GASTRONOMIC APPLICATION OF ENZYMES

Collaborating with:

Enzymes are hitherto unknown ingredients in restaurants, although they have been used in the food industry for years. By using these ingredients in our restaurant, bar or pastry shop, we will have the opportunity to achieve textures that could not be achieved otherwise

We have developed this dossier with the aim of providing knowledge and making known how to use them and the options they can offer us.

That is why we will explain what enzymes are, and we will delve into each one of them so that you can understand them and apply them in your own gastronomic recipes.

20 Liquid gnocchi with truffle sauce

22 Creamy sweet potato panellet

24 Rice pudding without sugar 25 Banana water

ENZYMES: WHAT ARE THEY AND HOW ARE THEY USED

Enzymes are proteins that catalyze (speed up) biochemical reactions that occur naturally in all living organisms.

Enzymes are natural origin proteins present in most plant or animal foods that we consume on a daily basis, and which, applied to food products, can be used to modify some of their properties. They are commonly used to improve and transform products on an industrial scale, but until now very few restoration methods and applications have been developed.

Enzymes, unlike other texturizers, are very specific. This means that each enzyme will only work with one type of fiber or molecule. This compound that reacts is called substrate, and is transformed into the so-called products.

As you can see in the image, for enzymes to work they have to fit the substrate in question, so they will only work when the substrate is compatible

Enzymes are of natural origin. Most have been generated through the fermentation of natural products of plant or animal origin, or even extracted directly from fruits or vegetables.

There are different parameters that can affect the proper functioning and performance of enzymes, and that we will take into account when using them. This occurs due to the shape of the enzyme and the way the substrate fits with it, that is, due to its specificity.

• The product: If the food does not contain the substrate that the enzyme needs, there will be no reaction. So, if we apply pectinase to a food that does not contain pectin, it will not undergo any change.

• Substrate accessibility: The substrate must be accessible for the enzyme, since, if they do not meet and do not fit, no change can occur. The main barrier that we find is the external skin of the vegetables since the impermeability of the skin does not allow the enzyme to penetrate. We will have to make some cuts in the skin, puncture it or peel it so that the enzyme can penetrate.

• Proportion: If there is little substrate, even if we add a lot of enzymes, we will not achieve more effect. If, on the other hand, we have a lot of substrate and little enzyme, it will work, although slowly.

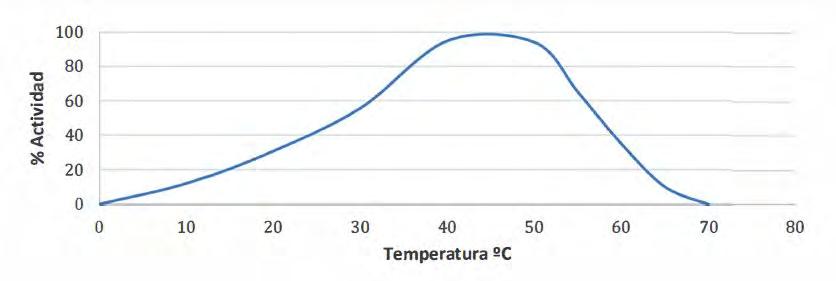

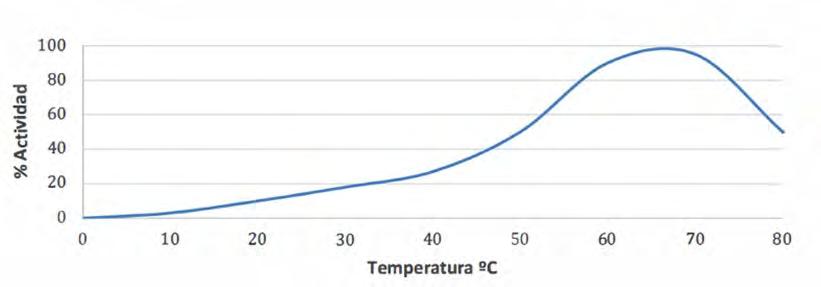

• Temperature: It is one of the most important factors to take into account. The enzyme has a temperature curve on which its activity depends, much like the temperatures used for fermentation:

→ At 0º C or less, the reaction stops because, as the product is frozen, so the two parts cannot fit together. As the temperature rises, this change is recoverable.

→ From 0 to 60°C the enzyme is active. In general, most enzymes have an optimum temperature where their activity is maximum. It is usually between 45°C and 60°C, depending on the enzyme.

