Beyond thirty

Wastech CEO Clete Elms has a clear vision to transform the company into a national entity for waste solutions.

FEATURES

Tour of duty

Calcuated risks

Grinding in the Top End

New hope for mining waste

PROUDLY SUPPORTED BY:

AUGUST 2023

PMS 380 PMS 376 PMS 355

COVER STORY 20

BEYOND THIRTY

Australian manufacturing company

Wastech marks a major milestone and sets a vision statement for the future.

46

WOMEN IN INDUSTRY

Student

“WASTECH SEES A REAL OPPORTUNITY TO BECOME

SUSTAINABILITY EXPERTS THROUGH TECHNOLOGY AND INDUSTRY INNOVATION.”

- Clete Elms, Chief Executive Officer, Wastech

In this issue

Features

32 CHEMICAL BROTHERS

DAF trucks helps keep Unanderra Tanker Hire, a leader in chemical transportation, on the road.

34 RESOURCES RECLAIMED

National Resource Recovery leverages a growing demand for hazardous waste solutions.

36 NO FIRE OR FLAMES

FLIR explains the benefits of thermal imaging cameras to help prevent fires.

38 GRINDING IN THE TOP END

When home is 700 kilometres away, Komatsu Forest helps get things done.

40

NOT THE STANDARD FARE

National Transport Research Organisation helps increase the use of recycled materials.

42 SWITCH IT UP

44 REDEFINE RELIABILITY

Caterpillar boosts machine performance and reliability in an already robost landfill compactor.

46 TAIL’S END

A winner at this year’s Women in Industry Awards, Ashara Moore aims to make the mining sector ‘better’.

48 WASTE WATCHDOGS

Victoria’s leading waste regulators come together for an industry breakfast at Waste Expo 2023.

51 BUILDING MOMENTUM

The inaugural 2023 Inside Construction Expo is taking shape.

52 COUNCIL IN FOCUS

Bayside Council New South Wales adds another award to its collection.

Regulars

54 PRODUCT SPOTLIGHT

WestRex

ALLU buckets keep recycling and resource recovery operations one step ahead.

57 LAST WORD

12 HUNGRY FUNGI Researchers discover strains of fungi that could offer a solution to help break down Polypropylene. 15 INDUSTRY INSIGHT Tony Khoury reflects on more than 30 years in the waste and resource recovery industry. 18 THE BREAKDOWN Industry leaders have their say on current issues. 20 COVER STORY Wastech Engineering sets a course for beyond 30. 24 GLOBAL RECOGNITION Water & Carbon Group technology is achieving success in leachate treatment around the world. 26 CHARGING AHEAD E-waste recycler Ecocycle prepares for a massive increase in EV battery waste. 29 CALCULATED RISK

provides sustainable solutions to a niche market.

awarded for research that could positively impact mining’s greenhouse-gas emission targets.

4 / WMR / August 2023

Call: Email: Visit: 03 9706 8066 sales@appliedmachinery.com.au appliedmachinery.com.au genoxmachinery.com.au At Applied, our number one priority is ensuring that our customers across the country get the machinery they need, with the support they expect. With nearly 30 years’ experience, and thousands of satisfied customers across the country we’re here for the long term. We’re a true machinery partner – just ask Steve Morriss. Real Service. Real Support. Real People. That’s Applied Thinking.

ISSUE IS FIXED STRAIGHT

THAT’S

“ANY

AWAY.

THE BENEFIT OF A LOCAL SUPPLIER WITH FULL TECHNICAL SUPPORT AND BACK-UP.” STEVE MORRISS, CLOSE THE LOOP, SOMERTON, VIC

From the Editor

Handle with care

Lithium-ion batteries have found their way into common household devices from mobile phones and laptops, to e-bikes and e-scooters.

Recent research suggests an increasing uptake in electric vehicles (EV), driven by environmental and cost benefits, will mean Australia is left with up to 30,000 tonnes of end-of-life EV batteries by 2030.

The numbers alone are concerning, but it’s exacerbated when you consider Australia doesn’t yet have the capacity or infrastructure to safely handle that number of end-of-life EV batteries.

In Melbourne, e-waste recycler Ecocycle is on the front foot, investing millions into transportation devices and technology to safely strip back and recycle battery components.

Zoltan Sekula, Product Stewardship Manager, says it’s too late to shut the gate once the horse has bolted. In this edition of Waste Management Review, Sekula outlines the lengths the company has gone to in preparation for the influx.

It’s not just batteries that require a specialist approach. Hazardous waste continues to grow faster than other waste streams in Australia. Tighter regulatory controls and community expectations add complexity to an already dangerous situation.

As this edition highlights, Australia is rich in industry experts who have pivoted their business to maximise resource recovery from wastes that were previously destined for landfill.

Our cover story is also an example of a company leveraging its expertise to take it into the future. As Wastech marks a 30-year milestone it’s asking the question –what does 30 and beyond look like? Recently appointed Chief Executive Officer Clete Elms provides a glimpse into the company’s future.

And when it comes to the future, the industry is in good hands. Ashara Moore, winner of the Excellence in Mining award at the recent Women in Industry Awards, takes us through her work to find a more sustainable solution for tailings waste.

Happy reading

Lisa Korycki

CHIEF OPERATING OFFICER

Christine Clancy christine.clancy@primecreative.com.au

GROUP MANAGING EDITOR

Sarah Baker sarah.baker@primecreative.com.au

MANAGING EDITOR

Mike Wheeler mike.wheeler@primecreative.com.au

EDITOR

Lisa Korycki lisa.korycki@primecreative.com.au

JOURNALIST

Chris Edwards chris.edwards@primecreative.com.au

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR

Blake Storey blake.storey@primecreative.com.au

DESIGN

Louis Romero, Kerry Pert

BRAND MANAGER

Chelsea Daniel chelsea.daniel@primecreative.com.au

p: +61 425 699 878

CLIENT SUCCESS MANAGER

Justine Nardone justine.nardone@primecreative.com.au

ACCOUNT CO-ORDINATOR Marina Milisavljevic marina.milisavljevic@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd 379 Docklands Drive Docklands VIC 3008 Australia p: +61 3 9690 8766 f: +61 3 9682 0044 enquiries@primecreative.com.au www.wastemanagementreview.com.au

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au

Waste Management Review is available by subscription from the publisher. The rights of refusal are reserved by the publisher

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Waste Management Review is owned by Prime Creative Media and published by John Murphy.

All material in Waste Management Review is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Waste Management Review are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

6 / WMR / August 2023

DELIVERING A GREENER FUTURE

Komptech CEA is a leading supplier of machinery and systems for the treatment of solid waste through mechanical and mechanical biological treatments, as well as the treatment of biomass as a renewable energy source. Komptech CEA is proud to provide innovative solutions for handling waste and biomass.

Komptech CEA’s extensive range of products cover all key processing steps in modern waste handling. At Komptech CEA the focus is always on innovative technology and solutions ensuring maximum benefit to the customer. Like to know more? why not speak to one of our team today?

SHREDDERS TROMMEL SCREENS STAR SCREENS WINDROW TURNERS

1300 788 757

TERMINATOR

Where Function Meets Technology

A slow-running, single-shaft shredder suited to all types of waste.

CRAMBO

Less Fuel, More Power

Ideal for shredding all types of wood and green cuttings.

TOPTURN X

The Ideal Combination of Performance and Design

With a sturdy frame, powerful hydraulics and large drum, the Topturn X is ready to handle any work situation.

MULTI STAR

Screening with a Star

Makes waste wood and biomass processing highly efficient.

NEMUS

Robust and Reliable

Combining the practice-proven virtues of its predecessors with new solutions for even greater performance.

AXTOR

Shredding and Chipping Made Easy

One of the most versatile machines around for processing wood and green cuttings.

komptechcea.com.au

$8M for waste-to-energy projects

The Victorian Government has funded 24 projects to create renewable energy from organic waste that would otherwise end up in landfill.

More than $8 million has been provided through the Waste-toEnergy – Bioenergy Fund which is supporting farming and food production, and other industry sectors to turn organic waste –including agricultural, livestock, food, and wood waste – into electricity, heat, gas, or liquid fuel.

The funding supports a range of Victorian businesses to transition their operations to renewable energy and drive down their emissions.

