17 minute read

AFTER THE PRINT

Post-Processing Considerations for AM

by Industrial Print Staff

Often a three-dimensional (3D) printed piece isn’t completely finished right off the printer. Various technologies are employed to create a final product that is acceptable to the end user. Post processing of a 3D printed piece means many things from removing the support structure to achieving the desired look and feel of the finished surface through technologies like sanding, polishing, or de-powdering.

“Post processing is a crucial step in the additive manufacturing (AM) workflow, where 3D printed parts undergo various finishing processes to achieve customer-ready quality,” states Marc Farfaglia, head of technical services and application development, PostProcess Technologies.

Determining if Necessary

Many factors help determine whether and which post-processing technique is necessary. This includes the type of material and end use of the part, as well as the 3D print method employed.

According to Farfaglia, the intended purpose or end use of 3D printed parts influences the need for post processing. “If the parts require additional steps such as painting or plating, postprocessing becomes crucial to prepare the surface for subsequent treatments.” One example is before painting, a part might require surface finishing to achieve a smooth, uniform texture. This ensures better paint adhesion and a visually appealing final result.

The part itself, and how complex it may

Post-processing is a crucial step in the AM workflow...

be, is another reason to consider post processing like sanding or polishing. “Intricate geometries, fine details, or delicate features may require additional post-processing steps to refine the part’s appearance and functionality,” explains Farfaglia.

Achieving highquality surface finishes is possible with the

— Marc Farfaglia, head of technical services and application development, PostProcess Technologies

