Agenda

o PLS (Plant Layout Simulator) – How to design an efficient line

Software developed since 2006, used in 24 green fields (as of today)

Demo

o REDS System Harmonizer – How to make converting smart

REDS Harmonizer software used in more that 200 installations, 6 in Wepa

Demo

o Quatis Quality in Tissue – Correct errors to reduce scrap products

Data collection system installed 70

Introduction and Qpocket demo

o New frontier of sustainability – Pack technology for professional in poly / paper

Introduction and MBF machine demo

o Antares PAL – new technologies from the single roll to the pallets

Introduction and Antares demo

Folded in robotics tray demo

How to design an efficient line

How to design an efficient line

TISSUEPLS is the software that allows to analyze and simulate the layout of the plant and machinery of a converting line . Its primary purpose is to help to avoid errors during the design phase of a production line or facility . By verifying the accuracy of input data, TISSUEPLS helps identify and address bottlenecks in plant operations . It allows to create custom layouts to simulate various production scenarios, making it easier to evaluate and improve operational efficiency . This system supports both the early design stages and ongoing operational assessments, ensuring efficient and error - free plant layouts .

Key Features:

How to design an efficient line

• Optimal Layout Design: it assists in determining the best positioning for the machineries of the plant, considering also the operators positioning, ensuring the correct distances between machines and material loading points, such as rolls, bags, or other raw materials.

• Production Capacity Calculation: it enables users to verify potential outcomes by calculating the production capacity of the entire line, allowing for better planning and optimization.

• Bottleneck Identification: it checks the accuracy and consistency of data across all machinery and products, running multiple trials to pinpoint bottlenecks and other inefficiencies.

• Flow Diagram Representation: it transforms technical layout models into intuitive flow diagrams, visually representing the network of machines.

• Speed and Productivity Assessment: By matching machine data with product information, users can compare the speed of different machines, calculate overall productivity, and optimize workflows.

• Utilization and Availability Forecasting: it enables the user to track machine usage and forecast future availability, predicting both potential breakdowns and routine maintenance stops, ensuring smooth plant operations.

• Cost and ROI Analysis: it provides detailed cost analysis and return on investment (ROI) evaluations as part of its assessment. This includes the ability to evaluate energy consumption, material usage, including both raw and processed materials, trims and depreciation of machinery and materials, allowing users to calculate the industrial cost per product.

How to make converting smart

How to make converting smart

It automatically regulates all the speeds of the machines without operator intervention on the line including the speed of the rewinder, the accumulator, the log-saw, the primary and secondary packaging and the palletizing. It sets up all the machines at the maximum possible speed.

BENEFIT

More production

• More availability

• Less maintenance

• Less energy consumption of all machines

According to the data collected in 80% of cases downtime is less than 8 minutes

How to make converting smart

The REDS System Harmonizer/Supervisor is a sophisticated software solution designed to optimize customer investments by maximizing the effective use of available space within the plant. This innovative system enables users to control and manage the entire converting line from a single unit, seamlessly integrating processing machines with conveyors for enhanced operational efficiency. It is possible to:

• control the speeds of the conveying system and of the machines;

• show the line diagnostics;

• plant production according to product types;

• organize a database of the characteristics of the single machines;

• manage product tracing

• enter the system with different priority levels.

Correct errors to reduce scrap products

100% Quality of the products

Correct errors to reduce scrap products

Avoid the jams of the primary packaging machines (wrappers & bagfillers)

Data collection for analysis and optimization of the line operation process

EFFICIENCY GOALS

Increased efficiency

OEE from 3% up to +5% more

Reduction of non-compliant products

Reduced logistics for returns (Lower CO2 emissions)

Reducing paper waste on the line for equals hours worked

Increasing the efficiency of the production process for the same amount of electricity consumption

QUATIS ROLLS

Correct errors to reduce scrap products

PACKS QUATIS BAGS

QUATIS VISION

Correct errors to reduce scrap products

QUATIS POCKET

QUATIS INTERFOLDED

Le informazioni qui riportate sono di proprietà di Pulsar Engineering Srl che ne vieta la diffusione senza specifica autorizzazione

The information hereint are property of Pulsar Engineering Srl which prohibits copying and diffusion without authorization.

