BARTON AERODROME VISITORS CENTRE

RAEVEN BRANCH

CTA 2023

02 04 05 01 TABLE

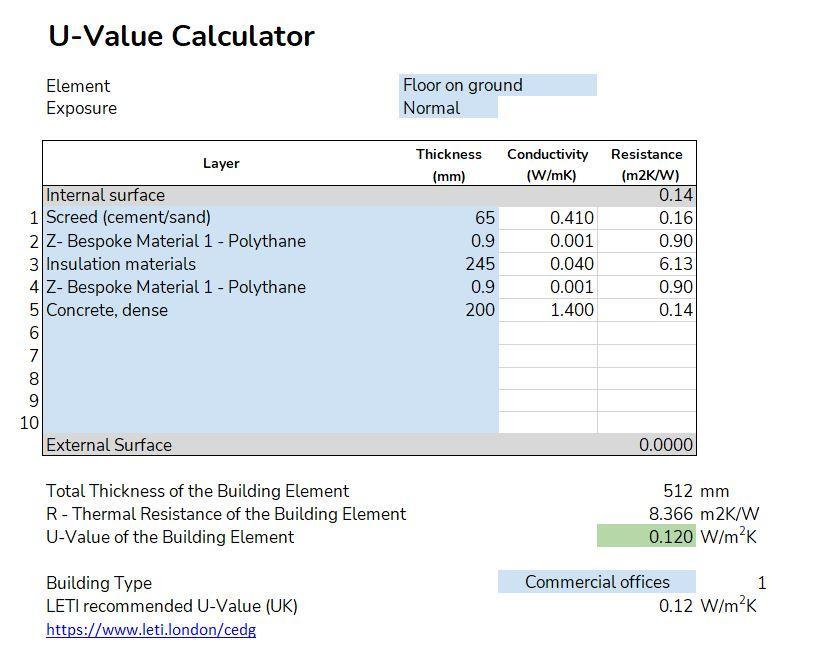

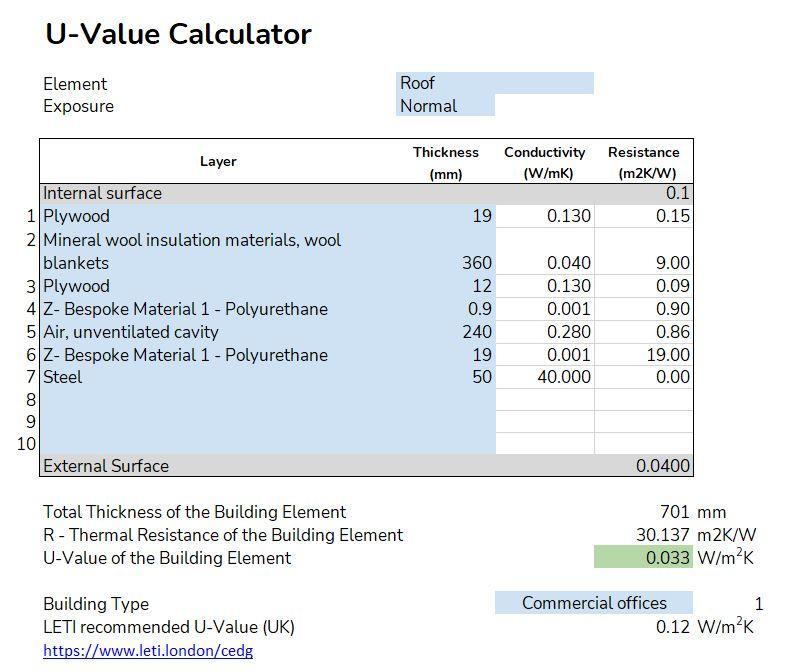

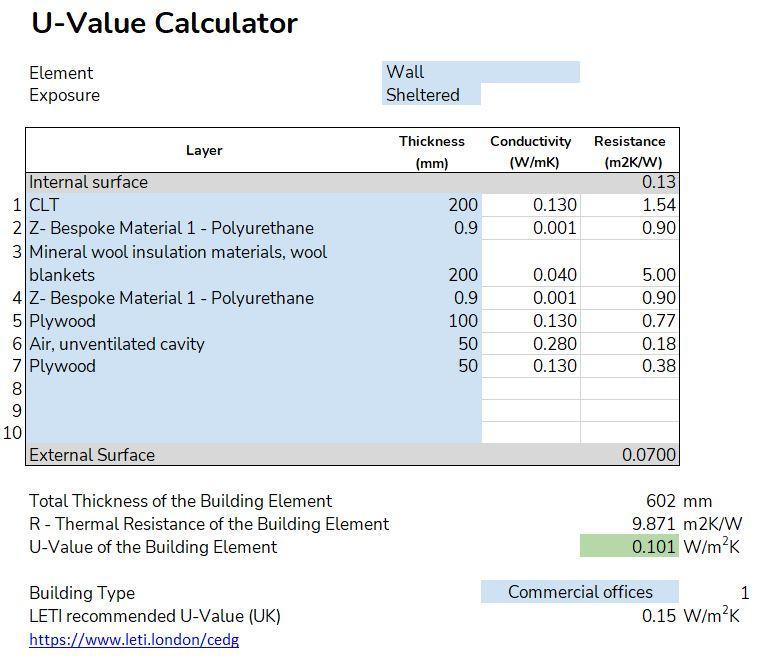

Introduction to the project and internal and external views of the visitors centre, orthographic drawings Sections and evasion of the visitor centre Wall, floor and roof U-Value calculations Sample board of chosen materials BARTON AERODROME 1:20 SECTIONS & ELEVATIONS U-VALUES MATERIAL SAMPLE BOARD 03 Foundation, door, window and eaves details 06 1:5 SECTIONAL DETAILS REFERENCES

