The Industry Yearbook & Buyers Guide 2023

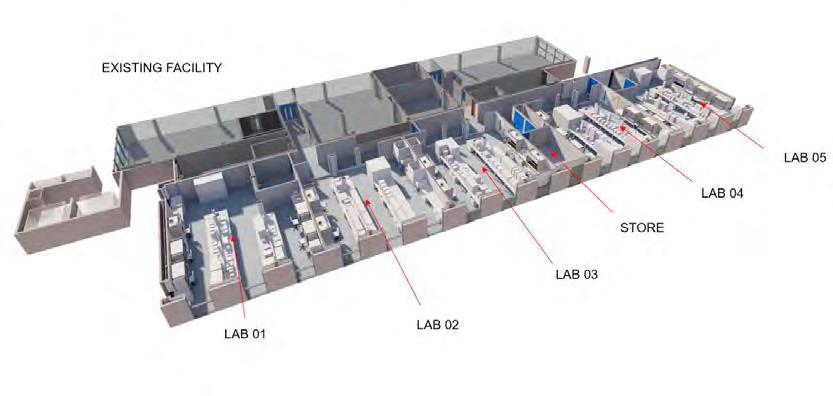

Eurofins BPT Dungarvan, Ireland Laboratory

Eurofins BioPharma Product Testing Dungarvan is part of a network of laboratories with over 40 facilities throughout Europe, North America and Asia-Pacific delivering the world’s most comprehensive scope of harmonised GMP testing services and seamless regulatory acceptance.

www.eurofins.ie/biopharma-service

EurofinsBPT-IE@eurofins.ie

Our services range from Oligonucleotides, Biologics, Gene Therapy, Chemistry, Process Control, Molecular Cell Biology, Bioassay, Raw Materials and Microbiology. With continuous investment in these areas.

IN ASSOCIATION WITH BIOPHARMACHEM IRELAND

Elite Technical Support

150 engineers, operating on and off site, nativespeakers in 10+ languages, ITIL accredited

Ensure critical enterprise technologies are always available. Our highly skilled, multilingual teams of engineers in Ireland, US, UK and New Zealand deliver a collaborative global service model that drives productivity with excellent customer satisfaction ratings.

24/7/365 remote and onsite support for all your business needs. With offices based in several countries, we can provide technical assistance in all of the top 10 European and Asian languages.

Westbourne provides onsite technical support for all your lab applications ranging from LIMS to CDS. We also offer a remote service for those wanted to save on desk-space.

We support companies for short term projects, from lab based CDS to Windows 10 IT upgrades. We can provide onsite staff from 1-9 months to support you through your project.

Westbourne IT - Experts in Global Enterprise Service Desk including Manufacturing and Labs IRELAND | USA | New Zealand, www.westbourneit.com, James.Symington@westbourneit.com +353 (0)21 431-4310

Enterprise Service Desk Project Services Lab IT Services

CONTENTS

4 TAOISEACH’S FOREWORD

Ireland is in prime position to remain at the forefront of the development of the next generation of biopharmaceutical and medical products, including personalised medicines and Advanced Therapy Medicinal Products, writes An Taoiseach, Leo Varadkar TD.

6 SECTOR OVERVIEW

Matt Moran, Director, BioPharmaChem Ireland, explains how BioPharmaChem Ireland and its members worked intensively of the preparation of its latest industry strategy report for the sector, entitled ‘Make Ireland the Global Leader in Sustainable Biopharmaceutical and Chemical Manufacturing, which clearly outlines a way forward for this important sector.

11 BIOPHARMACHEM IRELAND STRATEGY

BioPharmaChem Ireland’s latest strategy identifies six strategic themes which will underpin the future success of the sector here and ensure Ireland remains at the forefront of sustainable biopharma and chemical manufacturing into the future.

17 NIBRT

Darrin Morrissey, CEO, NIBRT, highlights the post-pandemic trends in the global biopharma industry, the innovations driving the sector forward and the role of NIBRT in strengthening Ireland’s leadership position in global biopharma manufacturing and supply.

23 LABORATORY APPRENTICESHIP PROGRAMME

Siobhán Dean, BioPharmaChem Ireland, explains the overwhelming success of the Laboratory Apprenticeship Programme, which has recently expanded to Munster Technological University, Cork.

27

TRAINING & DEVELOPMENT

The BioPharmaChem Skillnet provides businesses with industry-specific and even company-specific training programmes, reveals Susan Costello, Network Manager, BioPharmaChem Skillnet.

30 ENTERPRISE IRELAND

Garrett Murray, Head of Life Sciences, Enterprise Ireland, reports on the strong performance of Irish life sciences companies supported by EI, and explains the pillars of Enterprise Ireland’s new strategy, Leading in a Changing World.

34 IDA

Rory Mullen, Head of Biopharma, IDA Ireland, stresses the continued importance of Foreign Direct Investment in the Irish pharma sector and highlights the areas to focus on to ensure that Ireland remains a key player in biopharma going forward.

39 MEDICINE SHORTAGES

Grainne Power, Director of Compliance, Health Products Regulatory Authority, explains how the HPRA has developed a framework to tackle medicine shortages nationally, in conjunction with other stakeholders.

42 SUPPLY CHAIN LOGISTICS

DHL have a deep knowledge of pharmaceutical market dynamics, standards and regulations, combined with many years of experience of developing specific solutions for the industry, including temperature assurance, special handling for vaccines and biologics, customisation, packaging and direct delivery to patients and customers.

46 SSPC

SSPC has proven itself to be a dynamic hub of research expertise, bringing together academia and industry to address key challenges facing the biopharma sector.

51 PMTC

An emphasis on collaborative engagement with its industrial partners ensures that PMTC is strategically positioned to address real-world challenges within the pharmaceutical manufacturing sector, writes Sarah Hayes, Centre Director, Pharmaceutical Manufacturing Technology Centre.

54 CUSTOM FORMULATION/MANUFACTURING SERVICES

Leading supplier of custom formulation and manufacturing services, Ortec officially opened its European Headquarters, Manufacturing and Operations Centre in Newcastle West, Co. Limerick.

55 ADVANCED THER APEUTICS

VLE Therapeutics went from concept to reality in just seven months, explains Paul McCabe, COO, who argues that Ireland needs to move fast if we want to be leaders in Advanced Therapeutics.

58 ELI LILLY

Eli Lilly is creating a new facility for biologic active ingredients in Limerick, which will support increased demand for existing products and play a key role in bringing new therapies to patients worldwide.

60 MERCK

Merck is expanding its membrane and filtration manufacturing capabilities in Ireland with an investment of €440 million in two sites in Cork.

62 COVER STORY – LABORATORY TESTING

Eurofins BioPharma Product Testing Ireland offers unique and unparalleled breadth of service and experience for Biologics, RNA based drugs and highly potent products.

64 SK BIOTEK

From standalone analytical services to Cell & Gene Therapy, SK pharmteco is growing from strength to strength. Here in Ireland, the Dublin-based pharma plant of SK biotek Ireland, an SK pharmteco company, celebrates five years operating as a CDMO this year.

68 ACTYLIS

Limerick-based A&C Bio Buffer has been fully integrated into and has become a key part of the newly formed Actylis, a leading global manufacturer and sourcing expert of critical raw materials and performance ingredients for the life sciences market.

Irish PharmaChem | Industry Buyers Guide 2023 1

Editorial and Marketing Director: Kathleen Belton Editor: John Walshe

6 42 34 30

70 PACKAGING

Tekpak Automation designs, develops and manufactures end-of-line packaging systems for pharmaceutical manufacturers, with a core expertise in high-speed robotic pick-and-place applications.

72 PHARMACEUTICAL INGREDIENTS

Univar Solutions is bringing innovation to the future of pharmaceutical ingredient distribution.

74 LIQUID ANALYSIS

Endress+Hauser are introducing the next generation of Memosens digital technology for simple, safe and connected liquid analysis.

76 WASTE MANAGEMENT

Discover how European waste management experts Indaver can contribute to a cost-effective, CO2-reducing and environmentally friendly waste management.

78 CHEMICAL SOLUTIONS

Chemifloc Group provides specialist chemical solutions and technical services for multiple industrial and municipal applications.