The projects are forecast to boost Victoria’s renewable energy capacity by an additional 6.82 megawatts (MW), enough to power 3410 homes with renewable energy.

Ingrid Stitt, Environment Minister, said the funding sends a strong signal to the state’s industries of the critical role waste-to-energy has towards reducing emissions.

“These funded projects will create regional jobs and income streams for farmers, while increasing Victoria’s bioenergy generating capacity by over 6.8 megawatts,” Stitt said.

“This is a win for cutting the amount of waste we send to landfill, a win for generating more renewable energy in Victoria, and a win in helping drive down our emissions.”

Goulburn Valley tomato grower Katunga Fresh has received a $1 million grant to turn spent tomato plants into a gas that will be used to heat the grower’s glasshouses, with excess gas returned to the grid.

Another project will allow dairy business Australian Consolidated Milk to convert cheese whey waste into biogas that will be used to power its dairy manufacturing plant, reducing reliance on fossil fuels.

Gayle Tierney, Minister for Agriculture, said the projects will allow producers to become more energy efficient while providing them with new opportunities to develop new revenue streams. Funded projects will create up to 192 shortterm jobs.

Minister rules on Wanless Park

The Queensland Government has refused part of the Ministerial Call In for the development application for the Wanless Recycling Park in Ipswich.

Steven Miles, Deputy Premier and Minister for Planning, has approved the resource recovery facility and waste transfer station and refused the landfill and void rehabilitation components of the development application, following advice from the Department of State Development, Infrastructure, Local Government and Planning.

Miles said the proposed resource recovery facility and waste transfer station facility supports the government’s vision for a zerowaste society, supports jobs, and contributes to the local economy. However, key reasons cited by the department for refusal of the landfill and void rehabilitation components include no demonstrated requirement for additional landfill capacity, insufficient economic benefit, non-compliance with applicable planning instruments and significant community concern and opposition.

Waste company Wanless had proposed to construct a resource recovery and recycling precinct at Ebenezer, southwest of Ipswich CBD.

In September 2021, the Ipswich City Council rejected part of the application for a new landfill while supporting the transfer and resource recovery facility.

In January 2022, the Queensland government called in the application to allow an assessment of the project, including its ability to support the waste reduction and recycling objectives.

8 / WMR / August 2023 News

Australian Consolidated Milk will convert cheese whey waste into biogas.

WASTE MANAGEMENT SERVICES

Specialising

Family owned and operated.

in Prescribed Hazardous Waste/EPA Regulated Waste with a fleet of licensed vehicles, including tankers and rigid trucks collecting waste from Automotive, Manufacturing, Industrial and Construction Industries.

nationalresourcerecovery.com.au

For additional information or a confidential consultation on any of our services, please contact us 03 9720 4177

| P.O. Box 267, Bayswater 3153

Follow the crumbs in Tasmania

The Tasmanian Government expanded the use of crumb rubber in the state’s road resurfacing tenders from 1 July 2023.

Michael Ferguson, Minister for Infrastructure and Transport, said the opening of a new crumbed rubber blending plant in Launceston demonstrates the growing use of recycled materials in road surfaces, underpinning a record road and bridge infrastructure program in Tasmania.

He congratulated Fulton Hogan for its commitment to promoting sustainability in its roadworks operations, with its new Mowbray plant now employing 50 Tasmanians.

A total of 18 sites were completed using a crumb rubber asphalt mix during the state’s 2022-23

resurfacing season. Following the civil construction industry’s positive response to the initiative, crumbed rubber has been expanded into the government’s broader resurfacing tenders from 1 July 2023.

“Through the Department of State Growth, we are expanding the use of crumb rubber in the state road resurfacing program,” Ferguson said.

“Nine sites will be targeted for resurfacing using crumb rubber in 2023-24, with consideration also given to including crumb rubber in some new construction projects.

“We are providing $4 million over four years to assist industry through the transition to using crumb rubber in road resurfacing and ensure there is no disruption to our roads program.”

He said the government will continue to work with industry to look for further opportunities to expand the use of crumb rubber in road resurfacing in the future.

In November 2022, the government began an expression of interest process for its Waste Tyre Reprocessing Grant Program: Roads to Resource Recovery.

Under the program, the government will provide up to $3 million to partner with industry to develop a rubber crumbing plant, or provide alternative and sustainable solutions for the recovery of end-of-life tyres.

The primary focus of the grant program is to invest in a rubber crumbing plant to produce materials for reuse in road surfacing across Tasmania.

10 / WMR / August 2023 News

Eighteen sites were completed using a crumb rubber asphalt mix during the Tasmanian 2022-23 resurfacing season.

Pure unites people and technology to transform the circular economy through advanced resource recovery.

We strive to be Australia’s leading resource recovery specialist, providing viable solutions to meet our customers needs.

pure-environmental-pty-ltd 10/333 Queensport Rd North, Murarrie QLD 4172 T: 1300 652 774 E: info@purenv.au W: purenv.com.au pure transforming the circular economy

Hungry fungi

UNIVERSITY OF SYDNEY RESEARCHERS

Polypropylene is a common plastic used for a variety of products from packaging and toys to furnishing and fashion. According to the University of Sydney, it accounts for about 28 per cent of the world’s plastic waste, but only one per cent of it is recycled.

A team of University of Sydney researchers have found strains of fungi that will degrade plastic over time. The team hopes to use its findings to develop disruptive recycling technologies, especially those driven by biological processes, that improve the circularity of plastics.

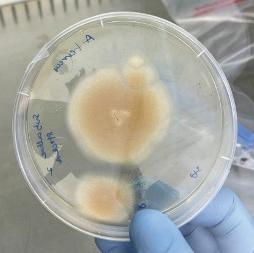

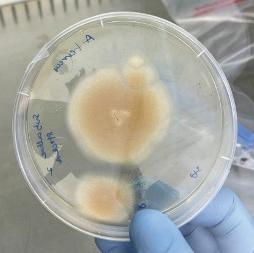

Amira Farzana Samat, a PhD student under the supervision of Professor Ali Abbas, a Professor of Chemical Engineering at the University of Sydney and Australia’s Chief Circular Engineer, and Dee Carter, Amira’s Co-supervisor and Professor in the School of Life and Environmental Sciences at The University of Sydney, were all involved in the research into the plastic’s degradation.

“A biological approach has attracted increasing interest over the past decade as a form of low-energy waste recycling,” Amira says. “Fungi possess mycelium, a root-like structure with the ability to bind to most surfaces, and can produce enzymes to degrade polymers or utilise carbon in the polymer chain as their carbon source.”

The trio have been conducting research into two types of fungi, Aspergillus terreus and Engyodontium album, and their ability to break down polypropylene after being pre-treated

with either UV light or heat.

Ali says the fungi reduced the plastic by 21 per cent over 30 days of incubation, and by 25-27 per cent over 90 days.

“A. terreus is a fungus commonly found in soil and is predominant in tropical and subtropical climates. They can also be isolated from decaying vegetation, specifically in compost heaps and hay silage,” he says.

“This fungus was known to produce acids, cholesterol-lowering drugs, and many biologically relevant compounds such as enzymes, for biotechnology purposes. Making it a great specimen for this research.”

Ali says that unlike A. terrus, Engyodontium genera (E. album) is rarely used in biodegradation studies.

“Only one paper mentioned the utilisation of E. album on the degradation of PP,” she says. “It showed a promising result, that lead to the current exploitation of this fungi.

“This fungus is usually found on plant materials, soil and marine sediments.

It can produce the laccase enzyme, one of the key enzymes responsible for plastic degradation.”

Professor Dee Carter, an expert in mycology (the study of fungi) and co-author of the study, says that fungi is versatile and known to be able to break down many substrates, offering a solution to plastic pollution.

“This superpower is due to their production of powerful enzymes, which are excreted and used to break down substrates into simpler molecules that the fungal cells can then absorb,” she says.

“Often, these fungi have evolved to break down woody materials, but this ability can be repurposed to attack other substrates.

“Recent studies suggest some fungi may even degrade some of the ‘forever chemicals’ like PFAS (Per- and polyfluoroalkyl substances), but the process is slow and not yet well understood.”