OF CONTENTS /

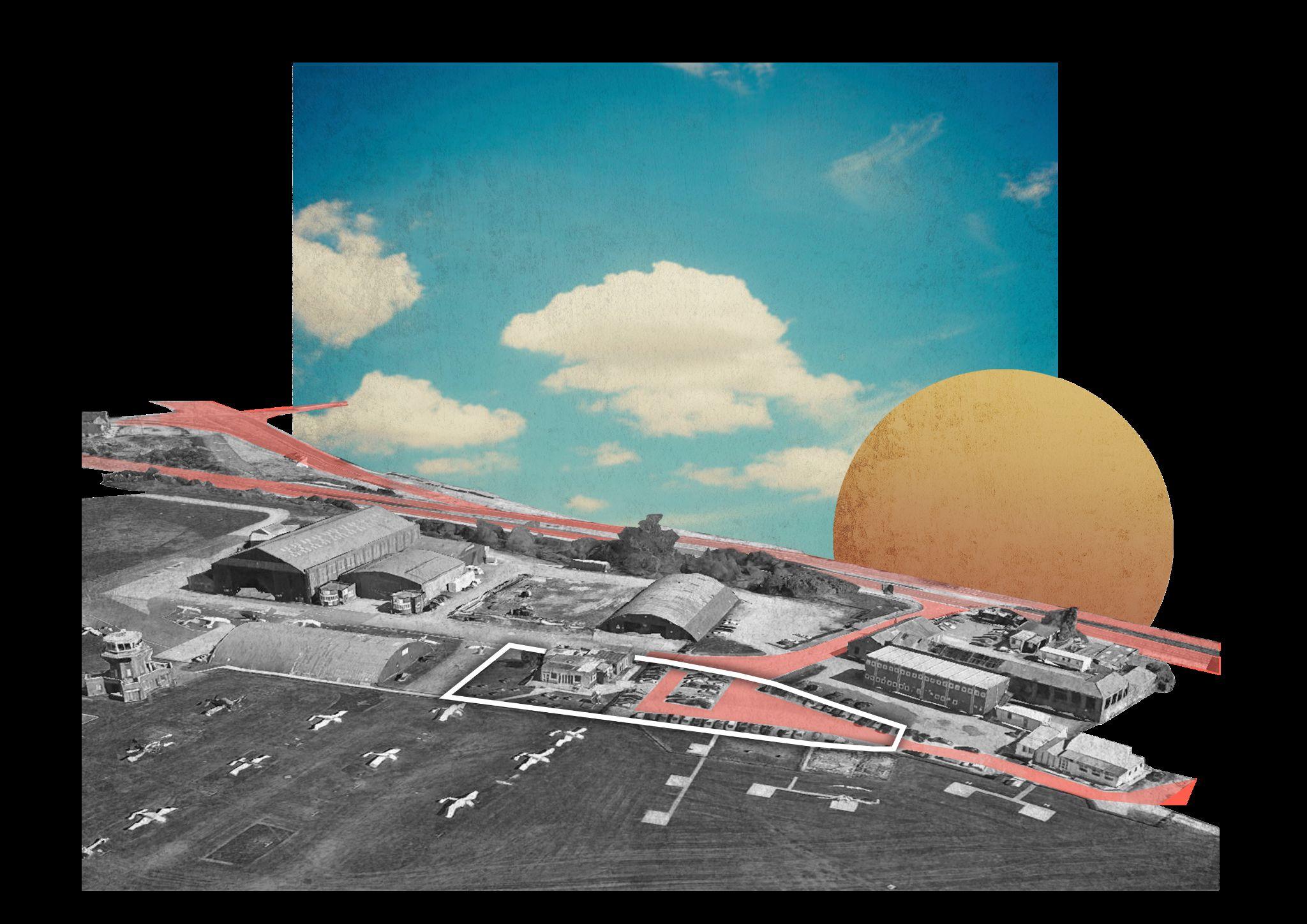

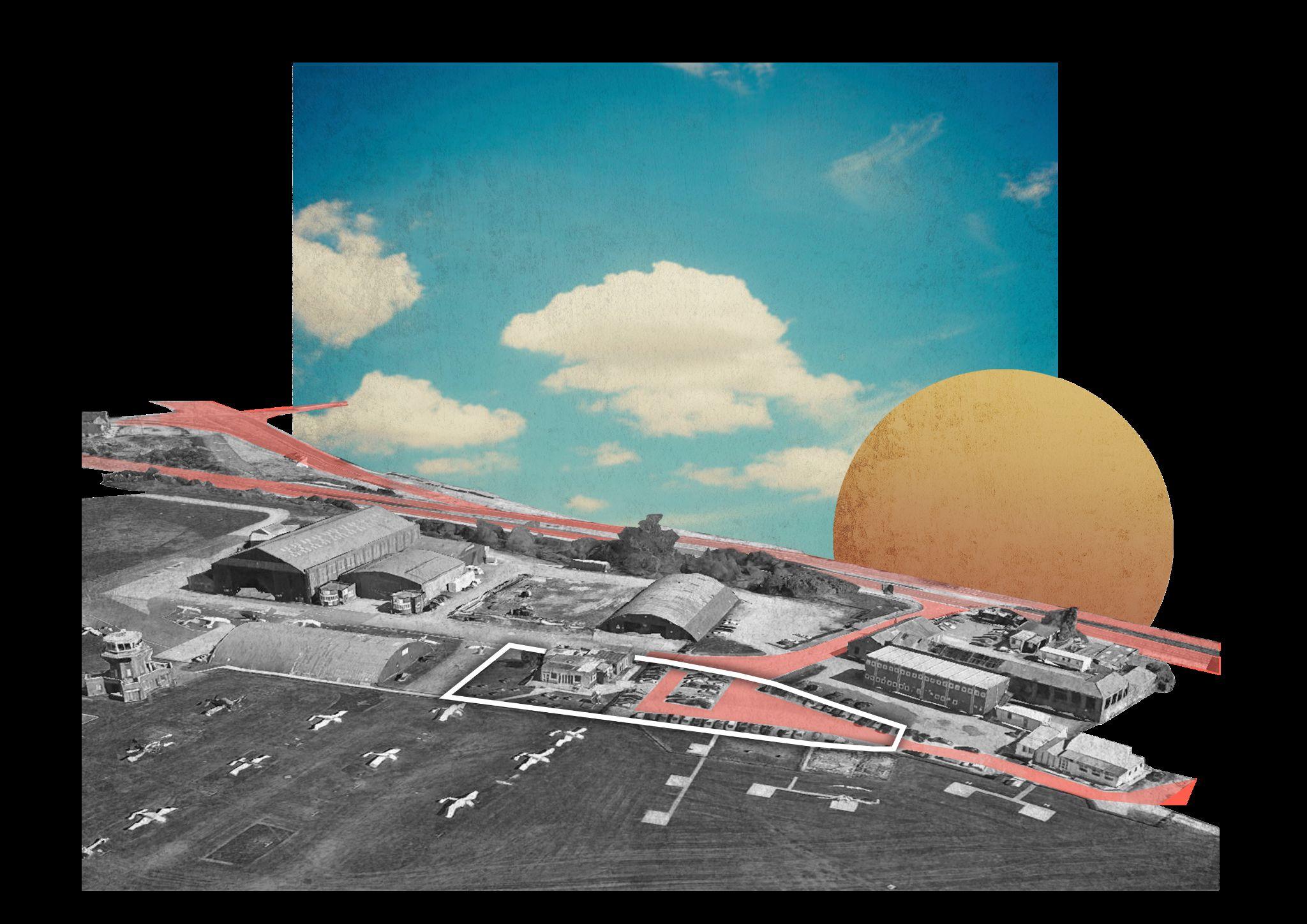

BARTON AERODROME VISITORS CENTRE

Site location: Barton Aerodrome, Chat Moss, Irlam

The brief: Design a visitors centre with a two-scopic regime for plane spotters for Barton Aerodrome (City Airport).

