Discover potential. Drive performance.

With over 30 years’ experience working in the rail industry, specialising in the safety sector, the OPC provides practical, reliable ways of improving performance and assessing ability.

railprofessional @railpromag

PUBLISHER

EDITOR’S NOTE

EDITORIAL EDITOR

Sam Sherwood-Hale editor@railpro.co.uk

DISPLAY ADVERTISING

Adam Overall adam@railpro.co.uk

Jamie Tregarthen jamie@railpro.co.uk

RECRUITMENT ADVERTISING recruitment@railpro.co.uk

SUBSCRIPTIONS subscriptions@railpro.co.uk

ADMINISTRATION

Cherie Nugent info@railpro.co.uk

Lisa

admin@railpro.co.uk

Summer is finally here! We’ll be stepping outside in a few weeks for Rail Live and the convivial spirit will continue with the Chartered Institution of Railway Operators annual conference taking place this month as well. The High Speed Rail Group’s (HSRG) annual conference which is also being held in June.

Centred on the theme ‘Delivering HS2 in Full: Spreading Prosperity and Driving Growth’, the event follows the recent announcement of delays to the project and will consider the ways in which delivering HS2 in full will benefit the UK, including job creation, economic growth, connectivity and the ability to reach net zero.

The event will feature speeches from members of both the Cabinet and Shadow Cabinet on the value high-speed rail brings to the UK. Attendees will also be able to hear a number of industry professionals speak, including Mark Thurston, CEO of HS2 Ltd.

We’re focussing on high-speed rail in this month’s issue with a story about a procurement solution providing a constantly replenishing supply chain for HS2. We also look at electrification, signalling, and trackside with features from Asa Whitfield, Fellow of the Institution of Civil Engineers and Leo Scott Smith of safety technology startup Tended.

As always, we have our usual collection of opinion pieces with comments this month from Andy Bagnall at Rail Partners, Mark Phillips CEO of RSSB, Alison Bell People & Corporate Affairs Director at MTR UK and our regular columnists.

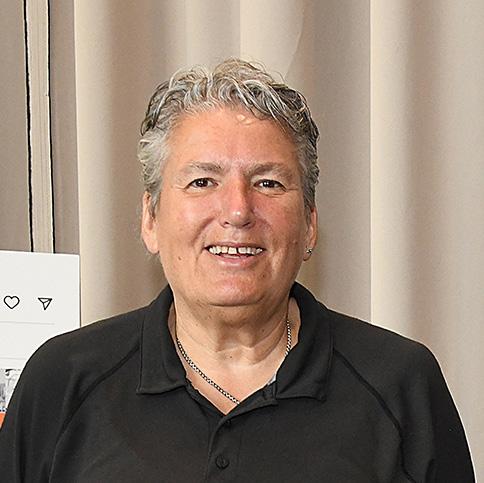

We also have a whole suite of interviews this month. We talk to Sarah Sanderson at Dräger Safety UK Ltd, Clem O’rourke at Frazer-Nash Consultancy, Steve Whitmore of Engauged, Ric Kirman of Korec Group, Martin Osman at Chevron Green Services, Kevin Babstock at Advanced New Technology Ltd, Chris Renshaw of Bratts Ladders and Chris Manning from Sumo Services Ltd.

In this issue

11

NEWS

16

30 Twenty years ago, the Rail Safety and Standards Board was born, Mark Phillips, Chief Executive Officer takes us through the journey since then

33 Jonny Campbell on customer service in the transport sector

34 Nikhil Kaitwade on embracing sustainability in transportation FEATURES

38

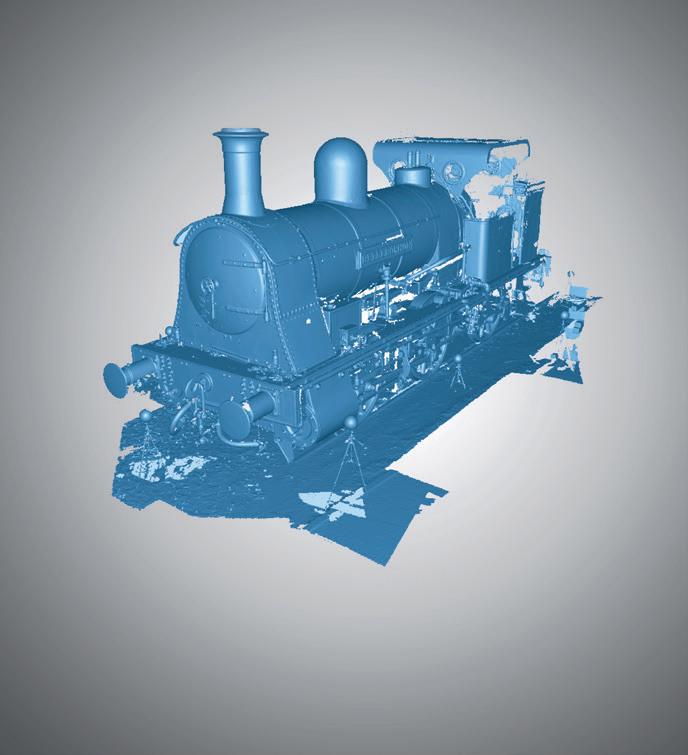

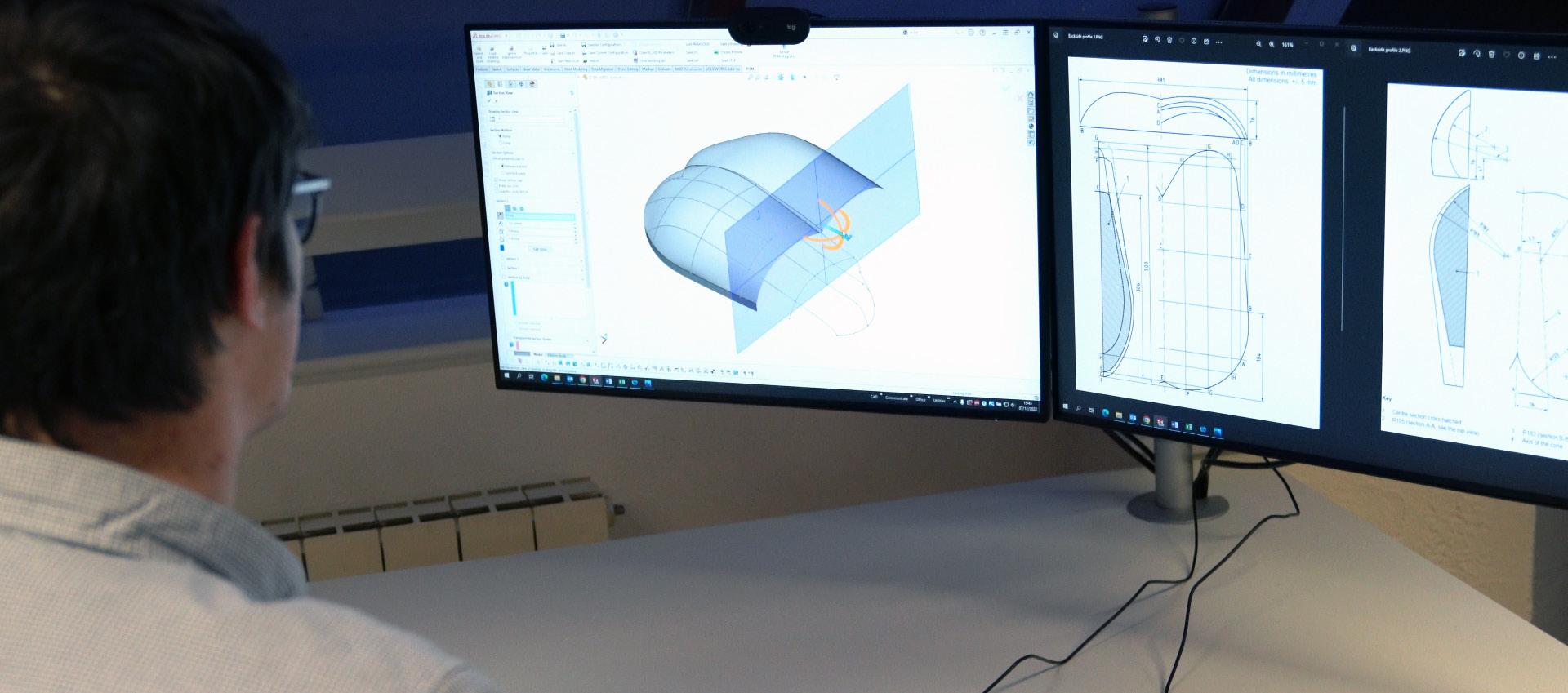

Clem O’rourke Advance Modelling Group Leader at FrazerNash Consultancy BUSINESS

40 Central Scanning

43 Axiomtek

48

Steve Whitmore Managing Director of Engauged

Ric Kirman Business Area Manager Rail & Monitoring at Korec Group

51 RAIL LIVE 2023

Innovation Emerging technologies

Health and wellbeing

Research Data insights

Sustainability Standards

Safety RSSB

Efficiency

We’re with you every step of the way

Leading and facilitating continuous improvement for rail

Twenty years ago this month, the Rail Safety and Standards Board was born. RSSB was created after the Ladbroke Grove crash, as a direct recommendation of the Cullen inquiry.

For two decades, we’ve worked hand-in-hand with the rail industry to make the network safer, more efficient and more sustainable. Now our materials and insights form a dynamic, impartial link between innovation, standards and safety. We close knowledge gaps, ensure new technology can be used safely and efficiently, and help codify and share best practice.

For more about our plans for the future, visit rssb.co.uk/RSSBat20

FEATURES

56 IN CONVERSATION

Martin Osman Consultancy Director at Chevron Green Services

60 IN CONVERSATION

Kevin Babstock UK Sales and Customer Service Manager at Advanced New Technology Ltd. (Ant)

64 IN CONVERSATION

Chris Renshaw Business Operations Manager at A. Bratt & Son Ltd (Bratts Ladders)

66 IN CONVERSATION

Chris Manning Head Of Rail And Infrastructure at Sumo Services Ltd.

