Fiberdur has been one of the major players in glass fibre reinforced plastics (GRP) pipe systems for the maritime, industrial, offshore, and power station markets for over 60 successful years. As a market-leader in the design and manufacture of composite thermosetting pipe systems and other specialised liquid transmission systems, Fiberdur creates custom-made solutions that are both durable and reliable, and never compromise on quality.

The company offers a complete consultancy, devel opment and production service, supported by technical and production facilities that enable Fiberdur to meet the requirements of virtually any project. Report by Jordan Yallop.

Since the 1960s, Fiberdur has been providing bespoke engineering solutions to major companies the world over and has remained a key player in the glass fibre reinforced plastics (GRP) sector due to extensive experience in design, development, and project management. Fiberdur provides the maritime, industrial , offshore, and power station sectors with durable and reliable engineering services borne from the result of innovative tech nology and high-quality craftsmanship.

Since its founding the company has been providing tailor-made engineering services to major companies around the world, with a focus on quality, on-time delivery and solution-driven processes.

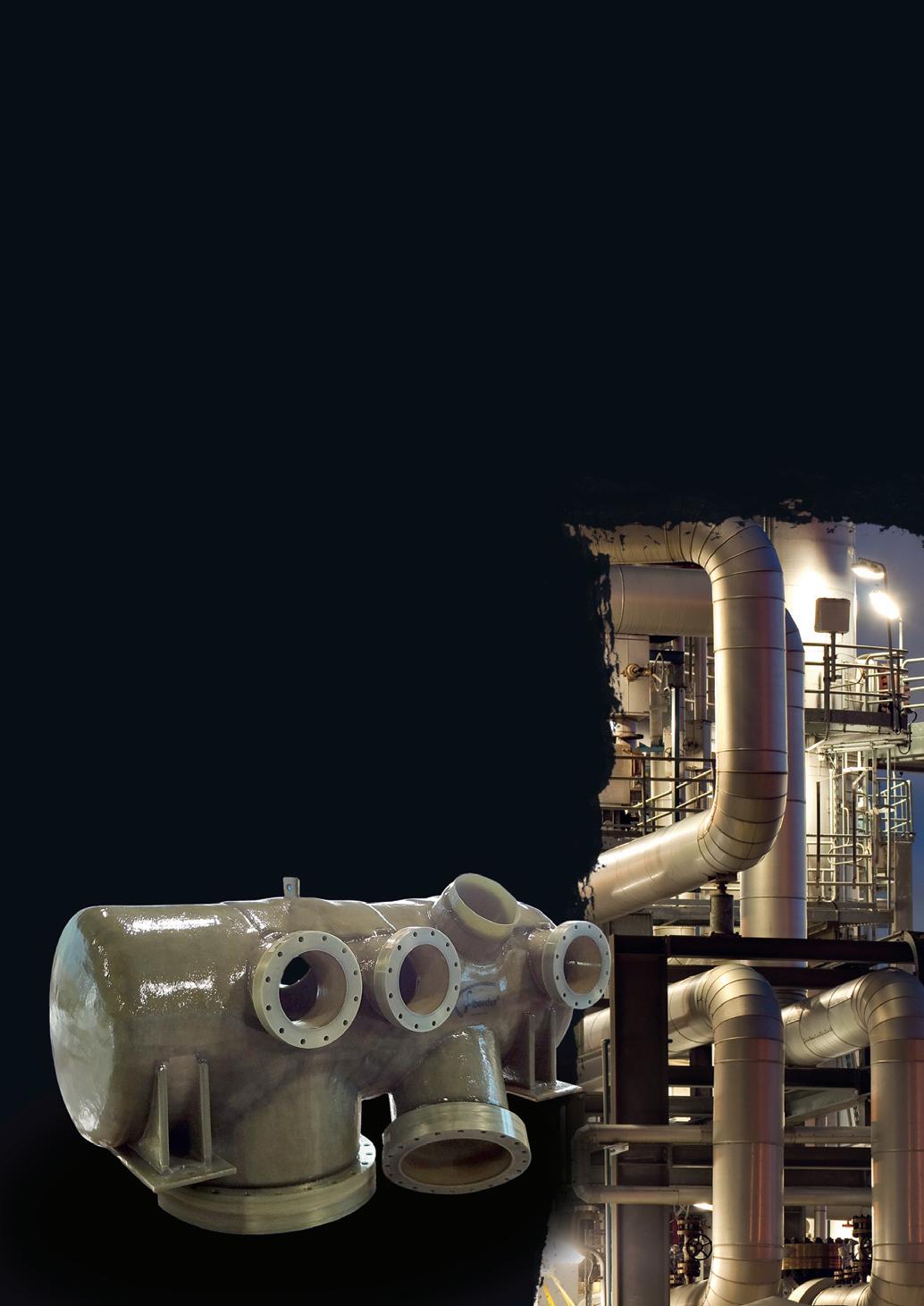

Fiberdur offers a wide range of FRP/GRP pipe systems. Based on polyester, vinyl ester or epoxy resin, Fiberdur pipe sys tems are produced as filament wound in diameters ranging from 25mm to 2,000mm and in section lengths up to 10m.

