West Coast Edition For: WA, OR, and CA Vol. 13, No. 3 JUNE / JULY ’23 BUYER’S GUIDE PAGES 32-45 a2zMFG.com a2zMFG.com Customer-Centric Is The Renewed Focus At Phoenix Heat Treating

GROOVING THREADING PARTING BORING TURNING FACE GROOVING CUSTOM TOOLING FORM TOOLING MILL TOOLING Follow us on: 888-THINBIT | WWW.THINBIT.COM

What Is the American Dream?

The American dream is the belief that anyone, regardless of where they were born or what class they were born into, can attain their own version of success in a society in which upward mobility is possible for everyone.

The American dream is believed to be achieved through sacrifice, risk-taking, and hard work, rather than by chance.

I have had the privilege to work in this precision manufacturing industry with some very talented Vietnamese Americans and their stories are so heart warming and so profound at the same time. One was a friend of mine that worked with me at various shops in the Phoenix Valley and he was and is very bright, upbeat, and determined to succeed. I met my friend about 20 years ago when he was the machine shop foreman of a shop I was Director of Sales for and I always told him that he should start his own machine shop as he was so gifted/smart in programming, machining, problem solving, and he was a very likable individual. He told me he would start his own shop, if I would help him. Of course I told him I would in any way I could.

While working with the Vietnamese team he had put together in the machine shop I got to know these great folks and I would study them and their interactions with each other. I noticed a lot of similarities between his culture and my family of Hispano culture from New Mexico. These guys always ate together, shared their food, laughed and told jokes, picked on each other in a jovial way, worked like there was no tomorrow, and helped each other!

I would ask my friend questions about how he got his US citizenship and he would smile and say, “Well Keem it took a long time after I left Vietnam moving from one refugee site to another, in various countries. But I learned as much as I could and I learned and studied as much English as possible and I learned the American mannerisms and ways of interaction, joking, hand shakes, and I held on to my American Dream. At that time my main dream was to get to America with as much knowledge as I could, so I would fit in, and succeed”.

My friend said he was in and out of around 7 refugee camps in various countries, for almost 10 years before he was accepted for US citizenship. He told me about sleeping on the floor next to his wife and his new daughter as they slept on the small double bed, so he could wake up early for work as to not wake up his family so he could go to work early and then go to school to learn machining and programming after his shift was over.

His hard work and his wife’s hard work and determination paid off as eventually both achieved business ownership, he called their achievement the American dream. They raised their children to work hard in school and to maintain high grades (A’s), to always be very humble and respectful, so that they too could realize their dreams.

My friend owns a machine shop, his wife owns her own nail salons, his kids have succeeded in school and are very successful. They say they owe it all to the American dream.

I believe in the dream. There are millions that believe in this dream here in the USA, and still work hard to live as an example of what our forefathers envisioned when they forged the way of life we call being American.

I encourage all of you to remember where you came from, to harbor your pride for what we all have accomplished, and to work hard and smart for the dream you will pass on through the ages, “The American Dream!

In closing, God Bless our troops, and God bless the American Dream!

Thank you!

Kim Carpenter

At Phoenix Heat Treating Pages 20-21

Is The Renewed

PUBLISHERS/EDITORS

Kim Carpenter & Linda Daly

Kim@A2ZManufacturing.com

Mail Address: 1538 E. La Vieve Ln. Tempe AZ 85284

Telephone: (480) 773-3239

Website: www.A2ZManufacturing.com

CONTRIBUTORS

Linda Daly, Eugene Wirth, Stephen Hannemann,

Published

supply a viable supplier source for the industry.

Circula tion: A2Z Manufacturing West Coast maintains a master list of over 14,000 decision makers consisting of fortune 1000 companies, small manufacturing companies, engineering firms, DOD & Scientific Lab facilities, machine shops, fab-shops, and secondary source businesses. It has an estimated pass on readership of more than 25,000 people. The majority of our readers are based in CA, OR, WA area!

Advertising Rates have remained the same since 1999, deadlines and mechanical requirements furnished on our website at: www.a2zManufacturing.com.

All photos and copy become the property of A2Z Manufacturing.

T he Publisher assumes no responsibility for the contents of any advertisement, and all representations are those of the advertiser and not that of the publisher.

The Publisher is not liable to any advertiser for any misprints or errors not the fault of the publisher, and in such event, the limit of the publisher's liability shall only be the amount of the publishers charge for such advertising.

bi-monthly to keep precision manufacturers abreast of news, contracts, trends, and to

Cover

Published by: A2Z Manufacturing West Coast

E-mail:

Announcements/Releases ................... 6-14 Feature Articles ...................... 1,20-21, 28-29 Buyers Guide Equipment Services ..... 32-38 Buyers Guide Processes ...................... 39-45 Card Gallery ........................................ 32-45 Index Of Advertisers ............................... 46 Editorial .................................. Throughout A2Z MANUFACTURING WEST COAST • 4 • JUNE - JULY ’23 Customer-Centric

