SPRING 2024

www.timbermedia.co.uk ISSN 2517–26X (PRINT)

SPRING 2024

www.timbermedia.co.uk ISSN 2517–26X (PRINT)

Five industry tips to help woodworking and joinery businesses get the most out of factory teams and deliver quality products to customers

BUSY AS BEESLEY 28

Beesley & Fildes talked to us about the shape of the timber merchant sector and what to expect in 2024

MATERIALS & FINISHES SHOW 40

The UK’s furniture manufacturing and joinery industries gather at the Birmingham NEC

A

22 Positive Growth Path

Despite the volatility of recent years and the subdued start to 2024, the longer-term trend of UK timber and panel product imports remains upward, according to the latest TDUK statistics.

26 Cover Story: 5 Ways to a Lean and Efficient Joinery Factory

TXM Lean Solutions identify five key tips to help your company get the most out of your factory team and deliver quality joinery products.

28 Busy as Beesley

We spoke to James Beesley, commercial director at Beesley & Fildes, about development plans, the shape of the merchant sector and what progress to expect in 2024.

30 RAVIC Facility Gets Timber Boost

Muir Construction has officially completed a state-of-the-art innovation hub for Scotland’s Rural College, Inverness and was recently opened by HRH The Princess Royal.

34 Engineered Ingenuity

The National Manufacturing Institute Scotland (NMIS) new world-class, flagship facility has opened its doors, paving the way for the future of manufacturing in Scotland.

38 New Learning Hub for Timber

In a move that will significantly improve access to high-quality timber skills training, the STA has launched an online Skills Hub incorporating its new STA Installer Training Scheme.

40 Get Ready to Connect

What to expect from the upcoming Materials & Finishes Show as those in the furniture manufacturing and joinery industries gather at the Birmingham NEC.

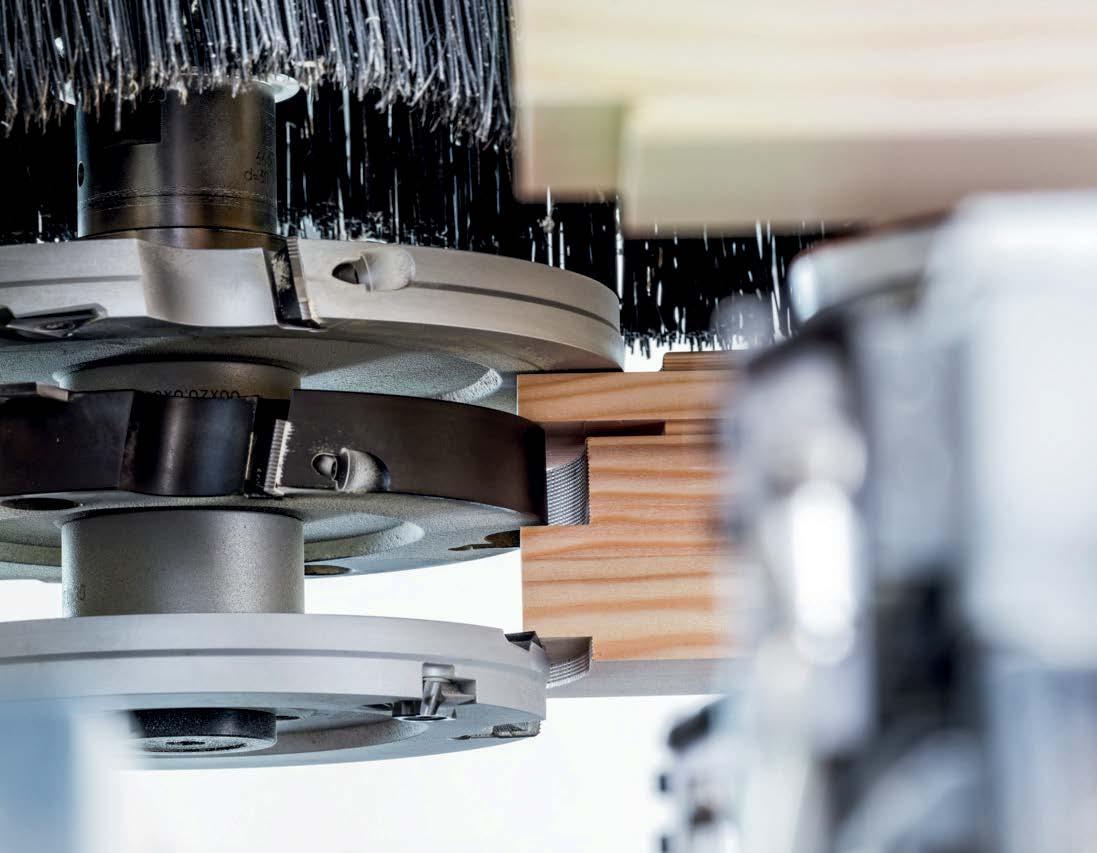

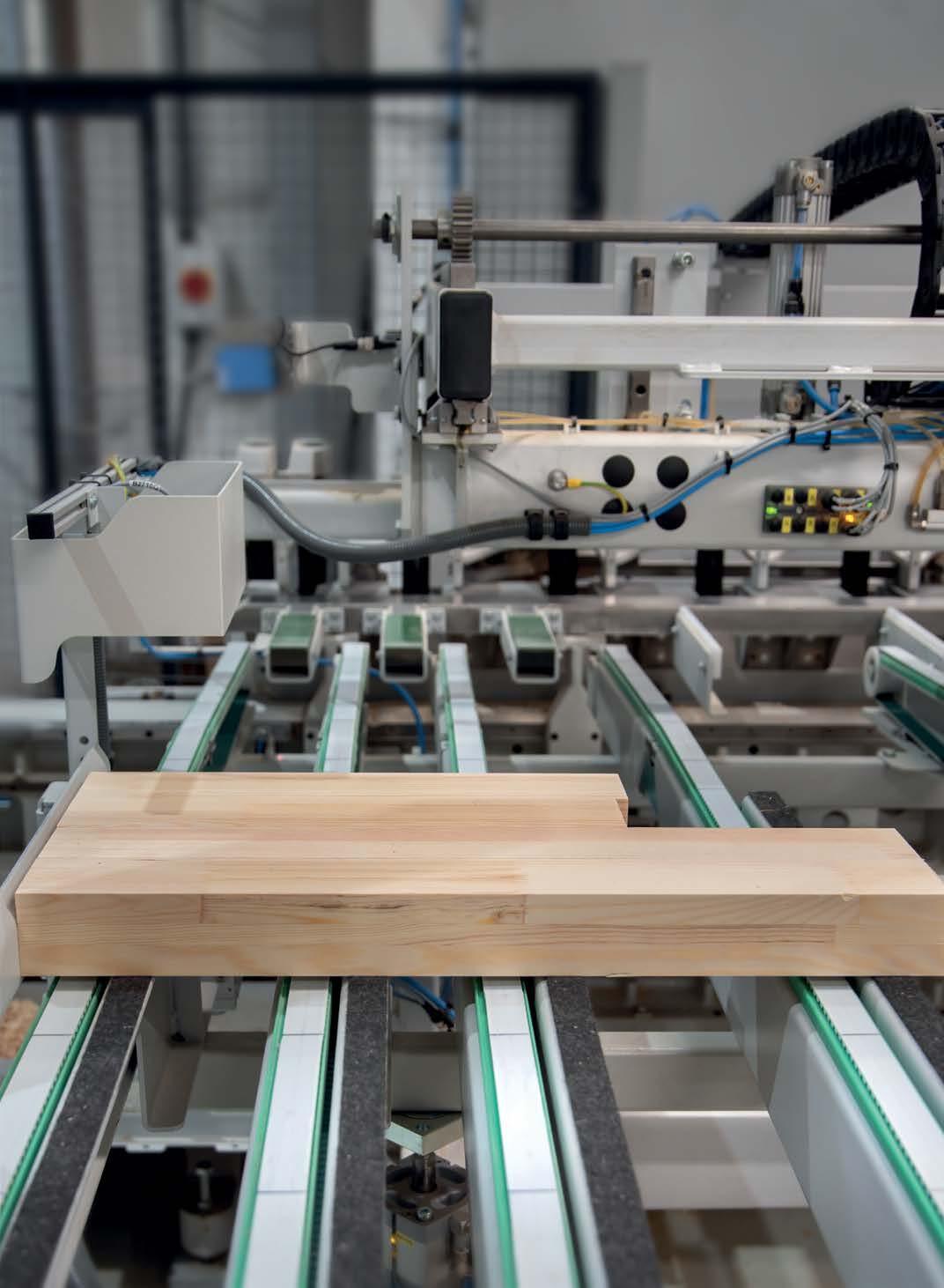

44 Make Double Capacity a Reality

How do you double your manufacturing capacity without increasing your overheads? Working with industry partners, machinery specialist Weinig prove exactly what can be achieved.

48 Know Your Plywood

BM TRADA’s Gavin Fidler, clears up some common misunderstandings surrounding buying plywood and what can be used safely for structural applications.

The New Model Institute for Technology & Engineering (NMITE) has announced the reconfiguration of its pioneering Timber Technology Engineering Design (TED) courses into specialised, concise programmes tailored for professionals within the UK’s built environment sector. An evolution of the award-winning, twelveweek part-time courses (TED1 and TED2), this initiative reflects NMITE’s proactive approach to sustainable construction education, addressing the needs of learners to access short courses to suit individual circumstances

Responding to the industry’s demand for specialised knowledge, NMITE has segmented the comprehensive TED 1 and 2 curriculums into focused three-week modules. A four-week module, including a week in residence for Timber Design, has also been introduced. The beauty of this new course design is its flexibility. It allows learners to participate in a selection of courses based on their availability and job roles.

