MEMBER PROFILE

Workington supersize The Confor team (right) recently enjoyed a fascinating visit to member site Iggesund Paperboard in Workington – about as far north and west as it’s possible to go in England. Stuart Goodall reports.

T

he Workington site is strategically located to a port and plentiful supplies of fresh water that are a crucial element of the process to produce 200,000 tonnes of paperboard a year under the market leading brand name Incada. The area had been home to iron and steel mills, so investment in a new manufacturing process in the 1960s has helped secure relatively well-paid jobs in a geographically remote location. Originally Thames Board Mills, Workington has been producing high quality folding boxboard since 1967. We were welcomed to the site by Gavin Davidson, who as well as being a Board member of Confor is Forestry General Manager and Fibre Buyer at Iggesund Paperboard, and our entertaining tour guide for the

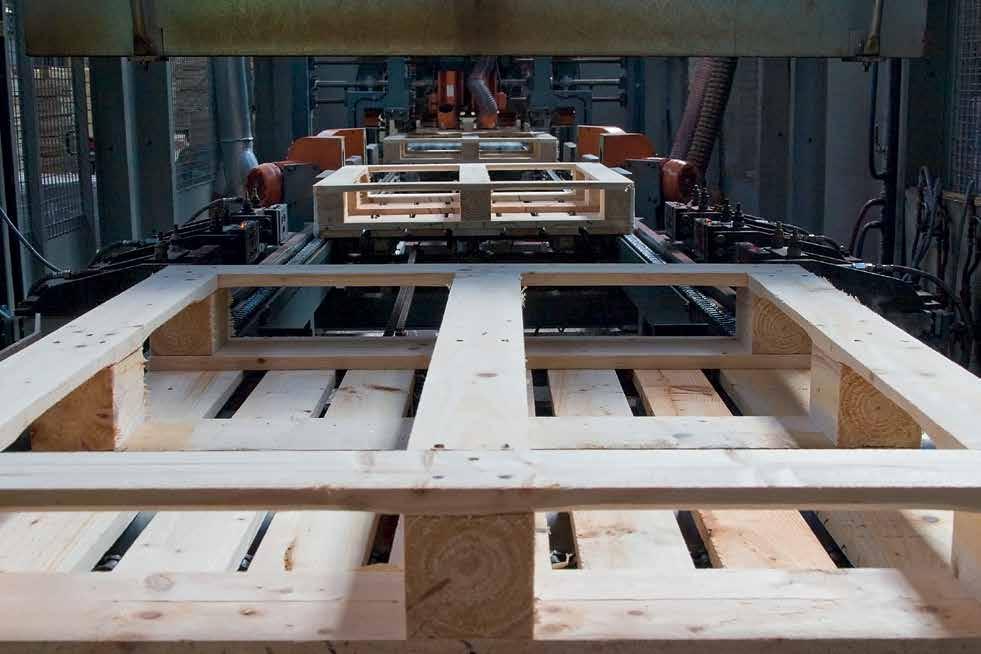

day Phil Baggley, Technical Service Manager. The Workington mill (not to be referred to as a factory!) is an integrated pulp and paperboard mill. Since 2013, it has been powered entirely by bioenergy, producing around 50Mw of electricity and 150Mw of steam. A further 7Mw (approximately) can be exported to the grid to coincide with periods when electricity demand is high and it’s relied upon as base-load energy for times when, for example, it’s frosty and the wind isn’t blowing. The site consumes one million tonnes of virgin fibre a year, with two-thirds of that being utilised in the biomass boiler. The feedstock for the site is diverse, including small roundwood, sawmill co-product and willow coppice. For the latter, Iggesund enter into agreements with lo-

18 FORESTRY & TIMBER NEWS • December 2019

cal farmers to guarantee to buy their crop for the predicted life-span of the biomass boiler. The remaining volume is Spruce fibre in the form of roundwood and sawmill chips that are used in the production of Folding Box Board (FBB). Iggesund Forestry have been pioneers in transporting roundwood by sea dating back to over thirty years. The material is shipped from

CONFOR.ORG.UK