MetzFab Industries

Your Manufacturing Partner For Laser Cutting, Tube Laser Cutting, Machining, Waterjet Cutting, Welding And More.

Vol. 29, No. 4, July / Aug 2023

(AZ, NV. and NM.)

Southwest Edition

YOUR MACHINE TOOL BANK BANTERRA.BANK | MEMBER FDIC Contact Us Today For Your Machine Tool Financing Needs Why Shops Choose Banterra Bank Loan products designed speci cally for machine shops World-class deposit products including Treasury Management Industry-leading service with local decisions Bank commitment to Made In USA and Made In Arizona values ARIZONA DIVISION 950 W. Elliot Rd., Suite 114 | Tempe, AZ 15100 N. 78TH Way | Scottsdale, AZ 480-645-9005 Banterramachinetool.com

BUILDING LOANS EQUIPMENT LOANS SBA LOANS DEBT CONSOLIDATION LINES OF CREDIT BUSINESS CHECKING AND CASH MANAGEMENT

Product Offerings

GROOVING THREADING PARTING BORING TURNING FACE GROOVING CUSTOM TOOLING FORM TOOLING MILL TOOLING Follow us on: 888-THINBIT | WWW.THINBIT.COM

You can’t read an article about the labor force in general and manufacturing, in particular, that doesn’t reference the labor shortage. Covid exacerbated this, especially with a stream of Baby boomer early retirements (with an estimated 2.4 million Americans deciding to leave the workforce during the pandemic), but there are systemic issues that are more responsible for the labor shortage, and won’t go away, as Covid has.

Fertility rates play a role in our labor shortage. To maintain its population, fertility must stay at a “replacement rate” of 2.1 children per woman. America’s fertility rate has been declining for decades, and today it is 1.66—a level so low that legal immigration can no longer make up for the shortfall.

What can be done to alleviate this pain business owners and managers are experiencing? There is a model outside of the US, in Japan, that offers insights into how to help with this.

In the past decade, Japan has expanded its labor force by around 4.2 million even as its population has fallen by more than three million. To meet its labor needs, Japan found a way to engage three groups that had been under-represented in the country’s employee base, traditionally dominated by prime-age—25 to 54—men.

• Older workers. Japan understood that many older workers looked to find ikigai— translated as “purpose”—from their work. They found that more than 40% of Japanese workers in their early 60s wanted to continue working part-time after 65 and that more than 60% of employers were able to hire them. In response, Japan raised the eligibility age to 65, and they amended laws to require employers to provide opportunities for employees up to 70.

For older workers who want greater flexibility or a different line of work, the government set up a network of “Silver Jinzai” centers that offer retraining and placement services. At a given time, roughly 700,000 seniors are registered with one of the centers. Adjusted for population, this would be roughly equivalent to the U.S. discovering more than 1.8 million job-ready workers.

• Women. Increasing the number of female employees in Japan has required government support. Today, companies with more than 300 employees must report on their female labor force. And it’s working, as the labor-force participation rate among prime-age female workers in 2021 exceeded that of the U.S.

• Foreign workers. Japan has long had a training program for foreign workers from developing economies, and today this program provides workers for lowskill, low-pay roles in the Japanese economy. A 2018 law created a pathway for 260,000 to 345,000 guest workers across 14 industries.

Japan’s example shows how necessity can change attitudes. It’s important to note that government policy alone didn’t drive change. According to a 2019 survey, nearly 70% of Japanese firms had devised their own plans to tackle labor issues.

U.S. business must incorporate talent that has long been neglected. In the U.S., that means finding ways to employ workers who lack traditional credentials or who have been marginalized by such factors as poverty, substance abuse and criminal records. As in Japan, success for the business community will lie in promoting labor where it can be found today, not where it was in the past. In closing, God bless our troops and I wish you continued success.

Linda Daly,Publisher

MetzFab Industries

Your Manufacturing Partner

For Laser Cutting, Tube Laser Cutting, Machining, Waterjet Cutting, Welding And More.

Announcements. 6-19

Feature Articles 1,36-38,42-43

Feature Articles..................... 52-53,58-59

Buyers Guide Equipment...............73-81

Buyers Guide Processes 82-93

Card Gallery 73-93

Index of Advertisers 94

Editorial.................................Throughout

Published by: A2Z Manufacturing

PUBLISHER/EDITOR Linda Daly

linda@a2zMANUFACTURING. com

Address: 1538 E La Vieve Lane

Tempe, AZ 85284

Telephone: (602) 412-7696

Kim Carpenter

Takashi Sato

Gene Wirth

Published bi-monthly to keep precision manufacturers abreast of news and to supply a viable vendor source for the industry.

Circulation: The A2Z MANUFACTURING has compiled and maintains a master list of approximately 8500 people actively engaged in the precision manufacturing Industry. It has an estimated pass on readership of more than 19,300 people.

Advertising Rates, deadlines and mechanical requirements furnished upon request or you can go to A2ZMANUFACTURING. com.

The Publisher assumes no responsibility for the contents of any advertisement, and all representations are those of the advertiser and not that of the publisher.

The Publisher is not liable to any advertiser for any misprints or errors not the fault of the publisher, and in such event, the limit of the publisher's liability shall only be the amount of the publishers charge for such advertising.

CONTRIBUTORS

Cover

A2Z MANUFACTURING SW • 4 • July / Aug 2023 Editors Corner

A2Z MANUFACTURING SW • 5 • July / Aug 2023 Designed and built for use with Haas ST and DS series CNC turning centers, the Haas Bar Feeder connects directly to the Haas control. YOUR ONE SOURCE FOR THE BEST SELECTION IN AUTOMATION SYSTEMS HAAS FACTORY OUTLET A Division of Ellison Machinery Co. LLC 1610 S. Priest Dr., Ste. 101, Tempe, AZ 85281 | HaasCNC.com | 480.968.5877 Sales & Service Scan for our complete line of integrated automation products. Haas Integrated Automation Systems. Making your job as a machinist easier. Optional Automation • 4th- and 5th-Axis Rotaries • Sub-Spindles • Parts Catcher System • Auto Door for Mills and Lathes • Automatic Coolant Refill Haas Bar Feeder All-inclusive design, with plug-and-play capabilities to Haas lathes Pallet Pool Systems • 3-Station for VF-2YT/SS, VM-2 • 6-Station for EC-400 • 6-Station for VC-400/SS • 6-Station for UMC-1250/SS • 10-Station for UMC-750/1000/SS • 10- or- 20-Station for UMC-500/SS Automatic Parts Loaders • Turning Center APL • VMC APL • Small UMC APL Robot Systems • HRP-1 System – 7 kg capacity • HRP-2 System – 25 kg capacity • HRP-3 System – 50 kg capacity

Haas Factory Outlet-Phoenix Invites Machinists to CNC Mill & Lathe G&M Code Programing Courses

Mill and lathe classes are scheduled every other month. Each course consists of 3 days of hands-on instruction led by a Haas Certified Instructor. Students will learn the basics of the Haas control, operation of machines, and Haas programming using G & M codes. Classes are free to all Haas CNC machine owners and operators. Classes are held Monday through Wednesday from 2:00 P.M. to 5:30 P.M.

Please join us for an upcoming session of the Haas CNC training. We recommend registering as early as possible as class sizes are limited.

Mill Training Class — 7/17 - 7/19

Lathe Training Class — 8/21 - 8/23

Training is held at Haas Factory Outlet- Phoenix, a Division of Ellison Machinery facility located at 1610 S Priest Drive, #101 Tempe, AZ 85281. To register and for additional information visit www.EllisonAZ.com or call 480-968-5877.

T. J. Snow Stocks Water Chillers for Industrial Applications

T. J. Snow Company of Chattanooga, TN is now stocking a variety of a water chillers for industrial applications under its new Industrial Water Chiller (IWC) division.

T. J. Snow originally entered the chiller market many years ago to provide recirculated cooling water for its line of resistance welding machines. However, the company soon started selling chillers for a diverse range of applications.

IWC sells, services, supports and stocks chillers and spare parts from its Chattanooga, TN headquarters. An experienced service and engineering group is ready to assist nationwide.

Chillers in stock for quick delivery range from ½ ton to 20 tons. Larger sizes are also available, as are customengineered plant-wide systems.

Industry veterans Don Joyce, Jim Kirchoff and Billy James have joined the team in

A2Z MANUFACTURING SW • 6 • July / Aug 2023 Announcements Con’t Next Page

Backed by Okuma’s Industry-Leading Warranty Program

Okuma’s MULTUS U3000 Multitasking Machine offers an ideal combination of power, speed, and process flexibility. A broad scope of machining functions and the ability to complete tasks in a single setup make this machine simple and efficient for producing a variety of parts. Combining powerful turning and milling capabilities, made possible with Okuma’s OSP-P300 control, equals one thing – increased production capacity.

Explore all of the powerful features of the MULTUS U3000, including:

• Full 5-axis contouring (available as an option)

• New compact B-axis spindle

• 240-degree B-axis range

• 30 hp milling motor spindle

• 12,000 RPM H1 milling spindle

• Wide range of ATC configurations available (40 to 180 tools)

A2Z MANUFACTURING SW • 7 • July / Aug 2023 A2Z MANUFACTURING SW • 9 • March / April 2022

Okuma. Welcome to open possibilities.

CALLING ALL MULTITASKERS MORE IS POSSIBLE

To

Tempe,

www.arizonacnc.com 480-615-6353

To learn more, visit: okuma.com/products/multus-u3000

inquire, visit: okuma.com/distributors Arizona CNC Equipment, LLC 1205 S Park Lane, Suite 2

AZ 85281

support of IWC sales and service. For sales or service inquiries, visit www.IndustrialWaterChiller. com or call (800) 934-0785.

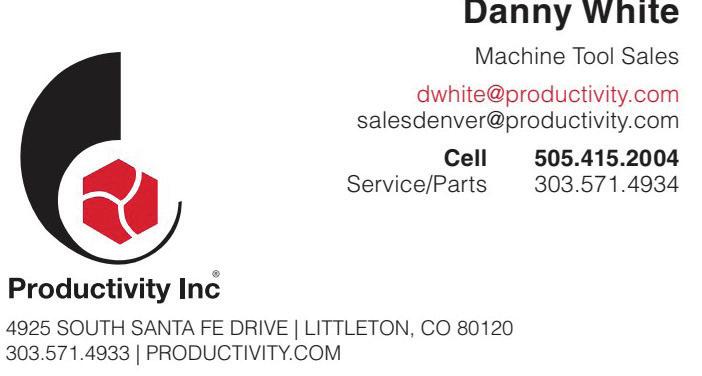

MMT Productivity Adopts Productivity

Name to Complete Merger

MMT Name Change to Productivity Inc. Streamlines Communications and Processes and Strengthens Offerings

another step in the integration. And now, this name change is the final official step in the merger of two leading metalworking distributors.

