GROOVING THREADING PARTING BORING TURNING FACE GROOVING CUSTOM TOOLING FORM TOOLING MILL TOOLING

GROOVING THREADING PARTING BORING TURNING FACE GROOVING CUSTOM TOOLING FORM TOOLING MILL TOOLING

Hysol® MB products are the best-selling, highest volume coolants sold by Castrol® due to their all-around performance and overall value.

Product advantages

• High-quality finish across multi-metals and operations

• Excellent anti-corrosion properties

• Clean running and have a very mild odor

• Wide tolerance to water hardness

• Robust pH stability fights bacterial growth

Simplify operations and make it easier to meet the demands of your business. Contact Star Metal Fluids today to learn why Hysol® MB products are the favorite among machine operators.

Just like athletes, entrepreneurs have an acquired skill.They have the same grit, drive and determination that we don’t always hear about.This ambition is what empowers them to surpass the competition and create hugely successful companies.

People want the grand end results, but they don’t think about all the grueling steps involved or take into consideration all the unpredictable roadblocks along the way. Everybody wants to be like Steve Jobs or Richard Branson, but not everyone wants to put in the hard work and obsession-like resolve to get there.

According to the U.S Small Business Administration, two-thirds of companies will survive their first two years in business, half of all businesses will survive their first five years, but only one-third are likely to survive 10 years.

According to the NCAA, only 0.6% of high school baseball players and 11% of college players make it to the professional league. As a prospective professional baseball player, those are slim odds. And of course, these players need the talent and the ambition to succeed, but they also need to have an almost obscene amount of confidence in themselves in order to push through.

In business, obsession is necessary because, without it, business people wouldn’t put themselves through the stress, anxiety and mental strain that comes with dealing with all of the moving parts. And being obsessed means thinking about your business at all times — at night before you go to sleep, first thing when you wake up and even on vacation.

Genetics helps when it comes to talent, skill and ability, but it’s determination, practice, drive and focus that really make a great athlete or a businessperson. A company founder may have natural intelligence or a great idea, but that’s not the drive behind a well-oiled machine. It’s the desire and ability to always learn and grow your skill set. Challenges will test you in all fields — in professional sports, in business and beyond. But in both of these fields, in particular, there are a number of factors that will be constantly on your mind and pushing you to fail. If you don’t love what you do, you’ll never get off the ground. If you don’t love swimming, but you jump into a pool hoping to become the next Olympic swimmer, you’re going to fail because you’re not going to be in the right mindset to push through the pain and the suffering.

It’s up to you to make your business succeed — if you don’t love what you’re doing, if it isn’t what you eat, sleep and breath, if it isn’t something you’re constantly working to improve, it will inevitably fail. And no amount of money can help save it.

Much like athletes need to practice, obsess and love what they do, business owners need to push themselves, and believe in themselves, because stress will always test your devotion and mental toughness, just like physical stress tests the muscles of athletes.

In closing I wish you all continued succeess! Try and make this growing a business fun,, this will take a lot of stress out of the process!

Thank you all for your continued support for our precison manufacturing magazines!

Kim Carpenter

Kim

Telephone:

Website:

Published bi-monthly to keep precision manufacturers abreast of news, contracts, trends, and to supply a viable supplier source for the industry.

Circulation: A2Z Manufacturing West Coast maintains a master list of over 14,000 decision makers consisting of fortune 1000 companies, small manufacturing companies, engineering firms, DOD & Scientific Lab facilities, machine shops, fab-shops, and secondary source businesses. It has an estimated pass on readership of more than 25,000 people. The majority of our readers are based in CA, OR, WA area!

Advertising Rates have remained the same since 1999, deadlines and mechanical requirements furnished on our website at: www.a2zManufacturing.com.

All photos and copy become the property of A2Z Manufacturing.

The Publisher assumes no responsibility for the contents of any advertisement, and all representations are those of the advertiser and not that of the publisher.

The Publisher is not liable to any advertiser for any misprints or errors not the fault of the publisher, and in such event, the limit of the publisher's liability shall only be the amount of the publishers charge for such advertising.

Vacuum: Power, Precision, and Unmatched

[Elk Grove Village, IL] — MIDACO CORPORATION, a leading name in industrial solutions, proudly introduces the M264VFL Industrial Dry Vacuum, setting a new standard for efficiency and reliability in managing shop dust, metal and wood shavings, and challenging materials.

Designed for versatility, the M264VFL comes equipped with multiple attachments and hoses extending several meters, catering to a diverse range of applications. The Teflon-coated pocket filter ensures peak performance with damp materials, complemented by PTFE nanotechnology for tackling the most stubborn dust particles.

Effortless maintenance is at the forefront with the manual filter cleaning system, conveniently operated by a side-mounted “shaker” lever to expel debris from the filter and into the receptacle container. The detachable wheeled container, boasting a generous 100L capacity and reinforced outer support, prioritizes safety when handling substantial loads.

Specifications: Power: 3.9 kW, 3.3 HP, Motors: (3) 110v single-phase bypass motors, Dimensions: 26” x 31.5” x 59.65” (660mm x 800mm x 1515mm), Tank Capacity: 26.4 gal. (100L), Max. Vacuum: 250 mBar, Vacuum Inlet: 2.76” (70mm), Air Flow Rate: 570 m3/h, PTFE Nanotechnology Treatment, Sound Level: 78dB(A), Weight: 154 lbs (69.85 kg).

Accessories Included: 1 flexible hose (124” / 3149.6mm), 2 rubber m/f connectors, 1 18” (457mm) wide floor tool, 1 15.5” (393.7mm) metal flat crevice hand tool, 1 “S” extension pipe, 1 elbow connector, 1 Tefloncoated pocket filter, 2 reducers, Upright floor attachment.

Experience the power, convenience, and reliability of the MIDACO M264VFL Industrial Dry Vacuum — your ultimate solution for tackling the toughest industrial cleaning challenges.

About MIDACO: In addition to Industrial Vacuums, MIDACO is known for Automatic and Manual Pallet Changers and Multiple Pallet Pool Systems for small and mid-size VMCs up to large Bridge Mill Machines with a 190”x72” XY travel and 32,000lb capacity. Accessories for Pallet Changers include Robot/Cobot machine tending solutions, Trunnion Systems for 4th axis machining on a VMC without needing cable management, self-charging cableless Hydraulic Docking Systems for automated fixtures and vises, Chip Shields, Chip Fans and Blower Nozzles. For automated machine access MIDACO manufactures AutoDoor Openers for single and double door CNCs and Robot Access Door Systems for enclosed milling and turning

centers - ideal for robot/cobot applications. Additionally, MIDACO offers the Grinder-GuardTM LED illuminated safety shield for bench and pedestal grinders/buffers and the Grit-GrabberTM vacuum pedestal cabinet to capture grinder dust and debris.

As a veteran owned business since 1969, MIDACO is a renowned provider of innovative industrial solutions, committed to delivering highperformance products that enhance productivity and safety in challenging work environments. With a focus on quality and reliability, MIDACO continues to be a trusted partner for industries worldwide. For more information, visit www.midaco-corp.com or contact sales@midaco-corp. com, ph: (855) 593-5668. See MIDACO at IMTS 2024, September 9-14, McCormick Place, Chicago, South Hall, Booth #3339347.

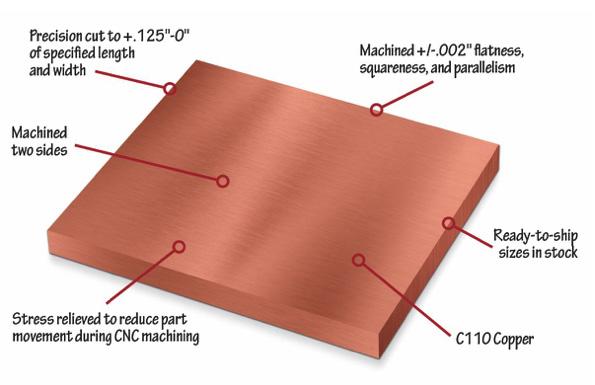

TCI Precision Metals announces that its C110 copper, Ready-to-Ship blanks are now available from OnlineMetals.com, the World’s leading e-commerce metal and plastics supplier.The pre-machined blanks allow customers to order flat, square, and parallel materials to close tolerance specifications.

C110 copper is 99.9% pure copper and has a conductivity of 101%

IACS (International Annealed Copper Standard). C110 copper plate and sheet material is well suited for environmentally challenging applications. For marine usage, copper provides natural antifouling properties, making it ideal for many boat components, both above and below the waterline. Given the natural conductivity of copper, it is an excellent choice for electrical components. The thermal properties of copper make it an excellent choice for heating and cooling applications. Copper is often specified for aerospace and defense applications for its conductivity and corrosion resistance.

“C110 copper Ready to Ship Blanks help customers shorten setup time, reduce scrap, and increase overall throughput up to 25% or more by eliminating material prep. Blanks arrive machine-ready for production,” said Ben Belzer, President, and CEO of TCI Precision Metals.

Precision blanks eliminate the need for in-house sawing, grinding, flattening, squaring operations, and outside processing. Blanks are consistent, part-to-part, which reduces setup time. In the case of flat blanks, the production process alleviates the material’s residual stress,

resulting in reduced part movement during CNC machining.

C110 copper Ready-to-Ship blanks are available in common thickness from 0.25” to 1.00” and are guaranteed flat +/- .002”. Precision saw or waterjet cut dimensional sizes are available up to 24” x 24”, +.125”0” of specified length and width. Each blank is deburred, cleaned, and individually packaged to avoid damage during shipping.

“We are seeing a growing number of customers looking for pre-machined materials. At OnlineMetals.com, we specialize in cut-to-size, small-tomedium-quantity orders shipped directly to any location. Pre-machined C110 copper blanks provide that extra processing value that lets customers order materials that arrive ready to go directly from receiving to machining. Customers can use the time they previously spent in setup and prep for more productive use of CNC machining centers,” said Matt Holzhauer, Marketplace Manager at OnlineMetals.com

Founded in 1956, TCI Precision Metals is a family-owned manufacturer producing precision Machine-Ready Blanks from aluminum, stainless steel, and other alloys. The company also provides Sawing, Grinding, Milling, and Finishing operations on customer-supplied materials.