There is a hope, through this research, that the biological method could one day reduce the amount of plastic polluting

HAVE FOUND TWO STRAINS OF FUNGI THAT COULD OFFER A SOLUTION TO HELP BREAK DOWN POLYPROPYLENE NATURALLY UNDER CERTAIN CONDITIONS.

FEATURE NEWS 12 / WMR / August 2023

Aspergillus terreus on the Potato Dextrose agar (a growing medium for the fungi).

Engyodontium album on the Potato Dextrose agar.

the environment. Amira says she hopes the research leads to a greater understanding of how plastic pollution might biodegrade naturally under certain conditions.

“The vast majority of polypropylene isn’t adequately recycled, which means it often ends up in our oceans, rivers and in landfill,” she says.

“It’s been estimated that 109 million tonnes of plastic pollution have accumulated in the world’s rivers and 30 million tonnes now sit in the world’s oceans – with sources estimating this will soon surpass the total mass of fish.

“Since completing this part of the research, we have isolated other micro organisms from the marine environment and used a similar process to degrade marine plastic waste, with preliminary results showing better degradation.”

Amira says that this research is just the beginning and the team hopes to receive funding to continue digger deeper.

She says the study has not optimised the experimental conditions and there is room to further reduce the degradation time. Something the team hopes to look further into with ongoing support.

For more information, visit: www.sydney.edu.au

TRANSFORM WASTE INTO USEABLE MATERIAL

ALLU Material Processing Buckets turn waste into profit by producing aggregates and reusable materials from bricks, concrete, metals, wood, cardboard, glass, asphalt, waste soil or just about anything.

Wet or dry.

One ALLU can produce multiple fragment sizes, with various blade and drum configurations.

For excavators and loaders from 8t to 160t.

Processing times, cycle times and processed tonnes can be viewed and analysed via ALLU app

Scan for ALLU dealer locations in Australia or visit attachmentspecialists.com.au/allu

“Recent studies suggest some fungi may even degrade some of the ‘forever chemicals’ like PFAS.”

Professor Dee Carter University of Sydney

Ali Abbas and Amira Samat hope to expand their research.

Hazardous & Regulated Waste

WestRex Hazardous & Regulated Waste

Our sustainable range of hazardous waste treatment technologies and regulated waste disposal services are focused on maximising resource recovery from various waste streams and reducing the volumes of waste going into landfills.

WestRex are licensed to receive the following types of hazardous and regulated wastes: & Sludges Mud & Fluids

Tour of duty

AS TONY KHOURY STEPS DOWN FROM HIS ROLE AS EXECUTIVE DIRECTOR OF THE WASTE CONTRACTORS AND RECYCLERS ASSOCIATION OF NEW SOUTH WALES, HE REFLECTS ON MORE THAN 30 YEARS IN THE INDUSTRY.

Australia’s waste and recycling industry has a way of enmeshing those who work in it. Once you’re in the industry, generally you are here to stay.

Tony Khoury is testament to that. When the Fellow Certified Practicing Accountant took up the role of Financial Controller for Pacific Waste Management in New South Wales in 1991, it began a more than threedecade long commitment to the industry.

He moved on to Clinical Waste Australia where he was tasked with raising the required capital to upgrade the emissions system so that air quality met the then new Environment Protection Agency environment standards.

Today, the plant operated by Cleanaway Daniels Silverwater Medical Waste Services, is still in operation and is the last of the medial waste incinerators in NSW.

“It wasn’t as complicated or challenging back then,” Tony says.

“The waste and recycling sector is a much more sophisticated and complex industry in 2023 than it was in the early 90s.

“Thirty years ago, you’d provide a driver with a run sheet, he’d pick up the waste and drop it off. Today there are more laws, regulations, policies, procedures, and restrictions.”

The now Executive Director of the Waste Contractors and Recyclers Association (WCRA) of New South Wales, Tony has helped shape the association and turn it into a successful business entity, supported by its members and sponsors, and respected by stakeholders, including across all levels of government.

WCRA members own, operate, or control an estimated 90 per cent of the available commercial waste and recycling collection vehicles used in New South Wales and the Australian Capital Territory.

Tony’s acutely aware of the many and varied challenges faced by business operators – he references demands for better customer service, cost control, higher productivity, workplace health and safety issues, skills and labour shortages, the challenges posed by the introduction of new laws and regulations, insurance issues, and the urban sprawl, to name a few.

A staunch advocate of the industry, he’s shared his knowledge, providing training opportunities for workers including delivery of nationally accredited TAFE material across the waste management sector.

There’s been many successes along the journey.

Tony describes as “wonderful”, watching the evolution of occupational health and safety laws and national heavy vehicle regulations into national systems, laws and regulations, and his involvement in the introduction of the federal Waste Management Award 2010 (now 2020) that governs payment and conditions to all waste and recycling workers.

“It was a big job,” he says. “In developing the Award, WCRA was the only waste employer body consistently involved in the Fair Work Commission (FWC’).

“Now that it is in place, this Award has removed aggressive behaviour from the wage negotiation process with the FWC handing down an annual increase on 1

July of each year. We also have the Fair Work Ombudsman providing advice when workers and employers require support.”

Tony says one of the biggest challenges has been a lack of waste and recycling infrastructure across NSW and a disconnect between government expectations and business.

He says Sydney needs more disposal solutions in the metropolitan area. The current network of transfer stations funnels putrescible waste to the Woodlawn Eco Precinct near Goulburn and Lucas Heights for disposal.

“If there’s a breakdown in the system, or an oversupply as happens during wet weather or from bushfires, the whole system goes into stress,” Tony says.

“We require disposal solutions within the Sydney metropolitan area. Transfer stations are great, but that’s all they are, transfer facilities, not end-disposal points.”

He says a combination of factors have added to the challenges – population

INDUSTRY INSIGHT www.wastemanagementreview.com.au / WMR / 15

Tony Khoury has helped shape some pivatol national systems for Australia’s waste sector.

growth, a “throw-away society” where everything has an expiration date, an abundance of packaging materials and the closure of waste facilities over the years.

The answer, Tony says, is energy-fromwaste (EfW), but state regulations have forced the withdrawal of several projects.

“Unless things change, it is highly likely that within a decade, Sydney will experience a significant waste disposal problem. I don’t know of any other way of disposing of waste residues other than landfill or energy-from-waste.

“We can minimise the amount of waste we generate, and we can recycle more (via bins with yellow and green lids), but when it comes to the contents of the bin with the red lid, I don’t know how else we can get rid of this waste residue.”

The only live application for EfW in New South Wales is one by Veolia for a facility at Woodlawn. Tony believes it’s important for this application to be approved, not only for the waste industry, but to provide a reference point for regulators of what is possible and what good quality EfW infrastructure should look like in the state.

But even if Woodlawn is approved, there will still be an element of time involved to construct the facility.

“For the business sector to invest there needs to be certainty that regulations will not change, along with an opportunity for

an adequate rate of return on investment,” Tony says. “Many waste and recycling projects take 15 to 20 years for capital to be depreciated and for the organisation to obtain a payback on the investment.

“With the right regulatory settings, industry will develop the confidence to raise the required capital to invest in further processing solutions for New South Wales.”

The state’s waste levy is another area that needs addressing. Tony says increases in the levy have led to waste being transported from New South Wales to Queensland.

“At the height of the issue, 1.8 million tonnes of waste a year was leaving New South Wales to go to South-East Queensland for no reason other than to avoid payment of the levy,” he says.

“The waste levy was designed to encourage resource recovery and diversion from landfill and should not be used by transporters to subsidise the cost of longdistance transport. While it can be argued that it is an economic decision to avoid paying the levy, in reality there are very significant road safety and environmental issues involved.”

In Tony’s 33 years in the industry, the New South Wales waste levy has increased from $2 per tonne in 1991 to the current level of $163.20.

In terms of unfinished business, Tony believes there should be strong

consideration given to harmonise waste management laws into a federal system.

“Having six states and two territories with their own waste management laws is a bit archaic,” he says, while adding that “550 councils across the country making different decisions on waste and recycling is also far from ideal”.

Tony plans to finish up with the Waste Contractors and Recyclers Association NSW late in 2023 and is hoping to pursue a board opportunity.