Kim@A2ZManufacturing.com

Focus

Editor’s Corner

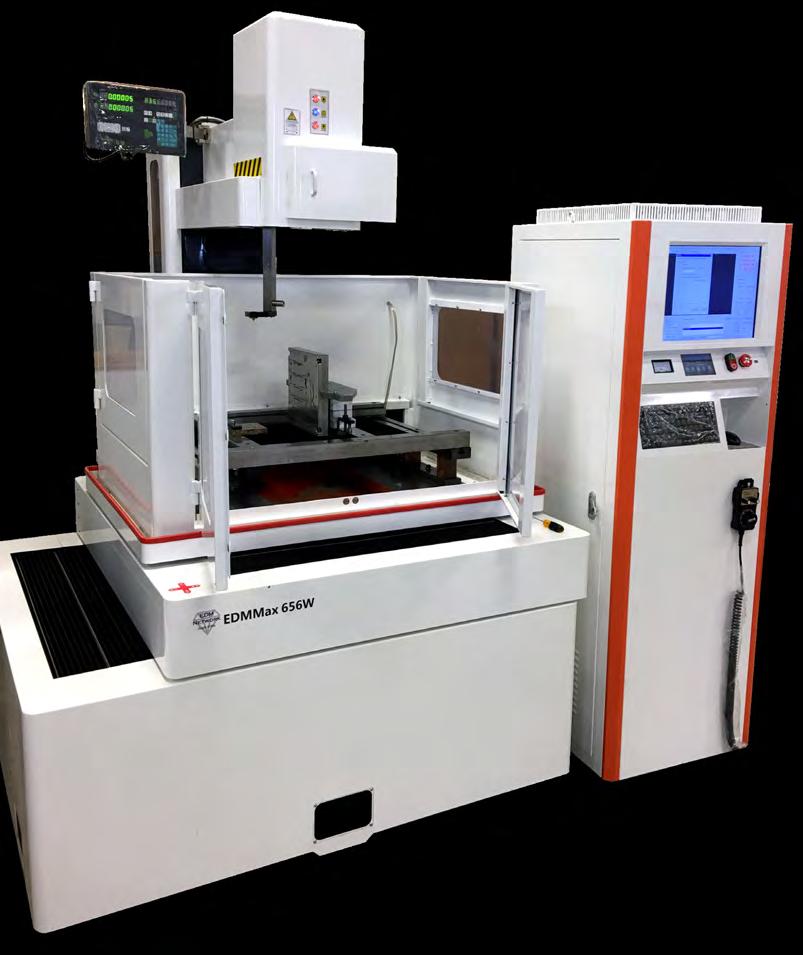

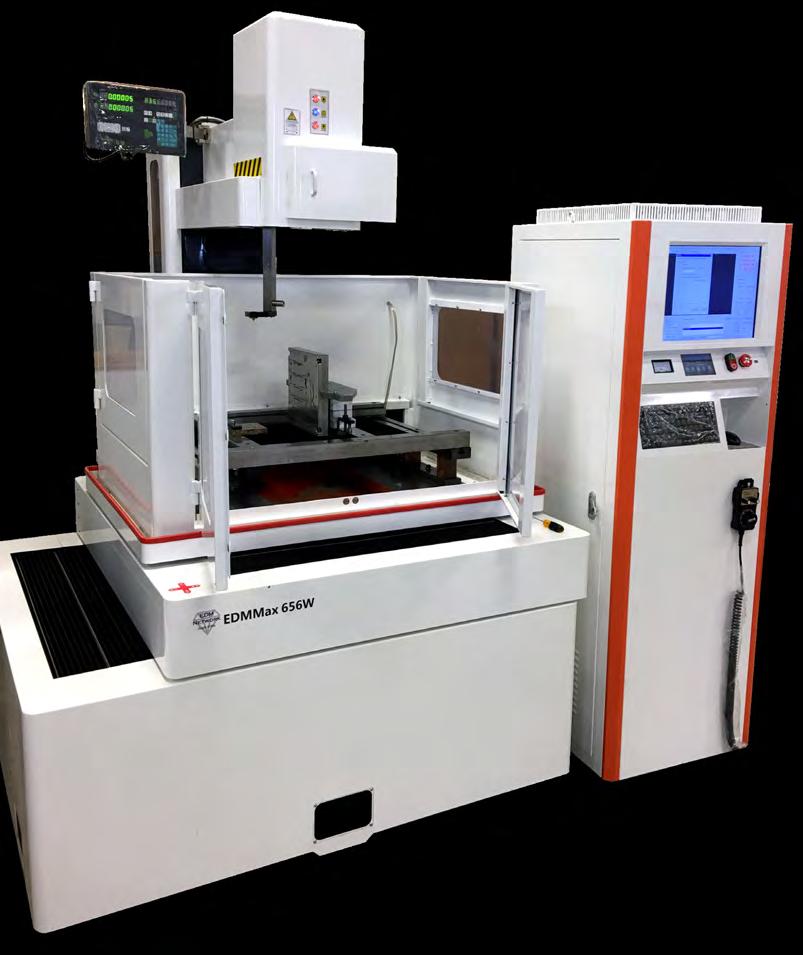

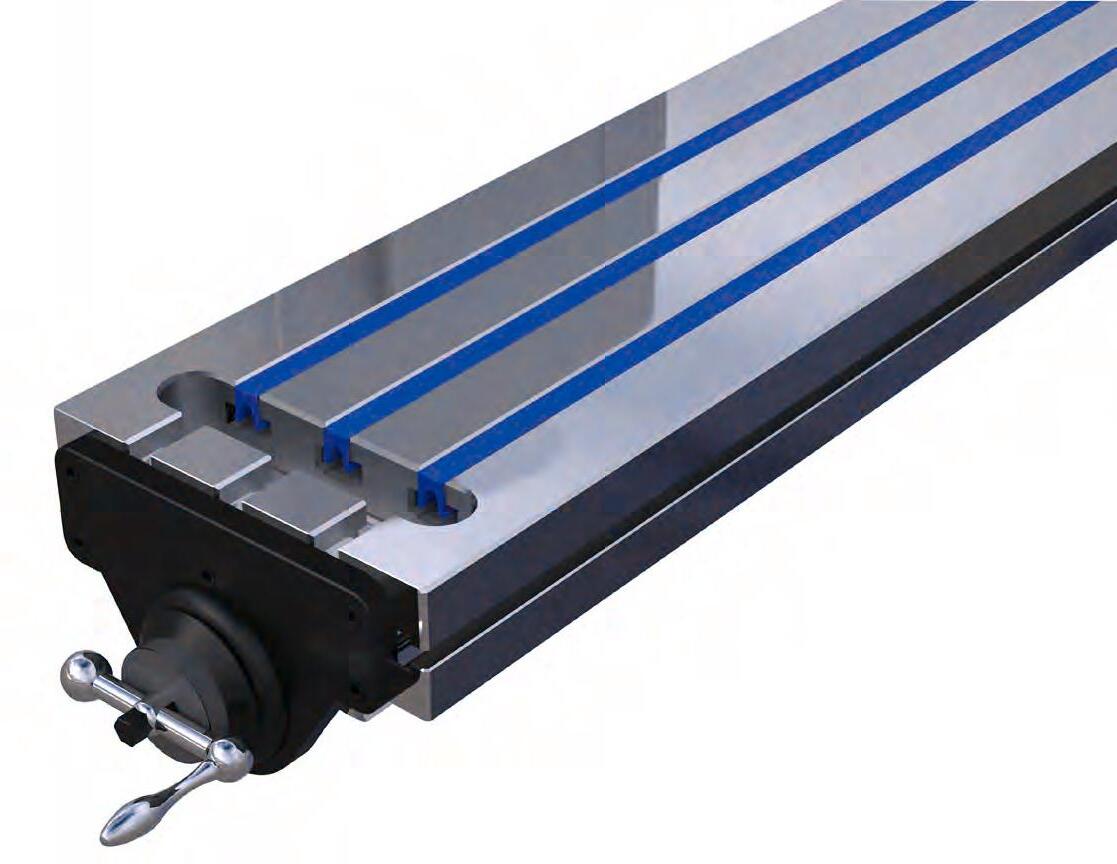

We have added a number of improvements over the standard Fast Wire Edms including:

• Cutting capacity of 625 x 625 mm

• Panasonic AC Servo motors and drivers

• Hiwin Linear Guideways

• Build in Cad System

• Two filters

• Increased height side walls to reduce splashing

• View windows to see the wire progress

• Automatic spent wire spooler

• Optional build plate support fixture

• Optional Anti Electrolisis (AE)

sizes available: • 400x320x410mm H

630x500x625mm H

1000x800x1050mm H

Horizontal Model 1000x1000x1000mm 1974 Bucktail Lane, Sugar Grove, IL 60554 1-888-289-3367 www.edmnetwork.com EDM Network provides “Everything in EDM”

EDMMax 656W 37 min TIME TO CUT

Four

•

•

•

The new model

T.J. Davies Company, Inc. was started in 1965 by Thomas Jared Davies.Tom originally named the company Deb-Sher Machine after his two daughters, Debra and Sherry. He later changed the name to T.J. Davies Company.

Soon after Tom finished his service in the United States Navy, he moved his family to Cleveland, Ohio, where he took a position with Swagelok, a well-established fittings manufacturing company. After working briefly at Swagelok, Tom’s parents gave Dad a small loan to start his company. Fred A. Lennon, Tom’s boss and founder of Swagelok, contracted with the new company to manufacture parts for them. After serving in the Vietnam War, Uncle Russell (one of Tom’s younger brothers) joined the company.

The company started as a “job shop,” making various products, including retention knobs for Mazak.

About 45 years ago, they began to produce retention knobs on lathes. T.J. Davies Company was the first to use this production method to manufacture retention knobs. Currently, they offer over 500 different styles of retention knobs and add new knobs as new machines or technology is introduced. If someone has a machine and is unsure what knob they need, they are the company they call. Additionally, they make custom knobs for older machines that no other company makes. They have full-time Programmers and a full-time Mechanical Engineer on staff who can assist with your custom retention knob needs.

In August 2018, Tom passed away, leaving the business to the next generation. Although Tom is no longer here, the company’s values, mission, and vision remain the same. His daughters have been making strategic changes to grow the business. The first order of business was to purchase a much larger building so they would have room to grow; the move was completed in December 2021. Next, a new website was launched, updated branding, and a new 132-page catalog. Davies said, “Our customers love the new catalog with all the additional information and images of all the new retention knobs.”The book is available spiral-bound as well as an electronic flipbook that links to their website that can be kept on your smartphone.

Call them if you are looking for excellent customer service, inventory in stock, and same-day shipping for orders received by 3:00 PM EST

For more information on the best Retention

Knobs in the industry contact them at:

440-248-5510, sales@tjdavies.com

T. J. Snow Stocks Water Chillers for Industrial Applications

Our company was founded in 1963 by T. J. “Jim” Snow, Sr., whose values continue to drive our growth and success. He believed that metal fabricators deserve service, expertise, and fair prices on Resistance Welding Machinery and Supplies. Thanks to this philosophy and strong foundation, we’ve developed a global customer base that relies on T. J. Snow Company’s dedication and consistency.

Not only do we meet our customers’ needs for Resistance Welding Parts and Supplies, we also offer three standard machine designs with our Slim Line Pedestal-type Spot & Projection Welders, our HeavyDuty Projection and Spot Welders, and our Standard Multi-Gun “Lean Machines.” The design and manufacture of each custom resistance spot welding single cell or fully equipped production line includes a comprehensive engineering effort. In addition to our standard spot welding machines, we also offer custom-designed complex Multi-Gun Welders and Turnkey Robotics Systems.

T. J. Snow has increased capacity over the past 50 years, and in 2010, the company moved to a new 52,000 square foot facility on more than 12 acres adjacent to the Chattanooga,Tennessee, Lovell Field airport.

T. J. Snow Company of Chattanooga, TN is now stocking a variety of a water chillers for industrial applications under its new Industrial Water Chiller (IWC) division.

T. J. Snow originally entered the chiller market many years ago to provide recirculated cooling water for its line of resistance welding machines. However, the company soon started selling chillers for a diverse range of applications.

IWC sells, services, supports and stocks chillers and spare parts from its Chattanooga,TN headquarters. An experienced service and engineering group is ready to assist nationwide.

Chillers in stock for quick delivery range from ½ ton to 20 tons. Larger sizes are also available, as are custom-engineered plant-wide systems.

Industry veterans Don Joyce, Jim Kirchoff and Billy James have joined the team in support of IWC sales and service.

For sales or service inquiries, visit www. IndustrialWaterChiller.com or Call (800) 934-0785.

A2Z MANUFACTURING WEST COAST • 6 • JUNE - JULY ’23 Announcements & Releases

Golf – A Fun Diversion

By Stephen Hannemann

By Stephen Hannemann

For the 21st year, the Columbia River chapter of the Society of Plastics Engineers (SPE) hosted their annual golf tournament at Eastmoreland Golf Course. The course is bordered by Portland’s stunning Rhododendron Gardens and picturesque Crystal Springs Lake. The historic 107-year-old golf venue is as challenging as it is beautiful, making this event a particularly bright spot on the local plastics industry’s calendar.

The day’s oftentimes dreary Oregon weather did not dampen the spirits of the eight fourman teams this year. A grand time was pulled off once again due to the efforts of the SPE Columbia River chapter’s president, Elliott Dundas, along with Denys Sanftleben, and Dave Lipinsky, another memorable event in this tournament’s storied history book.

Elliott Dundas, 3D Plastics’ Project Manager, deemed “The Ambassador of Levity”, spent the day zipping around the course in his chariot visiting and cheering the teams on. The festivities culminated with a luncheon

and social time enjoyed by all.

The tournament ended in an exciting two team tie:

Team – Shaw Polymers / James King,Tom McMullen, Scott Taylor, Brent Johnson, Jeff Laurence

Team – Denton / Sean McMullen, Rick Anderson, Dennis Denton, Matt Denton

Team – 3D Plastics – the outrageously fun foursome, did not place. Ken Houston, Kelly Dundas, Steve Waddle, David Ness

Everyone was having such a great time no one thought to take pictures of the winning teams. However, KUDOS to the SPE Columbia River chapter and 3D Plastics for leading the way to another great golf experience. It’s just one of the of the valuable gatherings on the SPE Columbia River chapter’s plastics industry calendar of events.

Be sure to look for the all-new 3D Plastics ad on page 16 of this publication.

A2Z MANUFACTURING WEST COAST • 7 • JUNE - JULY ’23

Introducing The New Collins Metal Finishing Team

Collins Metal Finishing (CMF) opened its doors in 1968 in response to the plating needs of the burgeoning manufacturing scene of the Phoenix area at the time. It was the brainchild of businessman Robert Wilkinson and electroplater John Collins.

Over the years, CMF grew in both size and complexity, finding its niche in Anodizing and Electropolishing supplemented by a variety of similar,

1979

“less complex” services. Despite its growth, CMF has never strayed from its family roots.

In the late 90s, John’s son, Mike, took over his position while Robert’s daughter and son-in-law, Kathy and Chuck Garcia, took over his responsibilities.

Under the direction of these three, CMF left its original location— a shack built during the WWII era— and opened a 5,000 sq. ft. facility with modernized equipment and environmental protections.

Grandson of Kathy and Chuck, Gavin Garcia (now 26 years old), grew up often accompanying his grandfather to work. Intrigued with how the various processes worked and enamored with the finished products, he began working at the shop the day after he turned 16. Gavin is pictured above.