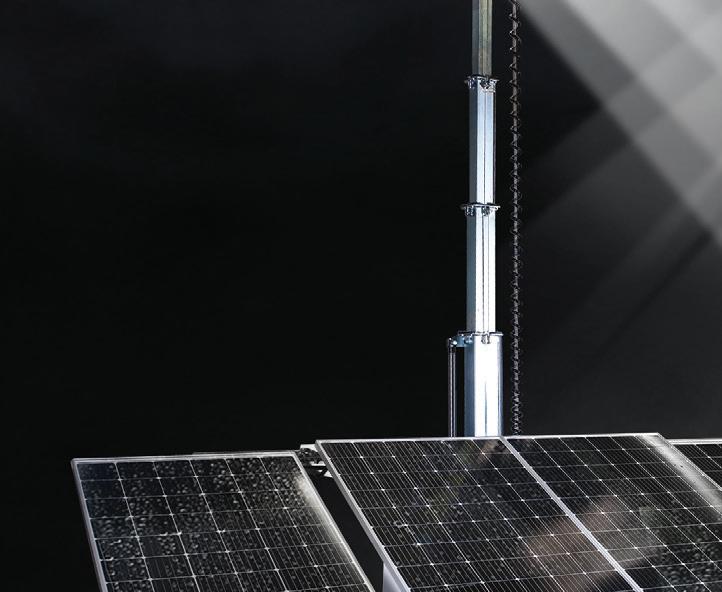

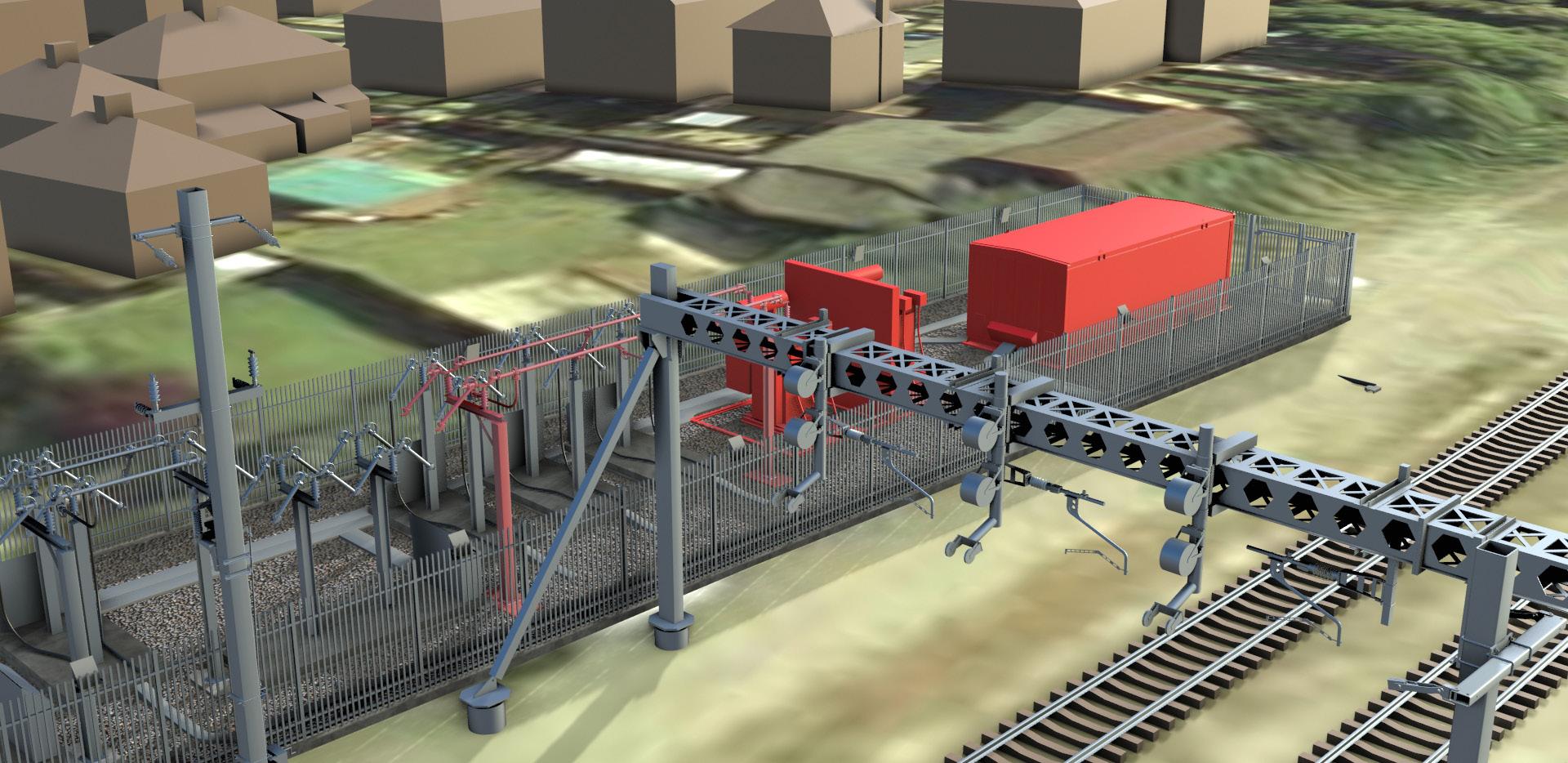

69 HIGH-SPEED RAIL

Align JV chooses unique onsite procurement solution to support HS2 construction

VIEWPOINT

71 Nuclear Success at the Northern Power Women Awards

73

Andy Bagnall, Chief Executive of Rail Partners takes stock of the plan to revolutionise the country’s railways

FEATURES

75 TRACK & TRACKSIDE

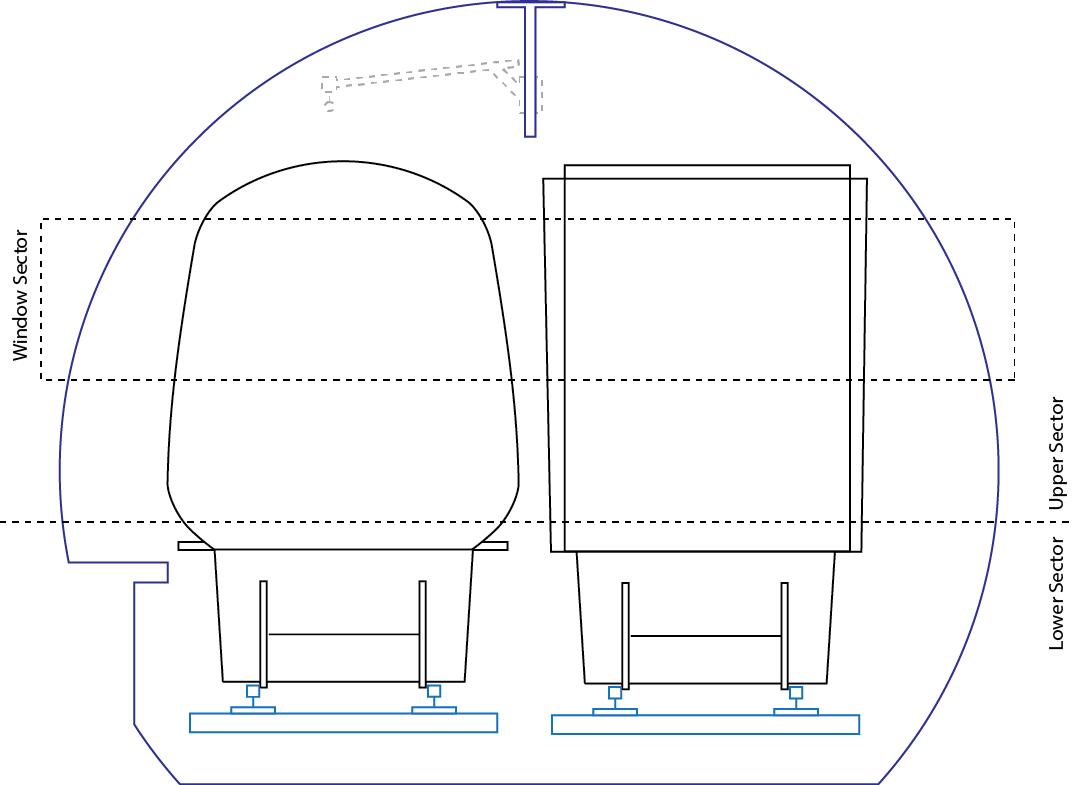

Fit more Square Vehicles through Round Tunnels

79 TRACK & TRACKSIDE

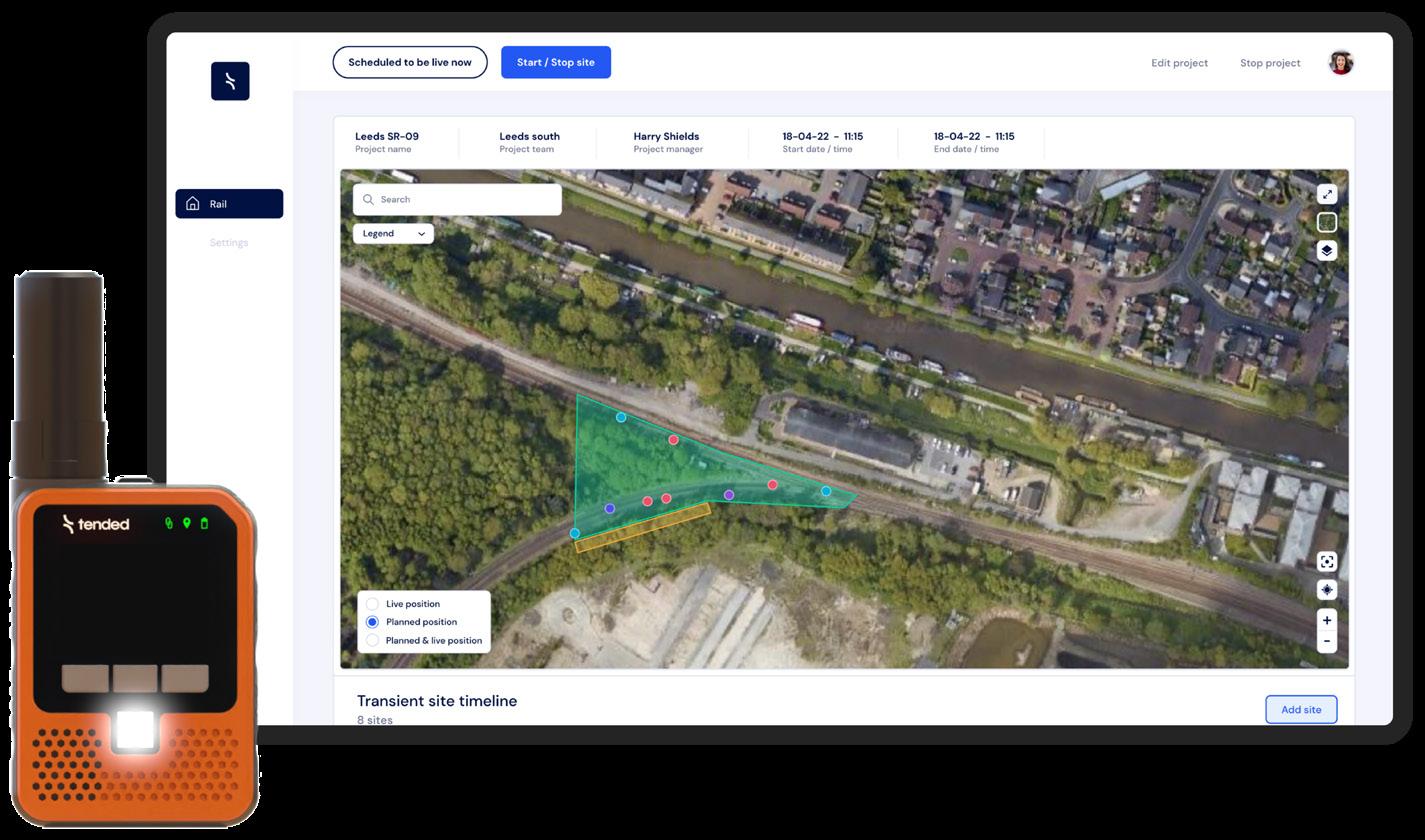

Due to the high-risk nature of trackside environments, ensuring worker safety continues to be an industry priority, says Leo Scott Smith