Roman Scholler, Marine Sales Manager said: “What stands out for us as a company is certainly the demand to develop further with the requirements of our customers in order to implement individual GRP solutions with innovative technical approaches.

“Through close relationships with cus tomers and suppliers, we have developed many long-term relationships that have been an essential basis for the company’s success over the past 60 years.”

Fiberdur has four locations, is headquartered in Germany, and has around 100 employees working in engineering, R&D and produc tion. The company has further locations including a production and service facility in Germany, a sales and service facility in Romania and a similar location in Italy.

CEO Jürgen Wingert said: “We are con nected around the globe with our strategic partners who have the same high standards as Fiberdur in engineering, R&D, production, prefabrication, installation, and final accep tance to ensure a trouble-free system for the whole life of a vessel.

“We arrange on-site support according to customer needs. From the supply of

loose material up to a complete prefabri cation workshop, installation teams and supervision. We have now been active in the GRP market for more than 60 years.”

Fiberdur has made extensive invest ments in its machinery, especially the pipe winding systems. In addition, the company relies on electricity from renew able energy sources with its own photo voltaic system, and significantly reduces its gas consumption through the use of a modern gas heater.

“We make significant efforts to improve our production processes on an ongoing basis while maintaining our high-quality standards,” said Mr Scholler.

“The energy transition brings challenges and opportunities. With our fields of exper tise, there are many opportunities for us to make a significant input in solving challenges. We don’t just use the advan tages of GRP as a material, but we think of GRP as a system solution from the beginning to the end – from customised engineering to the final installation.”

Fiberdur is the world-copyright commer cial name of the quality glass fiber rein forced products which have been supplied for more than 60 years. This is included in a large catalogue of piping systems that are systematically checked and tested to ensure the continued high-quality stan dard of Fiberdur products. One of the main sectors that Fiberdur supplies is the marine and offshore market, which by its very nature is highly corrosive.