→ At 70°C, or more, the enzyme is irreparably destroyed, since by heat the shape of the enzyme is modified and coagulates, so that the substrate can no longer fit with the enzyme anymore.

• Acidity: Enzymes are also destroyed if they leave a certain pH range and become inactive, although in the kitchen it is very difficult to reach these extreme values since they are either too acidic or too alkaline.

We have developed a line of Töufood Enzymes intended for use in restaurants and haute cuisine. This project is still open today and with research in constant development in order to expand the range with a much broader spectrum of applications.

Pectinase is the enzyme responsible for degrading pectin in fruits and vegetables, softening them and giving them a cooked texture, but without cooking.

Cellulase is the enzyme responsible for breaking down cellulose in fruits and vegetables, thus breaking down the hard parts of vegetables.

Invertase is the enzyme responsible for transforming sugar into inverted sugar, enhancing the sweetness of the ingredients and providing them with antifreeze and moisturizing properties.

Amylase is the enzyme responsible for breaking down starch in fruits and vegetables, giving starches creamy textures and adding sweetness.

Glucosidase is the enzyme responsible for degrading the dextrins resulting from the application of amylase. It greatly increases the degree of sweetness of the food.

Lipase is the enzyme responsible for breaking down fats and triglycerides, modifying their aromatic profile and enhancing mature flavors.

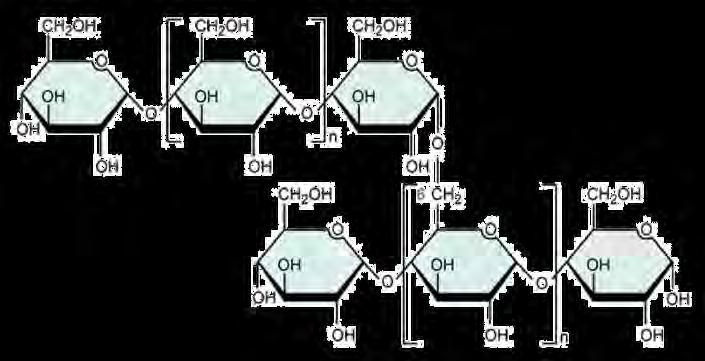

Amylase is an enzyme that has the ability to hydrolyze starch, obtaining free dextrin and sugar chains. In this way, it changes the structure of starches giving them different textures and properties.

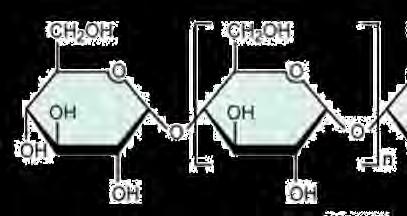

Starch

Greek ‘a-myl(o)- ( ἄμυλος) means ‘that does not grind’

The most common energy reserve polysaccharide among vegetables. It is made up of long chains of more or less branched glucose, so when it breaks down, it will release dextrins (short glucose chains) and other saccharides.

Using Amyläse, we can degrade starches in such a way that, by releasing sugars, the product is sweetened without adding sweeteners and the fermentative power of the mixture is increased. It is an enzyme widely used in the industry, mainly the bakery, and is present in almost all flour-based preparations for pastries or fermented doughs.

We must use amylase with gelatinized starches, so, with the cooked product, to maximize its enzymatic performance (for example, in baking).

• Impregnation: By previously making multiple holes in the product, and adding the enzymatic solution, we achieve a homogeneous degradation throughout the product.

• Injection: We achieve internal enzymatic degradation while leaving the outside intact.

• Sprinkle or immerse: We manage to degrade the exterior while the interior is left intact.

To obtain maximum performance, it is recommended to peel or puncture the skin over its entire surface and impregnate with 2 or 3 cycles of vacuum at 90-95%, and if desired, carry out a final cycle with sealing.

The starches that we treat with amylase need to be hydrated; that is to say, the rice, flour, legumes, or others, have to be cooked.