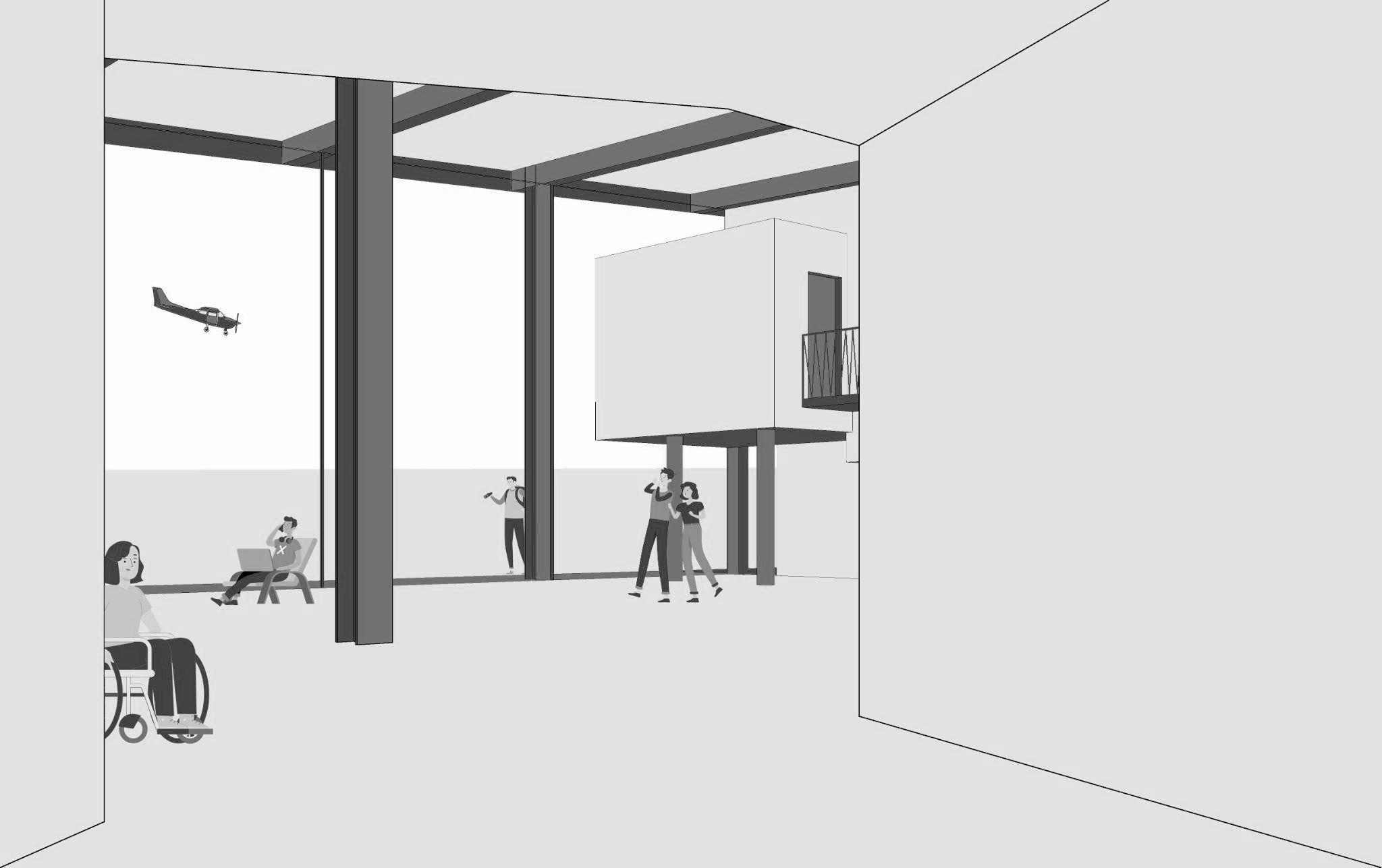

Response: A visitors centre designed make space in order to create a community within the local area. The centre has a double height atrium space, a cafe, gift shop, VR room, covered outdoor balcony, a gallery balcony and 3 private pods.

01

A 10x10m grid is used as the steel can reach a maximum length of 14m

MATERIALS:

● Concrete strip foundation

● Steel portal frame

● CLT

● Curtain wall

Not to scale

EXPLODEDAXONOMETRIC

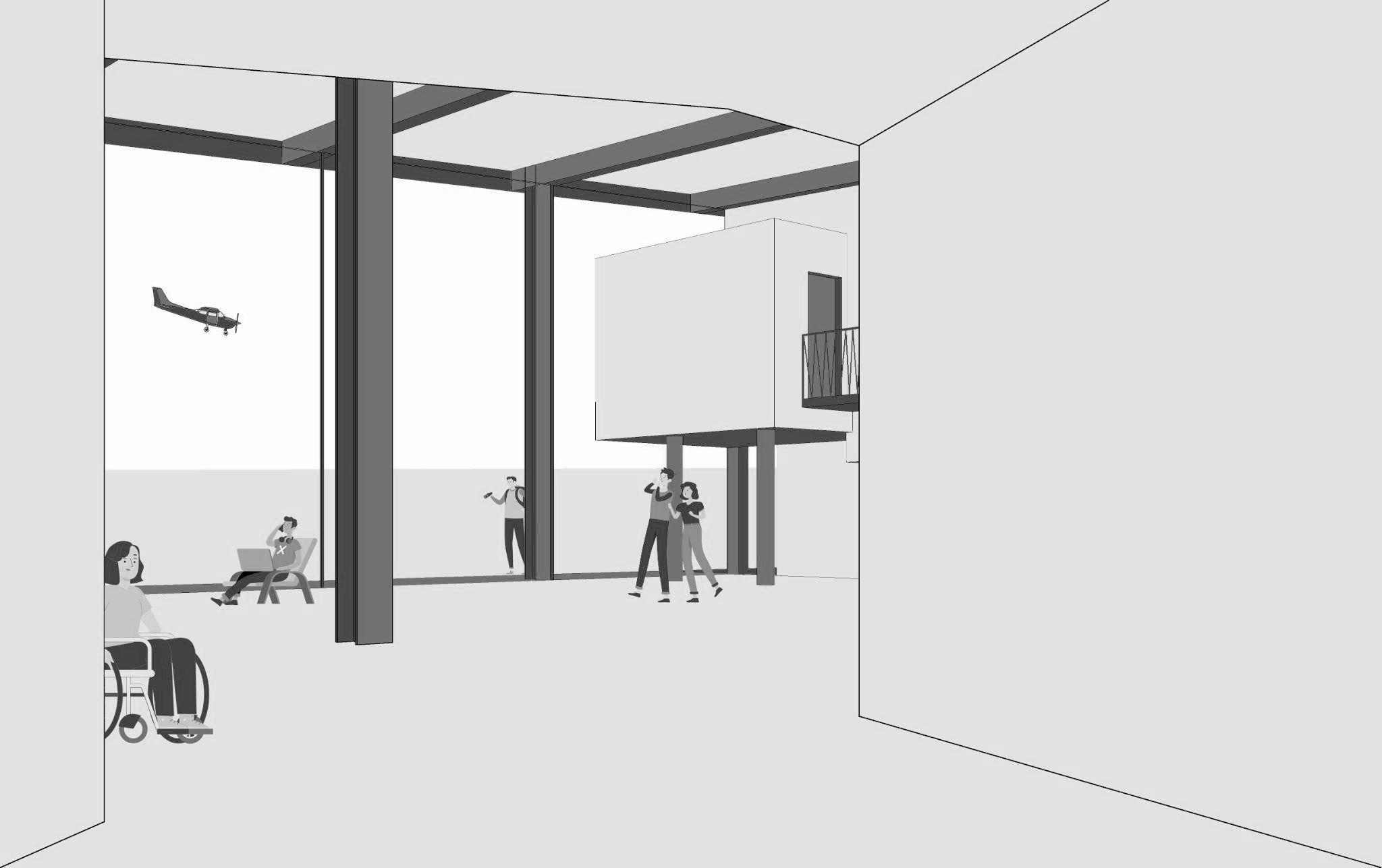

INTERNAL VIEW

FROM THE ENTRANCE INTO HALL

EXTERNAL VIEW

FROM THE LEFT ELEVATION TO THE FRONT ELEVATION

FrontElevation

BackElevation GroundFloorPlan

0 2m 2m 4m 6m 8m 10m 1:100

0 2m 2m 4m 6m 8m 10m 1:100 LeftElevation RightElevation FirstFloorPlan A A B B

1:20 SECTIONS & ELEVATIONS

Two sections have been chosen in order to best depict the makeup of the structure.

Section B: A drawing of the fire escape and external fire escape stairs.

Materiality:

Fire escapes: There are 4 fire escapes in total. 2 on the left elevation and 2 on the right. All escapes provide doors opening to the direction of the exit. The fire escape on the intermediate floor include external fire escape stairs with landings wide enough to provide a safe area for disabled persons.

02

Section A: A drawing of on of the private pods with its connection to the curtain wall system.

8644mm8853mm

10589mm 2999mm 2702mm ViewingpodwithCLT interior Curtainwallsystem Steelcolumnassembly

10698mm 3523mm 2750mm Metalmeshfireescape stairs 200mmmineralwool insulation 200mmCLT Outwardopeningfire escapedoor Timberrainscreen Metalseamcoldroof

1:5 SECTIONAL DETAILS

Detail drawings of the wall to foundation, intermediate wall to floor, external door, curtain wall to intermediate floor, and the eaves.

Thermal performance and control of moisture: The details show the measures taken in order to increase thermal performance and control the moisture in the structure. Materials such as vapour barriers, breather membrane and damp proof membranes have been utilised throughout the structure. Mineral wool insulation has also been used to decrease the U-value and eliminate thermal bridging.