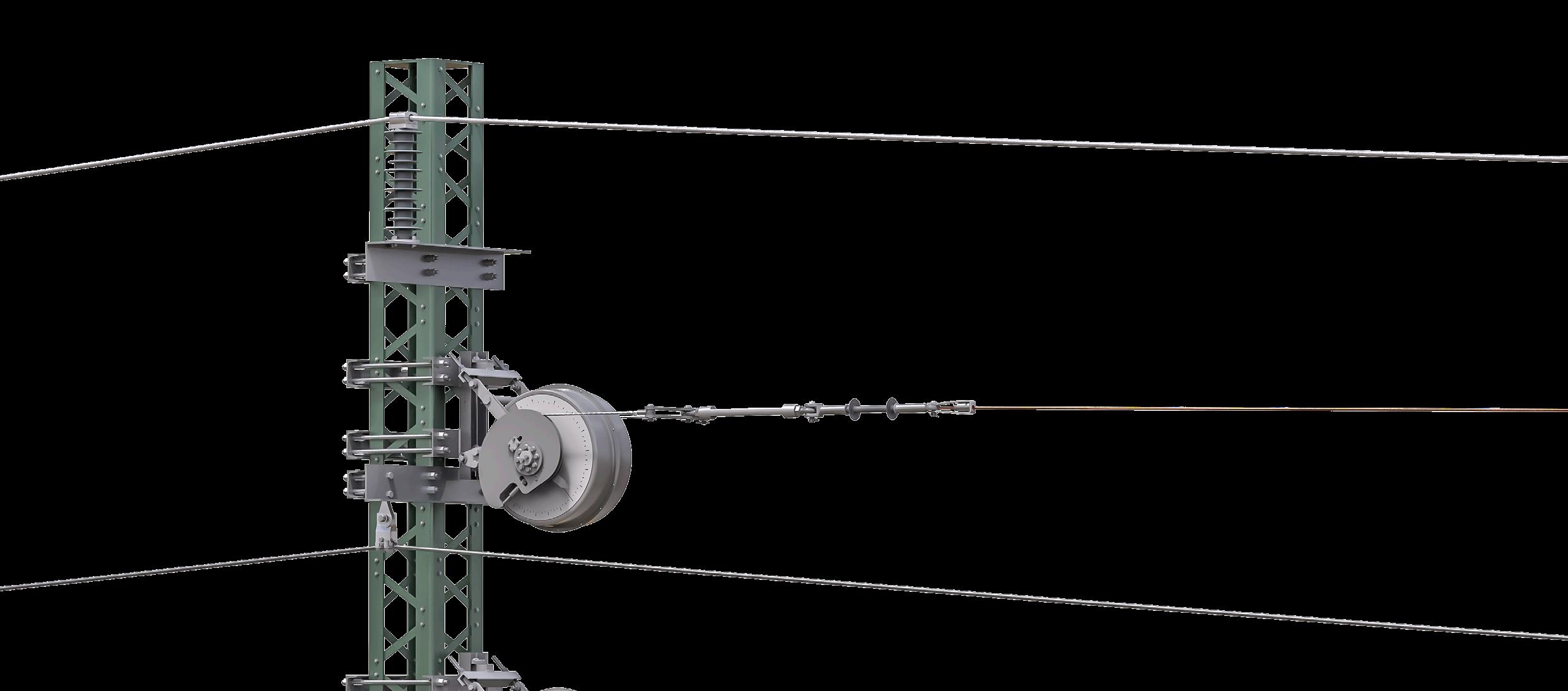

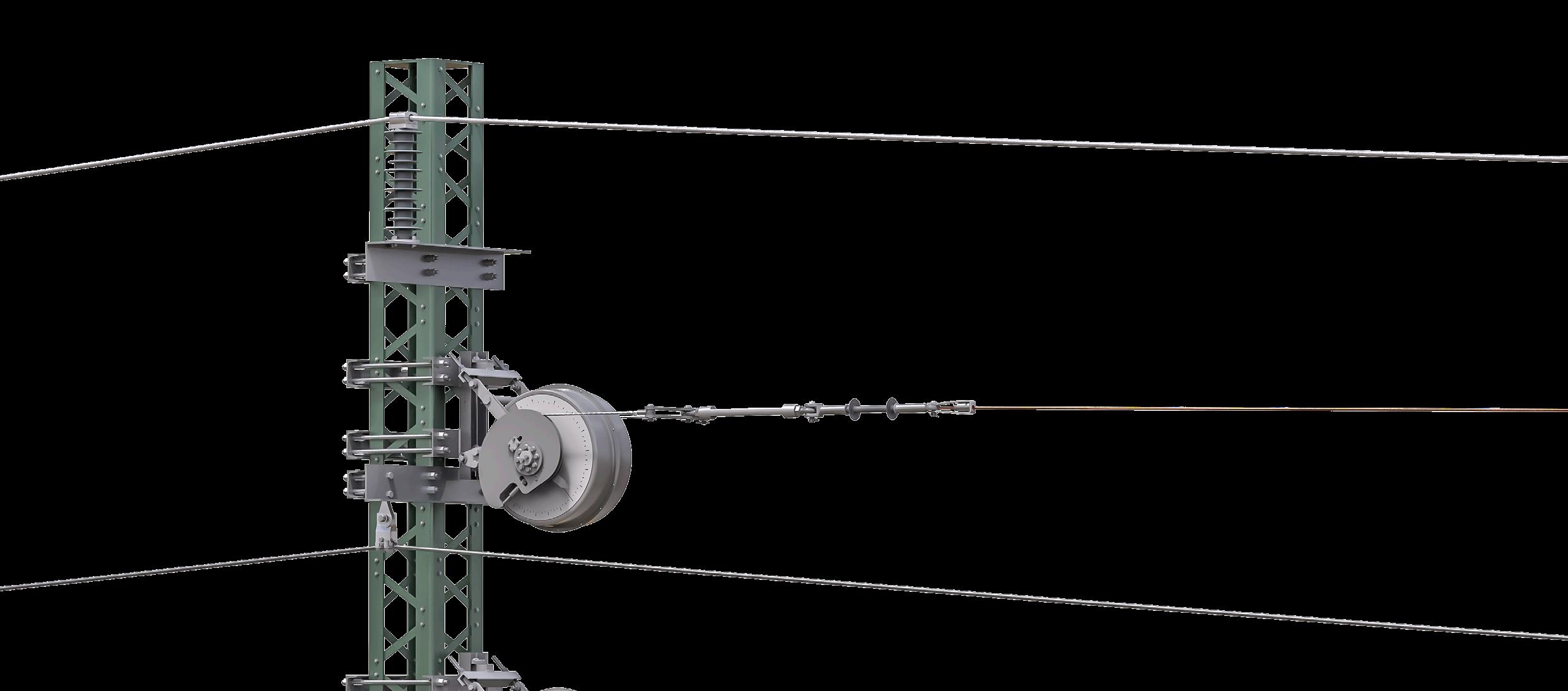

83 ELECTRIFICATION

Asa Whitfield, Fellow of the Institution of Civil Engineers and rail electrification expert on what the UK is doing in this area and why, and whether goals will actually be reached

86 COSS & SIGNALLER NTS

Laura Hedley, Senior Occupational Psychologist at the OPC shares reflections on the inter-dependent safetycritical relationship between Controllers of Site Safety (COSS) and Signallers and how key Non-Technical Skills (NTS) closely fit together to keep track teams safe

90 TRACK & TRACKSIDE

A Geogrid for Demanding Geotechnical Conditions

101

92

102 PEOPLE

Jon Bradley, John Downer, Jessica Ellery, Katy Dowding, Mike Cliffe, Nick Millington MBE, Marcus Jones, Sophie Bancroft, Kevin Storey, John Dowie, Mattias Bjornfors, Llewelyn Morgan, Dr Peter Weldon

KEEP PRODUCTIVITY ON TRACK

When critical industry processes and concerns require the elimination of lost tool issues, the solution is to minimise human error. Let Snap-on ATC handle the control and tracking automatically

CUSTOMER BENEFIT

• Standardise Work

• Improve Productivity

• Control Inventory

• Reduce Losses

• Control FOD

• Improve Security

• Audit Trail

• Increase Accountability

• Oversight Prevention

• Calibration and Maintenance Reminders

AUTOMATED TOOL CONTROL

With advanced digital imaging technology and proprietary software, Level 5 Automated Tool Control System (ATC) scans the tool drawer and records which tools are removed and replaced in real time. You know where everything is at all times without your techs being slowed down for a second. The system also knows when tools are broken, allowing you to replace or repair them right away. It’s tool control that works hard to keep your techs working at their best.

snapon-industrial.co.uk snaponlevel5.com

ATC BOX

PRODUCTS AND SERVICES

• Automated Tool Control Box

• Automated Tool Control Locker

• Value Add: Networking

• No individual scanning required

• No RFID tags to install

• No limitations on tool sizeif it fits in the drawer, it works

• Optional polyurea elastomer coated top vs. stainless steel

WORKS WITH

AUTOMATION

FEATURES & BENEFITS

CONVENIENCE

• Intuitive touchscreen interface

• Audible voice confirmation of tool removal and replacement

• Automatic locking

• Errors announced and displayed for incorrect tool position

• 10.1” widescreen, 16:9 LED, resistive touchscreen

• Dual wireless antennas for improved connectivity

• Hardware – 64-bit processor with 8GB RAM

ATC LOCKER

• Track irregularly shaped items like extension cords, tools kitted in plastic or fabric carrying cases, personal protective equipment and more

• Track serialised items like torque wrenches, multimeters or micrometers

• Fully networkable – connects to Level 5™ administrative interface

• Recharge while storing power tool

ALL THE ACCESSORIES YOU NEED

• FastFlag™ adds status display lights

• ZoomID™ gives you the ability to track serialised, certified and calibrated assets in the ATC Box

ZoomIDTM

FastFlagTM

Tel: 01536 413 904

industrialuk@snapon.com

POWERFUL ADMINISTRATIVE SOFTWARE WITH REAL TIME REPORTING

• Comprehensive analysis, reporting, and inventory tracking can be performed from administrator workstations located anywhere on the network in real time

• Reports are fully customisable and exportable to Excel or PDF

• Registers transactions in real time – both at the box and between the box and the admin client

• Real time communication includes email alerts when tools are used, when calibration is required, when tool status changes and lost or broken events

STATE-OF-THE-ART BATTERY POWER

• 16+ hours of battery run-time; 30 minutes of backup power for uninterrupted power supply

• Snap-on rechargeable batteries feature state-of-the-art circuit protection that prevents overload

SPECIFICATIONS

• 1 year electronics warranty

• Extended warranty available

• Unlimited number of assigned users

• Networking through Ethernet or wireless

• 1 copy of ATC software required for each administrator

Improvement Works to Begin at Chester Station

As part of Transport for Wales’ (TfW) Station Improvement Vision, work to deliver improvements to customer facilities at Chester station will begin next month.

At the beginning of June MPH Construction will begin work on a number of upgrades that aim to enhance the overall customer experience of visitors to Chester station, including new branding and signage, a new passenger assist point, cycle stands, roaming mics and hearing loop systems, full station new CCTV system, toilet refurbishments on the concourse and platforms 4 and 7, a new changing place toilet, water refill unit, platform and concourse seating, waste facilities and LED lighting upgrades.

New Customer Information Screens will be installed throughout Chester station in current and additional locations. This will increase the train service information on the platforms and within the station waiting rooms. New screens will be installed for onward journeys, including bus information, and an interactive screen will be installed within the concourse.

Improvement works in the concourse also include, repurposing of the ticket office to create a new retail unit for the future, a new customer service desk with ticket selling facilities, additional ticket vending machines and a repositioned gateline with additional standard and wide aisle gates. A new quiet room will be introduced as a place for customers who require a safe, isolated space while waiting for their train.