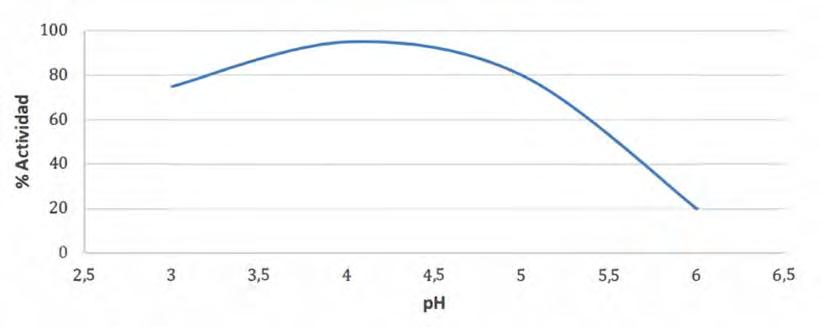

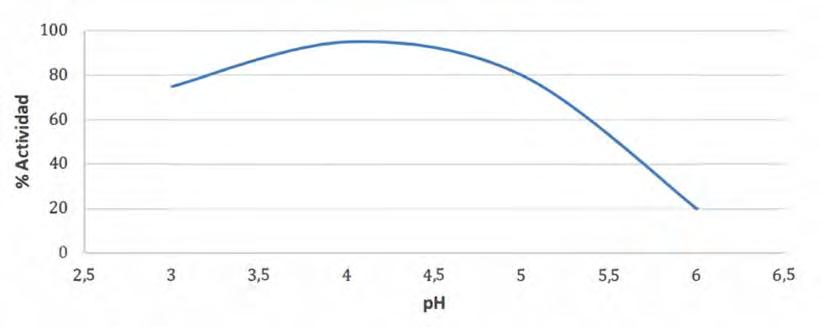

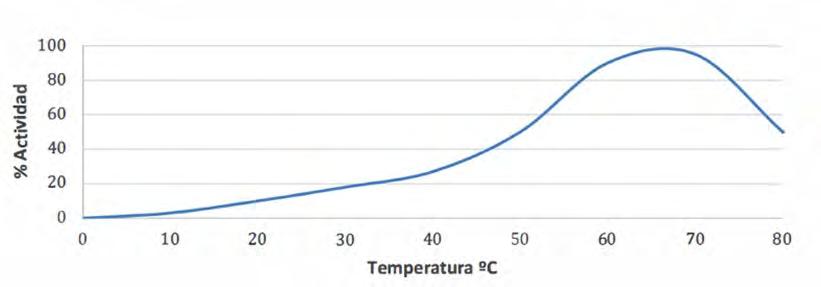

As mentioned, temperature and pH affect the activity and thus the yield of amylase. Plots of amylase activity for pH and temperature are shown below.

Another factor to be taken into account for the enzyme to act is the amount of starch contained in the food to be treated. Because amylase only works on starch, it will only work on products that contain it.

In general, starchy foods tend to be tubers, grains, legumes, nuts and pulpy fruits, as well as processed products such as bread or pasta. Even so, there are several foods that may contain a small amount of starch and that will allow the enzyme to work.

Below is a brief list of some foods that contain starch.

Vegetables: Potato - Sweet potato - Cassava - Pea - Broad bean - Chickpea - BeanCorn - Rice - Wheat - Oats - Pumpkin - Banana - Hazelnut – Walnut

Processed products: Flour - Bread - Cakes - Croissant - Brioche - Pasta - Mochi - Vegetable milk

Glucosidase is an enzyme that has the ability to hydrolyze (break) dextrin-type carbohydrates and obtain glucose-type monosaccharides. These dextrins are mainly extracted from starch, which makes it an ideal enzyme to combine with the enzyme amylase. In this way, amylase breaks down starch macromolecules initially and releases dextrins, which are in turn degraded by glucosidase, obtaining free glucose-type monosaccharides and other small sugars.

Latin ‘dexter - ine’ means ‘substance on the right ’

Oligosaccharide produced by incomplete hydrolysis of starch. It is made up of short glucose chains, so when it breaks down it will release glucose and some disaccharides such as maltose.

Using Glucosidäse, we can finish degrading the starches so that, by releasing sugars, the product is sweetened without adding sweeteners and increases the fermentative power of the mixture. By removing the few long chains of dextrins, it helps to clarify the products liquefied with the Amyläse.

We must use Glucosidäse with previously hydrolyzed starches, that is, products that have already been treated with Amyläse, to maximize their enzymatic performance.

• Impregnation: By previously making multiple holes in the product, and adding the enzymatic solution, we achieve a homogeneous degradation throughout the product.

• Injection: We achieve internal enzymatic degradation while leaving the outside intact

To obtain maximum performance, it is recommended to peel or puncture the skin over its entire surface and impregnate with 2 or 3 cycles of vacuum at 90-95%, and if desired, carry out a final cycle with sealing.

It is necessary that the starches that we treat with Glucosidäse are hydrolyzed; that is to say, the rice, flour, legumes or others must be cooked and previously treated with Amyläse. Both enzymes can also be mixed to work simultaneously.