Reaction to fire: The details contain drawings of how to manage the structures reaction to fire and the control of the spread of fire. For example, the curtain wall system to intermediate floor shows a cavity closer that will expand to stop fire from spreading between floors. Another example is the fire escape door which is outward opening and provides a safe barrier between the fire and means of escape.

03

Curtainwallsystem

Mullion

Plywoodskirting

Rigidinsulationblockundercurtain walltoavoidthermalbridge

Rigidinsulation

Concretestripfoundation

Steppeddrain

Steelcolumnassembly

65mmscreed

Perimetermastic

Plysheathing

Fixingbatton

Timberrainscreen

200mmCLT

Vapourcontrollayer

200mmmineralwool insulation

Breathermembrane

Rigidinsulationblock

Steppeddrain Vapour controllayer

200mmrigid insulation

DPM

200mmconcreteslab castinsitu

Sandblinding Hardcore

Concretestrip foundation

Metalmeshbalcony 65mmscreed 100mmmineralwool insulationforacoustics 300mmCLT 300mmCLT PerimeterMastic

Vapourcontrollayer

175mmmineralwool insulation

Insulationtoreveal Sealanttobackof doorframeandwood packingtodoorhead

Outwardopening externaltimberdoor

Outwardopeningfire escapedoor

200mminsulation Breathermembrane

Verticaltimberrainscreen

Breathermembrane

Insectmeshunderfixing batton

Leadflashingunder breathermembrane

Outdoormetalmeshfire escapestairs

Cbracket

65mmscreedwith perimetermastic Fireescapestairs

200mmCLT

MineralWoolInsulation Board

CavityCloser

Mullion

CurtainWallSystem

SteelClosurePlate

CurtainWallAnchor

CLT

Glu-LaminatedCloser

PerimeterSteelBeam

SteelColumnAssembly

PressedMetalFascia

Waterproofing Membrane

19mmSheathing(Ply)

240mmColdRoofSpace

19mmSheathing(Ply)

