5 minute read

Bridges

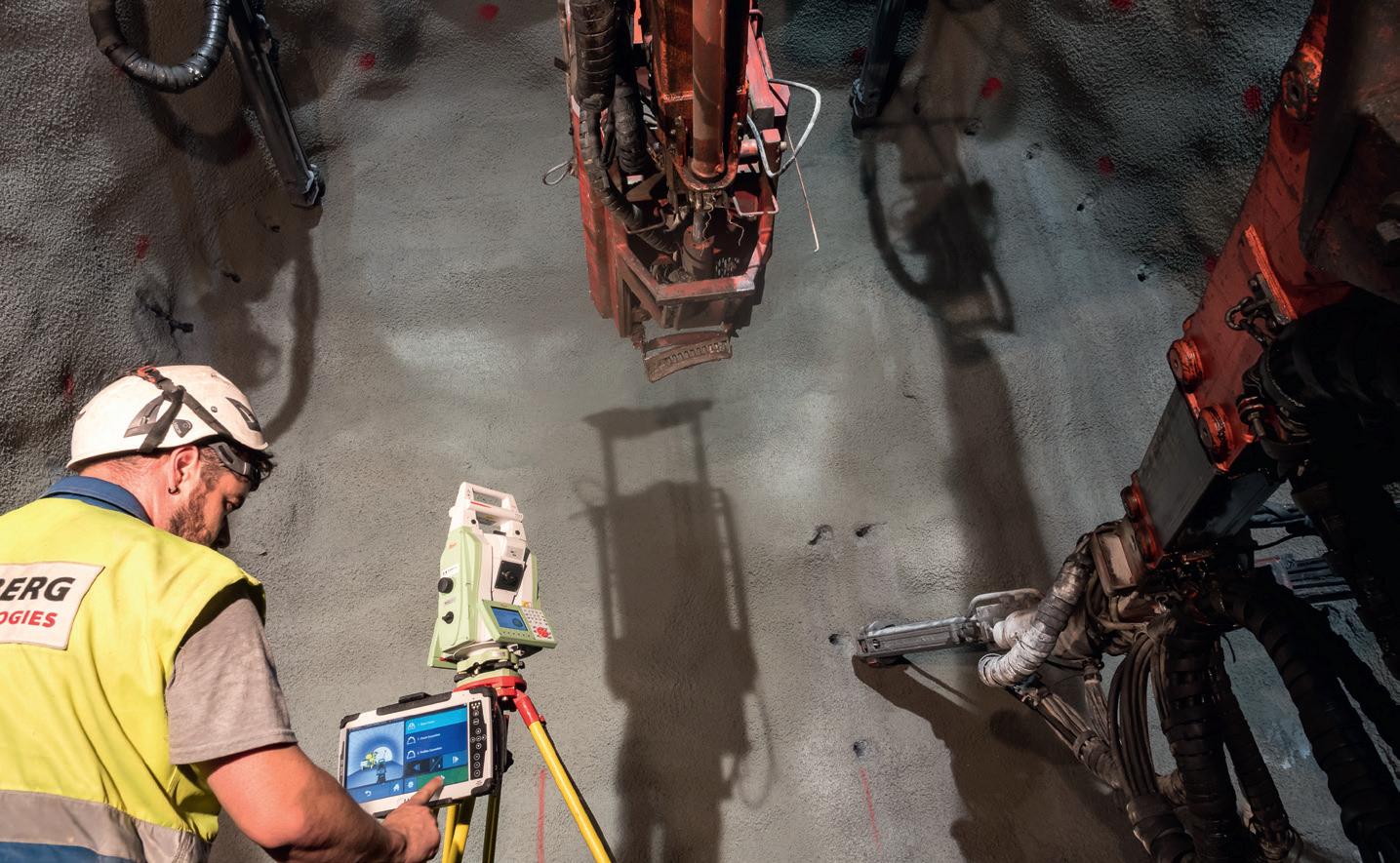

Underground design and construction

Part of the Swiss based Amberg Group, Amberg Technologies/Amberg Engineering are one of the world’s leading engineering and technology companies in underground design and works

For more than 50 years, we have been developing design and construction solutions in the fields of underground railway, road, and metro tunnels. Amberg specialize in innovative solutions for the subterranean space.

In Britain Amberg have been a strong partner for local contractors, building and maintaining tunnel and railway infrastructure for more than 30 years. Multiple landmark projects have been realised in the UK with the technology and engineering of Amberg Switzerland.

Crossrail London The contractors carried out tunnel survey and construction utilising the Amberg Tunnel application and the Amberg Navigator, an intuitive tunnel construction and verification method.