These offerings are designed to enrich professionals, including architects, engineers, and construction experts, who deeply understand sustainable timber use in building projects without disrupting their work commitments. Endorsed by the CIOB, CIAT and TDUK for industry excellence, the courses are as follows:

• Timber Sustainability (TED 1): Learn how to design and build in a highly sustainable way

• Timber Materials (TED 1): Delve into the nuts and bolts of traditional and engineered wood materials

• Timber Design (TED 1): Apply practical knowledge of timber to create real-world functional designs

• Timber Construction (TED 2): Develop new knowledge to specify construction methods for different contexts

• Timber Technology (TED 2): Delve into the digital technologies used in the timber construction industry

• Timber Design (TED 2): Explore construction with timber to reduce costs and create more sustainable environments.

“Adapting our Timber Technology Engineering Design courses to the evolving educational and professional landscape signifies our

dedication to sustainability and innovation in construction,” said Steve Bertasso, Timber TED Course Lead. “The revised format allows professionals to experience the same content with few disruptions to work schedules and a lower carbon footprint to attend. Our courses are a cornerstone in our mission to nurture a generation of professionals equipped to lead the transition to sustainable building practices.”

The newly structured courses are designed for utmost convenience and efficacy, catering to the busy schedules of professionals. Each course is compact, enabling participants to immerse themselves in intensive learning sessions over the three weeks with opportunities to engage with other students in discussion and project-based learning. This format not only facilitates a deep dive into the specific aspects of timber technology but also ensures that the learning experience is manageable and compatible with the demanding timelines of professionals in the field.

Delivered in collaboration with Timber Development UK and Edinburgh Napier University, the updated courses maintain NMITE’s tradition of excellence in timber education. By offering these focused educational pathways, NMITE seeks to expand its influence on sustainable practices in the construction industry both nationally and globally.

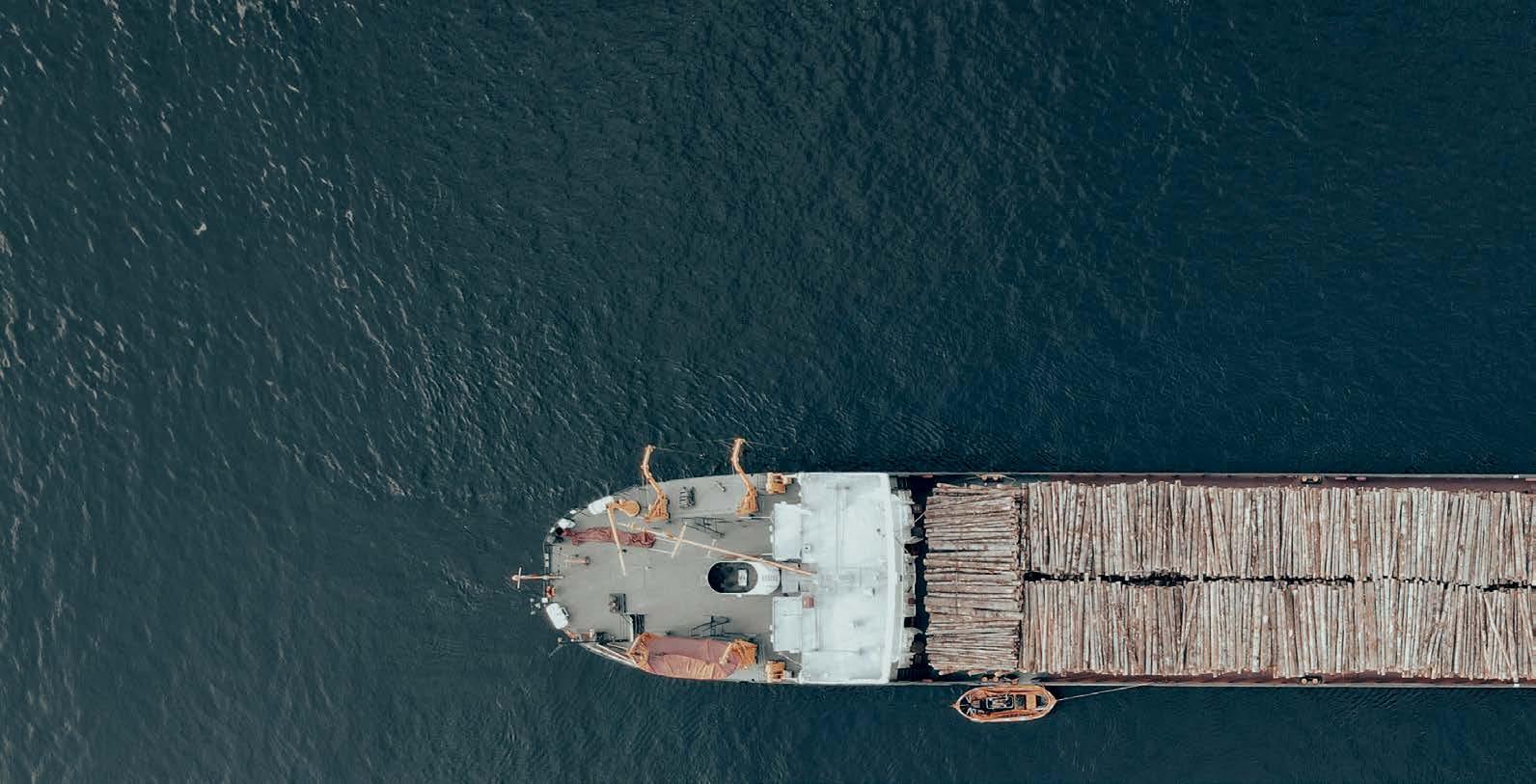

New research from iov42, a technology company specialising in digital identity, trust, and data integrity has revealed that almost one in five (18%) European timber importers are not aware of any incoming deforestation legislation, despite the fact that regulations like the EU Deforestation Regulation (EUDR) and UK Environment Act will imminently become law.

Despite the uncertainty around deforestation regulation timings, more than a quarter (27%) of respondents claim to be fully prepared, although there is a marked difference in levels of preparedness from country to country. 44% of UK respondents feel somewhat prepared, whereas in Belgium almost a quarter (24%) have not even commenced preparations.

iov42’s ‘2024 Deforestation Regulation Readiness Survey’ is based on responses from those with active involvement in importing timber and related commodities in the UK, Germany, France, Belgium, Austria, and Italy. All of whom will be or are affected by existing and incoming regulation designed to combat deforestation, one of the biggest environmental challenges of our time, significantly contributing to climate change, biodiversity loss, and disruptions in indigenous communities.

The survey reveals that over half of respondents (51%) have said they prefer to see what others in the market are doing before they adopt traceability systems or solutions. This is despite half of respondents saying they believe better traceability is beneficial for the industry at large and for

their organisation in particular. A notable 58% of respondents indicate that their suppliers are either unwilling or unable to support their efforts towards enhanced traceability, with almost three in five (59%) of organisations reporting insufficient funds to implement necessary traceability solutions.

Despite some uncertainty, 40% are still planning to achieve compliance within 6-12 months of the regulation being enforced. The survey has also uncovered a great deal of positive sentiment towards deforestation legislation. A significant majority (59%), agree that adhering to regulatory requirements will bolster their customer base, while 54% foresee a positive impact on their profits. Almost two thirds (63%) also anticipate that compliance will expand their market share.

Half of all respondents believe that full traceability would notably enhance their organisation’s growth. Additionally, 53% acknowledge that sourcing timber would be significantly streamlined through the adoption of traceability systems. This sentiment is echoed by 51% of organisations surveyed who said they were eager to implement traceability solutions, underlining a widespread acknowledgment of their benefits.

Despite the imminence of regulation and the need for compliance, consumer pressure was cited as the single biggest driver towards increased traceability with one third (33%) of respondents saying this was their biggest influence. This was followed by regulatory pressure (31%), market access (29%) and the need to combat disrupted supply chains

(29%). The environment (25%) and social impact (24%) were the least pressing drivers with a quarter of respondents citing these as their biggest influences.

Over four fifths (82%) of organisations report dedicating half or more of their operational time to tracking down information for customers, a figure that rises to 90% within the UK. The absence of a dedicated team to manage compliance exacerbates this issue, with over half (52%) of organisations acknowledging this gap. Over a quarter (26%) of respondents cite the lack of time and/or resources as the primary barrier to adopting traceability solutions, which could significantly mitigate the burden of customer information requests.

Dominic von Trotha Taylor, CEO and chairman at iov42 said: “The 2024 Deforestation Regulation Readiness Survey from iov42 gives a unique insight into the mindsets of those most affected by incoming deforestation regulations. These ambitious legislative frameworks all place stringent due diligence and traceability requirements on affected companies, so it is positive to see that European Operators are optimistic about the benefits regulation and traceability can bring. It is clear, however, that meeting the requirements of these regulations is a huge undertaking for time-poor companies, but help is out there, notably from a range of best-ofbreed technology solutions working together to help collect, analyse, verify, store, manage and securely share data.”

More at www.iov42.com

The Scottish Timber Trade Association (STTA) brought the timber and wood products industry together at Holyrood on 30 April to host a reception about driving net zero awareness and timber’s benefits to the economy.

Along with three other leading timber and wood products organisations – Confor, Timber Development UK and the Structural Timber Association (STA), the STTA invited more than 40 businesses operating in the timber and wood product industry supply chain to meet with MSPs and discuss the critical role it plays in the economy, and its place in supporting the drive to net zero.

The reception was sponsored by Fergus Ewing MSP and Willie Rennie MSP, who each spoke about the benefits of timber as a lowcarbon construction product: how timber planting, processing, and use in construction creates skilled career opportunities and supports employment in rural areas, and how Scottish Government policies on tree planting can support the long-term future of the industry.

Wille Rennie MSP said: “This is an opportunity for parliamentarians to fully understand this important sector, what makes it a success and what government needs to do to allow it to make an even larger contribution to jobs and the economy. There’s been much talk about tree

planting from ministers to tackle climate change and biodiversity which is right, but we also need to understand that for construction purposes we also need to plant the right type of trees in the right numbers and ensure the supply chain and sector is working effectively.”

