GEMINI RAIL SERVICES STAYING ON TRACK

Train travel is decarbonising, and Gemini Rail Services are making it happen. Through its GemEco brand, it is aiming to put Gemini on the map as the leading company for converting existing train vehicles. They are currently working on a number of exciting new and innovative projects alongside several prominent organisations to help meet the developing needs of the UK railways. Ed Williams is the Head of GemEco. He explained the nuts and bolts of this dynamic sector to Hannah Barnett.

ITis an electrifying moment in the rail industry. The rise and rise of ever more sustainable modes of travel created a gap in the market for the genesis of GemEco, founded in 2019. A division of Gemini Rail Services, it spe cialises in transformation of rolling stock into hybrid rail vehicles. GemEco began as the brainchild of Gemini’s former CEO Tim Jenkins, and Ed Williams, who heads up the brand.

As Mr Williams tells it, as soon as he was approached with the idea, he was all in: “There was no thinking, it was a ‘yes’ straight away.” From there, GemEco was born. Arising from humble beginnings, Mr Williams oversaw most of GemEco’s early days, taking the reins on everything from branding to project strategy, and came

up with the logo at his kitchen table. He recalls: “The logo came to life on a Sunday afternoon of brainstorming and doodling, I would like to take all the credit for the design of the logo, however in reality it was probably 20% my design and 80% of my son Zak, who was 11 at the time.”

The rise of the ‘go anywhere’ train Establishing a clear and coherent com pany ethos was important from the start. Mr Williams explains how Gemini immedi ately aimed to stand above competition. He claims that the company continues to do so because it can convert rail vehicles to be “more efficient, more leasable for our Customers and also kinder to the environment.” This can be achieved in many ways, a good example being by

reducing diesel emissions in stations or cut ting out diesel fleets completely by way of introducing the more environmentally friendly ‘go anywhere’ train.

These are modified electric trains that can run on lines with partial electrification, or none at all. The most important benefit of this is making older electric trains work off the electrical grid when they are dis placed by newer models. This, in turn, retires older diesel units, reducing emissions.

Converting old trains certainly sounds like an exciting option but that does not always mean it is a simple one. As Mr Williams explains: “This may sound easy, it is ‘just fitting batteries’, however in reality this is very complex. Sadly, there is no ‘one solu

tion fits all’ model, each route, each class of vehicle will require slightly different battery capacities and configurations.”

The company also designs hybrid con versions for diesel-powered units. This too can be challenging, especially when it comes to allocating space and weight for the battery. Expanding on this, Mr Williams said: “Diesel vehicles are highly utilised in terms of the available space where addi tional equipment can be installed.”

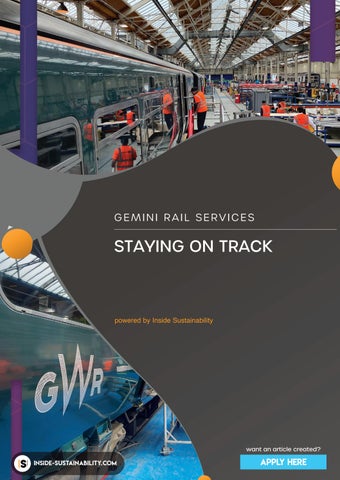

Wolverton

Production takes place at the historic Wolverton Works. With around 180 employees, it has the auspicious claim of being the worlds

longest operating railway works facility. The place is steeped in innovation history; in 1901 Wolverton was the first railway works to use electricity for lighting and driving machinery throughout.

Wolverton is now a specialist rail vehicle overhaul and upgrade facility. Gemini is involved at all levels of production, main tenance, and modification work. As Mr Williams puts it, the company “pro vides a complete service from concept design to unit delivery.” At the Wolverton Works, Gemini Rail Services also offer a wider range of services to rolling stock like incident repair and modernisation. Unsurprisingly, there are no corners cut at any stage of development. Instead

GemEco upholds a strict design process with staged safety reviews and approval gates. Mr Williams strongly emphasises the significance of this approach: “The design cannot progress to the next phase until these safety gates have been fully reviewed and approved. We must ensure compliance with all relevant safety stan dards and where required we bring in third-party experts to review our work to validate compliance.”

Originating from a background this impressive, it is no surprise that GemEco are at the forefront of some of the most innova tive projects across the industry. One of the

m ost illustrious feathers in their cap is work on the HydroFLEX train, the UK’s first hydrogen-ready passenger train that can operate under electric power or battery.

GemEco designed and installed the battery and control equipment for the HydroFLEX unit, and it was demonstrated at the COP26 climate conference in Glasgow.

The company are keen to stress the importance of building a network of strong, long-term partners. Mr Williams paints a picture of a small pool of key technology partners who work closely

on all GemEco projects. With most of them backing the ethos of the projects, and some even investing, he is keen to stress that these relationships are one of the things that sets the company apart: “These are not just suppliers, they are true partners. We find this collabora tive approach is the key to our success.”

At the moment, GemEco is still relatively small. Inevitably, the company faces competition from much larger rail sup p liers on some contracts. And when they

“THESE ARE NOT JUST SUPPLIERS, THEY ARE TRUE PARTNERS. WE FIND THIS COLLABORATIVE APPROACH IS THE KEY TO OUR SUCCESS”

win, it is a thrill, or “a ‘David and Goliath’ scenario” as Mr Williams put it.

GemEco’s success is testament to the scale of innovation it is pioneering. Going forward, Mr Williams said it hopes to “con tinue developing and expanding the capabilities of our offering, whilst also investing in new technologies and oppor tunities. We are also keen to explore how we can support and work with adjacent industries in the future.”

As head of the division, what Mr Williams said most excites him about the job falls loosely into three categories: innovation, diversity of projects and sustainability: “Having the opportunity to work on new and exciting technology projects really drives me. They are all different, and this adds a real challenging dynamic to our work. In addition, it is also the opportunity to make a real difference, not only to UK rail but to our environment too.” n