In the following stages, Amberg Rail provided the technology and the equipment

to lay the slab track in the new tubes. Additionally, the Amberg GRP was deployed to do the quality control plus the clearance verification.

Equipment used: • GRP 1000 Slab Track to lay the tracks. • VMS 1000 for the relative and geometric quality control. • GRP 5000 for Clearance verification. What are the benefits for the customer and the track owner? • The confidence that the tracks are perfectly laid, meaning only minimal maintenance is expected during the operation. • Reduction in maintenance costs. • Properly aligned tracks are an important safety factor. What are the benefits for the contractor? • Cost-effective solutions allowed the delivery of the track above the highly set specifications. • Cost savings on equipment and crew. • Timely delivery of the tracks in the tunnels. • Minimal training of the track builders due to the unified Amberg Rail field application even when using altering applications. • Strong local support by SCCS.

Network Rail With a doubling of passenger numbers in the last 20 years, Network Rail were looking to improve their track maintenance work as the amount of free track time available was being reduced each year. In early 2016 Network Rail decided to use the latest development by Amberg Technology, the IMS 3000 Tamping.

The systems are being used in Network Rail’s high-output depots, where Network Rail carries out track renewals and ballast cleaning. The IMS 3000 systems are used to carry out design verification surveys before the work begins, for pre and post tamping surveys and finally for as-built surveys to ensure the

required track geometry has been installed.

Up until then, surveys were done using a tape measure and five-point laser with a list of required offsets to the adjacent track. The productivity for the increased demands and less available track time decreased more and more.

This benefitted Network Rail as half the number of staff were needed, along with: • Double production output. • Double measurement accuracy. • One hundred per cent digitalized.

Furthermore, the Amberg IMS systems were used on the WCML (West Coast Main Line) for maintenance. The WCML is one of the only tracks in the UK with a full control network with a control point on each OLE gantry (Overhead Line Equipment) and a 3D design. The systems are used to carry out maintenance surveys against the existing design and create slue and lift campaigns to improve and maintain track geometry and safety.

Thames Tide Way Tunnel After looking at the excellent results and the cost savings on the Crossrail project, all of the contractors on the Thames Tide way project decided for the Amberg Tunnel solution. Currently Amberg Tunnel is being used to help the construction of HS2 in support of the JV contractors building the various twin bore tunnels.

European Tunnel Projects Amberg Engineering AG is proud to associate themselves with all the major rail Alp crossings. They led the design and engineering joint venture of the Gotthard Base Tunnel, which, at 57 kilometres, is currently the longest railroad tunnel in the world. Its design and construction represents one of the engineering masterpieces of the 21st century.

Currently, they are involved in all project phases in the realization of the Semmering Base Tunnel in Austria, which is characterized by its complex geology. Through our leading role in the design and construction of the Brenner Base Tunnel, which with its final length of 64 kilometres will replace the Gotthard Base Tunnel as the longest railroad tunnel in the world, we are ensuring that the south and north of Europe come closer together.

Furthermore, Amberg Engineering AG is providing our decades of continued growth in underground expertise and design capabilities as part of the ever-growing metro network in our major cities, such as Brussels, Paris, Porto, Munich, Berlin and Bucharest.

We like the challenge on a project. And on such urban projects particular, Amberg Engineering AG like to rise to the occasion to face and successfully overcome challenges that an urban environment entails; constrained space conditions, maintaining stations and train lines in operation; complex logistics and construction sequences, groundwater and difficult geological conditions, major temporary support measures and ground improvements, to name a few.

There are two projects to highlight, first is the Stuttgart 21 which comprised design and construction within densely populated areas, maintaining full operation of tracks, exceptional geology entailing swelling ground conditions due to the presence of anhydrite and the unique natural mineral water resources in the region.

Second is the underground railway line U5 in Berlin, which was challenging as there were a number of historical buildings and the route passed under the River Spree and the Spree Canal with a few metres of cover. The work required us to maintain settlement at acceptable boundaries and ensure there was no entry of water from the Spree or the Spree Canal into the tunnel.

A wealth of experience with proven track records Over more than 50 years Amberg Engineering has realised over 800 projects worldwide, spread through five continents and in more than 25 countries. Amberg Engineering can master all phases of the lifecycle of underground infrastructures and are capable of advising and providing support to implement future-oriented solutions. We provide clients with a single competent partner – even with interdisciplinary tasks and technology. Well established practices make for short decision-making processes, enabling quick and competent reactions to changed conditions or unexpected events. Everything from a single source.