It is estimated that the built environment is responsible for 40% of the UK’s carbon emissions, and the construction industry contributes 60% of the waste produced in the country. As the UK Government announced its Timber in Construction Roadmap last year to boost UK construction and reduce emissions, timber is identified as the solution to creating high-quality, sustainable homes.

Alex Goodfellow, CEO of Offsite at the Donaldson Group and STA board member, spoke about Scotland’s need to increase the production of timber as global demand grows, and to preserve jobs for the future. These topics also impact the UK more widely. In 2023, the UK Government introduced a target to increase the tree canopy and woodland cover in England to 16.5% by 2050. The increased safe use of timber in construction in England will create an opportunity to increase demand for domestic timber.

Speaking about the event, Alex Goodfellow said: “The reception was the first time the timber industry has gathered at

Holyrood to discuss sustainability and how timber in construction supports the drive to net zero. Scotland excels at timber production, and we lead the UK in the use of timber frame construction, both of which support the country’s economy and sustainability goals. However, more production is needed.

“Global demand for timber is increasing and we predict that based on current production levels, we will be fighting for product by 2050. There is ample scope for increasing productive woodland in Scotland and especially as we promote increased use of timber across the rest of the UK, we have a great opportunity to further support the Scottish economy through the supply of this low carbon construction product.”

Crawford Churchill, STTA president, said: “As timber is increasingly recognised for its structural applications as well as its sustainability, it is important that we continue to advocate for both its production and its use in Scotland. As a low embodied carbon material that can be repaired, reused, and recycled, it has a vital role to play in construction here and across the UK. Bringing the industry together with policymakers at Holyrood in an important step in this process.”

More at www.stta.org.uk

The alternative to creosote, Tanasote® provides long-lasting protection to industrial, high-performance timbers.

The globally trusted wood preservative brand, Tanalith® E is especially suited for external building applications and outdoor timbers, both in ground contact and above the ground.

Metal-free and VOC-free, Tanalith® MF is perfect for sensitive applications and comes with a range of vibrant built-in colour options.

Jacksons Fencing has launched its new and innovative Jaksun™ Solar Fence Panel, providing homeowners with a remarkable garden fence option which not only provides an attractive boundary but produces energy too.

Incorporating conventional solar panels into its structure, this pioneering fence panel transforms outdoor spaces into hubs of green energy production, whilst enhancing visual allure by combining it with Jacksons’ range of appealing timber fence panels. With an impressive 425-watt capability per panel, the Jaksun™ Solar Fence Panel harnesses the power of renewable energy. Homeowners can optimise their energy production by strategically positioning panels in areas with maximum sunlight exposure, such as south-facing locations with minimal shading. Its sleek and pleasing design not only adds elegance to any garden but also offers a substantial return on investment, making it a wise choice for those looking to enhance their property’s appeal and sustainability credentials.

Installation of the Jaksun™ Solar Fence Panel is straightforward, mirroring the simplicity of traditional panel fencing methods. Equipped with solar variants of standard Jakposts, the Jaksun™ Solar Fence Panel seamlessly integrates cabling within its posts and capping rail, ensuring a tidy appearance without compromising on performance.

For connection to the mains electricity network, the expertise of a qualified solar installer is essential. Their proficiency ensures a seamless integration of the solar power system with existing or new electrical infrastructure, ensuring safety and efficiency.

Students at an Ofsted-outstanding construction college have been learning about thermal bridging, airtightness, U and R values – with help from one of the specification team at insulation specialist Actis. Budding builders from Barnsley College Construction Centre were also given a chance to test out one of the Actis Hybrid products as part of the session.

Regional specification manager Amaret Chahal was invited to speak to the 17, 18 and

Crafted with durability in mind, the sturdy construction of the Jaksun™ Solar Fence Panel makes it an ideal choice for eco-conscious homes and Passivhaus developments. Backed by Jacksons Fencing’s 25-year guarantee against rot and insect attack for the timber, and a 25-year product warranty and 25-year linear power output warranty provided by the solar panel manufacturer, customers can invest with confidence, knowing they’re making a lasting contribution to a more sustainable lifestyle.

Peter Jackson, Managing Director of Jacksons Fencing, said: “The introduction of the Jaksun™ Solar Fence Panel marks a significant milestone in our commitment to sustainable innovation. By seamlessly integrating solar technology into the very fabric of our fences, we’re empowering homeowners to make meaningful and sustainable action right in their back gardens.”

19-year-olds courtesy of Louise Wagstaff, a former Actis colleague who now works for Howarth Timber in Wakefield – and is keen to spread the message about the merits of reflective insulation. Amaret’s role was both academic and hands on, with the students reinforcing their learning about energy efficiency before measuring, cutting and installing Actis honeycomb style insulation Hybris into stud walls in the dedicated timber frame workshop.

Amaret, who co-wrote one of the Actis CPD modules explained: “The students already knew about other forms of insulation and wanted to learn about reflective insulation too to broaden their knowledge.

The Construction Centre is excellent and one of only a few in the country with an outstanding Ofsted report. We hope to be able to return during ‘Skill Build Week’ to help the students when they create both a mini timber framed building and a full-size one in their workshop, which will see them develop a structure to meet Passivhaus standards.”

The Barnsley College Construction Centre offers T-levels and apprenticeships in various professions including bricklaying, tiling, plumbing, plastering, joinery, decorating, carpentry and surveying as well as HNDs and HNCs in Modern Methods of Construction (MMC).

More at www.insulation-actis.com

Leading manufacturer of engineered timber components, Donaldson Timber Engineering Ltd (DTE) has promoted Anya Mayor to business systems director, as the business continues to invest in developing talent from within. In her new role, Anya will be responsible for managing the business systems, streamlining processes and sharing best practices within DTE branches, while also taking learnings from her extensive time in the I-joist side of the business into the truss side.

Anya began her career as a graduate trainee at the Wolseley Group, before becoming an I-Joist Designer. Since joining DTE in 2010, she has moved up the ranks from an I-Joist Designer and Design Office Manager to General Manager, before taking on her current role as Business Systems Director.

Anya’s promotion has also enabled five other colleagues to progress, into leadership positions at DTE - Tom Edwards (General Manager), Lauren Murdoch and Tom Pocklington (Assistant General Managers), and Abbie Murphy and Lynsey Fowler (Team Leaders). This reflects DTE’s continued focus on investing in talent and nurturing progression. Anya succeeds Callum Henderson, who has retired after more than 27 years with the business.

Commenting on the appointment, Luke Roberts (managing director) said: “Having worked with Anya in the I-Joist team for over a decade, she has continued to make an impressive contribution to the business. With a diligent approach and strong relationships with customers and colleagues, she is a great asset to the team. I look forward to working with Anya in her new role as we streamline and future-proof the business.”

Anya added: “I am excited to take on this new role to drive growth and further DTE’s outstanding reputation for product quality, service and delivery. Since joining DTE over 14 years ago, I have seen a lot of positive change within the business, and I hope to help continue driving this in my new role. Developing talent from within has always been a key commitment from Luke and the team, and by giving employees the opportunity to try different areas of the business, as I have, we are proud to help colleagues, including women, move up.”

DTE is the UK’s leading and longest-established manufacturer and supplier of roof trusses, open web joists and I-joists, with a regional network of nine branches across the UK.

MDF Recovery, the UK based innovator which has developed proprietary technology to recycle MDF waste, has announced that Rob Elias has joined the company as head of business development within its newly created commercial team. The technology development organisation is transitioning from an intense period of R&D into its commercial growth phase, and Rob’s appointment reflects company ambitions.

Rob will work alongside managing director, Craig Bartlett and head of commercial, Steve Harvey to help provide sustainable technology to those organisations who want to embrace being part of the circular economy. Recovering high-value wood fibres from discarded MDF means organisations can be part of a growing desire to be more environmentally friendly.

Steve Harvey, head of commercial at MDF Recovery said: “In Rob we’ve hired an expert in the science that underpins our proposition to the marketplace – there’s simply no one who knows more about MDF production technology or could be better placed to join the team. As a company looking to license the technology to manufacturers and other organisations, Rob’s knowledge in talking to customers and prospects will be invaluable – he understands their challenges and I’m hugely excited he’s joining the team.”

Rob, with a PhD from Bangor University, Wales, currently directs the institution’s BioComposites Centre, overseeing its management, scientific endeavours, and strategic vision. In collaboration with MDF Recovery, he currently offers technical guidance and contributes to research programs advancing technology – including facilitating MDF Recovery’s demonstration of fibre drying technologies to prospective clients. Previously, Rob worked at Kronospan and later at CSC Forest Products (now West Fraser) in Scotland.

In his new role, Rob will use his vast knowledge of the production processes to help unlock the potential of MDF Recovery’s revolutionary technology for organisations including MDF manufacturers, furniture manufacturers, construction and building companies, retailers and even government agencies.

“I’m thrilled to be joining MDF Recovery and am excited to apply my knowledge and experience gained over many years of collaboration to help further develop and commercialise its innovative fibre recovery technologies,” said Rob Elias. “MDF Recovery is pioneering a more sustainable future for the wood products industry, and I look forward to contributing to continued success.”

The Construction Products Association (CPA) is delighted to welcome Adam Turk, CEO of Siderise Group, as its new chair. With decades of experience across the construction industry, and having supported the CPA for over fifteen years, Adam is well placed to provide both leadership and insight as we move into a new phase for the sector.

The last few years have seen many challenges for the construction industry, from the impacts of COVID to the repercussions of the Russo-Ukraine war and far-reaching implications of the Grenfell Tower tragedy. The CPA has been instrumental in working with the industry and with government bodies to meet these challenges and find solutions, and our outgoing chair, Phil Johns has skilfully guided the Association to navigate these challenges for the last two years. Our heartfelt thanks go with him as he takes a new direction.