82 ERT COMMUNICATION

Advancing technology allows ERT critical communications equipment from Hubbcat to offer a range of elements into one digital device.

84 SPECIALTY CHEMICALS

Greenfield Global is a trusted partner for multi-compendial raw materials.

86 PHARMACEUTIC AL RAW INGREDIENTS

Paul Power, Strategic Sourcing & Supply Chain Executive, NCC, discusses the impact of the energy crisis and how it may affect the pharmaceutical industry.

88 HOVIONE

Hovione is a global company with over 60 years of experience as a Contract Development and Manufacturing Organisation.

CONTENTS

89 IT SERVICES

Westbourne IT Global Solutions Ltd work with their clients’ IT department as an outsourced extension of their team, delivering short, medium- and long-term projects in their laboratories.

91 CALIBRATION

Paperless calibration is here to stay, with Bonner leading the way.

92 INGREDIENTS

Ingredients distributor Barentz offers pharmaceutical manufacturers a range of ingredients to suit every application, including challenging formulations.

94 MODUL AR CLEANROOMS

Dawsongroup TCS Ireland have introduced a wide range of cleanroom solutions for customers, including modular cleanrooms to rent as well as buy.

96 GRIFOLS

Grifols’ new 17,000 square metre albumin plant in Grange Castle brings its total investment in its Irish operations to around €300 million since 2012.

98 CONTRAST MEDIA

GE Healthcare’s new $30 million pharmaceutical imaging agents facility in Cork secures the future supply of contrast media, as demand is projected to double.

99 E-LEARNING

Paula Álvarez, Information Developer, Technically Write IT, explains the company’s human-centred approach to eLearning.

100 ROBOTICS

Robot technology from KUKA can be employed right along the process chain, from API recipe testing and ingredient measuring to packaging product in clean room facilities.

Irish PharmaChem is published by: Tara Publishing Ltd

14 Upper Fitz william Street, Dublin 2. Tel: 00 353 (0)1 678 5165

Web: www.irishpharmachem.com

Managing Director: Patrick Aylward

Editorial and Marketing Director: Kathleen Belton

Email: kathleenbelton@tarapublications.ie

Editor: John Walshe

Advertising Sales: Brian Clark, Aaron Stewart

Design: Tony Hunt

Production: Ciara Conway

Printed by: W&G Baird

Irish PharmaChem | Industry Buyers Guide 2023 2

SECTION 103 Chemical Suppliers 104 General Suppliers 110 Company Listings 120 Useful References

LISTINGS

100 62

Janssen Never Stops

As the world finds its way forward, people never stop needing ways to conquer disease. Ways to live with immune-related disease. Ways back from cancer. That’s why we never stop working toward a future where disease is a thing of the past.

Learn more at www.janssen.com/ireland/

Consolidating Ireland’s Strengths in Life Sciences

Ireland is in prime position to remain at the forefront of the development of the next generation of biopharmaceutical and medical products, including personalised medicines and Advanced Therapy Medicinal Products, writes An Taoiseach, Leo Varadkar TD.

I’ll begin by congratulating you all on another great year for the pharmaceutical sector in Ireland.

Earlier this year, I took the opportunity to introduce the Special Edition of the Irish PharmaChem Yearbook to focus on and celebrate the importance of innovation and research to our continued health. Ireland has a strong track record of excellence in design, development and manufacture of biopharmaceutical products, and we are well placed to deal with the complex data, quality, regulatory and supply chain issues associated with the growing trend towards personalised medicines and increasing regulatory requirements.

NIBRT Cell & Gene Therapy Facility

September of this year marked another important step forward in our life sciences journey when I turned the sod on the new cell and gene therapy facility at the National Institute for Bioprocessing Research and Training. This €21 million investment in NIBRT, an important incubator for biopharmaceuticals in Ireland, underscored the Government’s commitment to meeting the needs of future employers, manufacturers, and patients alike.

Through IDA Ireland, we have invested over €80 million in NIBRT. This cutting-edge, state-ofthe-art facility is world class, and since 2013 has grown from strength to strength, training and preparing people in Ireland today to step into tomorrow’s roles.

Transforming the Global Pharma Landscape

Looking to the future, digitalisation and increasingly sophisticated technology will transform the ways that we develop and manufacture medicines, as well as how we diagnose and treat patients. Advanced Therapy Medicinal Products (ATMPs) are transforming the global pharmaceutical landscape and revolutionising health for millions of patients.

We are no longer on the threshold of a digital transformation of manufacturing that will change the very bedrock of how we

create, control, and produce quality medicinal ingredients and products. We are already there. The advent of digital, smart, and advanced manufacturing methods will benefit us all.

ATMPs such as cell and gene therapies, antibacterial treatments, and microbiome therapies are poised to enhance the lives of those who live with cancer, cardiovascular disorders, diabetes, HIV and AIDS, Alzheimer’s, as well as immunological, neurological, and mental health disorders.

The Contribution of Life Sciences

These last few years have shown us our vulnerabilities. The Covid-19 pandemic has brought home to every one of us that what happens in laboratories and on production lines affects us all. The innovations and breakthroughs in the development of mRNA vaccines have helped to give us back our society and to resume our normal lives.

The hard work, perseverance, and innovation of you who work in the life sciences has meant

Taoiseach’s Foreword

2 4 Irish PharmaChem | Industry Buyers Guide 2023

Leo Varadkar, An Taoiseach

that 2022 brought a relieved and welcome return to our everyday lives. Without your efforts in producing life-saving vaccines against Covid-19, we might again have spent a distant and lonely holiday period. We are all grateful for your enormous contribution.

Strategic Direction of Ireland’s Enterprise Policy

The Department of Enterprise Trade and Employment’s Enterprise White Paper outlines the strategic direction of Ireland’s enterprise policy. It does so in the context of challenges, opportunities and new drivers of growth and will work to protect the core elements which make Ireland an attractive location for enterprise.

It examines the risks we face as a small, advanced economy, the compromises that we may accept, and the policy choices that underpin it all.

Taking stock of Ireland’s industrial policy in the round has afforded us a moment to consider what is working well? What should be continued and cultivated? What can be adapted? Unquestionably, continuing to foster talent and innovation in sectors such as pharma will be a priority for Government.

Next year marks 50 years of Ireland’s membership of the European Union and our unwavering commitment to the single market. There is much to do to ensure adequate pathways for patients to access lifesaving and life-changing medicines. Closer collaboration between industry and the State on the operating environment for medicines innovation and investments is the way forward.

Consolidating Our Strengths

As we look to the coming year, our focus is on consolidating our strengths and on remaining resilient in the face of challenges. Competition for global investment is stiff, but we are confident that we remain a world-class destination to invest and grow business.

We know how important the life sciences are to our economy and we look forward to attracting and sustaining further investment from the sector well into the future. I am confident of Irish PharmaChem’s continued success in 2023 and wish you all the very best for the coming year.

Leo Varadkar, An Taoiseach

Leo Varadkar, An Taoiseach

Taoiseach’s Foreword

5 Irish PharmaChem | Industry Buyers Guide 2023

BioPharmaChem Ireland

BioPharmaChem Ireland Publishes Sixth Industry Strategy

BioPharmaChem Ireland (BPCI) and its members used the recent lockdown to work intensively of the preparation of its latest industry strategy report for the sector. Titled ‘Make Ireland the Global Leader in Sustainable Biopharmaceutical and Chemical Manufacturing’, it is the sixth in a series of such reports published by the association. We consulted with the members of BPCI over a period of about 18 months to come up with the report, which clearly outlines a way forward for this important sector. The entire project was led by BPCI Senior Executive, Nessa Fennelly, supported by BPCI Chair, Paul McCabe of APL/ VLE Therapeutics. It is intended that this report will inform our stakeholders of our priorities in the coming three years.

The report was shared first at a private dinner for the sector held during Biotech Week in Boston in late September. The dinner was held in partnership with IDA Ireland and The National Institute for Bioprocessing Research

and Training (NIBRT) and included a number of US-based companies, as well as some Irish companies, including Thermofisher, Vertex, MSD, APC/VLE, Avantor, DHL, MorphoSys and many others.