In January 2017, he completed a formal program and passed the required exams admitting him to the Australian Institute of Company Directors. He has held a number of board positions including Sydney Catholic Cemeteries where he chaired the Audit & Risk Committee and currently with DOOLEYS Lidcombe Catholic Club where he chairs the Sports Council.

As well as being an FCPA, Tony is a Fellow Member of the Institute of Corporate Governance, a Fellow Member of the Australian Institute of Company Directors, holds a Bachelor of Business Degree, a Diploma in Corporate Management and has a Certificate IV in Training & Assessment TAE40110.

He describes his time with WCRA as the best years in his working career.

“In my travels around the world, nobody does containerisation, transport and collection of waste better than the Australian waste and recycling industry,” he says.

“All aspects of the system are consistent, workers are very well trained, the equipment used is at a very high standard, productivity is generally high and work health and safety standards are the highest I’ve seen.

“As transporters we are number one in my opinion, and we should all be very proud of that.”

To view the activities of WCRA, visit: www.wcra.com.au

16 / WMR / August 2023 INDUSTRY INSIGHT

Tony Khoury describes his time with WCRA as the best years in his working career.

1800 465 465 wastech.com.au BUILDING SMARTER EQUIPMENT TO HELP MINIMISE THE WORLD’S WASTE Wastech Engineering is the distributor of McCloskey Environmental in Australia. TROMMELS STACKERS SHREDDERS SCREENERS

The Breakdown

‘The Breakdown’ is a monthly column giving industry leaders and decision makers a chance to share their views on topics central to the sector.

This month we asked: ‘How can legislation better support waste-to-energy in Australia?’

Clear, nationally aligned guidelines should be developed to promote waste-to-energy adoption, covering waste segregation, disposal regulations, and emission standards. Financial incentives and grants can encourage investments, making it economically viable. Streamlining the permitting process and maintaining environmental assessments ensures efficient project development. Monitoring and reporting mechanisms should be stringent to ensure compliance and transparency, fostering an environmentally conscious waste-to-energy sector. Research and development programs must be strengthened, encouraging innovation through collaboration. Public awareness campaigns can address misconceptions, educate the community, and garner support for waste management efforts.

WCRA commissioned the Centre for Economics to undertake a review of waste-to-energy regulations and to determine the economic and environmental impacts of New South Wales regulations. Current regulations have resulted in about $2b of capital expenditure not proceeding on waste-to-energy in NSW. The last remaining proposal is the Veolia proposal for WtE into Woodlawn. WRCA absolutely supports that proposal. That facility, if it gets up, will give NSW regulators a reference point for what good, quality wasteto-energy should look like. The last thing NSW needs is another failed WtE proposal.

As we don’t recover the energy content of combustible waste consistently across Australia, it perpetuates our reliance on landfill. There are more than 500 WtE facilities operating in Europe without causing material impacts to human health or the environment. While WA and Victoria have made progress in enacting legislation to enable WtE, other jurisdictions have more constrained frameworks. To ensure WtE plays a more effective role in the waste hierarchy in Australia, we would benefit from greater flexibility to support industrial facilities pivoting to alternate fuels, a national harmonisation of regulatory frameworks, removing ambiguity around licensing and approval risk, and streamlining approvals in dedicated waste infrastructure precincts to reduce sovereign investment risk.

Better legislation should support the circular economy and not only waste-to-energy (WtE). Enforceable source separation legislation would stop the leakage of organics and recyclables into landfill. The choice between a landfill and WtE is mainly economic, which brings me to the low and inconsistent landfill levies. The levy should go uniformly to $250/t to account for the high local cost compared with the current $200/t in the United Kingdom. Invest the levy into infrastructure, not a general tax. Such legislative and financial signals will drive change, avoid emotional caps on WtE, and bring certainty to the community, industry, and investors.

If you or someone at your organisation is an industry leader and would like to be a part of this monthly column in 2023, please get in touch with Editor, Lisa Korycki lisa.korycki@primecreative.com.au

Tony Khoury Executive Director, Waste Contractors & Recyclers Association of NSW (WCRA)

Brad Searle Acting Chief Growth Officer, BINGO

Brett Lemin Executive Officer Victorian Waste Management Association

Dr Marc Stammbach Managing Director, Hitachi Zosen Inova Australia

OPINION 18 / WMR / August 2023

Versatility that’s good for business

Versatility is what distinguishes the DAF range from other trucks in its class. So you’re in the business of transporting liquid goods? There’s a DAF for that!

Whether your needs are long-distance haulage, city distribution, construction transportation, bulk or tank transport, the versatility of DAF keeps you moving, and that’s good for business.

A PACCAR COMPANY DRIVEN BY QUALITY SEE DAF VERSATILITY IN ACTION DAF PURE EXCELLENCE

Thirty and beyond

AUSTRALIAN MANUFACTURING COMPANY WASTECH MARKS A MAJOR MILESTONE AND SETS A VISION STATEMENT FOR THE FUTURE.

What does Wastech beyond 30 look like?

For Clete Elms, it’s acknowledging the work of founding brothers Neil and Paul Bone, while pivoting the company to the future to ensure it’s around for another 30 years.

The recently appointed Chief Executive Officer has a clear vision of growth to transform the engineering, manufacturing and service company into a truly national end-to-end and resource recovery solution provider.

“The industry has changed,” Clete says. “Companies are taking more

ownership of their waste management and realise resources are precious.

“Wastech sees a real opportunity to become sustainability experts through technology and industry innovation.

“We want to supply global-leading equipment to help take resource recovery into the future.”

SOLID FOUNDATIONS

Wastech was founded in 1993, designing and engineering solutions for the waste management and resource recovery sector. It’s grown to more than 100 employees across Australia and has

partnered with global brands to offer a stable of cutting-edge equipment contributing to the nation’s path to a circular economy.

Known for its technology-enabled solutions, Wastech is driven by the goal of environmental sustainability. It does not just question the “what if” but explores “how will it be done” and “how to make it happen”.

Clete’s appointment is a strategic move to build on recent years’ momentum and leverage the Bone brothers’ expertise. Clete is an executive with 20 years of experience with ASX-listed

COVER STORY 20 / WMR / August 2023

corporations, including Cleanaway and Boral. He’s drawing on his results oriented operational background to drive a high-performing, customer-centric culture at Wastech. That, he says, means being responsive to customers and the market.

Clete is aiming to identify emerging market segments and build a leadership team and a business that responds to them.

PEOPLE POWER

“We’re looking to be the solutions provider of choice for the resource recovery sector with a range of products that meet a range of requirements,” Clete says. “That has a lot to do with increasing our bench strength at Wastech

and getting people with the right skill sets into the business. For sales and marketing, that means professional sales executives who understand customer value proposition as well as the industry.

“For production, it means highly efficient design and manufacturing capabilities combined with a highly engaged workforce.

“For service, it means empowering our technicians with leading edge workforce planning systems to make their ability to meet customer requirements seamless.”

Proudly Australian, Wastech is a recognised leader in consulting, designing, and manufacturing waste handling equipment. From cardboard, plastic and polystyrene to e-waste and general waste, it’s developed a range of products and services to meet all waste types.

Head office and manufacturing remain in Victoria. Service and repair centres in Brisbane, Sydney, and Perth all stock a large range of spare parts, while skilled technicians operate 24/7 Australiawide and can attend on-site to service, repair and refurbish all products in the industry.

The aim, Clete says, is for Wastech to be a one-stop shop for the waste and resource recovery sector. But it’s customer service that will set it apart.

“We’re aiming to be an industry leader in design, development, manufacture as well as repairs, parts, and service,” he says. “We’re creating processes and structures to enhance our core business that will only help us continue to grow.”

GLOBAL PARTNERS

The key to growing the business is global partnerships. Wastech is the Australian and New Zealand distributor of Fire Rover, an early fire protection solution that can detect and extinguish fires before they start.

It has exclusive rights to Bramidan Balers and Flexus Balasystems. In December 2022, Wastech signed a deal to distribute McCloskey Environmental equipment when the 35-year mainstay in crusher, trommel and screen design branched out into the waste and recycling sector. Wastech is also bringing robotic sorting technology into the fold, as well as odour control and alternate day covers for landfills.