As mentioned, temperature and pH affect the activity and thus the yield of glucosidase. Graphs of glucosidase activity for pH and temperature are shown below.

Another factor to be taken into account for the enzyme to act is the amount of starch contained in the food to be treated. Because glucosidase only acts on dextrins from starch, it will only work on products that contain it.

In general, starchy foods tend to be tubers, grains, legumes, nuts and pulpy fruits, as well as processed products such as bread or pasta. Even so, there are several foods that may contain a small amount of starch and that will allow the enzyme to work.

Below is a brief list of some foods that contain starch.

Vegetables: Potato - Sweet potato - Cassava - Pea - Broad bean - Chickpea - BeanCorn - Rice - Wheat - Oats - Pumpkin - Banana - Hazelnut – Walnut

Processed products: Flour - Bread - Cakes - Croissant - Brioche - Pasta - Mochi - Vegetable milk

As a result of our research, different techniques applied to these specific enzymes have been determined. Each technique will provide us with a change in texture and a different result that we will apply according to the consistency we want to achieve.

By degrading the starch, the thickening and structural capacity is lost, so the products fall apart.

Starch is a product with great thickening and structural capabilities, as we can see in doughs or sauces thickened with flour or cornstarch. When Amyläse acts, this starch breaks down in multiple places, giving rise to smaller structures that no longer have this structuring capacity. In this way, the products and ingredients lose their shape and remain with creamy and fluid textures. This process is not instantaneous, and the vegetable loses its shape over time.

Potato is a food whose composition is mostly starch. Degrading it using amylase will allow to achieve creamy textures with a slight sweet taste.

By softening the roasted sweet potato with amylase, a very sweet fluid liquid is obtained, as many sugars naturally present in the sweet potato are released. By reducing this liquid, the sugars are concentrated and thicken the product, achieving a molasses texture made only with sweet potatoes.

By modifying the texture of the cooked rice, a thick rice-based cream is obtained with an important sweetness coming from the degradation of its starch, which makes it possible to obtain sweet preparations without the need to add sugar or other sweeteners. The final texture is similar to that of a well -cooked risotto.

Using enzymes, you can extract the water found in vegetables that contain starch. When they act, they break the structure that generates the starch, releasing the water contained and eliminating the usual turbidity that liquefied starchy products present. Applying a filtering technique to remove the parts that have not been liquefied, a cold liquefying of the product is obtained.

Clarified and transparent banana water can be achieved through the use of enzymes. This water, naturally sweetened also thanks to enzymes, allows multiple elaborations such as foams, ice creams, molasses...

When the starch is destroyed, the thickening power is eliminated and therefore the turbidity in smoothies and juices.

By applying the glucosidase enzyme together with the amylase enzyme, sweet recipes can be prepared without the need to add sugar or any sweetener, since with its use foods rich in starches are sweetened. This change occurs because the combination of both enzymes releases glucose from starch.

Popcorn is kernels of corn where the interior starch has grown disproportionately, thus leaving the starch highly exposed for enzyme use. The mixture of amylase and glucosidase will release a large amount of glucose which, in addition to a greater degree of sweetness, if the product is crushed, the resulting juice can be concentrated to make molasses, ice cream, foam, gelatin or other preparations.

Since starch is made up of glucose, when broken down by enzymes, they will be released, sweetening the final product.

If we generate free sugars by applying glucosidase and amylase in starchy products, they will caramelize faster. This technique is ideal for crisping starchy foods, since instead of gelling the starch and obtaining an elastic mass by dehydration, a caramel is generated.

When a mashed potato is dehydrated, the starch it contains gels due to heat, thickening the mashed potatoes, obtaining an elastic and translucent film with a leathery texture. If the amylase and glucosidase enzymes are applied to this puree, this starch is transformed into sugar and therefore, when it is dehydrated by heat, it crystallizes and caramelizes, obtaining a crunchy and sweet product. Also, it is possible to shape it while it is still hot.

If free sugars are generated, it is easier for them to caramelize and more crispy and golden products are obtained.

With the use of the amylase and glucosidase enzymes, the fermentation speed is considerably increased.