Productivity Inc. announced that MMT Productivity, formerly MMT, LLC and Moncktons Machine Tools, has officially changed its name to Productivity Inc. In 2015, Productivity joined forces with Moncktons Machines Tools to expand its presence into the Rocky Mountain region. In 2020, Moncktons Machine Tools took the name MMT Productivity, representing

Unifying under a single name better symbolizes Productivity’s range of capabilities as a complete supplier of metalworking services and products. This allows the company to expand their territories and combine resources. Productivity now has an official presence in 12Productivity Inc has 5 locations serving 12 states states with five office locations. Although the MMT/Moncktons name is going away, customers will continue to experience the same on-time delivery, fast, responsive service, and dedication to excellence they depend on. It’s still the same company and

A2Z MANUFACTURING SW • 8 • July / Aug 2023

& Releases Continued Announcements Continued Page 10

Announcements

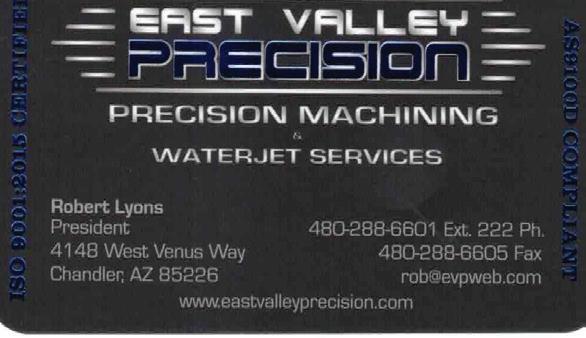

√ ISO 9001: 2015 Certified

√

3 Companies Under 1 Roof

Family Run For 35 Years

Family-Run For 34 Years

Competitive Pricing

√

Competitive Pricing

First Light F-35 Helmet Test A Success

Announcements & Releases Continued people, just a new name and logo.

“When Productivity joined forces with Moncktons Machine Tools in 2015, it was a natural combination of two long-established distributors serving the metalworking industry,” stated Greg Buck, President of Productivity Inc. “The name Moncktons in the Rockies was synonymous with machine tools, so it only made sense to partner with them to help expand our brand,” Greg added. “Once we were able to get Productivity’s name out there becoming one entity was the logical next step to streamline processes and resources.”

The first test of a new, lightweight F-35 helmet was successful, according to the prog ram office, a promising sign that the Pentagon can qualify and implement all three fixes to the jet’s escape system by the end of the year.

Recently, at Holloman Air Force Base, New Mexico, Lockheed Martin’s F-35 conducted the fir st test combining all three solutions designed to reduce the r isk of neck injury to F-35 pilots during ejection, according to spokesman Joe DellaVedova. Once the full gamut of testing is completed, hopefully by the end of the summer, the JPO can beg in implementing the two modifications to the ejection seat and issuing the new Generation III “light” helmet to the fleet, he said

About Productivity Inc.

The recent sled test, conducted with a 103-pound mannequin, is the latest sign that the JPO can make good on its promise to finish the three design fixes by November, allowing the military services to lift restrictions on lightweight pilots flying the F-35 Last year, Defense News first repor ted that pilots under 136 pounds were barred from flying the fifth-generation aircraft after testers discovered an increased r isk of neck damage to lightweight pilots ejecting from the plane. The US Air Force has also acknowledged an “elevated level of r isk” for pilots between 136 and 165 pounds.

The prototype helmet tested weighs about 4.63 pounds, approximately 6 ounces lighter than the orig inal Gen III helmet, and is designed to ease some strain on smaller pilots’ nec ks during ejection

“Productivity is a top-notch, well-trusted machine tool company offering the highest degree of honesty, integrity and responsiveness,” said Mark Smith, Vice President & General Manager for the Rocky Mountain region. “We are happy and excited for this final step. While our name is changing, we are still the same people customers trust to support their metalworking needs.”

Since 1968, Productivity Inc., based in Plymouth, Minnesota, has been distributing a broad range of CNC metalworking products and services. As a single source machine tool supplier, Productivity offers machine tools, tooling and accessories, machine repair, preventive maintenance, rotary and live tool repair, turnkey systems, robotics and automation and much more. In addition, their MachinesUsed.com division will sell your surplus equipment via its online auctions. Productivity services 12 states including Minnesota, North Dakota, South Dakota, Iowa, Nebraska, Wisconsin, Colorado, Utah, Idaho, Montana, New Mexico and Wyoming with five branch offices located in Plymouth, Cedar Rapids, Omaha,

Although the test was the fir st test of the new helmet, the JPO, Loc kheed Mar tin and seat-maker Mar tin Baker have conducted at least seven other tests with the latest version of the seat, which is equipped with two modifications designed to reduce r isk to pilots.The fixes to the ejection seat itself include a switch for lightweight pilots that will delay deployment of the main parachute, and a “head el,” a fabric panel sewn between the parachute r isers pilot’s head from moving backward dur ing the parachu

Over the next few months, Productivity Inc. will roll out rebranded collateral. Customers and vendors can expect email addresses and the corporate website address to be updated to productivity.com, and MMT social media accounts to now be under the Productivity name.

t another 10 tests planned, which will use a mix of low- eight mannequins.

The prog

“This in

joined the Erickson team as Director March 20, 2023 in our

g results and the F-35 enterpr ise is on a path to qualify end of this summer,” DellaVedova told Defense News. ghte xpected to be fielded by the end of the year is in line with the seat timeframe as well.”

Announcements Continued Page 12 A2Z MANUFACTURING SW • 10 • July / Aug 2023

Denver, and Salt Lake City. Please join us in welcoming Michael Medina to Erickson Metals Corporation! Michael

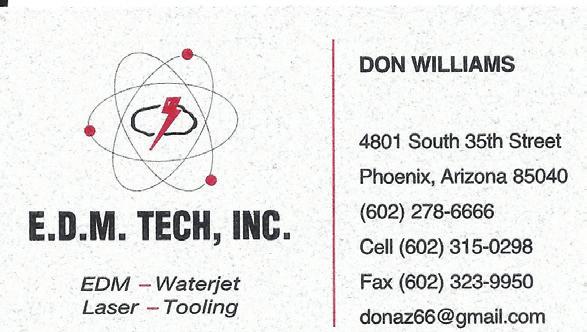

A 2 Z MANUFACTURING SW 41 EDM Wir e/ Sinker Sma ll Hol e 14 Machines WATERJET CUTTING UP T O 6 ’ X 12’ 2 Mach ine s LASER NTC 2500 Watt DIE REPAIR & METAL STAMPING SCREW MACHINING Up To 32 M M whitleym achine.com www.s tp-az.com 4801 S 35 St, Phoenix Ar izona 8 5040 Tel 602-323-5550 Fax 602-323-9950 Em ail C liff@whitleym achine.com √ √ √

ISO 9001: 2015 Certified √

SPECIALTY TURN PRODUCTS

√

11 CNC Swiss Screw Machines √

AS9100 Revision D Certfied

3 Companies - 1 Ownership

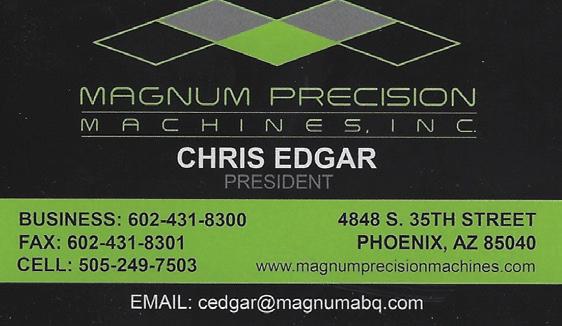

www.magnumprecisionmachines.com PHOENIX OFFICE P: 602-431-8300 F: 602-431-8301 E: sales@magnumaz.com EL PASO OFFICE P: 915-856-7900 F: 915-857-4700 E: sales@magnumep.com ALBUQUERQUE OFFICE P: 505-345-8389 F: 505-344-7167 E: magnumalb@magnumabq.com

ARIZONA MEP WORKSHOPS

Arizona MEP offers workshops designed to meet the business needs of manufacturers.

Arizona MEP Lean Green Belt Certification - August 2

Designed for leaders in charge of implementing and sustaining Lean activities, this 5-day workshop is loaded with practical examples, breakout sessions and a real-world project where key concepts are applied.

AZ MEP Leadership Academy - Emotional Intellegence - September 7

Research shows that exceptional leaders, executives, and managers are not just smarter or luckier but rely on their emotional intelligence (El) to drive better business outcomes. Join us for this master class and see how EI helps you to better understand, motivate and develop yourself and others.

4-Day OSHA 30 Workshop - General Industry 29 CFR 1912 - September 20 This class will help raise safety awareness in the workplace; improve safety performance and well-being of employees. Includes a course completion card from DOL upon successful completion.

602.845.1256

Announcements & Releases Continued

Santa Teresa, New Mexico location.

Michael joins Erickson Metals New Mexico after an extensive career as a Founder/President in the steel door and window industry.

Feel free to contact Michael: MMedina@ericksonmetals.com or call: 575-874-3003

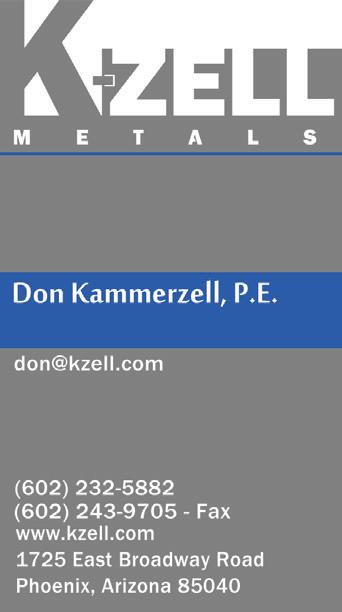

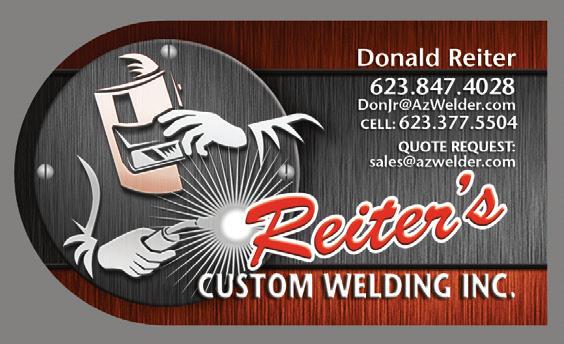

Reiter’s Adds To Its Capacity With the Newest Bystronic Xpert80 Press Brake

Reiter’s Custom Welding is excited to announce its addition of the new Bystronic Xpert80 press brake. Donald Reiter says, “In order to enhance the speed of our production for any and all of our customers, we have acquired another state-ofthe-art press brake to ensure our customers’ projects are within tolerance and meet their qualifications.” He continued, “At Reiter’s, we pride ourselves on delivering high quality, excellent turnaround times, and exceptional

customer support.”

