DIGITAL RAILWAY

of

& GEOTECHNICAL ENGINEERING

IN

INDUSTRY

www.railprofessional.com

How the Internet

Things is strengthening global supply chains SUREVEYING

Geospatial data has the potential to change our lives for the better A Net Zero Solution for Rail Ambitious sustainability targets require greener, cleaner solutions THE BUSINESS RESOURCE FOR RAIL OCTOBER 2022 | ISSUE 286 | £7.95 FIBRE OPTICS

THE RAILWAY

How to overcome unprecedented demand in the railway industry

Sam Sherwood-Hale editor@railpro.co.uk

Jamie Tregarthen sales@railpro.co.uk

recruitment@railpro.co.uk

subscriptions@railpro.co.uk

Cherie Nugent info@railpro.co.uk

Lisa Etherington admin@railpro.co.uk

DESIGN

Alicia Bannister Lukasz Saczek production@railpro.co.uk

Rail

ISSN

©

No

The

any printing errors or otherwise which may occur.

EDITOR’S NOTE

One of the busiest months in news has just passed by, fresh off the shortlist for the Great British Railways HQ being announced we had a leadership contest for the Conservative party and the subsequent cabinet reshuffle. The Rt Hon Anne-Marie Trevelyan MP Anne-Marie Trevelyan was appointed Secretary of State for Transport at the start of last month and Kevin Foster MP appointed Rail Minister just the day before writing – whilst the entire rail industry was occupied with Innotrans in Berlin. Then the morning of writing the new Chancellor of the Exchequer Kwasi Kwarteng released The Growth Plan 2022 – with many in the media commenting on this government’s positive, ‘go big’ approach. One such comment I saw came from Chief Executive of the Civil Engineering Contractors Association (CECA) Alasdair Reisne who said ’Ahead of today’s Fiscal Event, we called on the Government to publish an updated pipeline of schemes to enable our members to plan for growth, and it is to be welcome that today’s announcement provides some of the clarity industry requires.’

Stephen Marcos Jones, CEO of the Association for Consultancy and Engineering (ACE) said ‘Ahead of the statement we called for an assured programme of projects from the public sector to drive growth and support jobs across the UK. This is why we were pleased to see positive steps announced on expediating 100 infrastructure projects and the establishment of new investment zones.’

Following on from that, Rail Partners’ Chief Executive, Andy Bagnall, said ‘Rail Partners welcomes a focus on accelerating delivery of rail infrastructure projects and look forward to detailed proposals.’

Could these detailed proposals include the Eastern leg of HS2 and Northern Powerhouse?

Within these pages you’ll find advice from Marie-Claude Hemming of the CECA who examines the challenges facing the new government and how it will impact the supply chain alongside Chris Cheek who reflects on the composition of the new Government and the likely implications for public transport.

We are focussing on Surveying and Geotechnical Engineering in this issue, with articles from the British Drilling Association and Allan Jamieson of Ordnance Survey. We also focus on Digital Railway with stories from Dyan Crowther of HS2 Ltd, Jo Lawrence of the OPC and Steven Tompkins of Inmarsat.

SAM SHERWOOD-HALE EDITOR

Quality products for modern overhead contact lines

Quality products for modern overhead contact lines

3 railprofessional @railpromag PUBLISHER RAIL PROFESSIONAL LTD Hallmark House, Downham Road, Ramsden Heath, Essex CM11 1PU Telephone: +44 (0) 1268 711 811 EDITORIAL EDITOR

DISPLAY ADVERTISING

RECRUITMENT ADVERTISING

SUBSCRIPTIONS

ADMINISTRATION

& PRODUCTION

Professional welcomes contributions in the form of articles, photographs or letters, preferably by email. Original photographs may be submitted, but, while every care will be exercised, neither the editor nor the publisher take responsibility for loss of, or damage to, material sent. Submission of material to Rail Professional will be taken as permission for it to be published in the magazine and online.

1476-2196

All rights reserved.

part of this magazine may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording or by any information storage and retrieval system, without prior permission in writing from the copyright owners.

views and opinions expressed in this publication are not necessarily those of the publisher, nor does it accept liability for

DIGITAL RAILWAY How the Internet of Things is strengthening global supply chains SUREVEYING & GEOTECHNICAL ENGINEERING Geospatial data has the potential to change our lives for the better A Net Zero Solution for Rail Ambitious sustainability targets require greener, cleaner solutions THE BUSINESS RESOURCE FOR RAIL OCTOBER 2022 ISSUE 286 £7.95 FIBRE OPTICS IN THE RAILWAY INDUSTRY How to overcome unprecedented demand in the railway industry

Arthur Flury (UK) Ltd │ Milton Keynes, MK14 6GD │ +44 1908 686766 │ www.aflury.co.uk │ info@aflury.co.uk

Arthur Flury (UK) Ltd | Milton Keynes, MK14 6GD | +44 1908 686766 | www.aflury.co.uk | info@aflury.co.uk

4 01904 403 322info@seprail.co.ukwww.seprail.co.uk Engineering Support for the UK’s Railways Need engineering support on your projects? Get in touch Providing critical support to projects throughout the UK, we work alongside the leading names in rail, delivering the engineering, management and consultancy their schemes demand. HOW CAN WE HELP? � Stressing levels 1 to 3 � Hand back levels 1 to 4 � Tamping (using WinALC) � Excavation and ballast installation Site Engineering � Track installation � Setting out � Datum and cant plate installation � CREs and CEMs � Principal engineers Engineering Management � Early engagement with client and long-term planning � Support with AMP management � Train plans Projects and Renewals Development � Planning documents to support prep, core and follow up work � Constructability reviews � Core renewal methodologies � AMP management � CRT management and coordinators

In this issue

11 NEWS

Railtex 2023: A Clear Focus on the Rail Industry of Tomorrow, RIA Urges New PM to Adopt Six-Point Plan for the Future of UK Rail, Rail Wellbeing Live 2022, HS2 Celebrates Chiltern Grassland Transformation, New Transport Secretary, Digital Container Summit, Balfour Beatty VINCI Digitises HS2 Construction Workflows with New Drone Software, Jobs Boost for West Midlands with New HS2 Station Construction Contract, MidWales Railway 10,000 Tonne ‘Rock Armour’ Defence, Swing Bridge Work in East Anglia to Take Place This Autumn

VIEWPOINT

25

Marie-Claude Hemming of the CECA examines the challenges facing the new government and how it will impact the supply chain

27 THE CHEEK OF IT

Chris Cheek reflects on the composition of the new Government and the likely implications for public transport

31

LAYING DOWN THE LAW

Martin on the UK Government's new pensions regulations

39 Eliot Gillings, Policy Analyst at Public Policy Projects believes rail could save supply chain, but first it needs to get its own house in order

41 Chris Hitch of COWI explains why collaboration and reuse will be key to the Transpennine Route Upgrade

45 Andreas Wibowo, Head of Business Development at RedCabin examines the results of the Future of Rail Interiors Survey

FEATURES

47 ELIZABETH LINE

The Nichols team looks back on over three decades of working on Crossrail, having held multiple strategic roles throughout the life of the programme

51 SURVEYING & GEOTECHNICAL ENGINEERING

Richard Fielden, Director of the British Drilling Association describes what the Association’s audit entails

23 INTERVIEW

David Girdler, a seasoned Executive within the Civils sector, joined McCulloch Group in 2021 as CEO. Here he tells us what the McCulloch Group has achieved and how they’re driving the business forward

55

58

SURVEYING & GEOTECHNICAL ENGINEERING

Geospatial data has the potential to change our lives for the better says Allan Jamieson of Ordnance Survey

SURVEYING & GEOTECHNICAL ENGINEERING

When an employee enters a confined space, how can you be sure they will come out alive and well? Fall protection specialist, Alfonso Fernandez explains

5

CONTENTS | ISSUE 286 | OCT0BER 2022

6

FEATURES

60 SURVEYING & GEOTECHNICAL ENGINEERING

Hannah Bailey, of Intoware on unlocking drone image data for Network Rail’s maintenance teams

61 SURVEYING & GEOTECHNICAL ENGINEERING

Andrew Lees, Senior Application Technology Manager at Tensar International on a new design method for geogridstabilised trackbed

65 DIGITAL RAILWAY

Jo Lawrence of the OPC on digital initiatives to help identify quality recruits and improve training success

69 DIGITAL RAILWAY

Peter Prater of Hexagon’s Safety, Infrastructure & Geospatial division explains why innovation spending should go towards safety transformation

71 DIGITAL RAILWAY

Dyan Crowther, CEO of HS1 Ltd explains how a new tech partnership is helping HS1 to improve the passenger experience

73 DIGITAL RAILWAY

Steven Tompkins of Inmarsat explains how the Internet of Things is strengthening global supply chains

