruptor, not the disrupted.

The views expressed in this article are the views of the authors, not Ernst & Young. This article provides general information, does not constitute advice and should not be relied on as such. Professional advice should be sought prior to any action being taken in reliance on any of the information. Liability limited by a scheme approved under Professional Standards Legislation.

Data is now a crucial part of the decision-making process, with the ability to report on events as they occur now more important than ever. NHP offers a variety of analytics and reporting solutions that ensure your data is always visible to those who need it.

Ensuring the right operational information gets to the right people in your organisation at the right time is becoming increasingly challenging. With the likely reality of scattered data sources, legacy equipment with limited integration capability, and insufficient security, an organisation’s ability to get data into the hands of their decision makers has never been more critical. Add to that the varied corporate and IT requirements, and the puzzle becomes even more complex.

NHP delivers reporting and analytics solutions for operators using FactoryTalk® Analytics for Machines by Rockwell Automation. This software easily integrates with Allen Bradley® controllers, gathering important data in the background and reporting on machine performance in real time for machines located anywhere in the world.

The web-based application delivers user-specific reports of real-time Key Performance Indicators (KPIs) to decision makers. This contextualised information, gathered from what used to be separate systems, allows decision makers to take action as events occur on the plant floor.

The Azure cloud application integrates seamlessly with

The web-based application delivers user-specific reports of real time Key Performance Indicators (KPIs) to decision makers. This contextualised information, gathered from what used to be separate systems, allows decision makers to take action as events occur on the plant floor.

the machine, turning your assets into true Industrial Internet of Things (IIoT) devices. This ability to monitor operation remotely allows the machine builder to constantly adapt and enhance your machine’s performance, even at a distance.

Moving from a mindset of infrequent, major machine upgrades, to one of continuous improvement of assets throughout their lifetime, will fundamentally change your approach to selecting equipment in the future.

The benefits of improved data visibility is by no means limited to new machines. NHP offers enterprise-wide, locally hosted reporting and analytics solutions via FactoryTalk® VantagePoint and FactoryTalk® Metrics. These platforms connect to Allen-Bradley® Automation Controllers, Historians and SCADA to collect, interpret, display and report plant-wide data easily and meaningfully.

Whether management needs a site-wide real-time dashboard and regular reports sent directly to their inbox, or maintenance staff need access to a granular, detailed view of a machine’s performance on their handheld device, NHP can customise the perfect solution to improve your operation using the data you already own.

When it comes to bolstering your water and waste water capabilities, it’s not just about accessing and aggregating data, it’s about making that data work for you. Control systems are inherently data-heavy, but that data provides no value unless it’s transformed into information.

NHP

Rockwell Automation’s FactoryTalk®

Analytics for devices is a hardened appliance that helps avoid costly downtime and improve productivity by proactively identifying device health.

From a sensor to machines all the way through your enterprise, NHP brings to the local market complete industrial automation solutions that will lay the foundation for the future direction of your IIoT (Industrial Internet of Things) strategy.

To implement NHP’s scalable analytics, visit nhp.com.au/more/FactoryTalk

Icon Water has been delivering water and sewerage services to the nation’s capital and surrounding areas for over 100 years. More recently, the utility has been focusing on modernising its systems and processes, recognising the importance of big data and analytics in informing business decisions. It’s this data-driven approach that won Icon Water the 2017 Australian Water Association’s Infrastructure Project Innovation Award.

Icon Water service Australia’s largest inland city with a reach of roughly 400,000 people through 6,600km of water and sewerage pipes and an asset portfolio worth over $2 billion.

Last year, Icon Water, in collaboration with industry partners SEAMS and AECOM, won the 2017 Asset Management Council Cost, Risk and Performance Excellence Award and the ACT Australian Water Association’s Infrastructure Project Innovation Award for its customercentric approach to its Sewer Network Maintenance program using big data.

These awards recognise how Icon Water has applied Enterprise Decision Analytics to develop its Sewer Network Maintenance program to achieve a balance between cost, risk and performance objectives.

The project is an example of an emerging area in asset management using big data and advanced analytics to inform investment decisions. SEAMS UK and AECOM developed the asset management model in conjunction with the University of Exeter in the UK. The model has been used widely with UK utilities, including Scottish Water, Yorkshire Water, Sever Trent Water and South West Water - but is a first for Australia.

Enterprise Decision Analytics allows Icon Water to effectively locate high risk sewer pipes in the network to ensure they can minimise impact to customers. It allows for efficiency improvements in completing maintenance activities and monitor the “hit rate” for locating pipes to repair or replace through CCTV work investigation.

