TEXTILES WITH

Liberty Mills Limited is one of the largest textile processing and production companies in Karachi, Pakistan. The company is part of Liberty Group, which generates a yearly revenue of $650 million. VP Apparel, Sales & Marketing Shakeel Akhtar discussed innovation and sustainable initiatives. Report by Antonia Cole.

Established in 1964, Liberty Mills recently celebrated its 60th anniversary, VP Apparel, Sales & Marketing Shakeel Akhtar said: “The company has grown so much over the years. We are now a top 10 supplier to Europe and the USA, and we continue to enhance our capabilities year-on-year. Our clients include globally recognised brands, department stores and mail-order firms, so you can see our products everywhere.”

Liberty Mills is a vertically-integrated textile mill that produces home, apparel and institutional fabrics. The company has a state-of-the-art facility that produces approximately 500,000m2 of fabric per day, generating an annual revenue of $252 million. From this total, $127 million comes from

the home sector, $77 million from apparel and $48 million from institutions.

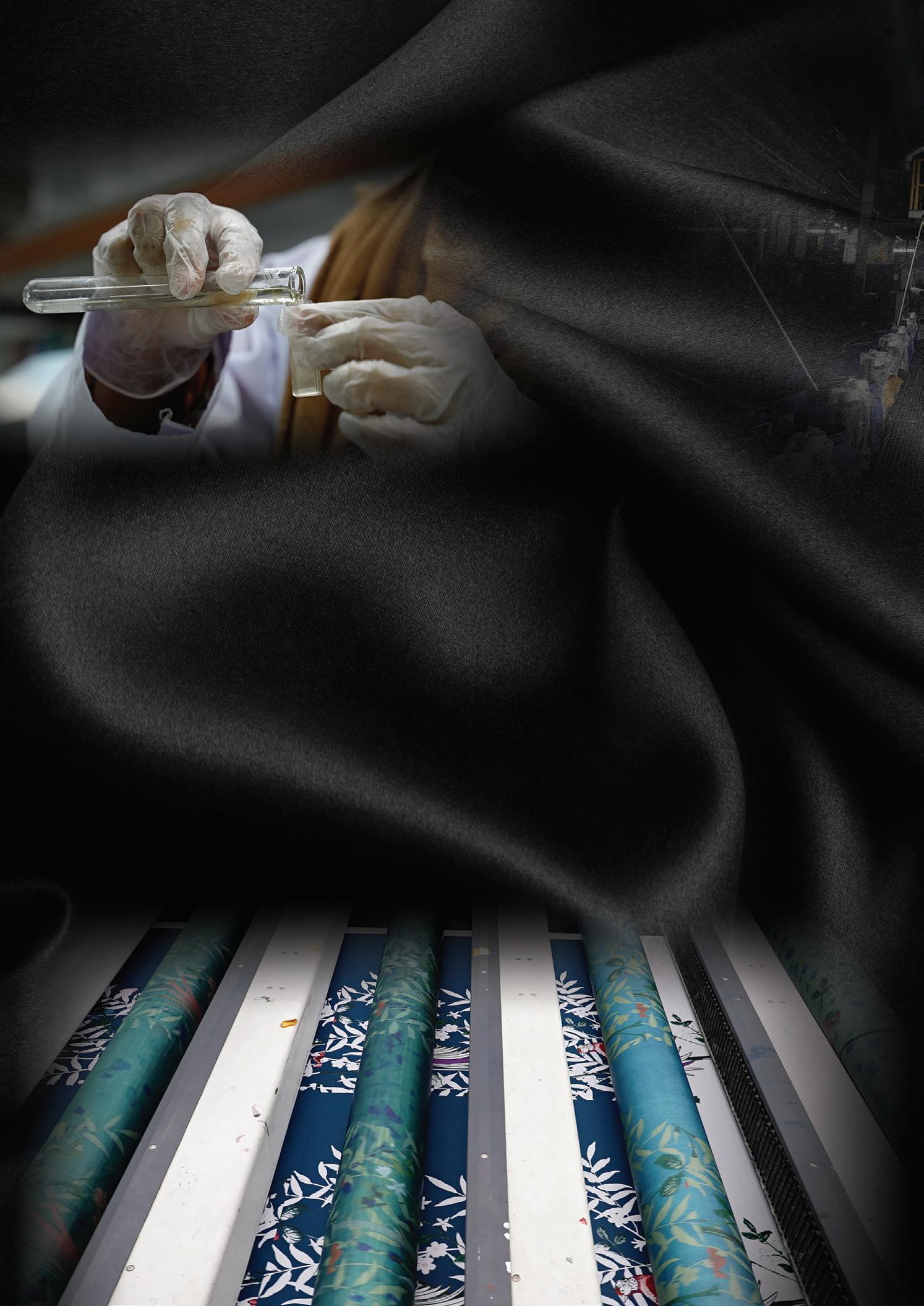

The company controls the whole process of production, guaranteeing high standards are met at every stage. From spinning, weaving and knitting, and fabric finishing to cutting,

sewing, packaging and fibre recycling, Liberty Mills’ skilled employees ensure quality controls are met in every finished product.