75 DIGITAL RAILWAY

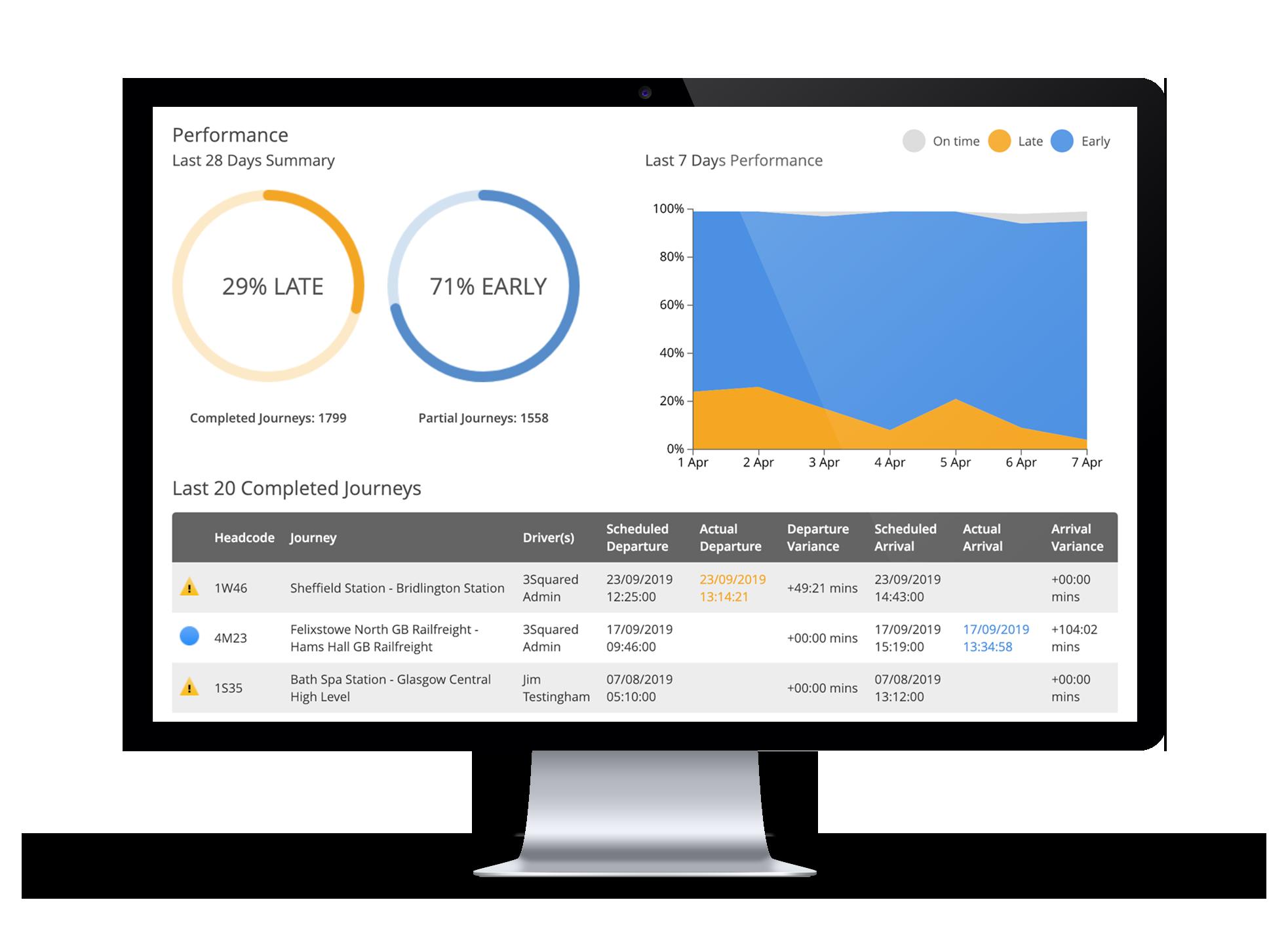

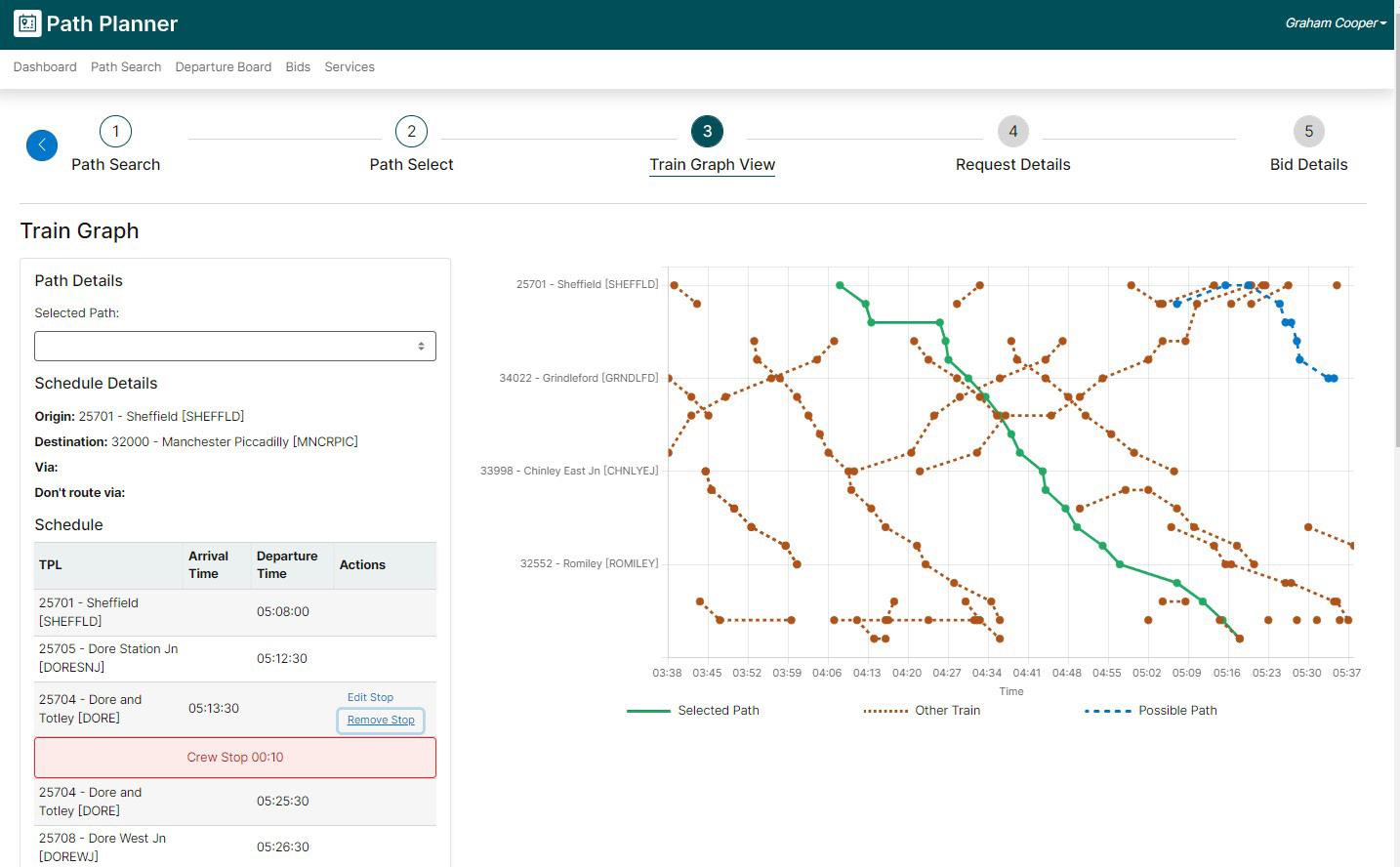

Fleet downtime can impact transport operators, causing delays which can result in dissatisfied passengers

77 DIGITAL RAILWAY

From IoT sensors and smart monitoring to paperless records and ticketless gate lines, rail is experiencing a tidal wave

81 FIBRE OPTICS IN THE RAILWAY INDUSTRY

Antonio Sequeira, Vice President Market Management Railway explains how to overcome unprecedented demand in the railway industry

84 COMMUNITY RAIL

Jools Townsend, Chief Executive of Community Rail Network explains how the grassroots network is putting social value at the forefront

FEATURES

98 MACHINERY

Ambitious sustainability targets require greener solutions like McCulloch Group’s TRTe™️

101 STATIONS

With Barry Eagle, founder and CEO at GripClad leans on his experience of making train stations safer over the past 20 years to provide insight to current rail professionals

BUSINESS PROFILES

105 Dovetail Games

FEATURES

106 TRAM & LIGHT RAIL

Pre Metro’s Charlie Merrell on how Very Light Rail could assist with the restoration of railway patronage and enable increased connectivity across the county

BUSINESS PROFILES

109 Railway Industry Association

112 Forbo Flooring

115 SPOTLIGHTS

Transport Scotland (Còmhdhail Alba)

North East Combined Authority Transport for Wales

Transport for Greater Manchester Department for Infrastructure (An Roinn Bonneagair) National Infrastructure Commission

BUSINESS PROFILES

122 PEOPLE

Kelly Pepper

Peter Hogg Anneka Hendrick

James Hobson

Rob Taylor

Steve Richardson-Frankton

Marc Donald

7

89 BAM Ritchies 92 Anchor Systems 94 Omnicom Balfour Beatty 96 Galvanizers Association

CONTENTS | ISSUE 286 | OCTOBER 2022

ON TRACK

When critical industry processes and concerns require the elimination of lost tool issues, the solution is to minimise human error. Let Snap-on ATC handle the control and tracking automatically

CUSTOMER

• Standardise Work

• Improve Productivity

• Control Inventory

• Reduce Losses

• Control FOD

• Improve Security

• Audit Trail

• Increase Accountability

• Oversight Prevention

• Calibration and Maintenance Remind ers

PRODUCTS AND SERVICES

• Automated Tool Control Box

• Automated Tool Control Locker

• Value Add: Networking

TOOL CONTROL

With advanced digital imaging technology and proprietary software, Level 5 Automated Tool Control System (ATC) scans the tool drawer and records which tools are removed and replaced in real time. You know where everything is at all times without your techs being slowed down for a second. The system also knows when tools are broken, allowing you to replace or repair them right away. It’s tool control that works hard to keep your techs working at their best.