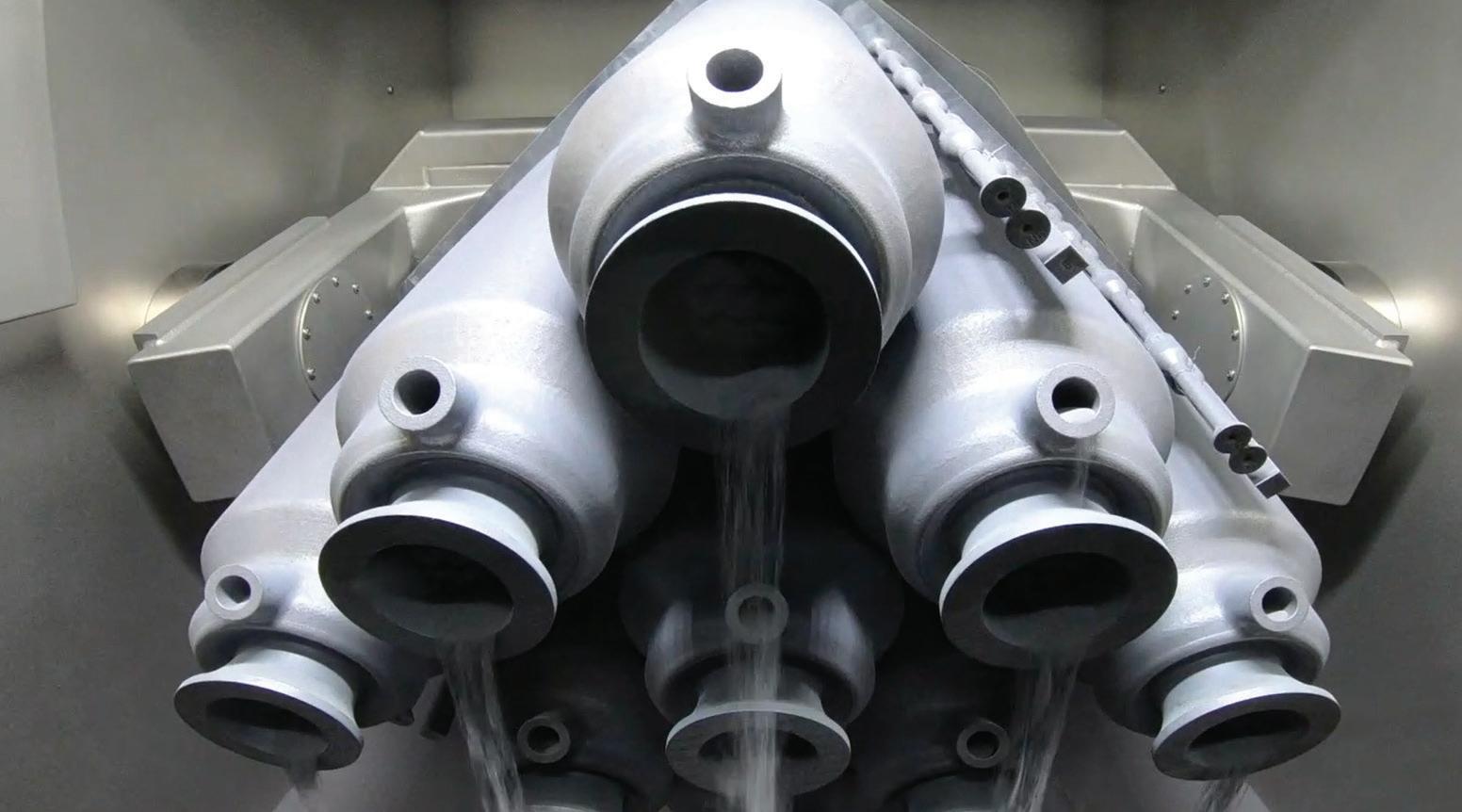

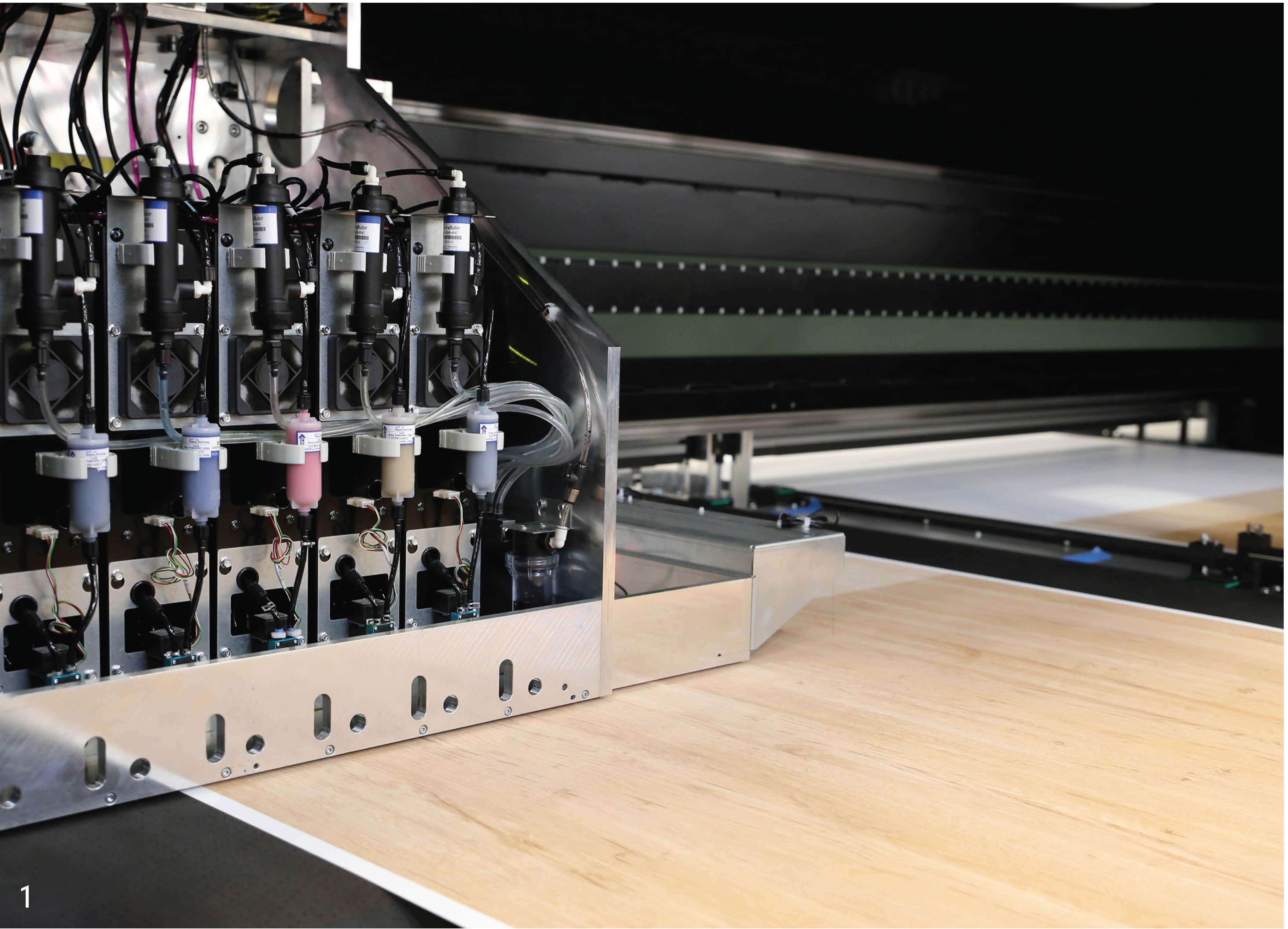

1. Since 2015, Solukon has established automated systems for powder removal.

PostProcess Technologies RADOR solution. This advanced system employs software-driven algorithms to achieve the desired roughness average on a 3D printed part. The RADOR solution reduces manual finishing and delivers consistent results.

More often than not, post processing is necessary. “While each technology requires different post processing, almost all will require at least one, if not more, postprocessing steps to make their 3D printed part customer ready,” shares Farfaglia.

Andreas Hartmann, CEO/CTO, Solukon, states that for the industrial use of 3D printed parts via laser powder bed fusion (PBF) technology adequate post processing “is always required to ensure smooth performance of the part and to meet safety and occupational health requirements.”

Post-processing parts manufactured from PBF involves de-powdering or removing powder from complex parts. Solukon offers automatic de-powdering solutions that utilize programmable (two-axis) rotation and targeted vibration, which allows the cleaning units to remove excess powder even from the finest internal channels of the component. All Solukon de-powdering systems are based on Solukon Smart Powder Recuperation technology (SPR).

Fused deposition modeling (FDM) is an AM method that requires post processing to remove support structures. While the support structures are essential during the build process, once printing is complete they must be discarded.

“Post-processing steps, such as support structure removal, are typically required to achieve the desired part geometry and surface finish for FDM printed components,” states Farfaglia.

For efficient support structure removal in FDM parts, PostProcess Technologies offers two solutions—the BASE and the VORSA 500. These intelligent spray systems leverage cutting-edge software algorithms to automate the support removal process, eliminating the need for time-consuming manual labor.

Stereolithography (SLA) also benefits from post processing, especially with resin printed parts. After printing, residual resin may remain on the parts and “postprocessing techniques are employed to remove and clean the excess resin, ensuring the final parts meet the desired specifications,” explains Farfaglia.