OnlineMetals.com is the world’s leading eCommerce metal and plastics supplier, specializing in cut-to-size, small to medium quantity orders shipped directly to any location. Online Metals was a garage start-up founded in Seattle in 1998. The company has grown over the years and expanded to six facilities across the U.S., offering over 55,000 products.

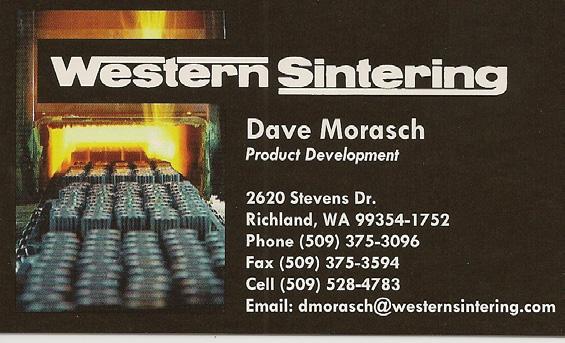

Selection of an outstanding and inspirational employee is a long-standing tradition at 3D Plastics in Newberg, Oregon.

3D’s annual “Most Inspirational Employee of The Year” award is by no means a popularity contest. It is a thoughtful consideration of their coworkers’ on the job performance, versatility, and positive interaction with peers. The nominees are selected and voted for by their peers only. Once again, the balloting was extremely close. This speaks volumes about the 3D culture and the character of their employees.

3D Plastics was proud to introduce Makayla Gould as their Most Inspirational Employee of the Year for 2023 at their annual Christmas party last December. In talking with her supervisors and coworkers, the honor is well deserved!

President Kelly Dundas observed about Makayla, “She has been here for eight years, and she does it all. Makayla has been an operator, training to be a setup tech, filled in as a shift lead, performed maintenance when needed, staging, materials handling, and I know there’s more. She is always eager to jump in and help out whenever an opportunity arises. She is well liked, and we feel lucky to have her.” Wow! Lucky indeed.

Speaking with Makayla, she is unassuming, and always enjoys helping whenever and wherever she can. “I like that 3D lets me try new things and supports me in the positions that I have held and now hold. I like the people I work with.” Makayla is a true student of the injection molding industry. She enjoys the company and going to work every day and there is much potential for Makayla at 3D. Congratulations, Makayla, for your well-deserved honor!

3D Plastics is a custom injection molder in Newberg, Oregon. Not only are they committed to their employees, but also to the success of their customers. 3D offers personalized customer service, superior quality, and complete project management. 3D manufactures parts and assemblies for dental, medical, electrical, and consumer goods. Be sure to check out our ad on page 16

To learn more about 3D Plastics, discuss a concept or receive a quote, visit 3d-plastics.com or call 503.537.0979.

3D Plastics – Peerless Attention to Detail.

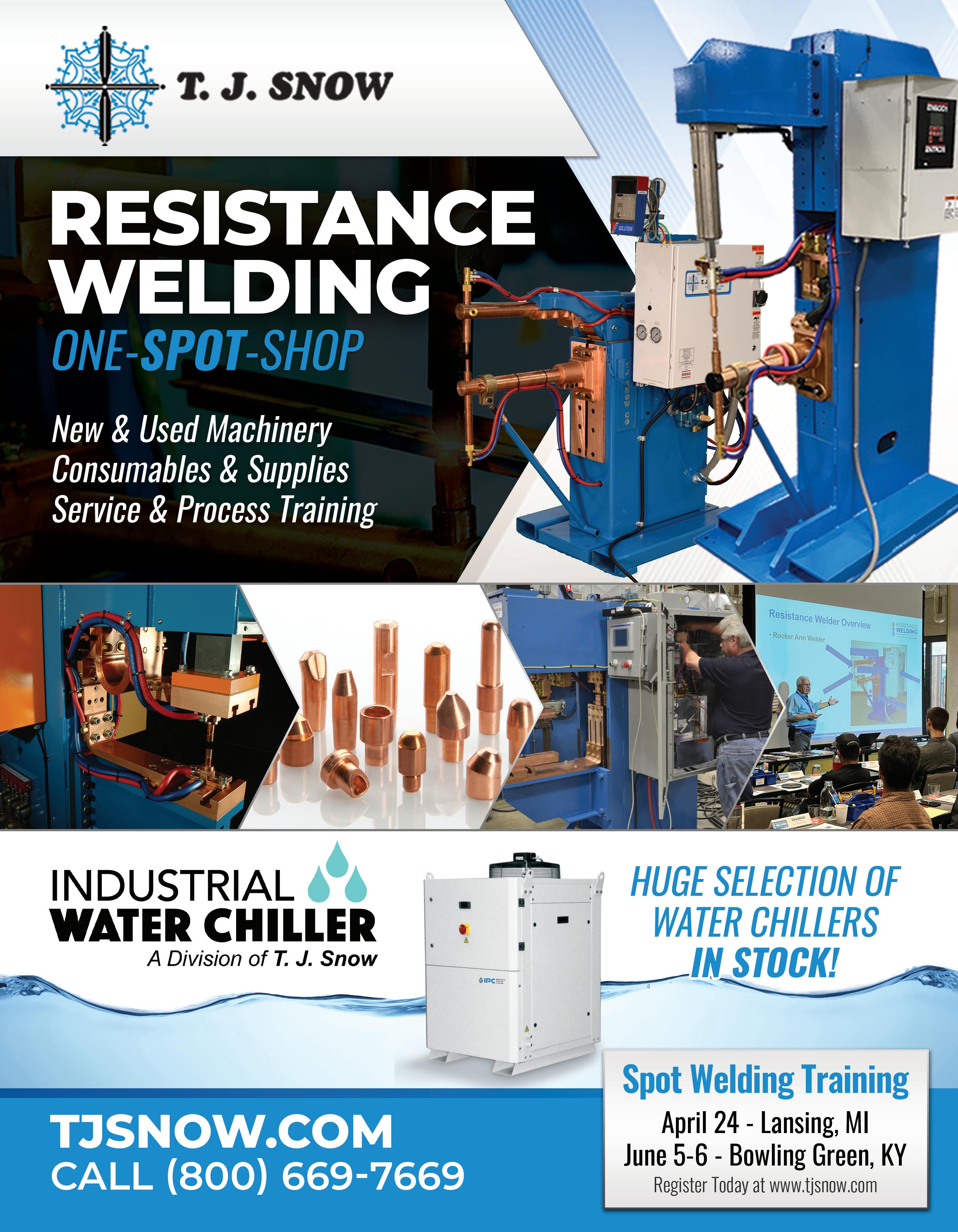

CHATTANOOGA,TN. ---- T. J. Snow is pleased to announce the return of their popular regional Resistance Welding Seminars in 2024. T.J. Snow’s regional seminars have been hosted throughout the United States for over twenty years and are always received with praise from attendees. These interactive and informative seminars are taught by T. J. Snow’s own AWS Certified Resistance Welding Technicians (CRWT) who all possess years of experience as professional resistance welding technicians and seminar instructors.

Seminar attendees will become familiar with the various types of resistance welding, pneumatic systems, weld control operation, basic welder set up, electrode selection, maintenance, operator safety and more. Our instructors will engage attendees in discussions and Q&A’s during the eight-hour training.

2024 Resistance Welding Seminar Dates:

• April 24 – Lansing, MI

• June 5-6 – Bowling Green, KY

• August 14 – Cedar Rapids, IA

Contact: Candace at candaceedmonds@tjsnow.com or call (423) 308-3235

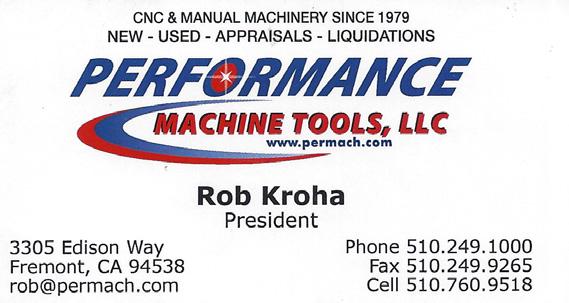

ROB KROHA

ROB KROHA

CONTACT US TODAY: 510-249-1000, PERMACH.COM

Our Showroom At: 3305 Edison Way, Fremont, CA 94538 Is Open Monday - Friday From 8am To 5pm

For decades Cutting Tool Control has consistently delivered solid solutions to machine shops in Washington, Oregon, northern Idaho, Alaska, and British Columbia. They also sell throughout the United States to solve manufacturing problems.

Since 2020, Cutting Tool Control has been selling 3nine mist eliminators to machining facilities in the Pacific Northwest. 3nine systems provide the cleanest air quality possible in high density machining environments. To prove a point, a visit to Treske Precision Machine in Sherwood, OR would provide an enlightening experience. If led blindfolded onto Treske’s machining floor and asked to take a deep breath, there would be little perception of being in the company of 20 Makino machining centers crowned with 3nine mist eliminators running flat out 24x7! All sold by Cutting Tool Control.

During a tour of the magnificent facility, Scott Ferguson, Business Development Manager for Treske, more than once proclaimed, “You’re going to love this,” He led the way to a bank of computer monitors displaying every detail in real time of what was happening in every one of the machining centers. According to readouts, most of the machines were

on average running steady state close to 23hrs of continuous operation. That equates to a lot of cutting mist being collected and recycled by the 3nine units, delivering a significant saving in cutting fluid costs, as much as 50%!

Later joined by Mike Olander, Manufacturing Service Manager, who happily mentioned, “The air quality is not the only advantage of the 3nine eliminators.You should have been here when we had our previous duct collection system.We could barely open the doors to get into the building due to the negative pressure!”