ATC BOX

• No individual scanning required

• No RFID tags to install

• No limitations on tool sizeif it fits in the drawer, it works

• Optional polyurea elastomer coated top vs. stainless steel

8

BENEFIT AUTOMATED

snapon-industrial.co.uk snaponlevel5.com WORKS WITH

ORGANISATION VISIBILITY ACCESSAUTOMATION CONTROL ASSET MANAGEMENT KEEP PRODUCTIVITY

ATC LOCKER

• Track irregularly shaped items like extension cords, tools kitted in plastic or fabric carrying cases, personal protective equipment and more

• Track serialised items like torque wrenches, multimeters or micrometers

• Fully networkable – connects to Level 5™ administrative interface

• Recharge while storing power tool

CONVENIENCE

• Intuitive touchscreen interface

• Audible voice confirmation of tool removal and replacement

• Automatic locking

• Errors announced and displayed for incorrect tool position

• 10.1” widescreen, 16:9 LED, resistive touchscreen

• Dual wireless antennas for improved connectivity

• Hardware – 64-bit processor with 8GB RAM

POWERFUL ADMINISTRATIVE SOFTWARE WITH REAL TIME REPORTING

• Comprehensive analysis, reporting, and inventory tracking can be performed from administrator workstations located anywhere on the network in real time

• Reports are fully customisable and exportable to Excel or PDF

• Registers transactions in real time – both at the box and between the box and the admin client

• Real time communication includes email alerts when tools are used, when calibration is required, when tool status changes and lost or broken events

STATE-OF-THE-ART BATTERY POWER

• 16+ hours of battery run-time; 30 minutes of backup power for uninterrupted power supply

• Snap-on rechargeable batteries feature state-of-the-art circuit protection that prevents overload

• 1 year electronics warranty

• Extended warranty available

• Unlimited number of assigned users

• Networking through Ethernet or wireless

• 1 copy of ATC software required for each administrator

9 AUTOMATION

SPECIFICATIONS

FEATURES & BENEFITS FastFlagTM ALL THE ACCESSORIES YOU NEED • FastFlag™ adds status display lights • ZoomID™ gives you the ability to track serialised, certified and calibrated assets in the ATC Box ZoomIDTM Tel: 01536 413 904 industrialuk@snapon.com WORKS WITH

Sustainable Development

Infrastructure Taking Safe Decisions Passenger and Public Safety Workforce Health Rolling Stock and wellbeing Safety Intelligence

We’re with you every step of the way RSSB. Workforce Safety

Since 2003, the Rail Safety and Standards Board has worked collaboratively with the rail industry to make Britain’s railway safer, more sustainable and more efficient.

If you work in rail, your organisation is probably already a member of RSSB. Giving you access to our huge body of industry knowledge, covering everything from models and tools to information and best practice.

RSSB’s huge body of knowledge is used daily by thousands of our members. So when you want to get up to speed on anything rail-related, make RSSB your first stop.

To explore what’s on offer or register for access, visit rssb.co.uk/firststop

10

Railtex 2023: A Clear Focus on the Rail Industry of Tomorrow

Taking place from 9 - 11 May 2023 at the NEC, in Birmingham, the UK’s number one event for the entire railway industry will bring together the whole rail community. Railtex 2023 offers a unique opportunity to experience state of the art equipment and innovative systems and solutions. The show will include live demonstrations, as well as an extensive seminar programme focusing on hot-button topics for the industry, such as sustainability, digitalisation, maintenance and passenger experience, alongside the well-established On-Track Display area.

The UK’s railway sector has embarked on a transformational journey, in tandem with the UK Government’s aims to create a greener and more sustainable rail industry. Railtex is the ideal platform for the whole railway industry to meet under one roof and to experience products and equipment in action. The exhibition serves as a forum for attendees to discuss all aspects of infrastructure, technological innovations, digitalisation, safety, and sustainability

across the entire rail supply chain. Exhibitors and visitors attend Railtex from the UK, across Europe and the wider world. ‘Railtex is the place to source new products and usher in business opportunities. The show allows you to discover the latest development in all the areas of the railway industry and an excellent cross-section of technologies and solutions to facilitate the safe, efficient, and sustainable operation of rail transport’ comments Martin Clarke, Railtex Event Manager, on behalf of MackBrooks Exhibitions.

The one-stop-shop event covers all aspects of railway technology and represents more than 180 categories of products and services including rolling stock technology, track and infrastructure, signalling and communications, passenger information systems, vehicle maintenance, fare collection systems, cable technology and many other rail-related sectors.

‘The next edition of Railtex in Birmingham, a city in the heart of the

RIA Urges New PM to Adopt SixPoint Plan for the Future of UK Rail

The Railway Industry Association (RIA) has set out six key priorities for the future of rail, which it is urging new Prime Minister Liz Truss to adopt. Taken together, these priorities would boost economic growth and levelling up, create jobs and facilitate the UK’s journey towards Net Zero.

RIA’s call comes after two challenging years for the industry, with the Coronavirus pandemic impacting both passenger and freight levels on the national network. However, with demand for both passenger and freight journeys returning quickly and passenger numbers now regularly hitting over 90 per cent of pre-pandemic levels, continued government support and investment is essential to ensuring the necessary increase in rail capacity – both infrastructure and rolling stock – in the years ahead.

RIA’s six key priorities for the incoming Prime Minister to support the rail supply sector are:

1. Ensuring certainty of the work pipeline.

A pipeline of work is the best way to keep

costs down and deliver value for money for the tax and fare payer. The industry needs a clear investment plan for Control Period 7 (2024 – 2029), which, allowing for inflation, is funded to at least CP6 levels, as well as publication of the Rail Network Enhancement Pipeline, the last iteration of which was published well over 1,000 days ago, as at mid-July.

2. Committing to deliver major rail projects. The industry is ready to deliver transformational rail projects, but it needs commitment from the Government to ensure the rail supply sector can gear up and ensure it has the capabilities to deliver. For example, projects such as HS2, including the Eastern Leg and the Golborne Link (or an effective replacement) needs to be delivered in full to get the full benefits of the scheme, and Northern Powerhouse Rail, Midlands Rail Hub, East West Rail and Crossrail 2 all need to be delivered too.

3. Ensuring the transition to Great British

exciting rail developments, will shape up to be another successful show where the rail industry professionals can exchange knowledge and gain more insights about the latest developments within the industry’ says Martin Clarke, Railtex Event Manager, on behalf of Mack-Brooks Exhibitions.

Railtex provides an excellent opportunity to rekindle contacts and will bring prominent industry experts, stakeholders, and decision-makers in attendance, along with the exhibitor presentations and an extensive conference programme. The programme will accentuate not only the opportunities but also the challenges that the industry has been going through, and it creates a chance to expand in-depth discussions about the latest developments in the rail industry.

With an extensive three-day agenda, the conference and seminar programme will bring together key players in the rail industry and will focus on the following topics:

• Passenger Experience

• Sustainability

• Net Zero

• Digitalisation

• Infrastructure

• Maintenance

• Women in Rail

Railways (GBR) is completed to schedule and there is no work hiatus. It is essential the Government ensures that there is no hiatus in current work as GBR is completed. Doing so will ensure projects are delivered promptly and mean that the positive economic impact of the rail industry is maximised.

4. Supporting digitalisation. The industry needs the backing of the Government to digitalise signalling – 65 per cent of current signalling needs to be replaced in the next 15 years – and also to exploit digital opportunities to improve customer service.

5. Decarbonise rail by accelerating electrification, hydrogen and battery trains. For the industry to phase out diesel-only trains by 2040 and decarbonise the railway network by 2050, it needs a commitment from the Government to accelerate plans on rail electrification, as well as support for hydrogen and battery trains on less intensively used parts of the network.

6. Invest in R&D and innovation roll out. R&D and innovation funding and support for its rollout is essential to developing cleaner and more efficient ways of operating the railway. In particular, there needs to be a focus on the deployment of innovation in order to realise benefits.

11 NEWS

12 65,000+ Component repairs per year 4 4,000 Calibrations per year Delivery of on-site calibration days per year 11,000+ Calibration engineers 22+ 450+ Service centres www.acutestdirect.co.uk sales@acutest-ukti.co.uk www.acutest-ukti.co.uk 01782 563030

Rail Wellbeing Live 2022

Rail Wellbeing Live is the brainchild of the Rail Wellbeing Alliance, a crossindustry rail group, made up of train operating companies, suppliers, and industry bodies. The free two-day online event offers everyone in the rail industry the opportunity to come together and connect with industry and high-profile speakers to get inspiration, tips and guidance on how to tackle a wide range of health and wellbeing issues.

Following the huge success of the event, and third year running, the rail industry's largest free health and wellbeing event returns online on 2 to 3 November and is set to be even bigger and better. Like last year, it will be open to Britain’s 240,000-strong rail workforce for free, where results revealed that rail employees experienced 1.5 times higher rate of anxiety compared to the rates seen in the general population.

John Halsall, Chair of the Rail Wellbeing Alliance and Managing Director for Network Rail’s Southern Region, said: ‘The aim of the two days isn’t to say to go to the gym three hours a day, but more if you dial this up, dial that down, do that a little bit different and you will be happier. As well as the impact on the individual, it also saves the organisation a lot of money as sickness costs businesses a fortune, so why not invest in health and wellbeing and stop those things from occurring.