Key features of the Bystronic Xpert80 Press Brake:

- Top of the market process efficiency

- 6-axis back gauge

- Highest application versatility

- High speed production applications

- Intricate software programming

- 60” bend length

- 88 tons

To learn more about how Reiter’s Custom Welding can support your fabrication needs, contact them at: 623-377-5504 or email: sales@azwelder.com

Gateway Community College’s Manufacturing Program Hosts High School Recruiting Event

In May, Gateway Community College hosted a ‘Careers in Automation & Advanced Manufacturing Open House. The even gave high school students an opportunity to meet with employers, Gateway faculty and current program students.

A2Z MANUFACTURING SW • 12 • July / Aug 2023

Announcements Continued Page 14

•

• www.azmep.org

info@azmep.com

Register today!

CUSTOM-BUILT BUSINESS SUCCESS.

BANK WITH PURPOSE.

Member FDIC ALERUS.COM/BUSINESS

COMMERCIAL BANKING

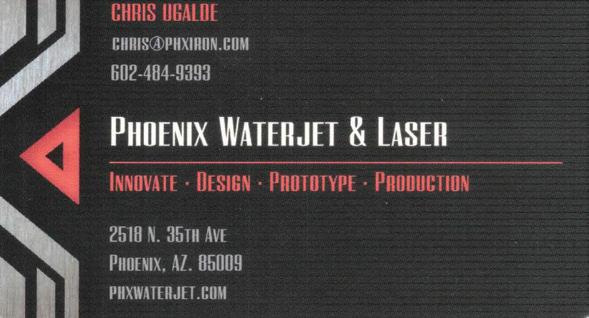

PHOENIX WATERJET & LASER

602-484-9393

WWW.PHXWATERJET.COM

2518 North 35th Ave, Phoenix, AZ 85009

• Quick Turnaround (5-7 Days Typical)

• Family-Owned & Operated Since 1981

• 3-D Scanning (Faro Arm Scan & Probe)

Cutting Capability Up” to 6’x12’ The

personal use, and business accounts. With the addition of Arizona Iron Supply, we can accommodate even larger industrial accounts and offer even more equipment and metal inventory to choose from.

Announcements & Releases Continued

Students were able to see machines in action and lear about career pathways, even hearing about apprenticeship opportunities to ‘earn while you learn’.

We feel privileged to continue to serve Phoenix and surrounding areas. We can’t wait to show you how this development will improve your metal purchasing, metal recycling, and Rolloff Service experience.

Visit one of our two locations to see how this exciting change will benefit you! Davis Metals: (602) 267-7208 / 3322 E. Washington Street, Phoenix, AZ 85034 Arizona Iron Supply: (602) 244-9649 / 130 S 23rd St, Phoenix, AZ 85034

The event was was cosponsored with Skillup Arizona and the Arizona Tooling and Machining Association (ATMA). Dave Zamora, lead faculty at Gateway’s Washington Campus, said,” We had over 100 people in attendance, many from high schools all around Tempe, Phoenix, and Mesa. This is our first of many to begin reaching out to students to get them interested in manufacturing.” Skillup is encouraging people to sign up for scholarship dollars to pay for an apprenticeship.To learn more, visit: skillupaz.org

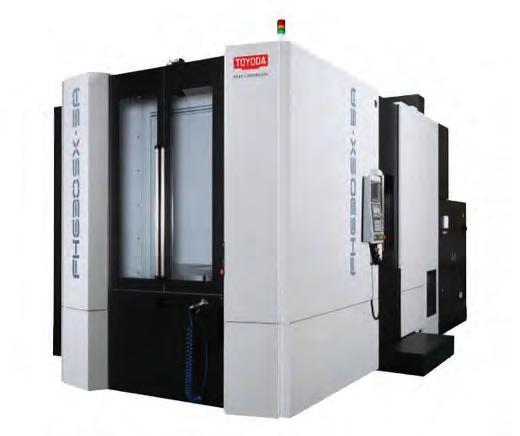

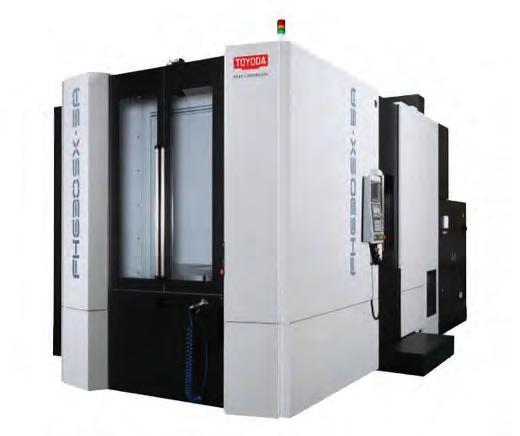

Landmark Hosts Open House At Metzfab Industries

How Much Do You Know AboutTHINBIT® by Kaiser Tool?

THINBIT®, by Kaiser Tool Company Inc., specializes in the manufacture of small cutting tools. THINBIT® tools are used for grooving, threading, parting, boring, turning, face grooving, form tooling, mill tooling and custom tooling.

L andmark Solutions held an Open House event at Metzfab Industries in Phoenix earlier this month.

Metzfab’s facility was chosen due to their company growth, and the addition of several new state of the art pieces of equipment. Metzfab is always pushing technology and equipment limits in an effort to build and deliver the best parts to their customers.

Metzfab recently installed a new OMAX 80x 5 axis waterjet, a Bystronic Tube Laser system, a Bystronic ByStar Fiber Laser with full automation, multiple large high performance press brakes, and a fully automated robotic press brake. Installing soon is a new material finishing machine also coming from the Landmark Team.

William & Hazel Kaiser began Kaiser Tool Company, Inc. in the 1950’s. That was the birth of THINBIT®. The idea of THINBIT® lathe cutting tools, its start and its subsequent growth to where it is today is a wonderful story. You can see Lenore Perry (Kaiser) tell the whole story of how Kaiser Tool Company, Inc. began on our YouTube page: Kaiser THINBIT®. You can follow THINBIT® on YouTube, LinkedIn, Facebook, Twitter and Instagram to keep up with what we are doing now and for tooling tips.

Kaiser Tool Company, Inc. supplies industries ranging

The Landmark Solutions open house event was a success, and we are all excited to continue our long term partnership with Metzfab. Everyone attending the event were impressed with the new equipment and technology, and how this has helped Metzfab grow and diversify their business.

A2Z MANUFACTURING SW • 14 • July / Aug 2023 Announcements Continued Page 16

A2Z MANUFACTURING SW • 16 • July / Aug 2022 Announcements Continued Page 18

INNOVATION • DESIGN • PROTOTYPE • PRODUCTION

BYSTRONIC XPERT 80 PRESS BRAKE

FLOW IBF 4020 WATERJET

Aerospace Military Defense Construction Automotive Marine Oil/Gas Mining Waste Water

Hobbyist Heavy Equipment

BYSTRONIC 3015 BYSMART LASER Industries Served:

Metal Fab

•

Ugalde Family

I N N O V A T E D E S I G N P R OTOTY P E • P R O DUCTI O N P H O E N i X E S T 2 0 0 7

TheHurcoControlhastheflexibilityyouneedforthehighmixofpartsthatcomes throughyourshop.

EquallypowerfulforNCandConversationalProgramming(withtheaddedbonusof NC/ConversationalMerge),theHurcoControlreducessetuptimesoyoucanmake morechips.

Whetheryou’reababyboomer,amillennial,oraGenX-er,timeismoney.Eventhough Bob(left)andCharley(right)arefromdifferentgenerations,theyarebothmachinists whoappreciatetheimportanceofCNCtechnologythat’sdesignedtomakeshopsmore productiveandmoreprofitable.Checkouttheirvideoseries.

Hurco Companies, Inc. | One Technology Way | Indianapolis, IN 46268 | 800.634.2416 | info@hurco.com | HURCO.com | Machines shown with options. Information may change without notice. Double Column Boring MillsHorizontals3-Axis Vertical5-AxisDouble Column BridgeTurning Centers A CONTROL FOR EVERY GENERATION.

Watch the series at Hurco.com/mygeneration (303) 466-3777 FoothillsMachinery.com » Integrated

path simulation » No

click and

» Transform

created automatically for easy 5-sided conversational programming

data entry

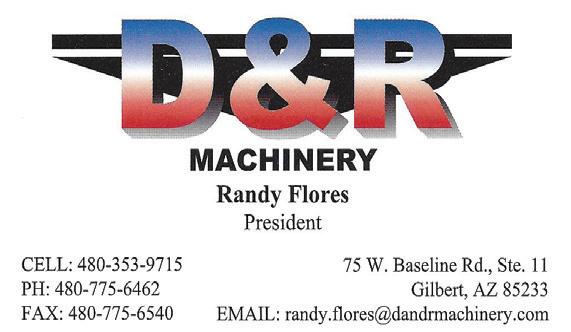

Hurco’s 3D Import feature includes 3D DXF technology that now displays all CAD geometry, including splines and Z-depths. Go from “solid to part” seamlessly. Eliminate extra steps. Introducing 3D Import Hurco Companies, Inc. | One Technology Way | Indianapolis, IN 46268 | 800.634.2416 | info@hurco.com | HURCO.com | Information may change without notice. Find out more at HURCO.com/3DImport Contact your local distributor to find out which one of our 65+ models powered by WinMax® will make your shop more profitable D&R Machinery (480)-775-6462 dandrmachinery.com

CAD/CAM and tool

need to enter feature dimensions – simply

cut

Planes

no

required

3020 South Park Drive ,Tempe, AZ

sales@stp-az.com • Tel: 602-426-9340

STP-AZ.COM

We Manufacturing Complex Intricate Parts Requiring Extreme Precision And Quality

We Are Built For High Production Parts And Can Handle Extremely Tight Tolerances

High Precision Swiss Lathe Machining 24x7

New State-of-the-art 12,500 square foot facility

ISO 9001: 2015 & AS9100D Certified

Our CNC Swiss screw machines can run lights out 24 x 7 Subsidiary of Whitley Machine

Industrial Production Returns to Growth After February’s Storms Subside

from medical to aerospace and stocks more than 100,000 tools for grooving, threading, parting, boring, turning and face grooving.

fastest and most efficient laser machines in the world.”