TfW is working closely with industry and local partners to minimise disruption during these works for both customers and

the local community. An essential work site compound will be in place during these improvement works in the Chester West car park from Saturday 27 May until early 2024 and will result in a small reduction in the number of spaces available in this car park. Chester Station East car park will be unaffected.

The aim of these improvements is to provide an enhanced customer experience

and work is currently scheduled to be completed by Spring 2024. TfW is encouraging customers to plan in extra time to allow for potential disruption.

As part of TfW’s Station Improvement Vision, improvements at Flint and Runcorn East stations will begin later in the Summer, with Taziker contracted to carry out the works.

Feasibility Study for Rail Link between Oxford, Witney and Carterton is Published

The case for a railway route connecting Carterton, Witney, and Eynsham to Oxford has been set out in a new feasibility study. The preliminary strategic outline case for the Carterton-Witney-Oxford Rail Corridor (CWORC) was commissioned by Oxfordshire County Council, following proposals from the Witney Oxford Transport Group. The aim was to establish if there is a strategic need for the proposed railway line and to give an indication of the likely investment required.

The study has shown that building a rail link would be feasible and could be justified in transport strategy terms but identifies a number of planning and environmental issues. It also warns about the high financial cost and difficulty involved in undertaking such a project. However, if it went ahead, it would be predicted to be profitable.

The study suggests the journey to and from Oxford could take as little 23 minutes from Carterton, 16 minutes from Witney, and eleven minutes from Eynsham (subject to a more detailed assessment of track and platform capacity). This would represent a saving of around an hour compared to anticipated bus and car journey times in 2031. However, construction costs of building the rail line alone are estimated by the report at between £700 - £900 million, with the scheme potentially being delivered in phases – although no route has been decided at this stage. It would therefore be a long-term project and would also depend on other rail improvements being funded and completed, including the planned upgrade to the North Cotswold Line. West Oxfordshire District Council welcomed the CWORC study and said it strongly supports the work being done to explore the potential new rail link.

Five-year Investment Plan for ‘Backbone of Britain’ Railway Revealed

RIA welcomes continued Government support for rail reform legislation and Network Rail’s publishing of Strategic Business Plans for CP7.

Passengers and freight customers are at the heart of the multi-billion pound 202429 business plan revealed by Network Rail’s North West and Central region on 19 May. The regional Strategic Business Plan (SBP) covers the projected activities, outputs and cost of operating, maintaining and renewing its railway infrastructure between 2024 and 2029.

The publication is a major milestone in the ongoing process to determine Network Rail’s funding requirements for the five years to 2029, which are known as ‘Control Periods’, and the next five years will be Control Period 7 (CP7).

The North West and Central region is the economic spine connecting the country’s main cities – London, Birmingham, Manchester and Liverpool, with vital links to Scotland.

It is devolved into three ‘routes’ – West Coast South, Central and North West –all working closely with train operators, politicians and partners to address the local needs of passengers while working together across the regional and national railway network to get passengers and vital freight goods to where they need to be.

In the North West and Central region the main priorities over CP7 will be:

• Improved train performance: Running a cost-effective and efficient railway for the taxpayer while keeping passengers and freight trains moving safely to a reliable timetable. Major investment will take place to prevent delays caused by adverse weather and climate change in the form of drainage upgrades to reduce the risk of tracks flooding, earthwork projects to prevent landslips and upgrading overhead power lines and track to make them less likely to fail in extreme temperatures.

• Environment: A focus on sustainability so the railway not only remains the greenest form of public transport, but its operations do too with the introduction of electric fleet vehicles and employing latest carbon-saving technology across offices and maintenance depots.

• Sustainable growth: Improving current infrastructure to improve

passengers’ experience and make the railway accessible for all. Plans include investment in technology and research and development, and will facilitate the introduction of major projects such as Transpennine Route Upgrade, preparing for HS2 and other targeted investment across the country, along with supporting the continued growth of rail freight through an ambitious but realistic target of 7.5 per cent growth across the national network.

Tim Shoveller, Network Rail’s North West and Central region managing director, said: ‘Running a safe, green and efficient railway on the West Coast and Chiltern main lines along with the Midlands, North West and Cumbria is crucial to the country’s economic success which is why our plan for CP7 is ambitious, focussed on our passengers and customers and reflects the current complexities and challenges facing the industry.

‘Yet it’s not only about running the railway we already have, but making sure it works in harmony with the construction of the new zero-carbon railway HS2 which continues at pace, and also East West Rail with services due to start running on Phase 2 by December 2024. This will no doubt be challenging, but when complete will transform Britain’s railway – and this funding from Government means the North West and Central region will continue to be a foundation stone of these new rail routes for the future.’

Network Rail’s funding is made available from governments over five-year periods, known as control periods, with control period 7 (CP7) starting on 1 April 2024 and running until 2029.

The Office of Rail and Road (ORR) will now review this initial strategic business plan and review how it measures up against the Government’s HLOS (high-level output specification) and SoFA (statement of funds available), and publish its draft determination on this plan later this year including targets, measures and incentives it will hold Network Rail to deliver over CP7.

The Railway Industry Association (RIA) has welcomed Number 10’s recommitment today to rail reform, and its confirmation that no decision has yet been made on legislation for the fourth session of this Parliament. This follows a letter to Prime Minister Rishi Sunak on 9 May, signed by the Railway Industry Association and over 65 rail business leaders, calling for him to ensure legislation creating Great British Railways in this Parliament is enacted.

RIA has also welcomed the publication of Network Rail’s Strategic Business Plans for 2024-2029 in England and Wales, following their approval by the Secretary of State for Transport, Mark Harper. The Strategic Business Plans provide important details about Network Rail’s spending proposals over the next five-year period (Control Period 7, which commences April 2024), which can help businesses plan ahead and deliver work as efficiently as possible. However, the plans have been published later than usual in the five-year funding cycle, and the equivalent Network Rail plans for Scotland have not yet been published, which are needed for rail supply companies to make their own plans.

Darren Caplan, Chief Executive of the Railway Industry Association, said: ‘The Railway Industry Association and our members will welcome the confirmation today that the Government still supports rail reform, and that no decisions have been made on the timing of legislation to create Great British Railways for the fourth session of this Parliament. We continue to call on Prime Minister Rishi Sunak to ensure the legislation necessary to create GBR is enacted in this Parliament, to ensure there is no hiatus either in key decisions about the future of UK rail or in work by the rail supply sector.

‘Rail supply companies will also welcome today the publication of Network Rail’s Strategic Business Plans and the additional clarity that they provide. We will study them carefully to understand the implications for the railway, including on whether they support a smooth pipeline of investment. We note that these plans have come later than usual, and so may make it more challenging for companies to make the full preparations they would normally be able to make – rail suppliers do need earlier visibility of the plans in future. We urge the publication of the outstanding plans for Scotland as soon as possible.’

TPE Set to Unveil Latest Investment at Hull Paragon

Train operator TransPennine Express is putting the finishing touches to its latest six figure investment at Hull Paragon Interchange. A new gateline, designed to reduce ticketless travel and provide a safer space for rail customers, is set to ‘go live’ next week following an installation process that has transformed the station concourse.

The automatic barriers, which will be staffed when operational, mean rail customers will now need a valid ticket to access the platforms at Hull station. People who want to access the platform to say goodbye to friends or family – or help them to the train – should speak to barrier staff who will use discretion to grant limited access.

Darren Higgins, Commercial Director at TPE, said: ‘The new gateline represents our latest investment in Hull and has been installed to provide an even safer travel environment for our customers.

‘The barriers mean customers will now have to buy before they board at Hull station and tickets for travel are available at ticket vending machines, via our website or mobile app, or from the ticket office at the station.’

Darren added: ‘As with any new technology, it will take people time to adjust to using the barriers and our staff at the station will be on hand to help customers and ensure the gates are used properly.’

Full peak Elizabeth line timetable introduced

Frequencies on the line have now been increased to up to 24 trains per hour between Paddington and Whitechapel at peak time, a train roughly every two and a half minutes. The Elizabeth line's full peak timetable commenced on Monday 22 May 2023 following the May timetable change. The introduction marked the final milestone of the Crossrail project, realising more of the benefits that were promised by Transport for London (TfL) and the Department for Transport (DfT) as joint sponsors including higher frequencies, greater connectivity and faster journey times.

From today, peak time frequencies will increase from 22 to up to 24 trains per hour between Paddington and Whitechapel, with 16 trains per hour running off-peak. The peak will also now last for longer, increasing capacity even further. On the east, more services at peak time will run between Liverpool Street National Rail station and Gidea Park, providing a faster route for those using the Bishopsgate entrance, and in the west, there will be an increase in peak services from Reading, with some trains that were previously operated by Great Western Railway transferring to become Elizabeth line services with reduced stops. The removal of any significant pauses for trains

outside Paddington, will also bring reduced journey times for customers travelling from the west into central London.

The week marked the first anniversary of the opening of the Elizabeth line to passengers on 24 May 2022. In its first week, more than 2.5 million journeys were made on the entire route. Now with journeys from the east and west running through central London, there are an average of around 3.5 million Elizabeth line journeys each week - with around 600,000 journeys on weekdays. This means that the transformational railway, which is on track to break even by the end of the 2023/24 financial year, has already become one of the most used railways in the country as it continues to support easier journeys and new jobs, homes and economic growth.

The railway has been crucial to helping London and the UK economy recover postpandemic, driving public transport demand. TfL figures suggest that the Elizabeth line has attracted around 140,000 additional journeys in London each weekday than otherwise would have been the case. Customer satisfaction is also high on the railway with a score of 82 per cent in TfL's Quarter 4 2022/23 Customer Satisfaction Survey (covering January - March 2023). It has transformed the accessibility of the transport network – with 41 step-free stations unlocking new journeys for disabled and older customers as well as parents with buggies and customers travelling with luggage.

An estimated 30 per cent of Elizabeth line journeys to and from Heathrow have

come from those who might previously have used Heathrow Express to the airport, and in the new timetable there are also more frequent Elizabeth line services to and from Heathrow with trains from Shenfield in the east now going all the way to Heathrow Terminal 5 all day. The airport overall now receives six Elizabeth line trains per hour all day. All Heathrow trains stop at Terminal 2&3, with four trains per hour continuing to Terminal 4, and two per hour continuing to Terminal 5.

Tottenham Court Road has seen the largest (absolute) growth in demand on the Elizabeth line since it opened, with more than 100,000 additional journeys passing through the station each day, more than doubling usage over the year. Farringdon, Whitechapel and Abbey Wood have also seen large rises in demand with 100,000, 60,000 and 30,000 extra journeys respectively, again doubling or nearly doubling the customer journeys that were seen through these stations before the Elizabeth line opened.

Journeys to Canary Wharf as a whole (Elizabeth line, London Underground and DLR) on Tuesdays, Wednesdays, Thursdays as well as at weekends are regularly outstripping pre-pandemic demand to the area. There are now twelve trains per hour running between Canary Wharf and Abbey Wood in the peak, restoring the frequency that was in place when the Elizabeth line opened last May, with a train around every five minutes. The morning and evening peak times also now last for longer, increasing capacity even further.

Technology for Life

Sam Sherwood-Hale spoke to Sarah Sanderson, Tunnelling Product Specialist at Dräger Safety UK Ltd about medical and safety technology and how their products protect, support and save lives

SSH: What was the founding inspiration behind Dräger?