With brief stints working various other jobs, he always worked either full or part time at Collins until the time he graduated ASU in 2021.

A couple of weeks later, he began training to take over for Chuck and Kathy amid Chuck’s battle with cancer.

On May 10, 2022, Chuck passed away at the age of 69, two days shy of his 70th birthday.

From then on, Gavin began his tenure as Director, working to continue the legacy of his grandfather.

Over the course of the last year, with Gavin at the helm, CMF has introduced a new logo, modernized their system, and expanded their electropolish services by introducing a brand-new line to satiate the demand of the semiconductor and medical industries.

Fully operational as of April of this year, the new EP line has cut lead times by more than 50% and supported their mission to keep prices as affordable as possible.

Recently, Kathy passed her role as President on to her son, Marc Garcia. Together, Gavin and Marc are looking to continue to grow CMF in its support of the semiconductor, medical, aerospace, and defense industries.

To learn more about how CMF can support your plating needs, contact them at : 602-275-3117 or email Gavin at gavin@collinsmetalaz.com

A2Z MANUFACTURING WEST COAST • 8 • JUNE - JULY ’23

CNC AND MANUAL MACHINERY SINCE

New - Used -Appraisals

Our Showroom At: 3305 Edison Way, Fremont, CA 94538 Is Open Monday - Friday From 8am To 5pm BOB KROHA ROB KROHA CONTACT US TODAY: 510-249-1000, PERMACH.COM

- Auctions

MarZee Cutting Services Adds To Capabilities With the Eagle 20kW Fiber Laser Cutter

MILL S & THRILLS

The versatile VMC lineup at DN Solutions is enough to get anyone excited.

MarZee Cutting Services is pleased to announce its lastest machine acquisition, the Eagle iNspire 20kW Fiber Laser Cutter. Ed Wenz, owner of the company, says, “The iNspire series of cutting machines are state of the art, extremely precise, and amazingly quick. They excel at the most demanding mass production applications with their rigid composite base and lightweight carbon fiber bridge as well as the long-life eVa cutting head.”

He adds, “We chose the Eagle iNspire line because they are the fastest and most efficient laser machines in the world.”

The lineup of vertical machining centers at DN Solutions is versatile, compact and born to make incredible parts for as long as you need them to. Get your ideal VMC, then get ready for the vertical leap. Talk to your local DN distributor or visit dn-solutions.com.

DEM: entry-level par t producer

SVM: swift and strong

DNM: global best seller

BVM: premium powerhouse

As a family-owned and operated business, located in Phoenix, AZ. MarZee is the industry leader for WaterJet, Forming, and Laser cutting with our CNC-controlled state of the art machines.To learn more about how MarZee can help you with waterjet, forming and now laser cutting, contact them at: 877-885-1059, email: marzee@ marzee.com or visit marzee.com <<< MACHINISTS - WANTED IN ARIZONA >>>

SALES (866) 567-2580

SERVICE (800) 994-0146

PARTS (888) 207-2787

www.ellisontechnologies.com |

At Tech Five Machining, we are a leading provider of precision machining solutions, specializing in delivering exceptional quality and unmatched expertise. With years of experience and a commitment to excellence, we have established ourselves as a trusted partner for a wide range of industries.

Our dedicated team of skilled professionals embodies our core values of precision, innovation, and customer satisfaction. We take pride in our ability to understand the unique needs of each client and provide customized solutions that meet and exceed their expectations. From initial concept to final production, we work closely with our clients to ensure their vision is transformed into reality.

For information on a great paying job with Tech Five contact them at: 480-699-4856, w.thomastechfivemachining.com

A2Z MANUFACTURING WEST COAST • 9 • JUNE - JULY ’23

Doosan Machine Tools is now

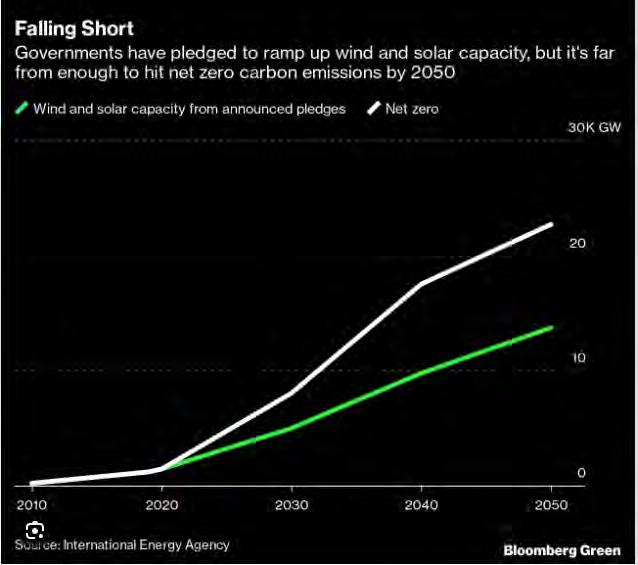

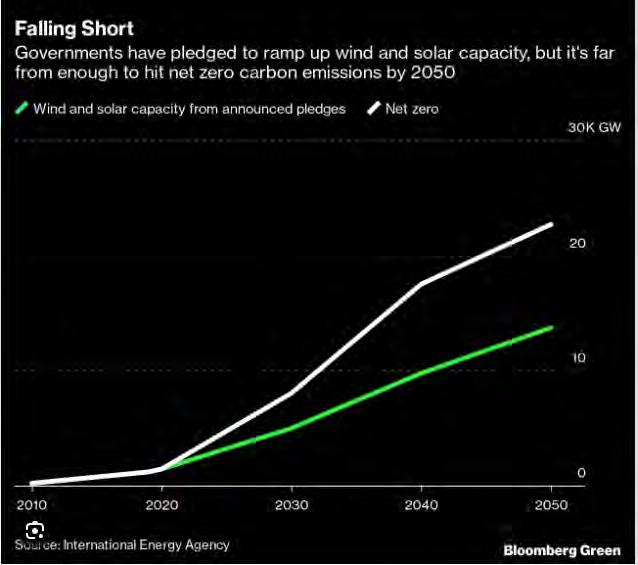

Global Net Zero Plans Aren’t Living Up To Expectations

Bridget McCrea

Bridget McCrea

A growing number of organizations are committing to net zero plans— but many governments are failing to meet their GHG reduction goals, according to a new report.

Bridget McCrea

A state in which the greenhouse gases (GhGs) being released into the atmosphere are balanced by removal out of the atmosphere, to “go net zero” finds organizations cutting those GhGs to as close to zero as possible, with any remaining emissions re-absorbed from the atmosphere (i.e., by oceans and forests).

According to the UN, science shows clearly that in order to avert the worst impacts of climate change and preserve a livable planet, global temperature increase needs to be limited to 1.5°C above pre-industrial levels. “Currently, the earth is already about 1.1°C warmer than it was in the late 1800s,

and emissions continue to rise,” the organization explains. “To keep global warming to no more than 1.5°C – as called for in the Paris Agreement –emissions need to be reduced by 45% by 2030 and reach net zero by 2050.”

Tackling a Monumental Challenge

Transitioning to a net zero world is one of the greatest challenges humankind has faced, the UN adds, and it calls for “nothing less than a complete transformation of how we produce, consume and move about.” A new report finds that despite their best intentions surrounding net zero, most cities, states and organizations are having a difficult time actually making progress in this area.

In its Net Zero Stocktake 2023 report, Net Zero Tracker says that growth in the number of national and subnational net zero targets has slowed, yet momentum among individual companies’ net target-setting continues. In fact, it says the share of publicly-listed companies with net zero targets has more than doubled in a little over two years, from 417 to 929.

A2Z MANUFACTURING WEST COAST • 10 • JUNE - JULY ’23

National government net zero targets underpinned by legislation or policy documents increased substantially in the last two-and-half years, from 7% to 75%.

A significant share of subnational and corporate entities still lack any emission reduction target whatsoever, at the global level and within the Group of Seven (G7), which is an intergovernmental political forum consisting of Canada, France, Germany, Italy, Japan, the UK and the U.S.

Collectively, Net Zero Tracker says there are “very limited signs of improvement” in the robustness of subnational and corporate net zero targets and strategies.

More entities are clarifying their intention to use carbon dioxide removals (CDR) in their value chain.

Despite having net zero pledges, no major producer countries or companies have committed to phasing out fossil fuels.

Emerging voluntary net zero standards have strongly converged on principles, but more specificity is required to give clarity to those wanting to set credible strategies.

Of the more than 4,000 entities Net Zero Tracker currently watches, at least 1,475 now have a net zero target, up from 769 in December 2020.

In particular, Axios says gaps in company net zero targets mirror problems at the national level. “Relatively few have laid out detailed plans to achieve their goals, and most others are falling short amid continued reliance on fossil fuels,” it adds. And while 67% of fossil fuel companies have set net zero commitments, it says “an absence of oil and gas phase-out plans leaves those targets misaligned with the scientific and policy consensus.”

Net Zero Targets are Trendy

The report also found that just 37% of corporate net zero targets fully cover emissions from end-users of company products, and that just 13% lay out the conditions where offsets can be used.

According to Net Zero Tracker, more specificity is required to make pathways clearer for all entities wishing to set credible and robust net zero targets. “Net zero has had to grow up quickly, but is now firmly in an age of implementation,” it concludes.

“Above all, we need more entities to sign up to net zero, and need those that have pledged to step up.”

A2Z MANUFACTURING WEST COAST • 11 • JUNE - JULY ’23 Other key findings from the new

STARTING$7680 AT 1-800-52 1-1740 KBCTools.com

It’s Time For Us To Wean Off Government Checks

By Sougata Mukherjee

By Sougata Mukherjee

Help Wanted signs are showing up across the U.S. but shortages are getting worse in the retail sector.

A slew of government reports, surveys and economic statistics were released in the past few days, and almost all of them point out to an economy that now needs to wean off government assistance.

Without a doubt, and the numbers prove it, stimulus checks have helped Americans tremendously, which in turn has helped businesses stay afloat.