The greatest value comes from being able to model customer impact of sewer breaks and blockages. This means Icon Water can estimate the probability and impact of sewerage incidents to customers, which will allow prioritisation of works to proactively prevent incidents.

Icon Water’s General Manager Infrastructure Services, Ray Hezkial, highlights the benefit to utilities when they put the needs of the customer first.

“Previously, modelling for renewal works was heavily influenced by the age of the infrastructure, not necessarily on what impact it might have on the customer," Mr Hezkial said.

“The assumption was that the older the pipe, the more risk of it breaking. What we found with our Enterprise Decision Analytics modelling is that this assumed relationship was not the case.

“The Enterprise Decision Analytics model highlighted that our water and sewerage pipes laid in the 1960’s-1970’s were more likely to break or block and have a greater impact on customers than our pipes that are closer to 100 years old.

“Going forward our mains renewal program is now based on our award winning Enterprise Decision Analytics which ensures we can proactively minimise impacts to our customers by more effectively targeting areas that are susceptible to failure.

“Our targeted sewer mains renewal program has already reduced blockages by 60 per cent since 2008, more than double our original target.

“Our water and sewer mains renewal program in 2018 will be one of our bigger years, with over 26km of pipe in over 40 suburbs across Canberra to be replaced before 30 June.”

Mr Hezkial highlighted the focus of Icon Water to ensure its technology systems and processes stay modern to continue to deliver value for customers.

“The next three years will be significant for Icon Water. We gave ourselves the mandate in our Enterprise Asset Management Strategy to maximise value to customers by balancing cost, risk and performance," Mr Hezkial said.

“A major deliverable in that strategy is the continuous improvement of asset information and data systems and the renewal of our asset and works management system.

“To ensure we continue doing great work for our community it is important we continually improve our systems and processes, and develop our people in the skills to use them."

Edge Underground is a precision microtunnelling contractor that operates in Australia and the USA. With a focus on innovative technology and expertise, Edge Underground designs and enhances the performance of trenchless equipment.

• Microtunnelling

• Pipe Jacking

• Thrust Boring

• Laser Tunnel Boring

The main game at Taggle Systems is the low-cost collection and delivery of data for our water service provider customers. So, it was with some excitement that, just before Christmas 2017, we reached the milestone of delivering one billion domestic water meter readings in a calendar year for the first time.

As exciting as it was then, and thinking about it now as we put our heads down for 2018, we realise there’s a very long way to go.

Depending on who you ask, we estimate there’s about 10 million domestic water meters in Australia, give or take, of which we currently collect hourly water consumption data from about 115,000. That’s less than one per cent of the national fleet.

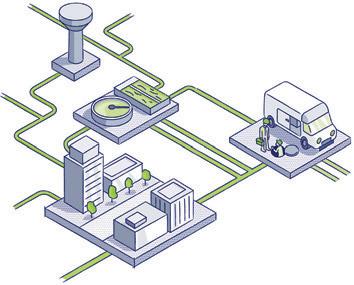

But that’s just water meters. When you look deeper into the Taggle ecosystem, you begin to realise that the scope of what we do extends way beyond simple water meters and that the potential for low-cost data acquisition using our LPWAN within the water sector is enormous.

SCADA has long been the monitoring and control hub for water utilities and will continue to be so for many years to come. What’s changing though is the availability of additional, what you might call secondary data, that provides much wider context for what is seen through a traditional SCADA system. Operational situations can now be seen through a wider lens which allows for better decision-making with greater certainty.

Taggle’s Low Power Wide Area Networks now enables the collection of data from a variety of devices that previously was uneconomical. We have established compatibility with equipment and software from well-known suppliers such as Siemens, ABB, Krohne, Itron, Enware, Schneider Electric, Evoqua, Honeywell/Elster, Hyquest, Vaisala, Davis Instruments, Tech One, Civica and others to create what might be described as a Taggle ecosystem.

Data collected in relation to water flow, water pressure, water quality, barometric pressure, wind speed and direction,

rainfall, sewer overflow, stormwater and flooding all add to the richness of the information to be seen in SCADA and other platforms.

The exploration of this data, looking at it from different angles and in different combinations, is already providing new insights into how water supply networks behave and how they might be improved.

To make all of this data as accessible as possible, we provide open standard delivery options such as DNP3, MQTT, AMQP, REST web-services, HyperCat and ODBC. Future developments will see OPC-UA added to the list. DNP3, in particular, should be of great interest as it is the de facto communications protocol for Australia’s water-related SCADA systems.

