Quaker Houghton is the leading global supplier of industrial process fluids to the automotive industry. From passenger cars and e-mobility solutions to heavy off-road equipment, we provide process fluids for a wide range of automotive and transportation needs. Together with our QH FLUID INTELLIGENCE™ approach, including QH FLUIDTREND™ cloud software, equipment, sensor and engineering expertise, we have the solutions to drive productivity, increase sustainability, improve quality, and reduce operating costs.

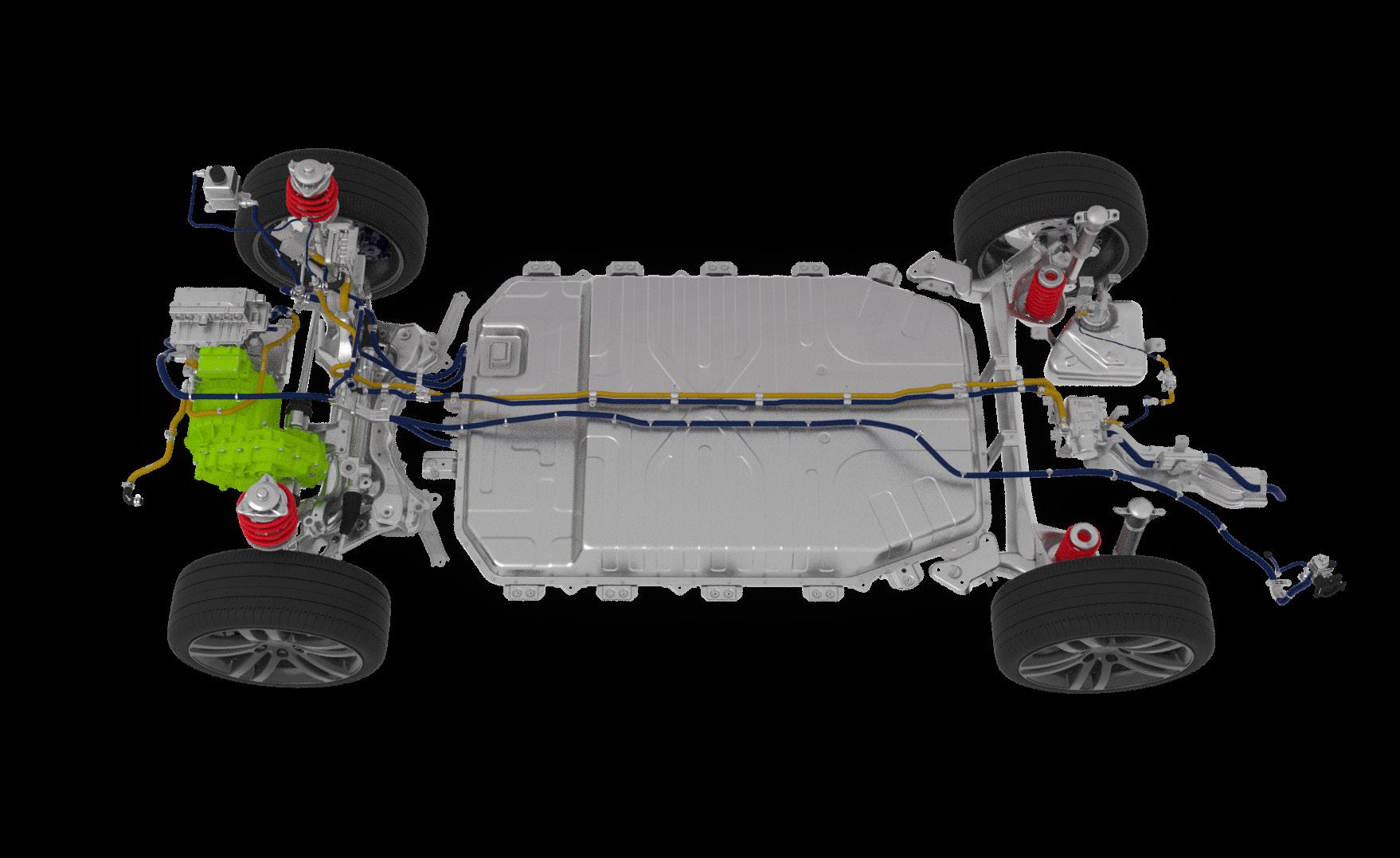

Under growing pressure to reduce costs and environmental impact, Automotive OEMs and component manufacturers are also facing challenges from the increased demand for hybrid and electric vehicles. For our customers manufacturing e-motors and components, this means more complex parts and increased quality standards. From the initial casting or forging process, to machining, cleaning, treating, and protection, Quaker Houghton has the product technology and expertise to support the growing demand for e-motors.