“At Liberty Mills, we are supported by our sister companies in the Liberty group,” added Mr Akhtar. “This includes Pakistan Aluminium & Beverage Cans, Liberty Wind Solar & Thermal Power, and Oncogen Pharmaceuticals. The establishment of these companies has allowed us to evolve Liberty Mills and its capabilities. Our renewable energy company not only supplies our own power sustainably, but also to other companies. This underscores our strong commitment to the environment.”

As Liberty Mills is vertically integrated, all aspects of the production process are completed internally. The creation of a piece of fabric begins with spinning the yarn. Liberty Mills has a monthly yarn production of 21 million pounds, as well as the ability to use a variety of yarn techniques including melanges, space dyes and blends. The company’s modern machines are also able to process sustainable raw materials such as recycled poly, cotton, viscose, hemp and linen. Additionally, the facility is powered by one of the group’s 6MW solar and wind power plants.

With 248 looms, including smart shed capability, and plans to have 600 looms by 2025, Liberty Mills is able to cater to a wide variety of clients. Moreover, the company has 20 knitting machines with a capacity of 45 tonnes per day.

“Another important part of our process is fabric finishing,” explained Mr Akhtar. “We have one digital and six rotary printers, three bleaching lines and 16 finishing stenters, as well as peaching and raising lines. We are fully equipped with the latest technology to

accommodate our clients’ needs and are able to dye 40 tonnes of fabric per day.”

Liberty Mills has Pakistan’s first LEED Gold

Certified home textile stitching unit, with automated fabric spreaders, stitching lines and smart system embroideries. The company’s focus on efficient production limits energy

use and minimises its environmental impact. Every month, Liberty Mills cuts up to 2.8 million pieces of fabric and sews 2.5 million.

“Sustainability is very important to us, which is why we recycle up to 700,000 pieces of cotton waste per month,” continued Mr Akhtar. “Our advanced technology shreds garments

and sheets, as well as both soft and hard waste from the entire production process. We also have a strategic partnership with Pinnacle Fibers for the recycling of polyester. Reducing waste sent to landfill is essential for a more environmentally-conscious future. We are always taking the necessary steps to become more sustainable.”

Protecting the environment in operations is a major target for Liberty Mills. The company aims to instil sustainability values throughout the company by giving employees the opportunity to participate in a range of environmental training programmes. This includes sessions on Scope 3 calculations. Additionally, Liberty Mills has its own sustainability team,

who are committed to continuously improving the company’s impact.

“Sustainability is important to us and to the wider industry too,” commented Mr Akhtar. “We are proud to have been recognised in 2022 by the Annual Environment Excellence Awards and to have received a certificate of excellence from NFEH’s Corporate Social Responsibility Awards in 2023. We were also runners-up in ASDA’s Sustainability Awards for our use of post-consumer waste to produce duvet sets, which saves on water, waste and carbon.”

Liberty Mills has submitted its Scope 1 and 2 targets to SBTi, demonstrating its commitment to reaching net zero emissions. The company is ISO 14001:2015 certified and is involved in various environmental initiatives. For example, Liberty Mills is passionate about better cotton farming and has one million acres of land dedicated to sustainable practices, producing 800,000 tonnes of cotton per year.

The company also implements recycling initiatives throughout production. This includes recycling up to 80% of water waste, 10 million plastic bottles and 72,000 tonnes of polyester. The knit fabric range prioritises recycled

cotton-based products, making sustainability accessible to clients.

“We use the Higg Index to measure the impact of our products’ life cycles,” added Mr Akhtar. “From this, we have been able to engage with our suppliers to limit our impact. Diesel consumption has decreased by 8.75 per cent, solar energy production has increased by 267 per cent and overall waste has been reduced by 28 per cent. These are fantastic results that we hope to maintain into the future.”

As a company, Liberty Mills is dedicated to diversity and inclusion within the workplace. CEO Taimoor Mukaty is a member of the Champions of Change Coalition, promoting women’s empowerment in the workplace. This initiative aims to develop the appropriate infrastructures to support female members of staff throughout Liberty Mills.

“We are an equal opportunity employer and are passionate about supporting the wellbeing of all members of staff, regardless of age, gender or disabilities,” said Mr Akhtar. “Some of our workforce are hearing impaired, so we provide sign language interpreters for

effective communication. We are partnered with NOWPDP to continue providing opportunities to those with disabilities.”

Liberty Mills works with suppliers and partners that share its values for corporate social and environmental sustainability, enabling the company to achieve more through collaboration. For example, Liberty Mills provides 18,000 free meals each day to those in need, as well as funding the education of 1,100 students.

“At Liberty Mills, we choose our partners based on quality and responsibility,” continued Mr Akhtar, in conclusion. “This allows us to work together to reach our common goals. We will continue to invest in the quality and production of our products, as well as opportunities for employees and environmental protection.” n