The Administrative Office of the U.S. Courts released its annual bankruptcy report that shows bankruptcy filings dropped 38% for the year ended March 2021 when compared to the previous year. “New filings fell in all federal courts, including the bankruptcy courts, as many federal courts closed their doors to in-person business,” stated the note from the U.S. Courts. “In addition, unemployment began to moderate, and state lockdown orders

depressed personal expenditures. Increased government benefits and moratoriums on evictions and certain foreclosures also may have eased financial pressures in many households.”

As individuals now begin to spend the stimulus money received in different tranches, small businesses across the country are sounding optimistic. A First Citizens Bank (Nasdaq: FCNCA) survey released May 3 concludes 80% of small businesses are confident in business growth over the next 12 months.

In essence, putting money in as many pockets helped – and clearly it was needed.

But rising prices of raw materials and a widespread shortage of parts may now be threatening to create enough headwinds for the economy.

And it all starts with the labor force. If the labor force that is unemployed is reluctant to get back in the employment line because of higher unemployment checks, small businesses – especially retailers – will suffer. Anecdotal evidence suggests this already is happening.

When Congress passed a slew of stimulus bills relating to unemployment benefits, lawmakers made sure workers get an additional $300 a week in federal benefits on top of regular state benefits. The Labor Department notes state benefits averages about $318 a week.You total both numbers and we are talking unemployed workers getting more than $15 an hour by remaining unemployed.Those enhanced benefits expire in September (maximum 18 months), and until then the labor market is expected to

A2Z MANUFACTURING WEST COAST • 12 • JUNE - JULY ’23

face serious supply side pressure.

What may be more concerning is the shortage in skilled labor may keep the prices high because of the manufacturing strain. On May 3, the Institute for Supply Management (ISM) said its manufacturing index fell to 60.7% in April from a 38-year high of 65% in the prior month.The number is still very strong but now we have to worry about inflation.

“Worker absenteeism, short-term shutdowns due to part shortages, and difficulties in filling open positions continue to be issues that limit manufacturing-growth potential,” said Timothy Fiore, chairman of the ISM survey. “What isn’t a problem is demand.”

To meet that demand, we need to make sure the supply is available. And it starts with government policy. Rather than issuing stimulus checks to everyone through multiple tranches, this is the time to devise a new strategy to get workers back to work to support our critical infrastructure. Without a doubt, there will be people in need of a stimulus check. But we need to use a fiscal syringe, not a hose.

If we manage to increase the supply of our goods and services to meet the demand, prices will get under control and inflation will remain in check. I agree with the Federal Reserve on that, although I am beginning to wonder if the Fed can keep its promise – keep interest rates near zero through 2023.

Phoenix Heat Treating Phoenix Heat Treating

The U.S. economy has made a remarkable recovery, thanks to some macro choices made in Washington. But we are reaching a new phase of growth, and we have to let go of the training wheels that were put on us during the pandemic.

The Big Role for Small Modular Reactors in the Energy Transition

Shafaq Hedstrom grew up in Pakistan, watching her father help build the country’s power infrastructure. “It was an early lesson in the reallife benefits that electricity brings to communities and countries and the essential role it plays,” she said.

“Energy was in my blood, so I knew I wanted to be in this industry from the beginning,” said Hedstrom, Senior Vice President for Strategy & Business Development at GE Hitachi Nuclear Energy.

She later moved to the United States, graduating from the University of California at Berkeley in 2006. “At the time, California was at the

forefront of the energy transition,” she said, inspiring her to join the utility Pacific Gas & Electric (PG&E), where she was “excited to be at a company that was leading the energy transition in real time.”

After nearly 16 years with the company and rising to a senior strategic planning role, she saw that California’s energy transition was heavily focused on renewables and nuclear power was not part of the dialogue on California’s energy future.This motivated her to look for an opportunity to be more proactive in ensuring nuclear power “had a seat at the [energy transition] table.”

In 2021, she moved to GE Hitachi where she works with customers and talks with energy stakeholders around the world about the important role that nuclear power – and small modular reactors (SMRs) in particular – can play in providing people and businesses with baseload electricity they need for economic development, while also addressing the urgency of energy security and climate change.

A2Z MANUFACTURING WEST COAST • 13 • JUNE - JULY ’23

GET TO KNOW US Servicing our industry and trade customers in intelligence heat treating for over 60 years. www.phoenix-heat-treating.com 602-258-7751 cs@phxht.com Established in 1963 Real Time Live Job Tracking 10+ Processes Performed 50+ Furnaces AOG and Line Down Services Over 10+ Prime Approvals 24/7 Processing

As Aviation Fans Head to Paris Air Show, a Survey of Industry Leaders Shows Broad Support for Sustainability

Will Palmer

Will Palmer

A lot has happened in aerospace since the 2019 airshow. It was just two years ago that the Air Transport Action Group (ATAG), of which GE Aerospace is a member, set an ambitious goal of achieving net zero carbon emissions by 2050, in support of the Paris Agreement. Where does the industry stand today on meeting those goals? GE Aerospace, which has long been at the forefront of making flight more sustainable, recently commissioned a survey of 325 aviation decision makers in the U.S., the U.K., China, India, the UAE, and France to find out.

The results, released today, show that the industry is taking the challenge seriously, citing sustainability goals as their top challenge today, surpassing issues like supply chain and labor, and putting their money where their mouth is to meet it. Fully 76% of the aviation

decision makers — who represent airlines, airframers, and airports, among others — say that the focus on sustainability has fundamentally changed the way the industry operates, and that these strategies have already had a major or moderate impact on how their company operates (74%), invests (73%), and hires (62%).

But even as two-thirds of stakeholders believe the aviation industry is united in its focus on implementing sustainability solutions, they also said that reaching the 2050 goal will mean stepping up the rate of progress. At the current trajectory, 46% believe the industry will meet its net zero goal by 2050, 32% say it will not, and 22% are unsure. Government needs to play a larger role in supporting sustainability efforts, with most (61%) believing that incentives and policy support should be prioritized over mandates and regulation, according to the survey, conducted by Ipsos.

Respondents also indicated that advancements in both fuels and engines will play the biggest role in making net zero a reality. Engines and fuels, as GE Chairman and CEO and GE Aerospace CEO Larry Culp points out, are “two areas in which GE Aerospace has taken a leadership role.”

A2Z MANUFACTURING WEST COAST • 14 • JUNE - JULY ’23

Culp is alluding to new technology development like CFM’s* RISE

technology demonstration program. RISE — which was unveiled two years ago this month — is advancing a suite of new technologies such as open-fan architecture with the aim of achieving at least 20% better fuel efficiency with 20% lower CO2 emissions than the most efficient engines today. Last summer, Airbus announced that it would participate in the RISE program by partnering with CFM to carry out a flight test demonstrator program on an Airbus A380 during the second half of this decade, to validate the open-fan engine architecture. A half-scale model of the open-fan architecture will be front and center during the Paris show — watch GE Reports in the coming week for more news.

Attendees at the show will also find out what GE Aerospace has been up to in fuels research. Sustainable aviation fuel (SAF) is one area where the company has been notably ahead of the curve, through research efforts going back more than 15 years, and a partnership with United Airlines that demonstrated the successful use of 100% SAF in one engine on a passenger flight. These fuels, which can be made from plant-based material, fats, oils and greases, alcohols, waste streams, captured CO2, and other alternative feedstocks, have the same chemical composition as conventional Jet A fuel. They have the potential to lower life-cycle CO2 emissions by up to 80% compared with conventional jet fuel. All

engines produced by GE Aerospace and its partners are able to run on approved SAF blends today.

Another path is electrification, which has rolled out on the world’s roads and could be coming to the skies soon. Under NASA’s Electrified Powertrain Flight Demonstration project, a five-year, $260 million effort announced in 2021, NASA and GE Aerospace are advancing development of a megawatt-class integrated hybrid electric powertrain, with plans to flighttest it later this decade. Boeing and its subsidiary Aurora Flight Sciences will modify the plane and perform system integration and flight-testing services.

Christine Andrews, executive hybrid electric systems leader for GE Aerospace, said that it’s “an engineer’s delight to have a new landscape of technology development both in the actual hybrid electric system as well as in the adjacencies such as certification, airworthiness, quality, power electronics, and components we haven’t looked at before.”

In collaboration with Airbus, CFM International in 2022 announced plans to test a GE Aerospace aircraft engine fueled by liquid hydrogen.

A2Z MANUFACTURING WEST COAST • 15 • JUNE - JULY ’23

Contracts

The Boeing Co., Oklahoma City, Oklahoma, has been awarded $47,327,689 firm-fixed-price, indefinite delivery/definite-quantity, cost-plus-fixed-fee, cost-reimbursement incentive contract for KC-135 engineering sustainment support. This contract provides follow-on engineering sustainment services from previously awarded contract FA8105-16-D-0002 and includes fleet support and recurring and non-recurring engineering services. Work will be performed in

Oklahoma City, Oklahoma; San Antonio,Texas; Huntsville, Alabama; Houston, Texas; Pleasanton, California; Long Beach, California; Mesa, Arizona; Tukwila, Washington; St. Louis, Missouri; Fort Walton Beach, Florida; and Vancouver, British Columbia, Canada. The work is expected to be completed by June 30, 2033. This contract involves Foreign Military Sales to Chile, France, and Turkey. This award is the result of a sole source acquisition. Fiscal 2023 operations and maintenance funds in the estimated amount of $22,900,000 are being obligated at the time of award.The Air Force Life Cycle Management Center, Tinker Air Force Base, Oklahoma, is the contracting activity (FA8105-23-D-0002).

DEFENSE LOGISTICS AGENCY

Belleville Shoe Manufacturing Co.,* Belleville, Illinois, has been

Precision Injection Molding Is What We Do!

3D can provide design assistance and work with existing products to produce them more economically.We are a ‘UL Certified’ molder offering low to high quantity production runs.

We produce many of our customer’s products with metal and plastic sub-components molded in. It is very common to use threaded inserts, bushings, contacts, and plastic substrates.

awarded a maximum $26,968,043 fixed-price, indefinite-delivery/indefinitequantity contract for combat hot weather boots. This was a competitive acquisition with three responses received. This is a three-year contract with no option periods. Location of performance is Arkansas, with a June 16, 2026, ordering period end date. Using military service is Army.Type of appropriation is fiscal 2023 through 2026 defense working capital funds. The contracting activity is the Defense Logistics Agency Troop Support, Philadelphia, Pennsylvania (SPE1C1-23-D-0053).