PostProcess Technologies' DEMI family of solutions is designed to address the post-processing needs of both resin-based and PolyJet materials. With proprietary chemistry and software intelligence, the DEMI series ensures efficient and effective removal of residual resin and support materials, resulting in clean and customerready parts.

When to Invest

When a 3D printer is purchased, it might be advantageous to purchase post-processing equipment at the same timehowever there could be cost restraints or even a lack of staff to help facilitate the process successfully.

Hartmann believes it is better to consider post processing when buying a 3D printer for two reasons, higher cost transparency, as you will know exactly what the AM line will cost in total; and better connection of the individual process steps. "Digital networking of prints and post-processing equipment in particular can be considered right at the start if everything is acquired at the same time."

Solukon considers the digital integration of the equip-

4 ment in its solutions. Its de-powdering software, the SPR-Pathfinder, uses the build job's CAD file to automatically calculate the motion sequence for the Solukon system to remove excess powder. The Digital Factory Tool-a sensor and interface kit-enables process tracking, quality assurance, and automation integration.

"It is crucial to establish a well-coordinated process workflow from the outset, ensuring seamless integration betweentheprinterandthepost-processing equipment. InAM, printers and postprocessing solutionsplayinterconnected roles in achieving the desired end result for3D printedparts," agrees Farfaglia.

It is important to approach the printer and post-printing solutions as connectedelementsthat work together, continues Farfaglia. The best results equal a seamless integration. "This integrationenables data transfer, process automation, and real-time monitor- maximizes efficiency and productivity. This proactive approach saves time, resources, and reduces the likelihood of costlyrework,"addsFarfaglia.

Thoughts to Note

In PostProcess Technologies' 4th Annual Post-Process Survey, the company found thatamajorityofusersare investing in material extrusion, VAT photopolymerization, and PBF technologies. While these methods offer versatility, application range, and reliability advantages, they do present unique post-processing requirements.