3nine eliminators are a machine shop’s best solution to a clean environment. There are other mist collectors available, but none have the low maintenance and total efficiency records of the 3nine systems. Be sure to call Cutting Tool Control for all the details regarding the most effective mist elimination available.

Cutting Tool Control can provide a solution to any machining challenge you may have. If Cutting Tool Control doesn’t have the solution you need – it probably hasn’t been invented yet. In the words of founder Bruce Lowry, “I say put us at the end of your list to call when others cannot deliver a quality solution.”

In the realm of laser cutting systems, the quest for efficiency is often hampered by bottlenecks in material handling processes. These bottlenecks, characterized by interruptions and delays, can severely impact production timelines and overall operational effectiveness. Recognizing this challenge, incorporating material handling automation has emerged as a pivotal solution, transforming the way laser cutting systems function and optimizing the entire fabricating value chain.

A part removal system sorts cut blanks to the appropriate pallet. Stacking can be planned in the right sequence and orientation. At the heart of this issue lies the loading and unloading process with laser cutting systems. Machines lacking material handling automation exhibit significant variability in production time, especially during these crucial stages. The waiting or idle times, meticulously recorded from the laser cutting machine’s data, clearly indicate the presence of these bottlenecks. These waiting times stem from two primary factors: the absence of raw materials supplied to the machine or the failure to unload cut parts before the machine completes processing the previous sheet. Addressing these bottlenecks at this pivotal juncture in the fabricating process is paramount, as it directly influences downstream operations and the overall process times.

Automation enters the scene as a gamechanger, particularly in material supply. Consider the scenario when cutting programs are released to the laser cutting machine for processing. In traditional setups, human intervention is required to retrieve raw materials from a storage area, often utilizing a forklift. The time accumulated in performing this action for each material changeover can be substantial, especially in high-mix environments with frequent daily changeovers. This manual intervention becomes a critical bottleneck.

However, with an automated material storage system in place, this bottleneck is effectively eliminated. Multiple material types and thicknesses can be supplied seamlessly across various machines. The beauty of automation lies in its ability to seamlessly communicate with the laser cutting machine. As programs are released, communication with the material storage system is automatic, and the subsequent material order can be delivered while the machine is still processing the last sheet of the previous order. This synchronized movement of raw materials

Automation plays a pivotal role in the material loading process. Once the laser cutting machine is presented with the raw material stack, automating the loading process becomes imperative. In an automated setup, loading the material is an integral part of the automatic sequencing tied to the machine’s material request. No longer does one need to wait from sheet to sheet or from order to order. Sheets are efficiently loaded onto secondary shuttle tables while the laser cutter is seamlessly cutting on the primary table. However, a crucial sequence must occur between loading and unloading: the timely unloading of cut materials. Failure to unload the cut material promptly results in accumulating waiting times, disrupting the flow of operations.

Automating the laser cutting machine material unloading and parts sorting process

Here enters the significance of automating the material unloading and parts sorting process. Automating the material unloading process is not just desirable but crucial. It is the linchpin upon which the loading and cutting processes hinge.Without timely unloading, a bottleneck is created, impeding the entire workflow. Addressing this challenge necessitates a thoughtful approach. Two methods of practice: unloading the entire cut sheet with parts using an unload fork system or having the parts unloaded and stacked using an automated sorting system for the parts and a fork system to remove the material skeleton when completed.

The system involving automated sorting proves to be efficient and transformative.The automated system separates cut parts from the sheet material based on the order they belong to. Similar parts are organized into neat stacks for subsequent fabricating processes. By reducing manual intervention and minimizing errors in stacking similar part revisions, the automated sorting system significantly reduces process times, enhancing efficiency and throughput.

By identifying, addressing, and eliminating material handling bottlenecks, sheet metal fabricators can pave the way for unparalleled efficiency, heightened profitability, and sustained business growth. By mitigating these bottlenecks, fabricators can deliver on their promises with greater precision, ensuring that customer delivery dates are met consistently. This newfound precision not only enhances operational efficiency but

also bolsters profitability. Inaccurate job quotes, a common consequence of overlooking these material handling bottlenecks, can erode profits significantly. By addressing these variabilities and accurately reflecting them in job quotes, businesses can maintain healthy profit margins, contributing to long-term sustainability and growth.

By Frank Arteaga, Regional Director Marketing – Americas Bystronic Inc., Hoffman Estates, IL Voice.bystronic@bystronic.com

Frank Arteaga is the Regional Director of Marketing and Communications for Bystronic Inc. Frank has over 30 years of experience in the sheet metal fabrication industry working directly with Laser, Waterjet, Press Brake, Software and Automation systems. Frank started his career at Bystronic as an applications engineer traveling extensively throughout North America, teaching customers how to operate and program Bystronic equipment. Frank has held numerous management positions at Bystronic including head of applications and product management for US operations. His unique experience and product knowledge provides insightful thought leadership to the sheet metal fabrication industry. Frank is a graduate of the State University of New York at Farmingdale and has authored many published technical articles on Laser cutting, Waterjet cutting, Software and Automation systems throughout his career.

Challenged with meeting customer deliveries and adapting to their ever-changing requirements?

Optimize your manufacturing workflow with modular end-to-end solutions from Bystronic. Combine best-in-class machines, automated production cells, and software for a highly agile and efficient production process that can expand as your business grows. Bystronic will guide you through your transformation journey step-by-step.

Your best choice for sheet metal processing. Modular

STEM workers are in fierce demand, and not just in the global epicenter of high tech known as Silicon Valley. According to the latest U.S. Bureau of Labor Statistics analysis, STEM — science, technology, engineering and math — professions are expected to grow 10.8% between 2022 and 2032, compared to just 2.3% for all other occupations. In addition, the median annual STEM wage is $97,980, compared to $44,670 for all nonSTEM occupations.

Overall Rank Metro Area* Total Score Professional

The Austin, TX metro area is the best place for STEM professionals in 2024, in part because STEM jobs make up over 11.5% of all employment, one of the highest rates in the nation. There are lots of open positions too, as more than 13% of Indeed job postings in the area are in the tech sector.

People in the Austin area can expect high earnings, too, as it ranks in the top 10 for median earnings for STEM jobs, at over $101,000 per year even after adjusting for the cost of living.

The Austin metro area is also good for tech education – students can find tech summer programs, and the area’s engineering universities are some of the best in the nation. Due to its promising conditions for this field, Austin has even been called “the next Silicon Valley.”

Seattle, WA

Seattle is the second-best area for STEM because it is one of the most well-known west-coast tech hubs, and the surrounding metro area has plentiful STEM jobs. For example, it ranks second in the country for STEM employment, with STEM positions making up over 13% of all jobs and more than 15% of new job postings on Indeed being in tech.

Plus, over 7.5% of the area’s GDP stems from research and development, which is one of the highest rates in the country. The Seattle metro area also has very productive inventors, with one of the highest numbers of invention patents per capita.

The Atlanta, GA metro area ranks third for STEM professionals in part because it has some of the best engineering universities in the country and one of the highest median wages for STEM jobs, at over $105,000 per year after adjusting for the cost of living.

Like the other top metro areas, Atlanta has a high share of STEM jobs and job openings, but it’s also notable for creating a good environment outside of work. For example, it ranks among the top areas for singles and recreation, which can help professionals who move for work find partners and de-stress after a productive work week. The Atlanta metro area is also a great place to network, as it ranks highly when it comes to tech meetups per capita.

Consider the Best Cities and Online Work: Moving to a city with an abundance of STEM jobs, high salaries, and a relatively low cost of living can set you up for success. If you are considering moving to a different city, make sure to look at quality of life factors like recreation opportunities and the environment for singles or families, which can be just as important as job openings. However, many STEM jobs can be done remotely now, so you can apply to jobs that are based in cities you might not want to move to as well.

Seek Out Quality Schools: If you haven’t gone through college yet, picking a university that offers robust STEM classes is key. Good schools may also help you connect with internships and employment opportunities once you graduate. Keep in mind that you don’t necessarily have to go to an expensive name-brand school, just one that has a good program.

Build a Strong Professional Network: Networking is key in STEM. Connect with professionals, attend conferences, and engage in online communities. Building a strong network not only opens up collaboration opportunities but also provides insights into industry trends and potential career paths.

Develop Strong Communication Skills: Effective communication is crucial, especially when dealing with complex scientific or technical

concepts. Hone your ability to convey ideas clearly to both technical and non-technical audiences. This skill is valuable for collaborations, presentations, and bridging the gap between science and the broader community.

Methodology

In order to determine the best job markets for STEM professionals, WalletHub compared the 100 most populated U.S. metropolitan statistical areas (MSAs) — metro areas, for short — across three key dimensions, “Professional Opportunities”, “STEM-Friendliness” and “Quality of Life.”

Sources: Data used to create this ranking were collected as of December 20, 2023 from the U.S. Census Bureau, Bureau of Labor Statistics, United States Patent and Trademark Office, National Center for Education Statistics, National Science Foundation, Council for Community and Economic Research, Indeed, U.S. News & World Report, Meetup.com, iDTech and WalletHub research.

The Equipment Leasing & Finance Foundation (the Foundation) releases the February 2024 Monthly Confidence Index for the Equipment Finance Industry (MCI-EFI) today. The index reports a qualitative assessment of both the prevailing business conditions and expectations for the future as reported by key executives from the $1 trillion equipment finance sector. Overall, confidence in the equipment finance market is 51.7, an increase from the January index of 48.6.

When asked about the outlook for the future, MCI-EFI survey respondent Jeffry Elliott, CLFP, President, Huntington Equipment Finance, said, “We believe there is a 50/50 chance of a recession this year, which will likely result in lower capex spending on equipment, at least in the first half or until interest rates decline. However, following the significant delay in equipment acquisitions last year, we still expect considerable activity this year, as equipment wears out and replacement can be delayed only so long. The speed of onshoring and reshoring also will determine the demand for acquiring equipment or capex. Fortunately, long-term growth prospects for the United States and North America are strong, and we think the largest-ever expansion in our nation’s history is on the horizon.”

February 2024 Survey Results:

The overall MCI-EFI is 51.7, an increase from the January index of 48.6.