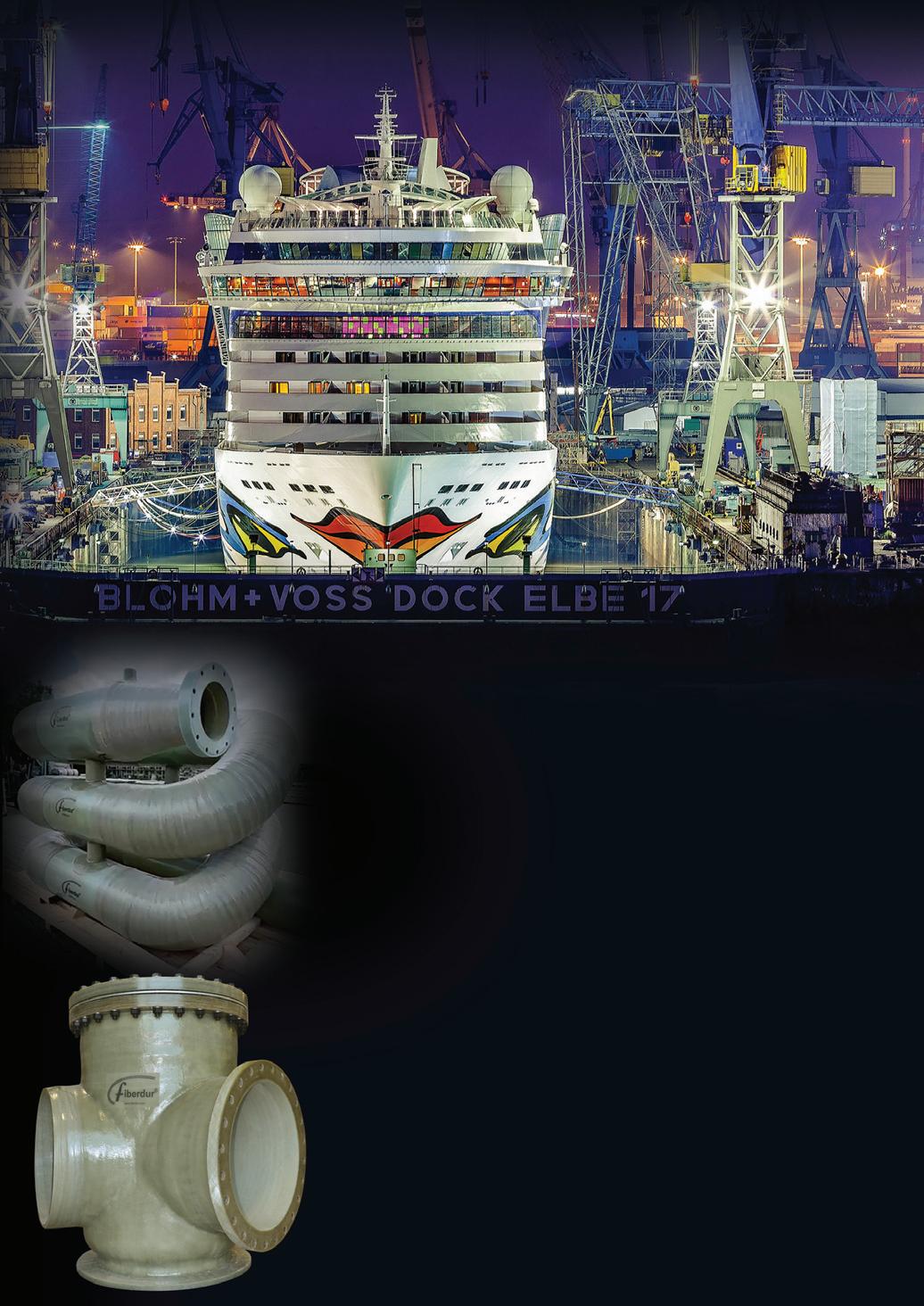

Fiberdur’s glass fibre reinforced pipe systems provide a state-of-the-art solu tion against corrosion. Fiberdur pipe systems blend the advantages of com posite materials, such as light weight, easy installation, and excellent durability, and have proven to last the lifetime of the vessel. The company’s pipe systems are corrosion resistant against seawater, min imised adhesion of algae, and are mainte nance-free. Materials used on offshore installations are faced with extremely high requirements.

Mr Wingert said: “We meet the high demands of customers from nuclear plants to the construction industry, for example, and have a long tradition in ship newbuilding and repair. In addition, we are active in numerous other indus tries, where more and more GRP mate rials are gaining acceptance due to their numerous advantages compared to steel or thermoplastics.

“We do not limit ourselves to delivering loose material. The basis of our success is that we put the customer benefit in the foreground and make our GRP know-how available as needed. We have high stan dards for ourselves and our results, starting with professional engineering and ending with successful installation and final commissioning.”

Scrubbers, or exhaust gas cleaning sys tems (EGCS) are used to remove harmful elements from exhaust gases. In cruise ships alone, Fiberdur has equipped 43%

FIBERDURof all scrubber installations worldwide with its material. But this is not limited to scrubbers alone; the use of glass fibre is in itself more environmentally friendly than alternatives.

“Compared to steel, GRP pipes are a more energy-efficient product in several aspects,” Mr Scholler said. “The energy demand during production is much lower and the energy consumption over the total service life of the GRP system is consid erably less due to the smooth inner sur faces of the pipes. In terms of energy, the lower weight during transport and the very long product service life also has a posi tive effect on the balance as well.

“It is important for all manufacturing companies to continuously improve their processes with a significant focus on sus tainability and energy efficiency. We take this responsibility very seriously and it is part of our corporate strategy to reduce the environmental impact of manufacturing our products as much as possible.”

When talking about how Fiberdur handled the many challenges presented by the Covid-19 pandemic, Mr Wingert cited the high level of commitment of the company’s employees as well as the advantages of

long-term partnerships with customers. These were an essential part of its ability to weather the particularly challenging phases. It has been shown once again that cooperation based on trust pays off, and that reliability is an essential component of Fiberdur’s corporate philosophy.

Recent months have, however, held new challenges in the shape of supply chain issues that have been felt across all sectors of industry. Fiberdur has miti gated these with the cooperation of its long-term suppliers and has succeeded in continuing to manufacture products eco nomically and with the usual high quality despite the significant impediment of the global supply chains.

When discussing the future of the com pany, Mr Scholler said: “We will continue to rely on our ability to recognise the require ments of the market and to develop indi vidual solutions for our customers. Due to the shortage of pipe materials for steel products, massive price increases and availability problems, GRP is more than ever a technically and economically con vincing material alternative for countless applications in pipeline construction.”

He concluded: “Explain your needs to us and we will implement a long-term, troublefree pipe system in GRP for you!” n