SS: Dräger are a leading manufacturer of both medical and safety technology products. In so doing, we protect, support, and save people's lives around the world within hospitals, through fire departments, emergency services, authorities, and within both tunnelling and its associated industries.

Founded in 1889, Bernhard Dräger invented the Lubeca valve, ultimately resulting in the first high pressure controlled-release valves and closed-loop technologies being created. While first designed to release carbon-dioxide gas into beer taps, this technology developed to become a crucial component of medical and safety technologies in the many years that have followed.

In 1906, following a mining disaster, Mr Dräger travelled to France taking with him a Dräger breathing apparatus he had developed two years earlier. Its continued use gave rise to the term ‘Drägerman’ –given to a group of extraordinary men and women all across the world who have volunteered to be trained in mining/ underground rescue. Whilst the technology has of course been modernised over the years, the ethos of the business remains the same: to protect and save lives in challenging environments.

SSH: How long has your company been in business?

SS: Dräger has been synonymous with technology for life for more than 130 years. Protecting, supporting, and saving lives is a key part of our DNA. The company was founded in Lübeck in 1889, and is now in its fifth generation as a family-run business. From humble beginnings, the company now has over 16,000 employees across the globe and is present in over 190 countries.

SSH: What types of products and services do you offer?

SS: The products and services we offer are vast and encompass numerous different sectors. Within the fields of emergency response and personal safety technology, our products include gas detection devices, self-rescuers, breathing apparatus, thermal imaging cameras, mine refuge chambers, impairment monitoring and detection alongside assorted PPE solutions and ancillaries.

But with great products, you need great support; the Dräger Training Academy

and Dräger Services teams are designed to enhance the efficiency of equipment, to consolidate best-practice and equip teams with industry-leading knowledge and experience to enable users to maintain and operate its technology for use in hazardous environments with minimised risk. Service agreements are also part of our offering, packages such as: TotalCare, PreventiveCare, ExtendedCare and PartnerCare are all available to our customers to ensure effective maintenance of equipment, extend manufacturer warranties and include provision of repair parts and labour, dependent on the level of care selected.

SSH: What are some major projects you’re currently working on?

SS: Several rail projects require, or have required, Dräger Safety equipment, utilising different products at different stages of the project timeline. Most recently, several stages of the HS2 project use the Dräger Oxy range of self-contained selfrescuers. These 30 minute and 60-minute devices provide additional options for the emergency planning concept and ensure the highest standard of breathing protection for personnel. Rescue trains are also in operation in Europe, across Switzerland and Germany to provide emergency aid for rail networks in the absence of road or air access through difficult and unpredictable terrain. Speaking more broadly, most major projects, including rail, require some form of PPE. Examples of the Dräger PPE range include reusable and disposable suits, head protection, respiratory protection and safety eyewear, continuing to protect personnel in the harshest and most dangerous environments with the confidence that they are safe from harm.

Whilst technology develops at fast pace, we anticipate future focus to be built around information and data processing with interconnected functionality.

Hazardous environments carry enough risk alone, so both Dräger Alcohol and Drug screening devices alongside Vehicle Immobilisers are used in a growing number of industries including many rail, transport and industrial applications, ensuring control of risk due to impairment.

SSH: What would you say is the most exciting technology in the industry?

SS: Whilst technology continues to advance at fast pace, real excitement has risen through the development of interconnected and multi-purpose emergency response systems that not only prevent dangerous incidents from taking place but also provide early identification.

Designed for long-duration deployment in hazardous environments, Dräger’s flagship Closed Circuit Beathing Apparatus (CCBA), the BG ProAir, prevents harmful substances and contaminants from entering the sealed breathing system. With the ability to allocate oxygen dosage according to your work rate and specific environment, rescue tactics can evolve according to the surrounding environment to further protect against danger. But where this technology is especially innovative, is in its ability to integrate with additional life-safety devices, and smart onboard electronics.

Hands-free thermal imaging cameras such as the UCF® FireCore added provide

hands-free vision in low-visibility, unfamiliar terrain that tunnelling personnel may encounter. This innovative product provides constant vision from a display screen within the Dräger full-face mask, meaning emergency and rescue teams have greater situationally awareness and an improved level of orientation.

SSH: What are some of the biggest challenges this sector currently faces?

SS: One of the biggest challenges within the tunnelling industry is that the numerous, on site, contractors and sub-contractors have different preferences between not only brands but also product types, a situation which can make safety planning and procurement particularly challenging. These challenges, however, are understandable, given the huge scale of certain projects.

The industry also suffers in the form of overlapping, or indeed underlapping guidelines and safety precautions that intersect with those found within the wider construction industry. Tunnelling often sits between the more stringent mining regulations and construction regulations in this regard. So, for example, a project manager working on a tunnelling project may be from a construction rather than a mining background, and that can lead to inconsistencies in how underground safety is approached.

Whilst presenting significant difficulty to industry professionals, the answer to both challenges can be found through greater transparency and cross-company collaboration. We as an industry need to work together to ensure that safety planning is as straightforward as possible, and that procurement can be viewed holistically thereby reducing project timescales and protecting industry personnel in the same breath.

SSH: How can we make tunnelling within the rail industry an environment people want to work in?

SS: Tunnelling environments can be extremely hazardous, with a variety of different machinery being used within a confined space, often at the same time. We regularly hear of global projects where stakeholders have been extremely relieved when there have been no major incidents after a year. The fact that these incidents are relatively common goes to show that serious accidents are not that rare, and safety equipment and planning should not be considered a ‘nice to have’ but deemed critical and essential.

Manufacturers hold responsibility to keep tunnelling personnel as safe as possible in the confines of such environments. Detailed safety and rescue strategies must be planned, coordinated, and agreed across all interest groups. These efforts must be made to increase the health, safety, and wellbeing of tunnelling professionals, to retain and indeed attract new staff in an industry with falling numbers.

If we can’t retain staff through feeling valued, safe, and healthy, the industry is failing in its mission.

SSH: In terms of technology, how do you anticipate things might change in the next five to ten years?

SS: Whilst technology develops at fast pace, we anticipate future focus to be built around information and data processing with interconnected functionality.

Knowledge, as the saying goes, is power and in an emergency, the quality of information received about an individual and the risks that they face can be the difference between life and death. By combining technologies, such as gas detection, SCBA/CCBA equipment and thermal imaging cameras with sufficient monitoring oversight, we can detect changes to a person, or their environment and adapt rescue or operational tactics to prevent potential dangers before they present worry.

Whilst Bluetooth® provides shortrange connectivity to several products, the development of long-range transmitters would be revolutionary in the tunnelling and associated industries, providing the ability to enhance communicative channels, present clearer commands and provide sufficient oversight to keep individuals and teams safe from harm.

RIA Annual Conference 2023

Promoting the case for rail and investment in uncertain times

1 and 2 November

Early Bird tickets now available!

2-day conference with inspiring keynotes, interview sessions and panel discussions

Large interactive exhibition area with spotlight pitches presenting services, products and solutions

Evening programme including networking drinks, dinner and entertainment

New to The Rail Industry and Want to Kickstart Your Career?

CIRO have three dates available throughout 2023 for a one-day Introduction to Rail training session, designed specifically for those who are new to the industry or more experienced members from support functions within rail.

What will I learn?

Throughout the day learners will gain a comprehensive picture of the rail environment and enjoy highly participative sessions where they are guided through interactive exercises. There are also regular opportunities for the learners to ask questions to affirm their understanding of the topics.

When and where is the training

Dates: Tuesday 7th Feb, Wednesday 12th July, Thursday 26th October

Times: 9.30am - 4.30am

Location: Beacon Building 2nd Floor, Stafford Enterprise Park West, Weston Road, Stafford, ST18 0BF

Refreshments and a light lunch will be provided for attendess on the day.

What is the cost?

Members: £350.00 inc vat

Non Members: £400.00 inc vat

Book to Attend

Available Dates

To book a place on any of the three Introdcution to Rail training days, or for more information about the day or course content, contact our learning and development team at learnserve@railwayoperators.co.uk. learnserve@railwayoperators.co.uk

Learning by Doing in a Virtual World

MTR’s UK operations continue to drive a technology-first approach and adapt to external challenges, to ensure that their driver training programme remains one of the most successful in the industry. Alison Bell outlines the company’s virtual learning programme

Change and innovation is critical to business success – bringing it about includes working with long-established professions to establish practical solutions to emerging challenges. One such profession is that of a train driver; a role that has changed beyond recognition in recent years.

Today’s drivers not only need to be fully conversant with the safety regulations and the routes they operate, they also need to have an unprecedented level of technical knowledge of the trains they drive. Traditionally, acquiring such knowledge comprised a mixture of classroom learning, shared experience with peers, and comprehensive practical experience in the railway operating environment.

Across the industry, there is a steady demand for new train drivers, and there is no shortage of candidates. However, the rigorous training programme acts as a pipeline, designed to deliver qualified drivers when they are needed.

The pandemic not only disrupted global supply chains; it also disrupted traditional methods of training, impacting the supply of newly qualified drivers to the rail industry. Effective training programmes usually require a high degree of social interaction; in the case of the rail industry this can include confined and enclosed spaces such as driving cabs. None of this is conducive to social distancing.

While MTR had already developed the technology to deliver experiential training, the pandemic accelerated the need for us

to draw on these techniques to develop the way we deliver mission-critical training in the future.

We chose to use our own in-house specialists to develop a toolkit for trainee and qualified drivers that includes Augmented Reality (AR) apps, targeted training video content, a bespoke learning portal, and Virtual Reality (VR) supported learning.

Previously we had delivered core operational and rule book principles either using a tabletop simulation kit (akin to a plastic ‘toy’ railway) or visuals in the classroom. Traditional forms of assessment, such as exams and tests, could be uninspiring and rigid, making it difficult for learners to receive immediate feedback on their performance.

VR technology can overcome this limitation by providing learners with realtime feedback on their progress, allowing them to adjust and make improvements immediately. This type of immersive learning recognises the benefits of an experiential learning style as outlined by David Kolb, an American psychologist and educational theorist. In layperson-speak, this means ‘learning by doing’. Whether we are learning to ride a bike or learning to walk, we achieve this by practising and refining our technique.

The course syllabus was enhanced to encourage experiential learning, resulting in the evaluation of various applications. We chose to develop our own mixed-use experience. This included our application

that can be used almost everywhere. It ensures that the user can access the same essential training remotely and not be tied to classroom delivery.

Our App is used to build and interact with anything railway related, including all elements of track, infrastructure, and signalling including European Rail Traffic Management System (ERTMS) principles. A key function of the App is that it is networked. By using built-in Voice over Internet Protocol (VoIP) networking, it allows a facilitator to deliver core operational rules and regulations for both training and assessments, whilst candidates are working remotely.

Adopting technology to enhance this type of training delivery helped us to introduce a much more immersive experience of driving a train. It not only allows a user to build railway infrastructure, it also acts as a train simulator and allows a trainee to simulate driving a train in the built environment.

Although there is no substitute for the real thing, mixed-reality applications have been used to allow a candidate to access traction training without the need for a depot or a real train. The application allows the candidate to place an augmented reality train anywhere they want, whether they are sat in a classroom, or if they are based at home or elsewhere. The principle is a candidate can access the App and use it for self-learning, revision, or during a facilitated session.