Kaiser Tool Company, Inc. is made in the Fort Wayne, IN and continues its tradition of dedication to quality products, fast delivery and superior customer service. We are proud to be part of the Fort Wayne community and manufacture our products in the USA. For more information on the entire THINBIT® line, please visit our website at www.thinbit.com.

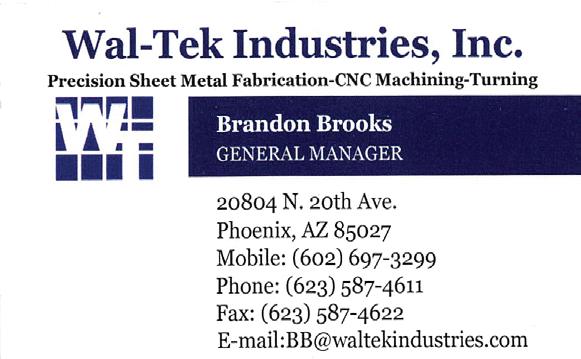

MarZee Cutting Services Adds To Capabilities With the Eagle 20kW Fiber Laser Cutter

The Federal Reserve reported that industrial production in March rose 1.4%, returning to growth after an unseasonably stormy February knocked it down 2.6%. The report shows total industrial production rose 2.5% at an annualized rate during the first quarter of 2021 despite the losses endured in February by manufacturing, mining, and utilities companies.

Motor vehicles and parts production, which fell 10% in February, rose 2.8% in March but remained depressed by a persistent shortage of semiconductors. Most durable goods indexes rose between 2% to 3%.

As a family-owned and operated business, located in Phoenix, AZ. MarZee is the industry leader for WaterJet, Forming, and Laser cutting with our CNC-controlled state of the art machines. To learn more about how MarZee can help you with waterjet, forming and now laser cutting, contact them at: 877-885-1059, email: marzee@marzee.com or visit marzee.com

The industrial production gauge includes productivity in three sectors: manufacturing, mining, and utilities. Manufacturing production (which excludes mining and utilities output) rose 2.7% in March after falling 3.7% the month before. Mining production improved 2.7%, while utility output fell 11.4% thanks to unseasonably warm March temperatures. Manufacturing output rose 1.9% at an annualized rate.

MarZee Cutting Services is pleased to announce its lastest machine acquisition, the Eagle iNspire 20kW Fiber Laser Cutter.

Ed Wenz, owner of the company, says, “The iNspire series of cutting machines are state of the art, extremely precise, and amazingly quick. They excel at the most demanding mass production applications with their rigid composite base and lightweight carbon fiber bridge as well as the long-life eVa cutting head.”

August 3rd High Performance Equipment Open House Event

In nondurable manufacturing, the index for the chemicals industry rose 4.1%, and petroleum and coal products rose 5.7%, although neither sector has fully recovered from severe weather damage—the Federal Reserve noted that some chemicals factories remain offline thanks to damage sustained from February’s winter storms. Most nondurable goods indexes rose between 0.9% and 3.0%.

Please join Landmark Solutions alongside Bystronic and OMAX for a High Performance Equipment Open House to be held at a busy Glendale, AZ operation on August 3rd.

Capacity utilization in manufacturing rose by 1.9 points, also reversing February losses.

See industry-leading machines in action, hear from key leaders at Bystronic and OMAX, and talk to real owners and operators about their experience running the equipment. Lunch to be provided.

Almost all market groups saw improvements in March, despite lingering challenges. The Federal Reserve’s index for other manufacturing, which includes publishing and logging, remained the same, but durable goods and nondurable goods indexes rose 3.0% and 2.6%, respectively.

He adds, “We chose the Eagle iNspire line because they are the

Please email info@landmarksolutionscorp.com for more details and to reserve your spot.

If February was notable for its storminess, March was notable for its heat. The unseasonably warm month coincided with a roughly 10% drop in consumer energy products, and the 11.4% drop in utilitie s utilization was the largest recorded in the history of the index’s 48-year history.

A2Z MANUFACTURING SW • 16 • July / Aug 2023

Announcements Continued Page 18

Announcements & Releases Continued

A2Z MANUFACTURING SW • 38 • May / June 2021

SPECIALTY TURN PRODUCTS

Tornos 6 axis Sigma

Tornos MultiSwiss 6x14

“Can you help us with supply chain logistics?”

“We need a distributor partner in the Intermountain West.”

“Our distributor needs to be uniquely integrated with our business.”

“Can you provide safety and compliance training?”

We’ve been saying “We can do that,” since 1916.

“We are looking for help with managing our inventory.”

“Our inventory needs are specific, timesensitive and cost-driven.”

Industrial Supply delivers results. Our vast inventory and integrated supply solutions have made us the trusted source for the products and services customers demand — when and where they're needed. Visit indsupply.com to learn how we can help your business run at peak efficiency. indsupply.com

Expect the Expected.

FULL 5-AXIS CAPABILITIES

RANGE UP TO:

Dynamic Machine &

Introducing T.J. Davies Company, Manufacturer Of Retention Knobs

T.J. Davies Company, Inc. was started in 1965 by Thomas Davies. Tom originally named the company Deb-Sher Machine after his two daughters, Debra and Sherry. He later changed the name to T.J. Davies Company.

Soon after Tom finished his service in the United States Navy, he moved his family to Cleveland, Ohio, where he took a position with Swagelok, a well-established fittings manufacturing company. After working briefly at Swagelok, Tom’s parents gave Dad a small loan to start his company. Fred A. Lennon, Tom’s boss and founder of Swagelok, contracted with the new company to manufacture parts for them. After serving in the Vietnam War, Uncle Russell (one of Tom’s younger brothers) joined the company.

The company started as a “job shop,” making various products, including retention knobs for Mazak.

In August 2018, Tom passed away, leaving the business to the next generation. Although Tom is no longer here, the company’s values, mission, and vision remain the same. His daughters have been making strategic changes to grow the business. The first order of business was to purchase a much larger building so they would have room to grow; the move was completed in December 2021. Next, a new website was launched, updated branding, and a new 132page catalog. Davies said, “Our customers love the new catalog with all the additional information and images of all the new retention knobs.” The book is available spiral-bound as well as an electronic flipbook that links to their website that can be kept on your smartphone. Call them if you are looking for excellent customer service, inventory in stock, and same-day shipping for orders received by 3:00 PM EST.

A2Z MANUFACTURING SW • 18 • July / Aug 2023

Fabrication

. 3845 East Winslow Avenue, Phoenix, Arizona 85040 Fax:602-437-8947 Serving the Aerospace/Aircraft, Military, and Commercial Industries Quality System is Certified ISO 9001:201 15 and AS9100" "D" HR-4R HAAS 4-Axis Horizontal Milling Center @ 150” x 66” x 48” Ikegai VTL CNC Lathe @ Ø 55” Diameter OKK VP9000-5-Axis Vertical Milling Center Ø 800 mm x 630 mm In Our 5th Decade of Manufacturing in Arizona 602-437-0339

EQUIPMENT CAPACITIES

About 45 years ago, they began to produce retention Announcements & Releases Continued

Corp

WE'RE LOOKING FORWARD TO MEETING AND EXCEEDING YOUR EXPECTATIONS

knobs on lathes. T.J. Davies Company was the first to use this production method to manufacture retention knobs. Currently, they offer over 500 different styles of retention knobs and add new knobs as new machines or technology is introduced. If someone has a machine and is unsure what knob they need, they are the company they call. Additionally, they make custom knobs for older machines that no other company makes. They have fulltime Programmers and a full-time Mechanical Engineer on staff who can assist with your custom retention knob needs.

602-483-4414

Manual Lathes, Tool Room CNC Lathes, Big Bore Lathes, 2-6 Axis CNC Lathes, 7-16 Axis Mill/Turn Centers, Swiss CNC Lathes, Large Capacity VTL ’s

Manual Mills, Tool Room CNC Mills, 3 -5 Axis CNC Mills, VMC’s, HMC’s, Automation, FMS Systems, Large Capacity HBM’s

3-5 Axis Laser Solutions, Bending Solutions, Workholding, Quick Change Fixtures, Probe Integration, Inspection/Measurement Equipment, Machine Monitoring, Robotic Integration, Saws, Tombstones.

CNC PROS HAS PARTNERED WITH THE RIGHT SOLUTIONS TO ENSURE OUR TEAM OFFERS YOUR TEAM THE RIGHT TOOL FOR THE JOB.

CONTACT US FOR MORE INFORMATION

WWW.CNC-PROS.COM

Precision Die & Stamping, Inc.

1704 West 10Th St • Tempe, AZ 85281

Ph: 480-967-2038

and dedication to customer service are number one priorities. This type of expertise and dedication has fostered a reputation of excellence in the tooling and stamping industry.

Located in Tempe, Arizona, our 100,000 Sq. Ft. Facility contains state of the art equipment , with production capabilities ranging from simple geometries to complex forms with intricate details. Precision enjoys a world-class reputation supplying a variety of OEMs, managing their inventory levels, and making certain product quality and timely delivery are NEVER compromised.

Introducing The New Collins Metal Finishing Team

Collins Metal Finishing (CMF) opened its doors in 1968 in response to the plating needs of the burgeoning manufacturing scene at the time. It was the brainchild of businessman Robert Wilkinson and electroplater John Collins.

Over the years, CMF grew in both size and complexity, finding its niche in Anodizing and Electropolishing supplemented by a variety of similar, “less complex” services.

In the late 90s, John’s son, Mike, took over his position while Robert’s daughter and son-in-law, Kathy and Chuck Garcia, took over his responsibilities.

Under the direction of these three, CMF left its original location— a shack built during the WWII era— and opened a 5,000 sq. ft. facility with modernized equipment and environmental protections.

Grandson of Kathy and Chuck, Gavin Garcia (now 26 years old), grew up often accompanying his grandfather to work. Intrigued with how the various processes worked and

enamored with the finished products, he began working at the shop the day after he turned 16. Gavin is pictured above. With brief stints working various other jobs, he always worked either full or part time at Collins until the time he graduated ASU in 2021. A couple of weeks later, he began training to take over for Chuck and Kathy amid Chuck’s battle with cancer. On May 10, 2022, Chuck passed away at the age of 69, two days shy of his 70th birthday.