“There are companies who might provide one or two services or products, but from a waste equipment point of view, no one offers everything and to the extent that we do,” Clete says.

“The breadth of services we offer can assist just about any customer with their resource recovery requirements.”

www.wastemanagementreview.com.au / WMR / 21

The future looks bright for Australian engineering and manufacturing firm Wastech.

Clete Elms, Chief Executive Officer, has a clear vision for Wastech’s future.

Bringing the shiniest and newest technology on shore is not all a rush. Clete says partnerships must be the right fit for both parties, and there should be a need for the technology in Australia. It comes back to the company ethos to be responsive to the market.

Brand reputation, product quality and an appetite for growth are also important.

“We live and die by the products we introduce,” Clete says. “We do have a great reputation for supplying products that last and do more than what we say they will do.

“We’re always looking to innovate and bring new technology. But it’s about ensuring the options we’re putting forward are sustainable and providing a closed loop where possible.”

22 / WMR / August 2023 COVER STORY

Manufacturing is based in Victoria but there are plans for additional locations in Sydney and Brisbane.

CIRCULAR SOLUTIONS

Closed-loop solutions are gaining more importance as Australia pushes toward a circular economy and national waste targets, including an 80 per cent average recovery rate from all waste streams by 2030.

Despite aiming to reduce the total waste generated in Australia by 10 per cent by 2030, waste generated increased by three per cent compared to 2018-19, according to the 2022 National Waste Report. That’s expected to continue to grow in line with population growth.

Clete says an increase in the amount of waste generated is also combined with an increase in client expectations for new ways to collect, transport, treat, process and recycle it. He uses the example of an evolving tonne to put the changing

waste landscape into perspective. Thirty years ago, a tonne of household rubbish would have gone directly to landfill. Now part of that tonne is sent to a materials recovery facility, part to organics recycling, possibly part to a glass beneficiation plant, with the remaining reduced residual component to landfill.

Escalating landfill levies also means it’s now more economically viable for companies to invest in the capital required for waste processing equipment.

“For a tech provider like us, there’s a whole lot of other things we can do for waste generators to meet their circular economy aspirations,” Clete says.

Looking ahead, Clete’s 10-year vision is for Wastech to be a partner of choice across a broad client base, whether it be a waste management company, retailer,

or waste generator. Expansion across the eastern seaboard, organically or partnering with like-minded businesses, is also on the cards.

He’d like to see fabrication decentralised from Victoria with additional locations in Sydney and Brisbane.

It’s a big ask, but Clete is looking forward to it.

“I like to build businesses and successful teams,” he says.

“This is an industry I’m passionate about and know well. Wastech presents a terrific opportunity to build up a business that responds to that industry We have the appetite for growth and expansion.”

For more information, visit; www.wastech.com.au

www.wastemanagementreview.com.au / WMR / 23

Wastech has been designing and manufacturing waste management solutions since 1993.

LEEF it to Water & Carbon Group

AN AUSTRALIAN DEVELOPED FOAM FRACTIONATION SYSTEM FOR PFAS REMOVAL IS GAINING GLOBAL RECOGNITION IN LEACHATE TREATMENT.

Aban on PFAS use is the only way to eliminate per– and polyfluoroalkyl substances (PFAS) contamination.

But you’d have to strip back the manufacturing process of many everyday products, from baking paper, non-stick cookware to cosmetics, carpets, and clothing, that it’s too big of an ask, says Mark Mullett, PFAS and Mining Development Manager for the Water & Carbon Group (WCG).

He says there are no official discussions around trying to reduce the

amount of PFAS that consumers use, but it’s a hot topic among waste and recycling operators who are left with the financial impost of cleaning up the forever chemical.

Landfill operators are often challenged by treating and managing PFAS in leachate and groundwater. One of the main difficulties is the complex chemistry of the leachate –high salinity, organic carbon, nonbiologically degradable compounds, suspended solids, and nitrogen compounds, particularly ammonia, are present.

“There are a lot of PFAS removal technologies available that all have their sweet spots in terms of the feedwater source chemistry,” Mark says, “but it’s very hard to find a solution to treat all of them.

“No single process can be developed for just any leachate. Even within a single landfill site, the leachate sources are sufficiently different to require their own assessment and process development.”

Granular activated carbon (GAC) absorption and ion exchange resins have been used to treat PFAS in simple waste streams.

Mark says membrane processes such as reverse osmosis (RO) can be applied to leachate treatment, but the volume of concentrated waste produced is high, 20-50 per cent of the raw leachate volume, resulting in high waste disposal and energy costs.

This is even more apparent when the RO concentrate is further treated using high energy evaporation processes to drive the excess water off as steam.

WCG has developed the LEEF (Low Energy Evaporative Fractionation) System to remove PFAS contaminants by harnessing air, and the chemical properties of PFAS itself, while using minimal energy, and no consumables.

PFAS are surfactants that can produce a stable foam when mixed with air and water. This characteristic is the reason PFAS is effective as a firefighting foam to suppress certain types of fire.

The LEEF System takes advantage of the way PFAS coats air bubbles in a process called foam fractionation. By adding air in a controlled setting, PFAS compounds will attach to bubbles and rise to the top where they can be skimmed off and separated.

Mark says the LEEF System has worked on some of the most challenging chemistries he’s seen in leachate.

“The LEEF System is not impacted by the co-contaminants and is quite robust to suspended solids,” he says. “It’s why foam fractionation in general is being considered the primary treatment option for leachate.”

The LEEF System is in full operation at the Shoal Bay Leachate Treatment Plant in Darwin, where it is successfully treating 50 million litres of leachate each year as part of a

FEATURED TOPIC – HAZARDOUS AND LIQUID WASTE 24 / WMR / August 2023

The LEEF system has been proven to successfully treat leachate.

holistic zero liquid discharge leachate treatment regime.

It’s also had success in treating about a dozen of the toughest leachates in US states including Tennessee, Vermont, Alabama, North Carolina, and Virginia in demonstration and pilot scale trials. The demonstration plant uses fullsized commercial fractionators to treat more than 12,000 litres per day in continued operation.

Mark says the level of demonstration has given clients confidence in the LEEF process and many are taking a proactive approach to implement solutions that best suit their situation.

That’s been spurred on by a US Environmental Protection Agency proposal for nationally enforceable limits for six PFAS compounds that are commonly found in drinking water. The regulation will require various industries, including landfill operators and those involved in leachate

management, to proactively prepare for compliance in advance.

WCG is also receiving requests for treating water from mining run-off, groundwater influenced by hydrocarbons, and landfill sources that carry industrial waste, not putrescible household waste.

“These are quite problematic in their own way for traditional treatment that are compromised by the background chemistry,” Mark says. “In some cases, very complex pre-treatment is required to accommodate the traditional removal technologies to eradicate contaminants.

“Each of these pre-treatment stages can produce its own PFAS contaminated waste. In these instances, the LEEF System has many advantages including operational efficiency and being cost-effective, and sustainable.”

The Water & Carbon Group continues to invest in a development

program at bench and pilot scale to refine and improve operations, and to develop operating parameters for more feed source types.

Mark says Australia’s proactive approach to PFAS – the government recognised PFAS as a potential problem far earlier than some other countries and has developed a nationally agreed guidance on the management of PFAS contamination in the environment – has resulted in many innovations, such as the LEEF process, originating in Australia.

“Australia has always been on the ball with PFAS and is a pioneer in terms of solutions development,” he says.

“To see these being exported, along with enhanced technical knowledge in terms of understanding PFAS and PFAS abatement, is very exciting.”

For more information, visit: www.waterandcarbon.com.au

www.wastemanagementreview.com.au / WMR / 25

The LEEF System has worked on some of the most challenging chemistries found in leachate.

Charging ahead

E-WASTE RECYCLER ECOCYCLE IS AHEAD OF THE GAME WHEN IT COMES TO CREATING A CIRCULAR ECONOMY FOR ELECTRIC VEHICLE BATTERIES.

The Electric Vehicle (EV) revolution is advancing.

Sales of electric vehicles in Australia more than tripled during the first four months of 2023 compared to the same period last year, according to CarExpert.