Correct errors to reduce scrap products

SOFTWARE FUNCTIONS

DB Quatis allows users to connect to Quatis machines on the line, however processing the data.

As a result of millions of processed data, DB Quatis generates tables and graphs easy to read and understand.

The report is sent every day and provides a percentage of Quality KPI of the machine

*Additional Service available: recipe change from remote and data collection.

New frontier of sustainability Antares PAL

STACK, ORIENT, FILL, LAYER, PACKAGE, PALLETIZE WITH ONE SYSTEM

ANTARES is not a machine.

ANTARES is a new solution based on robotic and modular system that allows making automated solutions in packaging processes, with features and performances not achievable with conventional system.

With only one system, you can stack, orient, fill, layer, package as well as palletize products in high flexible way, without many of the constraints posed by the machines available on the market.

ANTARES

ANTARES is not a machine is a system

ANTARES concept based on robotic and modular system.

Unconvencional

High adaptability to the formats required (rectangular, square, toilet paper, kitchen towels, handkerchiefs, facial tissue boxes, diapers and more over) reducing and almost eliminating the time for format change-over.

ROLLS HANDKERCHIEF INTERFOLDED DIAPERS

…AND MORE OVER

March 2018

End of installation in Italy prototype

DARWIN ANTARES (2017 2023)

from June 2022

ANTARES 2 - new format specification defined.

New robot technology:

• New ABB robots with better performances in speed and throughput on grippers

• New operator interface with more controls on grippers

New grippers for:

• single rolls packs

• double layer packs

• triple single layer pack picking

• both poly and paper wrapping

Increased size of bags formats (larger and longer) while still reducing machine footprint.

DARWIN ANTARES (2017 2023)

The new ANTARES is shorter, faster, easier to use and makes more formats.

New Order

ADVANTAGES

Increased pallet filling, thanks to the ability to orient packages with a high pallet stability less number of pallets

Lower logistic costs lower number of trucks savings estimated at 8% - 11%

REDUCED EMISSION CO2/TON

• Reduction of total cost of ownership

• Reduction in the stock of spare parts

• Lower shipping costs for spare parts

ADVANTAGES

Ease of use: operators don’t need a training

Increased line production capacity: thanks to the possibility of preparing pallets/bags or boxes’ layer in the same area with Delta robot that are faster than the other solutions (anthropomorphic robot systems)

Reduced footprint combined with palletizing area: save space from secondary packaging machine to pallet output

Different packaging possibility: in plastic, in paper and in cardboard boxes with the same system

Less waste of materials and time saving

Drastic reduction in changeover times with reduced changeover and format set-up times.

High level of accessibility: everything is in sight and easily accessible

LOWER COSTS OF INVESTMENT

ADVANTAGES

Lower Costs of the Palletizing Station

Simplifies palletizing area compared to current standard, removing robots and mechanical assemblies from the current areas

Less costs, less occupied space

Saves space by reducing footprint from secondary packaging machine to pallet output

Less layout costs

Less conveyors and simplified layout: no more by-passes and other routes are needed to bring products from wrapper machines (and/or logsaws) to the end of the line.

Reduced downtime costs

High level of accessibility by operators to enable rapid intervention when needed

Reduced costs of plant start-up time

Antares is a modular and integrated system that reduces interference problems compared to the systems adopted until now for transferring products between one machine and another from different suppliers

Reduced costs of future expansions and/or reuse of existing modules

ANTARES is a configurable modular system that allows easy integration and future expansions or reuse of modules for other applications while reducing investment costs.