From then on, Gavin began his tenure as Director, working to continue the legacy of his grandfather.

Over the course of the last year, with Gavin at the helm, CMF has introduced a new logo, modernized their system, and expanded their electropolish services by introducing a brand-new line to satiate the demand of the semiconductor and medical industries.

Fully operational as of April of this year, the new EP line has cut lead times by more than 50% and supported their mission to keep prices as affordable as possible.

Recently, Kathy passed her role as President on to her son, Marc Garcia. Together, Gavin and Marc are looking to continue to grow CMF in its support of the semiconductor, medical, aerospace, and defense industries. To learn more about how CMF can support your plating needs, contact them at : 602-275-3117 or email Gavin at gavin@ collinsmetalaz.com

A2Z MANUFACTURING SW • 20 • July / Aug 2023

• www.PrecisionDie.com Automotive • Semiconductor • Lockset Hardware • Power Tools • Lawn & Garden Equipment • Aerospace

• F: 480-829-0838

Announcements & Releases Continued

AZ US A SINCE 201 1

Virgin Galactic Prepared To Launch To The Edge Of Space

Virgin Galactic, the suborbital space tourism company founded by British billionaire Richard Branson, is gearing up for its first flight to the edge of space in nearly two years.

The flight will carry two pilots and a crew of four Virgin Galactic employees, the company announced. The company expects it will be the final test run before Virgin Galactic can open up rides for paying customers after years of promises, missed deadlines, and Branson selling off a huge chunk of his original stake in the company.

Virgin Galactic had appeared poised to begin commercial operations after it launched Branson to the edge of space alongside three crewmates in July 2021, a flight that came less than two weeks before Branson’s rival Jeff Bezos conducted his own flight to the edge of space.Several deadlines for the company’s expected return to space have passed. At one point in early 2022, the company was

targeting as early as last October for its first commercial missions. At the time Virgin Galactic went public in 2019, it had also been touting plans to start commercial service in 2020.

“We are making good progress on validating the enhancements made throughout 2022, and we remain on track for commercial service in Q2 of this year,” CEO Michael Colglazier told investors during the company’s latest earnings call on February 28, 2023.

Virgin Galactic conducted several test flights before Branson’s flight in 2021. But since then, the company has flown only one test flight of VSS Unity, which sent the space plane gliding through the air but did not attempt to fire up the plane’s rocket engine.

The company has sold about 800 tickets total, including 600 at prices ranging from $200,000 to $250,000 and 200 more at $450,000, which is the current ticket price.

Virgin Galactic is competing directly with Bezos’ Blue Origin in the suborbital space tourism business. Since Bezos’ flight in July 2021, the company has since completed five additional crewed flights to space. Blue Origin’s operations, however, have been on pause since an uncrewed flight of its New Shepard rocket exploded in September 2022.

Six people will be on board Virgin Galactic’s VSS Unity space plane for this month’s test mission. They include two pilots — CJ Sturckow and Mike Masucci — as well as four Virgin Galactic employees who will ride in the passenger cabin. Those four are Jamila Gilbert, a New Mexican native who works in the company’s internal communications; Chris Hume, a flight sciences engineer and the son of Jamaican immigrants; Luke Mays, an astronaut instructor and former NASA employee; and Beth Moses, the company’s head of astronaut training, who has joined two prior flights. Source: Jackie Wattles, CNN

A2Z MANUFACTURING SW • 22 • July / Aug 2023 MORE SATISFIED CUSTOMERS WORLDWIDE Locations in AZ, NC, TX, FL, WI, MN Arizona Facility: 1310 N. Hobson Street Gilbert, AZ 85233 (480) 892-7800 Email: wricoazjb@wrico-net.com We specialize in: • Custom Metal Stamping • Precision Sheet Metal • Laser Cutting • Press Brake Forming • Deep Draw Stamping • Mig & Tig Welding • CNC Machining • Wire EDM • Tube Bending • 5 Axis Laser Cutting • Wire Forming • Spot welding • Mechanical Assembly • Engineering Assistance

A GRIFFITHS COMPANY

For more info and to RSVP, email: info@landmarksolutionscorp.com

A2Z MANUFACTURING SW • 23 • July / Aug 2023 Stay in Touch (714) 393-3783 Info@landmarksolutionscorp.com landmarksolutionscorp.com 925 N. Shepard Anaheim, CA 92806 Take your next step with us. Fiber Lasers • Press Brakes • Automation • Waterjets • Plate & Angle Rolling • Plasma & Oxy Cutting Deburring • Saws • CNC Machining • Nitrogen Generation • Robotic Welding Your Partner in Manufacturing Equipment Bringing over 100 years of industry experience Now Offering Technical Service Best Choice Parts and Landmark Solutions are excited to announce the offering of local, factorytrained technical service and preventative maintenance on a wide range of equipment. EXCLUSIVE DISTRIBUTOR OF: Proud

Join us at a busy Glendale, AZ operation to see cutting-edge equipment in action and have your questions answered by key leadership from Bystronic and OMAX. Lunch

provided.

August 3, 2023 AZ Open House Event

to be

Adapting to New Possibilities

1.800.281.5734

Germantown, WI USA

www.hainbuchamerica.com

Lockheed, Airbus Pick GE Engines for USAF Tankers

The proposal to supply the A330-based LMXT strategic tanker aircraft as an interim replacement offers domestic supply and logistics advantages for the U.S. Air Force.

Lockheed Martin, with input from Airbus, selected GE Aerospace’s CF6-80E1 propulsion system for the LMXT strategic tanker, which Lockheed has proposed as the “bridge” tanker, to fill the U.S. Air Force’s refueling needs until a replacement is chosen for the Boeing KC-46A tankers.

The USAF is deciding how to address its current refueling requirements – either by purchasing new LMXT aircraft or by continuing purchases of the KC-46A. It’s

not expected to conduct a full program replacement for its air refueling needs – referred to as the ‘Next Generation Air Refueling System – until 2035, or possibly later.

The LMXT is a based on the Airbus A330 Multi Role Tanker Transport (MRTT), which is in service for multiple U.S. allies, including Australia, Canada, France, South Korea, the U.K., and several others.

Earlier, Lockheed and Airbus committed to manufacture the LMXT aircraft in Mobile, Ala., and Marietta, Ga., and Airbus will produce the LMXT’s aerial refueling boom system in western Arkansas.

Lockheed’s engine choice came in a competitive process, it said. Reportedly, the GE Aerospace design emerged ahead of the Rolls-Royce Trent 700, and Lockheed noted production of the GE engine will support over 3,000 U.S. jobs in more than 25 states. And, because CF6 engines are already in place on various USAF platforms, the LMXT is already part of a “supply chain and existing knowledge base that can translate to increased mission readiness rates,” according to Lockheed’s statement.

GE’s CF6 engine is an established design for wide-body aircraft. The CF6-80E1 variant was designed specifically for the A330, offering nearly 70,000 pounds of thrust and 15% greater fuel efficiency, according to GE Aerospace.

“America’s tanker fleet will play a critical role in meeting future mission requirements. This means the LMXT must use capable and proven technologies, such as the MRTT strategic tanker and GE Aerospace’s CF6 engine,” stated Lockheed Martin Aeronautics EVP Greg Ulmer.

A2Z MANUFACTURING SW • 24 • July / Aug 2023

n Change from O.D. to I.D. to jaw clamping in < 2 minutes

n Use the same adaptations on your HAINBUCH turning or stationary chucks

n Keep the basic clamping device mounted on the machine

Chucks and adaptations are available in round or hexagonal configurations

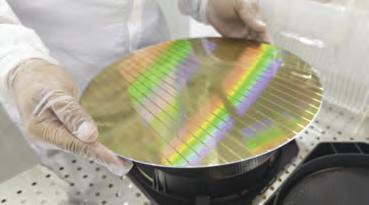

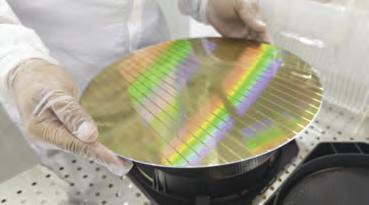

Cactus Materials, A Tempe Semiconductor Maker Led By Former Intel Manager, Ready To Start Production

An Arizona semiconductor company has quietly started production at its new Tempe fabrication facility.

Cactus Materials, a 10-year old company led by CEO Rafi Islam, focuses on products for self-driving cars, 3D sensing for facial recognition, medical imaging and other markets.

Islam spent 12 years working at Intel Corp. and most recently held the title of processing engineering manager for the technology giant, according to his LinkedIn page. The company will operate two fabs across a 40,000-square-foot space in Tempe.

“We are entering a new era of bringing back manufacturing in technology to the USA. Silicon Valley advances and products are no longer only in the San Francisco Bay Area anymore,” Islam said in a statement.

Cactus Materials touted the emerging talent pool at local universities and the emerging ecosystem of the semiconductor industry as reasons to do business in Arizona. The White House has designated Phoenix as a workforce hub to help meet the demand for qualified and diverse talent in semiconductors, renewable energy and electric vehicles.

Over the next five years, Cactus Materials said it intends to make further upgrades at its facility and invest up to $300 million. The company had previously been

awarded grants from NASA and the U.S. Department of Energy and has applied for funding earmarked for the semiconductor sector through the CHIPS and Science Act.

Earlier this year, the U.S. Department of Commerce opened the application process for the first round of CHIPS Act funding, which consists of $39 billion in incentives to build new factories and expand production nationwide.

More than 300 semiconductor companies across 37 states have applied for incentives for commercial fabrication, packaging, research and development. The CHIPS and Science Act has earmarked more than $52 billion toward revitalizing the nation’s semiconductor industry.

Dozens of semiconductor suppliers have made plans to operate in the Phoenix region and Pinal County.

By Ron Davis – Phoenix Business Journal

A2Z MANUFACTURING SW • 26 • July / Aug 2023 ,I NC. Equipment: Band saws Plate saws Shears Leveling Line Slitter Line Industries: Aerospace Semi-Conductor Medical Kitchen/ Restaurant Defense HVAC Automotive/ Racing Phoenix: Reno/Sparks NV Las Vegas, NV 602.278.5052 775.355.8100 702.719.6061 wwwCoastAluminum.com

SELECT COAST ALUMINUM? • ISO9001/AS9120 Certified • Offering Next Day Delivery • 80,000 sq. ft. Facility With Extensive Inventory • Stocking Stainless Steel, Aluminum Stock and Specialty Metals

WHY

U.S Solar Market Registers Best First Quarter in Industry History

The U.S. solar industry installed 6.1 gigawatts (GW) of solar capacity and had its best first quarter in history, according to the US Solar Market Insight Q2 2023 report released. The record quarter was driven in large part by supply chain challenges abating and delayed solar projects moving forward.