That number is expected to continue to rise as consumers seek out lower emissions, improved health outcomes and reduced running costs. Growing the national EV market is also at the heart of Australia’s first National Electric Vehicle Strategy, launched in 2023.

But the increased uptake has a downside. Research commissioned by the Battery Stewardship Council, released in June 2023, estimates used EV batteries entering the waste stream will reach 30,000

tonnes by 2030 and 1.6 million tonnes by 2050.

Currently, EcoBatt, the battery recycling division of e-waste recycler Ecocycle, is the only safe and efficient national solution for used EV batteries.

The Battery Stewardship Council is urging government and industry to begin discussions now to be prepared for the emerging waste stream.

Ecocycle is getting ahead of the game, investing in equipment and technology to collect and recycle used EV batteries.

Zoltan Sekula, Product Stewardship Manager for Ecocycle, says it’s too late to shut the gate once the horse has bolted.

“It’s coming, and somebody needs to be at the front,” Zoltan says. “Ecocycle has made it a mission to be ready, have

the right equipment and have everything in place.”

Lithium-ion batteries have come under scrutiny globally for their propensity to catch fire under certain adverse handling conditions. Their high voltage brings difficulties at end-of-life, requiring extra safety, specialised tools, protection, and training.

Zoltan says Australia does not have an official training program or code of practice when it comes to handling EV batteries. He says change is needed right through the supply chain.

The main issue is the high voltage of batteries – up to 800 volts. Even when classed as end-of-life, EV batteries can have a usable residual capacity. Not everyone can, or should, work with these

FEATURED TOPIC – HAZARDOUS AND LIQUID WASTE 26 / WMR / August 2023

Ecocycle has invested in specialised containers large enough to safely transport EV cars involved in an accident.

batteries particularly from a safety aspect, Zoltan says. “Anyone who believes it’s just a battery is wrong. It can cause severe injury, death and fire if not handled correctly,” he says. “Safety is paramount. They are dangerous goods and need to be respected accordingly.”

Ecocycle has undertaken its own staff training, following safety guidelines from the EV battery recycling industry in Germany and is working closely with the Institute of Scrap Recycling Industries (ISRI).

Zoltan says there needs to be a qualification program in Australia for people to work with high voltage EV batteries.

“Even at 10 per cent charge, an EV battery is a high-risk item,” he says. “There’s still enough energy there to start a fire or injure someone.”

Ecocycle has purchased special safety containers for transportation of EV batteries. The containers are equipped with built-in monitoring and fire retardant. In the case of a thermal runaway, the fire will be self-contained.

The company has also installed a Fire Rover, an early fire protection solution that can detect and extinguish early fires at every yard where EV batteries will be stored or recycled.

EV batteries in cars that have been involved in an accident have the potential

to reignite two to three weeks later, which is why Ecocycle has invested in containers large enough to safely transport cars.

“EVs involved in an accident can catch fire in transit on a tow truck,” Zoltan says.

“With these self-contained safety containers, it’s not going to be a problem. Monitoring will detect any heat build-up.”

A member of the Association for the Battery Recycling Industry, Ecocycle has a national reach with household battery collection points in major supermarkets across Australia, including regional and remote areas. Zoltan hopes that under a stewardship program for EV batteries the company can roll out the safety containers Australia-wide.

“Ecocycle will facilitate the vehicle to be transported safely, either to an insurance company or back to us. Ideally, we would then be responsible for dismantling the vehicle and removing the batteries for recycling.”

Repurposing of EV batteries is a hot topic. Batteries replaced in cars still have enough capacity to be used for energy storage devices such as solar power or broken down into back-up batteries for the leisure market, including caravans.

The elements used to create EV batteries, including cobalt, nickel, and lithium, are also scarce so recovering them to be reused in the manufacture of new batteries will be important.

The EV battery recycling industry is expected to supply at least 10 per cent of resources to build new batteries. It’s one of the reasons it’s important that battery recovery and recycling is tightly controlled.

Ecocycle has the technology and expertise to repair, reuse and recycle the batteries to ensure they stay in circulation.

Zoltan says Ecocycle has made a commitment to ensure EV batteries are recycled to a world class standard with capacity to process the increasing tonnage to 2030 and beyond.

For more information, visit: www.ecocycle.com.au

www.wastemanagementreview.com.au / WMR / 27

Special safety containers for transportation of EV batteries have inbuilt monitoring and are fire retardant.

EV battery recycling requires specalised tools and training.

IT DOESN’T JUST MEASURE VALUES. IT HAS VALUES. THE 6X ®. AVAILABLE NOW! The VEGAPULS 6X: A radar level sensor that is not only technically perfect, it also takes the user into account. It’s easy to set up and at home in virtually any process or industrial environment. Made by a company that bases its decisions on values that are good for everybody. VEGA. HOME OF VALUES. www.vega.com/radar

A calculated risk

WESTREX HAS GROWN FROM A SINGLE FACILITY PROCESSING COAL SEAM GAS WASTE TO MULTIPLE SITES PROVIDING SUSTAINABLE SOLUTIONS TO A NICHE MARKET.

Hazardous waste generated in Australia continues to grow faster than other waste streams, and faster than the rate of population growth, according to the Department of Climate Change, Energy, the Environment and Water.

It can include everything from chemical residue to resin and industrial waste by-products which, if not handled correctly, have the potential to cause human and environmental harm.

Between 2010-11 and 2014, average annual growth of hazardous waste was nine per cent, with a 34 per cent increase between 2017-19, the department’s Hazardous Waste in Australia 2021 report states. The growth was attributed to asbestos and contaminated soils and large flows to storage of coal seam gas (CSG) waste.

It was this CSG waste that WestRex, now a subsidiary of Pure Environmental, foundation directors Mark Scott and Gregg Chapple had in their sights when

they began construction of a purposebuilt facility in Jackson, Queensland.

The original intention was to provide the CSG industry with a licensed waste processing facility, in the heart of the Surat Basin, capable of treating and processing effluent and other liquid and hazardous waste from the CSG camps.

The first load of effluent waste arrived at the site for processing in April 2013. Since then, WestRex has grown, with additional waste facilities in Wacol, Narangba and Injune.

FEATURED TOPIC – HAZARDOUS AND LIQUID WASTE www.wastemanagementreview.com.au / WMR / 29

An aerial view of the Wacol site.

David Powell, General Manager of WestRex, has been at the helm of the liquid and solid hazardous waste management company since 2013. David has an innate understanding of the dangers of hazardous waste, both to the people who handle them and the environment.

He describes every day in the industry as a “school day”, learning to deal with emerging wastes and an increasing appetite for sustainable solutions.

With a team of industrial senior chemists with more than 70 years

combined industry experience, including John Pesavento, Sachin Patel, Kali Martin and Kevin Yip, WestRex’s Wacol site is at the cutting edge of processing, treatment, and resource recovery of hazardous wastes.

The facilities are licensed to accept a range of regulated and hazardous wastes, with a focus on maximising recovery of reusable resources and minimising what’ sent to landfill.

THE WAY FORWARD

The Wacol site is licensed to receive bulk

liquid and industrial wash water that is processed through a water treatment plant, as well as packaged waste such as the drums or vessels that contain waste chemicals and flammable material.

David attributes the success of Wacol to WestRex’s reputation for providing the best service and value – which often isn’t all about price.

The company recruits chemists and has focused on providing sustainable disposal solutions for difficult to treat wastes. Because WestRex is independent, it caters to everyone in the waste sector.

30 / WMR / August 2023 FEATURED TOPIC – HAZARDOUS AND LIQUID WASTE

David Wrenn, Business Development Manager WestRex, has been servicing the industry for more than 25 years and is one of the leading experts in hazardous waste management.

“In the hazardous waste industry, you’re dealing with chemicals that have reacted or been blended with something else,” David says. “Each waste drum has different compounds that need to be considered when coming up with a disposal solution.

“We’re actively involved in managing our clients’ challenges in terms of

hazardous or toxic waste streams; that’s where our chemists and engineers work hard.

“For new and emerging waste streams we will work out ways to manage the compliant treatment, reuse, and or disposal of material.”

David says all the processes used are aimed at making a waste less dangerous, whether that’s through fixation –blending and binding a chemical with cement powder to form a solid waste for final fate disposal – or using specialised equipment, that has been designed to maximise the recovery and reuse of oil, sludge, and industrial wastewater.