Free sugars are the main food source for microorganisms commonly used in different fermentations. By transforming starch into glucose, the fermentation process is accelerated very significantly, going from long periods of time to hours or even minutes

When enzymes are used in doughs that later have to be fermented, fermentation times are greatly shortened while the dough is sweetened. This allows the production of breads, brioches or other fermented doughs to which it is not necessary to add any type of sugar or sweetener, since the starch degradation process will provide the necessary sweetness to the recipe. During the cooking process, the browning of the piece occurs more rapidly, so it is necessary to fire it at a lower temperature

If the starch is degraded with enzymes and consequently the product is liquefied, the liquid that remains will be very rich in free and fermentable sugars. This provides a high fermentation capacity with a very high speed that allows the elaboration, above all, of alcoholic beverages from dough, tubers, vegetables or grain, such as pomace, beer, kvass and other liquors.

Collaborating with:

For the alginate bath

1 L water

5 g Töufood Algïnate

For the enzymes mix

100 mL water

5 g Töufood Amyläse

For the spherical gnocchi

1 L alginate bath

(previous elaboration)

800 g potatoes

240 g cream 35%

84 g butter

14,6 g Töufood Glücocal

10 g milk

1. Mix the alginate in the water with a blender until it is completely dissolved

2. Leave hydrating in the fridge for 12 hours.

1. Mix the enzymes in the water with a blender until completely dissolved.

1. Boil the potato in a saucepan with abundant water for 30 minutes.

2. Pass the potato through a fine sieve.

3. Add the cream and butter and emulsify using a whisk.

4. Dissolve the glucocal in milk and add to the preparation.

5. Refrigerate the spherical dough for 30 minutes

6. Shape the balls into gnocchi shapes with a fork and submerge in the alginate bath for 20 seconds.

7. Dehydrate at 40ºC and turn until they form a crust.

8. Prepare the enzymatic solution, stirring with a wire whisk and injecting the solution with a syringe, inside the gnocchi. Leave in dehydrator for 15 more minutes at 40ºC.

9. Arrange in an airtight container and store in the refrigerator.

For the truffle sauce

25 g black truffle juice

4 g black truffle

0,1 g hondashi

40 g water

0,1 g Töufood Xanthän

8 g mild olive oil

0,5 g salt

Other

50 g parmesan cheese

1 chervil

Extra virgin olive oil

1. Dissolve the hondashi in the water, and add the rest of the ingredients

2. Blend and emulsify. Reserve in the fridge.

1. Keep the gnocchi in a warm cabinet during service.

2. Place truffle sauce on the base of the plate and place 5 gnocchi on top.

3. Grate Parmesan and finish with a sprout of chervil on each gnocchi.

For the sweet potato water

500 g sweet potato

25 g Töufood Amyläse

1. Bake the sweet potato in the oven for 1 hour 30 minutes.

2. Cool, add enzymes and grind.

3. Pack and cook in sous vide at 55ºC for 1 hour and 30 minutes.

4. Cool and strain through superbag.

5. Reserve the water in the fridge.

For the sweet potato molasses 400 g sweet potato water (previous elaboration)

For the potato base 500 g potato 25 g Töufood Amyläse

1. Put the water in a saucepan and slowly reduce it until you obtain 150 g with a molasses texture.

2. Cool and store in the fridge.

1. Peel the potatoes and place them in a bowl, cover it with film and make holes in the film.

2. Microwave until a knife can be easily inserted.

3. Peel the potatoes and blend in the Thermomix with the amylase.

4. Vacuum pack and keep at 55 ºC for 2 hours.

5. Reserve in the fridge for 12 hours.

For the potato chips

200 g potato

Water

Sunflower oil

1. Slice to 0.5mm thickness with a mandolin.

2. Cut to 0.2 mm diameter with a cylinder and place in cold water.

3. Dry well and fry in cold olive oil for 3 minutes at minimum power.

4. Remove excess fat and place in the dehydrator for 30 minutes at 40 ºC.

For the sweet potato marzipan

250 g almond flour

95 g sweet potato molasses (previous elaboration)

1. Mix the almond flour with the sweet potato molasses with a wire whisk until a homogeneous texture is obtained.

2. Reserve in an airtight container and leave to rest for at least 2 hours in the fridge.

3. Freeze a sweet potato molasses sphere.

4. Roll the sweet potato marzipan, placing the sweet potato molasses sphere inside. Bake for 3 minutes and carefully place the potato chips in a pattern.

