poultrydigest August/September 2017

www.primarymedia.com.au

Volume 33, Number 1

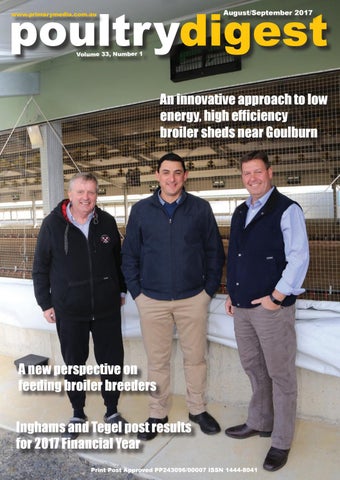

An innovative approach to low energy, high efficiency broiler sheds near Goulburn

A new perspective on feeding broiler breeders Inghams and Tegel post results for 2017 Financial Year Print Post Approved PP243096/00007 ISSN 1444-8041

Va x s

M P e af

in The new vacc

ef

w l Cho o F or

lera

VaxsafeÂŽ PM is a new product funded by the Australian Poultry CRC for the Australian poultry farmer to help control Fowl Cholera. This live vaccine offers significant improvements in control of Pasteurella multocida (PM) over previous vaccines. Its broad protection means it is the first stop for PM control irrespective of what PM you have.

Phone (03) 9876 0567 Fax (03) 9876 0556 bioproperties.com.au Brought to you by Bioproperties to help prevent blood from staining the wattle* *Apologies to Henry Lawson

poultrydigest

www.primarymedia.com.au

Volume 33, Number 1

August/September 2017

EDITORIAL & DESIGN EDITOR: JOURNALIST/PHOTOGRAPHER PRODUCTION EDITOR

Peter Bedwell Alex Bedwell Rosemary Embery

ADVERTISING Peter Bedwell Mob: 0419 235 288 Email: primarymedia@bigpond.com David Horsfall, Polytex, Edddie Wehbe and Rod Martin, Polytex.

Features Page 8: An innovative approach to low energy, high efficiency broiler sheds near Goulburn by Peter Bedwell

Page 18: A new perspective on feeding broiler breeders by Alex Chang

Page 38: Understanding the basics of Methionine sources comparison by Pradeep Krishnan and Girish Channarayapatna

News Page 4: Ingham’s first year operating as a public company meets and exceeds expectations Page 6: Queensland chicken farmers lose $150 million from Baiada closure Page 26: Is there a possible role for drones in poultry industry management? Page 32: Tegel posts results for 2017 Financial Year Page 34: Egg industry supporting the next generation Product News Page 40: Beating Salmonella with Aviator

SUBSCRIPTIONS AUSTRALIA One Year - $55.00* NEW ZEALAND One Year - NZ$80 OTHER COUNTRIES One Year: Airmail - $A90 Please send payment in Australian dollars. Send payment and full details to: 250 Hawthorne Parade, Haberfield NSW, 2045 *Australian subscription rate includes GST

ENQUIRIES OFFICE ADDRESS: 250 Hawthorne Pde, Haberfield NSW, 2045 Ph: (02) 9797 2406 Mob: 0419 235 288 Production: 0409 944 472 Email: primarymedia@bigpond.com Website: www.primarymedia.com.au Poultry Digest consists of a bi-monthly management magazine and an annual industry review, Poultry Industry Yearbook Published by CD Supplies Pty Ltd trading as Primary Media (ACN 091 560 557). All material copyright (editorial and advertisements) and may not be reproduced without the written consent of the publishers. Whilst every care is taken to ensure the accuracy of the contents of POULTRY DIGEST, the publishers do not accept any responsibility or liability for the material herein.

3

NEWS

Ingham’s first year operating as a public company meets and exceeds expectations Mick McMahon, CEO of TPG Inghams, had a good story to tell when his company’s first year results were released on August 22, 2017. Almost all of the targets outlined in the prospectus issued before the IPO were met with the exception of some operating costs associated with a truly dramatic increase in the volume of sales in the later half of the year, hardly a situation to worry about too much! Outlining performance highlights Mr McMahon mentioned, “very strong volume growth in Australia driven primarily through major retailer and quick service restaurant (QSR) channels and the fact that chicken remains the most competitive protein source, supporting the drive by our customers to deliver value,” he said. “There was significant improvement in the performance of our New Zealand operation in the second half of the financial year and volume growth translated to profit despite the supply chain challenges of rapid growth (including prioritising customer requirements and increased overtime costs). “Our strong cash flow generation helped to reduce net debt,” he said. “Our major strategic goals such as Project Accelerate (core intention to reduce costs from between $160$200 million in five years with three years to go) initiatives are delivering as expected. “The first phase automation benefits are now flowing through in primary processing plants associated with good progress on labour efficiency, procurement and other initiatives,” Mr McMahon stated. “We are making continued progress in extending key customer contractual coverage and made further investment in capacity with some new key appointments, improved IT capacity and capital assets. “Capital investment in capacity and efficiency are on track. We recently commissioned new South Australian hatchery and breeder expansions and have started construction of a new feed mill in SA and secured investor funding. There will be a new Queensland distribution centre anticipated to be in operation in the second half of FY 2018. The strategy first used by TPG

4

Above: Mick McMahon, CEO of TPG Inghams. Below: The new Inghams breeder farm at Monato in South Australia. in 2014 after acquiring Inghams of selling infrastructure then leasing it back is being continued with the sale and lease back of recently completed infrastructure projects, thus freeing up capital for faster upgrading of operations and debt reduction. The raw statistics best tell the story. Total poultry volume (495.3KT) is up 11.5% (core chicken & turkey products 7.5%).

Revenue growth of 3.3% ($2.383.9 m) and gross profit up by 8.1% ($456.8m) earnings before interest, tax, depreciation and amortization EBITDA, $195m up 16.4%, net profit after tax NPAT, $102m, up 22.8%, net debt down at $297.7 m. Earnings per share (EPS) were 27.4cps, up 22.8% and the final dividend 9.5 cps. Concluding the report Mr McMahon stated that, “the strategy implementation remains on track, and that growth in poultry volumes is expected to be closer to historical average as we cycle ‘every day low prices’ initiatives. “We will continue to optimise and rebalance the supply chain following rapid growth volume in FY 2017. “Improved New Zealand second half performance has continued into FY 18, and that ‘Accelerate’ benefits are expected to continue in underpinning cost reduction and profit improvement and help to offset increases in electricity costs, supported by energy efficiency and recovery via market pricing,” he said. “Further asset sales are expected as we continue to implement the Accelerate strategy, supporting cash flow, further debt reduction and help to any ongoing restructuring costs. “We are progressing a strategic review of our commercial stock feed

3

w

Ph: (03) 5979 1666

steve@agriculturalautomation.com.au

Victoria Agricultural Automation Ph: (03) 5979 1666

NEWS v

business (third party sales). “Capex levels are expected to reduce from FY 17 peak,” he said. Next came an interesting Q & A with a few of key financial markets experts who had obviously learnt a lot about the chicken meat industry since the Inghams IPO. One of the first clarifications statements made by Mr McMahon in answer to questions about the continued rise in volume of chicken consumption, was that the 8.8% experienced in the later half of FY17 was not going to be a constant, and volume levels would in all probability return to lower but still positive levels. Mr McMahon addressed the question of rising feed costs and pointed out that “Inghams as a major grain accumulator, was in a good position to deal with increased costs for at least nine months, a situation that was not as fortunate for their competitors.