Reuse is always a priority. Currently about one million litres per month of oil recovered at Wacol is sent for refinement and reuse in car engines – closing the loop on the waste stream.

The team works in close consultation with the waste hierarchy and always challenges itself to investigate and research opportunities to beneficially reuse certain regular hazardous waste streams. This could be through straight recovery or by processing to convert the waste into a reusable commodity.

“I see this as a growing opportunity to further divert hazardous wastes

that are fixated for landfill to be ‘remanufactured’ into products of use; by using a circular economy approach,” David says.

CPR, THE WESTREX WAY

He describes the WestRex team as dynamic and passionate about their values of compliant, professional, and responsive (CPR).

“Compliance is important to customers and generators. It’s something we hang our hat on,” David says. “We don’t do anything that’s not compliant. Dangerous goods need health and safety standards to ensure that no harm comes to staff, customers or surrounding environment.

“We’re professional in every interaction we have, and we’re responsive in terms of turnaround time from an initial inquiry to trucks arriving at the gate.

“We’re a solutions-focused business. We’re trying to innovate and stay focused on the customer. If they have something that’s hard to treat, we can treat it.”

For more information, visit: www.westrex.com.au or www.purenv.com.au

www.wastemanagementreview.com.au / WMR / 31

The WestRex Wacol site is licensed to receive bulk liquid and industrial wash water.

A team of industrial chemists ensures WestRex’s Wacol site is at the cutting edge of processing, treatment, and resource recovery of hazardous wastes.

Chemical Brothers, Chemical Beats

AS

A

NICHE

SEGMENT, CHEMICAL TRANSPORTATION BY ROAD OFTEN INVOLVES A DIFFERENT MINDSET TO FUEL HAULAGE. UNANDERRA TANKER HIRE IS ONE OF THE INDUSTRY’S LEADING PRACTITIONERS.

Unanderra Tanker Hire (UTH), a leading chemical transportation company based in Port Kembla, has recently acquired three DAF XF530 Euro VI prime movers. These additions have proven their worth in crucial areas such as fuel economy, driver acceptance, and safety.

As a specialist in chemical transportation, UTH caters to various industries with unique requirements. One of the new DAF XF530 trucks operates in Brisbane, delivering laundry chemicals and servicing breweries. The other two trucks are assigned to more traditional tanker tasks.

CHEMICAL NEEDS: GO

Unlike fuel or milk tankers, chemical transportation demands a focus not solely on optimising high-productivity combinations but also on meeting customer expectations and navigating challenging access points.

UTH addresses these challenges by using semi-trailers that offer the best compromise between productivity and accessibility. With a fleet of single trailers weighing 44 tonnes, UTH can handle tight entrances at metropolitan water treatment plants and waste station sites in regional areas.

Drivers at these sites are often confronted with problematic access that requires trucks to have cross-locks and power dividers, according to Jeremiah

Justice Wiedl, UTH General Manager. “Most of these entry points are just dirt roads better suited to a 4x4 passenger vehicle,” he says. “That’s where the big trucks don’t fit. We can make it work using a semi with a compartment of a product, and then we’ll leave. We reload the semi elsewhere and go away on a long trip.”

UTH’s chemical transportation operations are tailored to the needs of customers. UTH ensures that it delivers the precise amount of product required, whether it is 5000 or 20,000 litres. This meticulous approach to load optimisation

maximises fleet use and enables UTH to efficiently cater to a wide range of customer storage tank sizes.

UTH’s fleet comprises 21 rigids, primarily used for urban assignments. However, most vehicles are prime movers, totalling nearly 60 units. Alongside the three new DAF XF530 trucks, UTH operates five other DAF vehicles that have proven their reliability and versatility over the years. The decision to invest in DAF trucks was driven by their storage options, adaptability to urban confines, and performance.

FEATURED TOPIC – HAZARDOUS AND LIQUID WASTE 32 / WMR / August 2023

Storage options, adaptability to urban confines and performance are key selling points.

FLEXIBILITY IS KEY

UTH’s expertise extends to transporting hydrochloric acid, a critical component in the galvanising industry. With the flexibility afforded by the DAF trucks, UTH drivers can reload and embark on additional long-haul trips after completing early morning deliveries. For example, they may transport hydrochloric acid to gold mines in the state’s central west.

This flexibility enables UTH drivers to optimise their hours and cater to the diverse needs of their customers. It would be unheard of, Jeremiah says, in the fuel and milk markets.

Working under higher mass limits (HML), UTH has the provision for loading up to 46 tonnes of gross vehicle mass (GVM), although the payload rarely exceeds 25 tonnes.

UTH’s strategic decision-making has been pivotal in its growth and competitive positioning. The company’s approach to the total cost of ownership and technical proficiency has allowed for linear growth over the years. UTH has optimised its fleet and remains competitive by carefully considering traffic conditions, site access, and maintenance costs.

A mechanic by trade, Jeremiah emphasises the importance of maintaining and repurposing equipment. UTH’s fleet includes new and older models. The expertise of the company’s in-house workshop, supported by trusted external providers, ensures that the fleet remains well-maintained and reliable.

“I was brought up to try and maintain things and keep them going,” Jeremiah says. “That’s always been something Dad has emphasised from the start.”

The newest Euro VI DAF XF530 trucks are not, unlike some other European brands in the fleet, on contract maintenance schemes. Maintenance of the fleet in the main is performed in-house. The workshop employs six personnel, including a fabricator.

“The challenge with contract maintenance is you need to return to the dealer,” Jeremiah says. “If the fleet is not profitable, you’re paying a bloke to just sit with a truck at a dealership all the time. That becomes a false saving when you look at the wage component.”

FINDING THE GOLDEN PATH

The three new Euro VI DAF XF530 trucks have quickly become the preferred choice for UTH. Manufactured in the same factory where the company’s first truck was made, these DAF trucks offer readily available parts, competitive pricing, and improved cost of ownership. Jeremiah praises the XF530 turning circle, versatility, and support network.

“The chief reason is the impossible places we need to get into. You need a

conventional truck. Drivers need a truck with a really good turning circle. They’ve never let me down, and the drivers now love them,” says Jeremiah.

Unanderra Tanker Hire’s investment in the new DAF XF530 Euro VI prime movers marks a milestone in the company’s journey to revolutionise chemical transportation. By prioritising fuel economy, driver acceptance, and safety, UTH has set new standards in the industry.

With the performance of the DAF trucks and a dedicated team, UTH continues to thrive and adapt to the evolving needs of its customers.

For more information, visit: www.daf.com.au and www.uth.com.au

www.wastemanagementreview.com.au / WMR / 33

The DAF XF530 is ideal for delivery to sites with problematic access.

Resources reclaimed

NATIONAL RESOURCE RECOVERY

The hazardous waste space is an ever-changing environment. More than 70 classified types of hazardous waste were identified in the Hazardous Waste in Australia 2021 report, including contaminated soils and asbestos, wastes from chemicals and heavy manufacturing, and those from everyday sources such as oils, oily water, and grease traps.

Each of them requires specialised collection, transportation, and disposal to minimise the risk of environmental damage.

National Resource Recovery has been at the forefront of the hazardous waste industry across Melbourne since 1993 and continues to adapt to evolving community and regulatory expectations.

Sandro Accetta, General Manager of National Resource Recovery, says an increasing focus on governance and compliance means it’s crucial now, more than ever, for businesses to remain vigilant with their waste services.

“To comply with legislation and reduce the environmental impact of waste, every business in Melbourne needs an effective waste management solution,” Sandro says.

“At National Resource Recovery, we remain true to the cause and ensure hazardous waste is treated in the most cost-effective and compliant manner.

“Backed by a skilled group of people with almost 60 years of collective industry experience and knowledge, we pride ourselves on finding solutions for every challenge presented by customers.”

Sandro says National Resource Recovery understands the importance of reducing the amount of waste sent to landfill and offers recycling solutions across a range of sectors including business, industrial, manufacturing and domestic.

Recognised recycling services are available for oil filters, used rags, plastic and metal containers and aerosols. Where there isn’t a current path to reuse, the company will provide options to suit client circumstances such as business needs, size and work flows.

