4 minute read

Volumetric & Part L Requirements

Developers face significant changes with major steps taking place in the government’s drive to become carbon neutral. Richard Hipkiss, Development Director of the Modular and Portable Building Association (MPBA) considers the significant role volumetric modular can play in achieving new building regulations.

Paving the road to net zero targets and the nationwide commitment to create a cleaner and greener built environment, the new updates to Part L building regulations will have a big impact on the construction industry. The new regulations came into place in England on 15 June in the biggest change to building regulations since 2006, while Scotland can expect to see similar changes implemented later this year.

There are now higher performance targets and CO2 emissions are reduced by 31% for dwellings and 27% for other buildings and a new emphasis has been placed on low carbon heating systems. Part L sets out the rules that homebuilders must abide

1

by, while also setting out guidelines for the efficient use of fuel and power in new buildings, outlining what materials can be used and the correct procedures.

Homebuilders will face a range of changes, including how a property is insulated, as well as in relation to heat pumps and solar panels. The regulation changes also apply to non-domestic developments.

The changes continue to broadly follow a ‘fabric first’ approach, requiring lower U-values than previous versions of the regulations, whilst also incorporating renewable technology. In all new domestic builds, the new U-value for walls will be 0.18 W/m2 , 1.4 for windows and rooflights and 1.4 for doors. In non-domestic builds there is a lowered U-value of 0.26 for walls and the majority of windows and curtain walling must achieve 1.6 W/m2 .

Since the government amended the Climate Change Act in 2019 to commit the UK to achieving net zero carbon emissions by 2050, the construction industry has been confronted with the need to decarbonise. According to the World Green Building Council, construction and buildings in use are responsible for 39% of all carbon emissions in the world. This is broken down into two elements with 11% being linked to the manufacture of materials and construction processes known as embodied carbon emissions and 28% associated with operational emissions caused by heating, cooling and lighting systems when a building is in use.

As an industry association it is our mission to demonstrate how the route to 2050 could follow a number of different paths. We intend to achieve this by extolling the virtues of volumetric manufactured buildings as well as removing the complexity surrounding so called modern methods of construction by diluting the myths and embracing reality.

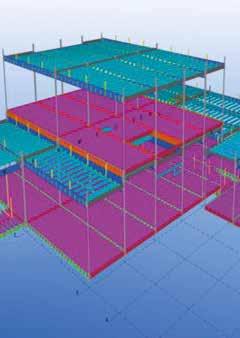

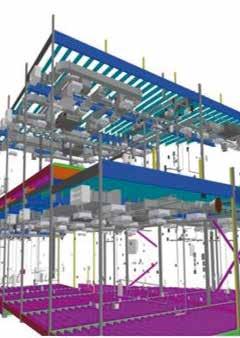

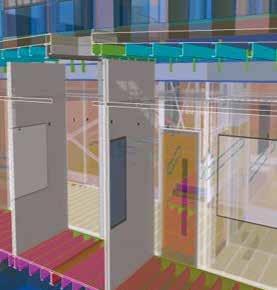

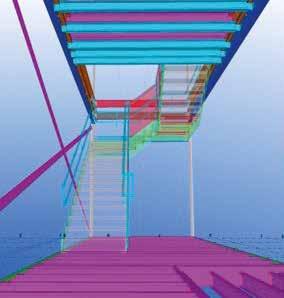

Volumetric modular buildings are less susceptible to poorly specified manufacturers’ products as time can be taken upfront to validate the correct specification of materials. Designs are digitally constructed and virtually tested before they move onto the manufacturing phase. This process eliminates waste and achieves highly accurate and airtight building envelopes designed and built to

2

higher sustainability standards. This allows clients to have confidence in the quality and performance that they can expect from their new building. Unlike factory manufactured buildings, there is significant evidence that traditional construction methods do not produce buildings that perform as well as design expectations and there is a void between anticipated and actual in-use performance. Findings from studies such as PROBE (Post Occupancy Review of Buildings and their Engineering) reveal that actual energy consumption in traditionally conceived buildings is often as much as twice of that predicted in the design.

Not only is the actual construction of the building ‘greener’ but volumetric manufactured buildings are also more energy efficient – reducing primary energy requirements and in-use operational emissions during the lifetime of the building.

At the core of the manufacturing of volumetric modular buildings is Design for Manufacture and Assembly (DfMA) protocols and Building Information Modelling (BIM) technology which empowers the optimal configuration of volumetric modular solutions by digitally connecting multi-discipline teams from the beginning of the concept design right through to the development process and beyond. DfMA means buildings are conceived for manufacture within a factory environment. BIM facilitates early design detail and three-dimensional design information, minimising the risk of errors by eliminating the timeconsuming process of translating engineers’ information into material requirements and assembly drawings.

The benefits of volumetric manufactured buildings begin in the factory, continue on to the construction site and last through the lifetime of the building. The volumetric modular

3

5

MPBA

The MPBA plays a key role in the connecting of sectors in the modular and portable building industry. The association collaborates with specialist technical advisors to enhance innovation in the design and manufacture of volumetric modular buildings. These can be designed and manufactured from timber or steel in any size and shape to meet individual client needs while ensuring full compliance with building regulations. To discover how volumetric modular

technology can benefit construction projects visit: www.mpba.biz

4

6

way limits the amount of concrete in the ground and eco-friendly materials are often specified and each individual component can be selected specifically for its performance characteristics, tailoring every inch of a volumetric modular build.

As the construction sector develops and adapts to meet changing government strategies to reduce carbon emissions, I firmly believe the upward trajectory of volumetric modular buildings will continue to meet new building regulations and we need to act now to help mitigate the impact of climate change for future generations to come.

Images:

01-06. Volumetric modular buildings can be designed, digitally constructed and virtually tested before they move onto the manufacturing phase.