Similarly with energy costs Inghams has contracts out into the future that keep costs manageable for the time being but he recognized the almost universal problem for industry in Australia that energy costs have become. A question from Credit Swisse analyst Paul Buys on the restructure of grower contractual arrangements drew an interesting comment from Mr McMahon. “Many of our grower contracts date back to a time when interest rates were typically between 13/16 % and today those interest rates are far lower. “Returns of 10 to 12% on capital were more typical of conditions created by the cost of lending but in today’s low interest climate returns of 7/8% would deem to be adequate,” he stated. In answering a question from Michael Pitt from Goldman Sachs on the falling prices of whole birds in major retailers, Mr McMahon commented that,

“it is our customers that are funding some of the low prices, particularly on small birds,” he said. Comments in the nation’s financial and news media made at the time of the TPG Inghams IPO were often quite pessimistic especially when the indicative share price initially flagged as being between $3.57 to $4.14 a share dropped to $3.15. However, the TPG decision to retain 47% equity combined with obvious and demonstrable progress in cutting costs and refreshing management, impressed investors and the share price climbed as high as $3.85 and has stayed above the $3.50 mark for a sustained period. A good first year result gives TPG Inghams a wide range of choices as to where to go in the future. Completing the full five years of Project Accelerate in an industry that though mature is still growing, and has every prospect of generating substantial returns for both investors and TPG.

Queensland chicken farmers lose $150 million from Baiada closure The announcement from Baiada that it will close its Ipswich processing facility and in turn cancel contracts with all farmers in South East Queensland, has come as a devastating blow to the entire industry and the local communities they support. The Queensland Chicken Growers Association (QCGA) has condemned the decision by Baiada and QCGA President Jodie Redcliffe estimated that the decision by Baiada to discontinue its SEQ production will strip growers of a conservative $150 million in lost production and devaluation of their farms. The 26 affected growers (28 farms) operate 155 purpose-built poultry houses and employ more than 80 workers within the SEQ region and supply the Ipswich processing facility with approximately 23 million chickens per annum. These farmers have been given notice that their existing contracts will be terminated and the plant will cease production in mid-January. “The entire Queensland industry is in shock at the timing and manner in which this decision by one of Australia’s largest chicken meat processors,” said Ms Redcliffe. “It is clear that Baiada’s decision

6

has been driven by a desire to consolidate its business in NSW rather than because of any questions about the viability of the industry in Queensland. “Our farmers were not given any warning or notice of this decision and they operate modern, efficient farms that meet and indeed exceed industry standards, within an industry that continues to see record profits and growth. “This decision has wide ranging impacts on the Queensland chicken meat industry and has rattled the confidence of farmers, financial institutions and all other supporting industries. “QCGA calls on the state government to consider how it can assist affected farmers over the next six to eight months as transitional arrangements are worked out and implemented. “QCGA also calls on banks and other financial institutions to consider how they can make relief considerations for farmers as they struggle though this financially and emotionally difficult time. “Affected farmers are now considering all their options in the aftermath of the decision and will make further comment in the coming weeks.” “Affected farmers are urged to contact QCGA as this situation continues to unfold and to seek assistance if

QCGA President Jodie Redcliffe. they are struggling, said Ms Redcliffe. “The Queensland Chicken Growers Association (QCGA) is the peak body representing Queensland’s meat chicken farmers, working on behalf of its members to secure a sustainable future within our social, economic and political environment to further the $588 million industry.

ROSS – THE COMPLETE PACKAGE

The Chick – The Support – The Performance You Want To learn more about Ross® visit aviagen.com/ross

GLOBAL REACH

LOCAL TOUCH

Patarker supplied the Clima 200 heat exchange unit which transforms the shed environment for the better.

An innovative approach to low energy, high efficiency broiler sheds near Goulburn

By PETER BEDWELL During conversations with Rod Martin from Polytex (see Poultry Digest Feb/ March 2017) the topic of a revival in curtain sided shedding came up. Rod told us about a broiler farm located in the hills behind Goulburn in NSW that had Polytex-supplied curtains for six new sheds that performed as well as any modern broiler shed design. Eddie Wehbe, a builder and now

8

the owner of these sheds, was in his own words, “getting a bit bored with residential construction” and seeking new challenges. He decided that he wanted to build his own broiler farm. With a fabulous site for his enterprise already acquired, he approached Patarker, the long established two generation poultry shed equipment suppliers run by Gerry, Paul, and Michael Bigeni, from Jamisontown in NSW. Paul Bigeni takes up the story. “Eddie was incredibly enthusiastic and wanted to try a rather different approach to climate controlled broiler sheds that suited the particular climate and location of his farm,” he said. As Poultry Digest approached Eddie’s farm, the first impressions were of a secure property down a long private road that with fencing and surveillance equipment, made for a very secure broiler farming enterprise. Eddie opened up the gates and

started to explain how his ideas had become reality. “This site has a climate more typical of Northern Europe than the prevailing warm and humid conditions of much of Australia’s coastal regions,” he said. “I fully understand why broiler farmers would build fully enclosed tunnel sheds in our warmer areas, but for my farm I wanted to look at the cool zone European approach. “I based my design philosophy on an abundant supply of cool fresh air and the ability to make the most of this feature for my farm,” he said. Windmills churning away on the crest of ridges some kilometres behind the farm, certainly bore out Eddie’s statements about prevailing conditions, as did the 5 degrees C at 9.00 a.m! “I liked the idea of being able to open up the sheds but still needed a thermally efficient answer to keeping the sheds at the optimum temperatures for the rearing cycles,” Eddie siad.

w

Five steps to move your animals’ nutrition at the pace of genetics. Issue Assessment

Report

Formulation

Recommendation

Measurement

Both genetics and management practices have been rapidly advancing in agriculture over the past 10 years. But has practical nutrition kept pace? Has nutrition been focused on only meeting the nutritional requirements of the animal? The BlueprintÂŽ Nutrition Program is that next step in nutritional evolution.

NUTRITION PROGRAM

Lienert Australia Head Office | 8 Roseworthy Rd Roseworthy 5371 | SA | Australia Tel: 1 800 649 231 Lienerts.com.au

Lienert

v

“Patarker helped us with ideas to achieve the design that suited both our climate and the requirements of our livestock. “The company then introduced us to Polytex and its ability to use modern materials to fabricate thermally efficient and easy to manage shed curtains,” Eddie said. Paul, Eddie and Rod initiated discussions for the design of the thermal curtains and Rod was able to recommend a triple layered fabric option. The curtains comprised of an inner and outer layer of Polyethylene fabric with a 15mm air-cell inner. The curtains had to meet three important benchmarks for it to be successful, firstly providing thermal efficiency, secondly the ability to be raised and lowered using modern and electronic winching systems and thirdly, a complete light block-out. The successful curtain design was proven as Eddie commented onsite “they are almost as thermally efficient as the 50 mm thick conventional foam shed wall material. “We used an electronic infrared thermometer and noted a two degree variation between the thermal curtains and the 50mm foam wall, and of course being fully flexible they can be adjusted i.e. raised and or lowered to suit the climatic conditions and bird requirement, unlike a fixed combination foam wall construction. The curtains are manipulated through electric winches and connected to a state of the art F38 Fancom controller. They are an integrated component of an overall climate control system that includes Fancom minivents, Patarker stirrer fans, and Fancom’s market leading ‘smart’ chimney fans. At this point in the story it is probably best to emphasise that Eddie’s sheds are not a retro ‘back to the past’ rehash of shed design from 50 years ago when the broiler industry started to go down the intensive track to satisfy growing consumer demands. No, they are a combination of the best available technologies to manage the shed climate in a very particular location. “I like rammed earth shed floors,” Eddie stated firmly. “They don’t sweat, are cost effective and absorb moisture and as with our other design features, they suit our climate”. We proceed to a tour of the farm and Eddie demonstrated key features of the shed design as we raised and lowered the Polytex curtains. Rod Martin and Managing Director of Polytex, David Horsfall joined us and pointed out critical details like the sealing strip where the curtains are fixed to the shed walls.

10

1

2

1. Polytex supplied curtains greatly assist automated climate control, making the most of fresh air. 2. Three layer Polytex curtains are flexible, durable and thermally efficient.