Our e-motor housing, shaft, and lamination portfolio includes fluid solutions for:

• Die casting

• Forging

• Machining and grinding

• Blanking

• Cleaning

• Heat treatment

• Porosity sealing

• Non-grain oriented electrical steel coatings

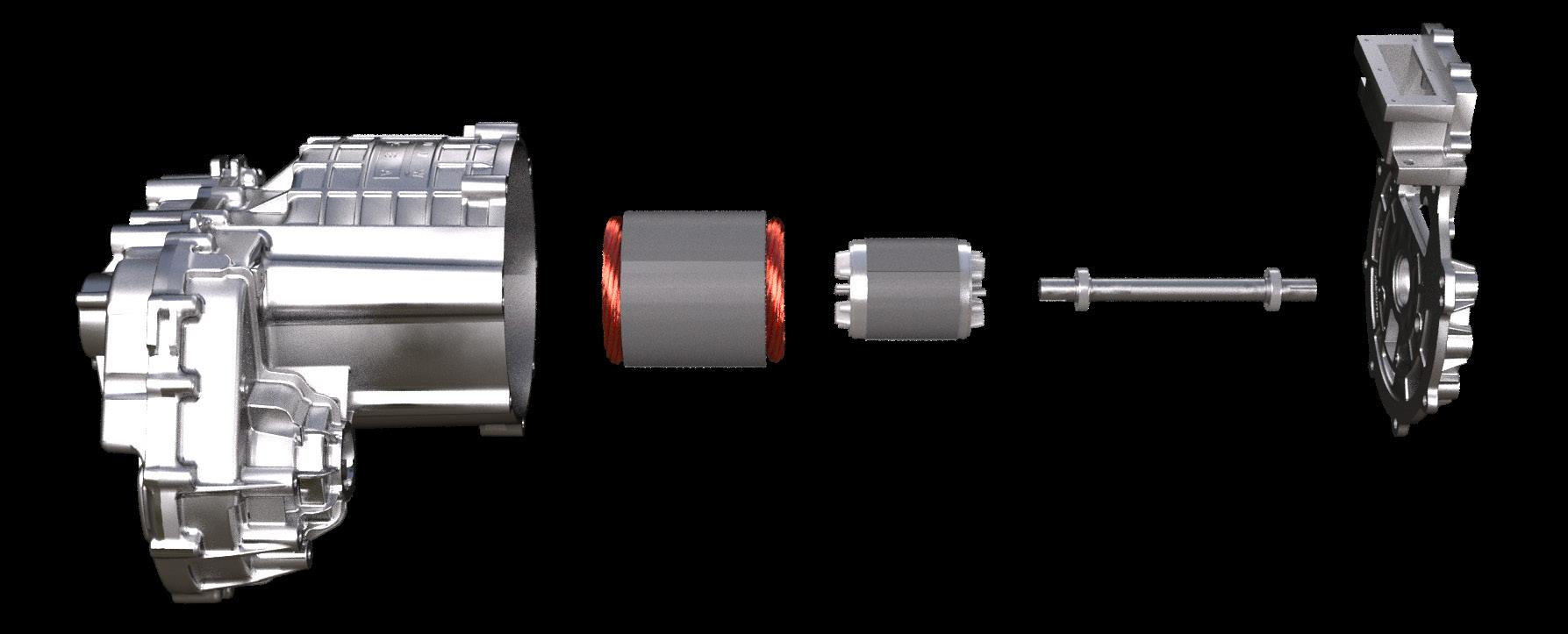

Stator Rotor Shaft Housing

Stator Rotor Shaft Housing

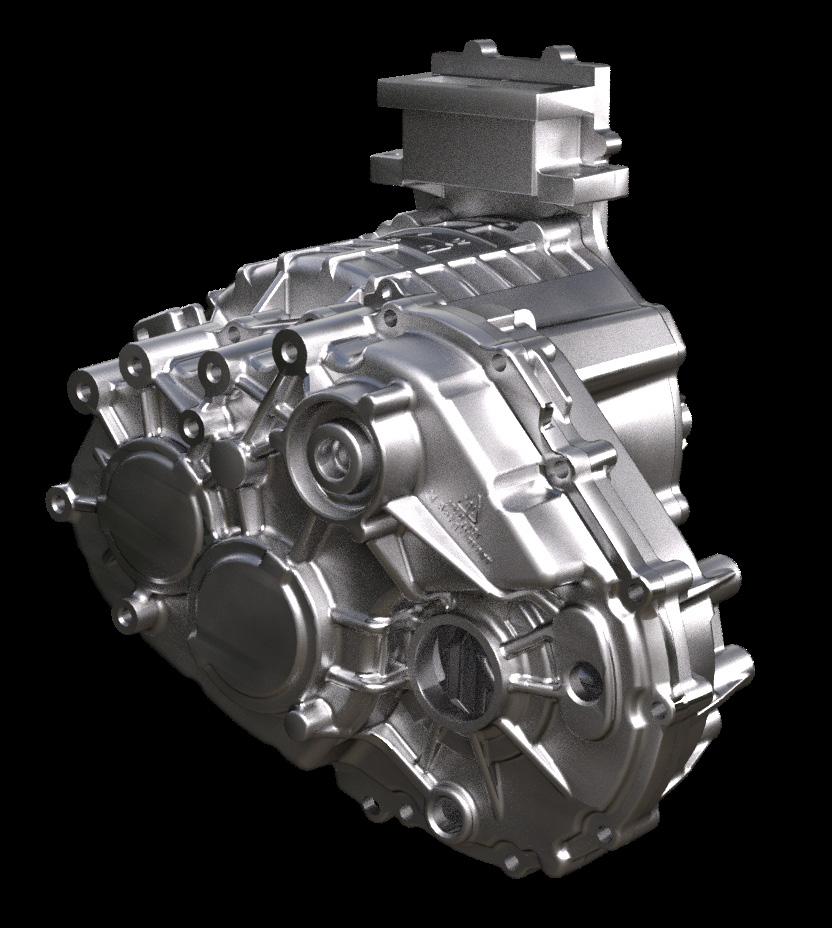

The e-motor housing is a complex aluminum component that is either die casted or formed, machined through milling, drilling, reaming, and then cleaned.

Die Casting Metal Forming Machining

Porosity Sealing Cleaning

Die Casting Metal Forming Machining

Porosity Sealing Cleaning

Our water-based, dilutable DIE SLICK® lubricants have been developed to provide exceptional release and die protection characteristics for even the most complex castings. In addition, our unique, patented, Lubrolene water-free electrostatic technology provides a uniform coating, unrivalled quality, operating cost, and environmental performance benefits.

Our die casting lubricants provide exceptional release and die protection characteristics, while promoting excellent metal flow, reducing soldering and producing bright and clean castings optimized for post casting operations.

We have a deep understanding of the forming and deformation process. Quaker Houghton has a long history of developing metal forming fluids and we have a significant supply position for these applications from beverage can drawing to heavy automotive forming. Our advanced HOUGHTO-DRAW™, QUAKERDRAW™ and DRAWSOL™ metal forming lubricants are easily applied by spray or rolling and are readily removed with our cleaners prior to downstream processes. Additional benefits include

• Easy release of shell from the die, reducing rejection rate