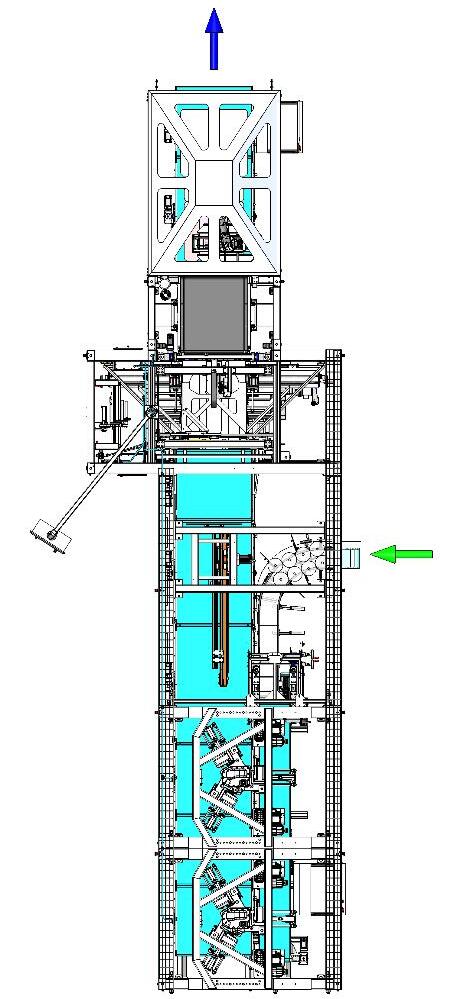

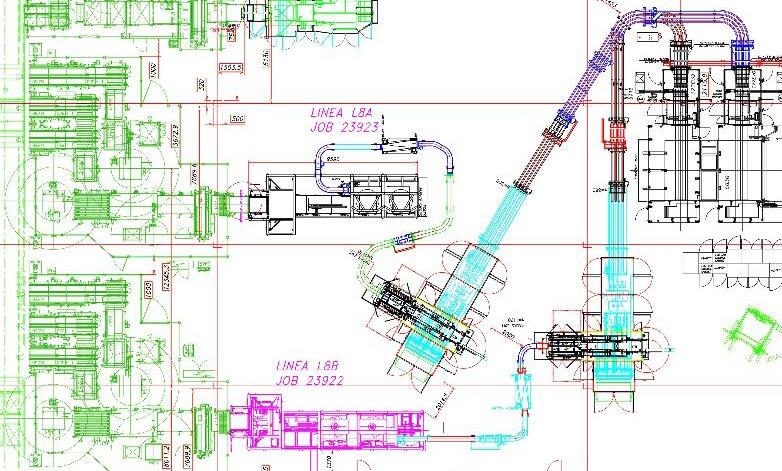

ANTARES – Configuration and footprint comparison

Pallet Layer preparation station

Antares Output

Application EU 2 A comparison with ANTARES

Current Layout

Antares Layout

Layout with standard bundle machine

Application EU 4

A comparison with ANTARES

Current Layout (Antares 1 and Standard Bundle)

Layout with Antares 1 and 2

Configuration BOX – BAG – DISPLAY for consumer rolls palletizing station

• 16 different products in depal with 12 robots

• 10 stations of inspection systems for check products the box

• 10 Station picking station for introduce product in the box

• 1 Main case erector

PRODUCTS ARE DEPALLETIZED, PLACED IN TRAYS AND THEN IN CARTON CASES BY THE PICKING STATION FOR FAST TRACK AND DELIVERY

MBF Professional

Rolls/folded

Premade bag Poly/paper

Advantages of paper bag:

Special Machines

The paper bag has less cellulose than cardboard, same resistance, up to 8.5kg Recyclable

PAPER BAGS

CLASS A - ATICELCA 501:2019 (UNI 11473:2019) PAP22>97% NO PAPER MATERIAL < 3% Afh

Special Machines

Videos and technical sheets available on the web page.