Dutch energy technology business EST-Floattech develops and supplies battery energy storage solutions for maritime applications. With hundreds of successful projects, the company is one of the strongest suppliers of maritime battery systems worldwide. CEO Mark Witjens, CTO Diederick Stam and CFO/CBDO Joep Gorgels spoke to Hannah Barnet.

Thanks to EST-Floattech’s innovative technology, 68 million litres of diesel have been saved and almost 250 million kg of CO2 emissions avoided. The company serves clients around the world from an HQ in the Netherlands and has a simple goal: to create a sustainable future via zero-emission shipping.

The milestones

EST-Floattech is a merger of two previous companies. Floattech was founded back in 2005, by current CTO Diederick Stam

and a Co-Founder, as a system integration company for superyachts. In 2009, Mr Stam and a Co-Founder created ESTechnologies, for the design and supply of maritime battery management systems.

In 2015, the companies merged, their strong application and integration knowledge paving the way for EST-Floattech to become one of the world’s strongest suppliers of maritime Energy Storage Systems. “From that day on, we said goodbye to system integration and focused on manufacturing and installing batteries in the field,” said Mr Stam.

In 2018, EST-Floattech was one of the first companies to obtain DNV certification for the second generation of its battery system. Today, the latest version of the system also has approval from Bureau Veritas, Lloyd’s Register and RINA.

The next milestone was launching the Octopus platform in 2023. The system showed how the company has continued to leverage its experience to optimally serve clients. Consequently, EST-Floattech is now the world’s second largest maritime battery supplier.

“We have delivered battery systems on over 300 projects, of which more than 250 are onboard ships,” said Mark Witjens, CEO. “Our production capacity is 50 megawatt hours. This can easily be extended to 100 megawatt hours per year.”

From Orca to Octopus

The company’s first flagship product was called Green Orca, with lithium-ion polymer pouch cells. This was followed by the

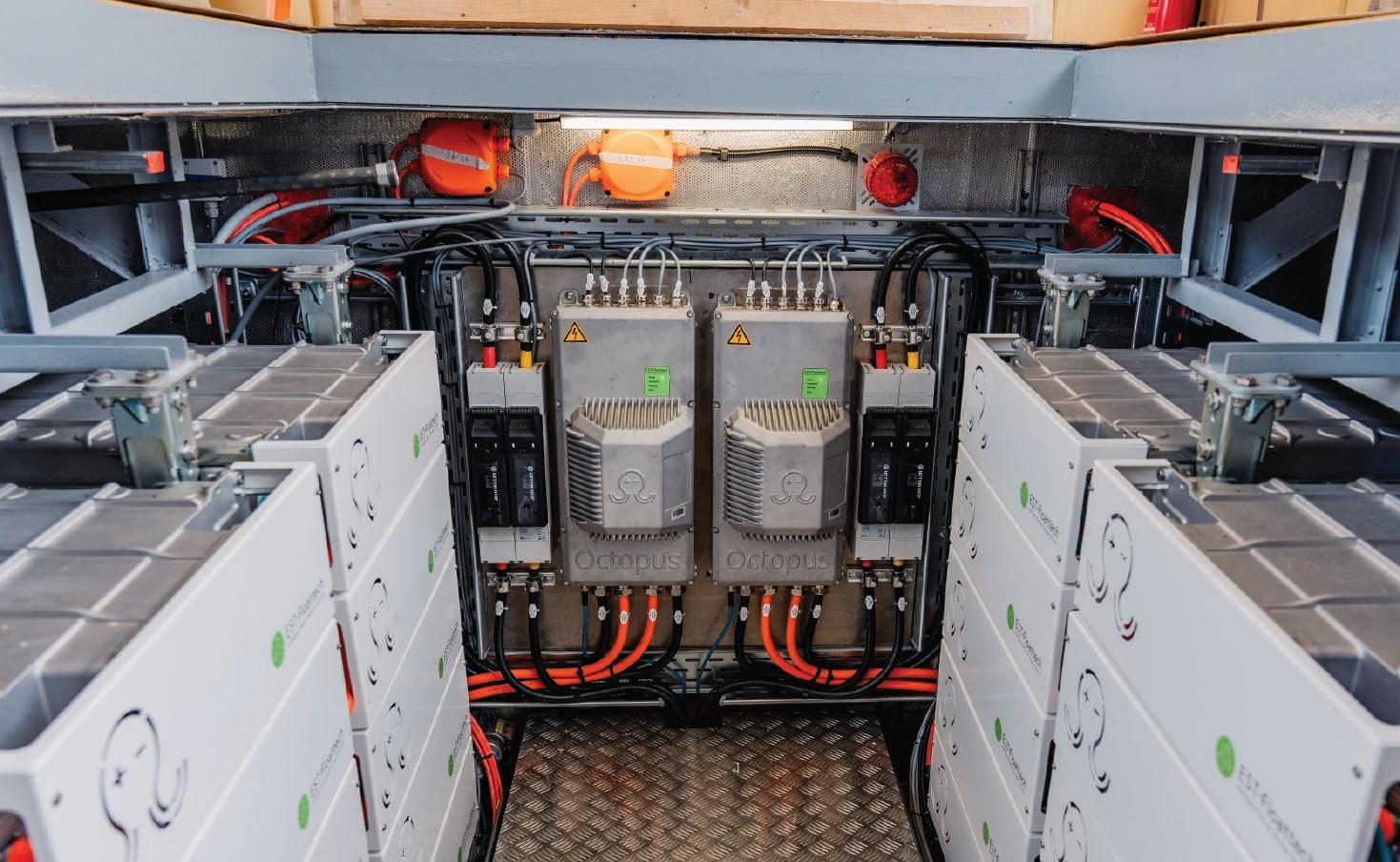

Octopus series, the next-generation maritime advanced Battery Management System (BMS). The BMS was developed to configure a variety of batteries and provide a userfriendly interface that connects the systems, with current modules based on Durapowers cell technology and developments for new modules and chemistries on the way.

“The Octopus system was built with the customer in mind,” Mr Stam explained. “It offers one platform to the customer, but we can integrate all kinds of battery types throughout. We developed everything in-house to make the system capable of handling all different kinds of properties of cell technology.”

“Plus, there’s a single interface for the client, so they can use whatever system they need and the interface stays the same,” Mr Witjens added. “That’s different from our competition.”

The system offers improved cooling, remote access and a more sophisticated safety and cyber security offering than the previous Orca

iterations. This created a system which can be remotely maintained.

“Before, we always had to send an engineer on board if something went wrong,” Mr Stam said. “It was one of our main problems. Now, we can easily diagnose the issue remotely, if necessary. It’s a big improvement.”

Securing projects

With over 300 to choose from, the range of impressive projects the company has been involved in is vast. One excellent example is a recent contract for KOTUG International, the leading international towage and maritime company. EST-Floattech was tasked with developing a containerised energy storage solution for the E-Pusher 1, the world’s first fully electric pusher boat.

The design revolutionised the way energy is stored and distributed in the maritime industry. All components were designed in house, making it easier for the company to accommodate specific requests from customers and to work fast.

“In about six months, we managed to design and deliver this system,” Mr Stam explained. “During this period, we developed the complete containerised solution and delivered the batteries. This is a good example of what we are capable of in a very short time. Thanks to the strength of our in-house R&D team we can design and deliver these sorts of bespoke solutions quickly.”

Working at speed and under pressure is certainly something the company is particularly good at. Even the first Octopus series was designed with a tight delivery deadline.