• Enhanced lubricity package

• Improved die life

• Bright surface post-forming both inside and out

• Chlorine free

Our comprehensive portfolio of soluble oils, semi-synthetic fluids, and synthetic fluids for cutting or grinding in a wide range of water conditions deliver:

• Low total cost of ownership

• Improved EHS profile eliminating boron, formaldehyde, nitrites and chlorinated paraffins

• Low residue and improved biostability

• Reduced consumption, decreasing chemical and water usage

Our spray and immersion metal cleaners have good oil splitting characteristics, are low residue, and can be used at ambient temperatures. Additional benefits include:

• MTM approvals for high pressure cleaning

• Synergistic technology – developed in conjunction with our metal removal fluids

• Fast acting cleaners to minimize process time and minimal residue

• Long system life, minimizing refills

• Good corrosion protection

Porosity is a major challenge for manufacturers of die cast components. Vacuum impregnation seals porosity so that components that need to be pressure tight, such as waterways, cooling veins or oil galleries, do not leak or to prevent moisture ingress.

Ultraseal, a Quaker Houghton Company, provides automotive OEM approved casting impregnation sealants, equipment and services. Combined with unrivalled process expertise and technical support, Ultraseal solves porosity sealing challenges reliably, completely and cost-effectively. Our impregnation chemistry, equipment and services can be customised precisely to your process needs, giving your business complete control over quality, operating costs and environmental performance.

The e-motor shaft is made of steel, and the typical manufacturing process includes forging, machining/turning, quenching, grinding, and cleaning.