HyperCat, widely seen as the up-and-coming API protocol, will enable a lot of a water utility’s data to be shared with other users. As an example, rainfall data collected from densely distributed low-cost rain gauges can be used for context within a SCADA system while, at the same time, be available for use in hydraulic modelling, flood prediction and sewer network monitoring within the water supply organisation.

External users could also have access and the relatively low-quality rainfall data could be used to augment the more accurate data collected by, for example, the Bureau of Meteorology, to provide more informative trend information. Or it could be used by local farmers to improve their management of soil moisture for their crop production.

All of these are not just possibilities. They are available now.

And we’re just getting started.

Platinum Sponsor:

August 20 -23, 2018

Gold Coast Convention and Exhibition Centre

Queensland

Join fellow colleagues from several Oceania nations for the inaugural damage prevention industry conference to educate stakeholders on damage prevention and safe excavation. A showcase of best practice and international learnings for damage prevention efforts on underground assets and essential infrastructure.

Gold Sponsor:

Supported by:

Founding Sponsors:

•Plenary Sessions

•Networking Functions

OceaniaDPC.com

Owned

by Roger Jeffrey, utilities sector specialist and consulting partner at Deloitte

by Roger Jeffrey, utilities sector specialist and consulting partner at Deloitte

The impact of distributed generation on residential customers is currently a hotly debated topic. Driven by the continued evolution of battery storage, improvements in solar efficiency and newer microgrid technologies, the spectrum in opinions of when the majority of residential customers will go off-grid ranges from a few years to several decades.

SWhat would it take for residential customers to go off-grid?

o what would it take for the majority of residential customers to go off-grid? There are a number of elements that need to be addressed and key challenges identified that would have to be overcome to accelerate adoption. Some of these include:

For many residential customers, the cost to procure and maintain microgrid solutions are perceived to be prohibitive. Significant cost reductions combined with improved efficiency in solar and battery will definitely increase adoption, however, government incentives or regulatory interventions will still be required for many customers, particularly for lower socio-economic groups.

‘Microgrid as a service’, where customers pay a regular fee and lock into a contract similar to a mobile plan, already exists, although take up so far has been low. The continued reduction in the overall cost, as well as more competition from traditional and nontraditional providers, should improve adoption of this offering.

Community microgrid sites significantly reduce the cost by sharing infrastructure and solar. Increasingly, developers are becoming generators for new estates and buildings which accelerate community grid solutions. Project Brooklyn in New York is a great example of this already happening.

There will always be reasons why customers are too busy to make the switch. A major black swan event, like the blackouts in South Australia, may drive customers to look for alternatives.

Accelerators will include the advancement of technologies, where a simple voice command will authorise required services. Others may include the increased role of aggregators and government regulations to improve the transparency of current tariffs and

alternative cheaper options. Simplicity to make the change is essential.

New house construction where micro-generation is mandatory will make an impact. For existing homes, government regulations, incentives for landlords, or shared solar schemes will be required.

It may eventually become feasible to develop ‘plug and play’ solutions. Regulatory and safety concerns will need to be managed, but these are not insurmountable. Why couldn’t solar panels be plugged into existing construction frameworks which landlords were mandated to fix to the top of house roofs?

Microgrids are still new, but rapidly maturing. Current technological limits mean the physical size of batteries and solar panels prohibit many households from deploying the amount required to meet their needs, though we are familiar with how rapidly technology can advance. It will happen faster than most people predict given the global investment occurring at present, particularly in China.

Global standards will need to be agreed and billions in research and development spent, but the size of the prize for successful providers is enormous. Limitations on materials required for batteries may slow progress in the short-term, but substitutes no doubt will be quickly found.

Solar power is great, but how do you meet demand at night? Time shifting of power generation will be required to meet peak demands.

The advancement of battery storage and technologies that allow power usage to be deferred to peak power generation times will be critical drivers for this success, but they are still

realistically three to four years away from widespread adoption. The ability to share excess electricity between neighbours, whilst a potential game changer, will be subject to a whole host of regulatory requirements.

Customers are used to incumbents automatically fixing outages that occur, but what happens when a massive storm hits that impacts a number of houses, or the batteries fail? Who will provide the operational support to restore power? Customers need confidence that if things go wrong, power will be restored quickly; support and maintenance plans will be important.

There are numerous regulations that need to be overcome before mass market adoption becomes mainstream. Changes to existing regulations to balance risk, safety and cost, with ease of deployment are required. New regulations to deal with emerging trends such as blockchain, electric vehicle charging, peer-to-peer lending, renewables on roofs, and data ownership will need to be created.

