Kanadevia Inova is a global green tech company making a mark in the Waste to Energy (WtE) and broader waste management infrastructure space. The business is based in Switzerland, and since 2010 it has been part of the Japanese Kanadevia Corporation, that rebranded from Hitachi Zosen Inova in October 2024. Bruno-Frederic Baudouin, CEO, explained more to Hannah Barnett.

Turning waste into value is the essential foundation of Kanadevia Inova’s work. The company offers solutions which view waste as a valuable resource; something which may be converted to a commodity and reused.

“Traditionally, waste removal has been seen as someone else’s problem,” said CEO Bruno-Frederic Baudouin. “This has numerous drawbacks, especially for the environment. People tend to think of circularity as reusing something for the same purpose.

“But if we can bring something back to its basic elements, then we might find a completely different usage. We might be able to convert organics to gas, fertiliser or biochar. The biochar might then be used as a substitution for coal in the production of steel.”

Kanadevia Inova now has over 3,000 employees and a turnover close to £1.2bn. Based in Zurich, the company maintains a presence in 17 countries, with most staff located in Switzerland, the UK and Germany, with more in Central Europe, the United States and the Middle East.

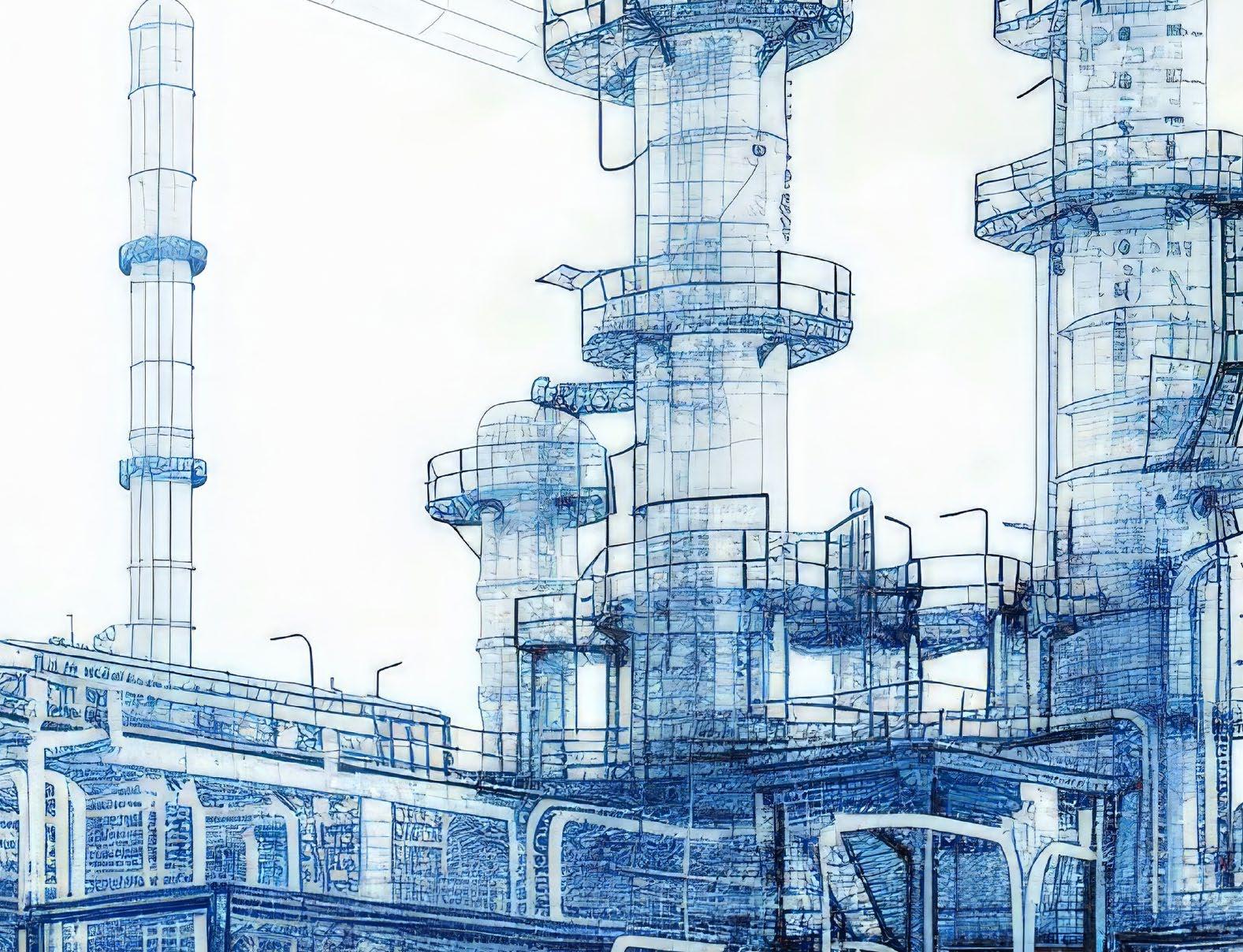

The plants built and run by Kanadevia Inova can be split primarily into two types of waste treatment. There is thermal treatment, which traditionally produces energy that can be converted to electricity or district heating for millions of homes, but has recently expended the outputs to commodities such as metals, salts and aggregates. And there is biological treatment, including through the well-known methanation process, converting organic waste to useful methane.