Looking forward, the new building safety regime is now fully established in law, and the next two years will bring both challenges and opportunities as the industry gets to grips with the requirements. Adam’s work on the CPA Marketing Integrity Group helped to deliver one of the most important tools the construction product sector has to demonstrate its commitment to this— the Code for Construction Product Information (CCPI).

Speaking at the annual Spring lunch on 25 April, Adam emphasised the need for the industry to get its own house in order. Citing the three

pillars of culture, competence and reliable product information, he called for “a top-down commitment to best practice, producing trustworthy product information and driving competence within our own organisations and the wider construction supply chain.”

Speaking on his appointment, he added: “I am very honoured to have been appointed as the next CPA Chairman. The construction products industry is a great industry. One I am very proud to have been a part of for many years, and one that I am now excited to help lead for what promises to be an interesting period as the building safety regime begins to embed itself. I believe that, with the right focus and application, the construction product industry can get the attention it deserves, and we can create a trusted, successful and financially strong sector of the British economy.”

Peter Caplehorn, Chief Executive of the CPA commented: “Change is inevitable, and the CPA is committed to working with its members, with government and with the wider industry to help ensure that it is driven in the right direction. This role has been ably conducted by Phil during a very challenging time. We now welcome Adam as Phil’s successor, and look forward to seeing how his drive, expertise and integrity will support us in achieving these next steps towards a safer and more sustainable built environment.”

More at www.constructionproducts.org.uk

Scotland’s largest independent specialist timber merchant, MGM Timber, continues to invest in its growth with the launch of a new online service for trade customers, giving them access to their agreed rates, invoicing, and full product range 24 hours a day.

The new platform will have the same functionality as a standard e-commerce site, with a full selection of products on offer, but it will also have individual user logins for trade customers to access the same benefits they would usually gain in-store. From agreed pricing and instant quotes, to finance details like the ability to pay outstanding invoices, it gives tradespeople the opportunity to do their admin outside of normal branch hours.

With decades of experience and strong customer relationships, MGM Timber has committed to adapting to customer feedback, and opening its trade services outside of usual trading hours is something that the business believes will transform the customer experience. As one of the UK’s most advanced e-commerce portals for merchants, it will also have functionality that allows tradespeople to customise their quote documents to be issued to their own customers, and individual project lists will enable them to keep track of all products and costs for multiple projects at one time.

The new and improved website will also have an increased product offering for DIY customers and those without trade accounts, including options to filter by scale to better determine required quantities. MGM Timber is an expert in timber products, supplying both trade customers and the public with a variety of sawn and finished timber. At the centre

of the product offering is a commitment to quality, sustainability, and customer service.

Steve Galbraith, managing director of MGM Timber, said: “Our customer service is one of our greatest strengths at MGM Timber, so we are not aiming to completely replace the in-branch experience for tradespeople. Our branches will still be open for in-person support, as well as by phone, but many of our customers have told us that fitting all their admin into their usual working day is challenging and having the ability to check costs, place orders, and pay invoices in their own time would make their jobs easier.

“We are also conscious that people expect better online services generally, so our new website will also improve the user experience for our DIY customers or anyone shopping without a trade account. We have made the site easier to navigate with clear product specifications, and a better range of deals and discounts. We’ll always be happy to welcome people to one of our 15 branches but we’re building for the future, and we hope this creates efficiencies for our customers and supports a better overall experience.”

Premier Forest Products has announced that its subsidiary, NorthEast Sheets & Panels Ltd. (NESP), will be rebranded as Decorpanel. This strategic move comes as part of Premier Forest’s ongoing commitment to streamline its operations and enhance its brand presence in the northern region of England. Premier Forest acquired NESP in November 2023. NESP is a specialist manufacturer and supplier of kitchen and bathroom cabinets, panels and worktops to contractors, installers and showrooms across the UK.

NESP is based in County Durham, just a short distance away from Decorpanel at Tyne & Wear. Established in 1998, Decorpanel has built a strong reputation as a specialised panel processing business, offering tailor-made solutions to its customers, with a four-acre facility encompassing 76,000ft² of warehouse and factory space, and a team of 63 skilled professionals.

Anthony Hopps, managing director of Decorpanel, said: “We are pleased to unite both companies under the Decorpanel brand. This move represents more than just a change in name; it signifies a strategic synergy of expertise, resources, and capabilities. By integrating the strengths of both NESP and Decorpanel, we are poised to offer our customers an unparalleled level of service and product quality. Together, as Decorpanel, we are committed to driving innovation, exceeding customer expectations, and achieving sustained growth in the timber processing and distribution sector.”

Terry Edgell, co-founder and CEO of Premier Forest Products added: “The rebranding of NESP to Decorpanel underscores our commitment to delivering value to our customers and driving our growth. As part of the Premier Forest family, Decorpanel will continue to uphold its legacy of excellence while benefiting from the collective resources and expertise of our organisation.”

More at www.decorpanel.co.uk

Timber Development UK (TDUK) is partnering with Carrefour International du Bois, the largest timber trade show in Europe, to offer VIP networking opportunities. Under the terms of the partnership TDUK will be offering limited-edition VIP Tickets (free for TDUK members) to the conference, taking place from 28-30 May 2024 in Nantes, France. These VIP Tickets allow members to benefit from special networking opportunities, access to the VIP/Press Lounge with free coffee and soft drinks, and an invitation to the closing Gala Drinks Networking event.

Speaking about the partnership, TDUK CEO David Hopkins, said: “We’re very pleased to be partnering with Carrefour International du Bois this year. Europe is the UK’s main source of supply for all timber products and Carrefour attracts the widest range of companies covering all product bases. TDUK acts as a window into the UK market for overseas suppliers, so we are looking forward to the networking opportunities this brings to both sides. These relationships are crucial, and we look forward to seeing many members there.”

well as a new publication from TDUK, Timber Policy, a comparative study of policies across Europe which aim to encourage a greater use of timber in construction.

David will be a key speaker at the Carrefour International du Bois session “Timber Architecture and Global Trends” on Tuesday 29 May alongside speakers from across France. During the session he will outline of the UK Government’s Timber in Construction Roadmap as

Carrefour du Bois is the largest timber trade show in Europe, bringing together hundreds of exhibitors and thousands of international visitors over three days in Nantes, France from 28-30 May 2024.

A packed audience of Trussed Rafter Association (TRA) members gathered recently to see who would win the hotly contested Roofscape Design Awards 2024. The Awards, now in their second year, celebrate the highly technical skills required to design trussed rafter roofs, joists, and panels. The awards took place at the TRA Annual General Meeting and Conference at Mercure Warwickshire Walton Hall Hotel & Spa. The awards were given in three categories:

• Residential Project of the Year (for newbuild dwellings)

• Conversion and Refurbishment Project of the Year (for existing housing projects)

• Commercial Project of the Year (for all non-domestic projects)

The judging panel included Nick Boulton, Chief Executive of the TRA, Rob Lockey (former Head of Training at the NHBC) and Les Fuller, Chair of the Technical Committee of the TRA. In the Residential Project of the Year

went to designer Phil Morgan of Wyckham Blackwell Ltd for – The Copper House project. The judges were impressed with the extensive knowledge of the architectural requirements of the designer and how the design applied a trussed rafter application and ensured that the ‘form did follow the function’.

Wyckham Blackwell Ltd also took home the award for the Conversion and Refurbishment Project of the Year with The Black Country Living Museum, designed by Joe Dudley. The judges agreed that it was an example of how to successfully comply with client and historical requirements and still achieve suitable timber engineering for a project.

For the Commercial Project of the Year, it was a unanimous decision that Acorn Timber Engineering’s Welton Extra Care Apartments and Bungalows designed by Simon Copley was the winner for the category. The project started with suppling metal web joists to ending up tendering for the entire roof structure of the main apartment building and ten individual bungalows - resulting in almost

3,500sq m of the roof surface and 2,500 manufactured items.

The highly commended design was awarded to DWB Roof Truss Ltd’s Phil Daniels for the Sianwood project. Judges were impressed by the application of Posi-Joists in ensuring a prefabricated design solution for the project that was creatively achieved.

Nick Boulton said: “The trussed rafter industry is keen to highlight the problemsolving and design skills required in such an important element of the roofing system in construction projects. Thank you to all the designers who have entered the awards this year, it was very fascinating to see the creativity and technical expertise in all the designs that were submitted. I would like to congratulate all those who took part, particularly the winners of this year’s Awards and look forward to watching your continued success in the industry. The Roofscape Design Awards will be returning in 2025.”

More at www.tra.org.uk

Building products supplier and high-performing homes specialist Green Building Store has announced a full rebrand to 21°, in line with its refreshed vision and common purpose: to help customers create healthy and comfortable homes through optimising energy performance.

The rebrand took full effect from 21 March 2024, with a fresh new website and the updating of its digital channels. The business’ signage, vehicle fleet, and other collateral went live with the updated brand on 21 February and has been received extremely well by customers and other stakeholders.

While the firm’s people, products, and services remain the same, 21° will look to focus on its offering of solutions that provide for life changing homes. This method consists of incorporating a core range of products and services — including triple glazed windows and doors to MVHR among others — that serve to make a property as airtight as possible.

This approach has the effect of reducing draughts and promoting air that’s free from outdoor pollutants, as well as maintaining an ambient temperature within the property all year round — with the added benefit of ensuring that the building is ultra-low energy.

Andy Mitchell, managing director at 21° commented: “We’re thrilled to announce the rebrand of Green Building Store to 21°. While our customers will be able to enjoy the same exceptional service and expertise, they’ve relied on for almost 30 years, we’re excited to have our vision for the future reflected in our brand and communications.

And while we’ll continue to offer advice and guidance for obtaining Passivhaus certification, we’ll also support those not able or looking to achieve full accreditation, but who still want to create a home that’s designed with wellbeing at the forefront.”