5. Reserve in an airtight container.

1. Arrange on a dish and serve freshly made.

For the rice pudding

180 g rice

1L milk

½ Cinnamon stick

1 Lemon zest

23 g Töufood Amyläse Cinnamon powder

1. In a saucepan, infuse the milk with cinnamon and the lemon peel for 20 minutes.

2. Remove the cinnamon and lemon from the milk.

3. Cook the rice for 20 minutes in the infused milk.

4. Once cooked, strain quickly and reserve the rice.

5. Vacuum pack the rice together with the enzymes and cook at 55ºC for 2 hours. Cool.

6. Pasteurize at 100ºC in sous vide for 10 minutes to prevent the enzymes from further degrading the rice.

1. 1. Place the rice on a plate and cover with the infused milk.

2. 2. Decorate with a little cinnamon powder.

For the plantain water

600 g plantain

100 ml water

30 g Töufood Amyläse

1. In a measuring cup, dilute the 30 g of amylase with the 100 ml of water using a blender.

2. Peel and chop the bananas, then put the amylase solution together with the banana pieces in a vacuum bag.

3. Seal the bag and let the mixture impregnate and act in the refrigerator for a minimum of 24 hours.

4. Take the mixture out of the bag, and transfer it to a measuring cup, then with a blender we finish blending it.

5. Pass the already liquefied mixture through a superbag and keep the liquid part

6. Reserve the banana water in a jar in the fridge for future preparations.

For the sweet pasta

100 g flour

1 u egg

300 water

15 g Töufood Amyläse

15 g Töufood Glucosidäse

1. Mix the flour and the egg until obtaining a homogeneous mass.

2. Film and keep at room temperature for 1 h.

3. Mix the water, amylase and glucosidase.

4. Roll out the pasta to a thickness of 1-2 mm and shape into ravioli.

5. Cook the pasta for 3 minutes in abundant water.

6. Cool and place in vacuum bags. Add the enzyme solution.

7. Vacuum pack and cook in sous vide at 55ºC for 2 hours.

For the sweet potato base

600 g sweet potato

30 g Töufood Amyläse

30 g Töufood Glucosidäse

For the sweet potato water

300 g sweet potato base (previous elaboration)

For the sweet potato molasses

200 g sweet potato water (previous elaboration)

1. Roast the sweet potato in the oven for 1 hour and a half.

2. Cool, peel and mash the sweet potato with the enzymes.

3. Pack and cook in sous vide at 55ºC for 1 hour 30 minutes.

4. Reserve in the fridge.

1. Strain the sweet potato purée in a superbag and decant.

2. Reserve the clarified part.

1. Put the sweet potato water in a saucepan, reduce slowly until you obtain 150 g with a molasses texture.

2. Cool and reserve in the refrigerator.

For the sweet potato sabayon

80 g butter

200 g sweet potato puree

(previous elaboration)

40 g egg whites

80 g yolk

For the mandarin reduction

750 g mandarin juice

65 g Töufood Glucöse Syrup

2 u orange zest

For the mandarin beurre blanc

250 g butter

150 g mandarin pulp

7 g Töufood Citrïc

2 u mandarin zest

1 g Töufood Xanthän

Others

15 g butter

1 u orange

80 g ricotta cheese

1. In a bowl, mix the yolks with the sweet potato puree.

2. Melt the butter and when it starts to bubble, pour over the sweet potato mixture little by little, stirring with a wire whisk and emulsify.

3. Pour into a siphon and fill with two N 2O charges.

4. Reserve in a 50ºC water bath.

1. Put the mandarin juice in a saucepan, add the Glucöse Syrup and the zest of the 2 oranges and reduce over low heat until there are 200 g left.

2. Reserve in a bottle until service.

1. Melt the butter. Remove from heat.

2. Add the mandarin pulp, the zest, the citric acid and the xanthan while emulsifying with a wire whisk.

3. Let stand and cool before serving.

1. Take the pasta out of the enzymatic solution and dry well. Heat a pan with butter and sauté the pasta with orange zest. Reserve.

2. Place the ricotta on the base of the plate and arrange a few points of mandarin reduction.

3. Cover with sweet potato sabayon foam.

4. Cover the foam with the sweet pasta with orange.

5. Cover half of the sweet pasta with the beurre blanc and pour the sweet potato molasses.

For the potato water

500 g potato

25 g Töufood Amyläse

25 g Töufood Glucosidäse

For the potato molasses

400 g potato water (previous elaboration)