“If these curtain sided sheds are going to perform like fully enclosed tunnel housing, efficient seal is vital,” Eddie said. After two years of continual use the curtains still look as new and Eddie confirms they have truly met expectations. Other features of the shed design that Eddie pointed out were the extended eaves, just short of 2m, gutter to wall. “It keeps a large area of the shed sides cool in summer and protects the shed from rain, and yes, around here, snow,” Eddie explained. “Snow and ice don’t stick to the curtains but quickly bond to other materials including steel and even

smooth solid walls, conditions that don’t help when the shed needs to be warm enough for the birds, particularly in the brooding phase. Inside the sheds we see how the shed would operate in fully sealed mode with the combination of minimum vents, stirrer fans and the smart chimney fans, along with the curtains all operated through a Fancom control system. However, there is another critical innovation that delivers a whole raft of benefits to the shed operation and bird well-being and that is the Agro Clima 200 heat exchanger units, one to each shed. Poultry Digest spoke to Paul Bigeni the day after visiting Eddie’s sheds. Paul, like Eddie, and now Poultry

w

Don’t mix your priorities. Best results with MetAMINO®

Reduce batch times – and boost productivity. Some methionine sources are better than others at accelerating animal growth. Alongside proven superior bio-efficacy, MetAMINO® can even give you increased throughput in the feed mill. Four productions sites and more than 50 warehouses worldwide guarantee short delivery times. MetAMINO®: not just better – best results. www.evonik.com/metamino Evonik Australia Pty Ltd Suites 33&37, 1 Ricketts Road, Mt Waverley, VIC 3149 Phone +61 3 8581 8400 Fax +61 3 9544 5002 amy.liu@evonik.com

1

v

Digest are truly impressed by the potential for better shed control offered by modern heat exchanger technology. “The heat exchangers at Eddie’s farm supplied by Patarker are from Agro Supply, a unit of the Vencomatic Group. “The Clima unit 200 heat exchanger ended up as being one of the most exciting parts of the project, especially for us as it gave us the chance to prove this advanced European technology,” Paul said. “Initially we were looking purely at gas savings and litter control but were even more excited when we discovered that other benefits for broiler farmers were of huge significance. “Agro Supply call them Clima units for a good reason and that is they can actually take over the whole climate of the shed, especially when the birds are young. “The main function of the units is humidity control and dust removal. If you are able to control humidity perfectly and capture internal dust and ammonia, a whole range of other benefits come into play. “These benefits, such as a clean environment for birds and staff, lower emissions, better litter control, uniformity of birds, reduced building and equipment corrosion, as well as a faster cleaning process at the end of flocks. “We see Clima units as potentially a new way of achieving efficient minimum ventilation into the future,” Paul concluded. Patarker supplied and designed all the internal equipment, electrical and plumbing on the farm, complete installation, commissioning and training of Fancom controllers and associated ventilation equipment. Other items supplied include Super Saver Heaters, Roxell feeders, Ziggity drinkers, Patarker stirrer fans, foggers and all equipment winches and Polytex CONTINUED ON PAGE 16 w

12

2

3

1. Excellent view of the farm from the ridge behind. 2. David Horsfall and Rod Martin from Polytex with farm owner Eddie Wehbe all pleased with the curtain solution. 3. Extensive hard areas around sheds manage water run off improving biosecurity.

R&DG Sanday Tunnel Ventilated Shed Specialists The ORIGINAL designer and builder of the

GENUINE CLEAN SKIN SHED with no exposed trusses, columns or internal bracing

Fully experienced in all aspects of poultry shed design and construction Fully licenced throughout Australia Highest quality workmanship and materials No project too large Competitive prices Reliable honest and friendly advice Flexible design which can be adapted to meet any client needs and shed size

Don’t be misled by companies claiming to be Australian but use overseas materials! 100% Australian Owned 100% Australian Designs 100% Australian materials 100% Australian, fullstop!

OVER 40 YEARS EXPERIENCE

Call Ron Now 0404 489 573

www.RDGSanday.com

v CONTINUED FROM PAGE 12 thermal curtains. Other important aspects of the farm design are that water is captured from the shed roofs but only used as ‘grey water’ for wash down purposes around the property. All drinking water for the birds is obtained from bores, filtered and treated before distribution to the drinker lines. “Given that heavy rain is not unknown in our part of the world we have installed hard surfaces around sheds and drive ways to ensure effective drainage,” Eddie pointed out. A further interesting aspect of Eddie Wehbe’s farm is that he is an independent supplier of grown birds. “This means that we can grow to the requirements of any of the integrators, including RSPCA protocols. “We know that bird quality is critical and that is why we have invested considerably to ensure we consistently maintain the best environment for bird health and optimal growth patterns,” Eddie stated. Eddie Wehbe’s dream of creating a state of the art broiler farm that works with his climate rather than against it, may become a signal for future growers to consider as energy bills rise but demands for more efficient and consistent broiler rearing increases. The innovative technology on this farm was firstly the result of an imaginative farmer who saw the potential for better poultry rearing, then by seeking advice, and following it, from a family company with decades of combined experience in the poultry industry. The end result is a combination of original thought, simple but effective components like more efficient shed curtains adapted to 21st century automation, and the simply amazing technology of heat exchangers. Driving away from Eddie’s farm back to Sydney, Poultry Digest reflected on the fact that we had just seen first hand what could be a steep change in broiler shed technology. And that is not the first time we have experienced this. Almost 17 years to the day, just weeks after acquiring Poultry Digest in 2000, we met a very young Paul Bigeni at a new tunnel ventilated shed at Marsden Park. Just before Sydney entered a month of Olympic frenzy we had to obtain a grower story for our September/October 2000 issue. It was our first experience of reporting on a state of the art tunnel shed. The day had started at around 5 degrees C at sun up but despite the fact that it was early September, by 11.00 a.m it was over 30 and still climbing. The new Fancom shed controller

16

1

2

3

4

5 1. Shed interior showing Patarker supplied stirrer fans, Roxell feeders, Ziggity drinkers and closed Polytex curtains. 2. Fancom F38 controller. 3. Fancom smart contoller chimney fan. 4. Fancom mini vents. 5. Internal end of the Clima 200 heat exchange unit. was struggling to compute the huge sudden temperature range but Paul went to work like a ten year old with a new iPhone. In a short space of time, computer, main fans and evaporative coolers were all singing from the same hymn sheet and the very young birds settled after a scary start to the day. That shed was one of many commissioned in the period to serve the rapidly increasing demand for evercheaper chicken. Energy in Australia was the second

cheapest on the planet, free range meant somebody had left a shed door open and supermarkets, integrators, and contract growers, were all getting on like a house on fire. That was then. Seventeen years on, the broiler industry faces a very different landscape, but as tunnel ventilation, automation, and cheap energy served the needs of growers in 2000, energy efficiency, more intelligent design, and ever more innovative technology, will, if applied properly, see the industry through in current circumstances.

Highly effective against Avian Influenza including H7

NUTRITION FEATURE

A new perspective on feeding broiler breeders By ALEX CHANG* Due to sophisticated genetic selection programs carried out by poultry breeding companies such as Aviagen, today’s broilers can grow with very efficient feed conversion and exceptional carcass and breast yield. Broiler performance objectives published by Aviagen (2014) show that a 10-day old Ross 308 male bird can reach a target bodyweight (BW) of almost 300g and a feed conversion rate of just below 1.00. The remarkable performance improvements in commercial broilers also change the way to rear and manage the parent generations. Like their progeny, genetically improved broiler breeders are now more sensitive to high intake of crude protein (CP) and amino acids such as lysine. At the same time, they will less likely develop body fat reserves. High intake of CP of broiler breeders would result in heavy birds and high breast meat yield. These characteristics are not required for broiler breeders and also they have negative impact on egg production and fertility. When broiler breeders are raised on a different profile, they will develop less breast meat, and produce more chicks during the production cycle. Although modern broiler breeders have the genetic makeup to support high peak egg production and persistency of lay but it is important to provide them with optimal nutrition in terms of body fat reserves and adequate dietary metabolisable energy (ME). The lower the fat reserves, the lower persistency of lay. Hence we have developed the concept of feeding low CP/high ME in the parents (PS and GP). 2016 Aviagen Parent Stock Nutrient Specifications In 2016 with the newer genetics coming through in the field, Aviagen published its updated PS Nutrient Specifications and Performance Objectives with a continued focus on BW and egg weight control, production persistency, better fertility and hatchability. This is to ensure that the bird’s needs for maintenance,