ORC Industries Inc., La Crosse, Wisconsin, has been awarded a maximum $12,076,750 modification (P00004) exercising the second one-year option period of a one-year base contract (SPE1C1-21-D-N154) with four one-year option periods for service dixie hats. This is a firm-fixed-price, indefinitedelivery/indefinite-quantity contract. The ordering period end date is June 27, 2024. Using military service is Navy. Type of appropriation is fiscal 2023 through 2024 defense working capital funds. The contracting activity is the Defense Logistics Agency Troop Support, Philadelphia, Pennsylvania.

Raytheon Technologies Corp., Pratt and Whitney Military Engines, East Hartford, Connecticut, is awarded a $293,771,544 firm-fixed-price modification (P00011) to a previously awarded cost- plus-fixed-fee, firmfixed-price, fixed-price incentive (firm-target), indefinite-delivery/indefinitequantity contract (N0001920D0013).This modification increases the contract ceiling to procure F-135 propulsion system spare parts and depot lay-in material in support of the F-135 propulsion system requirements for the Air

A2Z MANUFACTURING WEST COAST • 16 • JUNE - JULY ’23

Plastics, Inc.

Injection Molding

280.2278

3D

Custom

800.

Contact Us Today: info@3d-plastics.com, 503-537-0979

3d-plastics.com, 503-537-0979

NAVY

Force, Marine Corps, Navy, Foreign Military Sales customers and nonDepartment of Defense participants.Work will be performed in Indianapolis, Indiana (79%); East Hartford, Connecticut (14%); and Bristol, United Kingdom (7%), and is expected to be completed in December 2026. No funds will be obligated at the time of award, funds will be obligated on individual orders as they are issued. The Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity.

Lockheed Martin Space, Littleton, Colorado, is being awarded a $32,139,953 cost-plus-incentive-fee contract modification (P00059) for options under a previously awarded contract (N0003019C0025) for the design, development, build and integration of equipment for missile flight test demonstrations and fielding. Work will be performed in Denver, Colorado (51%); Sunnyvale, California (19%); Salt Lake City, Utah (12%); Pittsfield, Massachusetts (5%);

Cambridge, Massachusetts (4%); Courtland, Alabama (3%); Huntsville, Alabama (3%); East Aurora, New York (2%); and Simsbury, Connecticut (1%). Work is expected to be completed Feb. 25, 2025. Fiscal 2023 research, development, test, and evaluation (Navy) funds in the amount of $32,139,953 will be obligated upon award and will not expire at the end of this fiscal year.This contract modification is being awarded on a sole source basis under 10 U.S. Code 2304(c)(1) and was previously synopsized on the System for Award Management online portal. Strategic Systems Programs, Washington, D.C., is the contracting activity.

Raytheon Co., El Segundo, California, is awarded a $15,557,878 cost-plusfixed-fee contract. This contract provides support for Next Generation Jammer (NGJ) Mid-Band (MB) units under test intermediate and/or depot level test/repair information. This data will support the decision to use the consolidated automated support system family of testers or specialized test equipment for the testing and repair of the NGJ-MB system. Additionally, this contract provides for the generation and delivery of test requirement documents and fault detection/fault isolation analysis of units under test weapons replaceable assemblies/shop replaceable assemblies. Work will be performed in McKinney, Texas (46.2%); Fort Wayne, Indiana (40.4%); and El Segundo, California (13.4%), and is expected to be completed in June 2026. Fiscal 2023 aircraft procurement (Navy) funds in the amount of $15,557,878 will be obligated at time of award, none of which will expire at the end of the current fiscal year. This contract was not competitively procured pursuant to Federal Acquisition Regulation 6.302-1.The Naval Air Warfare Center, Aircraft Division, Lakehurst, New Jersey, is the contracting activity (N6833523C0407).

ARMY

General Dynamics - Ordnance and Tactical Systems, Garland, Texas, was awarded a $26,322,482 modification (P00002) to contract W519TC23-F-0047 to procure pipe for general-purpose bomb bodies. Work locations and funding will be determined with each order, with an estimated completion date of Dec. 31, 2025. U.S. Army Contracting Command, Rock Island Arsenal, Illinois, is the contracting activity.

A2Z MANUFACTURING WEST COAST • 17 • JUNE - JULY ’23 (800) 481-6271 www.pmplating.com We Are The Noble Partner With The Personal Touch! Precious Metals Plating Co., Inc + Gold Plating + Silver Plating + Nickel Plating + Electroless Nickel Plating + Tin Plating + Heat Treat With Plate + Nadcap Approved Processes + Boeing Approved Processes + Expedited Turnaround + X-ray Fluorescence Thickness Verification + In-House Laboratory With Atomic Absorption (AA) + Expanded Capacity In Vibratory Plating

Boeing Forecasts Demand For 42,600 New Commercial Jets Over Next 20 Years

- Air travel demand outpacing economic growth as domestic markets fully recover; international traffic returning to pre-pandemic levels by 2024

- About half of deliveries to replace older jets with more fuel-efficient models, reducing emissions - New airplane demand valued at $8 trillion;

$3.8 trillion

PRNewswire/ --With a resurgence in international traffic and domestic air travel back to pre-pandemic levels, Boeing [NYSE: BA] today projected global demand for 42,595 new commercial jets by 2042, valued at $8 trillion. Boeing released its 2023 Commercial Market Outlook (CMO), the company’s forecast of 20-year demand for commercial airplanes and services, in advance of the Paris Air Show.

The new CMO comes three years after the pandemic grounded most of the global fleet. Key findings include:

Passenger traffic continuing to outpace global economic growth of 2.6%.

The global fleet nearly doubling to 48,600 jets, expanding 3.5% per year.

Airlines replacing about half of the global fleet with new, more fuelefficient models.

“The aviation industry has demonstrated resilience and adaptability after unprecedented disruption, with airlines responding to challenges, simplifying their fleets, improving efficiency and capitalizing on resurgent demand,” said Brad McMullen, Boeing senior vice president of Commercial Sales and Marketing. “Looking to the future of air travel, our 2023 CMO reflects further evolution of passenger traffic tied to global growth of the middle class, investments in sustainability, continued

A2Z MANUFACTURING WEST COAST • 18 • JUNE - JULY ’23

commercial services

at

valued

Call Now! (503) 282-7239 info@abfinishingtech.com www.abfinishingtech.com 6724 NE 46th Ave. Portland, OR 97218 Quality and Service Since 1936 ON TIME, EVERY TIME! AB Finishing Tech prides itself on setting the standard for: • black oxide finishing • shot peening • sandblasting

growth for low-cost carriers, and air cargo demand to serve evolving supply chains and express cargo delivery.”

Boeing’s projections for regional demand and key trends through 2042 include:

Asia-Pacific markets to represent more than 40% of global demand with half of that total in China.

South Asia’s fleet will expand more than 7% annually, the world’s fastest rate, with India accounting for more than 90% of the region’s passenger traffic. North America and Europe each will account for about 20% of global demand.

Low-cost carriers will operate more than 40% of the single-aisle fleet in 2042, up from 10% 20 years ago.

After omitting demand for Russia and Central Asia in last year’s CMO due to uncertainty in the region, this year’s forecast covers Russia and Central Asia in the Eurasia region, which comprises about 3% of the global fleet by 2042. Commercial Services forecasts a total served market worth $3.8 trillion, including digital solutions that increase efficiency and reduce cost; robust demand for parts and supply chain solutions; growing maintenance and modification options; and effective training to enhance safety and support the pilot and technician pipeline. Also in the 20-year forecast period, Boeing anticipates demand for these models:

New single-aisle airplanes will account for more than 75% of all new deliveries, up slightly from the 2022 outlook, and totaling more than 32,000 airplanes. New widebody jets will be nearly 20% of deliveries, with more than 7,400 airplanes enabling airlines to open new markets and serve existing routes more efficiently.

Air cargo will continue to outpace global trade growth, with carriers requiring 2,800 dedicated freighters. This includes more than 900 new widebodies as well as converted narrow-body and widebody models.

NEW

DELIVERIES (2023-2042)

Boeing has published the CMO annually since 1961. As the longest-running jet forecast, the CMO is regarded as the most comprehensive analysis of the commercial aviation industry. Learn more about the Commercial Market Outlook on Boeing.com. Boeing will release its complete Pilot and Technician

Outlook the week of July 24.

As a leading global aerospace company, Boeing develops, manufactures and services commercial airplanes, defense products and space systems for customers in more than 150 countries. As a top U.S. exporter, the company leverages the talents of a global supplier base to advance economic opportunity, sustainability and community impact. Boeing’s diverse team is committed to innovating for the future and

A2Z MANUFACTURING WEST COAST • 19 • JUNE - JULY ’23

Customer-Centric Is The Renewed Focus At Phoenix Heat Treating

Becoming the most customer centric heat treater in the country is a lofty goal but one that Phoenix Heat Treating has its sights set on. Phoenix Heat Treating (PHT), located in the heart of Phoenix, Arizona, has served various industries since it opened in 1963. Originally established in a 700 square foot space, PHT has grown to two buildings totaling 43,000 SF on 4 acres of land. PHT also continues to expand their processing capabilities and their commitment to customer satisfaction.

PHT is a legacy of knowledge passed down from many generations, going back to the late 1800’s and the blacksmith trade. Charles Wesley Sr, was a Prussian Swordsmith. Charles immigrated to the U.S. in 1887 and opened his first heat treating facility in 1915 in Milwaukee,Wesley Steel Treating. He was also one of the founding members of the Metal Treating Institute. Charles’ grandson, Chuck Hushek, moved his family to Phoenix in 1957 and opened PHT in 1963.This year, the company is celebrating their 60th year of service in Phoenix and is run by its 2nd generation owner, Peter (Chuck’s son), and his son, Charlie Hushek. Heat treating is in their blood!

Not only does generational practical wisdom get utilized in their processing strategies, but Peter is also a degreed metallurgical engineer. It is estimated that less than 15% of commercial heat treaters have a metallurgist on staff. It is this combination of experience that has given Peter the nickname of Metal Whisperer. They have developed a reputation for being able to solve difficult processing scenarios and often receive parts from across the country from customers looking to achieve outcomes that they have otherwise been unable to achieve.