We have been described as pioneers, we push the edge as much as we can. “”

Kanadevia Inova CEO Bruno-Frederic Baudouin

It’s a jarring contrast to compare such advanced waste treatment technologies with the outdated landfilling approach of bygone days. Landfill sites emit ferocious amounts of methane, a gas 80 times more harmful than CO2 when freely vented to the atmosphere. Adopting waste to energy instead not only prevents these emissions, but also closes many circularity loops.

The company is trying to push this innovation one step further by exploring the circularity loop of CO2. This includes simple solutions such as compressing gas recovered during the methanation process for the food industry for use in fizzy drinks, but also more ambitious routes exploring the potential to blend CO2 with green hydrogen to produce methane and liquid fuels for all sorts of uses, including for aviation.

“We have been described as pioneers,” Mr Baudouin explained. “We push the edge as much as we can. There are many technical solutions available, but the issue is to bring them to the ground, which is largely a question of affordability. We want these to be the go-to solutions around the world and this is an enormous challenge. Today, only 15 to 20 per cent of the total waste produced is treated in a more or less advanced manner. Everything else goes to landfill.”

Becoming part of one of Japan’s largest industrial and engineering firms, Kanadevia Corporation, has proven highly significant for Kanadevia Inova. This is largely thanks to the scaling possibilities, which has allowed the latter to become an active contributor in the development of sustainable waste management infrastructures. This means that Kanadevia Inova does not just build turnkey WtE and Renewable Gas plants. It is also able to take charge of the entire development, operation, maintenance and, if required, co-invest in the facility.

“As we have progressively diversified, not only are we able to expand our technology effort on thermal waste management, but we have also advanced on biological waste management, cross fertilising the two domains to develop the best solutions,” said Mr Baudouin.

In 2019, the company signed a concession agreement in Dubai to build the largest WtE plant in the world. Located just outside the city, in Warsan, the facility can treat 5,000 tonnes of non-recyclable municipal solid waste from the Dubai area per day, making a total of 1,825,000 tonnes a year. The 190MW of electricity generated is then fed into the local grid to power around 120,000

homes. In addition, metals are recovered and construction materials produced from the bottom ash. And, as with most new WtE facilities, the option is there for a bolt-on carbon capture unit to further shrink the carbon footprint.

Technology with affordability

“Dubai is a very important milestone, because it demonstrated the fundability of advanced waste management solutions,” Mr Baudouin explained. “Until then, with limited exceptions, there was no affordable model for the technology, making such advance treatment exclusive to the privileged few. And here, in a country traditionally anchored on landfill, we

were able to democratise it and make it affordable, meaning it made sense both politically and economically.”

Flagship reference plants like Dubai serve as proof points for the company’s delivery capabilities on mega-projects. This helps Kanadevia Inova garner interest from surrounding states in the Middle East, which are similarly keen to leverage waste infrastr-uctures to achieve their sustainability goals.

And, blending Swiss quality and advanced technology with cost-competitiveness has proven quite a seductive combination further afield. In 2024, the company achieved another significant milestone when it managed to convince authorities in North Africa that it had a strong

enough business model to submit a bid for a project.

“The customer was looking to go by default for landfill, even though they knew it would be a super methane emitter, identifiable at the global level,” said Mr Baudouin, “and we managed to convince them that we could offer an alternative solution, drastically cutting the country CO2 equivalent emissions, based on waste to energy. Plus, while producing reliable base load green power, thus allowing a higher penetration of variable renewable power, we were able to come in at significantly lower cost than landfill, with no additional subsidies.

“So, we’ve demonstrated that advanced solutions, with their fantastic contribution to

Hitachi Zosen Inova rebranded as Kanadevia Inova in October 2024. The new name combines the Japanese word ‘Kanaderu’, which means ‘to play music in harmony’, with the Latin word ‘via’, which means ‘way.

“It’s about being in harmony with Mother Nature. For a Swiss company with Japanese ownership, it was really important for us to have some significant meaning in our name reflecting our purpose.”

Kanadevia Inova CEO Bruno-Frederic Baudouin

In order to be innovative and remain ahead of the pack, the company must maintain strong relationships with its partners. The key to maintaining these partnerships in the long term is to be both consistent and fair, according to Mr Baudouin.

“There are many players on the market taking advantage of the situation with a partner,” he said. “I’m not saying that we don’t leverage our bargaining power sometimes, but we want to build lasting relationships and to co-develop solutions. We believe this is absolutely critical, not just for competitiveness, but also for growth.

“It does not mean that we work exclusively with one supplier or with one customer, but I think one of the key secrets of success is this partnership spirit. We are continuously sourcing new suppliers, looking for new partnerships to enhance the competitiveness of our infrastructures, get inspired and create more value for the communities we serve.”

This will complement the company’s overall stated vision to enhance decarbonisation, resource circularity and supply security.

“We want to do it for the communities we are living with and for future generations,” Mr Baudouin said, in conclusion.

“A significant part is about upgrading existing facilities. We believe there is fantastic potential. I was in the US recently visiting a plant to learn how the guys are doing it over there. There are many solutions to learn from in the market, but we were also able to offer some good ideas to the remarkable plant we saw. So, cross fertilisation is happening.

“The fantastic thing is that we have backing from a larger group. This means we can channel tremendous financial capabilities to build lasting growth, helping more communities and countries address their waste management challenge. To have the ability to make an impact in this way, and to make a dream happen, is both very exciting and amazingly rewarding.”