"One of the key findings of the survey is that respondents frequently face challenges related to the time required ing, ensuring a smooth transition from to finish parts during post processing. printing to post processing."

This is achieved by PostProcess Technologies' CONNECT3D software platform, enabling streamlined and completely connected workflows that helpmaximize thepotentialofAM.

"By considering the entire process upfront, manufacturers identify potential bottlenecks, anticipate challenges, and design an optimized workflow that

This struggle is prevalent in material extrusionprocesses, whichofteninvolve manual support removal. The manual nature of this step can create bottlenecks in the additive workflow, resulting in slower overall production rates for manufacturers. Recognizing this issue, manufacturers seeksolutionsto streamlineandacceleratetheir post-processing operations," states Farfaglia.

Copper-based 3D printed parts are also challenging to post process, according to Hartmann, and increasing in usage as the material of choice for aerospace companies and rocket manufacturers. "Copper is an exceptional de-powdering challenge because powder residues on the inside of the part's channels show sticky behavior and powder tends to clog in cavities," he states. To loosen these powder bulks Solukon offers an additional knocking system for its de-powdering solutions.

Another issue to keep aware of as technology advances-larger manufactured parts. "This means outstanding challenges for post processing and automatedpowderremoval,"addsHartmann.

Finishing Up

A pivotal piece of the AM workflow, post-processing technologies range from removing support structures to de-powdering depending on the 3D print process used. As more materials become applicable for use in 3D printing, the post processing of the same materials will be an interesting area to watch. /PM inspection," says Ed Tlegenov, senior manager, researchscience,AutodeskInc.

Use It

AIisusedinAMfrom designiterationsto final results.

"Manufacturers are beginning to integrate various AI and machine learning (ML)-based algorithms into their 3D printing process in order to exploit the full potential of the technology. Applications ofAI and ML can be found in prefabrication design, quality assurance and defect detection, material usage control, and predictive maintenance," says Marcellus Buchheit, president/ CEO, Wibu-Systems USA.

ML is a subset of AL As Tlegenov explains it, "ML is where algorithms are designed to automatically learn and improve from experience without being explicitly programmed."

If we look at how a part is manufactured via 3D printing, AI as well as ML is being used from end to end.

In the design phase, stable diffusiontype AI is leveraged for generating conceptual shapes and aiding in ideation, according Tlegenov. "This technology enables engineers to explore ideas before modeling, facilitating conceptual shape generation, and optimization specifically tailored for AM. Designers can explore a wider range of ideas with higher efficiency, making what was once impossible now within reach."

''AI is used in optimization efforts relatedtocomponentdesignandimproved component performance. It is also used in the development of surrogate models to accurately predict complex AM build outcomes in near real time," adds Dr. Rashid Miraj, director of technical operations, AlphaSTAR Technology Solutions, LLC.

Additionally, AI is leveraged in the simulation of AM parts. "Deep learning algorithms are deployed to enhance the simulation of AM parts. The application of neural networks to these graphicsheavy computations accelerates the process and significantly improves accuracy. It's not just about quicker simulations; it's about making them more reflective ofreal-world conditions," explains Tlegenov.

During the actual printing process, AI is utilized. "From image recognition to real-time analysis ofsensor data such as vibration, temperature, and acoustic emission, AI systems are actively engaged. They make on-the-fly adjustments, reduce errors, and enhance the quality of the build. It's a dynamic system that adapts and corrects as it creates," comments Tlegenov.

During the final stages of AM, specifically scanning of the parts, Tlegenov also saysAI is used. "When 3D scanning of AM parts hits hardware limitations, AI algorithms fill the gaps, enhancing resolution. The application of AI in this area ensures that even the minutest details are captured and analyzed."

1. Design and engineering consultancy Dar created a five-meter smart bridge using 3D printing, robots, generative design, and Al with the help of Autodesk. 2. Authentise experimented with Al by providing free-to-use additive centric data on top of ChatGPT 3. Located at One Market in San Francisco, CA, the Autodesk Gallery showcases technology driven design and engineering innovations via interactive exhibits and events. Lightning Motorcycles manufactures some of the highest performingandmostadvanced electricmotorcyclesin the world. The Lightning Motorcycles team optimized its motorcycles swingarm using Autodesk generative design technology and AM.

“The most obvious application in AM is process parameter optimization and anomaly detection. Here, AI and ML can supplement data analysis and, more significantly, data mining,” shares Miraj.

Concerning Things

While AI and its involvement in AM presents advantages, there are also challenges.

Similar to other verticals, AI brings up concerns, although Andre Wegner, CEO, Authentise, believes that “since the AM industry is a laggard in adopting the technology, these issues will be solved by more advanced industries before we’ve even managed to establish our use cases.”

For Miraj, the old refrain “garbage in, garbage out” still holds. “Good analysis and decision making is based on reliable data and accurate descriptions of experience to augment learning.”

“While AI’s integration with AM offers vast potential, current closed and rigid data formats pose challenges in terms of collaboration, efficiency, transparency, and accuracy. The adoption of open data formats and cloud solutions

Protecting Ip In Am

Additive manufacturing (AM) and its relationship with artificial intelligence (AI) and subsequently machine learning (ML) is in transition. Much has already occurred in terms of the design process, printing of a part, and even final inspection. As such, security is something to think about, more importantly intellectual property (IP).

Marcellus Buchheit, president/CEO, Wibu-Systems USA, explains that the trained printing model that is generated from the ML process becomes the IP of the manufacturer. As such, it must be protected from inadvertent modifications or even intentional attacks. Counterfeiters could attempt to build similar systems by illegally copying the property of the original maker or others may plot to manipulate the entire system and its purpose.

“The IP comes in multiple forms. It is the data collected and used originally to train the model, the training setup itself, and the eventual trained model. At each step in this process, the IP needs to be protected against theft and piracy, but still be available for legitimate stakeholders to use, process, and reprocess,” explains Buchheit.

To protect the IP throughout the entire process, manufacturers consider security technologies like Wibu-Systems’ CodeMeter. The solution encrypts and signs the data to protect the IP from unauthorized access, copying, or espionage. CodeMeter is also used to authentic users and their assigned roles when using a model generated from the ML process.

can play a pivotal role in addressing these issues,” admits Tlegenov.

According to Tlegenov, “open data formats encourage interoperability, allowing different systems to work together seamlessly, while cloud solutions offer scalability, real-time collaboration, and centralized control. Together, they present a pathway to a more cohesive, transparent, and efficient use of AI in AM, empowering industries to fully leverage the transformative potential of these technologies.”

AI and AM in the Future

We are at the beginning of how AI and AM work together. The future is bright.

“The level of sophistication depends on the application. Automation, interactive user interfaces, design optimization, and defect detection are just starting points. At some point, AI will address the entire process including justification for production and finished part material handling,” foresees Miraj.

Tlegenov details how AI will impact AM throughout the various stages of the process. For example, in design, intelligent design systems, material optimization, and generative design are all possible with AI.

“AI will likely develop systems that collaborate with human designers more intuitively; understanding the designer’s intent, requirements, and goals; then suggesting optimized designs based on real-world constraints,” comments Tlegenov.

Wegner agrees that the future includes more true AI approaches to design. “The fastest development in AI currently is around large language models, which are especially powerful in processing text prompts. Therefore, we’re going to see more true AI approaches to design, especially around the nexus of communicating intent into designs using natural language.”

See page 16 for more information.

During the 3D print process, AI will be used in smart factories, quality control automation, and sustainability. “AI could enable fully automated smart factories where entire AM processes are monitored, controlled, and optimized by intelligent systems. Advanced image recognition and real-time adjustment algorithms may completely automate quality control, ensuring higher consistency. AI may drive improvements in energy efficiency and recycling within the AM process, contributing to more sustainable manufacturing practices,” suggests Tlegenov.

“From design to production to inspection, AI technologies will likely drive significant advancements in efficiency, quality, complexity, and sustainability. The convergence of these technologies points to a future where the boundaries of what can be designed and manufactured continue to expand, fueling innovation across industries,” explains Tlegenov.

Paradigm Shift

As AM continues its infiltration of manufacturing, AI isn’t far behind. Both technologies are a powerhouse combination.

“The convergence of AI and AM is not just an advancement; it’s a paradigm shift. From design conceptualization to the final product inspection, AI is proving to be an invaluable asset, enriching every facet of the process. The alliance of these two technologies illustrates the future of manufacturing a future characterized by efficiency, precision, adaptability, and endless potential,” states Tlegenov.

At industrialprintmagazine.com learn more about AI and AM by viewing an archived webinar. IPM

Additive Manufacturing with 3D Printers

3D Printing in premium quality: highlyproductive and compact

PrintS harp150

PrintGree n150

PrintGe nius l50

PrintS ha rp300

PrintGenius 300

With the next generationof theTruPrint 1000 wearecontinuingour success story. This metal 3D printerfitsperfectly on any shopfloor, and optimizes your part creation processwithcost savingfeatures.

More informationatwww/trumpf.com/s/truprint-1000 prints to manufacturers that have not yet invested in digital. So there is a big overlap in favor for digital."

Stephen Sanker, manager, digital printing products, Koenig & Bauer US, also sees growth in digital adoption for decorapplicationson anindustriallevel. In Europe, he says decor printing is very robust and other markets are becoming more aware of the advantages digital technology brings to this segment.

IncreaseAwareness,HeightenGrowth

As awareness for industrial printing capabilities grows, so does its projected use in decor, and as an extension-flooring.

Horsten predicts a growth of 12 to 15 percent in the next five years per annum. "This seems big but it's only a fraction of the decor market," he offers.

"Direct-to-product printing is increasing; so I would expect the same adoption in the flooring industry as well. There are many advantages to printing directly to a product, including versatility, cost, and consistency," shares Wilson Lee, director of business development, and Tom Gilbertson, VP of application engineering, Enercon Industries Corp.

Dr. Anke Pankake, head of marketing/PR, Hymmen GmbH, admits that while it took the market time to adopt to the technology, once one big player of the regional industry decided to invest into that new, innovative way of producing flooring, other market players followed very quickly. "This was the case in Europe, and it will be similar in the U.S. where the flooring industry around Atlanta/Dalton, GA is highly into digital printing by now. In the last 18 months alone, we have sold seven new flooring lines with our Digital Lacquer Embossing technology by Hymmen."

Sanker says growth in North American depend on substrates and digital capabilities to adapt to synthetic materials.

''As with most markets, in flooring digital printing will see widespread adoption only when the economics work," offersJohn Corrall, chairman, Industrial Inkjet Ltd. He says there are always niches within markets where print runs are short and a lot of variation is required-usually at the top ofthe quality scale. ''Any segment ofthe decor market will have 'designer' product that is sold in small volume at high prices, and this is where digital print first becomes profitable. However the real interest for manufacturers is the mass production volume product.”

The drivers for digital print are zero setup time, no tooling, and vastly reduced waste. “The break on adoption is always running cost, which is mainly ink or toner cost—or click charge. There is always a Catch 22 here, if the production volumes can be higher, the ink manufacturing cost will fall. But no ink manufacturer is going to sell at a loss for years in the hope of future sales. The result is usually a gradually increasing production volume and a gradually decreasing cost per print. The slow trend continues until someone realizes that the economics have bettered conventional or analog print processes. At which point the digital process suddenly becomes compulsory for everyone,” shares Corrall.

Materials

A variety of surfaces and materials are printed on for digitally printed flooring.

Lee and Gilbertson point to PVC, vinyl, foam, and laminated structures of various composition as popular material. “We work mostly with plastics and other man-made materials. We also work with a variety of metals, but not for this application,” they comment.

Horsten says most of the prints are on paper with special inks for décor. “Think high-pressure laminate (HPL) and continuous pressed laminates. There is little luxury vinyl tile (LVT) at the moment but this will grow slower than HPL. Not because of technology but because of the post-treatment equipment they already have.”

“Most often the board materials are stone polymer composite, or LVT, as well as wood-based panels such as high density fiberboard,” shares Pankoke. “As for décors, wood and wood interpretations are the most common in the digital printing of flooring. But we also often see different variances of stone and concrete décors in the décor design departments of our customers.”

Surface Considerations

Certain surfaces require pretreatment. “Pretreatment is necessitated by image and print quality in combination with the type of substrate,” says Sanker. “Some of these substrates are very specific and have exceptionally consistent surfaces. In most cases the nature of the quality and color requirements for décor will require pretreatment to ensure color accuracy and color consistency. Brand managers and specifiers will not compromise in these areas,” he offers.

Horsten says papers often need to be a primed to accept the inks. “As the melamine penetrates the paper the inks need to be binder free. This way the melamine can fill the paper and make it ready to be used in the normal industrial way.”