Charlie says that Pete understands metal from the inside out and it makes perfect sense to him. Early on, Charlie didn’t plan to join the family business as a 5th generation heat treater. In fact, he studied construction management in college, and pursued this passion building hospital rooms after graduating from college. A couple of years later, Pete asked his son to join the business, and Charlie left construction management. He first worked 2nd shift unloading baskets from furnaces. Charlie moved from this arduous task to day shift; first in the shop, then in customer service, then into other departments, learning how Phoenix Heat Treating operated in every aspect of the business. Charlie moved into the General Manager position when the company lost their General Manager to Covid. Charlie was instrumental in the new ERP implementation, Pete says.

A2Z MANUFACTURING WEST COAST • 20 • JUNE - JULY ’23

Charlie excels at a number of things, including communication with customers, suppliers and employees and a comfort level with adopting new technologies. “There is always a learning curve for family members working together but we seem to have found our stride and we actually enjoy working together. We have developed a respect for each other’s strengths,” said Charlie.

Phoenix Heat Treating has carved out a niche in the heat treat industry for doing the difficult orders but also for the wide variety of processes they are able to perform. Some of those processes include Vacuum, Aluminum, Carburizing, Carbonitriding, Mar-Quench, Austemper, Titanium, Cryogenics, Thermal Cycling, and Up-Hill quenching. PHT is also proud of their 18-month Nadcap Merit status and 24-month AC7004 quality certification. These approvals have afforded them the honor of processing work for Honeywell, Raytheon, GE, Pratt Whitney, Bell Helicopter, Rolls Royce, Lockheed Martin and Northrup Grumman to name a few. PHT also has a robust nonaerospace division which they call “PHT Precision.” This division services the unique needs of the tool and die, firearm and commercial industries. As Peter noted, “We pride ourselves on being the general store for heat treating. We can offer a little bit of everything to almost everyone.”.

Knowledge is just part of the equation – it’s how you use the knowledge and guard the knowledge that is equally as valuable. Phoenix Heat Treating has made tremendous investment into technology to leverage their years of experience. Every employee at PHT utilizes iPads to track, photograph, and record data on orders. Their company is filled with TV screen size monitors displaying live processing data, process recipes, and production schedules. All orders at PHT are processed using a recipe, and the ERP system will block untrained personnel from completing tasks they are not qualified for.

“This advancement in technology has been the foundation to adding transparency to the supply chain”, noted Charlie, adding “Our customer portal allows customers to view certifications, shipping tickets, invoices, and real time job tracking, and none of this would have been possible without the digitalization that we went through”.When asked to elaborate Peter noted “Customers can see what operation parts are on in real time, the modern supply chain demands transparency and access to information quickly. We feel that our portal pulls us into the modern era and shares information that has not been seen by any other heat treater.”

Phoenix Heat Treating is indeed well on their way to being the most customer centric heat treater; not only in the west but also in the country. When asked what’s next, Peter and Charlie agreed that exploring new processes such as Hot Isostatic Press (HIP) to service the additive manufacturing industry and new technologies is a focus. Utilizing their generational knowledge, Peter’s practical engineering to solve customer challenges, a wide range of capabilities and approvals, leveraging technology, and a transparent supply chain; it’s clear to see that they are focused on providing customers the best possible experience.

To learn more about how Phoenix Heat Treating can support all of your heat treat needs, as well as specialized services, contact them at: phoenix-heat-treating.com or call: 602-258-7751

A2Z MANUFACTURING WEST COAST • 21 • JUNE - JULY ’23

Pratt & Whitney Expanding Jet Engine Complex

The Columbus, Ga., MRO center for commercial and military engines is in line for a $206-million machinery update and capacity expansion. Pratt & Whitney initiated a $206-million capital investment program for new machinery and equipment at its Columbus, Ga., commercial and military jet engine complex, and to expand its manufacturing capabilities there. One goal of the investment is to expand the Columbus Engine Center’s overhaul capacity to 400 GTF engines per year.

The overall effort is expected to result in about 400 new jobs by 2028.

The Columbus Engine Center is a Maintenance, Repair & Overhaul (MRO) facility for Pratt & Whitney’s GTF geared turbofan commercial-jet engine, and for F117 and F100 military jet engines.The CEC operations perform disassembly, inspection, assembly, and testing for those engines.

The GTF engines are widely installed in various narrow-body commercial aircraft, including the Embraer E-Jets E2 and Airbus A220 and A320neo

Are you ready to implement or upgrade your Quality Management System to the new ISO 9001:2015 or AS9100D / ISO 9001:2015 Standard, AS9110C or AS9120B?

Special Packages available, take advantage of 20 plus years’ experience implementing and auditing quality management systems for commercial and aerospace companies!

Bretta Kelly, President and Owner of BMSC, LLC www.businessmsc.com has proven, copy written templates for ISO 9001:2015, AS9100D / ISO 9001:2015, AS9110C / ISO 9001:2015 and AS9120B / ISO 9001:2015 Standards with more than 30 companies upgraded and certified with zero to one finding results to date in their upgrade audits!

Packages Available:

Complete Electronic QMS System/Templates and 4 hours consulting – Manual, Policy, System Procedures, Work Instruction / Flow charts for some processes, internal audit program, management review program (including forms), competency / training program, objectives training template, risk training and how to document a corrective action training PowerPoint’s - $3,500

Complete Electronic QMS System/Templates and online webinar of how to complete – Manual, Policy, System Procedures, Work Instruction / Flow charts for some processes, internal audit program, management review program (including forms), competency / training program, objectives training template, risk training and how to document a corrective action training PowerPoint’s - $2,500

Do you need Quality Management System Software? Bretta Kelly is also President of CIS WWSG, LLC and is now offering the $3,500 Templates for FREE with purchase of CIS Software! www.cissoftware.com. CIS Software costs $5,000 upfront (one time) and $385/month license and server fees for UNLIMITED users, request a demo today! Testimonial from BMSC Clients featured in the A2Z Manufacturing Magazine who have taken advantage of the BMSC Templates for successful upgrades:

Bretta, I wanted to email you and let you know that because of the help of yourself and Debbie we completed our audit to the new revision with no findings! :) We very much appreciate all of the help that you both did for us and will recommend your company to anyone looking to get certified. Your system really makes it easy for companies like ours to stay organized and compliant to the guidelines. Kristie McKee, Gibbs Precision Machine

The GTF program has been under strain for several months due to parts shortage and some defective or inappropriately installed parts, leading to supplychain problems with Pratt & Whitney and the commercial carriers operating those engines. Parent company Raytheon Technologies (now relabeled as RTX) plans to absorb a $500-million charge to its free-cash flow during Q2 2023, due to the GTF engine problem. RTX chief operating officer Chris Calio announced the charge and described the problem, without identifying the engine part or its supplier.

Adjacent to the Columbus Engine Center is Pratt & Whitney’s Columbus Forge, where it manufactures compressor airfoils and nickel and titanium forgings that are machined into rotating components for GTF engines, as well as F135 engines for the F-35 Lightning II fighter jet.

A2Z MANUFACTURING WEST COAST • 22 • JUNE - JULY ’23

series jets.

A2Z MANUFACTURING SW • 25 • July / Aug 2023

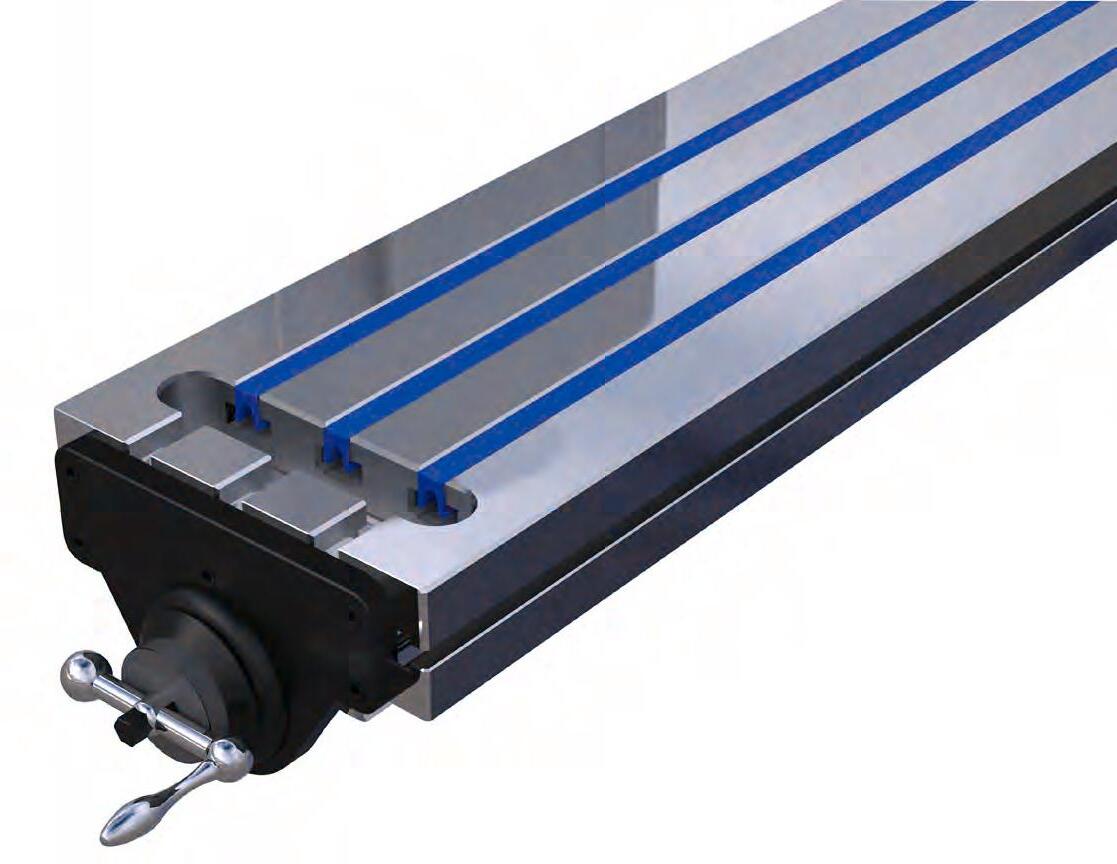

Upgrade Your Waterjet with

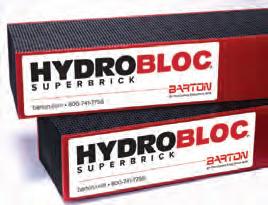

HYDROBLOC®

Experience cleaner, quieter cutting and better looking parts with HYDROBLOC waterjetbricks. The flat, even, honeycomb surface keeps parts from falling into the tank and drains water away to minimize splash back. HYDROBLOC’s laminated high-density polyethylene layers are welded and screwed together for unrivaled durability.