RigidInsulation

NotchedBlockingAt CurtainWallHead

Glue-LaminatedBlocking

CurtainWallSystem

MetalStandingSeam Roof

19mmSheathing(Ply)

12mmSheathing(Ply)

360mmMineralWool Insulation

PerimeterSteelBeam

19mmSheathing(Ply)

SteelColumnAssembly

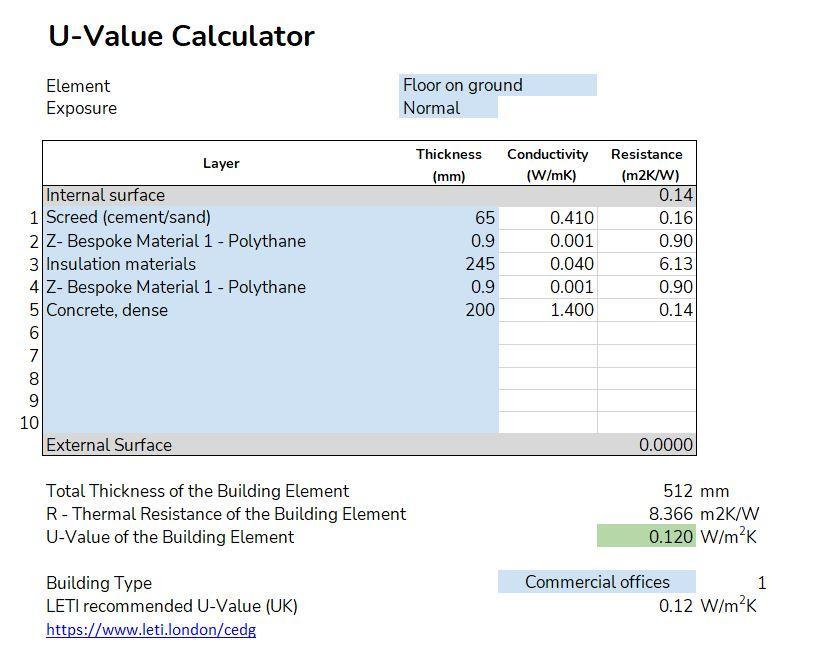

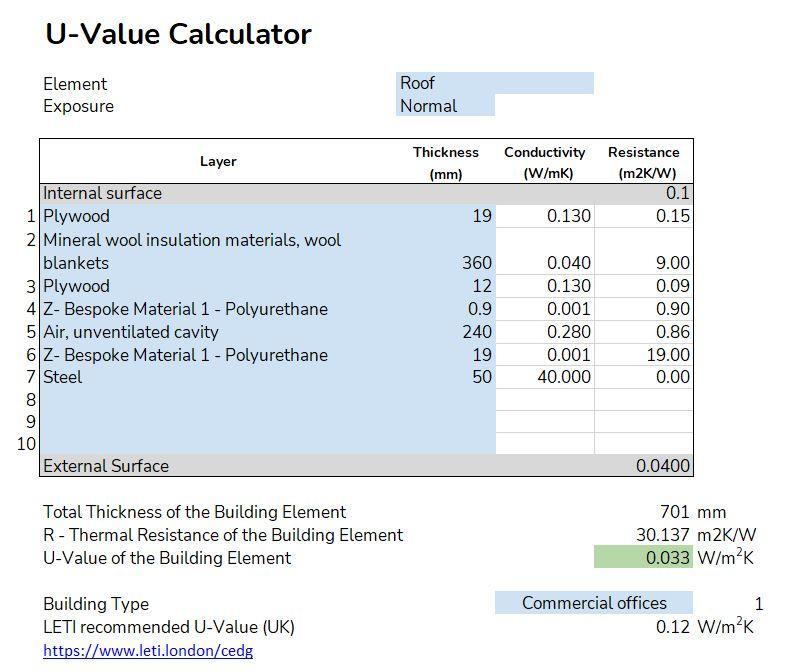

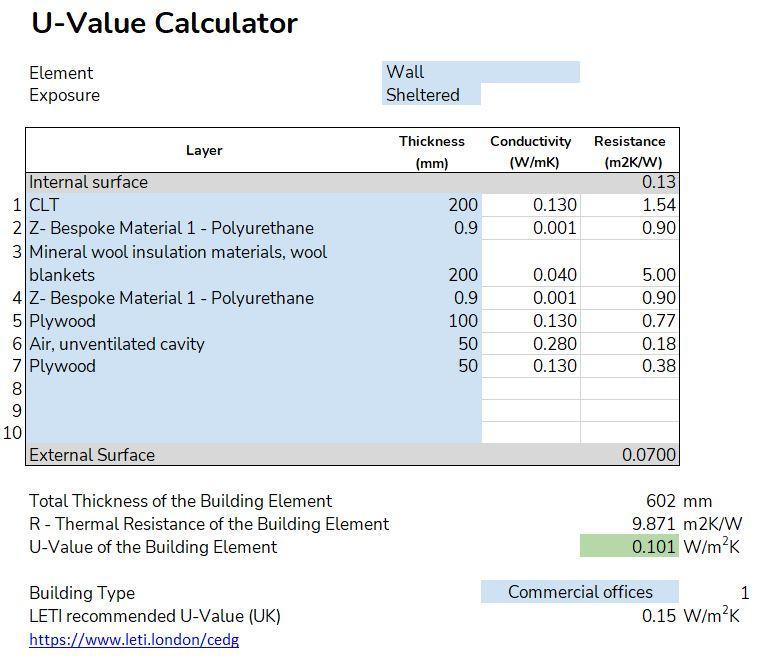

U-VALUES

04

MATERIAL SAMPLE BOARD

CLT interior finish Polished concrete flooring (screed)

Steel I-beam column Greencoat steel seam roof finish

British larch vertical timber raincoat cladding

Triple-glazed Norrsken curtain wall

The CLT is used as a load bearing and interior finishing material. This eliminates the need for extra materials such as plaster. The CLT can be sourced within the UK, cutting down the carbon emissions for the visitors centre. It is both durable, strong and out performs steel in the case of a fire.

Used as the interior floor finish. The material is very durable and has a life span of 100+ years is maintained well. This flooring is most appropriate to accommodate for the number of people using the visitors centre.

The steel frame is made up of steel I-beam column assemblies. The sexposed steel not only creates a strong structure, but adds to the aesthetic of the visitors centre and ties it in with its industrial surroundings.

The colour coated steel is UV-resistant, energy efficient and scratch resistant. The roof provides a flat surface for solar panels to be installed. It also adds to the aesthetic of the structure by initiating the steel roofs of the other buildings on site.

https://rb.gy/wmtyif