Given the importance of the US to the sector in Ireland through foreign direct investment, it was considered very important that the USbased industry was prioritised as a stakeholder to the Irish sector. The strategy was also presented to the International Council of Biotechnology Associations (ICBA) and the National Association of Manufacturers (NAM), both based in Washington DC.

BPCI held two events under the Biopharma Ambition banner in Ireland this year. Biopharma Ambition is a partnership between BPCI, the Irish and Pharmaceutical Healthcare Association (IPHA) and NIBRT. The first of these, titled ‘Davos by the Lee’, was held in Cork, where it brought together

most of the Chief Executives of the industry to debate key strategic issues for the sector with a panel of global industry experts. The event was sponsored by Thermofisher and the Biopharmachem Skillnet and was addressed by international speakers from Sanofi, J&J, Pfizer, Novartis, Thermofisher and Eli Lilly. The event also focused on promoting and supporting the indigenous or local based life sciences industry too, and we were joined by Poolbeg Pharma, Avectas and APC/VLE.

The second event was a joint policy forum on the future of medicines, supported by the Department of Enterprise Trade and Employment, which was held at NIBRT. More than 90 delegates attended to hear presentations around Advanced Therapeutics, talent, the role of Intellectual Property supporting biopharmaceutical R&D and the need for the EU to prioritise manufacturing in biopharmaceuticals. The event was opened by Minister of State at The Department of

Sector o vervie w

Irish PharmaChem | Industry Buyers Guide 2023 6

recently published its sixth industry strategy, entitled Make Ireland the Global Leader in Sustainable Biopharmaceutical and Chemical Manufacturing, writes Matt Moran, Director, BioPharmaChem Ireland.

Enterprise, Trade and Employment, Dara Colleary TD, and featured speakers from the Mater Hospital, Innopharma, NIBRT, Eli Lilly and Charles River Consultants, while we at BPCI took the opportunity to present our new strategy to the audience.

It was clear from the discussion that followed the presentations that there is clear need for an integrated approach to biopharma in Ireland where, despite significant investment in manufacturing and development, companies still find it difficult to provide the latest therapies to Irish patients. Clinical research and even the provision of clinical trials is underdeveloped in Ireland. This supported one of the central recommendations in the BPCI strategy – the urgent need for an Office of Life Sciences within Government. This office would be charged with developing a clear Life Sciences Strategy for the country. In a joint budget submission from BPCI and Ibec’s Medtech Ireland, this was recommended too, in concert with a clear national strategy for health technologies. This

Pictured at the BioPharmaChem Ireland strategy launch in Ibec Offices in Brussels on November 29, 2022, are (l-r): Matt Moran, Director, BioPharmaChem Ireland; Sean O’Reagain, Deputy Head of Unit, Industry 5.0 DG Research and Innovation – European Commission; Jackie King, Director, Ibec Global; Sean Kelly MEP; and Ian Jones, CEO, Innopharma.

will simply bring Ireland in line with other life sciences powerhouses such as the UK, Israel and France.

Central to the BPCI strategy are six thematics or pillars, which are outlined below:

• Industry 5.0

• Provision of Talent

• Support for the manufacture of Active Pharmaceutical Ingredients (APIs)

• Contract Development and Manufacturing

• Global Business Services

• Advanced Therapeutics, including Cell and Gene Therapies

A Growing Sector

The sector exceeded the €100 billion mark for exports last year and proved its worth to the economy during the recent pandemic, both as the sector that actually came up with the vaccine for Covid but also one of the essential sectors that stayed fully operational during the period. A period where those who worked within the sector kept the lights on at the many manufacturing plants all around

Sector o vervie w

Strategic themes 2023-2027 Cell and Gene Therapies (CGT)/ Advanced Theraputics • Adoption of an integrated approach to CGT by State Agencies • Realising Ireland’s potential in next generation biologics including the development of a thriving indigenous and start-up ecosystem • Identify a funding strategy for CGT Contract Development and Manufacturing Organisation (CDMO) Focus on development of project management and CRM skills • Ensure that labour intensive assets are kept in Ireland • Map the full-service provider ecosystem Global Business Services (GBS) National strategy to identify future GBS talent needs • Branding of GBS as Global Location of Choice Establishment of an “Office for Life Sciences Make Ireland the Global Leader in Sustainable Biopharmaceutical and Chemical Manufacturing 22 Active Pharmaceutical Ingredients • Sustainability grants for renewable energy Development of a major supply chain hub in Ireland • Develop a footprint of API in Ireland Industry (Pharma) 5.0 • Sponsor and promote Ireland as the location of choice for the sustainable manufacture of medicines • Focus on digital skills Bring new products to Ireland and grow the ecosystem Skills • Continue to provide adequate funding for competitive funding such as Springboard, Apprenticeships and Skillnets allowing the Biopharma industry to be talent developers – not just consumers. Ensure the recommendations of the Expert Group on Future Skills Needs (EGFSN) are implemented involving all relevant stakeholders. Ensure Ireland’s Higher Education Insitiutions are aligned and sufficiently resourced to meet the future skills needs of the Biopharma sector. 23 A strategy for the sector 2023 - 2027

Irish PharmaChem | Industry Buyers Guide 2023 7

Sector o vervie w Irish PharmaChem | Industry Buyers Guide 2023 8

the country, often at some personal risk. It is testimony to each and every one of these facilities that they were able to ensure that any risk to their workforces was minimised during that difficult period.

Every member of BPCI came together every week, led by Michael Gillen of BPCI, to exchange knowledge and ensure that the guidance that came down from Government and the Health Authorities was as clear and practical as possible.

As the membership of BPCI considers the future of the sector, a couple of underlying principles underpinned their thinking.

1. The Installed Base

Significant capital has been invested by the sector in all forms of biopharmachem manufacturing: in chemical manufacture, in the manufacture of APIs – or small molecule manufacture, in the manufacture of biotech or biologic substances, and the manufacture of medicinal products. It is now estimated that the sector is still investing at least €1 billion per annum in new capital projects.

Some of the major recent announcements are outlined in Table 1.

If this base is to be retained and if it is to continue to grow, it is vital that it stays competitive, hence the emphasis on Pharma 5.0. by the sector, which led to the establishment of a Lighthouse Project. Not only

A sample of investments in the sector in 2022

approach to digitisation or Factory 4.0; this must happen in biopharma where the employee remains central to continued production of medicines that are safe and efficacious so that the world’s patients can continue to benefit and be cured of diseases. Government is due to publish a major report on skills for the sector through is Expert Group on Future Skills Needs (EGFSN). This is a follow-up to their 2016 report and will be timely as the global war for talent hots up.

2. Future Trends

Over 1,000 clinical trials are underway globally in Advanced Therapeutics – this encompasses Cell and Gene Therapy, Gene Therapy, Regenerative Medicine and Car-T. If Ireland is to sustain its base into the future, it is important that it participates in this. This can take the form of manufacturing such products, and Takeda in Grangecastle have already invested in a cell based manufacturing facility. There could also be an opportunity for local companies to enter the market – APC/VLE have already set up a CGT unit in Cherrywood, Maynooth-based Avectas have developed a platform technology to help CGT companies, St James’ and CGT-Vector are developing and administering Car-T products to Irish patients.

Ireland has developed a thriving Global Business Services sector which continues to develop its remit beyond traditional financial services to more specialist medical services, which could also encompass digitisation of autologous CGT. If Ireland can align its GBS and manufacturing sectors, it can copper-fasten the sector more.

BPCI hosted a Round Table in the Ibec Brussels Office in collaboration with Ibec Global and Innoglobal (part of the Innopharma Group) at the end of November to share its strategy report with its EU stakeholders. The Round Table was joined by Members of the European Parliament; Sean Kelly MEP opened the event, and Sean O’Reagain, who heads up the Industry 5.0 unit and DG Research in the European Commission, also contributed, both sharing their thoughts on 5.0. An Irish Pharma 5.0 strategy was presented by Ian Jones, founder of Innopharma, and Bryan O’Donnell of J&J updated the group on the Lighthouse Project. Jackie King, Director of Ibec Global, joined the meeting too.

must it stay competitive but it must also operate sustainably – this too is addressed under the principles of 5.0.

