From humble beginnings in 1973, UK-based Kernow Coatings has evolved into a global leader within the specialised coated synthetic media arena. Now more than 50 years old, the company is gearing up to take its presence to new heights. CEO Steve Gulliford revealed all, during an in-depth interview with Inside Sustainability. Report by Imogen Ward.

Kernow Coatings has operated from the same premises in Penryn, England, since the company was established back in 1973. Although the business has remained loyal to its roots, the company looks a lot different today than it did over half a century ago. Originally operating as Sensitisers (Western) Group Ltd, the company quickly established an expertise in mill reel coated products.

With just one coating machine to its name, Kernow put the machinery to effective use, producing drafting film, Sepialine Diazo tracing paper and double matt Sepialine Diazo. Before long, the company was offering speciality films, translucent films and cardstock solutions to its customers too.

“As we evolved, we had to widen our net and expand our capabilities,” explained CEO Steve Gulliford. “Along the way, we have collaborated with key suppliers and partners that have helped enhance and progress our mission to create the best materials in the world.”

2010 saw the coatings expert expand into the North American market with the establishment of a brand-new distribution

partnership. This became an incredibly successful development for the company – eventually leading to the establishment of Kernow North America Inc.

Today, Kernow Coatings is recognised globally as a leader in high-performance, optimised coatings, which offers a diverse range of products including sustainable and eco environmentally friendly solutions tailored to meet the evolving needs of its customers and the marketplace.

Sustainability has remained a strong part of Kernow’s identity for many years. Over the past decade alone, the company has committed to planting and nurturing thousands of trees, actively reducing its CO2 emissions, and innovating new, exciting products with a strong emphasis on sustainability.

