5 minute read

STILL STUNNING

THE MACALLAN DISTILLERY

An integral part of the undulating wooden roof structure at The Macallan Distillery is Kerto LVL (laminated veneer lumber). Fast, light and sustainable, it helped deliver a hugely successful award-winning project that has drawn praise from construction and whisky enthusiasts from all over the world.

In 2018 The Macallan Distillery got a new home – a stunning contemporary building combining an undulating wooden roof with glass and steel with many elements fully-prefabricated. The Macallan Distillery in Craigellachie, Speyside, Scotland is a stunning sight. From far above on the hillside,

you see five domes, resting under a living meadow roof. As you get closer, the unique undulating wooden roof structure is revealed.

LVL is an essential part of the wooden roof structure, as Kerto LVL Q-panels and S-beams are used as cheeks on both sides of the glulam beams and Q-panels in the roof decks. Kerto LVL S-beams can also be found outside on the service road. The construction of the Macallan Distillery took only six months. It was a carefully co-ordinated operation with the roof containing some 3,600 beams and 2,500 roof panels.

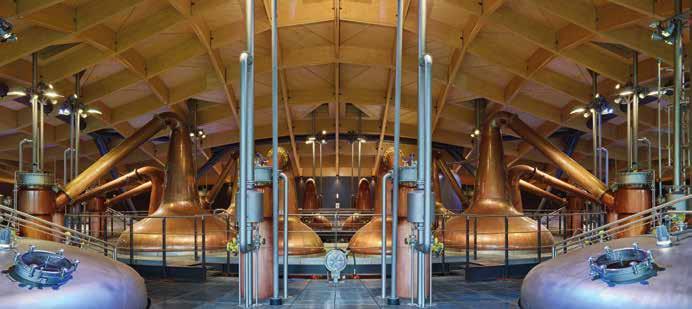

The building is an immersive experience: three still houses and a mash house with a common roof and fully glazed wall. This reflects the wishes of The Macallan Distillery – a worldrenowned brand – whose single malt whisky production dates back to 1824. The goal was a contemporary facility, celebrating style, authenticity and honesty.

01

Architectural principles

“The Macallan Distillery wanted to have a production facility whose capacity could be added to if required. That led us to start the work from the idea of a production module,” says Toby Jeavons, Project Architect at Rogers Stirk Harbour + Partners. “Enthusiasts can see how whisky is produced, because the machinery can be viewed from the fully-glazed immersive experience area. The architecture elevates the beautiful copper stills into something special.

“We wanted to celebrate the honesty of the materials rather than hide the roof structure with a ceiling. Wood is a nice counterpoint to the engineered, faceted roof structure, which consists of flat cassette panels and straight beams. Kerto LVL S-beams and Q-panels are an integral part of the structure of each beam, because they contribute to the overall dimensions. Every beam has the same dimension. We also achieve a contemporary aesthetic by using Kerto LVL, which has an omni-directional surface.”

02

03

Workability

The timber parts were CNC-machined and assembled at the Wiehag factory in Austria. The Kerto Q-panels and S-beams had high non-standard requirements. “All Q-panels and S-beams arrived on time, and their quality and specifications were fully met,” says Johannes Rebhahn, Sales Director, International Timber Projects at Wiehag, who was responsible for the engineered wooden roof construction. “The Q-panels, for example, had to be very thin, with a sanded surface. It was easy to add Kerto LVL to both sides of the glulam beams, because LVL has great workability while being a very strong and rigid material. It doesn’t warp or twist over time.

“Kerto LVL is a very good engineered wood material, because you can trust the material dimensions. In general, offsite construction is a great way to save construction time. When prefabrication such as cutting is done in the factory and connections have been designed to be simple, the easier, safer and more cost-effective life on-site is.”

Load-bearing structure

The Macallan Distillery features a wooden roof supported by a steel structure. The roof consists of a wooden waffle structure, which is triangular with 3 x 3m diagonals. The centre lines of the wood beams meet the centre lines of the supporting steel tubes. As the steel tubes are smaller than the glulam beams, they ‘run’ through the glulam beams.

The arrangement of the glulam beams, which feature integrated Kerto LVL cheeks on both sides, was designed to balance the load path to the steel frame. The primary members – hybrid beams strengthened with steel are interlaced with secondary members – regular beams. The timber grid and roof panels carry the heavy green roof loadings and all wind and snow loads down to the concrete foundation.

Connections

Steel plates, hangers, connectors and screws are used in the timber-to-timber connections, which contributes to the stiffness and stability. Hangers give strength to connections with hightension forces, and the shear forces are tackled with steel connectors. “The connections are beautifully hidden behind the beams, which feature Kerto LVL cheeks on both sides,” adds Rebhahn, who also says that the co-operation with Metsä Wood in the construction project went very well. “They understood our requirements and have been very flexible when we’ve asked for higher or non-standard specifications.”

Fire safety

The Macallan Distillery is built according to Scottish fire safety regulations. The glazed wall between the distillery and Visitor Experience had to achieve two hours’ fire resistance, including the relevant timber roof area above the glazed wall.

Visitor experience

The Macallan Distillery has been open for whisky enthusiasts for two years now, and it has become a highly popular destination. The guests are very fond of the experience. “We have received humbling praise for our brand new home,” says George McKenzie, Head of UK Engineering at Edrington, the parent company of The Macallan.

04

“One of the key elements is our roof design comprising of 380,000 individual components. It is always pleasing to see people’s reactions as they gaze up at the timber design when they enter the building.”

The living meadow on top of the roof is also in great condition. Any surface water from the roof is managed via a sustainable urban drainage system – a natural approach to drainage – helping to prevent water pollution and flooding. Johannes Rebhahn has experienced the same positivity with his clients who have visited the building with him and he is sure that The Macallan Distillery and other current timber construction projects will inspire more to build with timber. “The warm and cosy feeling combined with big dimensions has taken many by surprise. It is a very intense experience. Wood is a great way to construct carbon neutral buildings.”

LOCATION: Easter Elchies, Craigellachie, Banffshire AB38 9RX COMPLETED: 2018 ARCHITECT: Rogers Stirk Harbour + Partners STRUCTURAL ENGINEERS: Arup MAIN CONTRACTOR: Robertson CLIENT: The Macallan Distillers/ Edrington Group PRODUCTS USED: Kerto LVL is used in the prefabricated cheeks on both sides of the glulam beams and roof decks

www.metsawood.com

IMAGES:

01. Courtesy Mark Power Magnum Photos 02. Courtesy SchubertStarmühler Verlag 03. Courtesy WIEHAG 04. Courtesy Mark Power Magnum Photos