The availability of sufficient talent is also critical – there needs to be a huge emphasis here. Pharma 5.0 talks of a human-centric

It was great to see so many pharma industry folks gathered at the recent pharma industry awards – over 600 at the brand new Radisson Golden Lane Convention Centre. Congratulations to all those companies who were shortlisted and to those who won awards. There was real air of celebration in the room and a big shout out to Mark Barrett and Brian Glennon of APC/VLE who have shown that we can develop our own successful biopharma companies here in Ireland – they are going from strength to strength. Long may it continue!

Sector o vervie w

€400m invested in Limerick €36m invested in Dublin €27m invested in Dublin €12m invested in Waterford €100m invested in Dublin €150m invested in Cork €440m invested in Cork €140m invested in Tipperary 19 A strategy for the sector 2023 - 2027

Irish PharmaChem | Industry Buyers Guide 2023 9

Table 1: Sample of Investments from the sector

From Organic Intermediates to Biochemicals, from Performance Chemicals to Food Ingredients, Camida can source, manage and deliver your needs.

Whether your business is in pharmaceuticals, food, biotechnology or surface coatings, we meet the highest industry standards and conform to the most stringent international protocols.

Tap into our global network and over 30 years’ experience in sourcing specialised chemicals.

We understand your needs, we provide solutions, above all, we exceed your expectations.

Visit www.camida.com, email us at info@camida.com or phone us at +353-52-6125455.

LIFE SCIENCE INDUSTRIAL INGREDIENTS your

is

Search

over

BPCI Strategy Sets Out the Roadmap to Future Success

BioPharmaChem Ireland’s new strategy for 2023-27 aims to ‘Make Ireland the Global Leader in Sustainable Biopharmaceutical and Chemical Manufacturing’.

It clearly sets out its vision, whereby Ireland will be the globally recognised centre of excellence for innovation and development in the sustainable manufacture and supply of biopharmaceuticals, pharmaceuticals, and chemicals, and the location of choice for the launch of new products.

In his introduction to the Strategy, BPCI Director Matt Moran acknowledges that if this vision is to come to fruition, Ireland must overcome a series of challenges, including:

• The need for a future focused industrial policy championed by Government;

• The importance of broadening our sectoral ecosystem beyond manufacturing & supply;

• A supportive environment to enable indigenous SMEs to grow & flourish;

• The ongoing challenge to create a sustainable talent pipeline;

• The imperative to continue to stay competitive and innovative.

The Irish Government need to publish a Life Sciences Plan, Moran stresses, setting out a 10-year strategy for the sector to build on Ireland’s extensive life sciences expertise, demonstrated by the successes of the Covid-19 response over the past two years. The strategy, he writes, should highlight what all life science stakeholders (regulators, industry, academia, NGO’s, HSE etc.) need to do to create an environment in which the life sciences industry can continue to grow and flourish.

The BPCI Director stresses that a central part of this strategy needs to be the establishment of an Office for Life Sciences that reflects international best practice in industrial policy by embracing clustering to champion research, innovation and the use of technology to transform health and care services, led by the Department of Enterprise, Trade & Employment with support from other departments.

The Government and any subsequent Office for Life Sciences needs to review global best practice in ecosystem development as a mechanism for strategy/ecosystem development, such as the MIT REAP Regional Entrepreneurship Acceleration Programme (MIT REAP), according to the Strategy. MIT REAP provides opportunities for communities around the world to engage with MIT in an evidence-

based, practical approach to strengthening innovation-driven entrepreneurial (IDE) ecosystems. A typical MIT REAP region has a population of 1-10 million people.

By adopting industrial policies that promote clustering, we can create the means to achieve more strategic methods of cooperation across sectors both vertically and horizontally, with key stakeholders represented.

BioPharmaChem i reland Strategy

BioPharmaChem Ireland’s latest strategy identifies six strategic themes which will underpin the future success of the sector here and ensure Ireland remains at the forefront of sustainable biopharma and chemical manufacturing going forward.

The BPCI Strategy calls for the establishment of an Office for Life Sciences that reflects international best practice in industrial policy by embracing clustering to champion research, innovation and the use of technology to transform health and care services.

Irish PharmaChem | Industry Buyers Guide 2023 11

This view is reinforced by the OECD ‘Empowering the health workforce: Strategies to make the most of the digital revolutions’ which advises that a successful digital transformation requires system-wide reorganisation, underscored by an overarching strategy, with leadership that establishes a framework for coordination among decision making actors.

As we enter the new era of Advanced Therapeutics, partnership will be critical between industry, the Government and the HSE, Moran argues, if Ireland is to cement its place as a global hub for life sciences going forward.

Acknowledging Ireland’s successes in attracting FDI across the sector, the BPCI Director is also frank about where we have not been quite as successful, the development of a strong indigenous biotech sector, citing outliers like APC and Avectas as those who continue to break the mould and put Ireland on the map internationally in the biotech sphere, as well as the development of Spear Street Capital’s bioincubator at Cherrywood, South Dublin.

The Strategy reveals the six strategic themes, which BPCI believe will underpin the future success of the sector here:

1. Industr y (Pharma) 5.0

2. Skills

3. Active Pharmaceutical Ingredients (API’s)

4 Cell and Gene Therapies/Advanced Theraputics

5. Global Business Ser vices (GBS)

6. Contract Development and Manufacturing Organisation (CDMO)

1. Industry (Pharma) 5.0

The two most significant challenges facing Europe over the next decade are the transition towards a climate neutral society and the retention of our industrial competitiveness. Industry 5.0 can help drive this twin transition and involves the interpretation of Industry 4.0 Technologies through a human-centric lens, broadening the focus from solely shareholder value to value for all stakeholders in society and indeed greater resilience – particularly of supply chains and the manufacture of strategically important goods.

Recent disruptions have shown the importance for Europe to be more self-reliant and flexible in manufacturing and supply to adapt to changing conditions.

There lies an opportunity for the sector in Ireland to defend its competitiveness, while at the same time meeting its sustainability targets reducing its carbon footprint. By embracing the principles of Factory 5.0, Ireland can ensure the long-term future of the sector here.

The Strategy provides a case study in the form of the Lighthouse 5.0 Partnership, a cluster of Irish based high-tech manufacturers, service providers and Government agencies formed with the goal of leveraging sectoral competencies and best practice experience to accelerate the transition of current operations towards Industry 5.0. Lighthouse 5.0 members include Life Science leaders like Lilly, MSD, SK biotek, J&J, Merit Medical, Thermo Fisher Scientific, Pfizer, GE Healthcare, and Merck, and the cluster is supported by IDA Ireland and Enterprise Ireland.

2.

Demand for the right kind of talent is becoming ever-more acute, which has been recognised by Government, who have tasked the Expert Group on Future Skills Needs (EGFSN) with the job of preparing a report on the current skills scenario within the sector in Ireland. Attracting and retaining talent are key priorities and life sciences leaders are transforming their talent acquisition strategies, selecting partners, piloting technologies and customising new recruitment and retention strategies. There is a strong business case for diversity, equity, and inclusion (DE&I), including its profound and very real power to attract the best talent and build highperforming teams.

The areas of product and technology transfer, downstream processing and quality professionals are under increased pressure to

locate talent. The rise of automation and artificial intelligence (AI) has brought new opportunities and with that, new skills are required. Companies are challenged with finding these skills within the current workforce and are now battling with every other industry sector in the world for ultrahigh demand talent.

The Strategy highlights the importance of continuing to provide adequate funding for programmes like Springboard, Skillnets and Apprenticeships, allowing the biopharma industry to be talent developers

The Strategy’s vision is for Ireland to be a globally recognised centre of excellence for innovation and development in the sustainable manufacture and supply of biopharmaceuticals, pharmaceuticals, and chemicals. Image from rawpixel.com.

BioPharmaChem i reland Strategy

Skills

Make Ireland the Global Leader in Sustainable Biopharmaceutical and Chemical Manufacturing A strategy for the sector 2023-2027

12 Irish PharmaChem | Industry Buyers Guide 2023

The BioPharmaChem Skillnet and Laboratory Apprenticeship Programme are cited of examples of how we can address the talent challenge.

3. Active Pharmaceutical Ingredients (API’s)

API’s have formed the traditional core of the sector when many of the large multinationals first established in Ireland and still represent a very valuable component of the industry. As global networks come under increasing cost pressure, it is vital that Ireland’s API sector stays competitive and continues to grow.