Forging Machining

Quenching Grinding Cleaning

Forging Machining

Quenching Grinding Cleaning

Our versatile forging fluids are compatible with a wide range of water quality, materials, and process parameters. Quaker Houghton forging fluids have been developed in conjunction with our metal forming fluids and also offer the following benefits for the forging of e-motor shafts:

• Versatile products compatible with a wide range of water quality, materials and process parameters

• New lubricity packages to extend die life, improve component quality and reduce cycle time

• Meet the latest EHS chemical regulations

• Stable dispersion technology with less machine downtime and improved productivity

• Graphite-free products for cleanliness of machines and parts in use

Our comprehensive portfolio of soluble oils, semi-synthetic fluids, and synthetic fluids for cutting or grinding in a wide range of water conditions deliver:

• Low total cost of ownership

• Improved EHS profile eliminating boron, formaldehyde, nitrites and chlorinated paraffins

• Low residue and improved biostability

• Reduced consumption, decreasing chemical and water usage

Our biocide-free polymer quenchants are based on advanced chemistries to increase the life of the fluid and improve working conditions. Our experts have developed formulations that provide:

• Optimal cooling profile which enables improved distortion control

• Optimal cooling profile for a full martensitic structure, giving a high hardness

• Outstanding wettability to achieve low drag out therefore low consumption

Grinding is a critical application to reach high surface quality reducing noise and vibration. Our comprehensive portfolio based on different technologies : High quality mineral oils, Synthetic oils (SHP), Ester based or Mineral oils helping to mitigate CO² emissions.

Benefits include:

• Quality: excellent surface finish, clean parts, helps in Noise and Vibration Reduction (NVH)

• Safety and Environmentally focused: High flash point, low mist, low to no aromatics content

• Decreased operating costs: longer tool life, long sump life, less energy, good filterability

• Higher Productivity: higher production rates due to strong-lubricity, less burning, less rework

• Maintenance: good de-aeration-low foaming, oxidation stability, good compatibility with cleaning processes

• Approved by leading MTMs

Our spray and immersion metal cleaners have good oil splitting characteristics, are low residue, and can be used at ambient temperatures. Additional benefits include:

• MTM approvals for high pressure cleaning

• Synergistic technology – developed in conjunction with our metal removal fluids

• Fast acting cleaners to minimize process time and minimal residue

• Long system life, minimizing refills

• Good corrosion protection

E-motor laminations are thin metal sheets made of coated Non-Grain Oriented Electrical Steel (NGOES). These sheets are manufactured through blanking which make up the e-motor’s stator and rotor. Due to higher silicon content, thinner laminations, and increased efficiency demands, manufacturers are facing additional challenges with both the rotor and stator design and production. Quaker Houghton is a leading supplier of blanking fluids for e-motor lamination production and offers a full range of isolation coatings for NGOES, including bonding varnishes.

Blanking

Blanking

Our full synthetic soluble and vanishing fluids (including VOC free solutions) combined with our experience and expertise in lamination production can overcome these new challenges manufactures face by maintaining high production rate, long die life and high-quality finish of the lamination edge. Main advantages of our fluids include :

• High HSE profile and low smell

• High lubrication

• Leave minimum residue on parts

• Compatibility with coating

• Excellent corrosion protection

Our full range of non- chrome, ROHS- compliant, water-based NGOES insulation coatings, include C3-, C5-, C6and C3-bonding varnishes. We work closely with our customers to help make the best choice and achieve their requirements:

• Improved retention of magnetic properties

• High elevated-temperature strength and excellent weldability

• Excellent punchability

• Excellent corrosion resistance

• Reduced noise and vibration

• Improved thermal conductivity

• High degree of freedom in design

Our goal for QH FLUID INTELLIGENCE™ is to bring differentiated value to our customers so they can operate safely, sustainably and at the lowest total cost of ownership. Our comprehensive process fluid portfolio together with our QH EQUIPMENT and sensor technology, QH FLUIDTREND™ software, and expert engineering services delivers the ultimate fluid optimization solution for Industry 4.0.

Measure the correct parameters accurately for various manufacturing processes with differentiated sensors.

Control fluid performance using our expertise and QH FLUIDCONTROL™ to capture and analyze real-time data from QH FLUIDTREND™.

Optimize fluid and machine performance by delivering preventive insights that increase tool life, decrease downtime and reduce cost per part.

Quaker Houghton focuses on providing solutions that reduce waste, energy, water usage and chemical consumption, while improving operational processes, tool life and environmental impact. We are committed to creating a positive social, environmental and economic impact on our world. Our E-motor solutions include high performance fluids formulated for increased sustainability through:

• Low consumption – reducing water and chemical usage, and waste treatment costs

• Enhanced biostability- longer sump life, less additive handling and usage, improved operational efficiency by reducing down time, and improved odor

• Improved operator acceptance - VOC free blanking fluids, and improved EHS profile

When it comes to improving your overall business and getting the most from your process equipment and other plant resources, you need the expertise and experience of an established, recognized solutions provider to the industry. With chemists and application experts around the globe, it is our commitment to be at the forefront of sustainable & economical solutions for the automotive industry. As the market continues its move toward light-weighting and electrification, Quaker Houghton is your key partner for the manufacturing challenges of today and tomorrow.