7 minute read

Bringing 3D printing to the UK rail industry

to the UK rail industry Bringing 3D printing

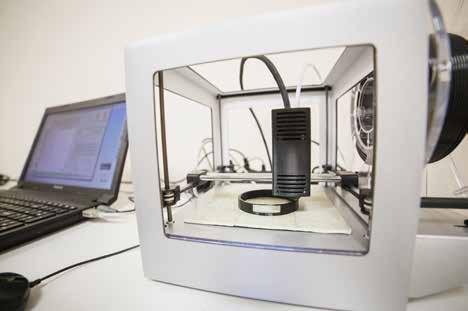

3D printing is an almost magical process, yet, in a way, it is also so simple. A normal ink-jet computer printer lays down a film of ink onto a sheet of paper to produce letters, words or an image. Now use thicker ink, and go over the image several times, and a three-dimensional shape starts to form.

Replace the ink with plastic or metal powder, and the paper with a sheet that can be peeled off once the printing is finished, and that’s the essence of 3D printing. The size of the object is only limited by the size of the printer, and the thickness depends on how may layers are put down - how many times the print head goes over the same area. Rail Engineer first became aware of the process in 2013, when Hobs 3D created a model of the upgraded King’s Cross station from the original computer-aided design (CAD) files, making the model extremely accurate.

Since then, 3D printing, now also called Additive Manufacturing (AM) as material is added through the process, has become a bona-fide manufacturing technique, used to make components for all types of equipment, including railway trains.

Derby-based DB ESG is part of a cross-industry partnership that is leading the way by being the first to apply 3D printing to the UK rail industry, providing engineering design, assessment and approvals for the introduction of 3D printed components on UK train fleets. Working together, Angel Trains, Stratasys and DB ESG have, to date, produced eight fully approved components using AM. Some of these parts are currently being trialled on in-service passenger trains by Chiltern Railways. This is the first time production-ready 3D printed parts have been fitted on passenger trains within the UK.

Unique manufacturing challenge Manufacturing for rolling stock is expensive, with train fleet production runs being of low volume compared to other manufacturing industries. This low volume drives up the manufacturing cost, removes the incentive to invest in research and development, and reduces the number of suppliers able to compete.

The challenge is exacerbated by the issue of obsolescence - trains can be in operation for 30 or more years. To keep these fleets operational and in peak condition, asset managers such as Angel Trains need to ensure the continued supply of parts for which the original manufacturing drawings may no longer exist, and that may only be needed in very small quantities for the remainder of the vehicle’s life.

Such legacy parts are generally expensive, have very long lead times, and are often not tailored to the specific fleet or application. They can be a real struggle for the existing supply chain and manufacturing methods, leading to many operators having to expend unnecessary amounts of effort and cost when managing these parts.

3D printing could be the solution to these manufacturing challenges, allowing replacement parts to be produced at low cost, in low volume and with short lead times. Depots could have their own printers to enable parts to be manufactured as required, and train operators could even personalise parts with their own badge or logo, knowing that the parts can easily be replaced if the train were to change hands.

Overall, the key benefits of using AM include: » On-demand production of replacement parts, eliminating the need for large spares holdings, reducing whole life rolling stock costs and replacement of obsolete parts; » Use of high-performance, cutting-edge materials, with advanced mechanical properties such as high strength, flame, smoke and toxicity requirements, and the ability to certify to industry standards;

Spot the difference – which is an original cast grab handle and which is 3D printed? (The centre one is original).

» Freedom to design customised parts, unique to the customer requirements; » Reductions in spare part costs; » Reductions in lost vehicle availability due to fast on-demand production of replacements; » Ability to keep passenger trains in service for longer with efficient replacement of parts.

Project overview

The cross-industry group decided to focus on FDM (Fused Deposition Modelling) technology, as it is one of the most established 3D printing processes for robust, industrial applications, with parts already deployed in service in comparable transport industries such as aviation.