The technology being used introduces the ability to both build and explore. For example, a question-and-answer style format helps the trainee to identify how a train is built. Although the train in the application is built on a Class 345 EMU

‘VR technology can overcome this limitation by providing learners with realtime feedback on their progress, allowing them to adjust and make improvements immediately. This type of immersive learning recognises the benefits of an experiential learning style … ‘learning by doing’.’

NEWS IN BRIEF

GREAT GARDEN RAIL TRAIL BRINGS

NEW TWIST TO ST ELIZABETH HOSPICE FUNDRAISER

Suffolk rail station gardens will join St Elizabeth Hospice’s Great Garden Trail this summer to help raise funds for the charity. The Hospice has partnered with Greater Anglia and the East Suffolk Lines Community Rail Partnership to add an exciting new element to its annual fundraiser, creating the Great Garden Rail Trail event, which will take place on 9 July 2023. Meeting at Ipswich at 10.30, guests will take a special trip by train for a guided tour of the East Suffolk Line between Ipswich and Lowestoft, highlighting the stunning station gardens that can be found along the route.

foundation, the concept is generic enough that it can be used by anyone who would like to understand how a train is constructed. Users can ‘build’ a train from the ground up, encompassing every aspect of traction familiarisation, including the electrical system, braking system and all other associated equipment required to get a train moving.

Another section focuses on the principles of identification and location of equipment. The candidate can ‘walk’ through the train and highlight all equipment while, at the same time, receive narration explaining details about that equipment.

Finding a train for initial training can be difficult, but once a driver is qualified, securing a unit for continual competence development can be even more challenging.

The application also introduces the functionality for a potential assessor to ask the candidate to identify the train equipment and the candidate can highlight that equipment. This removes the need for a train and allows the candidate to form traction-related competence management at a distance virtually.

It is important to emphasise this will not replace practical traction training but can enhance it in a way that provides a driver

with more experience. This negates the need to secure a physical train as often, whilst providing drivers with an opportunity to learn wherever and whenever they need to.

We now have the capability to provide accessible and flexible content that is designed to adapt to the various ways individuals learn and can be tailored to specific roles. Moving forward, we are exploring approaches to utilise technology further as we develop a range of training programs. For example, training on communication skills, problem-solving, and conflict resolution.

By developing new techniques, MTR has created innovative and engaging processes to adapt and future-proof training delivery. We now prioritise a blended approach to training and an experience-based learning environment, including a mixture of classroom, practical and virtual learning when a training module is constructed.

While our virtual learning approach to driver training has played a crucial role in demonstrating the benefits of innovation, we must not stand still. As an industry, we must continue to seek out new ways to embrace and adopt technology to remain forward-thinking and progressive. MTR intends to do just that.

Rail Industry Celebrates the Women in Rail Awards 2023

The sixth Women in Rail Awards took place on Thursday 18 May at the stunning and iconic Roundhouse, Camden London

The evening saw 14 awards being presented across 13 individual and team and corporate categories, with a further ten Highly Commended awarded to exceptional shortlisted nominees. Delivered by Nimble Media, the event was attended by over 760 individuals from across the rail industry, coming together to celebrate colleagues, teams and companies, who work hard to support others and to help create a more gender balanced, diverse and inclusive work culture in our industry.

Following the Champagne Reception, guests were serenaded to their seats by the Southeastern TRAXChoir. A welcome address from Huw Merriman, Minister for Rail and HS2, marked the opening of the ceremony, followed by Vice-Chair of Women in Rail, Shona Clive, then an inspirational address by Anit Chandarana, Lead Director, Great British Railways Transition Team. Returning host, Gemma Cairney - Broadcaster, Youth Rights Activist and Author – and selfdeclared rail enthusiast – added a witty commentary to the evening.

For more information about WR visit https://womeninrail.org/.

For 2023, a celebration of the allyship shown to Women in Rail over the past decade was rewarded, with the introduction of Male Rising Star and Apprentice of the Year categories. In addition, to add to the legacy left to the charity by its Founder, Adeline Ginn MBE, two categories were created to recognise an Unsung Hero and the dedication of a long serving member of the industry with the Lifetime Achievement Award.

The 2023 Adeline Ginn Unsung Hero was named as Laura Warwick of Avanti West Coast – who the judges felt went ‘BEYOND

above and beyond’ to support local charities, with a focus on mental health support, making a huge difference in the lives of her community’s most vulnerable people. Neil Pepper MBE of Transport for London was presented with the Adeline Ginn Lifetime Achievement Award, to honour his inspirational 36-year career in rail - during which he continues to be an avid STEM ambassador, inspiring thousands of children in London and the home counties, a passionate advocate for women within the industry – and a champion of equality, diversity and inclusion for all.

In a first for the event, the judges chose to celebrate the efforts of two exceptional women for The Equality Diversity and Inclusion Individual Award. Elizabeth O. Umoke of Arriva Rail London – London Overground – and Laura Phoenix of Alstom – both deserving winners and incredible EDI Champions, who, as part of their working and voluntary roles within their organisations, have spearheaded changes for EDI within their companies and the wider industry.

The judges specifically requested that all the nominees be commended for their hard work, selfless dedication, and commitment and that a huge thank you be directed to all those, and especially male allies, who nominated for this year’s Women in Rail Awards. The full list of Winners, Highly Commended and Shortlist is available to view on the Women in Rail website. Shona Clive, Vice-Chair of Women in Rail and Project Lead for the Rail cluster project and the Forth and Tay Offshore project, Scottish Engineering said: ‘The calibre of this year’s nominations was truly exceptional. We received over 430 entries from – and in respect of – a wide range of individuals, teams and companies in the railway sector, many of them from male allies nominating their female co-workers.

The judges admitted having a very difficult task selecting who should be shortlisted and ultimately win. Congratulations to everyone who was nominated – and of course to our winners –who continue to promote and improve EDI across the sector.’ Women in Rail would like to extend a big thank you to all the 2023 Sponsors:

• Headline Sponsors – SPL Powerlines UK Ltd.

• Category Sponsors – BAM Nuttall Ltd, Worldline IT Services UK LTD, Morson Group, Egis, KeolisAmey Docklands, West Midlands Trains, Beacon Rail Leasing Limited and Hitachi Rail Limited.

• Fundraising Sponsor – Telent Technology Services Ltd.

• Table Gift Sponsor – Kier Infrastructure and Overseas Limited.

• Table Decoration Sponsor – Rail People Solutions.

The awards received tremendous feedback and we look forward to celebrating our inspirational colleagues with you again next year at the Women in Rail Awards 2024!

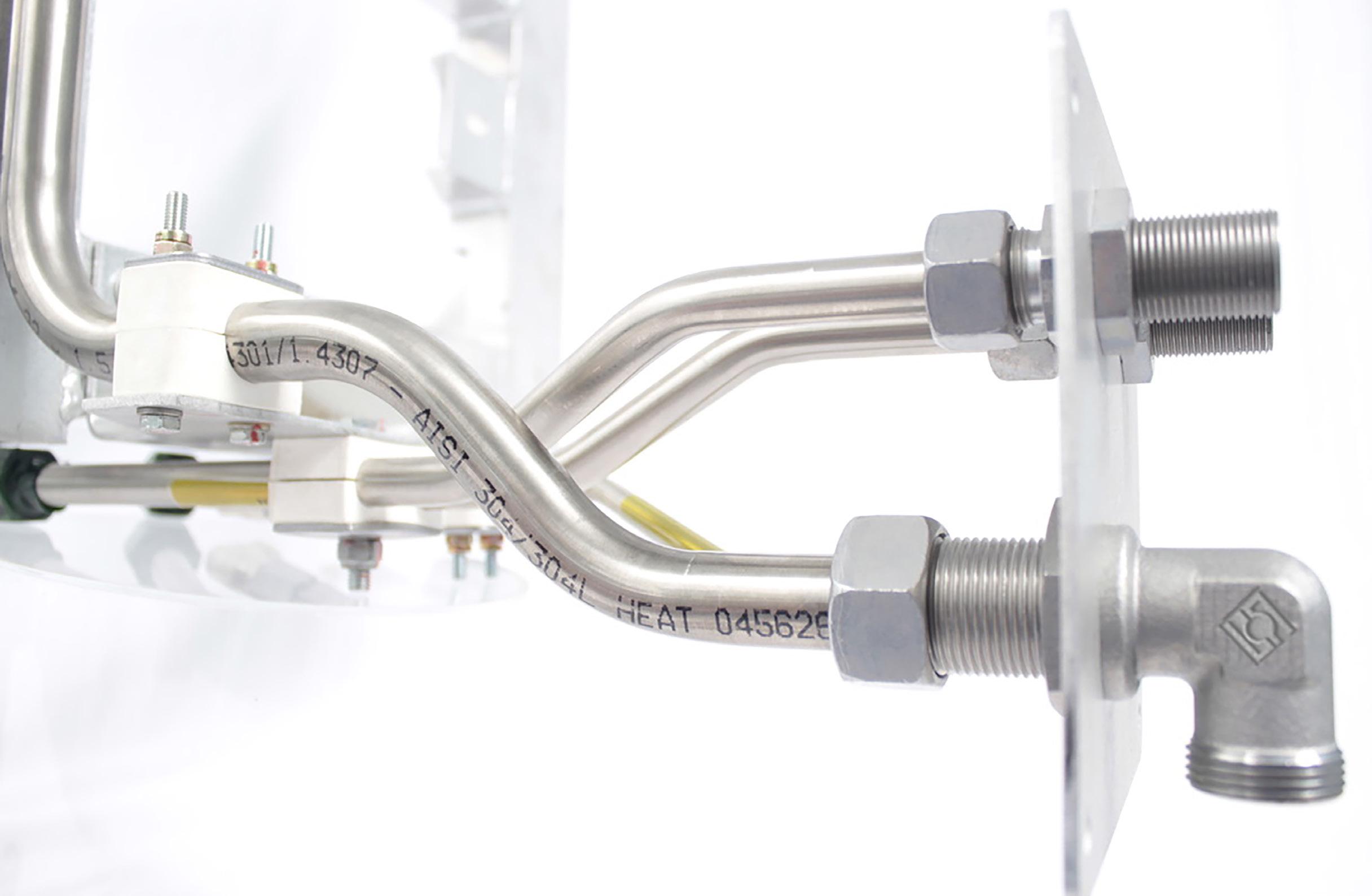

Approved Hydraulics have been supplying some of the largest rail build and maintenance firms for over 10 years, now considered some of the best in the world!

Over the past 20 years Gall Zeidler Consultants has completed 550km of tunnelling projects across the globe, establishing our position as a world-leader in tunnel design and consultancy services. Our specialists relish a challenge and always deliver – it’s why we’re a leader in innovative underground solutions, geotechnical engineering, bespoke tunnel design, tunnel rehabilitation, and project/construction management.

LAYING DOWN THE LAW

by Martin FleetwoodAnother Push Towards Greater Energy Efficiency in Commercial Property

The aim to reach carbon net zero by 2050 within the UK's rail sector tends to lead most people to think about power supply issues, with proposals for more trains and support vehicles to run on electricity, hydrogen or other alternative fuels

Others look at how electricity is produced to heat and light railway buildings. However, there is much more to reaching net zero, including considering the energy efficiency of the buildings being used on the railway estate and those of the contractors working in the rail industry.

Tenants are increasingly requesting ‘greener’ properties with better and more efficient facilities which will generally lower the operating costs of those properties. This is not just a cost issue but also a social responsibility one as businesses look to promote themselves as being energy

efficient alongside other green credentials. In addition to the desire for tenants to push for greener benefits, the law is also starting to bite on energy efficiency and is setting higher minimum standards for commercial landlords to comply with.