• Cleaner Cutting • Quieter Operation

• Better Looking Parts • Recyclable Watch the video to learn more at barton.com/hydrobloc

DOD Enters $13.8 Million Agreement to Expand Domestic Manufacturing to Strengthen U.S. Supply Chains

The Department of Defense’s Office of the Assistant Secretary of Defense for Industrial Base Policy (OASD(IBP)), through its Manufacturing Capability Expansion and Investment Prioritization (MCEIP) Directorate, announced it has entered a $13.8 million agreement with The Timken Company (Timken) to increase production of high-precision ball bearings at its facility in Keene, New Hampshire.Timken’s high precision ball-bearings are used in defense and space-related advanced systems.

The funds, appropriated to the DPA Fund by the Additional Ukraine Supplemental Appropriations Act (Ukraine Supplemental), will be used to make operational and technological improvements at the company’s facility, including upgrading equipment and operator training. Timken is also investing approximately $11 million to further expand these

capabilities at the facility. Congress identified capacity for high-precision ball bearings for defense and space-related advanced systems as a Defense Industrial Base (DIB) Area of Interest in the Ukraine Supplemental, enacted in May of 2022. The supply of these ball bearings is a constraint in increasing demand for advanced systems.

“The Office of Industrial Base Policy is moving forward with speed to support sectors of importance to American national security and deterrence,” said Dr. Laura Taylor-Kale, ASD(IBP). “The Timken Company manufactures components critical to the health of critical domestic supply chains as identified by President Biden.”

About the Department of Defense’s Office of the Assistant Secretary of Defense for Industrial Base Policy

Industrial Base Policy is the principal advisor to the Under Secretary of Defense for Acquisition and Sustainment (USD(A&S)) for developing Department of Defense policies for the maintenance of the United States defense industrial base (DIB), executing small business programs and policy, and conduction geo-economic analysis and assessments. The office also provides the USD(A&S) with recommendations on budget matters related to the DIB, anticipates and closes gaps in manufacturing capabilities for defense systems, and assesses impacts related to mergers, acquisition, and divestitures. IBP monitors and assesses the impact of foreign investments in the United States and executes authorities under sections 2501 and 2505 U.S.C. Title 10.

A2Z MANUFACTURING WEST COAST • 24 • JUNE - JULY ’23 OIL MIST AND SMOKE IN YOUR SHOP? Low-Cost, Highly Efficient Mist and Smoke Collectors Designed Specifically for the Metalworking Industry www.mistcollectors.com 1-800-645-4174

INTERNATIONAL USA/Canada 800-741-7756

• info@barton.com • barton.com • store.barton.com

BARTON

518-798-5462

The BARTON logo and our brands are registered trademarks of BARTON Mines Corporation.

Stratasys Stiff-Arms 3D Systems’ Bid

The company’s board says 3D’s offer is not considered superior and provides new financial projections about its plans to join forces with Desktop Metal.

The directors of additive manufacturing venture Stratasys Ltd. have voted unanimously to not start talks with rival 3D Systems Corp. over the latter’s bid to break up Stratasys’ planned purchase of Desktop Metal Inc.

Stratasys leaders and their peers at Desktop Metal on May 25 announced plans to join forces in a deal worth $1.8 billion. That plan, they said then, would set the stage for the combined organization to pull in $1.1 billion in sales in 2025 while cutting costs by $50 million annually. Just a few days later, however, 3D Systems offered to pay $1.2 billion in cash and stock for Stratasys and promised “simply the best outcome for the shareholders of both companies” in part because of the promise of $100 million in annual savings down the road.

On June 20, both companies issued statements on the proposed transactions. 3D President and CEO Jeffrey Graves said his team had not heard from Stratasys in the past three weeks but reiterated his belief in 3D’s bid, noting that investors had bid up his company’s shares and thus made its offer more valuable to Stratasys shareholders.

Soon after, the Stratasys board issued statements saying, among other things, that 3D’s acquisition offer does not constitute what the Desktop Metal agreement defines as a “superior proposal” because it undervalues Stratasys, doesn’t account for 3D’s (slower) growth plans and “lacks critical metal technology to be successful in mass production additive manufacturing.” That last element is a key selling point in having Desktop Metal, which has a stronger metal manufacturing business, join up with Stratasys, which is more established in marketing polymer products.

The Stratasys board also has published some new financial projections and now says that joining forces would goose top-line growth to at least $1.4 billion in 2026. The directors and their financial advisors now say they see EBITDA margins—previously forecast to be between 10% and 12 in 2025—growing to somewhere between 14% and 20% in 2026

A2Z MANUFACTURING WEST COAST • 25 • JUNE - JULY ’23 METALS Aluminum Steel Stainless Brass Copper Ornamental SHAPES Sheet/Plate Shim/Bar Tube/Pipe Channel Angle Beam Perf./Expand. SERVICES Production Cutting Precision Sawing Shearing So-Cal’s Source For All Your Metal Needs Next Day Delivery - No Minimum - Open Saturdays STOP BY TODAY! Los Angeles | Orange County | San Diego | Inland Empire 818-729-3333, www.IMSmetals.com

Geert De Lombaerde

Adapting to New Possibilities

Eviation, Zeroavia Ink Deals With Aircraft Leasing Companies

Arlington-based Eviation announced a deal to produce up to 50 battery-powered electric commuter planes for a Miami aircraft leasing company.

Three aircraft leasing companies have placed orders for zero-emissions planes and systems designed and built in Washington this week.

The deals, announced separately and timed to coincide with the

Paris Air Show, include an order from Miami-based Aerolease Aviation for up to 50 planes from Arlington electric plane startup Eviation Aircraft and two orders for hydrogen-electric propulsion systems designed in Seattle by ZeroAvia Inc.

With its latest deal, Eviation’s backlog has grown to over $4 billion, including more than 500 commuter aircraft on order as the company looks to transition from engineering to mass production. Eviation aims to begin deliveries of its nine-passenger, battery-powered electric plane in 2027, once it achieves certification from the Federal Aviation Administration.

Leasing companies have been a missing piece of the puzzle for prospective end users, Eviation CEO Greg Davis told the Business Journal.

The deal gives customers “more options on how they want to finance the aircraft,” he said, including through Eviation directly or other financing mechanisms, “so that our operators can scale up and down their operations without having to wait for a new slot to open up in our production line.”

Ideally, Eviation would have leasing companies make up around a quarter of its sales, Davis added.

ZeroAvia, whose technology is designed to retrofit existing aircraft, made sales to two companies, London-based Monte Aircraft Leasing and the French company Green Aerolease. Its deal with Monte is for 100 powertrains designed for Cessna Grand Caravans, which are capable of carrying between nine and 19 people. No details were available regarding the Green Aerolease order.

ZeroAvia hopes to see the first planes with its systems enter into service in 2025. The Southern California-based company announced plans to

A2Z MANUFACTURING WEST COAST • 26 • JUNE - JULY ’23

1.800.281.5734 Germantown, WI USA www.hainbuchamerica.com

n Change from O.D. to I.D. to jaw clamping in < 2 minutes

n Use the same adaptations on your HAINBUCH turning or stationary chucks

n Keep the basic clamping device mounted on the machine

Chucks and adaptations are available in round or hexagonal configurations

establish a research and development facility at Snohomish County’s Paine Field Airport early last year.

Announcements & Releases Continued

The Green Aerolease deal targets routes that have been prohibited under new French laws banning flights that can be served by train rides under 2.5 hours.

from outside North America to North America. Reshoring includes work that is produced either in-house or outsourced. A complete definition of “reshoring” is available here. Applications must be submitted by June 30. To view award details and enter to win, visit this webpage.

Eviation’s technology could help bolster aircraft operations at smaller, regional airports where noise and emissions are top challenges, Davis said.

“From 2010 to 2020, more than one million jobs were announced as coming to the United States from offshore. This is a tremendous achievement, and we seek to motivate and honor the companies that have made reshoring a reality,” said Harry Moser, founder and president of the Reshoring Initiative.

“Using our technology, we’re going to be overcoming the economic barrier that has suppressed the development of air travel at small airfields for decades,” he said, including routes like Arlington to Spokane or King

materials and services to the industry.

Following its first test flight in September, Eviation is working to adapt its Alice prototype design into a configuration more suited to mass production. That means taking components like the plane’s windows, which were built individually by hand, and standardizing them.

The Association For Manufacturing Technology (AMT) represents U.S. builders and distributors of manufacturing technology – the advanced machinery, devices and digital equipment that U.S. manufacturing relies on to be productive, innovative, and competitive.

As it establishes its manufacturing strategy, the company is conducting trade studies to determine how much of its plane it will build in-house and how much will be outsourced. That’s expected to take around half a year, during which the company’s workforce will remain relatively stable, Davis said.

Questions about the National Metalworking Reshoring Award can be directed to Harry Moser at 847-867-1144 or harry.moser@ reshorenow.org. For more information on AMT’s efforts on reshoring and supply chain efforts, visit IMTS.com/supplychain.

He declined to estimate to what degree production of major components such as the wings, fuselage, landing gear or electronics would take place in the Puget Sound region. While the company wants to ensure its bidding process is competitive, he added that a skilled workforce and supply base were key factors in its decision to establish operations in Arlington.

NTMA is the voice for the precision manufacturing and tool and die industries in the United States. Backed by nearly 1,300 member companies, representing more than $30 billion in sales, NTMA provides an array of benefits to members and the industry including advocacy in Washington, training and education programs and networking events nationwide.

The Reshoring Initiative, founded in early 2010, helps manufacturers realize that local production, in some cases, reduces their total cost of ownership of purchased parts and tooling. The Initiative also trains suppliers how to sell against lower-priced offshore competitors.