‘We often talk about health and safety on the railway, but what we really mean is “safety”. We haven’t got to the point where we say that health and wellbeing is more important, even though by any metric you care to measure these things by, improving wellbeing will result in staff taking less time off work and often being happier as well. For employers there is a compelling

HS2 Celebrates Chiltern Grassland

Transformation

The transformation of HS2’s largest construction site into a haven for wildlife reached a major milestone with the millionth cubic metre of chalk laid out around the south portal of the Chiltern tunnel. The ambitious environmental project will eventually see 2.6 million

cubic metres of chalk excavated during the construction of the ten mile long tunnels used to create one of the largest areas of chalk grassland in the Chiltern hills. Instead of removing the material by road, it is being used to landscape the site as part of plans to create 127 hectares of new chalk

New Transport Secretary

The Rt Hon Anne-Marie Trevelyan MP has been appointed as Secretary of State for Transport. Anne-Marie was Secretary of

State for International Trade and President of the Board of Trade from 15 September 2021 to 6 September 2022. Previously she

Digital Container Summit

The Digital Container Summit (DCS) is the ultimate networking event for the container logistics industry worldwide. This year’s theme is ‘Build your network

reason for investing in health and wellbeing initiatives and the underlying point for me is that a happy workforce is an efficient and a hardworking workforce.

‘So, it doesn’t matter where you work in the rail industry, so long as you have a mobile device or access to a computer, you can join us 2 to 3 November and we really hope you do. All the content is free, so please spread the word as we’d like as many people to benefit from this event as possible.’

Like last year, Rail Wellbeing Live 2022 will address all aspects of health and wellbeing in an engaging, fun way. Simon Weston, a Welsh veteran of the British Army who is known for his charity work and recovery from severe burn injuries suffered during the Falklands War, will be talking about finding opportunity in adversity. Scottish television personality, former model and actress, Gail Porter will discuss her experience of mental health illness, ups and downs of her career, and how she deals with reoccurring bouts of depression. This year there will be sessions in the evening which will cover a healthy cook-along, nutrition for night shifts and mental health.

and tackle global disruptions head on’. The event will feature demos, sessions and talks by industry leaders along with some of the most interesting product announcements

grassland, woodland, wood pasture and wetland habitats. Ninety hectares of chalk grassland will be seeded into re-profiled soil layers. This will sit alongside new areas of woodland, wood pasture and wetlands, including almost 65,000 trees and shrubs of 32 species and nearly 3.5 kilometre of new hedgerows. Around 4.5 kilometre of new footpath, cycling and horse-riding routes will give the public areas to large parts of the site, which sits between the Colne Valley Regional Park and the Chilterns AONB. Field trials are in preparation ahead of final seeding, and planting of trees and shrubs in 2025.

was the UK International Champion on Adaptation and Resilience for the COP26 Presidency between 7 November 2020 and 6 September 2022. She was Minister of State (Minister for Energy, Clean Growth and Climate Change) at the Department of Business, Energy and Industrial Strategy from January 2021 to September 2021.

by Container xChange which will truly make this year the most ground-breaking for the container logistics industry.

13 NEWS

Balfour Beatty VINCI Digitises HS2 Construction Workflows with New Drone Software

carry out drone site surveys, manage aggregate stockpiles and monitor progress of construction. Various 2D and 3D outputs are being generated for sharing with multiple stakeholders, including highdefinition imagery and 3D terrain models. The new software was rolled out across the BBV business to almost 400 users in autumn 2021, including 13 drone pilots.

The major civil infrastructure project spans from Long Itchington Wood tunnel in the south to the West Coast Main Line tie-in near Lichfield in the north, with a major junction into Curzon Street Station in central Birmingham. The main works civil engineering contracts will deliver earthworks, ground engineering and many structures including bridges, viaducts and tunnels along a 90 kilometre stretch of the UK’s new high speed rail line.

We needed the right software to manage an increasingly complex and varied use of drones and meet the needs of multiple teams, from logistics to site managers to engineers’ explained Dan Fawcett, Innovation Director at Balfour Beatty VINCI. ‘New digitised workflows are rapidly replacing traditional, physical working practices and introducing new levels of efficiency, accuracy and safety. On major projects such as HS2, the ROI achieved is significant.’

Esri UK has announced that BBV has rolled out its Site Scan for ArcGIS drone flight management and image processing software, to support its drone deployment strategy on its Midlands section of HS2.

Faster and more efficient drone surveys are already saving around £20,000 a year on monthly construction progress surveys on a single site, instead of using physical surveys and the subsequent updating of CAD models. BBV estimates this could save around £1.6 million if the same workflow

was applied across 80 sites in the first year.

Another benefit has been the removal of 800 ‘working at risk’ days and a cost saving of £30,000 per year from monitoring aggregate stockpiles, using a single drone operator to carry out 3D volumetric measurements in 20 minutes. Previously, contractors would take a full day to physically measure stockpiles and calculate transport requirements, often working in steep and difficult environments.

Site Scan for ArcGIS is being used to

Businesses ‘All Aboard’ for Rail Improvements Shows Survey

Sub-national Transport Body Midlands Connect recently surveyed local businesses representing over 12,500 employees across the region, in a bid to understand how proposed rail improvements could affect local businesses.

A massive 83 per cent of businesses also

agreed that rail improvements would result in them and their employees using services more frequently, even more so than having better station facilities and cleaner trains. Businesses were asked also whether the proposed rail improvements would benefit them, with over 62 per cent of businesses

Other applications of the new software include helping to show compliance with design tolerances in built structures against BIM and CAD models, speeding-up design cycles, particularly in earthworks and excavations design and monitoring the installation of utilities. Site Scan supports RTK drones to ensure highly accurate data capture and point cloud creation. Super-user training for Site Scan is being provided by Esri UK partner Heliguy, the drone consultancy, hardware and training specialists.

Site Scan for ArcGIS is Esri’s cloudbased drone flight management and image processing software, offering flight planning, hardware management, scalable image processing and unlimited data storage, plus seamless integration with BBV’s Esri enterprise GIS system.

agreeing that the proposed improvements would ‘Help the business grow’, 'Support company’s carbon reduction targets’, 'make it easier to meet customers’ and ‘Shorten the commute for employees’.

Just under half of businesses also said improvements would make recruiting new staff and doing business with communities in Wales much easier. The rail enhancement programme would boost line speed to 90 miles per hour with two minor track alignments, as well as signalling improvements along on the line.

14 NEWS

15 maccaferri.com/uk info.uk@maccaferri.com tel: +44 (0) 1865 770 555 SLOPE STABILISATION SOIL REINFORCEMENT RETAINING WALLS USED ON NEW AND OLD SLOPES BBA CERTIFIED MESH IMMEDIATE EROSION PROTECTION FLEXIBLE - EASILY PROFILED ONTO UNEVEN SLOPES EASY INSTALLATION STEEL WIRE “DOUBLE TWIST” HEXAGONAL MESH ANTI-BURROWING MESH PREVENT MAMMAL DAMAGE TO GEOTECHNICAL ASSETS TODAY

16 0115 922 5218 www.lineside.co.uk info@lineside.co.uk Vegetation Crossings Railway Civil Engineers Tunnels Viaducts / Bridges Stone / Brickwork Fencing Brickwork and Vegetation Management Management

Jobs Boost for West Midlands with New HS2 Station Construction Contract

homes and 650,000m2 of commercial space, generating £6.2 billion GVA per year and bringing 1.3 million people to within a 45-minute public transport commute of the station. The station site covers an area of 150 hectares within a triangle of land formed by the M42, A45 and A452. Significant progress has already been made on the site, including the construction of modular bridges over the M42 and A446 as part of a remodelled road network in the area to facilitate access to the new station.

West Midlands Mayor Andy Street announced that the contract to build HS2’s eco-friendly Interchange Station in the West Midlands, recently awarded to Laing O’Rourke, will support around 1,000 jobs over the next five years.

This new jobs boost heading for the West Midlands will include 22 new apprenticeship roles, providing exciting training opportunities for local people looking to learn new skills and start a new career on the UK’s biggest infrastructure project.

Supply chain contracts will also be available for businesses in the region,

including construction related services, specialist equipment supply and manufactured components, as well as catering, cleaning, printing and recycling services.

HS2’s Interchange Station will be the catalyst for huge growth plans in Solihull, creating an economic transformation for the region. The plans, being led by the Urban Growth Company, will support 30,000 jobs, up to 3,000 new homes and 70,000m2 of commercial space.

This forms part of the wider UK Central Hub area plans for 70,000 jobs, 8,000 new

In 2023, after an initial twelve-month planning stage, Laing O’Rourke will start the detailed design. HS2’s Main Works Contractor Balfour Beatty VINCI are currently preparing the site, ready for construction to start in 2024. The station is due for completion in 2027 in advance of the railway opening between 2029 and 2033. There will be up to five trains per hour passing through the station in both directions, with an estimated total of 175,000 seats per day, making this one of the best-connected transport interchanges in the country.

ScotRail Boosts High-Speed Cycle Travel

ScotRail is giving more cyclists than ever the chance to travel on its fleet of Inter7City High Speed Trains (HSTs). The train operator’s 25 HSTs are now able to carry up to six cycles, instead of the previous two, which is a trebling of the number of cycle spaces. It means more people will be encouraged to ditch the car and use the train to get out into the open air to experience some

of the country’s most beautiful areas. ScotRail customers who love exploring Scotland by bike have seen a huge increase in the number of cycle spaces on trains. In 2015, there were 932 spaces for cycles on ScotRail trains. Now, there are 1,506, a rise of almost 62 per cent, which means all ScotRail trains now have spaces for bikes.