The first stage of the project was to put procedures in place and to carry out 3D scanning visits to some of Angel Trains’ operator’s depots. Through this, a digital library of over 120 parts has been created,

Other 3D printed items include tray tables and armrests. including several parts for which original drawings do not exist, and which, due to their complex shape, would have been challenging to reverse-engineer manually. DB ESG then investigated the design, production and finish of FDM parts, checking whether they comply with rail standards and operating environments. The end-to-end process of supplying new 3D printed rail vehicle components was studied, from initial reverse-engineering design, through to approvals and manufacture of the final items. At each stage, the benefits and limitations of the FDM manufacturing technique were considered.

In particular, DB ESG focused on the: » Fire compliance of the FDM materials; » Physical properties of the FDM materials and their compliance to structural standards, such as GM/ RT2100; » Manufacturing limitations and tolerances; » Aesthetics - colouring and surface finish of parts, the match with existing parts and compliance with PRM requirements. DB ESG and Stratasys also evaluated the range of materials available for print. Three were shortlisted and Sabic’s Ultem™ 9085 black resin, which is a high-performance, high-strength, flame, smoke and toxicity compliant resin, was selected for the trial. Both Ultem 9085 and Stratasys’ own Antero 800NA have been tested and certified to rail standard EN45545-2. Importantly, these results were released back to Stratasys for wider use in the rail industry.

Other 3D printing thermoplastics have been tested. However, these could not meet the mechanical properties or fire

performance necessary for rolling stock applications. The industry requires very high fire performance, meaning that satisfying aerospace standards does not guarantee compliance in rail. This collaboration has enabled new, highperformance materials to be tested to demonstrate their compliance to the railway standard EN45545-2.

Five rolling stock components were initially chosen to test the capability of the technology, and reverse-engineered: » Interior seat armrest; » Two interior seat grab handle designs; » Interior seat fold-down table; » Cover for an inter-vehicle jumper receptacle. For each of the above, DB ESG then optimised the component design for FDM manufacture, reducing the internal part density in low-stressed areas and adding custom cut-outs and features to enable the addition of simple metal inserts to interface the parts to the vehicle. The structural competence of the final design was then assessed, and the components certified. One example of each component was finally manufactured. For each of the parts, the cost of manufacturing in-house is comparable to that of the existing part, but the real advantage is in a substantial reduction in lead time and order quantity, as low as a single unit.

Passenger service trials

FDM components are now being trialled on rolling stock in passenger service.

Angel Trains has been discussing the technology with its rolling stock operators and Chiltern Railways agreed to trial parts. In total, 11 parts are now being trialled on Chiltern Railway’s Class 165 units over a six-month period, commencing in the summer of 2019. After six months, a sample of the parts will be removed from the units and DB ESG will inspect them for signs of wear and/or damage. Chiltern is trialling: » Four left-handed seat back grab handles; » Three right-handed seat back grab handles; » Four arm rests. All components have been manufactured and finished to the required standards and are colour-matched to the existing parts.

Project summary

To date, the AM/3D-printing project has achieved: » 120 legacy railway components 3D-scanned and digitised; » Two 3D-printing FDM materials successfully fire tested, with the

PHOTO: ISTOCKPHOTO.COM

results freely released back to the manufacturer for use by the rest of the industry; » Eight railway components re-designed and manufactured using AM that have been fully certified for in-service use - these parts are comparable in cost to existing supplies while offering substantial lead time reductions; » The first in-service trial of productionready AM parts in the UK rail industry; » A range of further R&D work already agreed between all partners, to push the boundaries of the technology further and to speed up its adoption by the wider industry. Finally, all members of this collaborative project have also joined the trade body ‘Mobility goes Additive’, an organisation originally set up by DB in Germany that brings together additive manufacturing and transport companies from across Europe to advance the development and uptake of AM technologies within the transport industries.