Above: An Aviagen breeder flock in Albertsville. Below: Checking fatpads. growth and production of eggs are met at every stage. In the updated nutrient specifications the values for CP and most amino acids for both rearing and laying periods have been reduced, reflecting their lower requirements and the bird’s sensitivity to high CP intake. This should minimise early muscle tissue gains and reduce breast muscle and follicular development - this will influence breeder productivity positively. Table 1 and 2 show the 2016 vs previously released 2013 feeding programs for 4-stage rearing and production respectively. Note that under the 4-stage rearing feeding program the ME is low (2600 kcal/kg) in the grower period. This allows a higher daily feed volume which should reduce risk of feather pecking or cannibalism in pullets. The lower energy (2700 kcal/kg) and lower digestible lysine in the Pre-Breeder diet helps support better feed distribution and flock uniformity. Adopting a 4-stage instead of a 2- or 3-stage rearing feeding program would benefit breeder managers in terms of easier BW management and would assist pullets to achieve higher fat reserves before they come into production. Do we need breeder layer 2 and 3 diets? One-phase layer feeding program during production can be used, which will lead to successful breeder performance. However, one-phase only feeding regimen requires very good

18

w

www.potterspoultry.com

LEADING SUPPLIERS OF CAGE FREE POULTRY EQUIPMENT

NESTING SYSTEMS

MULTI-TIER AVIARY

FOR BREEDERS AND LAYERS

FOR FREE RANGE AND BARN SYSTEMS

Long life, strong and stable

Flexible design - maximises stocking density

SLATS

SINGLE AND TWO TIER NESTS FOR LAYERS

Probably the strongest and most stable available

Rack & Pinion lifting floor with original Astroturf

For further information please contact: Richard Beevis, Jerry Bailey-Watts Caption

Regional Business Export Manager

Potters Poultry Leigh Road, Swift Valley Rugby, Warwickshire

Development Manager

CV21 1DS

+44 7717 518548

United Kingdom

Richard.beevis@potterspoultry.co.uk

www.potterspoultry.com

+44 7789 721445

jerry.bw@potterspoultry.co.uk

NUTRITION FEATURE Table 1. 4-Stage rearing feeding program of 2016 Aviagen Parent Stock Nutrient Specifications as compared to 2013 version

Starter 1 (0-21 days)

Starter 2 (22-35 days)

Grower (36-105 days)

Pre Breeder (106 days 5% production

Energy (kcal/kg) WPSA

CP (%)

Dig Lys (%)

Dig M+C (%)

Dig Met (%)

Dig Thr (%)

Na (%)

2013

2800

19.0

0.95

0.74

0.40

0.64

0.16

2016

2800

19.0

0.95

0.74

0.46

0.66

0.18

2013

2800

17.0

0.67

0.58

0.28

0.51

0.16

2016

2800

17.0

0.67

0.59

0.37

0.53

0.18

2013

2600

14.0

0.52

0.47

0.31

0.40

0.16

2016

2600

13.0 -14.0

0.52

0.52

0.33

0.44

0.18

2013

2800

15.0

0.56

0.50

0.33

0.43

0.16

2016

2700

14.0

0.52

0.51

0.32

0.41

0.18

Table 2. Laying production feeding program of 2016 Aviagen Parent Stock Nutrient Specifications as compared to 2013 version

Breeder 1 (5% - 35 weeks)

Breeder 2 (36-50 weeks)

Breeder 3 (> 50 weeks)

Energy (kcal/kg) WPSA

CP (%)

Dig Lys (%)

Dig M+C (%)

Dig Met (%)

Dig Thr (%)

Ca (%)

Na (%)

2013

2800

15.0

0.60

0.56

0.35

0.47

3.00

0.15

2016

2800

15.0

0.60

0.59

0.37

0.49

3.00

0.18

2013

2800

14.0

0.56

0.55

0.34

0.45

3.20

0.15

2016

2800

14.0

0.56

0.57

0.36

0.47

3.20

0.18

2800

13.0

0.52

0.54

0.33

0.47

3.40

0.18

2013 2016

v

management with far greater attention to BW control (as the CP and amino acids are constant from point of lay to depletion). Having Breeder 2 and 3 diets is more beneficial as the CP/amino acids are stepping down from high to low. Calcium level is increasing from Breeder 1 to 2 to 3. This should enable birds not to receive excessive CP (and especially lysine) in order to achieve a good BW profile and egg size control, as well as to obtain sufficient calcium for improved egg shell quality. What about male diet? Trials conducted internally by

20

Aviagen have consistently demonstrated the advantages of introducing a male diet during production. Males provided with a low CP and optimal energy diets tended to have less breast yield and heavier testes

(Table 3). It should be pointed out that it is important to introduce male feed at start of lay or around 24-25 weeks of age and not much later as there will be no benefits of having a separate male diet when introduced late. When introduced at lay, benefits of improved fertility and hatchability will be seen from around 30-35 weeks onwards in the breeder flocks. Important consideration – daily nutrient intake

A male diet produces heavier testes

Regardless of CP and energy content in breeder diets (both males and females) a more important

w

World Class Brands. World Class Expertise.

At Ryan-Ryte we specialise in creating the right environment to grow poultry. From the construction of broiler, broiler/breeder, free range and barn lay housing complete with ventilation and equipment such as: • • • •

Feeders Cross Auger Drinkers Nesting Systems

• • • •

Climate Controllers Cooling and Ventilation Heating Electric Winches

Distributors of:

Ryan-Ryte Enterprises combines the worlds leading brands with over 35 years experience and expertise to provide a true turnkey solution for your poultry production needs. With a key focus on low repairs and maintenance, our solutions are renowned for their quality and durability. In addition, we are focused on giving our clients the best value for money, helping to achieve a quick return on investment and to make their business more efficient and more profitable.

Find out how Ryan-Ryte can help your business. Call 03 9782 5515 or visit our website www.ryanryte.com.au

NUTRITION FEATURE v

consideration is the actual daily nutrient intake by the birds compared to the bird’s requirements at various stages of production based on daily feed allocation. It is not good enough for breeder managers to know the feed energy (e.g. ME of 2800 kcal/kg) or the dietary CP level alone (e.g. 14% CP), but it is also important to consider daily feed allocation at the same time (e.g. 165 g/d). In this way, the actual energy or CP intake can be calculated and it can be compared with the bird’s requirements (these numbers can be found in the breeder company’s manual or performance objectives). A decision can then be made to either adjust daily feed allowance or to reformulate diets if the birds are over- or under-consuming a given nutrient.

Table 3 - Effect of male feed on body composition during production. Data from a 59-week Aviagen trial conducted in Europe 2010 involvong 50 males per treatment. Treatment

P-value

4960 1145 23.1% 31.7 0.64%

4771 1070 22.4% 34.1 0.72%

0.032 0.004

Hatchability improvement

Case study 1 – PS Customer A in tropical S.E Asia with both open-sided and environment-controlled closed housing systems. His production feeding program incorporates 3 phases with the following CP and ME values: • Breeder 1 – 14.6% CP, 2825 kcal/kg ME, • Breeder 2 – 14.0% CP, 2825 kcal/kg ME, • Breeder 3 - 13.0% CP, 2825 kcal/kg ME The feed amount given during peak production was 167g/d/bird for flocks in open-sided housing, amounting to CP intake of 24.2g/d/bird and 471 kcal/b/d of ME.

REDUCE YOUR ENERGY COSTS$ % ""#$% & '! "( # $ WITH... $ )% ' • Fan Covers Control Curtains • Brooder/Air • Door Covers • Cool Cell Covers • Shelters/Shelter Covers

BLOCKOUT BLINDS

22

0.097

+ 4.5% (very high); Average farms: +0.5 - 1.0%

Case Studies Below are two brief case studies of Aviagen’s broiler breeder customers in Asia who have applied the low CP and high ME intake concept and have achieved regular and successful breeder performance.