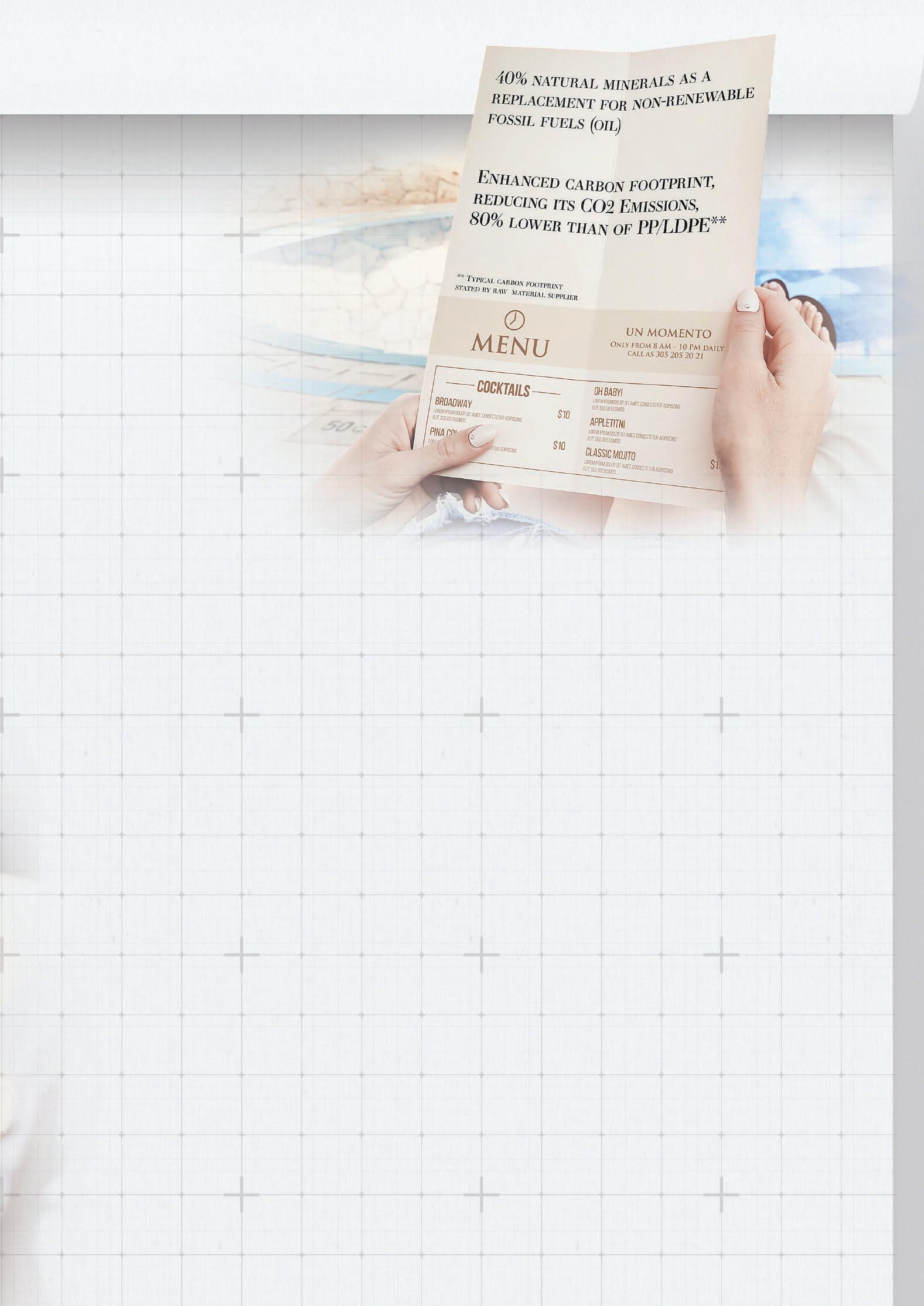

“Aligned with our commitment to sustainability, we developed eco-conscious synthetics

in collaboration with a strategic supplier: utilising polypropylene with up to 40 per cent mineral content,” explained Steve. “In relation to recycling polypropylene is preferred over polyester and with the addition of up to 40 per cent mineral content it makes it a more sustainable solution.”

The company has also been working alongside the University of Exeter to calculate its carbon footprint and produce a strategic plan. This initiative has already led to the installation of a 100kWh solar panel system, completed in partnership with a local business. This factor is incredibly important to the company. Being a part of the Southwest, it strongly believes in

supporting local businesses where possible, while helping the region thrive.

The company is also exploring the potential of biomass fuel as a future project and is currently evaluating the feasibility and practicality of installing storage capacity for surplus electric rather than going back to the grid.