17 NEWS

Mid-Wales Railway 10,000 Tonne

‘Rock Armour’ Defence

A multi-million-pound resilience project has been successfully delivered on the Cambrian Line, making passengers’ journeys more reliable in future. A trio of storms in February 2022 forced the railway between Welshpool and Newtown to close for six weeks while engineers from Network Rail and AmcoGiffen worked around the clock to fix over a dozen washouts caused by unprecedented levels of flood water. To minimise future delays and disruption, Network Rail quickly got to work installing 10,000 tonnes of rock armour along the bank of a-half-mile stretch of the Cambrian

Railway line. The tried and tested extreme weather-buffer had already proved to be a huge success to reduce flooding in other parts of Wales – on the Conwy Valley and near Abergavenny.

Rock armour prevents the ballast – the bed of stones beneath the sleepers - from washing away during extreme storms. It has proven effective in other parts of the railway, such as the flood-prone section of the Conwy Valley railway and near Abergavenny. It means the recovery of the railway following a harsh storm can take days, rather than weeks or months.

Swing Bridge Work in East Anglia to Take Place This Autumn

Network Rail will start work to upgrade electrical and mechanical systems inside three swing bridges this autumn, including for nine consecutive days in late October.

The iconic bridges at Reedham, Somerleyton and Oulton Broad are designed to carry trains over waterways and swing open to let boats through, but they are over 100 years old and their internal parts have become unreliable. During the project,

Network Rail’s engineers will replace these parts, making the bridges less likely to develop faults and reducing the need for costly maintenance.

The upgrade will help Greater Anglia train passengers and boat users get to their destinations on time for years to come, while enabling the historic structures to keep being used in the modern day.

The railway remained open to full service during the resilience upgrades at Welshpool – which involved the installation of locally sourced stone from Cefn Mawr quarry, in Flintshire.

Network Rail is returning, this autumn, to plant short hedgerows in the gaps along the railway boundary, which not only help in slowing flood waters in future, but also provide a continuation to nature’s corridors in the area.

Nick Millington, Interim Route Director at Network Rail Wales and Borders, said: ‘It’s hard to remember how devastating those February storms were, after the recordbreaking temperatures this summer, but we’re always planning ahead to the next extreme weather event, making sure we are prioritising investments that will make our railway more resilient.

The Cambrian Line is a hugely important rail link for the communities it serves, and I am delighted it’s now better protected from the impacts of climate change so we can continue to provide a safe and reliable railway for many years to come.’

Colin Lea, Transport for Wales’ Planning and Performance Director, said: ‘We welcome this investment by Network Rail in making the Cambrian Line safer and more resilient. The work to prevent damage and disruption from flooding will help secure the future of this important route, which provides a vital link for communities in North and Mid Wales. We would like to thank the teams who have been working around the clock on site over recent weeks in difficult conditions.’

Andy Crowley, Operations Director, AmcoGiffen, said: ‘We’re glad we were able to quickly and safely repair the damage caused by the storms in February and, crucially, take further steps to prevent another washout over the coming winter.

The work we’ve just completed at Welshpool means customers will experience better journeys, at a time when reliable public transport is needed more than ever.’

18 NEWS

Showcasing the future of

EXPLORE THE INDUSTRY

on industry

perspective of

latest developments and technologies on show as companies look to the future of Britain’s railways.

MEET WITH COLLEAGUES

Modern Railways EXPO brings the industry together to help shape the future of Britain’s railways. The show provides unrivalled networking opportunities, culminating in an exclusive networking reception at the close of the show on Tuesday 22 November, giving exhibitors and visitors a chance to relax and catch up with industry colleagues.

DISCUSS THE FUTURE OF BRITAIN’S RAILWAY

Modern Railways EXPO is the place to discuss the future of Britain’s railways. Conference and panel sessions across the two days will cover key topics, including:

• A keynote address on rail reform from Anit Chandarana, Lead Director at the Great British Railways Transition Team (GBRTT);

• A session on Train Service Delivery focused on improving operations, sponsored by Resonate;

• A focus on issues around rebuilding revenue and fares and ticketing, including a presentation by Suzanne Donnelly, GBRTT’s Director, Passenger Revenue. the close of the show on

Modern Railways EXPO will be laid out in dedicated zones based

areas, giving you an overall

the

Want to showcase how your company can contribute to the future of Britain’s railways? Then get in touch today by e-mailing david.lane@keypublishing.com or call 07795 031051 To nd out more please visit us at... www.modernrailways

REGISTER NOWfor our excitingnew show!

Britain’s railway

ENGAGE WITH KEY ORGANISATIONS

Modern Railways EXPO is supported by key industry players including Network Rail and the Rail Forum. Engage with these organisations at the show to discover how your organisation can contribute towards the future of Britain’s railways:

• Engage with representatives from a range of Network Rail departments, including seminars, panel discussions and the chance to explore some of the new technology being introduced onto the network.

• Engage with Rail Forum members and join the trade body for a series of workshops covering topics including sustainable supply chains and cyber security issues as well as the inaugural user conference for Hubble, the leading lineside inspection tool used by Network Rail.

Celebrating 60 years

Modern Railways EXPO marks the culmination of Modern Railways magazine’s Diamond Jubilee celebrations. For six decades the magazine has been charting key developments in the industry and looking to the future of Britain’s railways. We’ve marked this throughout the year and our show continues this celebration, including opportunities to meet key members of the team behind Modern Railways.

SUPPORTED BY CONFERENCE SPONSOR

ZONE SPONSOR

SUPPORTED BY CONFERENCE SPONSOR

ZONE SPONSOR

.com/expo

362/22

In addition to supplying individual components, the global companies of STAUFF and their authorised system partners use the STAUFF Line approach to support Original Equipment Manufacturers with the supply of custom-designed and ready-to-install fluid power lines from connection to connection and also provide supplemental services that create added value:

· Components · Systems · Services · Contact

Sheffield Tel: 0114 251 8518

Email: sales@stauff.co.uk

Aberdeen Tel: 01224 786166

Email: sales@stauffscotland.co.uk

Ireland Tel: 02892 606900

Email: sales@stauffireland.com

Southampton Tel: 023 8069 8700

Email: sales@stauffsouthampton.co.uk

Premier global manufacturer of components and kits for railway applications

The STAUFF Line process is adopted by global OEMs to successfully achieve cost savings in rolling stock manufacture.

22

www.stauff.co.uk

Growing Rail in a Year of Transition

David Girdler, a seasoned Executive within the Civils sector, joined McCulloch Group in 2021 as CEO. Here he tells us what the McCulloch Group has achieved and how they’re driving the business forward

McCulloch Group has a longstanding reputation for improving work on the rail infrastructure; they’ve been doing so for the last 30 years. With this service milestone looming ahead and the retirement of their previous CEO, founding brothers Billy and Danny McCulloch decided, it was time to appoint an individual with the experience and passion to drive the business forward, building on all they had achieved in the UK and Europe.

David Girdler joined the McCulloch team as Chief Executive Officer in 2021 after holding a range of senior positions in both Scotland, New Zealand and Australia, within Civil Engineering. As a Chartered Professional Engineer, David will testify to his fascination with innovation, particularly within engineering, so McCulloch Group and their products that replace dangerous manual rail tasks were an ideal fit.

Here, David answers questions about his career, the successes of the McCulloch Group, and what he sees for the future of the company.

SSH: Tell us about your career before McCulloch Group – here in the UK and in Australasia

DG: Before McCulloch Group, I mainly operated within Civil Engineering, managing civil infrastructure projects – with almost a decade spent working in New Zealand and Australia. I suppose you could say it was here that I really, ‘cut my teeth’ from the executive side of things. Within my role as Manager for Major Projects in the Northern Region at Downer Group, I took on my first significant opportunity in business development, which led to a role as National Business Development and Strategy Manager for MWH Global (who were later acquired by Stantec). Little did I know at the time, that this decade in Australasia would become so important for my future role at McCulloch!

After a return to Scotland with my family, I took on the role of Chief Officer for Roads at Scottish Borders Council and set up my own consultancy for professional

engineering services. Two roles which I found incredibly rewarding – and brought me back to Scotland, which is home.

SSH: With your more recent experience being in roads, what attracted you to the rail industry?

DG: I had an initial understanding of rail from my infrastructure days in New Zealand and Australia, but nothing too in depth. I’ve found since joining the industry that many of my contemporaries have spent their entire careers in rail – they know it inside out.

I was particularly drawn to McCulloch Group for its focus on innovation. I mean, there are lots of businesses who claim to be ‘innovators’ but McCulloch Group is built on innovation and keep striving to be ahead of the game. Billy and Danny McCulloch saw a problem, created a solution, and the rail industry loved it. They then did it again, and again, and again, solving various problems and 30 years later they have a fleet of

machinery that genuinely improves on-track safety and efficiency.

After fully being across our product capability, the rest was easy. I walked into a company full of collaborative rail specialists; a company where there is a strong sense of team, and everyone is bought into that joint success. It’s something that I find quite special about McCulloch Group as a whole.

SSH: And that strong sense of team is something you want to nurture as CEO?

DG: As I mentioned, McCulloch Group already had a hugely engaged workforce before I joined the team, but with employees up and down the country, in-office and ontrack, we in leadership can never do enough to nurture a strong sense of team within business.