Project1:PoltexAd2 21/03/14 3:47 PM Page 1

Separate male diet

Bodyweight Breast (with bone) (g) Breast % Testes (both) (g) Testes (both) %

Importance of vitamins & minerals For optimal breeder as well as offspring performance, the contents of added vitamins and trace minerals must satisfy the bird’s requirements. Among the vitamins, A, D3 and E in particular are of major significance for proper embryonic development and subsequent chick quality and should be adequately supplemented in the breeder diets. The use of more bio-available form of vitamins (D3) and organic trace minerals (Se, Zn, Mn) has shown to increase deposition in the egg and also transfer to the tissues of the hen and the embryo, thereby giving the newly hatched chicks best possible start in life to fulfill its genetic potential.

Control (No separate male diet)

With reasonable low CP and more than enough energy intake, the average breeder performance is something to be envious of: • Peak egg production > 89% • Cumulative hatchability >90% • Chicks/hen housed =154 (range 148 -158, depending on bird size). The performance with flocks in closed houses is even better. Case study 2 – PS Customer B in temperate Asia with an environmentcontrolled housing system. With using a Breeder 2 diet right from the beginning of production to 35 weeks of age and then followed by a lower CP/high ME Breeder 3 from 36 weeks, the egg production and egg weight records are again something to be proud of. Conclusions Less protein with adequate energy, appropriate minerals, vitamins and trace elements in both female and male breeder diets will enable better body weight and egg weight control in modern broiler breeders. This in turn will ensure production persistency, better fertility and hatchability to give a greater number of total eggs and hatching eggs during the laying cycle. * Alex Chang is the Senior Poultry Nutrition Specialist, Asia Pacific Region, Aviagen Group. For information– Email: achang@aviagen.com

RR & &E E SHEDS SHEDS Built Last Built to to Last

•• Over 2020years experience in in building poultry and machinery sheds Over years experience building poultry and machinery sheds •• AllAllstyles of of sheds – conventional, free range andand tunnel sheds styles sheds – conventional, free range tunnel sheds •• Well known Well knownreputation reputationfor forfast fastand andefficient efficienterection erectiontime timewithout without compromising good quality workmanship compromising good quality workmanship •• AsAs thethe owner of of R&E Etienne Mifsud thethe whole jobjob from owner R&ESheds, Sheds, Etienne Misfudoversees oversees whole from start starttotofinish finish •• Repairs, extensions, insurance work to to anyany existing sheds Repairs, extensions, insurance work existing sheds •• AllAllsheds cancan bebe customised to suit anyany client’s needs sheds customised to suit clients’ needs •• AllAllstructural steel work manufactured at at R&E Sheds, soso nono delays onon structural steel work manufactured R&E Sheds, delays completion completionofofthe theproject project •• NoNoproject projecttoo toosmall smallororlarge large •• WeWe travel totoallallareas of of Australia and New Zealand travel areas Australia and New Zealand •• Fully licenced to to build interstate and Fully licenced build interstate or overseas overseas

Call Misfud on on Mob: Mob: 0428 0428481 481811 811 Call for for aa quote: Etienne Mifsud or 481811 811 Office: Office: (02) (02)4774 47748764 8764 or 0417 0417 481 Fax: (02) 4774 47748415 8415Email: Email: reshed@bigpond.com Fax: (02) reshed@bigpond.com

EXPERIENCED BUILDERS AND GROWERS

NEWS

Is there a possible role for drones in poultry industry management? Poultry Digest has lost count of the number of keynote speakers at industry conferences who have spoken about the ability of new technologies to radically change and improve the way the industry runs its farm and business operations. The poultry industry is already a leading agricultural sector when it comes to automation with climate control and monitoring of all critical aspects of rearing birds. However when Poultry Digest attended a conference in South Australia to report for Primary Media’s other publication, Pork Journal, we were intrigued by a paper from Tim Croagh, a senior operative at the Western Plains free range pig farming operation. His topic was ‘Using IT smart pig farming’. Tim’s farm had combined a number of monitoring functions using computer-based technology and a central feature of his 21st Century operation included the use of drones. A labour intensive task on the expansive free-range farm was to regularly inspect the pigs, their progeny and the infrastructure, like the electronic sow feeding systems that ensures the pigs thrive and are in good condition. Tim reported that the initial idea to use drones to monitor pigs had been extended into a multiplicity of other vital functions and it occurred to us that the same could be said about free range layer and chicken farming. On August 24, 2017 Poultry Digest met Brad Aylett-Sloan and Kevin Gallagher from National Drones, a Melbourne based company that supplies drone based technology and industry dedicated programs to a variety of organisations including industry and government. Kevin first contacted Poultry Digest some time ago after researching potential use of his company’s drone based technology in agriculture. “Drones are already used in the beef cattle industry and for crop monitoring,” he said. “Looking for other applications we realized that there was potential for our technology and services in the broiler sector. “Technology once considered purely as the province of the wealthy, those that could afford for a helicopter and

26

Ac Brad Aylett-Sloan and Kevin Gallagher from National Drones. large, expensive cameras has now miniaturised both in size and cost. While the size and cost have reduced, the science and technology and science has increased. “We can for instance use our thermal imaging technology and analytics teams to support shed energy efficiency programs by providing pin point accuracy for heat dispersal and loss, within and without of the shed. “We can also potentially add value in the area of biosecurity by providing evidence of hidden habitats and changes in flora disturbance over time which will show increases or decreases in animal movement. “All of this with small and relatively quiet remote piloted aircraft that have a very low impact on the nervous condition of stock when deployed. “The basic rule is that drone technology is an enhancement and complimentary element in a broader business strategy. “When used in conjunction with our customer’s own experience and knowledge, drone based technology can and does add considerable value

and advantage to the business owner,” he suggested. By a happy coincidence Poultry Digest, relaxing on the weekend, but still pondering positive drone applications stumbled upon an article in the Sydney Morning Herald Good Weekend supplement (design & innovation issue), August 28 , 2017 by Greg Callaghan entitled ‘Forest Rangers’. “Desertification, wildfires, mud slides; we are now seeing the terrible cost of desertification,” it stated. “Can swarms of seed bearing drones help regrow the planet’s forests,” the introduction questioned. The answer, as revealed in the ensuing article seems to be ’yes’. “With just two operators running six or seven drones at a time, an astonishing 36,000 seeds can be planted in a day. That is more than 10 times the speed of hand planting, and at a fraction of the cost. “Just imagine what swarms of these machines, think hundreds of them, could achieve by re-planting vast areas devastated by bushfires or logging,” the author stated.

To advertise in Poultry Digest call Peter Bedwell on 0297972406 or 0419235288

BATCH TO BATCH POULTRY SPECIALISTS * Shed Wash Service * Spray Sanitise & Fumigation * Beetle Spray Service * Water Sanitisation (Chlorine Dioxide/Chlorine) * Brood Paper Supplies * Feed Caddy * Litter Management * Litter Amendment * Odor Control * pH Correction * Chemical Supplies * Ammonia Meters & Testing Equipment * Personal Protective Equipment (PPE) * Drum Pumps • 300% better spray coverage • reduced chemical usage • drier shed environment

ELECTROSTATIC SUPERCHARGED POULTRY HOUSE SPRAYER

Talk to us about our contract spray services or we can set up a unit for you. Let us help you to improve your Biosecurity, Productivity & Profitability. (02) 49423334 | 0427 886 866 | prowashpoultry.com.au | admin@prowashpoultry.com.au

ALL WEATHER RODENT STATIONS & RAT BAIT • All Australian made • Solid - heavy duty • Lockable & mountable • UV grade • Waterproof • Rat station ID# stickers

• Ensuring rapid eradication of rodents in & around buildings • Tested on farms • Multible rat bait types available • Registered for agricultural animal houses, farms, domestic & commerical buildings