For the potato base

500 g potato

50 g Töufood Amyläse

50 g Töufood Glucosidäse

For the sorbet base

150 ml water

40 g Töufood Invert Sugär

230 g sugar

190 g Töufood Glucöse Syrup

8 g Töufood Skimmed Mïlk

5 g sorbet stabilizer

1. Bake the potatoes for 1 and a half hours.

2. Cool the potato, peel, add the enzymes and mash.

3. Vacuum pack and cook in sous vide at 55ºC for 1 hour 30 minutes.

4. Cool and strain through a superbag.

1. Slowly reduce the water to 150 g with a molasses texture.

2. Cool and store in the fridge.

1. Peel the potatoes and cook in the microwave at full power for 8 minutes in a filmed bowl.

2. Peel and grind along with amylase and glucosidase.

3. Vacuum pack and cook in sous vide at 55ºC for 2 hours.

1. Mix the sugar, milk powder and stabilizer in a bowl.

2. Heat the water along with the liquids and heat to 40ºC.

3. Add the dry ones and continue heating until reaching 82ºC.

4. Remove the mixture from the heat, film tight and mature for 12 hours in the fridge.

For the potato ice cream

430 g potato base (previous elaboration)

70 g sorbet base (previous elaboration)

For the crispy potato peel

400 g potato

100 g water

5 g Töufood Amyläse

5 g Töufood Glucosidäse

1. Mix both bases.

2. Allow to rest in an airtight container.

3. Churn and store in the freezer at -16ºC.

1. Wrap the whole potatoes in foil and cook for 1 hour 20 minutes at 180ºC.

2. Dissolve enzymes in water.

3. Unwrap the potatoes and peel off the skin, being careful not to break it.

4. Arrange the skins in a vacuum bag with the enzymatic solution.

5. Pack and cook in sous vide at 55ºC for 1 hour 30.

6. Dry the skins with absorbent paper and place in concave aluminum foil molds, previously greased.

7. Bake for 40 minutes at 120ºC.

1. Fill the crispy potato skin with potato ice cream and potato molasses.

2. Flip the crispy potato skin over and serve on a plate.

For the banana base

1000 g banana

50 g Töufood Glucosidäse

50 g Töufood Amyläse

For the banana ice cream

400 g banana base (previous elaboration)

For the clarified banana water

430 g banana base (previous elaboration)

100 g water

10 g Töufood Pectinäse

For the banana gel

100 g clarified banana water (previous elaboration)

1,8 g Töufood Fishgël

1. Peel and steam plantains for 20 minutes. Cool.

2. Grind them with amylase and glucosidase.

3. Vacuum pack and cook in sous vide at 55ºC for 2 hours.

1. In a glass of the Giaz ice cream maker, put the banana base and freeze.

2. Make the ice cream with Giaz and store in the freezer at -16ºC.

1. Dilute pectinase in water.

2. Blend the banana base with the solution and leave it in the fridge for 12 hours.

3. With a syringe extract the intermediate part of the clarified and reserve.

1. Hydrate the gelatin in water.

2. Heat the banana water to 40ºC, add the hydrated gelatin and mix until it dissolves.

3. Place the gelatin at the bottom of a white plate and gel in the fridge.

For the banana molasses

200 g banana base (previous elaboration)

For the black banana

3 u banana

1L water (I)

50 g Töufood Cälx

100 ml water (II)

5 g Töufood Amyläse

5 g Töufood Glucosidäse

5 g Töufood Pectinäse

1. Strain the banana base with a superbag and collect all the banana water.

2. Reduce the banana water until obtaining a molasses texture.

1. Prepare a bath with a liter of water (I) and lime.

2. Peel the bananas and place them in the bath for 1 hour, stirring every 15 minutes.

3. Clean the bananas with abundant water and boil for 10 minutes. Cool.

4. Mix the water (II) with the enzymes.

5. Put the bananas in a vacuum bag with the enzyme solution. Cook in sous vide for 2 hours at 55ºC.

6. Cook in OCOO with the “Black Egg” program for 5 hours.

7. Cool and store in freezer.

1. Cut 4 slices of regular banana and 4 slices of black banana and place the slices on top of the banana jelly.

2. Place a quenelle of banana ice cream and sauce it with banana molasses.

3. Finish with grated black banana.

For the popcorn water

250 g popcorn

125 g water

12,5 g Töufood Glucosidäse

12,5 g Töufood Amyläse

For the popcorn molasses

200 g popcorn water (previous elaboration)