When asked to assess their business conditions over the next four months, 10.7% of the executives responding said they believe business conditions will improve over the next four months, a decrease from 20.7% in January. 82.1% believe business conditions will remain the same over the next four months, up from 62.1% the previous month. 7.1% believe business conditions will worsen, a decrease from 17.2% in January.

7.1% of the survey respondents believe demand for leases and loans to fund capital expenditures (capex) will increase over the next four months, down from 13.8% in January. 78.6% believe demand will “remain the same” during the same four-month time period, up from 65.5% the previous month. 14.3% believe demand will decline, a decrease from 20.7% in January.

14.3% of the respondents expect more access to capital to fund equipment acquisitions over the next four months, up from 13.8% in January. 75% of executives indicate they expect the “same” access to capital to fund business, down from 75.9% last month. 10.7% expect “less” access to capital, up slightly from 10.3% the previous month.

When asked, 21.4% of the executives report they expect to hire more employees over the next four months, an increase from 6.9% in January. 71.4% expect no change in headcount over the next four months, down

from 79.3% last month. 7.1% expect to hire fewer employees, down from 13.8% in January.

3.6% of the leadership evaluate the current U.S. economy as “excellent,” up from none the previous month. 89.3% of the leadership evaluate the current U.S. economy as “fair,” down from 93.1% in January. 7.1% evaluate it as “poor,” relatively unchanged from 6.9% last month.

17.9% of the survey respondents believe that U.S. economic conditions will get “better” over the next six months, up from 13.8% in January. 67.9% indicate they believe the U.S. economy will “stay the same” over the next six months, an increase from 65.5% last month. 14.3% believe economic conditions in the U.S. will worsen over the next six months, a decrease from 20.7% the previous month.

In February, 21.4% of respondents indicate they believe their company will increase spending on business development activities during the next six months, an increase from 17.2% the previous month. 67.9% believe there will be “no change” in business development spending, up from 65.5% in January. 10.7% believe there will be a decrease in spending, down from 17.2% last month.

“The U.S. economy is in transition and that brings opportunity to the creative and solution-oriented equipment finance and leasing companies in our industry. Our ability to pivot, meet our customers’ needs, and quickly

execute on opportunities will determine our success. The headwinds of rising bankruptcy filings, delinquency and overall portfolio performance trending to long term averages are a change to the incredible times our industry has had for over a decade. This shift will affect organizations’ commitment and harm some while helping others. I look forward to growth in 2024.” David Normandin, President and Chief Executive Officer, Wintrust Specialty Finance

Confidence in the U.S. economy and the capital markets is a critical driver to the equipment finance industry. Throughout history, when confidence increases, consumers and businesses are more apt to acquire more consumer goods, equipment, and durables, and invest at prevailing prices. When confidence decreases, spending and risk-taking tend to fall. Investors are said to be confident when the news about the future is good and stock prices are rising.

The respondents are comprised of a wide cross-section of industry executives, including large-ticket, middle-market and small-ticket banks, independents, and captive equipment finance companies. The MCI-EFI uses the same pool of 50 organization leaders to respond monthly to ensure the survey’s integrity. Since the same organizations provide the data from month to month, the results constitute a consistent barometer of the industry’s confidence.

New Directions Technologies Inc.,* Ridgecrest, California, is awarded an $111,409,699 cost-plus-fixed-fee, cost indefinite-delivery/indefinitequantity contract. This contract provides engineering support services or system, test, and transition engineering and management analysis and training services in support of providing concurrent engineering and subject matter expertise for major projects across various weapons systems such as missiles and sensor systems for the Naval Air Warfare Center Weapons Division (NAWCWD) Research and Engineering Department. Work will be performed in China Lake, California (70%); and Point Mugu, California (30%), and is expected to be completed in February 2029. No funds will be obligated at the time of award; funds will be obligated on individual orders as they are issued. This contract was competitively procured via a small business set aside; three offers were received. NAWCWD, China Lake, California, is the contracting activity (N6893624D0001).

Gilbane Federal, Concord, California (N69450-21-D-0056); Hensel Phelps Construction Co., Orlando, Florida (N69450-21-D-0057); The Korte Co., St. Louis, Missouri (N69450-21-D-0058); M. A. Mortenson Co., doing business as Mortenson Construction, Minneapolis, Minnesota (N69450-21-D-0059); RQ Construction LLC, Carlsbad, California (N69450-21-D-0060); Sauer Construction LLC, Jacksonville, Florida (N69450-21-D-0061); Walsh Federal LLC, Chicago, Illinois (N6945021-D-0062); B.L. Harbert International LLC, Birmingham, Alabama (N69450-22-D-0011); Balfour Beatty Construction LLC, Charlotte, North

Custom Injection Molding

800. 280.2278

3D can provide design assistance and work with existing products to produce them more economically.We are a ‘UL Certified’ molder offering low to high quantity production runs.

We produce many of our customer’s products with metal and plastic sub-components molded in. It is very common to use threaded inserts, bushings, contacts, and plastic substrates.

Carolina (N69450-22-D-0012); and The Whiting-Turner Contracting Co., Baltimore, Maryland (N69450-22-D-0013), are awarded a combinedmaximum-value $60,000,000 firm-fixed-price modification to increase the capacity of their respective previously-awarded contracts for general building type projects. Award of this modification brings the total cumulative value for all 10 contracts combined to $1,010,000,000.Work will be performed in Florida (15%), Georgia (15%), Louisiana (14%), Mississippi (14%), South Carolina (14%), Tennessee (14%) and Texas (14%), and is expected to be completed by September 2026. No funds will be obligated at time of award. The Naval Facilities Engineering Systems Command Southeast, Jacksonville, Florida, is the contracting activity.

General Atomics Aeronautical Systems Inc., Poway, California, is awarded a $43,131,929 cost-plus-fixed-fee order (N0001924F0008) against a previously issued basic ordering agreement (N0001922G0006).This order provides for engineering and logistics and support services, capability development and sustainment in support of the Marine Air-Ground Task Force Unmanned Aircraft System Expeditionary/Medium Altitude Long Endurance MQ-9A for the Marine Corps.Work will be performed in Poway, California (42%); Indo-Pacific Command Theater (20%); Yuma, Arizona (13%); Kaneohe Bay, Hawaii (11%); Patuxent River, Maryland (7%); Cherry Point, North Carolina (7%); and Mechanicsburg, Pennsylvania (1%), and is expected to be completed in February 2025. Fiscal 2024 operations and maintenance (Navy) funds in the amount of $9,000,000; and fiscal 2024 aircraft procurement (Navy) funds in the amount of $8,485,345 will be obligated at the time of award, $9,000,000 of which will expire at the end of the current fiscal year. Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity.

LAS CRUCES, N.M - The Borderplex Alliance and Spaceport America today signed a Memorandum of Understanding, formalizing a new collaboration between the two organizations. This partnership will open up thrilling opportunities to propel the Borderplex region’s economy to new heights.

“We are thrilled about teaming up with Spaceport America,” said Jon Barela, CEO of The Borderplex Alliance. “Together, we will initiate new programs that stimulate job creation and capital investment in our region. The commercial space industry is expanding rapidly, and this alliance ensures the Borderplex will be at the forefront of this 21st-century industry.”

Spaceport America, the world’s first purpose-built commercial spaceport, has seen great success since its 2010 founding. The spaceport enables aerospace companies to innovate and test technologies in rocket launches, space tourism, astronaut training, and more.

“Partnering with The Borderplex Alliance gives a big boost to Spaceport America’s mission,” said Scott McLaughlin, Executive Director of Spaceport America. “This collaboration broadens our reach and helps grow New Mexico’s role as a leader in the commercial space sector.”

With its proximity to Spaceport America, the Borderplex region is wellpositioned to capitalize on this partnership. The spaceport has already

spawned many new economic development opportunities in the region. This alliance will enable more economic activity in R&D, manufacturing, and high-tech services.

“Together, we will create more economic development opportunities in science, technology, engineering, and math,” added Barela.

Through this strategic alliance, the two organizations will collaborate on marketing, business development, and policies that enable the commercial space industry to thrive in the Borderplex region. Both parties look forward to launching transformative aerospace projects that create good-paying jobs and fuel economic growth.

Spaceport America is the first purpose-built commercial spaceport in the world.The FAA-licensed launch complex, situated on 18,000 acres adjacent to the U.S. Army White Sands Missile Range in southern New Mexico, has a rocket-friendly environment of 6,000 square miles of restricted airspace, low population density, a 12,000-foot by 200-foot runway, vertical launch complexes, and about 340 days of sunshine and low humidity.

Some of the most respected companies in the commercial space industry are tenants at Spaceport America: Virgin Galactic, HAPSMobile/ AeroVironment, UP Aerospace, SpinLaunch, and Prismatic Ltd., a subsidiary of BAE Systems.

The Borderplex Alliance is an award-winning economic development and policy advocacy organization. It is independent, non-partisan, and private sector-led. The mission of The Borderplex Alliance is to bring jobs, hope, and opportunity to the Borderplex region.

“Today is a day three years in the making,” CEO Gelsinger said as Intel touted its Intel Foundry business.

Microsoft Corp. (Nasdaq: MSFT) will use Intel Corp. (Nasdaq: INTC) to make chips on Intel’s most advanced technology, a victory for the fabrication business that CEO Pat Gelsinger has vowed to build as a key part of a larger revitalization effort.

The announcement came Wednesday morning as Gelsinger hosted a foundryfocused event in San Jose where he declared that the IDM 2.0 vision he unveiled shortly after his arrival as CEO in February 2021 — greeted then by no small amount of skepticism — had become real.

With it, what had been known as Intel Foundry Services on Wednesday was renamed Intel Foundry, which Gelsinger called “interdependent” with Intel’s own product line.

“We’re not fixing one company,” he said. “We’re establishing two vibrant new organizations.”