• One feed fast acting

Office: 4942 3334 | Lisa: 0427 886 866 | www.prowashpoultry.com.au

012221

Office: 4942 3334 | www.prowashpoultry.com.au | admin@prowashpoultry.com.au

VENTILATION FEATURE

Optimise broiler growth and welfare with correct ventilation systems By JACOB GAZIT and CATHERINE BRYNIELSSON*, Munters Broiler production systems that are used all over the world create a need for flexible and reliable ventilation solutions. When mentioning flexibility, the one thing that should not be flexible or random is the cost of running that same ventilation system. Farmers and growers want to know that their ventilation system performs well, but also what the operational costs are and what they will be. Most broilers today are floor-raised on litter in large structures, which are climate controlled. If there is a sudden cold spell, the system needs to be prepared for adding the right amount of heating power and a system for emergency opening when there is a power loss. Other requirements on the ventilation system are that it should be able to accommodate a day old chick weighing around 40-45 grams to a fully grown bird of 2,500 grams or more. Suitable temperature and humidity levels in the house vary with the bird’s growing cycle and ambient conditions from the climate zone where the house is built. All of the above coupled with sufficient feed and water access make the broilers comfortable and healthy, suitable to become food for humans. A healthy, closed indoor environment often means that the grower needs to spend less money on medicine for the birds, a cost saving that Munters have seen decreased with as much as 40%. Having stated the above, it is very important to choose an energy efficient and well performing climate control system that fits the production system, and also with the objective for the farmer/ grower to have as low Total Cost of Ownership (TOC) as possible, to increase farm profit. Let us look at which parameters should be focused on when meeting a farmer. In most cases the building structure and size has been chosen by the farmer already, which more or less decides the layout and design of the ventilation system. The next thing to take into consideration is the ambient climate

28

condition of the specific location. Average winter and summer temperatures, humidity levels and other specific weather types that the climate control system needs to be ready for, are carefully collected and investigated. The control at the heart of the system will be configured so that it responds to changes in temperature, humidity and strong winds. It should also have preset temperature curves adapted to the growing cycle of day old chick until the bird is ready for processing plant. In a large broiler house there are some design challenges and they are all more or less unique to every house one comes across, but it is possible to outline some general challenges. One important challenge is to create uniformity. With the birds being free to move around the broiler house, this is an essential challenge. Uniformity means there can be no cold or warm spots in the house. If that occurs during cold periods, the broilers will be clustered around warmer spots and there is a risk of disturbances, such as fighting in the flock. The same scenario of clustering will occur during warm periods if there are cooler spots, likewise creating an imbalance in the house. Uniformity always starts with

placement of the climate equipment for an even distribution of fresh incoming air and taking stale air out of the house. The type of inlet chosen depends on the climate conditions where the house is located. If the incoming air is cold for a period of the year, one generally wants to avoid that cold air drops down directly towards the birds, something which will inevitably disturb them and cause a non-uniform climate. For these cases, a horizontal and radial spread of air is desired which will mix it with warmer air next to the attic or ceiling before it drops down on the flock. In the design phase, attention should also be paid to the distance between the ceiling/attic air inlets so that the optimum air flow inside the building can be reached. How do we know that we got it right? Well, there is no second chance; we have to design it correctly from the start. We get a receipt that it is working when you see that the birds are uniformly spread in the house. When you visit a broiler house you will most probably find it a dusty and greasy environment with feathers all over. These kinds of deposits are normally occurring at any farm,

w

Inviting all poultry farmers in Australia for a special training programme/ customer meeting on ROTEM & MUNTERS controls. LEARN TO USE THE ROTEM CONTROLS IN THE BEST WAY AND TAKE ADVANTAGE OF THE BEST CONTROL IN THE MARKET.

Seminar conducted by Technical Expert from Rotem, Israel Date Location Venue Time Date Location Time Venue Mon 30 Oct 2017 QLD The Glen Hotel and Suites, 24 Gaskell St, Eight Mile Plains, Brisbane 9am-5pm To be advised to registered Monday 30th October 2017 Brisbane, 9am-5pm QLD 4113 Ph: 07 3270QLD 6666 customers by email or phone as Wed 1 Nov 2017 NSW Griffith Club, NSW Jondaryan Ave, Ph: 02 6962 1875 9am-5pm Wednesday 1st November 2017 Exies Griffith, 9amGriffith -5pm NSWit 2680 gets close to the date of the Fri 3 Nov 2017 VIC Whittlesea Golf Club, 160 Humevale Road, Humevale Melbourne 9am-5pm event in respective locations Friday 3rd November 2017VIC 3757 Phone: Melbourne, VIC267 9am-5pm 0417 500 Mon 6 Nov6th 2017 SA Royal Adelaide Golf Club, Hill Rd, Seaton SA 5023 9am-5pm Monday November 2017 Adelaide, SA 328 Tapleys 9am -5pm Ph: 08 8356 5511

Training to cover the following topics • • • • • • • • •

Best method to utilise the Rotem controls to full capacity Latest features in Rotem controller that can be incorporated in old controls How to upgrade your existing control with latest technology Latest software and unique new features Communication- Rotemnet, Mobile app, 3G upgrades, wired and wireless communication, RLink-One very high quality wireless communication Remote monitoring of your farm from anywhere in the world Precision ventilation using- weight of birds, Static Pressure, CO2 sensor, Relative Humidity Tested and proven silo and bird scales in managing FCR Open Question and Answer session

Registration fees AUD$50 per person to be paid by credit card or depositing the money into our bank account Option 1: Bank Transfer

Option 2: Credit Card

Account number: 10138008 BSB: 062-200 Please use Rotem and your last name as reference e.g ROTEM Smith

For credit card payments please ring Binjal Darji Phone: 02 8843 1516

Munters contact : Sudhee Satyan Email: sudhee.satyan@munters.com.au Mobile: 0418 206 157

Tich Mabunu Email: Tich.mabunu@munters.com.au Mobile: 0407 021 446

Limited places are available at each location. Request for confirmation from customers ASAP

Please fill in below and send back to us by email or Fax: 02 88431570 NAME: CONTACT NUMBER: FARM NAME AND ADDRESS:

REFERENCE NUMBER: LOCATION OF SEMINAR TO BE ATTENDED: HOW THE FEES HAVE BEEN PAID (circle the appropriate) bank deposit / by credit card

NUMBER/ NAME(S) OF PEOPLE ATTENDING:

DATE:

REFERENCE NO. OR RECIPT NO:

SIGNATURE

VENTILATION FEATURE v

especially towards the end of a flock. It is not possible to go and clean the ventilation equipment during a cycle without considerably disturbing the animals and causing wet litter etc. Before the flock is replaced, the entire house including equipment can be hosed down with high-pressure cleaners and disinfectants. Ventilation equipment should be adapted to these environments, being both dirty and containing high acidity levels. The second challenge for a climate control system is bedding quality at least for floor production systems where birds move around on the floor. This typically consists of straw, wood shavings or sand. The broiler farmer wants the bedding material to remain dry so that it does not stick to the birds’ feet thereby causing lesions. Wet bedding material mixed with manure will increase the ammonia levels inside the house, affecting both animals and people negatively. A well ventilated building with sufficient air flow and heating on a need basis will ensure that the bedding material is kept dry. So there are lots to win for the grower when it comes to keeping the bedding material dry; and it all spells better farm economy and better animal welfare. In some parts of the world, ammonia emissions are restricted by law especially in areas that are densely populated. In these areas the grower stands at risk of not being able to expand their production because of the concentration of ammonia emission from the site. This can however be solved in different ways. The most common one being a scrubber solution, which literally washes the ammonia out of the stable air before it is let out into the atmosphere. One major challenge in this respect has been filters that clog up and need to be replaced at a regular pace, often at high cost. A couple of years ago, Munters realized that it could use another of the company’s core technologies, mist elimination, to solve this problem. Today the ammonia emissions are reduced by as much as 89% on average, and with maintenance limited to high pressure cleaning of the mist eliminators every now and then. The third challenge revolves around heat waves and periods of hot weather that appear both unexpectedly and temporarily. The consequences are however