It’s definitely been one of my main priorities for the past year. To bring everyone together we’ve started internal comms programmes, employee reward initiatives and an annual employee

23

INTERVIEW

roadshow, where everyone comes together for a day-long event, employee awards show and social event in the evening. We’re also continuing our dedication to employee development. McCulloch Group has a staggering number of employees with long service – stretching across 10, 20 and 25 years. That’s testament to the company, the ethos, and the continual investment in our employees’ futures.

SSH: You mentioned that your experience in Australia was vital to McCulloch’s ongoing strategy. How so? Australia was vital to McCulloch’s ongoing strategy. How so? strategy. How so?

DG: You don’t spend a decade in Australasia without learning about the landscape for projects and how it differs from business in the UK! McCulloch Group had had early signals of international success when I joined – and as soon as I understood the future business pipeline in full, I was certain that Australasia, combined with other international markets, had untapped potential.

Understanding the market over there has helped hugely with the success we’re now experiencing in the Australasian market. With some initial interest in McCulloch products for rail infrastructure projects in

the Sydney area, we exhibited at AusRail –Australasia’s key exhibition and conference for rail infrastructure. We flew out three team members, one TRT™ and one Panel Lifter (4.5 tonnes of kit) to showcase at the event! Success has been such that as of January this year we deployed our first Development Manager to Australia – to make the process for our Australian clients as smooth as we possibly can.

The results of our focused efforts paid off, securing key partners in Australia, including Affective Rail and Laing O’Rourke, both of whom were driving large projects within the wider Sydney Area. We’ve seen similar success in North America – and it’s proving to be transformational for our business.

I’ve spoken a lot about our international business, but I need to mention our domestic success too. Our products are widely used across the UK rail network, as are our contracting services. The UK rail industry has only a few organisations who are responsible for the infrastructure and we’re fortunate to have close working relationships with these companies and key individuals therein.

SSH: With 30 years of successful business now past, what’s next for McCulloch Group?

DG: This one’s simple – our push towards greener rail solutions. Whilst safety has been a huge issue for the rail industry, developments in regulations – and the use of McCulloch products – have seen safety improve exponentially within the sector.

One of the industry’s biggest challenges now, is maintaining the same level of service, across the infrastructure, whilst reaching net zero targets – set out by the responsible organisations and by the government.

That’s why we’ve just launched our first all-electric rail solution – the TRTe™. This machine features all the same exceptional benefits as our TRT™, but with the added bonus that it’s entirely battery powered. Using the TRTe™means a reduction in carbon and a reduction in noise pollution for our partners. It’s a key development in our fleet and one which marks the beginning of something very exciting.

I’ve always been of the mind that you can’t wait for change – you have to be the catalyst yourself. We fully understand the importance of going green and reducing carbon emissions. If we can provide the right, responsible solutions for the industry then we’ll play a big part in that transition. And what better way to mark 30 years of successful business, than investing in the future of the planet?

24 INTERVIEW

Marie-Claude Hemming is an experienced communications and policy professional. Having started her career in public affairs consultancy, she moved to a policy role at the Federation of Small Businesses in 2009, before joining as Industry and Public Affairs Manager and undertaking a variety of roles in the business, before becoming Director of Operations in 2021. Marie-Claude is CECA’s media relations and policy lead and has complete oversight of CECA’s communications and public affairs work. She also develops and manages the corporate business plan and is responsible for other operational duties, including the establishment of CECA’s three-year plan.

Economic Impact on the Supply Chain

Marie-Claude Hemming of the CECA examines the challenges facing the new government and how it will impact the supply chain

of the Construction Playbook, the Value Toolkit, Project 13 and other transformative reforms. We also support the principle of Project Speed. As it continues to evolve, we suggest it is also applied to the maintenance and renewals sectors to maintain a growth momentum.

CECA research has indicated that for each £1 billion increase in infrastructure investment, UK-wide GDP increases by a total of £1.299 billion and for every £1 billion of infrastructure construction increases overall economic activity by £2.842 billion.

The Bank of England has predicted that the UK economy will soon fall into recession. This is notably due to the impact of Covid and the war between Russia and Ukraine which is impacting on supply chains and also causing a dramatic increase in energy prices. The impact of Brexit and its effect on the availability of readily available workers, products and materials also plays a role.

New Prime Minister, Liz Truss’ plans to freeze household energy bills this Autumn indicates inflation is unlikely to rise too much further, albeit domestic energy costs will be more than double than last year. Businesses are currently not protected unless they signed a fixed deal earlier in the year. However, a Government announcement on managing energy costs as a business consumer is expected in the coming weeks. At the same time interest rates are rapidly increasing and are anticipated to go even higher at the end of this month.

In response it is likely that businesses and consumers will batten down the hatches and manage as best they can. However, the length of the Ukraine war and energy costs are key to coming out of this recession relatively quickly.

Commentators have suggested that there may be tax cuts in response with little expectation of additional Government spend.

The election of Liz Truss to lead the Conservative Party, and subsequently taking over as the current Prime Minister was announced in early September. In her inaugural speech, Truss prioritised road building and later announced an energy review focusing on managing costs,

committing to new North Sea oil and gas licences and lifting the moratorium on fracking.

Following the period of national mourning, the Government reshuffle will be completed. CECA anticipates that more announcements will be made in the coming weeks with a fiscal event already confirmed for later in September. We are now at a critical time and there is severe concern that with a recession on the horizon, the wrong measures could be taken in an attempt to manage economic challenges.

The construction industry was hit hard by the 2008 recession but generally survived Covid-19. After the crash of 2008, subsequent governments scaled back investment in a range of public infrastructure projects. This led to the collapse of many businesses - and perhaps more importantly – scattered a key workforce into new sectors at home and new roles abroad.

This loss of staff from businesses of all sizes devastated our industry. Furthermore, the then paused projects were more costly in the long term - when governments of the day retrospectively acknowledged their strategic value and were forced to re-procure at much greater cost.

Over the last decade the construction industry has made the case for sustained infrastructure investment. This has been supported by governments and has been reflected in increased spend and the recognition that infrastructure investment goes hand in hand with economic and social growth. At the same time, industry has played its part in the drive to efficient, collaborative and optimum value projects by adopting and implementing the principles

We strongly believe that the new Government must fully commit to existing plans and projects such as the next rail, roads and water settlements and the Integrated Rail Plan. Just as important is continued support in the drive to net zero and energy efficiency. We acknowledge the challenges of arguing for further investment in these difficult times – and we are not doing so – but instead are warning about market decimation and increased long term public cost if existing opportunities and commitments fall by the wayside.

In the short-term we believe that there are three key steps Prime Minister Truss and her team can take now to support our industry and ensure market confidence in the coming months:

• Maintain certainty, consistency and continuity of existing investment programmes.

• Keep faith in recent work to improve commercial relationships and avoid backsliding into adversarial lowestbid culture.

• Work with industry to target business support where it is needed.

We will be attending the main political party conferences this Autumn, where we will be discussing our ideas with Ministers, their Shadows, Parliamentarians and other stakeholders.

If you would like to feed into our policy making process, please email marieclaudehemming@ceca.co.uk

*This article was written prior to the resumption of Parliament but after the period of national mourning.

25

VIEWPOINT

GO UNDER GO OVER

FURTHER

Whatever your project demands, we’ll be with you from the moment you need us, creating temporary works solutions that help you build with confidence. For over 60 years, our engineering expertise has helped to deliver rail projects, from the smallest projects to the most complex infrastructure schemes in the country.

We can help at every stage of your project, from early stage planning, design and tender submission through to supply and, if you need it, installation.

From a simple design to a bespoke solution, and everything in between, across every type of temporary works, we’ll be there from the word go, making our impact and helping you deliver your project.

26

Find out more at mabeyhire.co.uk WITH YOU FROM THE WORD GO GO

Strategic Considerations for Handling Disputes

Ron Nobbs, Partner and Amy Steenson, Managing Associate at Stephenson Harwood examine Disputes under the Access Dispute Resolution Rules

While the Williams-Shapps Plan for Rail envisages a –perhaps optimistic – future where there are fewer disputes between industry parties, it is a reality of the operational railway that there will sometimes be disagreements. Where this happens, train operators and Network Rail pre-agree – such as in track access agreements, station access agreements and depot access agreements (Access Agreements) – the process by which those disputes will be resolved. With a few exceptions, this will be the Access Dispute Resolution Rules, or ADRR.

With the process being agreed in advance, it sometimes comes as a surprise that there are still a number of key strategic decisions to be taken when a dispute does actually arise. What are those considerations and what factors might be taken into account in considering the best way forward?

What are the ADRR?

Before considering strategy, it's worth first taking a step back and taking a look at the ADRR. These are a set of rail industry dispute procedural rules annexed to Network Rail's Network Code. Of course, other infrastructure managers have emerged in the industry in recent years – such as HS1 and Rail for London (Infrastructure).

Where the infrastructure manager is not Network Rail, there is usually a similar set of dispute resolution arrangements bespoke to that infrastructure manager which forms part of the Access Agreements. While there will be similar strategic considerations, it goes without saying that it is essential for dispute parties to consider the relevant dispute resolution arrangements, as they may vary from Network Rail’s.

The Access Disputes Committee (ADC) administers the ADRR and appoints the following two key individuals who are integral to the dispute resolution process:

• The Secretary, who supports the parties when the dispute is initiated and allocated to a particular dispute resolution process. The Secretary is also responsible for managing the delivery of the dispute resolution process to which a dispute is eventually allocated.

• The Allocation Chair, who oversees the overall case management of disputes and will determine any disputes which arise in the initiation and allocation stages.