Energy efficiency regulations tightening their grip

Back in 2015 minimum energy efficiency requirements were established through the Energy Efficiency (Private Rented Property) (England and Wales) Regulations 2015 (MEES Regulations). While they only apply to property required to have an EPC rating (established under the Energy Performance of Buildings (England and Wales) Regulations 2012 (EPC Regulations)) a significant amount of commercial property will fall within this requirement.

Some types of commercial property and certain very long or very short leases are expressly excluded from the MEES Regulations, but in practice these exclusions are fairly limited. The MEES Regulations look at the substance of the relationship rather than the name given to the relevant document, thereby reducing the opportunity for parties to try to circumvent the regulations.

The MEES Regulations came into force in 2018 and made it unlawful to grant a new lease of a property with an EPC rating of F or G (as defined in the EPC Regulations) unless one of the exemptions set out in the MEES Regulations applied. However, any existing

Martin Fleetwood is a Consultant at Addleshaw Goddard’s Transport practice. The Rail Team has over 30 lawyers who advise clients in both the private and public sectors across a wide range of legal areas. As well as contractual issues, the team advises on operational matters, franchises, concessions, finance, regulatory, property, employment, environmental and procurement issues.

Disclaimer: This article is for informational purposes only and does not constitute legal advice. It is recommended that specific professional advice is sought before acting on any of the information given.

leases of properties with an EPC Rating of F or G were unaffected and remained lawful at that time.

An important role of the MEES Regulations is to create a slow tightening of the energy efficiency requirements of buildings which a commercial landlord can let. There is an aspiration of the minimum standard reaching an EPC Rating on B by 2030, with a number of stepped changes to increase the minimum permissible rating between 2018 and 2030. The first of these key dates has now been reached.

With effect from 1 April 2023, it has become unlawful for landlords to continue to let a commercial property with an F or G EPC rating, even if the lease was granted prior to the MEES Regulations coming into force in 2018.

Compliance is primarily the duty of the landlord

Where a commercial property continues to be let in breach of the MEES Regulations, it is the landlord, rather than the tenant who will be liable for the breach. The MEES Regulations do not require a landlord to actually carry out the necessary works to improve the EPC rating, but instead imposes a number of penalties, which include financial penalties (ranging from around £5,000 to £150,000) and reputation risk as breaches are published on a public register. It is intended that these penalties will encourage the landlord to undertake the relevant remediation work to increase the

‘With effect from 1 April 2023, it has become unlawful for landlords to continue to let a commercial property with an F or G EPC rating, even if the lease was granted prior to the MEES Regulations coming into force in 2018.’

EPC rating appropriately. Repeat penalty notices can also be served for a breach which has not been appropriately rectified, thereby increasing the cost of non-compliance to the landlord. Breaches are enforced by Local Trading Standards and to date there has been little evidence of any enforcement. 59 local authorities have recently been awarded government funding to help with enforcement, so it should be expected that more fines and listings on the public register will begin to take place.

An important part of the MEES Regulations is that while fines may be imposed and lack of compliance publicised, the lease itself continues to be valid and binding. This means that the tenant can continue to use the property and their business should not be particularly interrupted. The main source of business interruption is likely to come from the landlord wanting to carry out remedial works to improve the EPC rating. Such works should be carried out in accordance with the relevant terms for landlords works set out in the lease agreement.

In addition to the penalties imposed on landlords, there is a potential for some aspects of the MEES Regulations to affect tenants too. Tenants who grant sub-leases will take on the responsibility of the landlord

and be subject to financial penalties if the EPC rating of the property being sublet is below the relevant threshold. If a tenant refuses to allow a landlord access / permission to undertake works which would improve a below standard EPC rating to meet the relevant threshold this information may become publicly available on the national register. Such an action could have a negative effect on the tenant's own ‘green’ credentials.

Managing the squeeze on EPC ratings

In 2022, the Government estimated that around 18 per cent of commercial properties within the UK were F or G rated. While a number may have been brought up to a minimum EPC Rating of E by 1 April 2023, it is likely that there will remain a significant number of properties which fall below this. As a result, there is expected to be some tension between landlords and tenants as each party grapples with the risk of noncompliance and additional costs to raise the energy performance of buildings to higher levels.

If parties are unsure as to whether the EPC Regulations and the MEES Regulations apply to some or all of their properties, a review should be conducted on a propertyby-property basis. Simply assuming that all will be treated the same would be unwise.

As the minimum rating increases the potential fines and required remediation works could become more of an issue, particularly if the work that the landlord wishes to carry out is relatively disruptive. Ensuring that the relevant powers of the landlord are not too onerous will be important to the tenant, particularly when negotiating any lease renewal. Energy efficiency regulations tightening their grip.

Both tenants and landlords should be aware of their EPC rating, and any terms within their lease which permit the landlord to undertake remediation works to improve that EPC rating. Such works may also have an effect on the rental that can be changed. Tenants should take note of how increases may be calculated and when rents may be increased as a result. It will be interesting to see the extent to which landlords will balance the cost of remediation works compared to potential fines for having below standard EPC ratings, particularly in the first year of the process. The next part of the process will be the extent to which new terms which take account of the EPC rating changes are incorporated into lease renewals.

WHAT’S THE COST OF LIVING?

Rail Still Needs Industry Skills

A City & Guilds report – released in February 2022 – states that only 23 per cent of people looking for work would consider a career in transport and logistics, and with the ongoing shortages, Ellis Shelton, Policy Advisor at Logistics UK explains why it is vital this is addressed

The UK’s most vital industry is still being threatened by skills shortages due to factors such as poor reputation and a lack of understanding surrounding the opportunities and progression available for employees.

The rail network is essential to keeping the country moving through a greener, more efficient mode of transport that delivers sustainability for logistics businesses. Yet rail is one of the sectors being seriously affected by the shortage, with the UK experiencing eight days of rail strikes leading up to and over the Christmas period as part of a long-running dispute over pay, jobs and conditions. A record high was recorded in January 2023 with Avanti West Coast cancelling the equivalent of 18.9 per cent of their services – one of the highest figures recorded for any operator in records dating back to April 2014.

An industry report ‘Keeping Talent on Track’ released in February 2023, outlined that up to 120,000 additional people will be required in the rail sector over the next five to ten years, with pinch points coming as an ageing workforce retires. Currently, 28 per cent of all rail workers are aged 51 and over with the potential for 15,000 to retire by 2025 and focus therefore needs to be on recruiting employees at a younger age and providing them with proper training and development prospects.

Diversity is a significant challenge in the sector. Women make up a significant portion of the UK workforce however only 16 per cent of workers in the rail industry are female, and only two per cent of those are engineers. Encouragingly, the percentage

of women in engineering roles across all sectors has increased from 12 per cent to 14 per cent over the past three years however, the same progress has not been reflected in rail and therefore the sector is missing out on a larger opportunity for recruitment. Upskilling of the workforce is also crucial as the use of digital technologies becomes more frequently used, with approximately 80 per cent of the industry requiring training over the next two decades. Government’s £96 billion investment for the integrated rail plan, published in November 2021, has the potential to create up to 12,000 jobs every year over the next five to ten years, but without the proper training and support in place to create a younger and more diverse network, the rail sector cannot thrive and grow.

Prior to Covid-19, the industry was not training enough apprentices to keep up with demand which contributed to the acute staff shortages the country is now facing. Apprentices play a key role in our economy as they provide significant support to the development of a skilled workforce and solving the sector’s long-term skills shortage. It is estimated that about 5,000 apprentices per annum, or two percent of the workforce, will be needed to meet current demand – effectively a doubling of current average levels.

The current funding model for the Apprenticeship Levy does not provide the support and accessibility needed by industry, with 94 per cent HR leaders reporting at least one barrier to accessing their levy funds. Logistics UK is therefore calling for the current format to be amended into a Training Levy which will allow greater

Logistics UK is one of the UK’s leading business groups, representing logistics businesses which are vital to keeping the UK trading, and more than seven million people directly employed in the making, selling and moving of goods. With Covid-19, Brexit, new technology and other disruptive forces driving change in the way goods move across borders and through the supply chain, logistics has never been more important to UK plc. Logistics UK supports, shapes and stands up for safe and efficient logistics, and is the only business group which represents the whole industry, with members from the road, rail, sea and air industries, as well as the buyers of freight services such as retailers and manufacturers whose businesses depend on the efficient movement of goods. For more information about the organisation and its work, including its ground-breaking research into the impacts of Covid-19 on the whole supply chain, please visit logistics.org.uk.

flexibility so that businesses can utilise the funding available. Workers currently looking to access apprenticeships are facing challenges due to the minimum skills requirement which dictates that people can only take up an apprenticeship if they have achieved a minimum standard of maths and English. Following conversations with members, Logistics UK believes this requirement is preventing a potentially valuable group of young people from joining the workforce via the apprenticeship route. The implementation of a Training Levy would support development at all ages from those without academic qualifications and new to work, to those looking for a career change.

Logistics UK believes that government must take steps to plug the skills gap through collaborating with schools and colleges, to challenge the current perceptions about industry. In addition, government must review and update its Industrial Strategy and Rail Strategy, so it is fit for purpose and benefits the logistics sector. Further investment in training and development for rail workers is crucial for reducing recruitment issues and improving job retention. There are still not enough apprenticeships being offered for logistics roles in general and with 99 per cent of logistics businesses being classed as SMEs, which are not able to access funding for apprentices aged over 18 years if they employ fewer than 50 employees, the sector’s ability to retain workers is hindered.

Mark Phillips was appointed Chief Executive Officer of the RSSB in 2016. He is a member of the Transport for London Board and a member of the Department for Transport’s Transport Research and Innovation Board. Mark is a Fellow of the Institute of Railway Operators and a Fellow of the Institute of Logistics and Transport.

Twenty Years of the RSSB

Twenty years ago, the Rail Safety and Standards Board was born, Mark Phillips, Chief Executive Officer takes us through the journey since then

When we were founded, Britain’s rail industry was very different. The Ladbroke Grove crash in 1999 was one of the country’s worst train accidents, and RSSB’s creation was a direct recommendation from Lord Cullen’s wide-ranging inquiry, as part of separating the setting of standards, investigation of accidents, and regulatory functions for rail. It proved a turning point.

Since 1999 Britain’s railways have enjoyed a lot of success; becoming the fastest growing and safest railway in Europe, with rail journeys doubling over 20 years. By the mid 2010s the UK was experiencing the largest shift by passengers to rail from other modes. 1.8 billion trips were made by more than 8 million people in the last year before the pandemic. Together with the wider supply chain, the UK rail sector supports tens of billions of Gross Value Added to the economy, helps promote social mobility and brings opportunity to deprived communities.

But there have been challenges too. The railways have experienced varying levels of state and private sector intervention, fluctuating economic health, accidents have not been consigned to history yet and, of course, the Covid pandemic. Rail has not always been prepared or resilient enough to manage climate change and extreme weather events. Many people feel rail doesn’t offer the frequency, reliability or price that they need. We are still working to adapt to new travel patterns, with commuting at roughly 60 per cent of pre-pandemic levels but leisure travel is over 120 per cent.