Due in part to the strong first quarter numbers and a surge in demand from the Inflation Reduction Act (IRA), Wood Mackenzie expects the solar market to triple in size over the next five years, bringing total installed solar capacity to 378 GW by 2028.

The IRA has also spurred a surge of new manufacturing announcements, with domestic module capacity expected to rise from fewer than 9 GW today to more than 60 GW by 2026. At least 16 GW of module manufacturing facilities are under construction as of the end of Q1 2023.

This quarter, the Biden administration provided some clarity on how the landmark law’s adder credits will be applied.

The law contains new credits that can be used in conjunction with the solar Investment Tax Credit, like the domestic content, energy communities, and low-income adder credits. In particular, the energy communities and low-income adder guidance will help drive solar and storage investment in underserved communities.

While the IRA has already catalyzed major investments in solar manufacturing and deployment, challenges remain with the implementation guidance for the domestic content adder credits in the near-term.

The utility-scale market rebounded from a difficult 2022 with a strong first quarter and a record 3.8 GW of installed solar capacity.

This quarter, more module importers were able to satisfy the documentation requirements under the Uyghur Forced Labor Prevention Act (UFLPA). This enabled more solar equipment to

make it to project sites and allowed the industry to build out its long pipeline of delayed projects.

Despite rising interest rates and economic headwinds causing customer hesitancy, the residential segment installed 1.6 GW of solar capacity in Q1 2023, a 30% increase from Q1 last year. The residential market segment is on track to add 36 GW of solar over the next five years, growing at an average annual rate of 6%.

The commercial market also had a record first quarter, with 391 MW installed, putting the segment on track for 12% growth in 2023. Meanwhile, the community solar segment installed 212 MW, a 13% decrease from Q1 2022 due in large part to ongoing interconnection challenges.

A2Z MANUFACTURING SW • 27 • July / Aug 2023

WWW.NORTHSOUTHMACHINERY.COM UNLOCK

480.382.4880 INFO@NORTHSOUTHMACHINERY.COM NORTH

DR

AZ AD copy.pdf 1 6/21/23 9:08 AM

REPRESENTING A WIDE RANGE OF TOP BRANDS. NORTH SOUTH CAN HELP YOU REACH MANUFACTURING EXCELLENCE WITH OUR EXTENSIVE PORTFOLIO.

YOUR MANUFACTURING POTENTIAL TODAY. OUR TEAM CAN MAKE IT HAPPEN.

SOUTH • ARIZONA 2412 W HUNTINGTON

TEMPE, AZ 85282

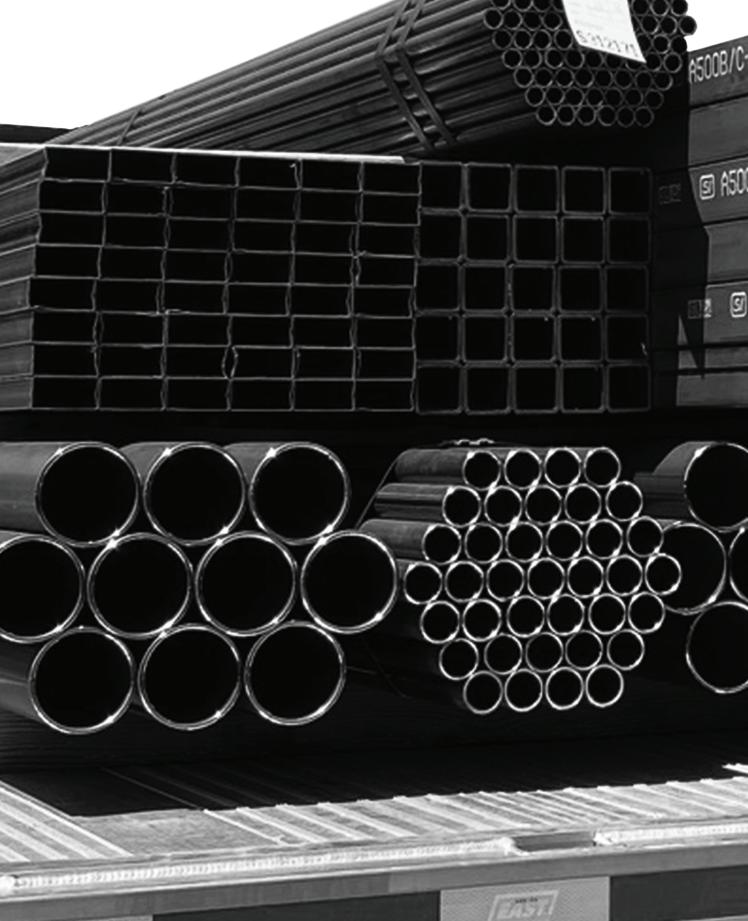

ALL THE METAL YOU NEED UNDER ONE ROOF

state has become a destination for high-tech manufacturing operations in semiconductors, batteries, electric vehicles and biotechnology.

“Thanks to our talented workers and robust base of suppliers and supportive industries, Arizona is home to one of the fastestgrowing manufacturing sectors in the country,” said Arizona Gov. Katie Hobbs. “This growth means more and more goodpaying jobs and billions of dollars in international investment into Arizona’s economy.”

Manufacturing growth can be seen around the Phoenix metro area and beyond, from an LG battery plant in Queen Creek to the massive Taiwan Semiconductor Manufacturing Co. (TSMC) semiconductor factory in north Phoenix to electric vehicle manufacturers cropping up in Coolidge and Casa Grande.

Yet another manufacturing project was announced in March by EVelution Energy with plans to open a cobalt processing facility in Yuma County for use in electric vehicle batteries. The plant will be the first of its kind in North America.

Arizona In Midst Of High-Tech Manufacturing Transformation

When manufacturing jobs began leaving the U.S. and heading overseas beginning in the 1980s, general wisdom concluded those jobs were gone for good.

But while U.S. manufacturing may not be what it was in its prime, it could be making a comeback thanks to a talented workforce, federal and state investments and Arizona’s wide-open spaces.

In Arizona, approximately 70% of projects in the Arizona Commerce Authority pipeline are manufacturing-related, including expansion of existing operations, and the

Arizona’s manufacturing boom owes its success to a talented workforce and a variety of state and federal investments.

The state, educational institutions and corporate partners encourage talent needed to fill jobs in the growing manufacturing sector.

Central Arizona College, for example, has partnered with LG to help train workers to staff the $2.8 billion plant in Queen Creek, which is expected to create 2,800 jobs.

A similar program exists through Estrella Mountain Community

A2Z MANUFACTURING SW • 28 • July / Aug 2023 800.528.9875 www.azironsupply.com 130 S. 23RD STREET PHOENIX, AZ 85034 OPEN: MON-FRI: 7:30AM-5PM /azironsupply /company/az-iron-supply /az_ironsupply /arizonairon • Bar, Flat, Sheet, Channel, Tube, Square, Rectangular Steel and more • Ornamental Metals • Delivery Across Arizona • Cutting Services • CNC Plasma Cutting • Custom Fence Pickets • Roll-o Container Services • Metal Recycling • Wiping Rags

College, training students to become semiconductor technicians.

“We need to grow these pipelines to get workers into this industry,” said Arizona Senator Mark Kelly, a vocal supporter of technical training programs.

Kelly has also been supportive of President Joe Biden’s various programs encouraging manufacturers to bring production back to the U.S. — programs such as the CHIPs and Inflation Reduction Act, which have boosted Arizona’s manufacturing sector as companies seek to benefit from federal grants and other investments.

While the U.S. manufacturing sector is still a long way off from what it used to be, Arizona’s manufacturing boom will help decrease dependency on foreign production, stabilizing U.S. supply chains, creating good-paying jobs and contributing billions of dollars to the economy. By

Madeline Salazar

Madeline Salazar

Raytheon wins fresh contract to build hundreds more Sidewinder missiles for US, foreign militaries

Raytheon’s Tucson-based Missiles & Defense division will be building hundreds of new Sidewinder aircraft missiles under a $263.72 million contract modification, one of several recent deals the company has landed in recent weeks.

The AIM-9X Sidewinder missile is a joint project of the U.S. Navy and Air Force, and Raytheon has been a part of it for more than two decades. This contract modification calls for Raytheon to build 571 of the rockets for the U.S. Air Force and Navy as well

as for foreign military customers. Work is expected to be finished in August 2026.

The Navy will receive 91 of the Sidewinders, while the Air Force will receive 257 and foreign customers will receive 223. Those foreign customers were not identified.

Raytheon describes the AIM-9X Sidewinder as a “triple-threat” missile that can be used on several different aircraft and can be used for air-to-air, surface-attack and surface-launch missions without modification. The new orders are for the Block II variant, which Raytheon says has improvements for handling and safety and electronics updates.

In addition to the tactical missiles, the contract modification also calls for delivery of 48 training missiles, and a large amount of support equipment such as containers, target detectors, guidance units and more.

By Jeff Gifford – Phoenix Business Journal

By Jeff Gifford – Phoenix Business Journal

A2Z MANUFACTURING SW • 29 • July / Aug 2023 /davismetalsandsalvage /company/davis-salvage-co.-l.l.c. /davismetalsandsalvage /davissalvage YOUR ARIZONA METAL SUPPLIER & SCRAP METAL RECYCLING CENTER OPEN: MON-FRI: 7:30AM-5PM / SAT: 7:30AM-NOON 3322 E. WASHINGTON ST. PHOENIX, AZ 85034 602.267.7208 davismetals.com 3RD GENERATION FAMILY OWNED & OPERATED • Metal Recycling • Roll O Services • Used Metal Supply • New Metal Supply • Ornamentals • Wiping Rags • HVAC Equipment Recycling • Delivery Available • Corporate Accounts

Why International Companies Are Choosing To Invest In Arizona

Last year, Taiwan-based chip company Taiwan Semiconductor Manufacturing

Co. (TSMC) announced plans to expand its footprint in north Phoenix from $12 billion to an estimated $40 billion to build its massive U.S.-based semiconductor hub — one of the largest foreign investments ever made in U.S. history, and the largest ever made in the state.

The TSMC plan may be the biggest example of foreign investment in Arizona but it should come as no surprise that foreign investors have taken notice of Arizona, which is quickly emerging as a thriving hub for global commerce.