The ADRR include rules which apply to all disputes, such as the ADRR Principles, as well as the rules in relation to commencing proceedings. There are also rules which apply only to the individual dispute resolution processes which are available under the ADRR:

• Mediation.

• Early Neutral Evaluation.

• Arbitration.

• Access Dispute Adjudication (ADA).

• Timetabling Panel.

• Expert Determination.

There are pros and cons to using each of these processes which parties to a dispute will need to consider carefully with their advisors as this will be an important strategic decision to make early on in the dispute process. Sometimes, there will not be much, if any, choice about the route that will be followed.

ADRR Principles

Under the ADRR, all parties – including the Allocation Chair, the Secretary, and

NEWS IN BRIEF

GREATER ANGLIA HIGHLIGHTS RAIL TRAVEL CARBON SAVINGS

To mark Car Free Day on 22 September, Greater Anglia put five of its most popular routes through a carbon calculator to demonstrate the enormous carbon savings that can be made by choosing to travel sustainably.

62.7 MILLION KILOGRAMS OF CO2E

It reveals that over 8.5 million people travelled on the five routes between 1 January and 31 August 2022 and together saved over a whopping 62.7 million kilograms of CO2e from being emitted into the atmosphere. That is equivalent to over ten million tree seedlings growing for ten years.

OVER THREE MILLION PEOPLE AT RISK OF TRANSPORT-RELATED SOCIAL EXCLUSION

New research by Transport for the North (TfN) reveals that 3.3 million people from across the North of England live in areas where there is a significant risk of transport-related social exclusion (TRSE). This study, the first of its kind in the UK, estimates that 21.3 per cent of the population of the North of England live in areas in which there is a relatively high risk of social exclusion because of issues with the transport system. These areas are widely distributed across the North but are particularly concentrated in former manufacturing and mining communities, in coastal areas, and in smaller towns and cities.

3.3 MILLION PEOPLE

Ron Nobbs is Partner and Amy Steenson is Managing Associate at law firm Stephenson Harwood LLP

Ron Nobbs is Partner and Amy Steenson is Managing Associate at law firm Stephenson Harwood LLP

27 VIEWPOINT

NEWS IN BRIEF

AMBITION FOR STEP-FREE STATIONS ACROSS LIVERPOOL

Plans to make the Liverpool City Region rail network the most accessible in the UK remain on track as a bid to make ten more stations step free is confirmed. And as part of plans to upgrade the remaining 21 stations, the Combined Authority is nominating 10 of them to be considered by the Department for Transport (DfT) for funding under the next round of its Access for All scheme.

decision-makers such as Hearing Chairs and arbitrators – are required to apply certain principles. These include that:

• Dispute parties must conduct themselves with the objective of resolving the dispute. They must also cooperate with reasonable requests made by the other party to the dispute.

• Every decision-maker must reach their determination with regard to other, relevant, published decisions, and in a timely manner consistent with the nature and complexity of the dispute.

The Allocation Chair and other decisionmakers are required to consider compliance with the ADRR Principles when making any decision in relation to costs, which is intended to make sure dispute parties behave appropriately.

Initiating a Dispute

UNIVERSITY OF BIRMINGHAM TO COLLABORATE WITH GLOBAL CENTRE FOR RAIL EXCELLENCE

A new agreement will see railway expertise from academia, government and industry driving forward rail innovation at a world class rail testing centre in Wales. The University of Birmingham’s Centre for Railway Research and Education (BCRRE) and the Global Centre for Rail Excellence (GCRE) have signed an agreement to partner on R&D and innovation activities on the site of the Welsh test centre which is due to open in 2024. The Global Centre for Rail Excellence

KILOMETRE TEST TRACK

was set up by the Welsh Government to establish the facility, in Neath Port Talbot. It aims to offer a ‘one stop shop’ for railway innovation from R&D, through testing and verification, to applied innovation on the mainline passenger and freight rail systems.

BCRRE is the largest specialist railway research, education and innovation centre in Europe and was selected by the Welsh Government to lead the development of a Centre of Excellence for Railway Testing and Validation. This Centre will sit alongside the new 6.9 kilometre test track that is being built at the head of the Dulais and Tawe valleys.

The first step in the ADRR process is for the party wishing to refer a dispute to serve a Notice of Dispute on the other parties to the dispute and the ADC Secretary.

Importantly, the ADRR Notice of Dispute is in addition to any other notice requirements that exist under the Access Agreement between the parties. The parties must comply with all such requirements. For example, under track access contracts, parties are generally required to notify the other as soon as reasonably practicable, and in any event within a year of first becoming aware of the circumstances giving rise to an indemnity claim. A party which has not issued such a notice may face an argument from the other party that the claim cannot be brought because the contractual notice has not been given, even if an ADRR Notice of Dispute has been given. It is vital to ensure all relevant notices are given.

There is no express requirement under the ADRR for parties to engage in preaction discussions before issuing a Notice of Dispute. However, before issuing a Notice of Dispute, parties should be comfortable that:

• A dispute has crystallised between the parties.

• Any other requirements in the underlying Access Agreement – such as entering into negotiations in relation to the claim –have been satisfied.

Allocation Process

An unusual feature of the ADRR is the Allocation Process, where the dispute resolution process is determined:

• Following issue of a Notice of Dispute, the parties have an opportunity and will, impartially, be encouraged by the Secretary to agree which of the dispute resolution processes will apply.

If agreement is reached by the parties to the dispute, this is formalised in a Procedure Agreement.

• If the parties do not agree a Procedure Agreement within 28 days of the Notice of Dispute, an Allocation Hearing will be convened. The Allocation Chair will

seek to facilitate agreement between the parties, provide any view the Allocation Chair has on the most appropriate determination procedure and in some cases determine that the parties have no choice as to the process.

• If there is still no agreement within seven days of the Allocation Hearing, and the Allocation Chair has not determined that there is no choice on the process, the Allocation Chair will determine that the dispute is referred to the default dispute resolution process. This is ADA under the latest version of Network Rail's ADRR, but was previously arbitration.

Strategic considerations

A failure to agree the dispute resolution process could ultimately lead to the default process being adopted – so this should be at the forefront of minds during the Allocation Process. If the default ADA process is adopted:

• After the ADA determination is delivered, key documents from the proceedings will generally be made public, whereas in arbitration or mediation, documents would generally be confidential.

• An ADA determination is binding subject to appeal to arbitration. Unless agreed otherwise in a Procedure Agreement, parties have an automatic right to appeal an ADA determination, whereas in a mediation the outcome would be a nonbinding view as to the likely outcome of the dispute. An arbitration award would be final and binding and subject to appeal in the courts only in very limited circumstances.

• A Hearing Chair in an ADA will normally be supported by two independent railway Industry Advisors, which may be beneficial where the dispute is technically complex in an industry-specific way.

• An ADA process may be more informal and the timetable more compressed than if the parties had agreed to arbitration.

• Commencement of an ADA may not stop limitation – which is the time period within which a party must bring its claim – running, whereas commencing an arbitration would.

While some parties may prefer ADA for its flexibility, there is clearly a wide range of factors to take into account when considering the approach to take to dispute resolution. So, while the ADRR sets out a process by which disputes will ultimately be resolved, there are plenty of strategic decisions which still need to be made. Disputes are rarely an easy period for industry parties and while the ADRR provide a framework within which the dispute will be dealt, there is still plenty for parties to consider.