Customers need to trust the products they are purchasing are durable and the providers will survive and honour any warranty issues. They need confidence the performance of microgrid solutions won’t rapidly deteriorate over time requiring additional, ongoing and expensive upgrades. Solutions that show the performance of microgrid technologies

and how to optimise them must be a standard.

Governments and suppliers would need to provide certainty to the market that customers would not retrospectively be subject to additional charges should they go off-grid, for example new charges to cover the diminishing number of customers who have to share the burden of those leaving the grid.

Governments and private enterprise have invested billions of dollars in building and maintaining networks. The financial implications of stranded assets, and the loss of revenue for incumbents and the government would be substantial.

Incumbents would need to quickly adapt to a world of mass market adoption by introducing new business models that may include selling and/or maintaining solutions and warranties. For utilities with long-term government leases, the response would depend on the contract and any potential guarantees of supply. The impact on government revenue would need to be modelled to balance increased revenue from providers of off-grid solutions, with the loss of revenue from incumbents.

There will always be customers who don’t want to change no matter how good the deal. At the very least, legislation to mandate solutions, word of mouth and proven solutions will be required to win over the final resistors.

Whilst there will continue to be lots of discussion about the impact of batteries, solar and more complete micro-generation solutions, the reality is there are numerous obstacles that must be overcome before the majority of residential customers go off-grid. It will take many years, if not decades. In the meantime, the most likely scenarios leading the way will be early adopters, more remote locations and community grids whilst the general population take a wait and see approach and regularly check the cost, benefit, risk equation.

Energy Queensland’s new business Yurika has built Australia’s biggest Virtual Power Plant. Here, Executive General Manager, Charles Rattray, explains why it is a game changer for the industry, market participants and customers.

In listening to customers and visiting communities from the Torres Strait to Tasmania, it is clear to me that affordability is the biggest issue. Before we can work out the most cost-effective, innovative and simple energy solutions, we need to speak with customers to understand their challenges.

One solution is to reduce their overall demand or energy usage at high price times. We have an innovative solution that works – a Virtual Power Plant (VPP). VPPs save customers money by avoiding some demand charges, avoiding peak price events or by selling their capacity into the wholesale market for additional revenue or to support networks in some areas.

Virtual Power Plants (VPPs) help to optimise distributed energy resources (DER) to maximise their value for the VPP user and provide other market benefits, taking into consideration the operational constraints of the underlying DERs, the prevailing markets and physical condition of networks.

In the Yurika VPP, we utilise a cloud-based, load control platform which provides visibility and remote control of DER, connected to the VPP through Internet of Things devices. There are a number of different software platforms in the market. We opted for Australian company GreenSync’s technology, which is DER agnostic.

Most VPPs have effectively been born out of a fleet management system for whatever kind of asset they have been asked to switch. It is a logical evolution from fleet management to a VPP.

Recognising the need for DER and devices that support them, engineering companies built physical devices in order to fill a gap in the market.

It soon became clear that those assets were worth more coordinated together, not only in terms of value but also in the additional services they could offer. All of a sudden, the product offering has had to become more sophisticated.

If you had a choice between a battery that could be installed, but you had to go out and check on it every six months, or a battery that was internet connected which you could monitor and control as frequently as needed and understand how it was performing or remotely re-configure it – there is clearly a lot more value for the user in the second option.

The value of a VPP, compared to a regular power plant, is the cost of acquisition and that it utilises assets that have already been purchased and deployed.

At the end of the day, both regular power plants and VPPs are trying to help balance supply and demand. A VPP is used to increase supply through smaller assets rather than large power stations, or decrease demand in terms of curtailing load.

The net impact on the system is the same, albeit with lower capital requirements, and the VPP allows you to aggregate many smaller devices, which may be more economic for the end customer than the large capital requirements to build a regular power station.

There are clearly environmental benefits as well. Most traditional power stations are currently burning fossil fuels, be that gas or coal or some other fuel, whereas most VPPs can assist with the uptake of renewable technologies.

AGL’s decision to close the aging Liddell Power Station in 2020 is a sign of the times. Regardless of the politics, regardless of the environmental issues, from an economic point-of-view it is fast becoming cheaper to roll out grid-scale renewables and soon battery storage will be widespread.

Because of the inherent intermittency of wind and solar, we need to balance them out with flexible loads in addition to the use of storage. As the supply fluctuates due to environmental conditions, we can tap into additional generation assets, like storage, or reduce demand through industrial processes, agricultural processes and smaller things such as air-conditioning systems or pumping loads.

The real advantage of pairing those two things in a VPP is that you can actually create a much firmer generation product because you can remove the intermittency associated with those assets, firming up that portfolio over time.