British larch is a renewable material that is grown in the UK. using this material will reduce transportation carbon emissions. This raincoat will help to protect the structure whilst providing and aesthetic finish to the exterior.

The triple glazed curtain wall will help to increase thermal performance and will also control the daylighting within the building. The centre has a large curtain wall which could palace it at risk of over-heating. Using this glass as well as proper ventilation methods will help to control this risk.

05

REFERENCES

Cooper Development Association Inc. (Unknown).ArchitectureDesignHandbook:ArchitecturalDetails:WallCladding-CurtainWallSystems. Copper Development Association. https://www.copper.org/applications/architecture/arch_dhb/arch-details/wall_cladding/curtainwall.php

FB. (Unknown).CLTDetails|anonarchitects. Wix.com. https://florencebooth.wixsite.com/anonarchitects/clt-details

Greencoat Steel. (2019, April 11). Home. YouTube.

https://www.ssab.com/en-gb/brands-and-products/greencoat?gclid=CjwKCAjwzuqgBhAcEiwAdj5dRkLjdhWDsVg-HY3Yeg1lbUOEojK69nZKES

bCiXhQCFcHAHKH-PblBxoCzjQQAvD_BwE

McLeod, V. (2010). DetailinContemporaryTimberArchitecture. Laurence King Publishing.

Norrsken. (Unknown).Thehomeofhighperformancewindows. Norrsken - The Home of High Performance Windows and Doors.

https://www.norrsken.co.uk/

Pintos, P. (2020, May 29). ABHouse/bwa. ArchDaily.

https://www.archdaily.com/940445/ab-house-bwa?ad_medium=widget&ad_name=navigation-prev

Russell, J. S. (2020, April). CECenter-PassiveHouse. CE Center. https://continuingeducation.bnpmedia.com/courses/multi-aia/passive-house/2/ Walshaw, E. (2020).UnderstandingPassivhaus(2nd ed.). First in Architecture.

06