28 VIEWPOINT

6.9

29

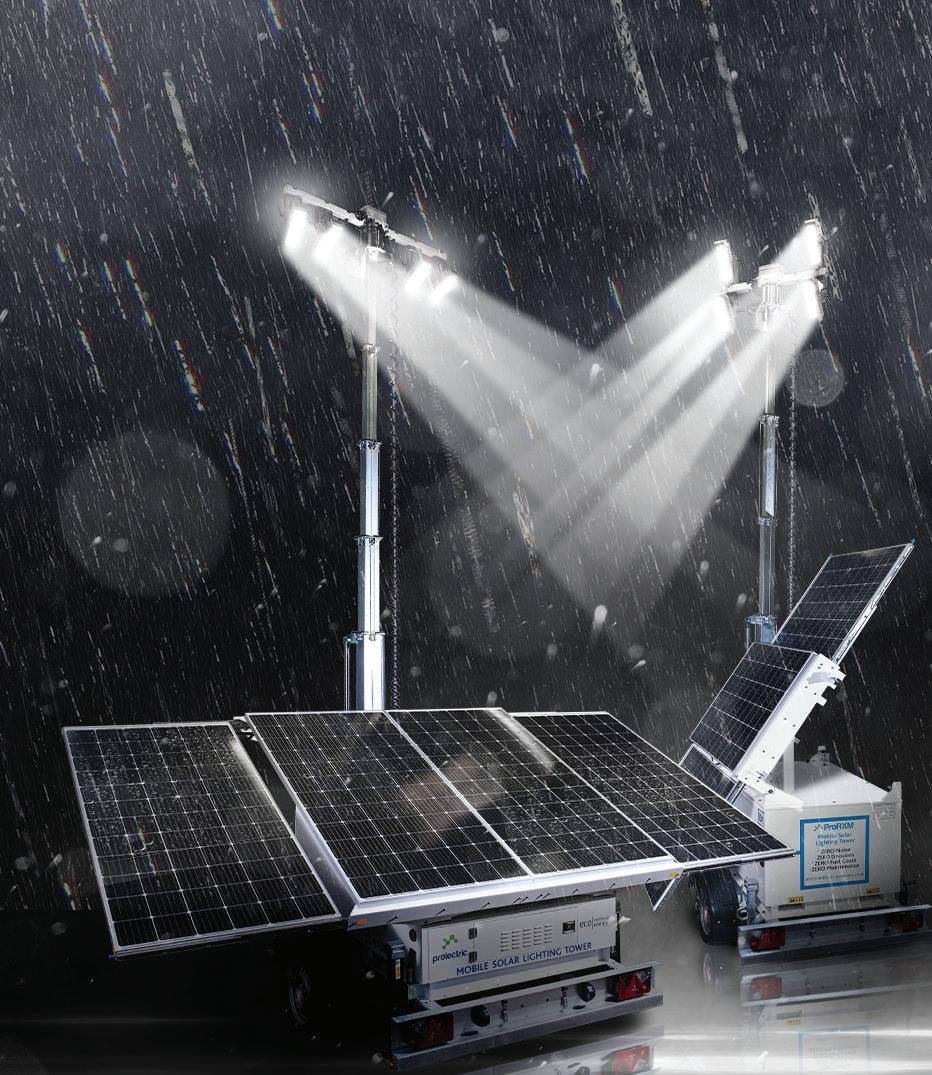

30 A HELPING HAND TO PUT YOUR PROJECT ON THE RIGHT TRACK. We offer a fresh approach to the rail, construction and utilities sectors without compromising on quality or safety. We deliver innovative design and build projects and supplying highly-skilled labour across the UK rail network. T: 02030 316 511 info@rcusolutions.co.uk www.rcusolutions.co.uk Expert solutions. No compromise. Electrical Telecoms Civil Engineering Labour Supply 01275 403 171 www.prolectric.co.uk/rail Are your solar tower lights ready for autumn and winter? Prolectric’s are. Others aren’t. Our range features solar tower lights tried, tested and proven to last 16 hours per night, all year, in all weathers. That’s what makes us different. 010702 Prolectric Tower Campaign_183x130mm-1609.indd 1 16/09/2022 16:10:34

THE CHEEK OF IT

by Chris Cheek

by Chris Cheek

Uncertain Future for Rail as Tories Swing Right

month consultation on the bill’s contents. This came as something of a surprise since the outline of the government’s plan has been clear ever since the launch of the new plan in May 2021. It was assumed that the fifteen months since had been occupied by drawing up the necessary legislation. Not so, it seems, since June’s consultation sought ‘views of all those with an interest in our railways, to help shape these reforms’. The consultation sought views on three main areas of the proposed legislation, being:

• The establishment of GBR, including its proposed functions and duties and how the government proposed to legislate and work with stakeholders to enable the new organisation to become the single guiding mind for the railways

• How to ensure clear accountabilities in the rail sector through a new governance framework, including the regulator’s role in providing independent scrutiny and challenge

Though swept aside by the death of the late Queen and the period of national mourning that followed, the business of politics has now resumed, and the new Prime Minister Liz Truss can complete the appointment of her administration as well as delivering on her promises to deliver tax cuts and reliefs for small businesses and consumers from the energy price crisis.

These will have been announced by the time you read this article, but what is likely to be less clear are the consequences for the future of public transport of the new Government’s policies. On the one hand, the massive cost of the energy bail-out and promised tax cuts dwarfs any spending supporting public transport; but on the other hand, savings will surely have to be made somewhere in order to appease a very sceptical City and keep the huge borrowings flowing into the government’s coffers.

On the one hand, the signs may not be promising – especially for big projects such as HS2 and Northern Powerhouse Rail. Truss herself whilst Chief Secretary to the Treasury was famously unkeen on HS2, whilst her new economic adviser Matthew Sinclair was on record as opposing the scheme whilst in a previous role as Director of the right-wing pressure group Taxpayers’ Alliance. During the Tory leadership contest in July this year, she committed to completing Northern Powerhouse Rail but refused to commit to restoring the eastern leg of HS2 into Leeds.

A more interesting question may well be the fate of the Shapps-Williams plan and in particular the promised legislation to establish Great British Railways (GBR), the planned new ‘controlling mind’ for the industry. The Bill figured in the Queen’s Speech (for the third time) on 10 May this year, and in June the DfT began a two-

• Reform of wider industry structures and processes needed to deliver transformation and ‘a new industry culture’, which DfT said should include a new Passenger Champion role for Transport Focus as well as proposals for open data sharing.

So despite the apparent certainty of previous statements on the subject, it seems that significant details concerning the form and function of the new organisation are still up for decision, giving ample room for those voices in the Treasury and on the Tory right who have been sceptical about the whole plan. There is still said to be opposition to the permanent transfer of revenue risk back to the taxpayer whilst also giving GBR sole power over fares and ticketing. The Competition and Markets Authority has already fired several warning shots across the bows of DfT in its response to the consultation, published in August. They noted that the proposed legislation would result in diminished competition for passengers whilst also expressing

Chris Cheek reflects on the composition of the new Government and the likely implications for public transport

31 VIEWPOINT

THE BIG PICTURE IN PUBLIC TRANSPORT FIND A FRESH ANGLE GET ON BOARD WITH OUR TRACK RECORD OF INSIGHT One of the UK’s most experienced business intelligence services on passenger transport, offering comment, analysis and understanding since 1991. Articles, company reports and statistics on bus, rail and rapid transit systems in the UK. Visit our web site to subscribe or buy our reports. Read our blog or ask us for bespoke analysis. passtrans.co.uk PASSENGER TRANSPORT MONITOR

concern about GBR’s proposed powers to enforce inter-TOC co-operation, which they considered might be in breach of the competition legislation.

It has also been suggested in some quarters that there may be a touch of foot-dragging going on in Marsham Street amongst civil servants unwilling to relinquish the degree of day-to-day control they currently exercise over the network, or anxious to postpone any action until after their retirement. How accurate such suspicions might be is open to speculation, but it is clear that the whole reform process has progressed at a snail’s pace, especially compared with previous railway legislation in 1993, 2000 and 2005.

To come then is the whole process of getting the Bill through Parliament, which may not prove to be an easy task – especially if a sizeable chunk of right wing Tory backbenchers oppose the Bill, whilst the Government’s majority in the House of Lords is never entirely secure. The previous legislative timetable is bound to slip with the introduction of major Bills to give effect to the government’s capping of energy prices for both consumers and businesses, as well as the procedures necessary to give effect to the promised tax cuts.

Meanwhile, the May and Johnson

governments’ record on and commitment to projects to upgrade and electrify the network in pursuit of Net Zero and modal shift looks decidedly poor, with frequent changes of plan and stop-start projects, especially in the Midlands and the north. The TransPennine upgrade is a good example of what has gone on and was the subject of a highly critical report from the National Audit Office published in July this year.

The current plan was announced in May 2021 after ten years of discussions, scope changes and arguments, after the then Chancellor George Osborne had first announced the electrification of the route. He said in the 2011 Autumn Statement that this would proceed, at a planned cost of £290 million, with a completion date of 2019.

According to a highly critical report published in July by the National Audit Office, work on the upgrade first started in 2015 but was then paused. ‘Since 2017, the Department has repeatedly altered the scope of the Programme to meet differing ministerial priorities and budget constraints’ the NAO noted. As a result £190 million of the £1 billion Network Rail had already spent on the project was on work no longer needed.

The most recent iteration of the plans, published last year in the Integrated Rail

Plan, abandoned the idea of a new line via Bradford to the east of the Pennines, focussing instead on building new alignment between Manchester and Marsden, but thereafter improving the current route via Huddersfield and Dewsbury. In May 2021, DfT forecast that the upgrade would cost between £9 billion and £11.5 billion in cash terms and that it would be completed between 2036 and 2041.

However, during one of the Tory hustings in Leeds at the end of July the new Prime Minister Liz Truss made a commitment to building the full Northern Powerhouse Rail scheme, telling party members that the project was ‘absolutely crucial for the future of the north of England’. Despite the scaling back announced in the Integrated Rail Plan last November, Transport for the North and the local authorities continue to lobby for the full high speed project. If Ms Truss is true to her word, we could well see yet another revision to plans – though how a business case could be made for the project, and where the money might come from, is less clear.

All of which means that there will be plenty to discuss, chew over and speculate about in this column and elsewhere during the coming months. Interesting times, yet again.

32 April 2022 Issue 20 20 7.00am - 5.30pm 7.00am - 5.00pm Prostate Cancer UK is a registered charity in England and Wales (1005541) and in Scotland (SC039332). Registered company 02653887. ID:000888 Trust Score 4.7 | 6,579 reviews as of 17/2/2022 ERY ON O This catalogue is recyclable POWER TOOL ACCESSORIES POWER TOOLS FIXINGS STAINLESS STEEL FASTENERS CHANNEL SYSTEMS HANDRAIL SYSTEMS FASTENERS SAFETY EQUIPMENT PAINTS, ADHESIVE TAPES & JANITORIAL SILICONES & SEALANTS ELECTRICAL ACCESSORIES HAND TOOLS ID:000888 VIEWPOINT

33 info@layher.co.uk www.layher.co.uk The past, present and future of system scaffolding SAFE WINNER NASCInnovation oftheYearAward2021 LayherAllroundAGSFaçadeSystem VGS-L 1007 PZ-8.22.64 and Z-8-22-64.1FS 554413Approved Training Provider FAST From footbridges spanning up to 30m LAYHER ALLROUND BRIDGING SYSTEM VERSATILE PROVEN BACKUP to heavy load support girders

Delivering Excellence since 1976