The Strategy highlights the Lighthouse Project on Factory 5.0, whose aims include digitising the sector, driving sustainability in the industry and developing a roadmap to support an ecosystem to bring the small molecule API sector towards the principles that underpin Factory 5.0. Advancements in automation, artificial intelligence (AI) and machine learning in recent years have improved the success rate in the structural design of small molecules. API companies are adding more sustainable manufacturing processes in line with stated aims to achieve zero carbon emissions from global operations by the mid-2020s onwards.

4. Cell and Gene Therapies/Advanced Therapeutics

Advanced Therapeutics represent a significant opportunity for the Irish biopharma sector. The Strategy notes the opening of Ireland’s first stem cell therapy production facility, with Takeda’s cell therapy production unit at Grangecastle. Cell and Gene Therapies comprise a major part of Advanced Therapeutics, with technologies such as CAR-T able to provide a route to the permanent cure of diseases such as cancer; the Strategy highlights the opening of Ireland’s National Adult CAR–T Cell Centre at St James’ Hospital, Dublin.

It is widely predicted that advanced therapeutics and vaccines will be the next big wave of biopharma growth, with analysts now predicting that CGT revenues will reach $1060 billion globally by 2025/26.

The Strategy highlights the development of the Cell & Gene Therapy (CGT) Forum and its mission to help make Ireland a global leader in the development, manufacture, supply and adoption of Advanced Therapies, including Cell and Gene Therapies and novel vaccines, through strong investment in worldclass training, an innovative research base, a supportive entrepreneurial environment and excellent clinical trials infrastructure.

5. Global Business Services (GBS)

A growing number of biopharma companies operate Global Business Service (GBS) centres in Ireland. While originally set up to manage finance for corporate networks, they have laterally diversified into other areas, including HR, management of medical information, and connected health. Such centres are becoming more aligned with the manufacturing part of the industry and could look to establish control towers to manage supply chain in CGT products, for example.

The Irish based GBS operations have earned a reputation for managing complexity and uncertainty, through their high knowledge base, and we need to ensure that Ireland is the location of choice for pharma GBS against other very competitive locations through our talent pool and raising the sector’s profile in the labour market. The key to this, it argues, is managing knowledge-based activity, as transactional activity moves to lower cost locations. Ireland is ideally placed to host CGT

‘Control Towers’ and leverage co-location with manufacturing sites, in addition to leveraging data to provide new insights/opportunities into the business.

The Strategy highlights the development of the GBS Skills Pathway Programme, a structured learning and development initiative that spans entry level to leadership development, with two accredited qualifications – a CPD Diploma in GBS and an MSc in GBS.

6. Contract Development and Manufacturing Organisation (CDMO)

The CDMO sector is expanding and evolving globally, driven by existing operators and the transfer of some existing API operations. The Strategy recognises the potential to expand this sector, building on Ireland’s excellent reputation for quality and strong regulatory compliance, as well as our geographical advantage, sitting at the bridgehead between the US & Eurasia.

CDMO is a labour-intensive enterprise, and an extensive ecosystem of suppliers is in place in Ireland (a mapping exercise of the fullservice provider ecosystem will demonstrate this) and should therefore be supported and promoted. There are enormous employment benefits associated with growing a service offering in CDMO, the Strategy maintains.

Government agencies need to focus more on the CDMO opportunity for Ireland and support growth for a service offering not only in small molecule but also in biologics CDMO’s, according to the Strategy. Specialist CDMO’s with a dedicated biologics capacity will be best placed to support companies in getting their innovations to market.

The pharmaceutical CDMO market has been valued at circa $90 billion, growing at 7% per year. Traditionally, investment has been directed at small molecule Therapeutics but recent years have seen the market share of small molecule treatments decline, while there is rapid growth in the volume of large molecule and biologic treatments.

To encourage the growth of CDMO’s in Ireland, we need to:

• Focus on development of project management & CRM skills;

• Ensure that labour intensive assets are kept in Ireland;

• Map the full-service provider ecosystem.

BioPharmaChem Ireland’s full Strategy is available to download at: www.ibec.ie/connect-and-learn/ industries/life-sciences-and-healthcare/ biopharmachem-ireland/bpci-strategy-2022.

BioPharmaChem i reland Strategy 14

12 of the

medicines

11.2bn Covid-19 vaccine doses

in a single year 85+ companies Biopharmaceutical and chemical sector had an export value of €106bn in 2020 – the first time a sector has exceeded the €100 billion mark in a single year. Over 80,000 employed directly and indirectly by the

Over €10bn in

investment A profile of

BioPharmaChem Sector 67% of the total goods exported from Ireland Make Ireland the Global Leader in Sustainable Biopharmaceutical and Chemical Manufacturing 14 Ireland has one of the largest shares of tertiary education with 47% of 25-64 year-olds having third level degrees, with 85% of tertiary educated adults employed and enjoying greater earnings according to the OECD Ireland has an exemplary compliance record with regulatory agencies like the Food and Drink Administration (FDA) and European Medicines Agency (EMA), who collaborate and work closely with our Health Products Regulatory Authority (HPRA) to achieve trouble-free compliance. 10 of the top 10 world’s Biopharma companies 19 of the top 20 global pharma and biopharma companies based in Ireland 50 FDAapproved pharma and biopharma plants 25% of all PhD researchers in the Irish industry are employed in the sector. 15 A strategy for the sector 2023 2027 Irish PharmaChem | Industry Buyers Guide 2023

topselling

manufactured

produced

sector

capital

Ireland’s

Astellas Ireland Co., Ltd.

Kerry Plant

Killorglin

Co. Kerry

Astellas Ireland Co., Ltd.

Damastown Road

Damastown Industrial Park

Mulhuddart

Dublin 15

We are in the business of breakthroughs – the kind that transform patients’ lives. Dedicated to our mission of discovering, developing and delivering innovations that help patients prevail over serious diseases. We’ll never give up on our search for more hope, for more people, around the world.

Visit bms.com/ie to see how we’re driving meaningful change for patients, their loved ones and for the communities and societies we all share.

2022

All rights reserved. NO-IE-2200034 November 2022

©

Bristol-Myers Squibb Company.

Investing in Ireland’s Biopharma Future

In early November 2022, I was privileged to be invited to attend the Biomanufacturing World Summit in San Diego. The Summit is an annual gathering of a few hundred of the world’s leading biopharma and biotech executives, who come together to discuss the state of the biopharma and biotech sector and focus on how best to address the challenges and seize the opportunities in the world of biologic medicines manufacturing. It was the first post-pandemic in-person running of the event and, as well as the great buzz created by people coming together to meet each other after the long break, there was also a surprisingly positive overarching theme evident over the two days.

The general sense was that in spite of the devastating impact that the Covid-19 pandemic had on every person and community around the world, the industry had learned many important lessons over the pandemic period, including how to navigate the clinical development and regulatory systems more efficiently, how to manufacture at scale quickly and safely, and how

Darrin Morrissey, CEO, NIBRT, highlights the post-pandemic trends in the global biopharma industry, the innovations driving the sector forward and the role of NIBRT in strengthening Ireland’s leadership position in global biopharma manufacturing and supply.

to get supply chains for life-saving medicines and vaccines cranking at speeds never before seen. As the pandemic dissipates, what is now emerging is a biopharma industry that has developed much greater resilience in how it manufactures and supplies medicines than before, as well as an appetite for greater and quicker rates of innovation.

A standout moment from the conference was a presentation on day one from Arleen Paulino, Senior Vice-President for Global Manufacturing at Amgen, who presented on the top five

post-pandemic trends that are impacting the biopharma industry. In summary, these trends are:

1. The world is in a period of unprecedented change and headwind – and this will be the situation for the foreseeable future.

These headwinds include the pandemic itself, the inflationary effect of war and other factors, shrinking margins, the price pressure on innovative medicines, geopolitical threats, and the accelerating crisis of talent attraction and retention. These changes are challenging

NIBRT

Irish PharmaChem | Industry Buyers Guide 2023 17

At PBC Biomed we can help your idea become a reality by partnering with you to accelerate your innovation to patients.

AIM takes an idea from concept to commercialization quickly, while de-risking potential roadblocks along the pathway to success.