The future is about bringing as much flexibility into the grid as we possibly can to support renewables. VPPs require and complement the grid.

Furthermore, a significant strength of a VPP is that it aggregates loads and supply which have disaggregated locations. It’s made up of individual DER working in a coordinated way, and the only way they can be coordinated is if they’re physically connected.

That is where the grid comes in – that’s the physical connection, that’s how we tie this whole thing together, it is a physical system. It is the physics of the electrons powering our society. You need that physical connection in order for it to work.

That’s why the future of the distribution business is incredibly bright, albeit in newer ways as new markets emerge. Those networks will effectively form the internet of energy.

I cannot see any major roadblocks and certainly no technical impediments to the success of VPPs in bringing value to communities. It’s really about how quickly large companies in our sector can get their heads and strategies around evolving towards where the future is going.

For Yurika, part of the Energy Queensland Group, innovation is a core value. Our core business is the safe delivery of affordable, reliable and sustainable energy solutions, in partnership with our customers and communities. I see this ground-breaking VPP as a shining example of both, and a beacon for the energy industry.

Increased levels of clean, locally generated electricity and rapid technological change mean that customers want better and fairer solutions for their power. In order to stay relevant and not get left behind, electricity retailers need to reinvent their relationships with customers.

Customers are becoming more concerned about their power bills and are investing more and more into technologies that allow them to better manage their electricity use such as rooftop solar, batteries, and other tools that allow them to monitor and control household appliances. Modern customers also care about more than just themselves, and are looking for ways to be part of the solution to global energy problems, rather than adding to the problem.

The dramatic and continued drop in costs of technologies like solar PV has also impacted energy markets with onsite, utility or community-scale generation projects now becoming a genuine option for commercial and community organisations.

The challenge then, for retailers, is to work out how to fit into this changing environment and provide customers with what they want.

This new generation of energy customer wants things like:

• Freedom to pick and choose how they interact with the energy market to make it work for them and their lifestyle

• Accessibility to see their usage and daily charges via phone apps

• Community sharing to make a positive difference

Our Energy works in partnership with retailers and customers to bridge the gap between the old retail model and new customer expectations.

For example, Our Energy’s Lemonade is a white label tool for retailers - a digital marketplace which creates virtual local energy markets that operate alongside traditional systems.

Lemonade allows customers to buy, sell or gift clean, local energy with their community, and helps retailers improve acquisition and retention results in a rapidly changing business environment

Lemonade provides customers with a digital experience that is simple, accessible and transparent at no additional cost. Delivered under a software-as-a-service model, a retailer adopting Lemonade retains its customer, billing and market reconciliation responsibilities.

Lemonade’s focus is on tying individuals into actual communities, not virtual ones. For example, families can gift energy from their home solar system to their child’s school, buy energy from the community wind or solar farm, sell energy to neighbours or give it as a fundraiser prize for a local club.

By building communities of customers, Lemonade can help retailers in two key ways:

1. Firmly aligns the brand with the values and behaviours of a new and expanding generation of customers; freedom, accessibility and community

2. By making customers ‘stickier’, allowing them to choose community over commodity. Being part of a community makes them more reluctant to switch as they won’t just be leaving a retailer, but their community as well.

By partnering with Our Energy, and putting communities at the heart of rapidly evolving digital, decentralised and decarbonised energy systems, retailers can unlock new opportunities in the face of unprecedented technological change.

If you’d like to learn more about working with Our Energy, including running pilots of Lemonade, contact team@ourenergy.co.nz.

A new transformer was recently delivered and installed at AusNet Services’ Richmond Terminal Station with detailed planning and careful stakeholder management proving to be vital to the project’s success.

The new transformer is part of the Richmond Terminal Station rebuild, involving the replacement of the 22kV, 66kV and 220kV Air Insulated Switchgear (AIS) with a mixture of AIS and Gas Insulated Switchgear (GIS), along with constructing new buildings to house the switchgear, replacing old transformers and reconfiguring the site layout.

While the rebuild takes place, the terminal station must continue to supply electricity 24 hours a day, seven days a week, which makes the delivery and installation of a new transformer extremely challenging.

As AusNet Services’ delivery partner, Zinfra’s role in the transformer delivery was the coordination of all the stakeholders involved, to ensure alignment of the many moving parts in this large, complex, brownfield project.

Delivery of the single new transformer, weighing 279 tonnes (or roughly 46 elephants) required months of planning and preparation. Multiply these preparations over the removal and installation of four transformers and this extrapolates to weeks of work just for this aspect of the project.