“We’ve come into a place where we’ve never been before in foreign direct investment,” Mackay said, adding that foreign investment in the state is now primarily focused on advanced manufacturing, especially semiconductors, batteries, electric vehicles and biotechnology.

Last year, expansion projects were announced by companies such as Switzerland-based Nestle, which announced a $675 million investment to build a factory in Glendale, and South Korean electronics giant LG Energy Solution, which invested $1.4 billion to build a high-tech battery facility in Queen Creek.

Foreign investors are attracted to the state for many of the same reasons domestic companies are flocking to Arizona: the state’s favorable regulatory environment, strategic geographic location, availability of land, amenable climate and a built-in talent pipeline to draw a skilled workforce.

Another big draw has been government programs aimed at strengthening U.S. supply chains by bringing high-tech manufacturing back to the states. The CHIPs Act, for example, was among the reasons TSMC decided to expand its Arizona operations, said Senator Mark Kelly, who championed the CHIPs Act and called the TSMC investment “a big win” for Arizonans.

Foreign investment isn’t just a boon for Arizona’s economy, it’s also a job creator. The TSMC fabrication plants (fabs) in north Phoenix alone will create 21,000 construction jobs and will employ an estimated 4,500 permanent workers. Today, foreign investment provides jobs for more than 133,500 workers in the state.

Your one stop shop for 623.847.4028 - NEW 10KW BYSTRONIC FIBER LASER - NEW CNC PRESS BREAK - 5-AXIS WATERJET CUTTING (table 13’10” x 6’7”) - CERTIFIED MIG, STICK, & TIG WELDING - LASER CUTTING SERVICES - DEBURRING SERVICES - PUNCH & SHEARING - STAINLESS STEEL FABRICATION - PRECISION SHEET METAL WORK - GENERAL METAL FABRICATION & DESIGN - SAW CUTTING - TUBE BENDING SERVICES - PRODUCT MANUFACTURING & ASSEMBLY - PRODUCTION & PROTOTYPING - MOBILE FABRICATION & WELDING 623.847.4028 Address : 5815 W McLellan Rd Glendale, AZ 85301 Our Phone : 623.847.4028 Email : sales@azwelder.com QUICK TURNAROUND 1-2 Day Lead TIME

Experts anticipate recent highprofile investments will only make Arizona a more attractive destination for foreign investors.

The surge of foreign investment in Arizona shows no signs of slowing down, with the state continuing to attract companies from all corners of the world. As more companies set up shop in the state, they will contribute to job creation and economic growth, further cementing Arizona’s status as a top destination for global commerce. By

Madeline Salazar

A 30-year partnership with Goodyear shows how businesses can work with New Mexico’s national laboratories

In 1993, Sandia National Laboratories and Goodyear Tire and Rubber Co. signed an agreement to collaborate on research to help develop technologies used by the Akron, Ohio-based tire company. Thirty years later, researchers at the national laboratories put together a computer model to simulate tire noise in electric vehicles — the latest work in the two organizations’ three-decade-long partnership.

The agreement signed between the laboratories and Goodyear is called a Cooperative Research and Development Agreement, or CRADA. CRADAs allow technologies and research conducted at the laboratories — like the labs’ computational simulation technology, which models situations that are difficult to test in the real world — to boost private businesses.

“[Goodyear] would rather not do physical tests if they can do numerical tests,” said Gregory Bunting, Ph.D., the technical point of contact for Sandia’s partnership with Goodyear. “They would like

Treating

Heat Treating

to do new designs and new capabilities without huge upfront costs, and use all of these capabilities that we’ve developed historically.”

But Goodyear isn’t the only company that has relied on research and technology at Sandia for its own development. Technology transfer and partnerships with private businesses are part of the labs’ mission, said Joel Sikora, a manager of technology partnership agreements at Sandia.

It’s one of the ways, he said, that Sandia can be a boost for New Mexico’s economy. “It excites everybody at the laboratory, the ability to be involved in something that isn’t mission related but that they can see in their day-to-day life,” Sikora added. “It’s a positive for both sides that way.”

There are some other laboratory programs that private businesses inside and outside of New Mexico can take advantage of, including CRADAs.

One is the Technology Readiness Gross Receipts initiative, which graduated from

A2Z MANUFACTURING SW • 31 • July / Aug 2023 Continued Next Page Phoenix Heat

Phoenix

GET TO KNOW US Servicing our industry and trade customers in intelligence heat treating for over 60 years. www.phoenix-heat-treating.com 602-258-7751 cs@phxht.com Established in 1963 Real Time Live Job Tracking 10+ Processes Performed 50+ Furnaces AOG and Line Down Services Over 10+ Prime Approvals 24/7 Processing

a pilot program into a five-year initiative through a bill passed by the state legislature in March 2022. That program, abbreviated to TRGR, helps companies that have existing licenses or work agreements with Sandia or Los Alamos National Laboratories take their technologies to market with up to $150,000 in financial assistance.

Advanced hCMOS Systems, an Albuquerque-based startup formed in early 2022, is one local company that’s used the TRGR program. A report on the program notes other New Mexico businesses, such as Build With Robots, mPower Technology Inc. and Pajarito Powder, have participated in the TRGR initiative.

A sensor used in an ultrafast X-ray imager is inspected under a microscope at Sandia National Laboratories. Advanced hCMOS Systems wants to commercialize that imaging technology, and it’s received some support from the Technology Readiness Gross Receipts initiative to do just that.

Another is a program for New Mexico small businesses, funded by state gross receipts taxes, that devotes between $20,000 to $40,000 for laboratory researchers to support businesses’ needs.

“In talking with my peers at other labs, there are very few programs that I believe are as good, and certainly as mature, as what we have in New Mexico,” Sikora said. “So, there are a lot of really great opportunities for small businesses.” Businesses

ranging from large companies like Goodyear to nascent startups like Advanced hCMOS Systems can leverage different capabilities and technologies that already exist at the labs, Sikora said.

“We’re not here to compete with industry,” Sikora said. “We’re here because … there are complex problems that no one else is able to solve or require machines or — in the case of Goodyear — very specific physics codes.

Companies can request to partner with Sandia through forms on the labs’ website. Sikora said he and his team receive the requests and then point businesses to the right partners within the labs.

The cross-application of technological and research expertise can be a boon for private businesses — but it can help the labs’ own development, too.

By Jacob Maranda - New Mexico Inno Reporter

A2Z MANUFACTURING SW • 32 • July / Aug 2023

A2Z MANUFACTURING SW • 33 • July / Aug 2023

Arizona On Track For Impressive Solar Industry Growth

The solar energy sector continues to gain strength in Arizona, with robust growth anticipated in the coming years, according to a new industry report. That outlook comes along with good news for the sector nationwide, according to the US Solar Market Insight Q2 2023 report released recently by the Solar Energy Industries Association.The latest data shows that the industry had its best first quarter ever, with 6.1 gigawatts of solar capacity added nationwide.

In Arizona, 6,457 megawatts of capacity was added to the grid during Q1, giving the state a No. 5 ranking in the nation for total megawatts installed, at 6,457 MW. The report projects that Arizona will rank No. 4 five years from now, with 10,651 MW installed by 2028.

Right now, solar makes up 9.82% of Arizona’s electricity, with enough capacity to power 984,047 homes. In 2022, $1.5 billion was invested into solar, helping to bring the total value of the solar market in the state to $16.5 billion. The price for solar installation has continued to go down as well, and in Arizona it’s 54% lower than it was a decade agot.

Currently, 368 solar companies operate in Arizona, the report found — with 76 manufacturers, 171 installers/ developers and 121 other companies. Those businesses

account for 8,278 jobs in the state.

Still some questions around solar industry credits

On the national level, the report found that supply chain challenges have tapered off and the federal Inflation Reduction Act’s incentives for the industry have started to kick in. However, questions about the credits remain for the industry and have prevented the law from having its full impact, the report’s authors said.

“As the Inflation Reduction Act begins to flex its muscle and drive demand, the U.S. solar and storage industry is eagerly awaiting further guidance on some of the most impactful pieces of the law,” said Abigail Ross Hopper, SEIA president and CEO, in a statement. “Timely, specific, and workable implementation guidance from the administration will have a major impact on our success in both the near and long-term.”

The report also indicated that the issues related to the credits, the fact that the U.S. lacks manufacturing capacity for crystalline silicon solar cells, and a lack of clarity on the rules for the residential market, combine to keep the law’s full impact from being felt so far.

Leading the nation for solar installations in the first quarter was Florida, with 1.46 GW installed. That was 70% more than the next highest state, California.By Jeff Gifford –Phoenix Business Journal

A2Z MANUFACTURING SW • 34 • July / Aug 2023 OVER 26 PRIME APPROVALS OUR CAPABILITIES 3027 E Washington St, Phoenix, AZ 85034 • (602) 275-1917 Semiray a Division of Mistras Group www.semirayinc.com www.mistrasgroup.com *Penetrant *Magnetic Particle *Anodize Type I, II, III *ChemFilm Type II ROHS Compliant *Passivation *Pre Penetrant Tech *Pressure Test *Paint *Dry Film Lube *Flow Test / AF5333 *Borescope Inspection *Ultrasonic Cleaning *Millipore Clean & Inspection ...And Many Other Value Added Services