Eviation initially expects to make a few aircraft a year. The delivery timelines established in the contracts offer opportunities for the company to “make sure we’re adapting our program based on real operator feedback,” Davis added.

PMA, an inaugural sponsor of the National Reshoring Award, is the full-service trade association representing the North American metalforming industry — the industry that creates precision metal products using stamping, fabricating, spinning, slide forming and roll forming technologies, and other value-added processes. Its

The Benefits Of Worki ng With P4Swiss / Lindel CNC Machining

“When you get a new product in the market, people want time with it to understand how to operate it,” he said.

Founded in 1987, Lindel Precision CNC Machining merged with Precision 4 Swiss in 2019. Together, P4Swiss / Lindel CNC Machining is dedicated to providing quality CNC machined parts at

A2Z MANUFACTURING WEST COAST • 27 • JUNE - JULY ’23

nearly 900 member companies also include suppliers of equipment,

County International Boeing Field to Wenatchee.

A Z MANUFACTURING WEST COAST • 28 • JUNE - JULY ’23

A2Z MANUFACTURING WEST COAST • 29 • JUNE - JULY ’23

Let’s Celebrate!

The Manufacturer’s Secret Weapon

By Stephen Hannemann

Celebrate what, you ask? Well, chances are, if you are reading this article, you’re an owner, an officer, a buyer, or a manager in a manufacturing organization of some type. The business you own or work for is still in operation!

Over the past three years our government has facilitated the decimation of small businesses through covid lockdowns while the corporations have been permitted business as usual. Some reports state as many as 75% to 80% of small businesses have been shuttered, never to reopen. The exception has been manufacturing. Although navigating these past years may have been difficult and challenging, you are still in business and reading this article – so celebrate!

The ongoing challenge that will be with us for some time to come is finding a workforce to keep your machine spindles turning, your injection molding presses cycling, your foundry furnaces hot, and your fab presses forming. This will not be a quick fix. The most effective way to reverse this trend is to get involved. A massive effort is needed to educate young students to the reality that a college degree will not necessarily guarantee a fulfilling life. Manufacturing can provide a long, fruitful, and satisfying future.

Education and manufacturing need to align in this effort. Contact your local community college, meet with the school deans and program directors, let them know your needs. Partner with them in developing comprehensive training programs. Owners and managers can create advisory boards in conjunction with local high schools, community colleges, and trade

organizations like the Society of Manufacturing Engineers (SME), the Society of Plastics Engineers (SPE) and so on. Develop training and apprenticeship programs with the assistance of professional organizations that support your industry.

Create a fullcourt-press marketing campaign with presentations that showcase the magic of the products or components your company produces. Illustrate your manufacturing employment opportunities with the compensation packages you offer. These presentations must begin at the high school freshman level and continue for four years, offering students a perspective that making viable products is an admirable and fulfilling vocation.

As you can see by the photos provided, Chemeketa Community College in Salem, Oregon is all in, and is just one of many community colleges providing occupational skills training programs.These institutions give career-oriented students the opportunity to earn college credit for hands-on training with various companies throughout your state and beyond. Seek them out, visit the community colleges in your area and partner with their programs. They will be more than willing to host field trips for students to visit your plants.These will positively heighten young students’ enthusiasm for manufacturing.

I have said this before, but it bears repeating: Manufacturing is the backbone of a country’s sustainable economy! So yes, Celebrate! You are still in business, and you can provide a stable future for future generations by reaching out to them.

For more information regarding the well-vetted principals represented by SMH Inc., visit www. smhincllc.com, phone 425.501.7342 or email stephen@smhincllc.com.

A2Z MANUFACTURING WEST COAST • 30 • JUNE - JULY ’23

SMH Inc. – “The Manufacturer’s Secret Weapon”

A2Z MANUFACTURING WEST COAST • 31 • JUNE - JULY ’23 Stay in Touch 925 N. Shepard Anaheim, CA 92806 (714) 393-3783 Info@landmarksolutionscorp.com landmarksolutionscorp.com Take your next step with us. Fiber Lasers • Press Brakes • Automation • Waterjets • Plate & Angle Rolling • Plasma & Oxy Cutting Deburring • Saws • CNC Machining • Nitrogen Generation • Robotic Welding • Waterjet Parts Your Partner in Manufacturing Equipment Bringing over 100 years of industry experience Waterjet Parts and Technical Service Landmark and its affiliate, Best Choice Parts, are proud to offer factory-trained service on all equipment, along with thousands of American-made OMAX OEM, AccuStream, and Hypertherm spare parts. Call us today! +1 855-WATRJET EXCLUSIVE DISTRIBUTOR OF: Proud Industry-leading customizable parts finishing solutions to increase your productivity and efficiency. Contact us today to learn more, schedule demos or run samples on your own parts! www.bestchoiceparts.com

Buyer’s Guide & Card Gallery Equipment and Services

ACCESSORIES

Abrasive Systems

KBC TOOLS & Machinery___714-278-0500

Air Cleaning Guns

Royal Products 631-273-1010

Auto-Bar Feed Systems

Western Machine Center____408-955-1000

Automation

Hainbuch Workholding____818-970-7874

Ballscrews

C & M Precision Spindle, Inc._ 503-691-0955

Band Saws/Saw Blades

Bandsaw Tech 562--419-7675

Cycle Time Solutions_____510-708-8665

Saw Service 877-738-6437

Sterling Saw Blades 800-828-11800

Band Saw Replacement Parts

Service __________ 877-738-6437

Cycle Time Solutions _____ 510-708-8665

Horizon Carbide 602-524-3802

KBC TOOLS & Machinery____714-278-0500

KBC TOOLS & Machinery____714-278-0500

Royal Products ________ 631-273-1010

Sulli Tool & Supply 714-863-6019

US Shop Tools 800-243-7701

CNC Lathe Accessories

Trusty-Cook 877-240-2462

Von Ruden Manufacturing, Inc. 763-682--3122

A2Z MANUFACTURING WEST COAST • 32 • JUNE - JULY ’23

Saw

Band Saw Repair Saw Service 877-738-6437

Saw Blades 800-828-1180

Feeders Automatics & Machinery Co., Inc 303-990-6190 Edge Technologies 951-440-1574 Spinetti Machinery ______ 775-996-3770 Bar Feeder Repair Edge Technologies 951-440-1574 Boring THINBIT 888-844-6248

ALMCO_____________507-380-1009 Cams Dayton Lamina. 708-203-6684 Carbide Tools, Indexable

Sterling Saw Blades ______ 800-828-1180

Sterling

Bar

Caabinet Spray Washers

909-282-7463 Star Metal Fluids ________ 800-367-9966 Swift Tool Co, Inc. 800-562-0900 Cutting Fluids & Oils Saw Service 877-738-6437 Sterling Saw Blades 800-828-1180 Cutting Tools made in the U.S.A. since 1964 www.thinbit.com A2ZWCBG2019.indd 1 12/6/2018 10:33:33 AM Division of Curran Manufacturing Corporation 200 Oser Avenue Hauppauge, NY 11788 U.S.A. www.royalprod.com Tel: 1-631-273-1010 1-800-645-4174 Fax: 1-631-273-1066 1-800-424-2082 orders@royalprod.com 4740 NE 166th Avenue Portland, OR 97230 (503) 224-6061 (877) 398-6061 Fax (503) 253-1790 Cell (503) 572-9331 www.coastaluminum.com jpalmer@coastaluminum.com John Palmer Jr. Vice President: Northwest Region Go from Receiving to Machining with Precision Machine-Ready Blanks • Eliminate Material Prep • Flat, Square, and Parallel • Improve Throughput and Quality 800-234-5613 • www.tciprecision.com

Coolant Systems & Chillers MP Systems ___________

Star Metal Fluids

Swift Tool Co, Inc.

Cutting Tools

Horizon Carbide

Innovative Tool Sales

800-367-9966

800-562-0900

602-524-3802

714-780-073

KBC TOOLS & Machinery____714-278-0500

MESCO

Rosco Precision Machinery

Sulli Tool & Supply

THINBIT

626-303-5680

206-818-6813

714-863-6019

888-844-6248

US Shop Tools 800-243-7701

Cutting Tool Holders

Hainbuch America

253-293-2062

KBC TOOLS & Machinery____714-278-0500

Sulli Tool & Supply

714-863-6019

Cutting Tool Systems

Cycle Time Solutions 510-708-8665

KBC TOOLS & Machinery____714-278-0500

THINBIT

888-844-6248

Deburring Tools

Royal Products ________ 631-273-1010

Die Tooling Springs

Dayton Lamina. 708-203-6684

Dot Peen Markers

MarkinBox 310-214-3367

Draw Tubes

Lucy’s Machine Co._______323-587-6162

Drills/Cutters-Magnetic

KBC TOOLS & Machinery____714-278-0500

Sulli Tool & Supply 714-863-6019

Drills/Reamers/Taps

Bilz USA 224-563-7233

Sulli Tool & Supply 714-863-6019

EDM Materials & Supplies

Desert EDM 480-816-6300

EDM Network_________480-836-1782

EDM Performance 800-336-2946

End Mills

Horizon Carbide_______602-524-3802

KBC TOOLS & Machinery____714-278-0500

Sulli Tool & Supply 714-863-6019

Filiter Mist Collectors

Royal Products_______631-273-1010

Fixturing

Hainbuch America______253-293-2062

KBC TOOLS & Machinery____714-278-0500

Form Tooling

THINBIT 888-844-6248

Grooving Head, Grooving Tools

Cycle Time Solutions

THINBIT

510-708-8665

888-844-6248

Guide Bushings, Swiss

Edge Technologies

951-440-1574

Indexible Tools

SCT-USA.___________805-584-9495

Inserts

Horizon Carbide_______602-524-3802

Sulli Tool & Supply______714-863-6019

Jaws

EDM Network________480-836-1782

US Shop Tools________800-243-7701

Keyseat Cutters

Sulli Tool & Supply

714-863-6019

Lifting & Material Handling

Ingersoll Rand_________ 206-472-0826

Live Centers

Royal Products

631-273-1010

Load Unload Systems

Edge Technologies 951-440-1574

Lubricants / Systems

Star Metal Fluids 800-367-9966

Machine Tool Acccessories

US Shop Tools

800-243-7701

Port Tools

SCT-USA. 805-584-9495

Power Tools