Both will lean on advanced technology, and Gelsinger said Intel had made good on a promise to push its process technology five nodes in four years after a series of stumbles in the 2010s. He also revealed what’s next for Intel on the technology front for the first time, a node called 14A, for 1.4 angstrom (an angstrom is one hundred-millionth of a centimeter).

The Microsoft chip will be made on 18A, the last step of the five-nodes-infour years plan. Intel says that node moves it past Taiwan Semiconductor Manufacturing Co. (NYSE: TSM) on advanced technology.

Intel said it now had $15 billion in lifetime revenue locked for its foundry business, though details on the Microsoft contract — the chip, the timing, the size of the deal — weren’t revealed. And the announcement didn’t appear to wow markets, with Intel’s stock down down around 1.5% in the hour or so after the announcement.

But the message from Microsoft was exactly what Intel wants broadcast to the technology world.

“We need a reliable supply of the most advanced, high-performance and high-quality-semiconductors,” Microsoft Chairman and CEO Satya Nadella said in a videotaped appearance at the Intel event. “That’s why we are so excited to work with Intel Foundry, and we have chosen a chip design that we plan to produce on Intel 18A process.”

Gelsinger’s plan to bring Intel back from years of doldrums has it investing billions in Ohio, Arizona and Europe to boost its chipmaking prowess and capacity. Casting it as a national security issue — Gelsinger said silicon was the new oil as an indispensable economic building block — the company is also looking for big federal support.

Reports have Intel receiving up to $10 billion through the Biden administration’s CHIPS Act program.The Commerce Department is overseeing that award process and Secretary Gina Raimondo made a remote appearance at the Intel event on Wednesday. She delivered no revelations about Intel, but Gelsinger alluded to the expected bounty.

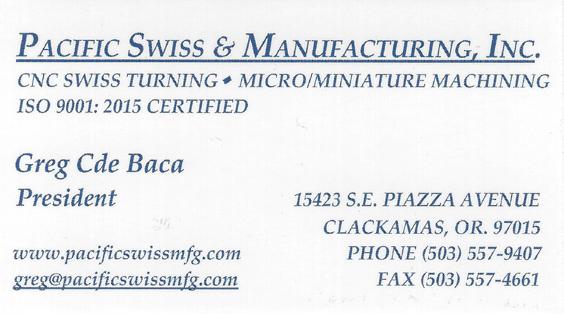

Pacific Swiss, like a Sports Team, Continues To Hit It Out Of The Park! When a company is cultivated through a successful team of workers, it’s like building a team that is much like a sports team.

Unless your business is like the New York Yankees and you can afford to throw money at the industry’s top performers, you’ll have to build your team methodically. That starts with recruiting and hiring the right team players.

Turning a good team into a championship one, or a good company into a successful company isn’t an exact science. To make your company successful you need a good mix of young, energetic talent alongside your established veterans. In sports, the rookies make the hustle plays and bring tons of enthusiasm to the locker room.

The same is true for a sports team as-is for an office. The young employees who you bring in will flood the environment with positivity and eagerness. They’ll also prove very useful in providing insight into youth markets and emerging technologies.

(Ethical comes from the Greek ethos “moral character” and describes a person or behavior as right in the moral sense - truthful, fair, and honest. Sometimes the word is used for people who follow the moral standards of their profession.)

One of Greg’s daughters, Paige Cde Baca, decided she wanted to work in the family business. Paige has worked many areas of the business from the shop helper, parts cleaner, shipping department, and vendor support. Paige, under the tutelage of her father, learned the business and developed a deep appreciation for what her father had to do for many years to run and build the business.

That’s what Greg Cde Baca Owner of Pacific Swiss, a life long baseball player, a team player, and a great family man weaves into his business model.

Greg started his Precision Swiss shop in 1995 with meager means, one machine, a single spindle with 7 tools, the Citizen B12. This machine was the foundation that Greg’s dream was built from, a focus on small precision parts made by a cohesive team, in the Pacific Northwest!

Today: Pacific Swiss and Manufacturing Inc. offers a specialized combination of CNC Swiss Turning and CNC Swiss Micro/Miniature Machining. Part sizes typically machined are from .010” diameter to 1-1/4” diameter with up to 10 axis of machining capability. Pacific Swiss supports some of the major precision companies in the world including medical, dental, defense/ military, aerospace, flow control, motion control, lock & hardware, electronics, automotive, semiconductor, recreation, telecommunications, plastic molding, interconnect, linear & motion control, and fiber optics, to name a few.

Soon after, Paige’s sister Kaylee Cde Baca joined the company as Office Manager. She took a liking to the administrative side of the business and what it takes to get parts through the shop. Managing the daily operations from the administrative side allowed her to build relationships with our customers, suppliers, and our outside sales representatives.

Paige and Kaylee are chips off the ole block; they are an integral part of the business. Paige is now Shipping/Receiving Lead, Materials Management and Vendor Support. She is the last layer of quality that assures a quality product and ISO paperwork is in order with every shipment. Kaylee transitioned to Operations Coordinator. She manages the schedule, production floor and customer support. In addition, she works very closely with our tight-knit supply chain to assure materials, goods and services meet customer and P/O requirements. They both manage this through a unique and detailed proprietary Excel based MRP/ERP system that manages and tracks every job in the shop from quoting to shipment.

Paige and Kaylee told me that over the years they have realized a great appreciation for their father and what he has had to do to weather to build the business.They never understood why dad had to run to the shop in the middle of the night for a service call and what was so special about this Swiss machine shop. Now they know and appreciate the dedication it takes to build and maintain a great precision manufacturing business.

Another integral part of this precision business is certification and compliance. Pacific Swiss is an ISO 9001:2015 certified, ITAR registered precision CNC Swiss machine shop and they are in compliance to AS9100 an aerospace certification, with sights set on complete AS9100 certification by 2025.Their Quality Statement is: Understand (understand their customers’ complete requirements and needs), Deliver (serve their customer’s with great communication, positive feedback, and a delivery that exceeds their expectations) Improve (Do better, think better, perform better, learn more daily, and be accountable for what you do.)

It starts with a dream, passion, and a visualization of a heartfelt goal to succeed.Then, you need to build a team that is accountable for their actions and decisions based on the training you have afforded them and their sound ethics. Pacific Swiss is about building relationships and being consistent with ourselves, our customers, outside sales representatives and supply chain. This is done through communication, commitment, integrity, and products of the highest quality delivered on time and reasonably priced.

Why is Pacific Swiss so successful at what they do? Well, because they only focus on Swiss machining, both micro miniature machining and standard precision Swiss machining, only Swiss! In fact they are so good at what they do that their parts are shipped into China, Thailand and Mexico. That’s right it’s usually the other way around but Pacific Swiss is so proficient at what they do the cheapest labor markets can’t produce the precision parts they make at their great

competitive price, their high quality, nor their on time consistent delivery!

Another key factor in their success is their almost nonexistent returns or perfect parts shipped to customers. I asked Greg what the quality rating is for Pacific Swiss. Greg said, “ We are very good at not letting anything leave our facility that does not exceed our customer requirements or expectations. With hundreds of thousands of parts shipped we have an impeccable quality rating! We are AS9100 compliant and our system is written to AS9100 standards so we will certify to this high quality standard by December of this year.”

Paige and Kaylee collaborate on everything together, from perfectly ground material coming from qualified suppliers, running production through the shop floor, to inspection and packaging prior to shipment in their customer’s delivery window.

This dynamic duo sets the stage for a seamless flow through the shop to their valued customers.The rest of the team take the job traveler, programs, and tools to machine the parts to specification.

The Pacific Swiss Team are setup operators with CNC Swiss backgrounds and a production mind set.They say Greg has opened their mind in regard to superior Swiss machining and say his company is doing some real progressive manufacturing. They said they love working at Pacific Swiss and continue to grow & learn every day.

Pacific Swiss is poised to increase sales by 30% this year. Managing that growth will be part of the responsibility of Kim Sparber, Director of Personnel and Finance. Kim’s background is accounting. She has over15 years of business and finance knowledge specific to Pacific Swiss. This strong financial background has been a contributing factor in Pacific Swiss’s continued yearly growth.

that same day. I can’t say enough about the great service and support Page Spinetti and his team has given us over the years. I highly recommend Spinetti Machinery and their great crew!”

We are an American manufacturing company with over 75-years experience, producing products for NASA’s astronauts. Our product is also the perfect tool for trade professionals, first responders, military, rugged outdoor enthusiasts, trekkers, backpackers, industrial manufacturers, underwater divers and anyone who values a product that doesn’t fail in extreme circumstances. That’s why we work with Pacific Swiss. As a thriving business with a rich history, Greg and his team help us maintain and elevate the integrity of our products. Their expertise is evident in their attention to precision, quality, and craftsmanship and their dedication to customer service is truly unparalleled.

-A President –Writing Instruments Industry

Over the past 15 years, Pacific Swiss & Mfg., Inc. has proven to be an exceptional partner, consistently exceeding expectations across the board. Greg and his team have a proactive approach and commitment to our success that elevates them beyond the role of a mere supplier, transforming them into a strategic ally. Whether it’s meeting tight deadlines, challenging projects or innovating solutions, Pacific Swiss demonstrates unwavering dedication and expertise, making them an invaluable asset to our operations and have contributed significantly to our own success. Their trustworthiness, responsiveness, and commitment to excellence makes Pacific Swiss & Mfg., Inc. an ideal partner.

-A Sales Manager – Arizona Manufacturer

This continued growth is only possible because Pacific Swiss has great employees, a great system for facilitating customer parts from A to Z through the shop and they utilize the best machines in the industry Citizen. Greg only buys Citizen Swiss machines like the Citizen L32XII that includes the Y-axis to the back tool post and also has an integrated B-axis live tool spindle mounted on the gang tool slide. This B-axis block includes 4 live front working and 4 live back working positions. The swivel angle can be set over the range from 90 to -45 degrees. This feature allows for easy contouring and drilling slanted holes at any number of different angles. These Citizen machines are set up at Pacific Swiss to run lights out, all night long.