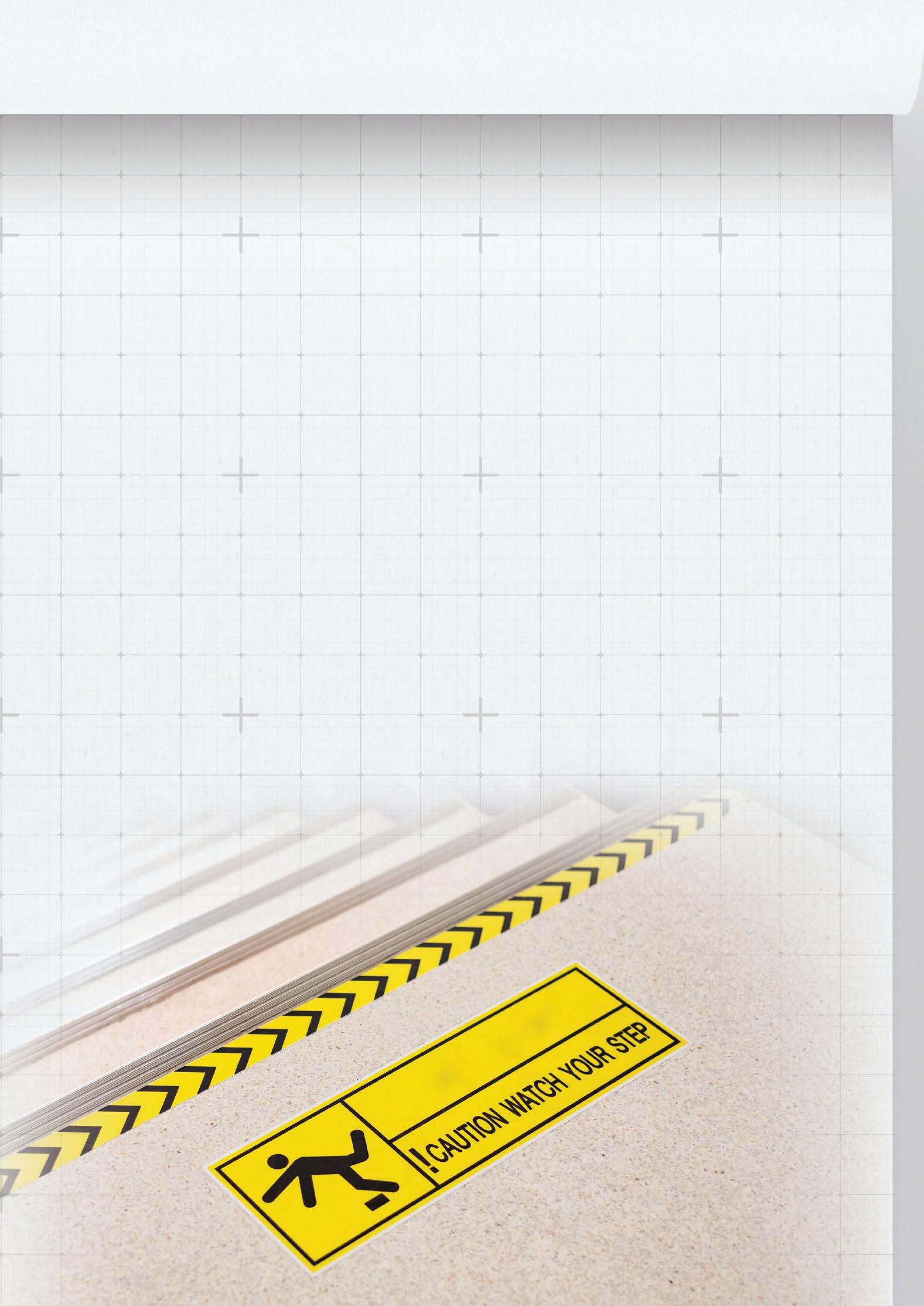

Kernow has been working hard to adapt some of its bestselling products to expand its range. One such product, which became incredibly popular during the pandemic, is FloorSharK™ – an anti-slip floor graphic.

Made from PVC-free film that promises to stand the test of time, FloorSharK™ is of durable construction, making it the perfect solution for versatile and attention-grabbing floor signage.

FloorSharK™ offers the added advantage of slip resistance, while its high-quality construction ensures long-lasting visibility and exceptional tear resistance, making it a popular choice for use in supermarkets, healthcare settings and public spaces, as well as industrial floor safety signage.

The success of FloorSharK™ has also inspired Kernow to explore an adaptation,

opening possibilities into a new segment of the market.

“We are currently adapting FloorSharK™ to meet the needs of sports and pop-up events,” said Steve. “The product was designed to benefit from the same anti-slip properties of FloorSharK™, but with the added benefit of easy residue-less removal. This will provide organisers with a low-tech, cost-effective way of displaying their sponsorships no matter when or where the games are held.”

This is just one of the many exciting projects underway at Kernow, a company that consistently drives innovation. With a robust pipeline

of product development, Kernow is poised to introduce a plethora of new offerings over the coming years.