When it comes to planning for a high-performing home, Luke Gilman, windows department manager at 21° advised, “When looking to create an enjoyable home environment, we must consider radiant heat — meaning the warmth or coolness of the surfaces around us — rather than the air temperature itself. As humans, we’re much more sensitive to this type of heat, and our perception of comfort is affected more by the internal surface temperatures that surround us.

Tom Heywood, 21°’ MVHR department manager, added, “To create a healthy environment, air quality is central to the equation — managing the pollutants within is the key to wellbeing. By utilising Mechanical Ventilation with Heat Recovery (MVHR), you can ensure a good ventilation rate, replacing the indoor impure air with fresh air from outdoors, filtering out any pollutants before it enters the home. This also has the added benefit of ensuring humidity levels are kept within healthy limits of 40-60%, stopping condensation buildup and preventing mould, therefore positively impacting health.”

BSW Group has appointed Gavin McLaughlin as head of ESG (Environmental, Social and Governance) across the group’s stable of brands. A component of BSW’s long-term commitment to responsible and sustainable business practices, this new role aims to create lasting and purposeful change for the business and wider forestry industry..

Gavin has worked in the environmental sector for over 16 years at a variety of companies operating in very different parts of the supply chain. Having gone on to join BSW as environmental manager in 2022, his breadth of experience makes him uniquely suited to the task of creating and implementing initiatives that will unite the wide range of companies in BSW’s brand stable, bringing them together with a shared purpose and commitment.

As part of his duties, Gavin will chair BSW’s ESG Governance Committee, working to drive forward ESG at the timber group, supporting the various teams to achieve targets across the UK. Gavin will also work to develop a comprehensive ESG strategy that will provide a detailed programme to tackle key elements around environmental and social impact, as well as how governance structures are managed within BSW.

Gavin McLaughlin, head of ESG at BSW Group said: “I am delighted to be moving into this role. BSW is unique in its position as a fully contained forestry ecosystem, where each step of the supply chain seamlessly leads into the next. This offers us unprecedented opportunities to create systems and efficiencies that allow us to make the most of every natural resource, piece of machinery

and by-product throughout the timber process. We are committed to building longterm, sustainable businesses, which will grow, provide employment, and generate economic benefit in an environmentally and socially responsible manner.”

More at www.thebswgroup.co.uk

The UK Government recognised timber’s place in the route to sustainable projects by setting out its groundbreaking Timber in Construction Roadmap in December. With full support of the initiative, aimed at aiding supply, Nine Zero Timber Windows and Doors has gone one step further in setting out its commitment to reducing carbon emissions, by detailing to customers the eco-centric decisions and practices it has in place.

Nine Zero manufactures and supplies FSC-certified timber windows and doors with an unrivalled 6-8 week lead time to meet every project demand. Three day-to-day processes demonstrate Nine Zero’s overarching sustainability goals: recycling timber waste, providing renewable energy to local homes, and selecting an eco-responsible energy supplier.

Nine Zero products are made in the UK, and an intrinsic part of the manufacturing process is ensuring all waste produced is appropriately reused. Partnering with farms

local to its Cornwall workshop, Nine Zero supplies timber waste for animal bedding and composting, reducing landfill contributions and supporting the agricultural community.

Since its launch in 2017, Nine Zero has taken strides towards sustainability. By converting the energy generated from recyclable materials into renewable energy, the company supplies power to local homes, reducing the UK’s reliance on fossil fuels. Nine Zero has also chosen to partner with green energy supplier, Pozitive Energy, strengthening the business’ ownership and accountability in taking action against climate change.

“It’s reassuring to see the government setting out a clear roadmap to increase timber supply, which is so needed to reach our sustainability goals, both in construction and globally,” says Steve Winscott, company director at Nine Zero. We have always taken a proactive approach to reducing our carbon footprint at Nine Zero, and I think it’s

important that manufacturers look at their own processes to see how they can drive this down. It may feel like a ‘small act’ here and there, but these small acts, when multiplied by millions, will lead to significant change.”

SAM, the market leader in the manufacture of MDF mouldings celebrated outstanding success at the recent STARK UK Supplier Awards Dinner held in Birmingham. SAM clinched two prestigious accolades – the Overall Supplier of the Year Award and Supply Chain Award, marking an unprecedented back-to-back victory in the former category.

For the prestigious Overall Supplier of the Year Award, Mark Esling, CCO STARK Building Materials UK praised SAM’s excellence in their partnership, saying: “SAM Mouldings has truly gone above and beyond in every aspect of their partnership with us. It’s not just about providing exceptional products—it’s about embodying our values, exceeding our expectations, and consistently delivering excellence in every interaction. They delivered excellent service, at all levels of the organisation, with a collaborative approach that demonstrates their commitment to true partnership.”

The Supply Chain Award was awarded to SAM for its proactive and innovative approach to enhancing service delivery. Mark Esling added: “SAM Mouldings consistently goes above and beyond to improve the service we provide to our customer base. They demonstrated an unwavering commitment to partnership and collaboration, improving load flexibility, delivery options and simplified pricing, amongst others. They proactively undertook a range review, offering solutions to improve our stock turn. SAM continue to offer exceptional service to all parts of the STARK UK business.”

Sam McCrea, CEO at SAM, expressed immense pride in the team’s accomplishments: “Winning these awards, especially Overall Supplier of the Year for the second consecutive year, is a momentous achievement for

us and one we are extremely proud of. It not only reflects the hard work and dedication of our entire team but reflects the fantastic partnership we have built with STARK UK, who continue to put their trust in us year after year.” SAM recently announced a significant £7million investment aimed at enhancing product quality, expanding stock range, and improving logistics. This investment underscores the company’s dedication to providing superior service and maintaining their industry-leading position.

Pictured (L-R): John Carter, CEO, STARK Building Materials UK, Paul Lavery, joint managing director, SAM, Cat McCrea, joint managing director, SAM, Søren P. Olesen, CEO, STARK Group, Gerard Wilson, sales director, SAM, Martin Cunliffe, senior category manager, STARK Building Materials UK, Lisa Lynch, head of internal sales and marketing, SAM and Mark Esling, chief commercial officer at STARK Building Materials UK.

More at www.samonline.co.uk

The Bourdonnières School in Nantes, France becomes the first project completed using Stora Enso’s automated coating line for cross-laminated timber (CLT). The production line is levelling up the protection for mass timber against moisture, UV radiation and insects.

The 2,150sq m school, designed by forma6, was constructed by making use of Stora Enso’s prefabricated kit of parts – Sylva™ by Stora Enso. For the first time ever, these parts were automatically precoated with hydrophobic protection against moisture in the new fully automated production line at the Stora Enso mill in Ybbs, Austria, that is up and running since the beginning of this year. Coatings are applied as part of the prefabrication of the components and help streamline onsite construction, protect the mass timber elements as well as increase the speed of the project. A shorter installation time – an advantage for mass timber elements in general – meant less noise pollution and traffic in and around the school area.

The school’s façade is designed with recycled materials and certified bio-based wood fibre insulation in addition to sustainable and reusable wood. In the space developed using Sylva™ CLT Floors, Roofs and Walls a total of 230 students will be attending classes, spread across two levels. The building features excellent indoor air quality – vital for children’s lungs –, biophilic design, and high acoustic performance, all contributing to an excellent learning environment for both children and teachers.

Timber specialist OBM explained that the City of Nantes faced an urgent need for new sustainably built schools in the area. Stora

Enso’s range of prefabricated wood-based applications coated with hydrophobic protection, that shortened the construction time, was the perfect solution to meet those needs.”

Kim Ekberg, product manager at Stora Enso commented: “For the construction of the Bourdonnières school we were working on a very tight timeframe and had several constraints at the site itself. For example, we knew that we would have to leave the elements exposed on-site for a period of time, which can be a risk due to the weather. Our hydrophobic coating from our new coating line combats this risk by protecting the wood from absorbing moisture and making it easier to keep the surfaces clean from dirt.”

This first project completion follows Stora Enso’s initial investment of EUR 9 million in 2022 to develop this new state-of-the-art automated coating line at the Ybbs sawmill in Austria, which continues to serve the global market. The line offers coatings to protect Sylva CLT elements from moisture, UV damage and / or insects and additionally allows for a visually enhanced surface with several grades of white. The industrial application delivers shorter construction times as well as improved quality through prefabrication and quality control.

The Wood Products division is Europe’s largest sawn timber producer and a leading provider of sustainable wood-based solutions for the global construction industry. Additionally, it offers window and door components, and co-products such as pellets made from wood residuals.