Greg said, “ I buy my machines, parts and service from Spinetti Machinery and they are a great partner. If we’re ever down, it’s only a few days to get up and running again and sometimes they can coach us over the phone and we are back up and running

Every salesperson knows that their reputation can make or break them. We are very careful bringing on quality vendors so it does not hurt that reputation we have with our customers. Pacific Swiss fulfills this need with their incredible manufacturing team. They review drawings in detail and get all questions resolved before taking that information to their manufacturing floor. Our customers have been extremely happy with their quality of work. We are so happy to have them on our Line Card.

-A Sales Professional – California

For more information on Spinetti Machinery contact them at: 775-996-3770 or go to their website at spinettimachinery.com

For more information on how to get the best Swiss machining contact Greg Cde Baca at 503-557-9407, greg@pacificswissmfg.com.

Boeing named new executives to lead its 737 Max production and commercial quality efforts Wednesday, its latest response to a midair malfunction last month on an Alaska Airlines 737 Max 9.

By Marissa Nall

The head of The Boeing Co.’s (NYSE: BA) Rentonbased 737 Max program, Ed Clark, has left the company, according to news reports.

The move comes in the wake of the alarming in-flight incident last month in which a Max 9 airplane lost a panel of its fuselage, triggering the grounding and inspection of hundreds of planes.

Boeing Commercial Airplanes CEO Stan Deal reportedly sent an email to employees this morning detailing several leadership changes the company will undertake as it faces mounting pressure from customers

and regulators to demonstrate safety and reliability across its production.

Katie Ringgold, who has led delivery operations at BCA for the last two years, will succeed Clark as head of the Max program.

Elizabeth Lund, who was tapped to lead BCA’s airplane programs in late 2021, was also named to a newly created role of senior vice president of quality for the commercial division. She is succeeded as general manager of airplane programs by Mike Fleming, who has led development programs for Boeing Commercial and oversaw the 737 Max’s return to service following two devastating crashes that killed 346 people in 2018 and 2019.

The Jan. 5 in-flight incident involved missing bolts on a 737 Max 9 emergency exit door plug that had undergone repairs at Boeing’s Renton facility prior to its delivery to Alaska Airlines in October.

Planes were allowed to begin flying again in late January after the Federal Aviation Administration approved inspection and repair guidance for 171 affected jets.

Boeing has since faced audits from the National Transportation Safety Board and the FAA, which halted Boeing’s plans to increase production of the 737 Max this year, as well as appointing its own team of outside experts to conduct an analysis of its production and quality-control systems.

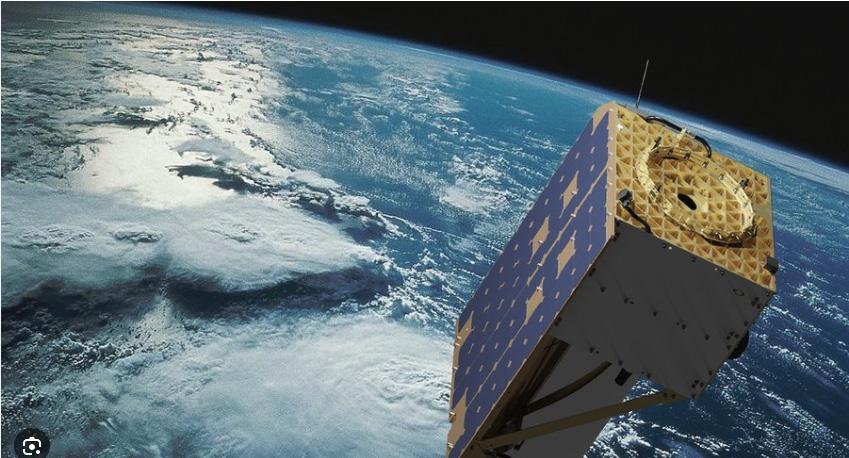

Amazon.com Inc. (Nasdaq: AMZN) could be expanding its satellite division to Everett, a recent job posting suggests.

The Seattle-based tech giant said in a Feb. 7 posting that it’s seeking an area warehouse manager for the company’s Project Kuiper, which plans to produce and launch 3,236 low Earth orbit internet satellites by mid-2029

Kirkland and Redmond already have Project Kuiper sites. Amazon’s Project Kuiper headquarters are in the Redmond Commerce Center, where it developed prototype satellites that it launched last year.

Amazon already has warehouses in Everett for its e-commerce operations network. It has a cluster of warehouses near Boeing’s Everett production facility as well as a same-day delivery site on the north side of the city.

The Puget Sound region is quickly becoming a major hub for satellite production, thanks largely to Amazon and its rival SpaceX’s Starlink, which is headquartered in Redmond. Both companies are planning constellations of satellites that provide low-latency broadband internet.

In the Totem Lake area of Kirkland, Amazon built a 172,000-square-foot facility for mass production of the satellites. The site is expected to produce as many as five satellites per day when it’s operating at full capacity.

Project Kuiper doesn’t have a presence in Everett yet, though Amazon confirmed the locations on the job posting are correct.

Amazon said in July its Kuiper division had more than 1,400 employees, most of which are based in the greater Seattle area. More than 800 Amazon workers were based between two Amazon facilities associated with Project Kuiper, according to an internal headcount tool viewed by the Business Journal. The company has more than 1,700 employees based in Redmond, all of whom work in Project Kuiper or Amazon Web Services offices.

Since Redmond is the heart of the region’s satellite production, the city has designated the area as the “space district.” The name was pitched to the city by Xplore chief operating officer Lisa Rich, according to communications between the company and city officials obtained through a public records request.

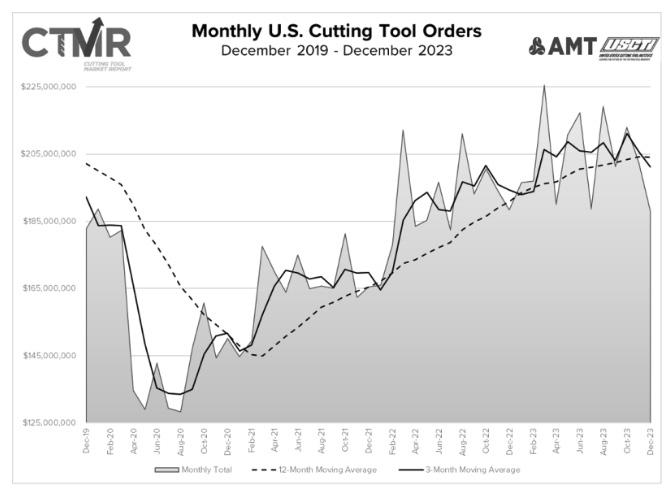

December 2023 U.S. cutting tool consumption totaled $187.9 million, according to the U.S. Cutting Tool Institute (USCTI) and AMT – The Association For Manufacturing Technology. by Christopher Chidzik

This total, as reported by companies participating in the Cutting Tool Market Report collaboration, was down 7.3% from November’s $202.7 million and down 0.3% when compared with the $188.4 million reported for December 2022. With a year-todate total of $2.45 billion, 2023 is up 6.9% when compared to the same time period in 2022.

“With 2024 comes change and challenge,” stated Steve Boyer, president of USCTI. “The U.S. cutting tool industry will continue to see growth opportunities in aerospace, automotive, medical, and computer-related segments but slowing and declines in other markets. While forecasts initially anticipated interest rate declines as we moved into 2024, recent inflation indicators appear to temper those expectations. We enter the new year with a guarded view anticipating continued challenges and uneven growth.”

1411

The Cutting Tool Market Report is jointly compiled by AMT and USCTI, two trade associations representing the development, production, and distribution of cutting tool technology and products. It provides a monthly statement on U.S. manufacturers’ consumption of the primary consumable in the manufacturing process –the cutting tool. Analysis of cutting tool consumption is a leading indicator of both upturns and downturns in U.S. manufacturing activity, as it is a true measure of actual production levels.

Historical data for the Cutting Tool Market Report is available dating back to January 2012. This collaboration of AMT and USCTI is the first step in the two associations working together to promote and support U.S.-based manufacturers of cutting tool technology.

The United States Cutting Tool Institute (USCTI) was formed in 1988 and resulted from a merger of the two national associations representing the cutting tool manufacturing

industry. USCTI works to represent, promote, and expand the U.S. cutting tool industry and to promote the benefits of buying Americanmade cutting tools manufactured by its members. The Institute recently expanded its by-laws to include any North American manufacturer and/ or remanufacturer of cutting tools, as well as post-fabrication tool surface treatment providers. Members, which number over 80, belong to seven product divisions: Carbide Tooling, Drill & Reamer, Milling Cutter, PCD & PCBN,Tap & Die,Tool Holder and All Other Tooling. A wide range of activities includes a comprehensive statistics program, human resources surveys and forums, development of product specifications and standards, and semi-annual meetings to share ideas and receive information on key industry trends.