30

disastrous to the grower, resulting in lower production and increased mortality in the flock. A temperature range specific to the age of bird, starting from 34 °C and ending at 18 °C depending on breed and other local variables, without humidity extremes, these are the climate conditions that have been generally found to be optimal, for growth performance as well as for animal welfare. Light control plays an important role in modern poultry farming and here it represents the fourth climate challenge. Having adequate light control enables a grower to reap benefits by achieving excellent production results since the broilers need a few hours of sleep (as recommended by breed suppliers) in order to grow properly. The house does not need to be absolutely pitch-dark, but it is necessary to create a brown out effect in the house and to avoid light spots. A practical problem here is the necessity for ventilation openings in the structure. These allow for fresh air to enter as well as for the extraction of stale air. Unfortunately, daylight penetrates the structure through both the air inlets and exhaust openings. Light filters are used to solve this problem, allowing air movement through, but absorbing the light. Other ways to avoid light spots would be to use drip pans underneath chimney fans and deflector disks of ceiling inlets reflecting the light from outside back up towards the ceiling or walls. The reflected light does not prevent the birds from getting their rest. By

properly configuring the climate system and equipping each project with the products and accessories suitable for that specific location, we can make sure that the farmer doesn’t end up with exhausted animals that don’t thrive or perform well. An unstable energy supply is the fifth challenge in intensive broiler farming. Inlets and extraction openings are handled by actuators regulated by a controller. If a power failure occurs, there must be a backup system connected to the controller, which makes sure that the birds are not suffocating. The inlets and fan dampers will automatically be set wide open, ensuring sufficient natural ventilation airflow in case of an emergency such as power loss. Set at the heart of each climate control system, you will find a number of controllers which orchestrate the equipment. The silo controller, which controls the chicken feed, the general temperature controller with extra sensors that monitor CO2levels and lets the farmer set temperature curves for the buildings, control the minimum ventilation and tracking historical data from the house. Intensive poultry farming of today deals with a highly competitive landscape, with limited financial margins. Therefor it is of outmost importance to safeguard the investment made and to let it materialise in a stable and even production at all times. * Jacob Gazit is the Industry Manager Broiler Industry, Munters and Catherine Brynielsson is the Global Marketing Manager, Munters.

If you wish to be included in the Poultry Industry Yearbook 2018, please send you personnel details to primarymedia@bigpond.com If you wish to advertise in the Yearbook, please contact Rosemary Embery on 0409 944 472 or 02 9797 2406 or email primarymedia@bigpond.com

RED-L

Think ahead with poultry people

Bolegg Terrace

Speedpack

Vencomatic Group is a global supplier of innovative and sustainable housing and egg collection systems for the poultry sector. With many years of experience, we are the expert in this field and a reliable partner for you for: • Turn-key aviary systems and building packages across Australia • Maximising your ROI • Spare parts and complete technical support

For more information:

www.vencomaticgroup.com

Patarker Paul Bigeni 8 Robertson Place - Jamisontown NSW 2750 - Australia Tel. Office (02) 4732 5520, Mobile (0)416 213 822 paul@patarker.com.au Vencomatic Group Simon McKenzie Area Sales Manager Pacific Tel. (0)419 881 005 simon.mckenzie@vencomaticgroup.com

NEWS

Tegel posts results for 2017 Financial Year On September 7 Tegel announced its financial results for the FY 17 and the Chairman David Jackson tabled a report showing solid growth and good prospects for the future. Poultry volumes reached a record 100,000 tonnes up 7% on FY16, revenue of NZ$ 614 m was up 5%, EDITDA of NZ$75.6 up 1% and net ptofit after tax NZ434.2m, up 203% year on year. “NZ’s poultry market has favourable macroeconomic trends including poultry growth consumption of around 5% since 1990 with poultry taking an increasing share of protein consumption (53% vs 28% since 2000). “Poultry is more affordable in NZ than any other protein sources at $10.78 kg vs $ 19.90 kg for beef,” he said. “Other advantages included NZ’s unique disease free status, being free of the three major avian diseases. Vaccinations are not required and New Zealand operates strict biosecurity by prohibiting imports. “Our high reputation increases Tegel’s ability to access international markets and achieve premium product positioning amongst global consumers,” Mr Jackson concluded. Tegel CEO Phil Hand next expanded on the results and prospects. “We are NZ’s leading poultry brand with strong heritage and apart from being the number one brand we have the highest brand awareness and preference. Our market share increased to 52% this year,” Mr Hand said. “This year we completed a full rebrand, including packaging re-design and launch of new advertising campaigns and the company launched a range of new products into both domestic and overseas markets. “We are a leading producer of high quality core and value added poultry products, exporting to 18 countries including Australia, the Middle East, Asia and the Pacific region. “We have recorded five years of continued growth in volume, revenue and underlying EBITDA,” he said. On financial aspects Mr Hand revealed a dividend of 7.55 cents a share was paid in FY 17. Net financing costs fell due to a lower interest rate on new facilities, and a reduction in net debt. Key highlights vs FY 16 results

32

were, “an increase in domestic volumes (up 7.2%) as all channels increased volumes in FY 17 as chicken consumption continues to grow and domestic revenue up 5.9% ($25.3m) despite softer pricing. “We experienced an increase in export growth of over 1000 tonnes, up 6.7% from both new and existing markets delivering an increased revenue of 1.1% or $1.1 m. “In FY 17 we delivered significant innovation including new ‘value added’ products, including the launch of our Tegel ‘Quick Cook’ range and Tegel Fresh value added products, kebabs and butterfly whole birds, delivering a sales increase of 25% over FY 2016. “Free Range product growth was included into the successful ‘Meal Maker’ range. FY17 sales of free range product increased by 28% from FY 16 contributing 25% of total sales growth,” Mr Hand revealed. Apart from New Zealand, where Tegel has a 52% share, its products sell in Australia, the Pacific Region, Philippines, Hong Kong and the United Arab Emirates Tegel operates 38 breeder farms, three hatcheries, three processing plants in Auckland, New Plymouth and Christchurch and is supplied by 93 contract grower farmers all located in close proximity to processing facilities. Summarising the outlook for 2018 for the domestic market the aim was “to drive category growth, innovate to increase value added sales, thus enhancing our market leadership position. “We expect continued domestic consumption growth of 4/5%, our re-packaging and branding initiatives will continue in FY18 with, in particular, free range brand investment and product innovation. “We will strengthen our position in current export markets and enter new ones in FY18. “There will be a diversification of channel and customer mix in Australia with new range product launches in the second quarter,” Mr Hand said. “Also, we will increase presence in Australia through the establishment of both offices and staff. “In Asia and the Middle East we will continue to build on existing capacity and launch our first products in Bahrain in Q1.

Above: Phil Hand, CEO of Tegel. Below: Some of Tegel’s new range of free range ‘Meal Maker’ products.

“Seeking in-market partners in Japan and to gain market access in Singapore, Korea and Taiwan are also part of our expanding export strategy. “Management is continuing to target export revenues to represent approximately 25% of total revenues within four years. On operational issues “smart investments to reduce costs and improve efficiencies with a capital expenditure guidance of $30 m across a range of efficiency and growth initiatives,” Mr Hand said. “These efficiency and cost saving improvements will continue through our ‘SIMPLIFY’ program. “Hatchery expansion and continued development of breeder and broiler farms will proceed into FY18 and we anticipate that FY 18 underlying EBITDA will be ahead of FY 17,” Mr Hand said.