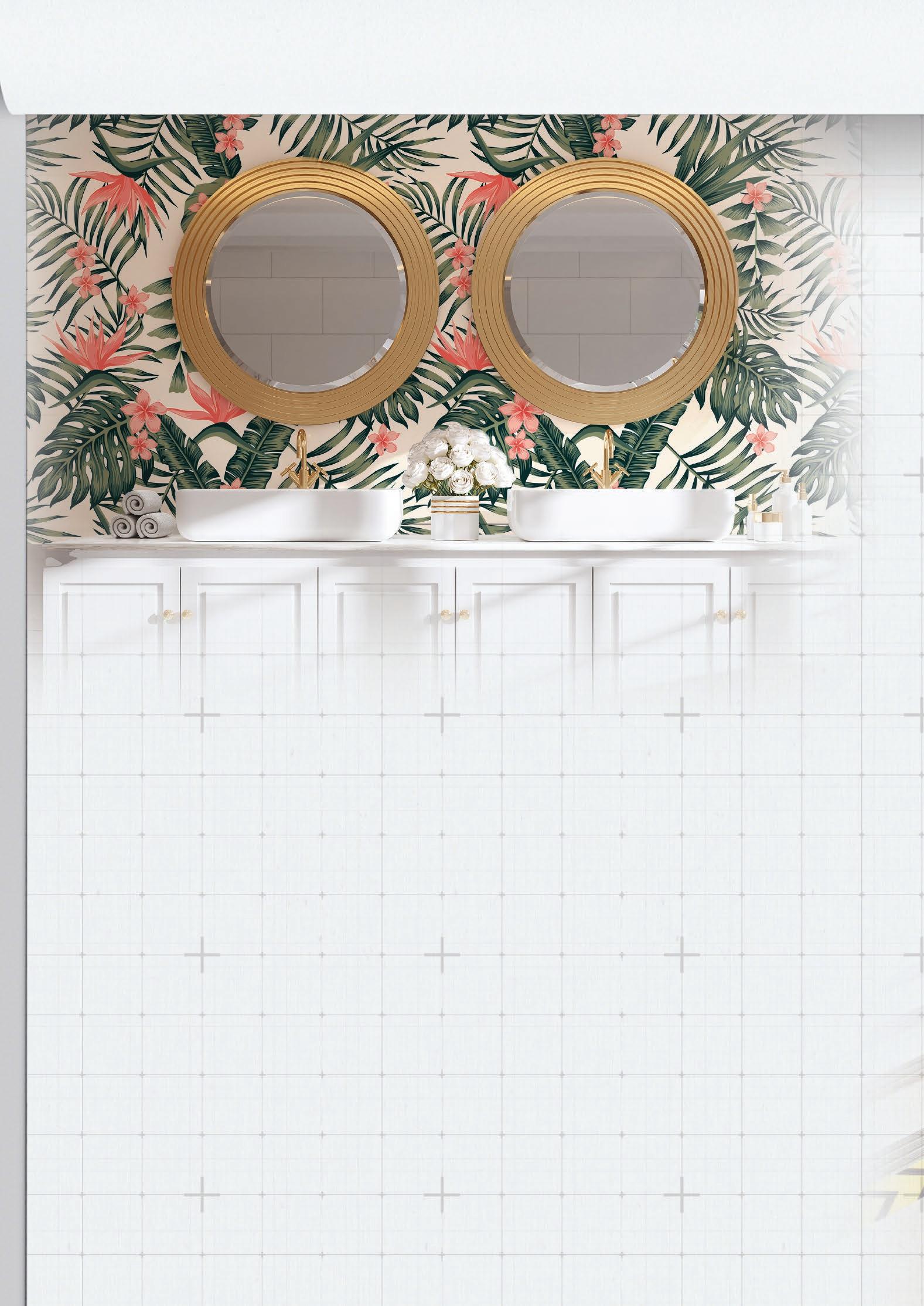

One of the most recent success stories that originated from Kernow’s funnel of creativity is its KernowJet Interiors digitally printable wallpaper. Launched in 2023, this product was developed in conjunction with a strategic partner.

“In the past, Kernow focused on doing everything alone, whereas now we employ a solid dedication to collaboration,” revealed Steve. “The development of our digitally printable wallpapers collection, KernowJet Interiors, is a great example of this and one that has been incredibly successful.”

Developed alongside an independent company, which is owned by an expert in the trade, Kernow’s wallcoverings hit the market

as a versatile and flexible solution for both residential and commercial interiors. With the only limit being imagination, this product line can be customised to any desired outcome, and with a guaranteed luxurious finish it fits right at home in even the most opulent of settings – or the more unusual.

“Our wallcoverings come in a whole range of finishes and have been used to decorate a number of unique spaces, from an A-List celebrity’s dining room through to the use of the gold to decorate a Greek Orthodox Church,” said Steve. “The results were not only visually stunning, but also highlighted just how limitless personalisation can be.”

Although already a hugely successful product in the UK and Europe, Kernow is now preparing to market its KernowJet Interiors range on a more global scale.

This is just the beginning of Kernow’s launch plans for 2025. Having already marketed its

KernowJet KlearWipe long-term dry-erase lamination film to classrooms across the globe, Kernow is now hoping to use this product as a gateway to a previously unexplored area of the market.

“KernowJet KlearWipe was designed to be an easy-to-clean lamination solution for whiteboards; however, its chemical makeup and anti-stick properties also make it useful for another more unusual application,” Steve explained.

When it comes to graffiti removal, whiteboard coatings might not be the first solution that comes to mind. Kernow is determined to change that with KernowJet KlearGuard, an upgraded product that combines the benefits of the original KlearWipe product, now with enhanced properties. The company is collaborating with a new customer to protect signs from vandalism and is preparing to market

the product as a robust anti-graffiti solution this year.

This initiative is just one of many ambitious projects Kernow has planned for the near future. Reflecting on the company’s evolving strategy, the CEO explained: “In the past, we have done everything alone, but the world is such a competitive space now that this is no longer feasible. We face significant competition from around the world, and to cement our place as number one, we must work with the right partners to implement our journey.

“We are in the final stages of developing our first-ever five-year strategy and look forward to seeing how it drives the business toward future growth and success. Since stepping into the role of CEO, the company has achieved many firsts, and witnessing these milestones come to life has been incredibly rewarding.” n

Inspiring future generations:

Kernow Coatings is currently in the midst of implementing a brand-new apprenticeship scheme to help retain valuable skills within the industry. Planned to go live later this year, the scheme is expected to commence with four apprentices.