More at www.storaenso.com/woodproducts

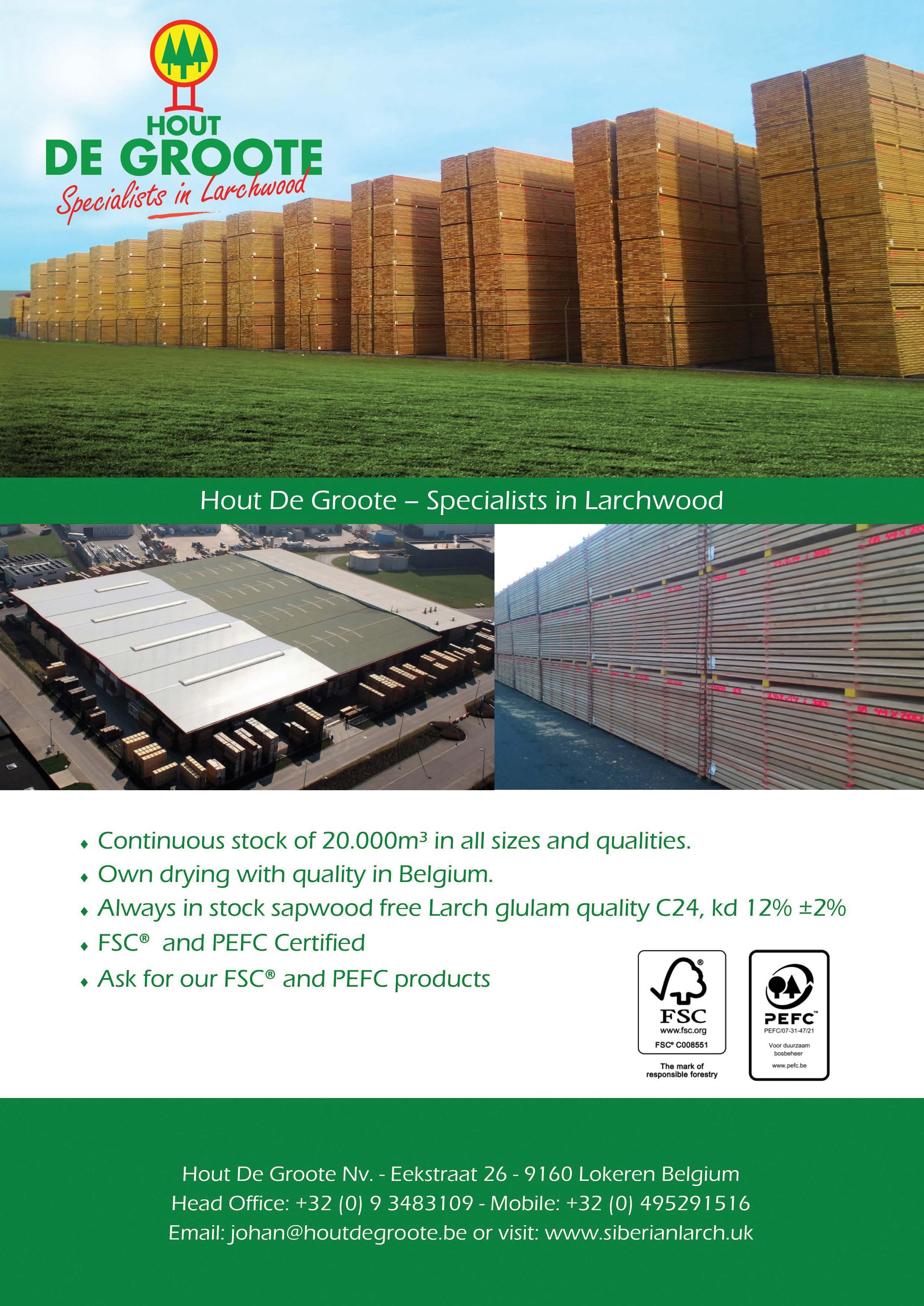

Falls in softwood, hardwood and plywood imports account for a 6% drop in volumes during January 2024, despite 2023’s figures finishing just 2% down on the previous 12 months, according to the latest TDUK statistics.

Timber import volumes started 2024 around 6% lower in January than the market saw in January 2023, down by around 45,000m3. Softwood, hardwood and plywood imports were all lower than in January 2023, but particleboard, engineered wood, OSB and MDF products all saw imports increase slightly.

This is despite the volumes of the main imported timber and panel products ending 2023 just 2.2% down on the previous 12 months after rallying towards the end of the year. In fact, despite the challenging end to 2023 seen across the construction sector, timber import volumes for the year were actually higher in three of the six product groups.

After a slow start, softwood imports gained impetus in the second half of the year, finishing 2023 1% higher. Hardwood, plywood, particleboard and engineered wood product imports were all lower in 2023, but OSB volumes were significantly higher (up 19.4%) and MDF volumes were 2.2% higher than in 2022.

Crucially, 2023 saw greater stability return to the market, with substantially less volatility in imports compared to each of the four quarters of 2020, 2021 and 2022, during which time the timber market fluctuated significantly.

TDUK’s head of technical and trade, Nick Boulton said: “The ability of timber products to weather the instability and adverse influences of the first three years of the 2020’s and emerge with virtually all products

remaining on a positive growth path is a testament to the strength and resilience of the UK timber industry.”

Breaking the January 2024 import figures down by timber product type, softwoods saw a 9.6% drop during the month, with import values also 15% lower in January 2024 than they were in January 2023. This was caused by the volume decline, coupled with a 5.6% fall in the average price of a basket of softwood products, down from £256m3 to £241m3

Hardwood imports experienced a 13.8% fall, largely due to tropical hardwood imports being down by around 3,000m3. There were signs of growth, however. Volumes of

temperate hardwoods increased 2% and, while overall plywood imports were also down 6%, hardwood plywood volumes rose 36%.

Particleboard imports grew 3.4% growth, while OSB and MDF imports were up 6% and 4.1% respectively. Finally, 12.8% growth in engineered wood product import volumes rounds out the varied January 2024 results.

The slight fall in timber import figures seen in January 2024 might be disappointing, but Nick has warned the industry not to be discouraged at this early stage, saying: “It’s always very difficult to accurately assess

import and export trends at the start of a year, because with just one month’s data available, small changes from last year can result in significant shifts in performance. A truer reflection of the sector’s product performance will be visible when the Q1 figures are available, but the 6% reduction we’ve seen in January’s figures does confirm the greater stability in the market when compared to the high increases and decreases experienced from 2020 to the end of 2022.

“We also need to bear in mind the latest housing start data, which indicates that while

“The ability of timber products to weather the instability and adverse influences of the first three years of the 2020’s and emerge with virtually all products remaining on a positive growth path is a testament to the strength and resilience of the UK timber industry.”

Nick Boulton, TDUK head of technical and trade

housing starts and completions held up well in 2021 and 2022, data for the full 2023 year is likely to be substantially lower once it is made available. Housing starts in England during Q4 2023, for example, were 51% below Q4 2022, on the back of a similar 52% reduction in Q3 2023 over Q3 2022. Given the importance of the newbuild housing sector to the timber industry, this is likely to indicate we can expect continuing challenges in the short term, and likely until after the coming General Election.

“However, despite the volatility of recent years and the subdued start to 2024, the longer-term trend of UK timber and panel product imports remains upward, and the government’s renewed focus on timber as a core construction material suggests that the future continues to look brighter.”

TDUK members can sign in and read the full report, as well as viewing regular monthly import statistics at www.timberdevelopment.uk

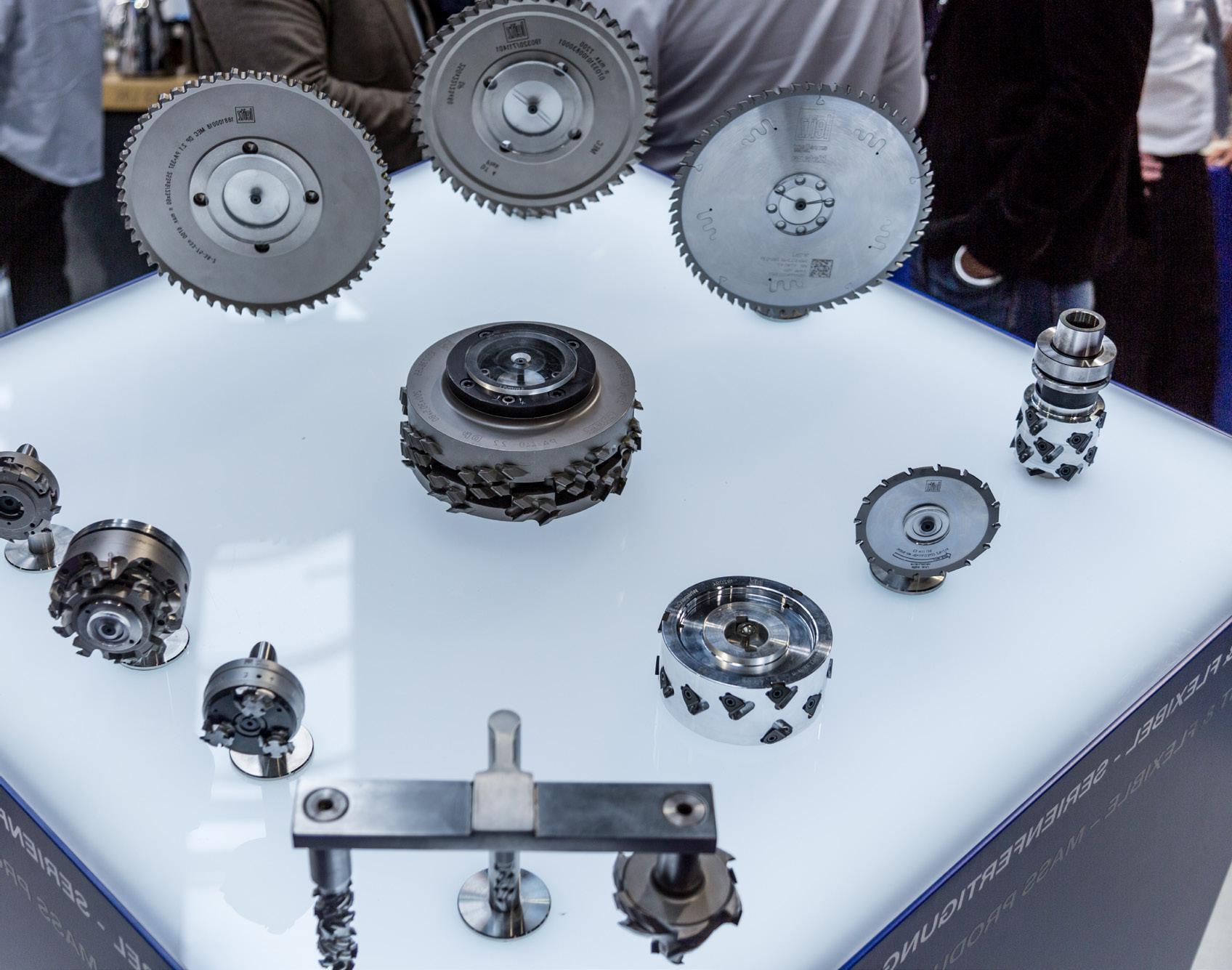

SLocal Exhaust Ventilation (LEV) specialist Extractly Limited is installing the extraction system to handle dust and wood waste from machinery operating in the Demo Zone at the Materials & Finishes Show.

ince Ecogate® was first launched in the UK, at the W-10 exhibition, the benefits of this energy-saving technology have continued to receive critical acclaim but today – with industry having been subjected to unprecedented rises in energy costs – it’s relevance to manufacturers in 2024 is more significant than ever before.