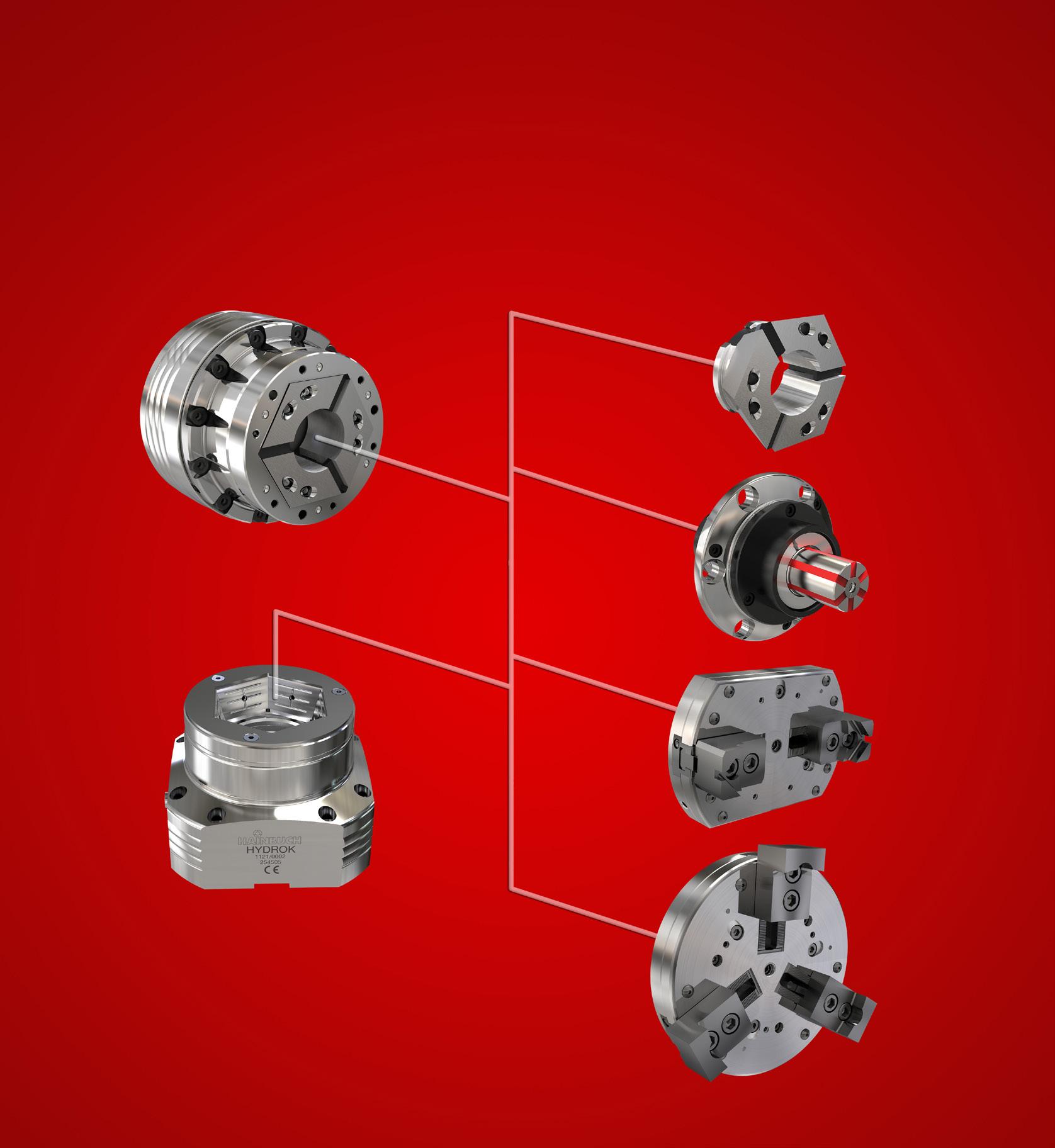

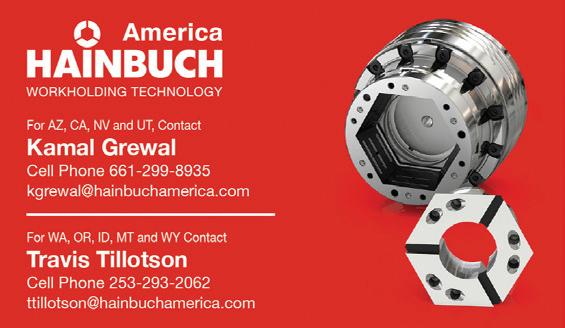

Chucks and adaptations are available in round or hexagonal configurations

n Change from O.D. to I.D. to jaw clamping in < 2 minutes

n Use the same adaptations on your HAINBUCH turning or stationary chucks

n Keep the basic clamping device mounted on the machine

1.800.281.5734

Germantown, WI USA

www.hainbuchamerica.com

SINGAPORE, -- (Singapore Airshow) -- Pratt & Whitney, an RTX (NYSE: RTX) business, today announced that JetSMART has selected GTF engines to power an additional 35 Airbus A320neo family aircraft, including nine

A321XLR aircraft. Pratt & Whitney will also provide JetSMART with GTF engine maintenance through an EngineWise® Comprehensive service agreement.

JetSMART, an ultra low-cost carrier (ULCC), selected the GTF engine to power 70 A320neo family aircraft in June 2019. The airline also operates an additional 15 leased GTF powered A320neo family aircraft and a fleet of 11 A320ceo family aircraft powered by the V2500® engine.

“We are building upon our collaboration with JetSMART as they drive continued expansion in the Latin American market,” said Rick Deurloo, president of Commercial Engines at Pratt & Whitney. “With unmatched fuel efficiency, payload and range, GTF engines will enable JetSMART to open new routes across South America and fly more people, farther, with less fuel and lower carbon emissions.”

“We are pleased to select additional GTF engines for our A320neo family fleet, as a key element to reduce fuel consumption and CO2 emissions by 20%, with a 75% smaller noise footprint. All of this contributes to our ULCC model and commitment to low fares and sustainable aviation, providing a better experience to our customers,” said Estuardo Ortiz, CEO, JetSMART.

JetSMART has also concluded a support package with Pratt & Whitney for inspections of GTF engines, further strengthening the relationship as strategic partners.

The Pratt &Whitney GTF™ engine, featuring Collins Aerospace nacelle and engine accessories, delivers industry-leading fuel efficiency and sustainability benefits for single-aisle aircraft.The engine’s revolutionary geared fan architecture is the foundation for even more efficient and sustainable propulsion technologies in the decades ahead, with advancements like the Pratt & Whitney GTF Advantage™ engine and beyond. Learn more at prattwhitney.com/gtf.

Pratt & Whitney is a world leader in the design, manufacture and service of aircraft engines and auxiliary power units. To learn more visit www. prattwhitney.com.

from outside North America to North America. Reshoring includes work that is produced either in-house or outsourced. A complete definition of “reshoring” is available here. Applications must be submitted by June 30. To view award details and enter to win, visit this webpage.

RTX is the world’s largest aerospace and defense company.With more than 185,000 global employees, we push the limits of technology and science to redefine how we connect and protect our world. Through industryleading businesses – Collins Aerospace, Pratt & Whitney, and Raytheon – we are advancing aviation, engineering integrated defense systems for operational success, and developing next-generation technology solutions and manufacturing to help global customers address their most critical challenges. The company, with 2023 sales of $68.9 billion, is headquartered in Arlington, Virginia.

materials and services to the industry.

RTX (NYSE: RTX) business, today announced it is ramping up the industrialization of repairs for certain components of Pratt & Whitney GTF™ engines across its Singapore-based maintenance repair and overhaul (MRO) facilities, including Component Aerospace Singapore, Pratt & Whitney Component Solutions, and Turbine Overhaul Services.

“From 2010 to 2020, more than one million jobs were announced as coming to the United States from offshore. This is a tremendous achievement, and we seek to motivate and honor the companies that have made reshoring a reality,” said Harry Moser, founder and president of the Reshoring Initiative.

Questions about the National Metalworking Reshoring Award can be directed to Harry Moser at 847-867-1144 or harry.moser@ reshorenow.org. For more information on AMT’s efforts on reshoring and supply chain efforts, visit IMTS.com/supplychain.

Adding GTF MRO repair capability for 235 parts by 2025

SINGAPORE / PRNewswire/ -- (Singapore Airshow) Pratt & Whitney, an

Repair industrialization at these three facilities has been achieved for 33 components, including seal assemblies, high pressure compressor stator segments and vanes, and combustion chambers. An additional 25 will be completed in 2024 with another 177 parts by 2025.

The Association For Manufacturing Technology (AMT) represents U.S. builders and distributors of manufacturing technology – the advanced machinery, devices and digital equipment that U.S. manufacturing relies on to be productive, innovative, and competitive.

“The investment and collaboration on repair development and capacity growth within our facilities, not just in Singapore but across our global MRO network, demonstrates our commitment to customers and the GTF fleet,” said Shangari Meleschi, vice president, Aftermarket Operations – Asia Pacific and Türkiye at Pratt & Whitney. “In addition to enhancing engine MRO efficiency, we are increasing the capabilities and productivity of our technicians and providing new opportunities for them to expand their skillset.”

The Reshoring Initiative, founded in early 2010, helps manufacturers realize that local production, in some cases, reduces their total cost of ownership of purchased parts and tooling. The Initiative also trains suppliers how to sell against lower-priced offshore competitors.

PMA, an inaugural sponsor of the National Reshoring Award, is the full-service trade association representing the North American metalforming industry — the industry that creates precision metal products using stamping, fabricating, spinning, slide forming and roll forming technologies, and other value-added processes. Its

NTMA is the voice for the precision manufacturing and tool and die industries in the United States. Backed by nearly 1,300 member companies, representing more than $30 billion in sales, NTMA provides an array of benefits to members and the industry including advocacy in Washington, training and education programs and networking events nationwide.

Pratt & Whitney’s industrialization also empowers the three repair facilities in Singapore to now perform certain tasks that were previously conducted at Eagle Services Asia as a result of the close proximity to the Singapore engine center. Leveraging this synergy, Pratt & Whitney will extend the repair offerings developed in Singapore across the GTF MRO network. Pratt & Whitney currently has 30 GTF customers with over 600 GTFpowered aircraft in the region.

Founded in 1987, Lindel Precision CNC Machining merged with Precision 4 Swiss in 2019. Together, P4Swiss / Lindel CNC Machining is dedicated to providing quality CNC machined parts at

TECH CENTER

Sterling Fab Tech is a fabrication machinery supplier that represents the most cutting-edge manufacturing technologies in the fabrication industry. With locally based sales and service employees, we support the Southwest region from California to Louisiana.

We pride ourselves in being the subject matter experts in fabrication processes and machine technologies. Combining this engineering approach to sales, our goal is to understand your needs and educate your team without any sales puffery.

Scan the QR code to get an inside look at customer facility tours and what our customers are saying about SFT.