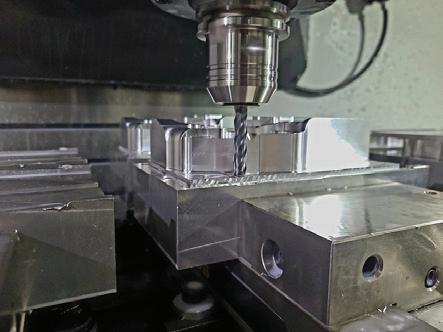

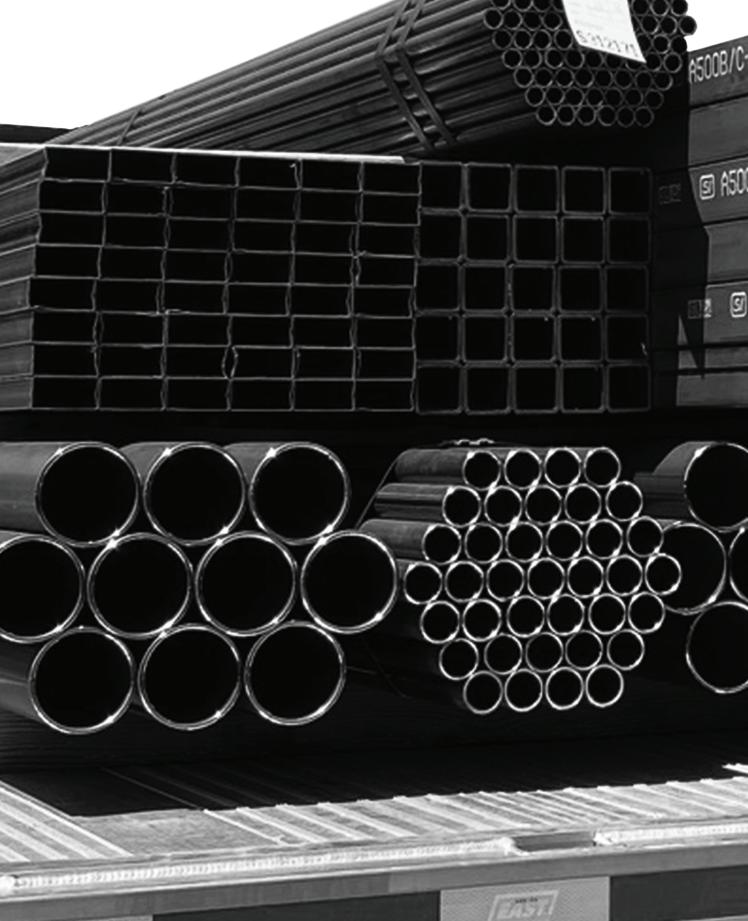

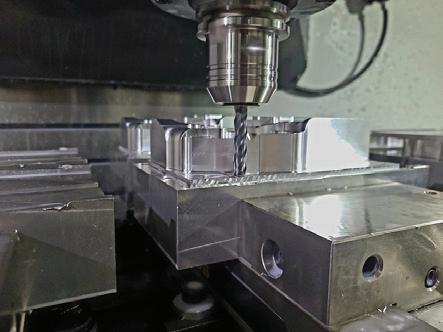

Metzfab Industries has come a long way since it opened for business 13 years ago. And since its inception, the company has pursued cutting edge technology and processes, always with the end goal of making parts faster and more economically. Their keen adoption of automation has been instrumental in their growth.

Today, the company resides in a 16,500 square foot facility in Deer Valley, a Phoenix, Arizona suburb. It is an understatement to say that Metzfab has state-of-the-art machinery, and that they offer more fabrication/machining services than you will see in nearly any other shop. While established as a fabrication shop, today, Metzfab provides much more than general metal fabrication — they also specialize in CNC machining, waterjet cutting, laser cutting, forming, tube bending, manufacturing, design and assembly. In fact, a number of Metzfab’s customers bring either new products or products that have been around for years — and with Metzfab’s expertise and their equipment, the end product that results is now better and less expensively manufactured. (They even guarantee to beat any competitor’s price by 5%). Often, Metzfab does all the sourcing and manufacturing, and drop ships the finished product, engraved and packaged, complete to their customers.

Metzfab’s customers hail from all over the world. Customers have made the company one of their key trusted suppliers because not only do they manufacture products on time and with high quality, but also because of the flexibility and plethora of services the company provides.

At Metzfab, capital machine purchases are made with significant research and analysis of the market and with surveys of their current customers. A few years ago, their customers who require tube Laser Cutting , as an example, were sending their parts to California or even further away. The company’s purchase of

the ByTube 130 tube laser enabled them to get their tube Laser Cutting done locally through Metzfab. Over the years, Metzfab has consistently added new services for their customers. In the last 5 plus years, they estimate that they have invested more than $1 million each year in new equipment. And while they offer the latest in technology, they focus less on acquiring ‘the fastest’ model, and more on acquiring the model that enables automation. Here are some of the main services Metzfab provides:

Laser Cutting

Metzfab offers comprehensive laser cutting services for short and long production runs. The company offers a full “lights-out” operation to accommodate largest production volumes and turnaround requirements for any business.

The company’s laser cutting technology produces consistently accurate parts with the highest edge quality possible across a wide range of materials and sheet thicknesses. They use advanced nesting software, so that they can utilize the majority of the raw material and eliminate metal waste, maximizing the value for their customers.

CNC Forming

Metzfab has an extensive array of press brakes and tooling to support their customers’ needs. They also manufacture custom tooling in-house when it is required to produce parts for custom applications.

CNC Tube Bending

Metzfab’s CNC bending service will bend and form materials to your requirements. Owner Brandon Metzger says, “At Metzfab Industries, we have invested in a Starbend 800 Rotary draw with mandrel and 3D Freeform capable CNC bending machine in order to offer our customers the creative freedom to not only bend tight radius traditional rotary draw bends with mandrel but also the very unique capability to design their parts with true variable

A2Z MANUFACTURING SW • 36 • July / Aug 2023

“If you can’t describe what you are doing as a process, you don’t know what you are doing”

—

W. Edwards Deming

radius and variable plane bends (3D Freeform).”

Tube Laser Cutting

Metzfab’s laser tube cutting services will cut all types and shapes of tubing – from stainless steel, carbon steel, aluminum, round, square, rectangular, oval, semi-oval, and elliptical with diameters from 3/8 to 5.25 “ and lengths up to 21.5’.

Brandon says, “Any company that still is using traditional methods to manufacture tubular assemblies is, in essence, wasting time and money. To put this into perspective, traditional methods versus tube laser cutting is synonymous with a writer using a typewriter versus a laptop. In the past, tubing was difficult, time consuming and expensive to process. With the introduction of tube lasers and CNC mandrel benders, tubes can now be cut with revolutionary accuracy and speed. Metzfab’s system offers the flexibility and freedom to create innovative new tubular designs by allowing the designer to specify complex end forms and hole geometry that cannot be created in a cost-effective manner with any other process.”

He adds, “Mix in CAD. Everything we do, we draw in 3D. 3D bending programs. In Solldworks in 3D. Regardless of how we get it, we leverage our software.”

Waterjet Cutting

Metzfab specializes in 5-axis precision waterjet cutting and machining for prototype, short run and long run productions. Metzfab’s waterjet cutting system is capable of cutting parts from 0.005” to 12 “ in thickness and their cutting area is able to handle 20’ parts.

CNC Machining

Metzfab’s full line-up of multi-axis CNC machines, including a Renishaw probe to assist in measurements, enables them to manufacture even your most complex components on time and within budget. They can machine parts to tolerances as close as +/-.0005”.

3D CAD/CAM Design and Assemblies

Using the latest 3D CAD/CAM systems, Metzfab’s engineers start by studying your current design environment, your operating constraints, and your design goals. Metzfab’s 3D CAD/CAM and assembly services Continued Next Page

A2Z MANUFACTURING SW • 37 • July / Aug 2023

offer machine prototypes and finished parts.

For customers who have parts that lack prints or digital files, Metzfab will create both the 3D model plus the drawing. When a customer opts to own the model and CAD files, they can be purchased through Metzfab via a Non Recurring Engineering (NRE) fee.

Precision Sheet Metal

Metzfab got its start as a precision sheet metal shop and today, their experienced team of precision metal fabricators are able to provide their customers the highest quality component parts and will guide you through initial design through prototyping to the completely welded and assembled product.

Product Manufacturing and Assembly

Brandon says, “By using our CAM software package, we are able to program using 3D data to program complex 3 and 5-axis simultaneous machine movements. We can import any 3D data and generate tool paths from your solid. Don’t have 3D data? Don’t worry; we can still operate with 2D data or print designs.”

Stainless Steel Fabrication

From architectural designs to restaurant kitchen equipment, the Metzfab team has completed countless projects, with customers as well known as Starbucks, Chick-fil-A, and Baskin Robbins., to name a few.

Deburring & Tumbling Services

Metzfab has invested in a COSTA grinding and deburring machine, which is designed for edge rounding and oxide layer removal from steel and stainless steel parts in one operation. Metzfab’s COSTA is a 4 headed configuration, which results in the most aesthetically and consistently beautiful parts.

This machine’s unique method of simultaneously edge rounding and oxide removal on inside and outside contours of laser cut parts on both sides in one single pass is highly efficient. It is estimated that Lissmac saves processing times of up to 60% compared to conventional grinding machines.

In addition to deburring, Metzfab’s tumbling services can be used to burnish, clean, descale, remove rust, and brighten or harden

the surface. The surfaces of the parts get worn away, sharp edges are broken, surface discoloration and blemishes are erased, and your parts come out smooth.

3D Scanning Arm

Metzfab’s Absolute Arm 7-Axis delivers tactile probing and non-contact scanning in a uniquely ergonomic package. It’s an excellent choice for high-end portable measurement applications. With the full-speed, fullaccuracy measurement delivered and its wide scan line – 150 millimeters wide at mid-range – 3D scanning and digitization is fast, delivers full performance at all times on all materials – full accuracy, full frame rate, and full laser scan width for full measurement productivity.

Welding Services

Metzfab offers a number of welding services, including LASER, TIG/MIG, ARC and Robotic.

Laser welding is often recommended for welding steel, aluminum, copper, titanium, and nickel alloys. Laser welding is often preferable for thick, thin, reflective and dissimilar metal welding without wire that is difficult or impossible with traditional methods, plus weld materials with different electrical conductivity.

Metzfab’s free-hand TIG, MIG, and ARC welding services can handle a broad variety of materials up to 1.25 inches thick. Additionally, their TIG, MIG, and ARC welding services can be applied to a wide range of applications, including boilers and precision assembly.

With its Robotic Cell, Metzfab specializes in automated robotic welding projects with a wide range of metal types with material thicknesses from 1/16 in. to 1/2 in. as well as circular welds or welding with contours.

What’s it Like Partnering with Metzfab?

When you choose to partner with Metzfab Industries, you get an extremely versatile and experienced team that has a tremendous amount of knowledge and experience in all areas of manufacturing in a wide range of industries. You get a shop that stands behind what they do, and always does the right thing. You get a shop that is on the cutting edge of technology and is always improving for our customers as well as making our employees’ lives easier. We are here for the longhaul and only interested in long-term relationships. We believe honesty and transparency is an essential part of being your partner and without these things, you cannot have a successful, long-term partnership. Which is why the culture at Metzfab is perfection — always clean — always organized — always striving to exceed customer expectations. To learn more about how they can support you, contact: 602.539.9591; sales@Metzfab.com or visit their website at Metzfabindustries.com

A2Z MANUFACTURING SW • 38 • July / Aug 2023

Taking CMMs to the next ALTERA C comes in three sizes, and is designed with a wide range of multi-sensor technology in mind to meet customer applications and budgets. All are priced less than you might expect, and are ready to unleash the potential of your shop. sales.us@lkmetrology.com - 810.263.6100 CONTACT US TODAY TO BOOK YOUR DEMONSTRATION