RSSB has been by industry’s side through both the good and bad times, as a dynamic, impartial link between innovation, standards and safety. We ensure that knowledge gaps are addressed,

new technology can be operated safely and efficiently, that innovation benefits the industry and passenger, and that best practice is codified and shared. With no commercial interest in the underlying data, we can offer independent knowledge of all rail systems and their interfaces.

Our research has allowed existing and new vehicles to operate at different speeds on the same track, optimising journey times and maximising route capacity. Our revised standards for AC electrification have the potential to save over £700 million over the next 25 years. This is mainly by reducing costs in the design, construction and maintenance.

Our insights and analysis have helped put rail at the cutting edge of health and wellbeing practice. We’ve started a programme to gather consistent sustainability-related data from across the industry, and our Rule Book ensures industry knowledge is reliably applied in train operations and maintenance.

The railways have a critical role to play in growing, connecting, and decarbonising our economy, with immense social value and huge opportunities for young people and career-changers. Unlocking this potential is crucial, but needs to be achieved while also getting to grips with cost.

We’re enhancing our data science abilities with new datasets, like weather data, to model how the changing climate will affect fixed assets. We have access to more data than any other rail organisation, and are working with academia to lay the groundwork for blue-sky innovations.

As industry embarks on a period of change, we will ensure we can play our part in enabling the public policy agenda, whatever the party in government, maintaining our role as an independent, objective counsellor to efficiency for the future.

NEWS IN BRIEF

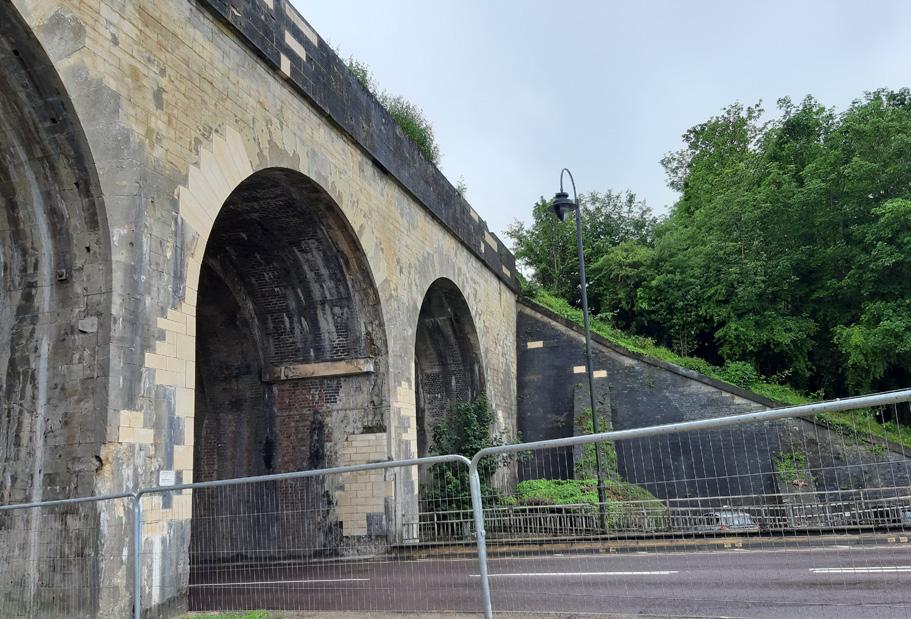

BRIDGE SET TO LIGHT UP THE BIRMINGHAM SKYLINE

HS2 Ltd has received Schedule 17 approval for a 150-metre section of viaduct carrying trains into Birmingham’s new Curzon Street Station, including a 25-metre-high truss which will create a new icon on the ci¬¬ty’s skyline. Birmingham City Council have approved the design of the Curzon No.2 viaduct, which is the tallest structure in the sequence of viaducts and structures that make up the Curzon Street Approaches taking HS2 trains into Birmingham.

The bridge consists of a gently curved truss in weathering steel which carries HS2 over the Victorian brick rail viaduct below, and which will reach 40 metres into the air, resting at least 17 metres above the ground. The bridge will carry three parallel high speed rail tracks over the existing east-west rail line. Closer to Curzon Street, the tracks will split further to serve the seven platforms being built at the station.

RIA NORTH RESPONDS TO TFN’S STRATEGIC RAIL REPORT

RIA North Chair, Justin Moss, said: ‘We very much welcome the publication of this report, which is strikingly consistent with RIA’s own calls for the full delivery of the TRU, HS2 and NPR and for a rolling programme of electrification. The prediction of a growth in demand is an important reminder that investment is needed now to prepare for the future.

‘The report demonstrates a clear link between investment and the delivery of desired outcomes for people in the region. With Oxford Economics data showing that for every £1 invested in the railway a further £2.50 is generated in the wider economy, RIA North stands ready to work with TfN and DfT to help make the case for this investment and provide practical support when it comes to developing and procuring major projects.

‘Separately, RIA North will be making the case for improving the procurement process to make it easier and more cost-effective to ultimately bring about transformational rail upgrades.’

Customer Service in the Transport Sector

The latest UK Customer Satisfaction Index from the Institute of Customer Service (ICS) paints a bleak picture for businesses, revealing an average decline of 0.7 points compared to July 2022 and January 2022. The transport sector produced particularly concerning results, with a drop in customer satisfaction of 1.7 points.

The UKCSI score is based on how customers rate organisations across 26 measures, from satisfaction with transactional experiences to broader relationship needs, out of 100 points.

This drop in customer satisfaction should be extremely concerning to the rail industry. In the midst of a cost-of-living crisis, rail companies are facing increasing competition from other modes of transport, reputational issues as a result of ongoing industrial action, and growing regulatory scrutiny. It’s therefore more important than ever that the industry is not taking its customers for granted and looking for ways to nurture customer loyalty.

There are of course several factors that will help to improve satisfaction scores, including improving on-time performance and pro-actively investing in the workforce and rolling stock maintenance. However, the value of outstanding customer service shouldn’t be overlooked, with it playing a critical role in customer retention and loyalty, and reputation management.

The ICS data highlighted issues with consumers’ satisfaction with the transport sector’s complaint handling, which dropped by 2.5 points year on year, as well as operators’ ability to express an emotional connection or ethics, which dropped by 1.0 point. Both indicate a greater requirement to address customer service provisions. So, what can be done?

Embracing new technology

Technology such as self-service platforms and AI-powered chatbots can be used to quickly and efficiently handle certain customer queries and complaints. With 1.8 billion passenger journeys made in the UK each year, finding more efficient ways to handle huge numbers of customer queries is vital. Although our research has shown that a proportion of consumers remain sceptical about the benefits of chatbots in the context of customer service, this is likely because some businesses have sought to cut costs by relying too heavily on the technology before it was sophisticated enough to do so.

Used correctly, however, chatbots can be a fantastic way to ease the burden on human operators by providing answers to simple queries and signposting customers to useful resources. In order to avoid frustrating customers, it’s crucial that when in conversation with a chatbot they always have the option to begin interacting immediately with a human agent instead. This way, customers with the most straightforward queries can be dealt with instantly by the chatbot, and those with more complex or sensitive issues can reach a highly trained operator more quickly as the overall number of customers waiting to speak to them will be reduced.

And given the recent rapid developments in conversational AI, widespread access to large language models such as Chat-GPT and Google’s Bard is likely to make chatbots far more effective for customer service purposes in the very near future. This will free up human operators even further to ensure that the most complex complaints are dealt with as sensitively as possible, driving up the quality of complaint handling and allowing them to build the emotional connection that the UKCSI showed is lacking.

Providing 24/7 customer service

Research has shown that 72 per cent of customers expect businesses to offer 24/7 customer service, and that businesses that offer 24/7 service have higher customer satisfaction ratings than those that do not.

Despite this, many businesses are still only contactable via phone or live chat within typical working hours. This means that customers with a query or complaint that occurs outside of these hours need to wait until the next working day to deal directly with an agent, and those who are unable to contact customer services during this time due to conflicts with their own work schedule might find it almost impossible to speak with an operator at all.

By making their customer service team available 24/7, rail companies can not only improve their competitive advantage, increase their customer loyalty and enhance their reputation amongst travellers, but they will also reduce the workload for their customer service agents during peak hours. Spreading the workload over a longer period can help to manage their resources more effectively, which can have a positive impact on quality.

Working with an outsourcer

Although there are clear benefits, offering 24/7, omnichannel customer service can be challenging for in-house customer service teams. With businesses facing tighter budgets in line with rising costs and inflation, many organisations are reluctant to employ more advisors. Using an outsourced team is the best way to scale up operations quickly and cost-effectively, with potential savings of £18,000 per annum, based on an average of 5,000 contacts a week.

A team of highly trained representatives can be fully onboarded into an existing team within just a few days to quickly increase access to resource. Support can also be scaled up and down at very short notice, ready to meet demand at peak times or in the event of a sudden influx of queries due to unexpected incidents such as extreme weather events or industrial action.

Final thoughts

The transport sector is facing a challenge: it needs to improve its customer satisfaction as both costs and customer expectations are rising. This may appear daunting, however there are some simple changes rail companies can make to improve customer satisfaction. By moving to more effective 24/7 customer care, with the use of AI-powered technology and a supportive outsourced team, companies can adapt their current offering to cope better with customer communications. Without doing so, they risk losing valuable customers during an already financially difficult period.

Nikhil Kaitwade is Chief analyst Automotive and Associate Vice President at Future Market Insights. He has more than a decade of experience in market research and business consulting having delivered over 1,500 client assignments predominantly in the automotive, chemicals, industrial equipment, oil & gas, and service industries. Learn more about Nikhil at: https://www.linkedin.com/in/nikhil-kaitwade-a45b7313/

Future Market Insights Inc. is an ESOMAR-certified business consulting and market research firm, a member of the Greater New York Chamber of Commerce, and is headquartered in Delaware, US. Find out more at: https://www.futuremarketinsights.com/

Battery Train – A Step to Embrace Sustainability in Transportation

Nikhil Kaitwade, Chief analyst Automotive and Associate Vice President at Future Market Insights explains how battery electric multiple units (BEMUs) can lessen the impact on the environment

An increase in demand for eco-friendly solutions and sustainable alternatives for diesel trains has been witnessed globally. Although batterypowered trains can be seen on rails, the refuelling and recharging infrastructure is still a work in progress.

50 per cent of energy consumption and CO2 emission.

To meet the challenge and provide an innovative alternative, the United Kingdom started a battery-powered train project. Several manufacturers have shown interest in the technology to bridge the gap between electrified parts of the network.

Therefore, the need for alternative fuel options such as hydrogen and battery trains for non-electrified railway lines is widely coming to the fore. The solution for non-electrified lines will not only reduce

of the railway networks in the urban areas use electric traction. The purpose of electrification is to reduce rail’s carbon footprint by replacing diesel-powered trains. Although around 80 per cent of the traffic is running on electrified lines, upgrading and electrifying the rail infrastructure is still an issue. Several battery train projects have been undertaken by governments with pioneer firms to replace conventionally fuelled generators.

A study was conducted in 2015 by the University of Cambridge, the University of Minnesota, and Minnesota State University Mankato on diesel engines. It claims that enclosed train stops for diesel trains not only put people at risk but also worsen air quality because of exhaust emissions. The trains powered by diesel emit nitrogen dioxide and sulfur dioxide does not comply with air quality standards imposed by the regulatory authorities.

With 22 per cent of global emissions, railways account for 0.8 per cent, according to stats provided by the European Environmental Agency in 2013. Though, new reduction standards were outlined by the International Union of Railways, to cut