William Kenyon, Technical Director at Extractly Limited, puts forward a compelling argument for the energy-saving Ecogate® system, saying: “Many joinery manufacturers and sawmill owners are having to deal with huge increases in the cost of electricity to power their dust extraction fans. The good news though, whatever your electricity bill is today, an Ecogate® installation can reduce by half the amount of energy consumed by a typical extraction system, which means you’ll be saving at least 50% off your electricity bill from day one.”

Come and see us on Stand K31 at The Materials and Finishes Show where we will be presenting an interactive demonstration of the latest in Ecogate® ‘on-demand’ extraction technology – the energy-saving system which can significantly reduce your extraction running costs.

Central to any Ecogate® installation is the greenBOX controller, and the greenBOX Nxt is truly the ‘next generation’ of Ecogate® controllers. Suitable for all industrial dust and fume extraction systems, this highly intelligent controller has the capacity to efficiently control the operation of an extraction system with multiple main fans and up to 72 individual workstations.

As well as controlling the extraction system, the Ecogate® greenBOX Nxt will monitor machine utilisation across the entire factory and continuously display real-time performance data to show how much electricity the fan motor is consuming. The greenBOX Nxt can also stop and start the extraction system automatically at both ends of the working day – system performance is checked at start-up and can be confirmed by text or email – and at the end of the day, greenBOX

Nxt will message again to confirm successful system shutdown. The greenBOX Nxt also monitors and reports on air volume data, fan and filter pressures, fan power and, of course, energy savings.

“In short,” adds William Kenyon, “If you’re still running extraction fans at full power, all day every day, installing Ecogate® is simply a ‘no-brainer’ – the typical payback period on your capital investment is generally less than two years and, after that, it’s just half price electricity.”

More at www.extractly.co.uk www.ecogate.co.uk

Ambitions to challenge the largest timber suppliers in the UK have taken a leap forward for Scandinavian timber group Moelven with the launch of a new saw line at Moelven Valåsen located in Karlskoga, Sweden.

mbitions to challenge the largest timber suppliers in the UK have taken a leap forward for Scandinavian timber group Moelven with the launch of a new saw line at Moelven Valåsen located in Karlskoga, Sweden.

With supply chain issues in Finland and the devastating situation in Ukraine, this represents a source of high quality timber from one of the most respected Scandinavian wood processing companies. Providing a ‘one-stop-shop’ Moelven offers only PEFC and FSC certified sustainable timber from Norwegian and Swedish forests.

The future is built with wood

“For more than 100 years, sustainability and a deep understanding of the market has been crucial to our competitiveness,” says Pehr Eriksson, Managing Director for Moelven. “Our research shows that our existing and potential customers want more planed products. We now have our own planer connected to the sawmill, so that we can ensure the supply of both sawn and planed wood products from Moelven Valåsen. Our

EOver the past 20 years, leading operational excellence consultancy, TXM Lean Solutions have worked with around 50 joinery and woodworking companies around the world and have identified five key tips to help your company get the most out of your factory team and deliver quality products.

veryone knows that ‘lean thinking’ originated in the automotive industry. What does a system of manufacturing developed for making cars on assembly lines have to do with manufacturing doors, windows, cabinetry, staircases, furniture, and other wood products?

There are lots of measures that you can apply to joinery, but improving one measure can have more impact than others – that is the lead time from receiving raw materials to shipping finished quality product to your customer. Lead time matters in so many ways.

Firstly, cash flow is a critical challenge for suppliers to the construction industry. Every uncompleted job on your floor is money you have invested for which you have not had a return. If you can turn jobs around faster, then you can turn your cash around faster and have more money in the bank rather than sitting on the shop floor.

Secondly, lead time is also space. Joinery and woodworking products are usually bulky. The longer your lead time, the more jobs you have in progress and the more space they take. Space costs money in terms of bigger buildings and more rent. Also, more space

means more double handling of jobs, wasting labour and increasing the chance that a job will get damaged.

Thirdly, lead time means flexibility. Builders are notorious for changing delivery dates. The longer it takes you to make a job, the earlier you must start it and the greater chance that the builder’s predicted delivery date will have slipped, and you will have to hold the finished job. Start by measuring the lead time on each job and understand where jobs are held up and what key improvements need to be made to overcome those bottlenecks.

Like many manufacturing processes – in woodworking the fastest processes are often the first processes completed. Cutting material to the required size and shape on a beam saw or CNC router is a fast process, whereas downstream processes such as assembly are often slow manual activities. Many businesses focus on keeping their expensive key machines running continuously and their key measure is the number of boards processed. However, in most cases the customer is buying finished products – not just boards – and the CNC machines are rarely the bottleneck. Therefore, all pushing production through your CNC machines does, is cause jobs

to build up behind the real bottleneck, which is usually finishing and assembly. This build-up of jobs is usually a key driver of lead time – your most important metric.

Whether you are making cabinetry, windows, doors, staircases or custom beams, most woodworking businesses make a product customised to customer needs. This means that jobs must be individually designed, drawn and programmed prior to manufacture. Your designers (sometimes called technical detailers) may sit in an office and work behind a computer screen, but they are as much a part of the production process as a joiner working on a carpentry bench. We frequently find woodworking businesses where the design office is the major bottleneck. It is surprising that most businesses don’t measure throughput, lead time or quality in their design office and even fewer focus on working with the designers to improve these metrics. Often improving lead time or throughput in the design office can be achieved with simple changes and at a fraction of the cost of changes in the factory. Your design team is critical to the performance of your factory and their daily performance needs as much focus and support as any other part of the factory.

Making custom wood products is complex. A huge amount of information needs to be transferred accurately and completely through the end-to-end process, if the customer is to get exactly what they want in terms of features, dimensions, finishes and performance. Too often woodworking companies deliver their products to site to find that the original site measurements were wrong, finishes are not exactly as specified, or defects and damage are visible on the product. Quality cannot be achieved by inspection at the end of the process. While this is necessary, true quality needs to be achieved by getting information complete and accurate and product right first time at every step of the process. This starts with the initial sales and quoting process, goes through design and every step of manufacturing to delivery and installation.

Start measuring the cost of defects in your business. How many hours are spent returning to site correcting or reworking jobs and how many parts and products are scrapped? The numbers are likely to shock you. Improving quality starts by measuring performance all the way through the process, from the completeness and accuracy of information collected from the customer by sales, to the accuracy and readability of drawings

and work instructions, to the number of parts and products damaged in production or transport. Each defect or error you find, should be seen as an opportunity to learn and improve your process rather than to “find the guilty.” Over time the combination of measuring defects and errors and fixing their root causes will lead to higher quality, quicker trouble-free installations, and lower costs.

Most people believe that woodworking shops are naturally dirty, dusty places. All those saws kicking up plumes of woodchips and sanders creating clouds of dust. However, the customer expects a pristine product delivered to their home or office and employees do not want to work in a mess. With modern extraction systems and good housekeeping disciplines, having a messy shop is not necessary. In fact, poor cleanliness often masks poor condition of machines which leads to breakdowns.

A disorganised workplace is also rarely safe or efficient. Tools, materials, and consumables are lost damaged and wasted and never to be found

where they are needed, when they are needed, leading to endless labour wasted “looking for things.” Practical ‘5S’ is a methodology for organising and standardising a workplace. It sets a standard for how the workshop should look and establishes controls and accountabilities to make sure that these standards are maintained and progressively improved. It is cheap to implement and a great way to engage your team in improving their workplace.

One of the biggest sources of mess and clutter in many woodworking shops – offcuts are a product of every woodworking process. Few designs can use exactly a full length of timber or a full sheet of board every time. As a result, large pieces of valuable materials are often left behind in the production of a job. Few business owners like simply throwing away offcuts (even though most will cost the full sheet or length into the job). The offcut is then simply put to one side in the hope it will be used later. We have seen woodworking businesses with literally decades of offcuts piled up around the walls of the factory.

To manage offcuts, first decide which offcuts you are most likely to use. For example, is there a minimum length or minimum sheet size that you are likely to use? Pieces smaller than that can be discarded immediately. Then sort the offcuts by size and type so that they are easily accessed. Next put a limit on how much you will hold (perhaps by limiting the size of the rack). Finally, consider ways to encourage your team to use the offcuts. By presenting the offcuts in an accessible way, only saving usable pieces and encouraging your team to use them, you will find you will throw out less and discover space you never knew you have. These ideas are just a start but will hopefully get you thinking about how a practical approach to ‘lean’ combined with an understanding of your industry can make a real difference.

As a timber merchant undertaking successful expansion and development plans, we spoke to James Beesley, commercial director at Beesley & Fildes, about the shape of the sector and what progress to expect in 2024.

Afamily builder’s merchant business with a 200-year heritage, Beesley & Fildes combines 11 branch locations with a team of in-house product specialists supporting customers and acting as a supply chain partner to all construction trades.

“We have a strong presence across the North West as well as national reach through online orders,” says James. “Timber has always been a core part of this offer and accounts for circa 30% of our business. To meet individual requirements, we seek to regularly update our range and provide customised solutions for many timber projects. Timber carcassing, redwood and plywood are the most popular products for the construction sector along with our engineered timber services for roof and floor build ups.”