Coil Lines

Flat Sheet & Tube Lasers

Punch and Laser/ Punch Combo

Waterjets

Press Brakes & Robotic Bending Cells

Panel Benders

Plate Rolls

Tube Bending

Deburring & Finishing Machines

Robotic Mig & Laser Welding Cells

Quality Inspection Machines

Sheet & Tube Storage Racks

Nitrogen Generators

Plasma & Oxy-Fuel Burning Tables

Gantry Style Machining Centers

Pipe & Tube Cutting

Robotic Plasma for Profile Cutting

High Tonnage Press Brakes

Heavy Duty Plate Rolls

Angle & Pipe Bending

Automated Beam Welding

Power Tools for Bevelings

SFT’s Applications team supports you during machine selection, installation/commissioning throughout the life of the machine. We offer services to improve efficiency and productivity, while reducing the common headaches of implementing new technologies or dealing with labor shortages.

SFT’s Service team are factory trained technicians dedicated to getting your machine installed correctly, preventing unexpected downtime through preventative maintenance, assisting with machine relocations, and promptly completing machine repairs. They are also trained to handle TRUMPF and Bystronic lasers.

+ Gold Plating

+ Silver Plating

+ Nickel Plating

+ Electroless Nickel Plating

+ Tin Plating

+ Heat Treat With Plate

+ Nadcap Approved Processes

+ Boeing Approved Processes

+ Expedited Turnaround

+ X-ray Fluorescence

Thickness Verification

+ In-House Laboratory With Atomic Absorption (AA)

+ Expanded Capacity In Vibratory Plating

We Are The Noble Partner With The Personal Touch!

(800) 481-6271 www.pmplating.com

AM General LLC, South Bend, Indiana (SPE7LX-24-D-0020); Ruta Supplies Inc.,* Dover, New Jersey (SPE7LX-24-D-0021); and SupplyCore Inc.,* Rockford, Illinois (SPE7LX-24-D-0022), are sharing an estimated $45,666,667 firm-fixed-price, indefinite-delivery/indefinite-quantity contract under solicitation SPE7LX-21-R-0071 for joint light tactical vehicle parts. This was a competitive acquisition with five responses received. These are one-year base contracts with two one-year option periods. Location of performance is Georgia, with a Feb. 17, 2025, ordering period end date. Using military services are Army, Navy, and Marine Corps. Type of appropriation is fiscal 2024 through 2025 defense working capital funds. The contracting activity is the Defense Logistics Agency Land and Maritime, Columbus, Ohio.

Northrop Grumman Systems Corp., San Diego, California, was awarded a $42,781,241 cost-plus-fixed-fee, cost-only and firm-fixed price contract for engineering and sustainment support, other direct costs, and provisioned item order in support of Joint Counter Radio-Controlled Improvised Explosive Device ElectronicWarfare Increment One Block One Systems.This contract includes options which, if exercised, would bring the cumulative value of this contract to $123,232,184.This contract combines purchases for the Navy (37%); Air Force (60%); and the government of Australia (3%), under the Foreign Military Sales program. Work will be performed in San Diego, California, and is expected to be complete by February 2024. If all options are exercised, work will continue through January 2028. Fiscal 2023 research, development, test and evaluation (Air Force) funds in the amount of $1,389,375 (30%); fiscal 2024 research,

development, test and evaluation (Air Force) funds in the amount of $835,205 (18%); fiscal 2024 research, development, test and evaluation (Navy) funds in the amount of $1,718,924 (36%); fiscal 2024 operations and maintenance (Air Force) funds in the amount of $600,000 (13%); and FMS (Australia) funds in the amount of $141,934 (3.0%), will be obligated at time of award, of which $1,989,375 will expire at the end of the current fiscal year. This contract was competitively procured via sam.gov, with one offer received. Naval Sea Systems Command, Washington, D.C., is the contracting activity (N00024-24-C-6400). (Awarded Jan. 31, 2024)

L3Harris Interstate Electronics Corp. (L3-IEC), Anaheim, California, is awarded a cost-plus-fixed-fee $15,141,987 modification (P00023) to a previously awarded contract (N00003022C2001) for TRIDENT II (D5) Flight Test Instrumentation systems support. This contract award also benefits a foreign military sale to the United Kingdom. Work will be performed in Anaheim, California (56%); Cape Canaveral, Florida (30%); Washington, D.C. (7%); Barrow-in-Furness, United Kingdom (3%); Kings Bay, Georgia (2%); Bremerton, Washington (1%); and Silverdale, Washington (1%).Work is expected to be completed by Feb. 8, 2027. Fiscal 2024 shipbuilding and conversion procurement (Navy) funds in the amount of $5,177,468, fiscal 2024 other procurement (Navy) funds in the amount of $599,666; and fiscal 2024 weapons procurement (Navy) funds in the amount of $502,216, are being obligated at time of award. No Funds will expire at the end of the current fiscal year. The total dollar value of the modification, including options, is $15,141,987 and the total cumulative face value of the contract is $335,161,461. This contract is being awarded on a sole source basis under 10 U.S. Code 3204(a)(1) and was previously synopsized on the System for Award Management online portal. Strategic Systems Programs, Washington, D.C., is the contracting activity.

Since January of 2004, nearly before the last of the fireworks flicker and die, I have adorned my office wall with the new Linnea Poster Calendar. It’s a ritual! A private rite that brings me joy. The first Linnea Calendars were annual Christmas gifts from my wife, and together, we have kept the tradition going. My office would be lacking without these works of art that bring enjoyment throughout the year.

Since the calendars arrived on Christmas, they remind me of the love, peace and joy the Christmas season represents. Every time I look at the beautiful wall, I try to tap into the joy of the Christmas season. No matter what is going on in my life, business, or the world, I try to recenter myself in the joy and peace of the Christmas season. It has the effect, I hope, of making me a better person. I won’t try to con you that I always succeed, but I do try.

possibly to teach and mentor others. Conversely, we can learn from our missteps, learn how we could have done something differently to achieve a better result. Again, possibly to mentor others. I realize not everyone has the luxury of a wall dedicated to a Linnea Poster Calendar, but there are all sorts of attractive 12-month calendars available.

As we ponder the new year, let us strive to love a little more, be patient a little more, forgive a little more and be thankful a little more, and relish the opportunities the new year holds for us. We can all agree that not everything that comes our way in the new year will be easy, but better planning will help us navigate the unexpected. Give looking at the whole year a chance, close your eyes and ponder the possibilities of what the new year holds.

Then there’s always the benefit of having the new year at a glance! When we can see a whole brand-new year beautifully displayed before our eyes, it can open a whole year of possibilities to ponder. We can reflect on the year past, we can relish our successes and file them away for future reference,

Abrasive Systems

KBC TOOLS & Machinery___714-278-0500

Air Cleaning Guns

Royal Products 631-273-1010

Auto-Bar Feed Systems

Western Machine Center____408-955-1000

Automation

Hainbuch Workholding____818-970-7874

Ballscrews

C & M Precision Spindle, Inc._ 503-691-0955

Band Saws/Saw Blades

Bandsaw Tech 562--419-7675

Cycle Time Solutions_____510-708-8665

Saw Service 877-738-6437

Sterling Saw Blades 800-828-11800

Band Saw Replacement Parts

Saw Service 877-738-6437

Sterling Saw Blades 800-828-1180

Band Saw Repair

Saw Service 877-738-6437

Sterling Saw Blades ______ 800-828-1180

Bar Feeders

Automatics & Machinery Co., Inc 303-990-6190

Edge Technologies 951-440-1574

Spinetti Machinery 775-996-3770

Bar Feeder Repair

Edge Technologies 951-440-1574

Boring

THINBIT 888-844-6248

Caabinet Spray Washers

ALMCO 507-380-1009

Cams

Dayton Lamina. 708-203-6684

Carbide Tools, Indexable

Cycle Time Solutions 510-708-8665

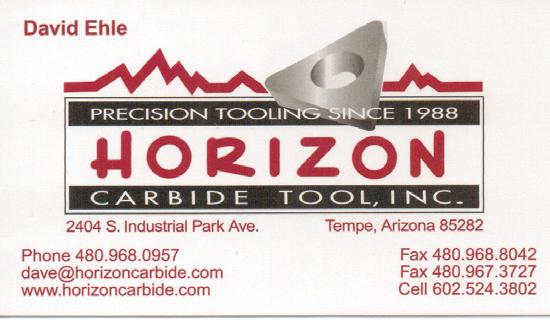

Horizon Carbide 602-524-3802

KBC TOOLS & Machinery____714-278-0500

Ceramic Cutting Tools

Compressor Systems

Ingersoll Rand 206-472-0826

NTK

Cutting Tools 425-365-3613

Chemicals: Ultrasonic

Star Metal Fluids _______ 800-367-9966

ChuckJaws & Adapters

Hainbuch America 253-293-2062

Lucy’s Machine Company 323-587-6162

Conveyor Parts Washers

ALMCO 507-380-1009

Cooling Systems

Buds Equipment Sales 435-659-9455

Coolant

Applications Specialities 253-872-0305

KBC TOOLS & Machinery____714-278-0500

MESCO 626-303-5680

Rosco Precision Machinery 206-818-6813

Sulli Tool & Supply 714-863-6019

THINBIT 888-844-6248

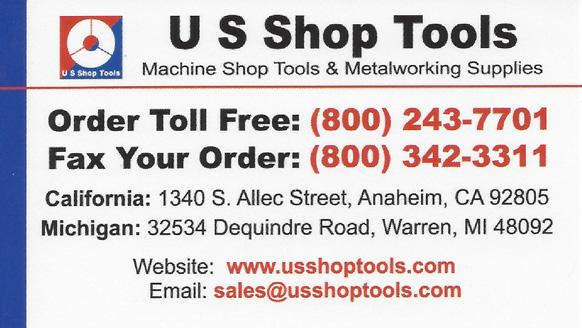

US Shop Tools 800-243-7701

Cutting Tool Holders

Hainbuch America 253-293-2062

KBC TOOLS & Machinery____714-278-0500

Sulli Tool & Supply 714-863-6019

Cutting Tool Systems

Cycle Time Solutions 510-708-8665

KBC TOOLS & Machinery____714-278-0500

THINBIT 888-844-6248

Deburring Tools