Lee and Gilbertson point out that most of the flooring materials that you would print on are low surface energy products. “This means that in order for the print to stick to the surface, you need a pretreatment of some kind. Plasma allows you to treat inline, generally right before the print step. This allows for the best adhesion of the print on the surface and increases the durability of the print long term.”

The need and type of pretreatment is determined by the absorbency or surface energy. If the surface is absorbent—e.g. some natural woods—then to get a high color density means a lot of pigment and therefore a lot of expensive ink. “It can make excellent economic sense to first print a primer that acts as a sealer and simply stops the ink penetrating too far. The cost of the primer is likely to be a small fraction of the cost of the ink saved,” notes Corrall.

When printing to non-absorbent surfaces, like plastics, Corrall stresses that the media surface energy is critical. “If the plastic has a low surface energy— for example, polypropylene or polyethylene—then typical UV inks will simply ‘reticulate’ or ‘bead-up’ on the surface. Getting a smooth, consistent ink layer that the ink needs to ‘wet’ to the surface requires a higher surface energy. Various techniques are used such as corona, plasma, or flame treatment. If none of these work, a primer might be the only solution,” explains Corrall.

Application Considerations

Depending on the specifics of a job as well as the materials and equipment used to produce it, primers/pretreatments are applied in many ways.

3 certainly-the more machines you include in your line the more expensive the technology," says Pankake.

The primer might be sprayed, applied by flexography, or even inkjet printed. “Note that inkjet is more demanding on material surface energy than conventional contact printing methods. A dyne level of say 36 might be fine for flexographic print, but 44 or 48 might be needed for inkjet inks,” says Corrall.

She adds that in her experience, post treatment is always applied inline because it is the only way to control the production process.

Lee and Gilbertson say application really depends on the exact details of the product being made. "Speaking generally, inline treatment is the best as it reduces additional steps in the manufacturing process," they comment.

"Today we see that post coat is often might cause a color shift or more usually applies the primer to the paper, which is applied as a separate process, probably a change in the gloss level. Customers later printed." because the coating equipment already don't like that so you want to restrict the primer so that it is only underneath the color print," he recommends.

Lee and Gilbertson note that priming is often performed inline right before printing.

With the Hymmen digital printing technology, Pankake confirms the pretreatments are applied inline.

Koenig & Bauer and the RotaJET also integrate priming inline. "Our customers are looking for industrial output-24/5 or 24/7-in most cases, which means in this case the nature of inline configurations are the most desirable and the most successful.This is what we are seeing in terms of adoption for decor applications overall," shares Sanker.

Post-Treatment Options

Post treatment is also a consideration when it comes to digitally printed flooring. Often post-treatment options come from the print specifier, says Sanker.

"The post treatment is usually a varnish. Typically it is applied by flexography, spray, or digital print. It may be UV cured or water based," offers Corrall.

With Hymmen, Pankake says operators can put on one or more layers of top lacquer on the digitally printed surface, or go in with digital structuring that needs several pretreatment layers again, then digital structure printing,and in the end the final finishing process steps.

existed.Pallets offloorboardsare moved from the inkjet station to a separate coating station. Longer term we would expect new flooring lines to install the post-coat inline with the digital print. This becomes more necessary if the post-coat is also used as a texture-Le. the top coat is applied with varying thickness to highlight the grain of the wooden image, which can look very realistic. It's much easier to match varnish print to color print if they are both in the same line," explains Corrall.

On theotherhand,Horsten sees many

She points out that the more process steps you take, the thinner each primersappliedoffline withagravure sys- layer can be and the higher the flex- tern that has a blanket as a cylinder. "It ibility and, in the end, also the quality

Sanker feels the advantages of post treatmentfordigitally printedflooring are clear in that they compress the production workflow for printing and eliminate steps in the process. "Other than cost, they have few drawbacks;' he admits.

Expanded Opportunity

of the outcome e.g., in terms of gloss Digital print technologies continue to 4. The Agfa lnterioJet 3300 is used forflooring. grades and depth of structure. "But- penetrate more industrial markets as they advance. Flooring is one area expected to see increased adoption of digital technologies. Depending on the material used and the specifics of the job, pre- and post-treatment options may be necessary.

For more on the discussion, check out our complementary web series online atindustrialprintmagazine.com. 1PM