HAS BUILT A REPUTATION ON SOLUTIONSBASED HAZARDOUS WASTE TREATMENT. NOW IT’S LEVERAGING A GROWING DEMAND TO PUSH IT EVEN FURTHER.

FEATURED TOPIC – HAZARDOUS AND LIQUID WASTE 34 / WMR / August 2023

National Resource Recovery uses waste audits and waste management plans for solid and liquid waste solutions.

Sandro says that a growing push for green credentials and a move to a circular economy has driven an increased demand for recycling options. In response, National Resource Recovery

continues to seek out innovation and technology.

“We want to be the one provider that offers a full suite of hazardous waste services for all our customers,” he says.

“We want to take away the worry for our customers so they can focus on their day-to-day business objectives.”

A fleet of EPA Victoria-licensed vehicles collect and transport both liquid and solid waste streams to either National Resource Recovery’s fully licensed facility in Bayswater, Victoria or to an alternative EPA-licensed facility, where the wastes are sorted, treated, and where possible, repurposed.

National Resource Recovery was one of the forerunners to introduce an electronic tracking service for hazardous waste. Sandro says from the moment of collection, the company takes responsibility of the waste,

ensuring customers complete peace of mind. All wastes collected are documented and follow a full tracking system until treatment has taken place.

“That’s what’s important for us,” Sandro says. “Compliance and governance are the key. We will ensure we protect our customers and look after all their hazardous waste disposal challenges.”

Growth and expansion are high on National Resource Recovery’s agenda. Sandro says the company has built a reputation as a hazardous waste specialist and is keen to leverage that to attract a bigger market share.

“We want to become that one provider customers think of when they consider hazardous waste.”

For more information, visit: www.nationalresourcerecovery.com.au

Optimise compaction and increase productivity with Carlson machine guidance. Backed by industry expertise & nationwide support at Position Partners. 1300 867 266 • positionpartners.com.au WANT TO

SITE MORE EFFECTIVELY?

Used rags are collected, stored and sealed in metal containers to prevent spontaneous combustion.

MANAGE YOUR

Through no fire or flames

FIRE CAN QUICKLY DESTROY BUILDINGS OR INSTALLATIONS. WITH THEIR NON-CONTACT METHOD OF MEASURING TEMPERATURES, THERMAL IMAGING CAMERAS CAN HELP PREVENT FIRES BY DETECTING HOT SPOTS BEFORE THEY IGNITE

Any waste can potentially be flammable when stored, regardless of the substance. Fire hazards include self-combustion, heat development due to pressure, and spontaneous chemical reactions between disposals and methane gas-building. Thermal imaging cameras can help prevent fires by identifying hot spots with the potential to flare up.

Storing some materials at waste sites, warehouses, fuel piles, and similar locations invites the risk of spontaneous combustion. This can occur due to rising pressure or unseen reactions within the stored materials.

For example, some recycling facilities prefer to organise materials into “fluff” piles. These piles consist of combinations of cloth, plastic, metal, and rubber – all potentially saturated with oils. The

right mix of fluff, chemicals, and environmental conditions can spark quick-spreading fires.

Preventing such fires is not just a matter of personnel and environmental safety: it’s also one of economics. But most fire systems are designed to contain a fire once it starts – which isn’t always the most cost-effective solution. A system that allows companies to avoid fires or stop them in their tracks can save lives and money, and prevent downtime.

Fixed-mount thermal imaging cameras trained on the flammable materials can watch for temperature increases, catching the rising heat before the target combusts.

INFRARED VISION

Because these cameras rely on infrared

instead of visible light, this system can provide fire prevention coverage day or night, regardless of the lighting conditions. Many thermal camera systems provide rapid temperature data updates that can trigger alarms when the heat spikes dangerously, allowing companies to safeguard materials or turn off equipment that could cause or spread a fire.

FLIR A50 and A70 smart sensor cameras are ideal for users who want built-in, on-camera analytics and alarm capabilities for condition monitoring and early fire detection applications. With options for WiFi, an integrated visual camera, and ONVIF S compatibility (advanced version only), FLIR A50/A70 cameras are a flexible, configurable solution to meet the unique needs of

FEATURED TOPIC - FIRE MANAGEMENT 36 / WMR / August 2023

Storing some materials at waste sites, warehouses, fuel piles, and similar locations invites the risk of spontaneous combustion.

Infrared can provide fire prevention coverage day or night.

automation customers across a broad range of industries.

When used as a system component for cloud and Industrial Internet of Things (IIoT) solutions, A50/A70 cameras can help companies protect assets, improve safety, maximise uptime, and minimise maintenance costs.

FEATURES OF A50/70

The A50/A70 can quickly access thermal characteristics with the widearea, non-contact temperature sensor. The high-quality sensor is designed to provide up to 640 × 480 (307,200

pixels) resolution and ±2°C accuracy.

Teledyne FLIR has focused on simplifying integration efforts with smart thermal sensors. The A50/ A70 can communicate with standard industrial protocols and video management systems, including HMI, SCADA, and optional ONVIF S compatibility. The lightweight, IP66rated camera with M8/12 connectors can easily be installed in any location –with multiple mounting options.

DESIGNED FOR SAFETY

Designed for early fire detection and other condition monitoring solutions, the FLIR A50 Compact Smart Sensor Thermal Camera offers built-in, oncamera analytics and alarm capabilities. It also features internal software that can isolate regions of interest and report temperature ranges from those areas.

The Smart Sensor configuration means the A50 can perform the basic analysis to report temperature spikes. Thanks to ONVIF S compatibility, the A50 offers simultaneous VMS video and alarm integration. This compact camera

can fit anywhere at just 107 x 67 x 57 millimetre (4.21 x 2.64 x 2.24 inches). It has a rugged IP66 exterior to ensure it’s tough enough for harsh indoor or outdoor environments.

WHO IS TELEDYNE FLIR?

Teledyne FLIR designs, develops, manufactures, markets, and distributes technologies that enhance perception and awareness. It brings innovative sensing solutions into daily life through its thermal imaging, visible-light imaging, video analytics, measurement and diagnostic, and advanced threat detection systems.

Teledyne FLIR offers a diversified portfolio that serves several applications in government and defence, industrial, and commercial markets. Its products are being used to help first responders and military personnel protect and save lives, promote trade efficiency, and innovate consumerfacing technologies.

For more information, visit https://bit.ly/3NKghbo

www.wastemanagementreview.com.au / WMR / 37

The FLIR A50/A70 can quickly access thermal characteristics.

FLIR A50/A70 cameras are a flexible solution to meet the unique needs of customers across a range of industries.

Grinding in the Top End

WHEN HOME IS 700 KILOMETRES AWAY YOU NEED EQUIPMENT YOU CAN RELY ON. FOR PHIL SNELL’S GRINDING OPERATION IN THE NORTHERN TERRITORY, KOMATSU FOREST HELPS GET THINGS DONE.

Aremote location, the wrong equipment and monsoon rains – Phil Snell’s entry into the recycling/grinding industry was far from polished.

“It was quite challenging to get the job across the line,” Phil recalls. “Looking back now, we probably looked like hillbillies going into the bush.

“It was definitely a learning curve.”

Phil admits that 19 years ago he’d never heard of putting mulch or woodchip on a garden.

When a government contract to replace 100 kilometres of fence in the Northern Territory required the old timber to be mulched, he was out of his depth.

So much so, that for his first attempt he used a backhoe.

“It was quite unsuccessful,” Phil says with a chuckle.

The wet season may have beaten him back then, but Phil, the owner/operator of Snell Contracting and Hicway Pty Ltd, has found a home away from home in the red dirt of East Arnhem Land.

He built his business on land clearing and grinding green waste for local councils and has secured a five-year contract for site clearance and rehabilitation at Rio Tinto’s 15,000-hectare bauxite mining lease in Nhullaby, formerly Gove.

The Gove site has been supplying the global aluminium industry with bauxite

for more than 40 years but is expected to cease later this decade. Work to support closure of the operation and rehabilitate the area is already under way.

Phil and his team are clearing and mulching timber to be used to rehabilitate the mine’s burrow and red mud ponds.

“We delivered 80,000 cubic tonnes of soil enhancer last season,” Phil says.