Please scan the code above to visit the PBC BioMed website and to find out more about AIM

Technology Valida on Technology Op misa on Concept Refinement Commercial Development

Introducing

AIM

for every person and every industry, including biopharma, but they also create a climate that promotes more innovation and a motivation to think differently.

2. Biopharma supply chain. From weak link to resiliency.

The pandemic has taught the industry valuable lessons on how to build quickly and maintain a resilient supply chain. There is now a strong appreciation that a strong supply chain strategy, coupled with resilient, adaptive supply chain infrastructure, are critical must-have assets for a successful biopharma company.

3. Innovation in biopharma is accelerating and this creates massive complexity.

The appetite for innovation in healthcare globally is increasing, and this need is being matched by new therapeutic modalities being developed and launched. This shift towards innovative products has been further accentuated by the pandemic. New drug modalities, including mRNA, oligonucleotides, cell-based and gene-based technologies, are being approved and introduced with increased speed, so much so that this rapid evolution in biological-based, genetically-targeted medicines is leading some to call this era the ‘biocentury’. Overlaying these new bio-therapeutic modalities are new digital technologies that are playing an ever-increasing role in the manufacturing and supply chain processes.

4. Smart Manufacturing is happening –now!

It is clear to see that the biotech and biopharma sector is increasing in sophistication and complexity. Automation and predictive technologies are increasingly being integrated with process and people at the heart of the biopharma manufacturing and supply chain process. Advanced automation, along with better data flow, visibility and analysis, digital quality

surveillance and the use of other technologies – like blockchain, artificial intelligence, virtual reality etc. – are leading to steady transformation and ultimately increased resilience and efficiency across the manufacturing and supply value chain.

5. Talent is now so important to the industr y that it has become a major differentiator and a point of competitive advantage.

The attraction and retention of talented staff, and the training and support of these key people, is now of critical importance to biopharma manufacturing companies. Moreover, the shift in the make-up of the workforce towards the new generation of workers is forcing companies to consider the ways of working and benefits on offer. Generation Y workers are now starting to enter the workforce in steadily greater numbers and are looking for more meaningful careers, professional development and flexibility over more traditional working practices. Companies’ ability to match these expectations will become

NIBRT delivers nearly 40,000 training days to 4,600 trainees and students annually.

ever stronger predictors of success in the future.

The biopharma pipeline – increasing innovation and diversity

The PhRMA report, Innovation in the Biopharmaceutical Pipeline, published in December 2021, represents a snapshot of drug development activity. The report outlines how there were approximately 12,600 potential NME projects at clinical development phase at the time of publication. Of the total number in development, approximately 50% are small molecule chemistry-based products and 50% are a combination of biological and Advanced Therapy products.

25% of the total clinical development projects involve more traditional monoclonal antibody and recombinant protein-based products. However, this category now also includes increasing numbers of more complex multi-specific antibodies and antibody drug conjugates (ADCs), which use highly selective monoclonal antibodies joined to other agents such as cytotoxic small

NIBRT

Irish PharmaChem | Industry Buyers Guide 2023 19

NIBRT has ambitions to also play a leading role in attracting the next wave of biopharma innovation.

NIBRT already has a curriculum of world-leading biopharma courses from Springboard+ and operator level to degree and Masters level, across the full range of traditional biopharma manufacturing skills areas.

molecules to target cancer.

4.3% of the total were projects involving cell therapies. Cell therapies are highly innovative products, in which healthy, functioning cells are themselves the therapy and are introduced to treat a disease or condition. An additional 2.7% (348 projects) were in gene-modified cell therapies, in which a functional gene is introduced into a cellbased therapy to improve its therapeutic effect. An example of a gene-modified cell therapy is chimeric antigen receptor T-cell (CAR-T) therapy, where a cancer patient’s blood cells are extracted and their T-cells isolated, which are then genetically engineered and reinjected back into the same patient. The engineered T-cells then activate that individual patient’s immune system to specifically target the particular cancer. CAR-T therapies have proven to be remarkably effective at not just treating but effectively curing certain previously fatal blood cancers.

Further exciting classes of therapies in development and highlighted in the PhRMA report include:

• RNA and DNA therapeutics (265 projects, 2%), where directly introducing RNA/DNA can produce a therapeutic or prophylactic effect – e.g. the Covid-19 mRNA vaccines.

• Gene therapies (281 projects, 2.2%), in which a corrective gene is introduced directly into a patient to treat or prevent a disease.

• Oncolytic viruses (133 projects, 1%), in which tumour-seeking viruses infect tumour cells and replicate themselves until the cells burst, releasing markers that allow the cancer to be recognised by the immune system and an immune response is then mounted against the cancer.

• Gene-editing products. These are highly experimental products based CRISPR-CAS9

Left and right: The €21 million expansion of the NIBRT facility will incorporate more Advanced Therapy research and training capacity.

technology, and at time of writing only seven clinical development projects were active globally.

Innovation, complexity and the shifting biopharma landscape - an opportunity for Ireland

Over the last 20 years, Ireland has established itself as a global leader in biopharmaceutical manufacturing and has experienced tremendous success in attracting multinational companies to establish monoclonal antibody and recombinant protein manufacturing operations across the country. Biopharma foreign direct investment (FDI) has topped €10 billion over the last decade, with the number of pharma manufacturing facilities now standing at over 85 across the country, biopharma facilities at over 25, over 40,000 people now directly employed in the sector and biopharma contributing over €40 billion in national exports annually – see http://IDAIreland.com.

At the San Diego World Summit meeting recently, it was highlighted that there is much work to be done on standardising the platforms for the manufacture of novel therapies, most notably

Cell and Gene Therapies and oligonucleotides. Similar to the productivity challenges experienced with monoclonal and recombinant protein manufacturing in the 1980s, improving the manufacturability of Advanced Therapies through process development and other intensive research is widely recognised to be a critical success factor towards ensuring these medicines can be more affordable, safe and available for widespread patient access. The availability of well-trained talent for the intensive manufacturing processes is also a critical factor for success.

Building on a successful track-record, strong existing infrastructure, a highly experienced workforce and a history of supportive government investments, Ireland has a strong potential to play a major role in the efficient, cost-effective and safe manufacture of Advanced Therapies. Ireland has a mature system of higher education, research and training institutes, and expertise across life science and digital technologies built up over the years, and a uniquely central geographic location, which when taken as a whole can be uniquely attractive to biopharma and biotech companies operating in the advanced therapies area.

NIBRT

20

Irish PharmaChem | Industry Buyers Guide 2023

NIBRT – expanding its important role, supporting biopharma growth

The strategic vision of IDA Ireland, and the Irish government of the day, to invest in the establishment of the National Institute for Bioprocessing Research and Training (NIBRT) in the late 2000s, and ongoing investment since then, has been shown to be pivotal in helping Ireland to win and sustain the biologics manufacturing investment over the last decade. NIBRT now has ambitions to also play a leading role in attracting the next wave of biopharma innovation.

On the training and skills front, NIBRT already has a curriculum of world-leading biopharma courses from Springboard+ and operator levels to degree and Masters levels, across the full range of traditional biopharma manufacturing skills areas, including upstream processing, downstream processing, fill-finish operations, QC Micro and single-use technologies. Recently, NIBRT has also been introducing various novel biologic modality and biopharma 4.0 / digital courses into its curriculum. A selection of these advanced technology courses are:

• Introduction to Advanced Therapies/CGTs;

• Introduction to Cell Therapy;

• Introduction to Gene Therapy;

• Fundamentals of Vaccine Manufacture;

• Introduction to Data Analytics for Biopharma Manufacturing;

• Advanced Data Analytics for Biopharma Manufacturing;

• Biopharma 4.0 Strategic Workshops in partnership with Boston Consulting Group (BCG).

More information on when these and other courses are running in 2023 can be found in the just-published NIBRT Training Catalogue 2023: www.nibrt.ie/nibrt-publish-trainingcatalogue -2023.

Growing research areas

NIBRT’s research team has been growing over the last decade, and we now have a team of over 50 researchers, led by eight principal investigators, working on industry collaborative projects with industry partners, as well as various SFI, Enterprise

Ireland and Horizon Europe-funded projects. From an initial core focus on monoclonal and recombinant protein research, which included research into the fundamentals of manufacturing cell biology, complex protein characterisation and integration, automation and digitalisation for applied process control, NIBRT’s research has recently been evolving into Advanced Therapy areas, including:

• Viral vector characterisation and optimisation of the manufacturing process, with potential applied uses in gene therapy and vaccine manufacturing;

• Cell therapy activities, such as novel modified cell therapy manufacture, developing workflows for CAR-T generation and process control/monitoring and utilisation of single cell ‘omics’ to monitor modified T cell therapy manufacturing;

• mRNA research focused on synthesis of modified oligonucleotides/mRNA, lipid nanoparticle formulation and characterisation, understanding and manipulation of translation.

At a national leadership level, NIBRT has played a strong central role in the establishment of the Cell and Gene Therapy Forum (CGT), along with many stakeholders from industry, academia and government. The CGT Forum produced a White Paper which laid out a series of recommendations for increased investment in workforce

development, research excellence and national infrastructure. The CGT Forum White Paper was important in supporting a business case that led to a decision by IDA Ireland to invest €21 million in the expansion of the NIBRT facility to incorporate more Advanced Therapy research and training capacity. This expansion is currently under construction, and it is anticipated that the new facility, incorporating dedicated research laboratories and training suites for Advanced Therapeutics, will be completed and open for business in Q2 2023.

In conclusion

As we anticipate the next few years of opportunity and challenge, NIBRT looks forward to playing its own uniquely important role in supporting the biopharmaceutical manufacturing industry in Ireland and internationally, by training the people who make life changing biologically-based medicines and undertaking research that grows the fundamental understanding and delivers impactful solutions to improve manufacturing processes of complex biopharmaceuticals and advanced therapeutics.

The foundations are already laid and NIBRT is committed to playing a leading role, along with our partners at IDA Ireland and across the ecosystem, in enabling Ireland to capitalise on the next phase of the biopharma opportunity.

NIBRT – the National Institute for Bioprocessing Research and Training – was established in 2007 with the mission of supporting the biopharma manufacturing facilities in developing talent and skills through world-leading training and addressing complex manufacturing challenges through excellent research. Over the years, NIBRT has gone from strength to strength and the Institute now delivers nearly 40,000 training days to 4,600 trainees and students annually, as well as delivering a diverse range of research projects with funding from industry partners, state funders and the European Commission.

NIBRT

Irish PharmaChem | Industry Buyers Guide 2023 21

The extension to NIBRT will incorporate dedicated research laboratories and training suites when it opens in mid-2023.

We make healthy possible.

Amneal Ireland is located on the Cahir Road, Cashel, County Tipperary.

Should you wish to be part of our team in the manufacture of high-quality, affordable medicines, please see all our job openings on the Careers section of our website

The facility is dedicated to the production of metered dose (MDI) and dry powder (DPI) inhalers.

www.amneal.com

If you are interested in a career with Anmeal Ireland, please send your CV to careers.cashel@amneal.com

www.amneal.com/cashel

Lab Apprenticeship Programme expands to Cork

The Laboratory Apprenticeship Programme provides apprentices with practical skills for a career in the life sciences sector and ensures businesses have job-ready applicants for laboratory roles.

Apprenticeships have been identified as an essential route to develop skills and shape new career pathways and address the emerging skills gaps industry are experiencing.

The Apprenticeship is quickly becoming a very popular route for those interested in roles across STEM.

Apprenticeships are an exciting and recognised way for employers to develop talent for their company and the sector. The positive influence of learning, which is closely linked to the workplace, provides huge benefits for both employers and apprentices, and is documented to improve social mobility. Employers can proactively support a pipeline of talent targeted to their own needs and learners have the unique opportunity to earn nationally recognised qualifications whilst also gaining invaluable hands-on work experience. Since 2016, the Government has invested over €620 million in the expansion of the apprenticeship system, launching the New Generation Apprenticeships to promote and support apprenticeship development in new and emerging sectors of the Irish economy.

This investment also saw the introduction of over 33 industry-led programmes to date, with many more in development, with qualifications ranging from Level 5 to Level

Siobhán Dean, BioPharmaChem Ireland, writes on the overwhelming success of the Laboratory Apprenticeship Programme, which has recently expanded, with 11 new apprentices beginning training in Munster Technological University, Cork.

9. The Government set out a target that by 2025 there will be 10,000 new apprentice registrations per annum. To help achieve this target, the action plan for apprenticeships was launched in 2021, outlining a range of recommendations and supports, such as the employer grant and opening applications for new apprenticeships on an ongoing basis, allowing employers and education providers to develop apprenticeships in response to evolving industry skills needs as they arise.

Laboratory Apprenticeships: Development and Outcomes

The Laboratory Apprenticeship is one of the newer pathways for candidates hoping to start a career in the laboratory. The programme not only offers opportunities within the pharmaceutical sector, but also medical devices and diagnostics, chemical manufacturing, independent testing labs and the food and drink sector. The programme was designed by industry in partnership with Technological University Dublin as one of the outputs from the EGFSN report on the skills needs of the biopharma sector in 2016. At the time it was

estimated that over 8,000 new roles would be developed by the sector by 2020. CSO figures have shown that the sector has surpassed this growth, showcasing the need for the sector to explore the different routes to develop skills.

The skills and tools apprentices learn are practical and applicable to a real-life role in a laboratory in the life sciences sector. The apprentice attends college two days per week (off-the-job) and the workplace three days per week (on-the-job) during term (they work five days in their sponsor company during college break) so naturally, by the time they complete the programme, they are already knitted into the fabric of their sponsor company and have a thorough understanding of the business needs and how everything fits together. On completion of the apprenticeship, participants are job-ready, equipped with the skills and knowledge required to work in any regulated laboratory environment.

Feedback from Employers and Apprentices

This apprenticeship programme offers an array of benefits not only to the candidate,

Laboratory a pprenticeship p rogramme

23 Irish PharmaChem | Industry Buyers Guide 2023

but to the employer as well. The apprenticeship programme allows the employer to access a completely new talent pipeline and helps them with talent attraction and retention issues. As the apprentice is learning theory in college to support practical work in the lab, it ensures that work-ready candidates graduate from the programme.

Our sponsor companies often speak about how the laboratory apprentices have brought a fresh new attitude to the laboratory and are extremely passionate about what they are learning.

Andrew Hayes, Senior Manager, Human Resources at Helsinn Birex Pharmaceuticals Ltd, said: “The creation and successful launch of the BPCI National Laboratory Apprenticeships was a passion project for many pioneers within the biopharmaceutical sector. We believed that these apprenticeships would engage and develop a parallel source of untapped talent into the evergrowing sector, giving a chance to those with different learning needs, while complementing the ongoing recruitment of those with the necessary traditional third-level qualifications, all to ensure the ongoing supply of much needed skills to the industry. The experience of participating companies has been overwhelmingly positive.”

The Laboratory Apprenticeship Programme has been delivered in Technological University Dublin, Tallaght and South East Technological University, Waterford, for the last number of years. The programme is being expanded nationally, with Munster Technological University, Cork, welcoming 11 apprentices in September 2022 and other education providers have expressed their interest to deliver the programme.

Hear from Apprentices Themselves

We recently caught up with some of our apprentices, to get their take on the programme:

“I am a qualified Dental Nurse, but always wondered about a new career and a dream job for me in the lab,” says Milena Smokowska, a laboratory apprentice with Merck. “I thought

a career change would not be possible as I would need to have a wage to provide for my family while gaining my qualifications. When I heard about the Laboratory Apprenticeship Programme, I was slightly sceptical but decided to apply the very same day. Once I learned about the structure of the course, I couldn’t have been happier. Gaining a degree while earning a salary and not compromising on family time couldn’t’ have been more appealing to me. The apprenticeship offers many benefits. Whether you choose a twoyear or three-year course, throughout this time, you are gaining valuable experience and

confidence, which gives you a huge advantage for future employment.”

Jennie Jones, a lab apprentice with Sanofi, says: “The Laboratory Apprenticeship Programme has allowed me to retrain whilst gaining great experience in the pharmaceutical environment at Sanofi. Applying the academic knowledge that I have learned from the course to my everyday roles and responsibilities has helped to accelerate and improve my understanding of the industry.”

For more information on the Laboratory Apprenticeship Programme, please email labapprenticeship@ibec.ie.

Laboratory a pprenticeship p rogramme

Irish PharmaChem | Industry Buyers Guide 2023 24

The Laboratory Apprenticeship Programme has been delivered in Technological University Dublin, Tallaght and Southeast Technological University, Waterford, for a number of years, and has recently expanded to Munster Technological University, Cork.

Your Ideal Partner for the Development and Manufacture of APIs

Our team in Cork is expert in developing and manufacturing API for clinical and commercial supply

Our campus in Cork is a state-of-theart contract API development and manufacturing facility, where our team support our customers in bringing medicines to patients through the relentless application of science in process and analytical development. We take chemistry from laboratory scale development through to large-scale commercial supply, made

possible by our driven and dedicated employees - a team of 500+ highly skilled chemists, engineers, analysts, operators and crafts personnel. Our facility meets with the most stringent production, compliance, safety and environmental standards. We take pride in our mission to enable our customers to make the world healthier, cleaner, and safer.

Learn more at https://www.patheon.com/sites/cork-ireland/ or email us at contactcork@thermofisher.com

Your advantages with DACHSER Chem Logistics Specialised chemical logistics expertise and standardised logistics solutions Automated processes with consistent electronic interface documentation High standards of safety and quality for the chemical industry, assessed according to SQAS A uniform European network Complete transparency with innovative IT systems A high degree of expertise in handling dangerous goods DACHSER Ireland Ltd. • Dublin Branch Blackchurch Business Park • Rathcoole County Dublin • D24 C796 • Tel.: +353 1 4013333 dachser.dublin@dachser.com • dachser.ie Logistics in its element. DACHSER Chem Logistics 211112_ANZ_CHEM_Keyvisual_680_IR-EN_180x130_V05.indd 1 15.11.2021 17:09:05 Carbon Group, Ringaskiddy, Co. Cork, Ireland, P43 R772 T: +353 21 4378 988 Contact: Carol Deegan T: +353 86 261 2485 E: carol.deegan@carbon.ie Suppliers of a wide range of raw materials/blending services to the pharmaceutical, biopharma and medical device industries

BPC Skillnet: Offering Flexible and Relevant Training

Established over 15 years ago, BioPharmaChem Skillnet’s goal is to promote an organisational wide climate of whole-company talent development in the area of industry specific technical and nontechnical training within the life sciences sector. ioPharmaChem Skillnet is a Skillnet Business Network that supports and enables the growth and development of staff in global and indigenous organisations across Ireland.

Promoted by BioPharmaChem Ireland (BPCI) and co-funded through Skillnet Ireland and participating companies, BioPharmaChem Skillnet, through continuous interaction and engagement across industry, has developed into a network with unique capabilities to support talent development, while also facilitating invaluable research, networking and benchmarking activities.

The BioPharmaChem Skillnet works in alliance with Ibec industry association BPCI to help companies across the broad life sciences sector to identify current and evolving skills needs. It meets those needs through the provision of a range of specially designed education and training programmes,

ranging from short rapid learning sessions to virtual reality programmes on highly technical aspects of the manufacturing process, and fully accredited diploma level programmes.

Customised Training Programmes

BioPharmaChem Skillnet also meets the specific needs of individual companies through the delivery of customised programmes which can then be reworked for roll-out to other companies in the sector. Participating companies and their employees are directly involved in the identification, design, delivery and evaluation of training, ensuring it is relevant and aligned to the needs of the sector. BioPharmaChem Skillnet provides programmes that are:

• Cost efficient – subsidised utilising the buying power gained through the wider Skillnet Ireland structure;

• Relevant companies can tailor the intervention to the exact training their staff need;

• Convenient – delivered at a time and a location that suits participating companies;

Susan Costello, Network Manager, BioPharmaChem

• Of a high quality – we source the best and most experienced training providers. Through networking, companies can accelerate learning and advance their competitive advantages, whilst employees up-skill and gain positive personal and economic benefits.

Evolving Talent Development Needs of Industry

Ireland has a strong international reputation for life sciences; the biopharmachem sector in Ireland employs over 72,000 people both directly and indirectly. Our workforce is well-known to be highly educated and agile. As outlined in the recently launched BioPharmaChem Ireland Strategy, 57% of employees in the biopharmachem sector are third level graduates and 25% of all PhD researchers in Irish industry are employed in the sector. The continued demand for highly educated, skilled workers will increase significantly over the coming decade,

27 Irish PharmaChem | Industry Buyers Guide 2023 TRAINING & DEVELOPMENT

The BioPharmaChem Skillnet provides businesses with industry-specific and even company specific training programmes, explains Susan Costello, Network Manager, BioPharmaChem Skillnet.

Skillnet.

TRAINING & DEVELOPMENT

BioPharmaChem Skillnet has commenced development of a sectoral map of Ireland that will profile the companies, products manufactured, supply chain and employment opportunities. In addition to this, the network is hoping to secure funding to develop a skills framework for the sector, demonstrating the occupations and skills required within the biopharmachem sector and having a clear, defined framework outlining the critical functions and key tasks, along with the skills and competencies required to perform them. The network will then work with industry and education providers to ensure that the relevant talent development programmes for the skills and competencies required are available.

Talent Needs within the Sector

In the early years of the 21st century, the sector saw significant expansion into biopharmaceutical manufacturing and a contraction in chemical API manufacturing. Through the past few years, another wave of technological change is evident, with a renewed expansion of the chemical API sector, driven by new product launches and the employment of new continuous manufacturing technologies. This comes at the same time as a new era for biopharmaceutical manufacturing emerges with the growth of Advanced Therapeutic Medicinal Products (ATMPs), also termed Cell and Gene Therapies (CGTs), encompassing cells as therapies, gene therapies and engineered tissues with applications across infectious diseases, oncology, immunology and autoimmune diseases.

the relevant talent development programmes are available.

Equality, Diversity and Inclusion Research

A major undertaking for the BPC Skillnet in the past year has been the completion of a research project on Equality, Diversity and Inclusion in the biopharma sector in Ireland, with the support of the BPCI Diversity & Inclusion Working Group. The aim of the research was to gain a demographic snapshot of the biopharma sector, including but not limited to: gender diversity, cognitive diversity, demographic diversity, and intellectual diversity.

As expected of a high tech sector, almost all biopharma manufacturing sites offer flexible working hours, with many having additional policies, including agile working programmes (93%), top-up to fully paid maternity leave (85%), other compassionate leave (85%), and formal training/support for further education & learning to facilitate promotional opportunities (80%). However, the research found that fewer businesses had policies for menopause (5%), neurodiversity (7%), fertility treatment (7%), chronic/ invisible illness (10%), transitioning/transgender (15%) and formal return to work programmes (17%). The data from this research will feed into appropriate learning offerings in the near future.

Looking to the Future

requiring the up-skilling of current employees for new digitised roles and re-skilling of people from adjacent industries who can successfully transfer over to the biopharmachem sector.

The past three years have been unprecedented, with periods of significant change and growth, which have driven organisations to increase the rate of change within their operations. These challenges have presented opportunities and we are very proud of our significant achievements over this period. These achievements, driven by the needs of the sector, have been guided by Skillnet Ireland’s strategic pillars of Workforce Design, People Development and Strategic Innovation. BPC Skillnet has been instrumental in facilitating business transformation in industry by offering talent development solutions to companies and allocating significant resources to future skills needs.

VR Training Programmes

As the industry increases its digitisation and leverages information technologies to improve its performance, the BPC Skillnet continues to develop and launch training programmes utilising virtual reality (VR). Having developed and launched VR programmes on Aseptic Technique for Biopharmaceutical Manufacturing and Powder Handling for API Manufacturing, the network has secured funding for the development of a third module, Health and Safety, aimed at SME businesses within the sector.

Additionally, there has been huge growth in Contract Development and Manufacturing Organisations in Ireland, where we are seeing an increase in outsourcing clinical and commercial activity, which are new outsourced roles. A number of these organisations have acquired manufacturing facilities in Ireland in recent years and are contracted not only to manufacture products, but also perform process development and validation work. We are working closely with companies nationwide to ensure the talent needs for these roles are met and