For the popcorn ice cream

450 g milk

30 g Töufood Skimmed Mïlk

35 g Töufood Dextröse

13 g Töufood Glucöse Syrup

4 g ice cream stabilizer

1 g salt

200 g cream

80 g popcorn

For the popcorn powder

50 g popcorn

1. Cook the popcorn in the microwave for the indicated time.

2. Blend the popcorn with the water and enzymes.

3. Pack in a vacuum bag and cook for 2 hours at 55ºC.

4. Strain through superbag.

1. Reduce the popcorn water to a molasses texture.

2. Reserve in the fridge.

1. Mix and heat liquids to 40ºC.

2. Add the solids and raise to 82ºC.

3. Infuse the popcorn with the ice cream base for 12 hours in the fridge.

4. Pass through a super bag.

5. Churn and store in the freezer in a spherical mold.

1. Crush the popcorn until it has a powdery texture.

For the lime and coconut foam

250 g coconut pulp

100 g lime juice

50 g cream

4g Töufood Fishgël

1 g salt

2 u N2O syphon charges

For the nitro popcorn

200 g coconut and lime foam (previous elaboration)

c/s Liquid nitrogen

1. Heat the lime juice with the salt and the hydrated Fishgël.

2. Remove from heat and add the coconut pulp and cream.

3. Pour into a siphon and fill with 2 N2O charges.

4. Rest 2 hours in the refrigerator.

1. Fill a container with liquid nitrogen.

2. Pour the coconut-lime foam over the liquid nitrogen and mix to break the foam into small pieces.

3. When it is well frozen, remove the foam popcorn.

4. Reserve in a polystyrene container at -16ºC.

1. Take the popcorn ice cream out of the freezer and coat with nitro coconut-lime popcorn and popcorn powder.

2. Place the popcorn molasses at the base of the plate.

3. Place the ice cream popcorn on top of the molasses and decorate with a few popcorns.

For the potato base

1 kg potato

50 g Töufood Glucosidäse

50 g Töufood Amyläse

For the potato crisps

200 g potato base (previous elaboration)

For the sweet potato water

500 g sweet potato

25 g Töufood Amyläse

25 g Töufood Glucosidäse

For the sweet potato molasses

400 g sweet potato water (previous elaboration)

For the potato cream

300 g potato base (previous elaboration)

1 u vanilla pod

30 g butter

20 g yolk

1. Put the potatoes in a bowl, cover it with film and cook in the microwave at maximum power for 8 minutes.

2. Peel the potatoes and mash with the enzymes.

3. Vacuum pack and keep at 55ºC for 2 hours.

1. Spread the cream of potato on a silpat, with a thickness of 1-2 mm.

2. Leave in the dehydrator for 48 hours at 40ºC.

1. Bake the sweet potato for 1 hour 30 minutes at 150ºC.

2. Cool, add the enzymes and grind.

3. Pack and cook in sous vide at 55ºC for 1h 30 minutes.

4. Cool and strain through superbag.

1. Reduce the water to 150 g with a molasses texture.

2. Cool and store in the fridge.

1. Mix the potato base, vanilla and softened butter.

2. Emulsify with a blender, gradually adding the egg yolk.

1. Place a tablespoon of potato cream at the base of the plate.

2. Cover with the crispy potato and put a dot of sweet potato molasses on top.

3. Repeat the process 3 times, until 4 layers are obtained.

For the brioche dough

500 g hard flour

10 g salt

20 g press yeast

6 u egg

250 g butter

55 g Töufood Amyläse

55 g Töufood Glucosidäse

1. Mix flour with salt, sugar and yeast.

2. Add the eggs one at a time until they are integrated.

3. Knead, giving the dough a lot of elasticity and developing the gluten mesh.

4. When the dough comes off the walls, add the cold butter. Knead until the butter is absorbed.

5. Add the amylase and then the glucosidase.

6. Leave to ferment for 1 hour at room temperature and reserve for 12 hours in the fridge.

7. Shape the dough and ferment for 1 hour 30 minutes at 28ºC in a baking pan.

8. Bake for 10-15 minutes until the temperature inside the product reaches 90ºC.

9. Quickly cool in the blast chiller.

For the brioche kvass

150 g dry brioche

1 L water

100 ml milk

2 g yeast

50 g sugar

15 g Töufood Amyläse

15 g Töufood Glucosidäse

1. Blend the dry brioche with 100 ml of milk and the enzymes.

2. Vacuum pack and cook in sous vide at 55ºC for 2 hours. Cool and store in the fridge.

3. Mix water with yeast and sugar.

4. Add the brioche mixture to the container and cover with an airlock.

5. Ferment 4 days at 20 ºC.

6. Keep cold.

Collaborating with: