ELBC 2022 Opens with Positive Messages for Lead Battery Future

First Person-to-Person Conference in Four Years Warmly Welcomed

The first European Lead Battery Conference since Vienna’s meeting in 2018 kicked off with a bang yesterday (Wednesday) as Andy Bush, the ILA head, started the ceremonies with a rousing address on the future of the lead battery business.

It was followed by a stunning presentation by Chris Pruitt, CEO of East Penn, that detailed, with a sober analysis, that the lithium pathway to world dominance was not as clear-cut as many suggested. (See story below.)

Further analysis of the future lead market from Avicenne, painted a slightly more sombre picture which was modified by a detailed analysis by Neil Hawkes from CRU as well as a highly informative presentation from the ILZSG on Chinese government policy on the use of lead in batteries in the country.

There were three other standout presentations to the first morning’s meetings.

There was one landmark moment with the announcement of the WGBI — Women in the Global Battery Industry with Mac Engineering’s Julie McClure detailing the creation of the group and relating, for the first time to a European audience, the importance of its function. A reception was held later in the afternoon (see elsewhere in The

Battery Street Journal) giving the group room to socialise and network.

The next landmark moment came when Alistair Davidson, director of the CBI, revealed details of three lead projects it had won and been funded — two in Africa (see full details elsewhere)

Pruitt… Getting Real about Lead

East Penn president and CEO Chris Pruitt gave a stunning, frank and wideranging presentation, looking dispassionately over the role that lead and lithium will play in future energy technologies. His US perspective had a universal quality to it.

He laid bare many of the myths that surround the lead-

lithium debate. Many of these include the (incorrect) line that electricity that charges battery packs is produced using zero carbon sources. Or that the US grid will be capable any time soon to have the transmission network to supply the country’s EV needs. (It won’t — and by a very long mark.)

He said the industry should

be unafraid of challenging the narrative surrounding recycling, noting that while lithium recycling techniques are still in their infancy – and might often appear to be a byword for dismantling — lead has an internationally-established network of battery collection

What’s News

n Andy Bush Launches ELBC 2022 with Positive Message for Battery Futures page 1-3

n East Penn’s Chris Pruitt’s Rallying Cry: ‘Shout Benefits of Lead From Rooftops’. A Dispassionate Look at Lead and Lithium Advantegs and Disadvantages page 1-3

n Back in the Party Mood as Delegates Drink to Return of In-Person Conference page 4-5

n €10m Funding Award Opens New Horizons for Lead in Africa. ArcArctive Promises Open Market Access in Two Years page 8

n WGBI’s Recruitment Drive, Core’s ELBC Debut, Return of the Källström ‘Vikings’ page 10

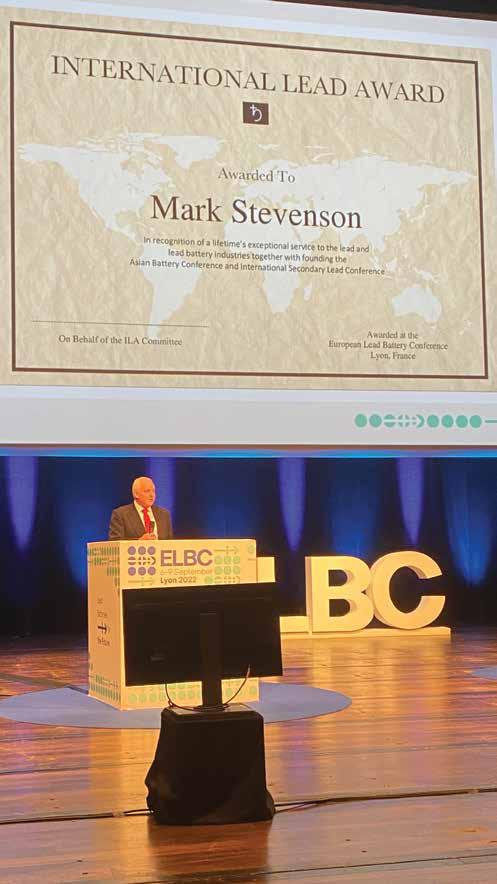

n International Lead Medal Winners Galore as Eckhard Karden and Mark Stevenson are Awarded the Global Prize for International Excellence page 12-15

n It’s Showtime! Meet the Exhibitors. Meet the Great and the Good of the Lead Battery’s Finest page 16-17

n The Last Word: Tales of Dark Deeds and Spurious Conquests at ELBC 2022 page 19

The latest news from ELBC 2022, Lyon, France • September 6-9, 2022 A Batteries International publication Continued on page 3 > Continued on page 3 >

Andy Bush, the ILA head, opened up the

ceremonies

WWW.BATTERIESINTERNATIONAL.COM PAGE 1

Pruitt… Getting Real about Lead ELBC 2022 Opens with Positive Messages for Battery Futures

and a near-100% recycling record.

The jury was still out to see if lithium batteries could be easily recycled.

He urged industry leaders

to focus on the demands of consumers, pointing out that whatever the diktats of governments and regulators to encourage the take-up of lithium batteries, it will be consumers that have the fate of

the technology’s future in their hands.

He said a January 2022 study from Deloitte indicated that 69% of US consumers said their powertrain preference for the next vehicle was an ICE car, compared to a range of HEV, PHEV and BEV alternatives.

There was a similar finding in south-east Asia (66%), while Germany came in at just under 50% in favour of ICE vehicles.

Range anxiety continues to be a concern. US motorists said they still expected a fullycharged battery electric vehicle driving range to be north of 500 miles, while those in China, Japan and India are content with a range of around 250 miles.

“USmotoristssaidtheystillexpectedafullychargedbatteryelectricvehicledrivingrangeto

The lead industry must play a leading role in the mobility and energy evolution and continue to have a strong voice at the table, Chris said.

Lead batteries will be key to creating successful results and are ready to meet the challenges of economics, safety and a circular economy.

Part of the genius of the rotating ELBC and ABC lead market meetings is that they permit a free, unfettered exchange between individuals, companies and organizations so vital to the health of our industry.

and one $3.5 million microgrid with the US military in Missouri.

This has been a clear vindication of the strategic vision Andy Bush had several years ago when he repurposed the existing ALABC offshoot into the Consortium for Battery Innovation, an organization that came into life just four years ago at the Vienna meetings.

“We needed to go beyond running a technical research body into one that could find a commercial expression,” Andy told The Battery Street Journal on the sidelines of the conference.

Certainly for a start-up to have come from nowhere to finding commercial funding and being able to prove its worth in a tangible way is a remarkable achievement. The CBI continues to grow and has some 120 members across the whole battery value chain.

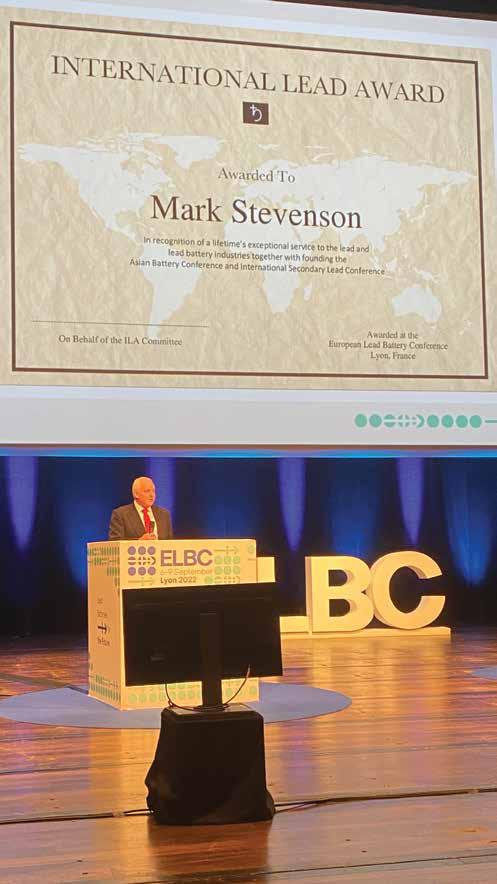

The morning was capped by a favourite moment for the veterans of the industry — the announcement of the International Lead Award. This is given to those who have made a sustained and sizeable contribution to the health of the industry. Over the years this has read like a Who’s Who of the great and the good in the business.

Because the last ELBC was a virtual conference it wasn’t possible to have a proper awards ceremony so this year there were two winners.

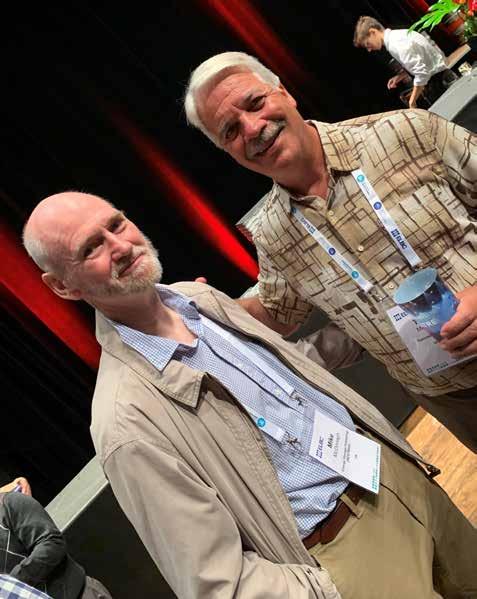

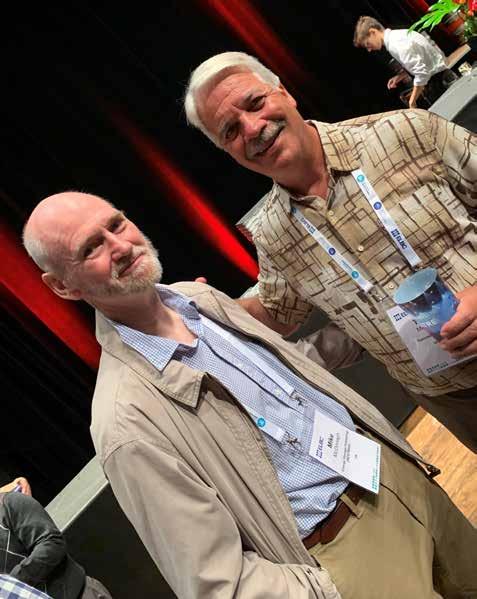

Mark Stevenson, winner of yesterday’s International Lead Medal was also inducted into the prestigious Alpha/Beta society. Here, celebrating with other members of the glitterati of lead.

The much loved Pam O’Brien, BCI vice president of operations, is stepping down at the end of the year.

The two picked by the judging committee were Eckhard Karden and Mark Stevenson, each were popular choices and universally respected. The selection was different from previous years, Eckhard, who is now regarded as a senior statesperson in the industry works for Ford, the automotive giant. Mark is also particularly revered both for his encyclopaedic knowledge of lead in recycling and alloys but also — like Eckhard— for his ready willingness to help explain some of the more complicated issues that face the industry.

WWW.BATTERIESINTERNATIONAL.COM PAGE 3 THE BATTERY STREET JOURNAL • ELBC 2022, LYON FRANCE • SEPTEMBER 6-9, 2022

be north of 500 miles.”

< Continued from page 1 < Continued from page 1

“I’ll miss the BCI staff and members but now it’s time to learn French, play golf and chill out for a while.”

ELBC 2022 Opens with

The champagne corks were popping as several hundred delegates milled round the amphitheatre of the Lyon conference centre at the opening of the conference. The atmosphere was more than just positive — many of us had not seen each other since Vienna four years ago — but there was a warm glow.

It was as if we had returned to the pre-Covid normal and the relief was palpable.

A selection of savoury canapés disguised to look

like sweets prompted anxiety among some of the more easily confused delegates. That said, there was a continuous stream of sparkling wine that kept the conversation light-hearted and the atmosphere gay.

“As ever it’s a good start to ELBC,” one delegate told Battery Street Journal . “But the best thing about this isn’t the food or the drink but rather it’s the chance to meet old friends again (and rivals too). And, of course, make new friends too.”

THE BATTERY STREET JOURNAL • ELBC 2022, LYON FRANCE • SEPTEMBER 6-9, 2022 PAGE 4 WWW.BATTERIESINTERNATIONAL.COM

Chris Pruitt chats to Moura Batteries’ team Tiago Tasso, Gustavo Moura and Spartacus Pedrosa of the Instituo de Technologia Edson Mororo Moura

John Barton, Michael Everitt, Tim Ellis

Pre-drinks Reception

Mike McDonagh, Terry Murphy

Mike McDonagh, Terry Murphy

WWW.BATTERIESINTERNATIONAL.COM PAGE 5 THE BATTERY STREET JOURNAL • ELBC 2022, LYON FRANCE • SEPTEMBER 6-9, 2022

Maryam Mahdipour, William Cross and Simon Moore

Dani Strickland

Farmer Mold’s Desi and Jim and ENTEK’s Carri Moffatt

Doug Bornas, Jade Beevor, Jimmy Stewart, Karen Hampton

Mike Halls, Stuart McKenzie, Shane Christie

The Performance Solution

Gravity GuardTM Delivers Results

Cell phone towers around the world have lead battery back up systems. Here, battery life really matters. Longer battery life is one of the reasons we engineered Gravity Guard.TM Hammond’s patent-pending innovation minimizes acid stratification for advanced battery applications.

HAMMONDGLOBAL.COM

FOR STATIONARY APPLICATIONS

Hammond Just Engineered the Cure for Acid Stratification GRAVITY GUARD

Patent-Pending Innovation Real-World Testing

Proven Results

TM

HAMMOND RESEARCH LEADS THE WAY AGAIN

Gravity GuardTM integrates with the active material, increasing surface area. “Micro-sponges” form, trap acid electrolytes, and slow its release during charging, minimizing the acid density gradient.

ON-SITE PRODUCT & PRODUCTION LINE VERIFICATION

After extensive research, development, and trials in our lab and manufacturing facilities, we implemented production line battery verification with trusted manufacturing partners around the world.

BETTER CYCLE LIFE, CHARGE EFFICIENCY & BATTERY LIFE

The results continue to exceed industry expectations. Full-scale battery testing shows Gravity GuardTM reduces acid stratification, improves electrical performance, and prolongs battery life.

HAMMONDGLOBAL.COM

€10m Funding Award Opens New Horizons for Lead Battery Tech in Africa, Conference Told

Aconsortium of international partners including the Consortium for Battery Innovation have won a €10 million ($9.9 million) call within Horizon Europe, the EU’s flagship research and innovation funding instrument.

Now entering the contractual agreement phase, the project will deploy lead battery technology at the heart of two innovative pilot energy storage systems for African nations.

The funding bid was the first made by the CBI and its partners under the Horizon programme, it will see the ‘LoCEL-H2’ (lowcost, circular, plug and play, off-grid energy for remote locations including hydrogen) projects deployed in off-grid communities in Zambia and Ivory Coast.

At the core of each project will be lead battery electrolyser components — the battolyser — paired with renewables for electricity generation and a hydrogen solution for clean cooking in isolated communities without access to a power grid.

CBI research and innovation manager Carl Telford coordinated the bid alongside academic and industry partners the French atomic energy

agency (CEA), Hoppecke, Hollingsworth & Vose, UNINA, Loughborough University, Sunkofa, University of Gabes, SAS Réseaux Hydrogène Décarboné RHYDE, and LUMS.

CBI director Alistair Davidson told The Battery Street Journal Telford had done “an incredible job” in developing the funding proposal.

“As far as I’m aware, this is the first time lead batteries have been involved in securing funding under Horizon Europe.

“This goes to show what can be achieved by the lead batteries industry and I look forward to potentially seeing more high-quality proposals being made in partnership with the advanced lead batteries sector to secure other such projects worldwide in the future.”

The Horizon funding comes just two weeks after Batteries International revealed that the CBI and Loughborough University had drawn up proposals for two additional, separate projects in the East African nation of Malawi.

For Malawi, the partners have submitted a funding bid to the UK government agency — Innovate UK — for just over £1.3 million

($1.5 million) to develop a novel hydrogenproduction energy storage system that uses a battolyser.

The Modular Energy Storage with Clean Hydrogen (MESCH) project will, if the funding application is successful, develop a first unit to support operations at a hospital in Malawi.

The system will provide essential backup power and also turn excess solar power into hydrogen for cooking.

The second funding bid proposed, for around £300,000-£400,000, is for the ‘AfTrac’ project — that aims to develop ‘micro tractor technology’ powered by lead batteries in support of African agriculture.

This project is being led by Loughborough University, with the CBI and another UK organization as partners.

Both Malawi funding proposals were under consideration by Innovate UK as BESB went to press.

Telford told The Battery Street Journal that CBI member companies would provide the lead battery technology for MESCH and could possibly supply the AfTrac project too — should the bids be successful.

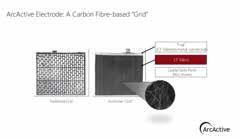

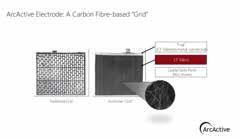

ArcActive Batteries ‘on Market in Two Years’

Batteries produced using pioneering carbon fibre technology from New Zealand-based ArcActive will be on the market in two years, company CEO Stuart McKenzie told The Battery Street Journal during a conference break.

McKenzie acknowledges it’s a bold prediction, but in a world increasingly focused on performance as well as burnishing environment credentials, he believes his electrode architecture will help shape the future of batteries not just for the automotive sector but energy storage systems too.

ArcActive is already working with around half-a-dozen battery makers producing prototypes around the world.

He says it’s a “pretty tight set up” in terms of confidentiality and who is doing what, but East Penn has been made as one of the development partners. All the companies involved receive the electrodes for the batteries from ArcActive’s headquarters in Christchurch, where he formed the company in 2007.

“I knew it would be a tough job and we’ve run into some problems of course, but we now have consistently high data.”

McKenzie revealed that the company has now produced a business case for the US

market — where its current focus lies — which shows cash savings in the realms of $50 per car for those using ArcActive batteries.

“We’re working with an adviser who used to be the CEO of one of the large US/China OEM JVs but we also have an eye on the European and Chinese markets.”

The company has spent the past several years developing its architecture to improve DCA, which McKenzie said had been a challenge without causing issues in other areas, such as water consumption, but those challenges had been overcome.

Instead of manufacturing electrodes with traditional processes, ArcActive has developed its own method.

Rather than use a lead grid with a lead paste, the company has substituted the grid for a carbon fibre fabric, with the lead paste put inside the fabric, which McKenzie says is a “really key element” of the technology.

“I think others have tried to restructure electrodes but you need to also strive for good performance, high speed manufacturing high tolerances, a low cost proposition and a configured supply chain that works. That’s what we’ve done.”

ArcActive has now gone from making cells

in New Zealand to working with partners making batteries on production lines in the US, Europe and China and Japan.

“At conferences such as ELBC, people used to talk about DCA for micro hybrids and the question I’ve been hearing again in the last few days again has been: ‘Is DCA still important?’

“It’s a good question. But in turn, I would ask whether micro hybrids are still relevant when everyone is going for EVs?”

The answer, he says, is that there is plenty of business to go around.

“There are an estimated 100 million cars produced worldwide every year. Even if you accept that about 20-40 million EVs a year will be being made globally in 2040, that still leaves a lot of other vehicles left over.”

THE BATTERY STREET JOURNAL • ELBC 2022, LYON FRANCE • SEPTEMBER 6-9, 2022 PAGE 8 WWW.BATTERIESINTERNATIONAL.COM

Solutions for all your supply chain needs A trusted partner in uncertain times www sorfinyoshimura com New York Tokyo Qingdao Paris São Paulo Bangkok Pune SILVER SPONSOR see us at booth # 36 SORFIN YOSHIMURA ELBC 2022

WGBI Gathers in Lyon for Momentous Meeting

Women in the Global Bat tery Industry kicked off their global recruitment drive at ELBC in what ILA chief Andy Bush welcomed as a momen tous, first European outing for

the group, which is approaching its first full year of programming and activities.

WGBI president Julie McClure, who is also chairman of MAC Engineering, addressed the first

full day of the conference ahead of giving an update on activi ties and plans for the future at the group’s own meeting on the ELBC sidelines.

Batteries International publish

er Karen Hampton was among the speakers at the WGBI meet ing, which was followed by a net working reception sponsored by Hollingsworth & Vose.

Nick Starita, H&V president, energy solutions and new ven tures, said the company was “proud to support the WGBI mission to promote and develop the growth of women profession als in the battery industry, both at events like ELBC and through membership and leadership in the organization”.

H&V quality manager Helen Keeling said: “Being a member of the WGBI is great for network ing with fellow professionals and helps us grow within the indus try. The WGBI is a great support and helps promote women pro fessionals in the battery indus try.”

The Vikings are Back! Källström Comes Home

Long term regulars at ELBC Anders Källström and Bo Johansson from Sweden’s Käll ström have returned to the con ference circuit again but their circumstances have changed.

As of the end of 2021 Källström became part of Beijer Tech, this is a group of companies special izing in value-added sales, manu facturing and automation with a focus on fluid technology and industrial products.

The group does seem a good fit for Källström. “AGM fillers are a big thing for us and our custom ers and we offer filling machines with high precision and tight tol erances of different sizes and ca pacities, with one to 10 stations,” says Anders. “A new and exciting segment is alsos opening up for us as fillers for the new genera tion nickel metal hydride batter ies.

“We’re convinced that we have found the right strategic partner

for Källström’s long-term devel opment, its broad product and service range strengthens our customers’ competitiveness and we are looking forward to devel op our business further together with Beijer Tech.”

ELBC Debut for Core Engineering

A

mong the new faces at ELBC 2022 were the team from UK-based Core Engineering, that were introducing their lead battery industry supply company to delegates face-toface for the first time at the conference.

Despite being formed just two years ago, Core comes with a wealth of experience as the engineering team has more than 30 years’ design and production experience supplying automated machinery to battery makers worldwide.

Founder and MD, William Cross, formerly of TBS Engineering, said the company adds unique value to the current market in

supplying the highest quality of manufactured COS moulds and tooling compatible with global manufacturers’ equipment.

The company offers turnkey solutions in design, manufacturing and delivery.

Co-founder and sales director Simon Moore, currently of Oxford Export Services, brings his industry experience to the team in applying the latest practices in lean manufacturing, driving down lead times and ensuring high quality, competitively-priced products.

All Core orders are designed and manufactured in the UK in line with OEM quality requirements.

THE BATTERY STREET JOURNAL • ELBC 2022, LYON FRANCE • SEPTEMBER 6-9, 2022 PAGE 10 WWW.BATTERIESINTERNATIONAL.COM

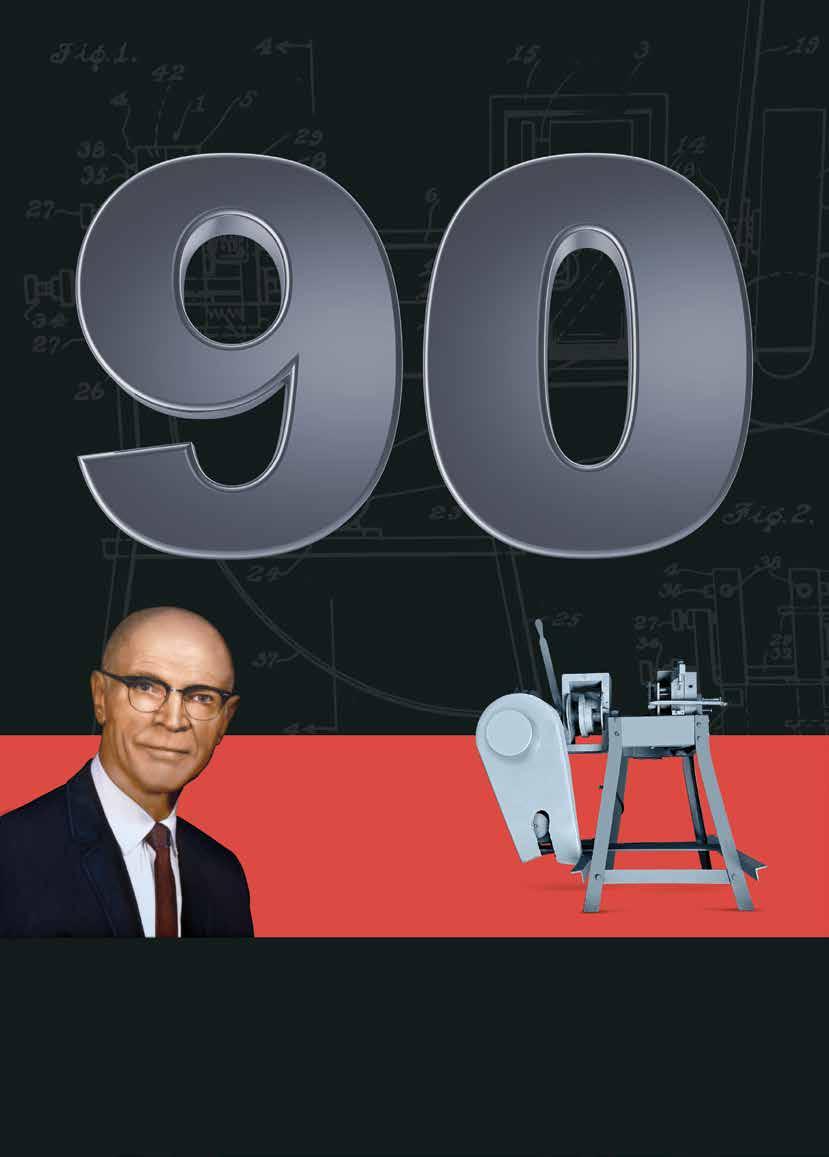

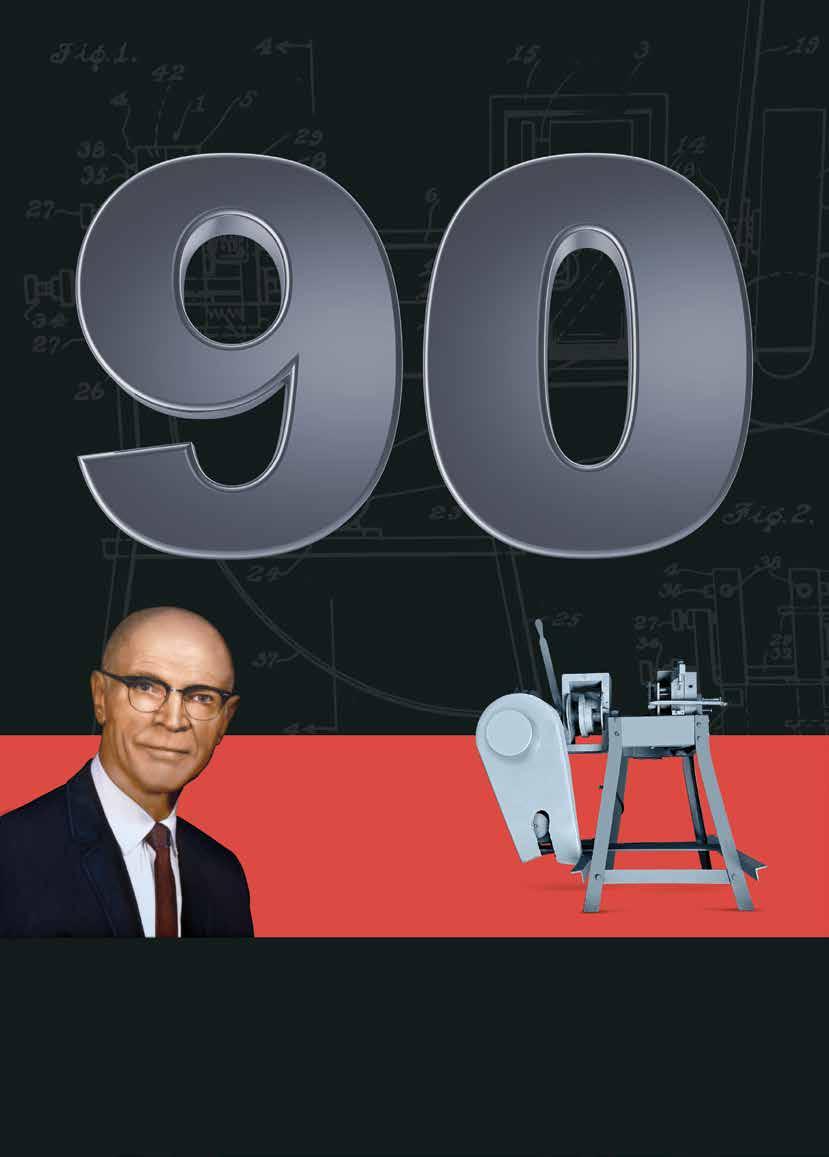

INNOVATIVE | RELIABLE | PERFORMANCE The Wirtz Group of Companies YEARS 1932-2022 AUTOMATIC BATTERY GRID CASTING MACHINE PATENT #2,079,727

INTERNATIONAL LEAD MEDAL

Karden, Stevenson, Win Prestigious Award for

to Lead and Battery Industry

The closing session of yesterday morning has always been one of the most interesting for the backbone of the lead and lead battery industry — it’s the award of the International Lead Medal.

The award, which is given each year, and alternates between ceremonies at the ELBC and the Asian Battery Conference, has honoured the great and the good of the lead business for an entire generation.

Because the 2020 ELBC had to be a virtual conference, no ceremony could be held so the judging committee decided that

this year there would be two medallists.

East Penn’s Norbert Maleschitz introduced the first recipient, Eckhard Karden — who is widely regarded as a genuine statesperson for the industry technical expert with a few words saying: “The award goes to a great scientist and engineer as well as a great presenter. One of the things I admire most about this person is just how well he can explain the most complex topics in a very understandable way.”

Later, Wirtz’s Doug Lambert introduced the next winner, Mark Stevenson long

regarded as a walking encyclopaedia on all things to do with lead metallurgy, smelting and alloys. He said: “I’ve known Mark for many a long year and without being pretentious about the word ‘worthy’ Mark is someone who is outstandingly worthy for this award.

“He seems to know every aspect of his subject and has been an inspiration to many for his willingness to impart his knowledge to the good of this industry. He is a bucket chemist in the very best sense of the word.”

Eckhard Karden — His Career

Eckhard has a very different background and perspective to the lead battery business than almost all of his contemporaries.

Eckhard’s involvement with automotive batteries goes back to his early days at Aachen University in Germany, generally reckoned as one of the best engineering/scientific institutions in Europe. Here he came under the tutelage of Hans-Christoph Skudelny and later Rik W. De Doncker, two powerelectronics professors who entertained the battery research group since the 1970s and had been electric vehicle enthusiasts for most of their lifes.

For his doctorate thesis Eckhard studied modelling of the voltage characteristics of batteries using impedance spectroscopy — a new approach for the battery group though the technique was just starting to be deployed elsewhere. It was during this period that Eckhard met his future wife Nathalie, a GP. More than two decades on, his daughter Fiona is also studying medicine.

One characteristic of the German university

THE BATTERY STREET JOURNAL • ELBC 2022, LYON FRANCE • SEPTEMBER 6-9, 2022 PAGE 12 WWW.BATTERIESINTERNATIONAL.COM

Services

“Theautomotiveapplicationisundergoingfurtherchange,andprobablyatayetfasterpace. Foramatureindustry,itwillremainachallengetoinnovatetheproductintelligently inresponsetonewrequirements.”

system is for research to be conducted in partnership with industry and Eckhard’s Phd involved collaboration with Ford, the automotive giant. With his doctorate completed he joined the company in Aachen as a senior research engineer in July 2002. In 2005 he earned the title of technical expert.

He recalls his early days with affection. “When I joined Ford, I thought my English was fairly good — I could chat in it and read academic papers relatively easily, but I soon realised that that had to reach another level working in such an international company.

“The work then, and now, consists of working very close with product and application engineers and suppliers. It’s never just about the battery but how it interacts with, for example, the power train. Or it could be to do with quality issues when demands on the electrical system changes.”

Eckhard entered the energy storage business at the same time as the huge explosion in lithium battery research started to happen. Although many doctoral students saw the then-relatively uncharted research areas of lithium as attractive, Eckhard saw it differently.

“One of the characteristics of lead battery research and analysis is that it encompasses a wide range of different disciplines — from powertrain controls and electrical system sizing to electrochemical reaction kinetics and ageing mechanisms,” he says.

“It’s a broad approach to the role of the battery. With lithium research it’s very specific it could just be on, say, one new type of anode material and you may never see the broader picture. This broader view is part of the fun of the work — besides helping formulate development processes and operating strategies, you have the chance to stay learning about battery technology itself all the time.”

Eckhard believes that many of the recent advances in lead battery development have been enabled by collaborative development of test methods and standards, he is a member of various European and international standardization working groups.

Eckhard joined Ford at the time when it was clear that the 42V system was not going to be the next automotive standard but has been at the forefront of looking at the development of 12V enhanced flooded batteries (EFB) and the rise of stop-start cars.

“Several battery suppliers suggested that

AGM batteries were the only kind capable of withstanding the stop-start demands being put on them, however we could make significant savings by developing EFB that could be manufactured on standard automotive battery production lines. I was involved from first concept studies and durability tests to field battery analysis after batteries had been several years in service.”

After mainstream stop-start introduction, Eckhard’s work shifted toward improving brake energy recuperation in 12V systems. In the meantime, Ford has introduced EFB with high Dynamic Charge Acceptance (EFB+C) that allow for a further improvement of fuel economy and CO2 emissions both under real-world driving conditions and in the new European homologation regime (WLTP).

Most recently, his work has shifted focus again, addressing auxiliary (AUX) batteries in battery-electric vehicles as well as battery reliability and diagnostics to support safetycritical 12V functions like driver assistance. Again, he sees pre-competitive collaboration in industry expert groups as a key enabler for cost-efficient and reliable commodity solutions — both in standardization committees and in the Consortium for Battery Innovation (CBI), an issue that will occupy automotive OEMs for the next few years. “This will lead to faster charging regimes,” he says.

Eckhard who is keen to share his knowledge and works with the CBI at their battery workshops and their just-started battery academy. He also regularly acts as session chair and co-organizer of industry meetings such as Advanced Automotive Battery Conference Europe. He has 18 patents to his name and has edited and co-authored many books on battery application technology.

So with two decades at the cutting edge of lead battery applications and technology, how does he see the next two?

“Some trends are very positive,” he says. “Over the last 20 years we’ve seen greater and deeper collaboration between different parts of the battery industry and that openness, as we’re seeing in the work that the CBI is doing, is starting to bear fruit.

“That said, the automotive application is undergoing further change, and probably at a yet faster pace. For a mature industry, it will remain a challenge to innovate the product intelligently in response to new requirements.”

Mark Stevenson — His Career

Although Mark is perhaps best known for his work as the organizer of the Asian Battery Conference, he is in fact one of the world’s leading metallurgical experts and has spent a lifetime studying and advising the lead and battery industry.

It has been a long journey for Mark. Born a second-generation coal-miner’s son in Lithgow, a remote township in New South Wales, Australia he remembers to this day his grandfather’s advice. “Whatever you do, promise me you’ll never work in the mines.”

He dates his early interest in metallurgy to his teenage years. “A hobby of mine was to collect scrap metal like used soft drink cans — in those days people used to throw them away by the side of the road — and then melt them up for the aluminium. You needed about 40 cans to be smelted to make a kilo which you could then sell for 60 cents. It was good pocket money and a start of a lifetime’s journey into the world of high-temperature metallurgy.”

He did well at High School but decided not to go immediately into full time study at university but do an extended part-time university course while gaining professional experience at Sims Metal Management through their cadetship program, one of the iconic names then (and now) in scrap metal and recycling expertise.

“I was extremely lucky to come under the direct tutelage and management of John Crabb, one of the greats of the scrap metal industry,” says Mark. “John believed in that we should all start at the very bottom so, though we were being trained for management, my first job was sweeping the factory floor. He insisted that we should not only be able to understand operators’ jobs but also know how to do them.”

“Sims gave me a basic understanding of lead, zinc, copper and aluminium and of course it was a perfect introduction into the world of batteries through its subsidiary Besco.”

As Mark grew in experience and seniority his work within the company changed from technical and analytic work to larger scale projects and advisory roles. In effect he had become, he says, “that rare animal, a metallurgist with hands-on skills.” Even now, Mark prefers to start his problem solving directly from the raw battery feeds into the furnace than in the laboratory.

In the mid-1980s he was transferred across to Pasminco which had been collaborating with Sims Metals for several years.

Some of the problems Mark has tackled over the years have since become standard industry practice. He was, for example, an early exponent and developer of slag-less melting. “All battery feeds have impurities within them but we developed a way of converting them so that they could be on sold,” he says.

THE BATTERY STREET JOURNAL • ELBC 2022, LYON FRANCE • SEPTEMBER 6-9, 2022 PAGE 14 WWW.BATTERIESINTERNATIONAL.COM

“Oneofthecharacteristicsofleadbatteryresearchandanalysis isthatitencompassesawiderangeofdifferentdisciplines —frompowertraincontrolsandelectricalsystemsizingto electrochemicalreactionkineticsandageingmechanisms”

“I’ve watched the way our industry has embraced advances in technology and noticed that each step forward often creates a new set of problems that have to be solved,” he says. “And, oddly enough, I’ve noticed how one generation of this industry solves issues that then become forgotten by the next and the wheel has to be re-invented.”

Mark is concerned that he and his peer group leave a legacy behind him just for this very reason. Part of this explains his enthusiasm and commitment to the Asian Battery Conference which runs every two years at a different location in Asia. While working for Pasminco, which organized the ABC in its early years, he was put in charge of managing the conference as part of his regular duties.

“I worked with John Manders on the ABC [Manders was co-founder of ABC with David Rand and Jerry McAuliffe in 1986 which was later to become the inspiration of its European counterpart] learning a lot about the technical program side and on his retirement, I realized conferences are more than just papers!

Since then the ABC has grown and grown. “My initial understanding of a conference — that it was a place for technical papers to be aired and debated — was completely wrong,” he says.

“I soon learned that it’s got to be that but also so much more. It must be an event that people enjoy, to be held at a destination that people will love going to and with interesting things to do. A place where networking is natural and not forced. Making things a little spectacular adds to the magic.”

A perfect example was the closing gala dinner at the 18ABC in Bali, 2019 was perhaps the most spectacular yet seen with squadrons of VW open-top jeeps — complete with police escort through the early evening rush hour traffic — driving delegates to a huge open-air array of plush tables with three stages displaying live dancing. “I don’t know how they arranged this” one of Batteries International reporters said afterwards,” but the detail of what went on was completely extraordinary.

Mark, like Eckhard, has serious worries about where the next battery leaders will come from. “An entire generation of battery experts is disappearing every year. The Ken Peters, the Mike Meyers and the Manders are no more.

“That said, this industry has come a long way in the past 40 or so years,” says Mark. “When I started we used to boast about how high our blood levels were. In my early days at Sims, you’d be automatically moved to another part of the plant if you hit levels of 70 mg per decilitre of blood and you’d be thought a slacker if you didn’t have levels near to that.

People used to think low blood levels were a sign of not pulling your weight. Now we’ve almost a whole industry comfortably reaching levels of below 15 mg per decilitre.

WWW.BATTERIESINTERNATIONAL.COM PAGE 15 THE BATTERY STREET JOURNAL • ELBC 2022, LYON FRANCE • SEPTEMBER 6-9, 2022

Peopleusedtothinklowbloodlevelswereasignofnotpulling yourweight.Nowwe’vealmostawholeindustrycomfortably reachinglevelsofbelow15mgperdecilitre.

It’s Showtime!

The hall below the conference amphitheatre was transformed virtually overnight on Tuesday into a showcase of exhibitors representing the spectrum of vital suppliers to the global lead battery industry.

There had been an air of hushed calm throughout the hall on Tuesday afternoon as roll-up banners and expo stands were dusted off, having been confined to enforced isolation during the long months of lockdowns and travel bans.

Amid the calm came the occasional moans of despair as someone confessed to forgetting the double-sided

sticky tape, but then realising they had a table or chair extra that could be ‘bartered’ for equipment, materials or tools needed to finish their stand.

There was an added incentive to finishing stands on time — the evening cocktails reception being held in the amphitheatre above, where the toil of the day could be rewarded with a refreshment or two.

As Wednesday dawned the big day had arrived and virtually all was present and ship shape and it was time for lights, cameras and action on the exhibition floor.

THE BATTERY STREET JOURNAL • ELBC 2022, LYON FRANCE • SEPTEMBER 6-9, 2022 PAGE 16 WWW.BATTERIESINTERNATIONAL.COM

Ace Green Recycling: Farid Ahmed, Meredith Matthews

Atomized Products: Lee Puckett, Jen Michoski

CEMT: Nancy Xie

Akümsan: Banu Coskun, Eren Unlu

Sorfin: Scott Fink,David Bortoni, Sadao Takano, Masami Lobo, Pierre Goto,Rahul Khale

TBS: Mark Gardiner, Kevin Selby, Danile Parker Gage, Justin Lewis, Rob Desborough

WWW.BATTERIESINTERNATIONAL.COM PAGE 17 THE BATTERY STREET JOURNAL • ELBC 2022, LYON FRANCE • SEPTEMBER 6-9, 2022

Farmer Mold, Jim Gilmour

MAC Engineering: Doug Bornas, Julie NcClure, Jimmy StewartFrötek: Ingo Koch, Sascha Brothuhn

Water Gremlin: Kurt Gifford

Wirtz: John Wirtz, Mike Romeo, Dave Wirtz, David Scott

Glatfelter: Lutz Goeppentin

Frimax: Diego Almendros, Ińigo Irastorza, Asier Zabala

Hammond: Brad Bisaillon, Steve Barnes

OMI: Melissa Maggioni

Kallstrom: Bo Johansson

Penox: Hamid Ramianpour, Ian Klein, Delphine Baumann, Denis Doiseau, Micha Kirchgessner

Core Engineering: Simon Moore, William Cross

CMWTEC: Martin Grosskreutz, Michael Wipperfürth,Mohammed Al-Ogaili

Eagle Oxide: Joe McKinley

The last word

New on board

The latest member of the lead battery community is Lewis McKinnon, trainee for business development at CTT Technical. Aged, just 16, Lewis is already hard at work educating his boss Mike Dunn on social media. It’s a bit difficult when Mike says to me every other week: “I’m on linked-in how the heck does it work?”

Fine dining or just better bladder control?

What goes in must come out? That was the difficulty for one select battery group — known to the cognoscenti only as the BBC — when half its men were pinned against a wall on a far too long bench for a prolonged multi-course wining and dining experience. “We were relieved to be relieved later,” said one diner mysteriously.

Practice, practice, practice

“Practice, practice, practice, it makes you better at everything,” says OMI’s Melissa Maggioni who has been treading the conference circuits for years. “And of course ELBC, ABC, LABAT and the rest have all come in handy when pressing the grapes for our family winery and some of our delicious wines…”

PAGE 18 WWW.BATTERIESINTERNATIONAL.COM

Getting

the low down on conference work is no tall order

From

the sublime to the ridiculous

THE BATTERY STREET JOURNAL • ELBC 2022, LYON FRANCE • SEPTEMBER 6-9, 2022

INNOVATIVE | RELIABLE | PERFORMANCE The Wirtz Group of Companies CUSTOM AND CONVENTIONAL AUTOMATED SOLUTIONS FOR: AUTOMATED ADDITIVES, FIBER EXPANDERS PASTE MIXING RFID, SERVOS, EQUIPMENT SETTINGS MONITORING LOADING, INGOT CASTING LEAD HANDLING VISION RECOGNITION SCANNING, HIGH-SPEED SPIDER ROBOTS SORTING - STACKING PALLETIZING ROBOTS, CUSTOM GANTRY SYSTEMS OFF LOADING - PALLETIZING Discover the benefits of robotic and automated solutions for increased production and productivity by calling +1.810.987.7600 or emailing sales@wirtzusa.com. www.wirtzusa.com AUTOMATION your solution for increased production

For over 55 years, MAC Engineering & Equipment Company, Inc. has sold more than 4500 machines, to over 300 customers, in 81 different countries, bringing the MAC Advantage worldwide. MAC ENGINEERING & EQUIPMENT COMPANY, INC. Visit www.mac-eng.com to see how we can bring the MAC Advantage to you!

Mike McDonagh, Terry Murphy

Mike McDonagh, Terry Murphy