With an extensive product range, the business has adopted a proactive strategy, which despite market challenges, has seen them continually invest in its facilities. “In 2022, we ploughed £1.2million into our timber mill in Widnes to create more efficiency and throughput for timber stock items as well as bespoke orders from our branches and customers,” says James. “Last year, we invested £300,000 in a new timber treatment plant at our Chester branch enabling us to treat timbers in green and brown from this site while tripling output.

“Timber for decking, fencing and posts can all be treated at the plant which uses pressure to reach the centre of the wood to preserve it. A blend of copper and organic co-biocides is used in the process to ensure long-lasting protection against wood decay and pests. As well

as the treatment area, the new plant comprises a secure storage facility and is fully bunded throughout to maximise health and safety.

“With no need for manual equipment, up to 38 cubic metres of timber can be treated per day. Thanks to new technology, drying time, which previously could take between 24 and 48 hours, has also been reduced so treated timber can be collected on the same day. Our engineered timber products, which are designed and manufactured at our Widnes branch, also help to set us apart. These include bespoke roof trusses available as a complete package as well as i-Beams and Posi-Joists.”

An e-commerce approach is so important with a cutting-edge digital shop front playing a central part in the customer experience. “Our website is an essential tool,” adds James. “If a customer chooses to buy a timber product from our website, we want the process to be as quick and simple as possible. We have invested in lots of improvements to make the website more user friendly and ensure it meets customers’ changing needs. This includes adding more product information to ensure transactions can be completed seamlessly, without the need to call the branch to ask questions. Most recently, this has seen us add tally sheets next to timber products which show the length options, how much stock is available for each, and the price.”

Further key concerns for all businesses surround sustainability. For timber merchants this doesn’t just mean sourcing certified timber but wider issues including electric vehicles and energy efficiency. “Our timber products are certified to FSC and PEFC standards.

“Merchants

must look forward rather than focusing on the hurdles of the past year or so. Times have been tough but staying proactive will pay dividends for merchants in the future, ensuring we can meet customers’ changing needs and are in strong position to take advantage of new opportunities.”

These certifications form part of a much wider sustainability strategy which has been evolving for several years,” says James. “As our company and our footprint have grown, so has our focus on green initiatives. One of our first and most significant measures was implemented in 2017 when we invested in a £500,000 biomass plant at our Widnes branch. Previously, pallets and offcuts would be put into several skips every week and taken to landfill. Now, the waste timber is chipped and sent directly into a storage area for the biomass fuel.

James Beesley, commercial director at Beesley & Fildes

“This enables our plant to generate enough energy to provide heating and hot water for all six departments at the branch. In the summer, the chippings are stored for extra fuel in the winter or if we need more energy at other points in the year. To further reduce our carbon footprint, we installed 600 solar panels at the Widnes branch last year, which are on track to save 49 tonnes of CO2 annually – the equivalent to 9,378 trees and more than 1,000 long-haul flights.

“In terms of transport, we have invested £3million in a new fleet of DAF trucks with lower emissions and which comply with the Government’s legal requirement to reduce nitrogen dioxide levels on local roads by 2026. We have also purchased two electric cars as well as six hybrid models for sales representatives and managers who need to travel regularly. A further six hybrid models will join the fleet later this year.”

The UK timber market faced many challenges throughout 2023 with prices rising throughout 2022 and started falling in early 2023 – but this has created problems. “As the price of timber dropped, merchants were left with the unenviable task of having to devalue their stock,” says James. “The impact of high interest and mortgage rates also put the brakes on newbuild housing which has had a knock-on effect on timber orders. This has required a tricky balancing act to ensure there is sufficient stock to meet customers’ demands without the risk of significantly reducing margins or losing money.

“These pressures have inevitably resulted in some timber merchants shutting their doors. But rather than cutting back, we have

remained proactive with an eye on the future and opportunities for growth. This strategy was the driver behind us acquiring stock from Silva Timber which went into administration in October 2023. The deal added a specialist timber range to our portfolio, including external cladding, coated wood, hardwood decking, slatted screen fencing and cedar shingles.”

Against a backdrop of ongoing economic uncertainty, there is room for optimism across the timber merchant industry. The Government’s recently released Timber in Construction Policy Roadmap aims to boost timber use in construction to help reduce emissions and reach net zero. This includes promoting the safe, sustainable use of timber as a construction material in homes and other buildings. How does James see the wider timber and merchant sector developing in 2024 and beyond?

“Although the past 18 months have been challenging, I think the timber market is now at a point where the only way is up,” says James. “Prices are beginning to stabilise, the demand for renovation is holding its own and there are signals that private housebuilding is on the rise in regional markets. As trading conditions continue to change for the better, a willingness to adapt will be key both in terms of timber product portfolios and services. Merchants must look forward rather than focusing on the hurdles of the past year or so. Times have been tough but staying proactive will pay dividends for merchants in the future, ensuring we can meet customers’ changing needs and are in strong position to take advantage of new opportunities.”

More at www.beesleyandfildes.co.uk

Muir Construction has officially completed a state-of-the-art innovation hub for Scotland’s Rural College (SRUC), Inverness and was recently opened by HRH The Princess Royal.

The all-new Rural and Veterinary Innovation Centre (RAVIC) is located at the Highlands and Islands Enterprise (HIE) Inverness Campus – which forms the heart of the Scottish Highlands’ thriving bioscience sector. The building was designed by Threesixty Architecture, Narro Associates and Rybka, and project managed by Currie & Brown, assisted by cost consultants Thomson Gray, who all collaborated closely with Muir Construction throughout the delivery of the project.

Enhancing energy-efficiency, Muir Construction worked closely with the centre’s designers and structural engineers to incorporate a number of passive design measures throughout. The structure has been designed using hybrid mass timber and steel frame, with bespoke insulated timber components with fire protective qualities manufactured by Muir Construction’s sister company – Muir Timber Systems – exceeding strict building standards and complementing the raw, natural feel of the building’s interior.

“High sustainability targets and our people first approach, combined with strong concepts informed the design of this project to successfully create an all-encompassing space in which academia, research and development can thrive together,” said Richard Scott, project architect at Threesixty Architecture. “Working collaboratively with Muir Construction, Muir Timber Systems, SRUC and all our

partners, we’re excited to see this ambitious vision come to life and we’re confident it provides a dynamic collaborative space for everyone to enjoy. Collaborating with both Muir Construction and Muir Timber Systems was a key factor in creating such a truly unique building that will play a significant role in SRUC’s future.”

The new facility provides a modern knowledge ‘cauldron’ to enhance collaborative learning and development. This offers an exciting and inspiring space in which academia, business and research and

development can come together to drive forward the latest industry innovations. This also supports the growth of Scotland’s life sciences sector on a global scale.

SRUC teams based in Inverness, including consultants, researchers and members of Vet Services, will all be located at the facility with a key focus on animal health, infectious disease control and zoonotic disease research. It will also build key connections in human health through close collaboration with NHS Highland and University of the Highlands and Islands. The centre is also set to bring a number of economic benefits to the wider community, using technology and big data expertise to create new jobs and support new and existing businesses in the industry.

Patrick Reel, managing director of Muir Construction, says: “The requirements for the centre provided a great opportunity to bring several of our divisions at Muir together, to not only build the exceptional facility, but also create bespoke high performance timber panelling that creates a distinctive feature throughout.

“Using building materials with lower embodied carbon and working with the design team to create a space that uses less energy, we have created a building that is truly sustainable. This exciting building will play a major role in bringing local organisations together. It provides a high-quality facility which will make a great impact across the country’s science industry for years to come.”

With distinctive cladding around its exterior, the building’s one-of-a-kind 11,450sq ft design is centred around a vibrant atrium. This brings all aspects of the facility together to encourage social interaction, and focuses on the use of height, colour and natural materials. Full height glazing maximises daylight and creates a welcoming environment for visitors.

The structure has been designed using hybrid mass timber and steel frame, with bespoke insulated timber components with fire protective qualities.

The building comprises superb new lecture, workshop and community events spaces. These are designed to enhance knowledge sharing by facilitating industry talks, presentations and showcasing of the latest innovations. A necropsy suite for wildlife, main office areas and high-quality laboratory spaces located in ‘The Blue Jewel’ – recognised through its rich colour and spacious surroundings - have also been incorporated to support the development of new products and services, as well as industry-focused research.

Martin Smith, CEO of Muir Group, said: “We’re thrilled to have played a key role in bringing this new, exciting bioscience facility to Scotland. The project had an extremely unique brief and we’re delighted to have gone above and beyond to exceed our client’s expectations. Seeing HRH The Princess Royal open this facility

demonstrates just how important this new building will be for the Highlands.

SRUC principal and chief executive Wayne Powell added: “We are delighted with our state-of-the-art Rural and Veterinary Innovation Centre, which will enable us to build new links between science and industry to help address planetary health challenges and grow the natural economy. Sustainability is at the heart of everything we do and was central to the building’s design, reflecting SRUC’s commitment to preserving natural resources.”

More at www.muirtimbersystems.co.uk

Due to popular demand, we are increasing capacity by 25% – more networking for you!

Enhanced marketing campaign – a 15% increase in the marketing budget –greater profile for you!

The offsite timber construction industry has undergone notable evolution, marked by significant progress and a commitment to a more productive and innovative future.

Videographer –more post-event profile for you!

The Structural Timber Awards serve as a prominent platform to showcase excellence within this dynamic sector, providing an opportunity to position your brand alongside influencers and pioneers.

Champagne on every table – now that’s the way to celebrate our 10th anniversary!

Live music and increased postevent entertainment in the bar area –fun until midnight!

Aligning your business with the Structural Timber Awards demonstrates your commitment to fostering progression, innovation, and talent in timber design, engineering, and construction. Sponsorship provides a unique opportunity to gain valuable exposure through our extensive event PR coverage, positioning you as a champion of sustainable construction and innovation to a wide audience.

Brand new entry platform for the 10-year anniversary

Headline Sponsor Acknowledgement in pre-publicity

A table for 12 in the front row at the Awards dinner to invite guests