NEWS

Applications open for 2018 Young Scientist competition Entering its 13th year, the Alltech Young Scientist (AYS) program is considered one of the world’s most prestigious agriscience competitions for university students. AYS has discovered some of the best and brightest upcoming researchers from universities around the world, and applications are now open for rising agri-scientists. Undergraduate and graduate applicants will compete first within their home regions of North America, Latin America, Asia-Pacific or Europe/Africa. Regional winners will be invited to attend an all-expensepaid Alltech Young Scientist Discovery Week in Lexington, Kentucky, where they will compete in the global competition during ONE: The Alltech Ideas Conference (ONE18), which will be held May 20–23, 2018. The prizes include a fully funded PhD position and $5,000 USD for the global undergraduate winner and a fully funded postdoctoral position and $10,000 USD for the global graduate winner. “Lifelong learning is a core value within Alltech and we are proud to invest in young, bright minds through our Alltech Young Scientist program,” said Dr Aoife Lyons, Director of Educational Initiatives and Engagement at Allteh. “It provides a global stage for students to present their research and have the opportunity to further their education and join the Alltech team.” Registration is currently open for the 2018 competition and will close on October 31, 2017. Students must be nominated by a professor in order to participate and may submit scientific papers on topics such as animal health and nutrition, crop science, agriculture analytical methods, food chain safety and traceability, human health and nutrition and other agriscience-related sectors. Paper submission may be completed online through December 31, 2017, and regional winners will be announced in March 2018. For more information and to register for the Alltech Young Scientist program, visit AlltechYoungScientist.com and stay connected through the Alltech Education Facebook page.

South Korea lifts ban South Korea has lifted its ban on poultry and egg imports from the United States. The ban had been in place since March, after highly pathogenic avian influenza was detected in a Tyson Foods broiler breeder flock in Tennessee. Two other cases of highly pathogenic avian influenza were reported in the state later in March. Additionally a temporary duty-free Tariff Rate Quota for eggs and egg products is also now in effect for up to 28,000 metric tons across nine categories of eggs and egg products, which can now be imported under duty free to the end of 2017. American Egg Board (AEB) President and CEO, Anne L. Alonzo, and USA Poultry & Egg Export Council (USAPEEC) President Jim Sumner, are pleased with the opening of the South Korean market.

®

Aviagen Management Essentials Judy Robberts Technical Service Manager, ANZ Judy graduated in animal and poultry science and has 11 years of experience with breeder and broiler production. Her most recent responsibility has been as a technical advisor for a poultry distributor company servicing Ross parents stock customers. “Bird uniformity and performance will be negatively affected if the feeder space provided for the broiler breeder is incorrect throughout the life of the flock”, commented Judy.

Provide Correct Feeder Space for Broiler Breeders Objective Follow recommendations to provide adequate feeder space at different stages in the life of the flock so that all birds can eat simultaneously. This provides uniform feed intake and prevents overcrowding at feeders. Key Points 1. 2. 3. 4. 5. 6. 7. 8. 9.

Use paper with plenty of feed in the first 1-3 days to give the chick sufficient feeding space to ensure a good, uniform start. Ensure there is correct feeder space for the number of birds in the house. Follow recommendations for feeder space according to the age of the flock. Too much or too little feeder space will negatively affect flock uniformity and biological performance. Track and pan feeders should be positioned a minimum of 1m apart to allow uniform and unobstructed access to the feeders. Feeder lines and litter in the house should be level and at the correct height to ensure all birds have uniform, unobstructed access to the feeders. Ensure feeders are stable. Feeder space and access will be affected if feeders move during feeding time. Monitor behavior during feeding as this is the most important time to assess if feeder space is correct and make the necessary adjustment for the age of the flock. Monitor feed clean up time on a daily basis. Feed clean up time of more than 3 hours may indicate a problem with feeding space. Feeder Space Female Age (days)

Male

Track Feeder (cm)

Pan Feeder (cm)

Track Feeder (cm)

Pan Feeder (cm) 5

0-35 days

5

4

5

36-70 days

10

8

10

9

71-105 days

15

10

15

11

106-140 days

15

10

15

11

141 days depletion

15

10

20

13

Table: Feeder Space Recommendations (Aviagen Parent Stock Handbook 2013). Photo 1: Uniform distribution of females Photo 2: Uniform distribution of males around a track feeder when adequate around a pan feeder when adequate feeder space is given. feeder space is given.

Aviagen and the Aviagen logo are registered trademarks of Aviagen in the US and other countries. All other trademarks or brands are registered by their respective owners. © 2017 Aviagen.

33

NEWS

Egg industry supporting the next generation Finding skilled applicants for a position, from research to administration to onfarm labour, is a challenge for everyone in the Australian egg industry. The egg industry has career paths which are highly technical, complex and innovative, providing an exciting opportunity to embrace university graduates to join the industry. Encouraging millennials to make their career in the egg industry can be a win for both the graduate and industry participants. There are an increasing number of programs available in the poultry industry which are helping to not only attract people to industry but are assisting the development or the capacity of those who have willingness to get involved. One program supported by Australian Eggs Limited is the Horizon Scholarship. The Horizon Scholarship is awarded to students in their first or second year of an agricultural related degree and who demonstrate a desire to have a career in agriculture. The scholarship provides financial assistance to the recipients, access to professional development workshops and two weeks of industry placement each year. One Horizon Scholar who is fast making her move on a career in the egg industry is Jasmine Whitten. Jasmine is currently a third-year Rural Science student at the University of New England, Armidale. Prior to being awarded the scholarship she had a background in beef cattle and limited knowledge about eggs. Jasmine has always had a desire to expand her views on what it means to work in Australian agriculture, and kept an open mind to where her career may take her. Over the last two years the egg industry has embraced Jasmine, providing her with the tools to proactively encourage other students to peruse diverse opportunities available to them in the sector. Jasmine said, “I honestly had limited exposure to poultry prior to university but after talking to many different people in the egg industry I soon realised that the skills I had developed in beef cattle could be transferrable to other sectors”. As a part of the Horizon Scholarship, Jasmine had to do two weeks of

34

Top: Horizon Scholar Jasmine Whitten with some free range hens and (above) gaining practical work experience at DE Hall & Co. work experience each year within the egg industry. However, Jasmine felt that two weeks weren’t enough so she has utilised the connections the Horizon Scholarship had given her to find some part time work for her final years of academic study. She now works part time with Greg Mills at GoAhead Business Solutions. During her holidays she continues to gain practical on-farm experience with DA Hall & Co. David May, CEO, DA Hall & Co said “Jasmine has brought a different perspective to the team and we have

found ways to utilise her knowledge and current skill set through a series of projects. “One project she has worked on is the development of a graduate program which is now open for applications. The program will begin at the start of next year.” The DA Hall Graduate Program will give university graduates the opportunity to gain practical skills across the business and will be tailored to meet the individual’s interest. It will run over a period of 24 months, encompassing six rotations of four-month placements in the areas of

w

MORE PROFIT FROM IMPROVED NUTRITION Lower your feed costs, improve uniformity and increase raw material flexibility, while reducing environmental impact with these innovative feed solutions. Used alone, or in combination, these reliable, heat stable enzyme and natural betaine products are customized to increase nutrient availability and improve profitability for poultry producers. Contact our distributor Feedworks, Australia. Tel: 03 5429 2411 Email: mal.mottram@feedworks.com.au david.cadogan@feedworks.com.au stuart.wilkinson@feedworks.com.au

Copyright© 2014 DuPont or its affiliates. All rights reserved. The DuPont Oval Logo, DuPont™ and all products denoted with ® or ™ are registered trademarks or trademarks of DuPont or its affiliates.

Danisco Animal Nutrition

35

NEWS v

nutrition, poultry, egg grading, veterinary support, sustainable farming and the supply chain. Each rotation will have the three key components of technical training, mentoring and support and practical experience. The graduate program was officially released on the University of New England Farming Futures Careers Fair on July 28. Applications for the 2018 intake are now open and close on the November 17, 2017. Jojo Jackson, Sustainability Program Manager at Australian Eggs said “The graduate program is incredibly exciting as it provides an entry point for graduates to enter the egg industry. Australian Eggs is currently investing significantly in capacity building programs to create linkages between future researchers, future farm managers, technical experts and farmers to help support the future research and capacity needs of the industry.” Jasmine believes that the egg industry is a fantastic career opportunity for both school leavers and university graduates. “It is an exciting time to be able

to enter the industry especially with demand for the product both domestically and internationally on the increase. Eggs provide an affordable protein source to households and given the price of red meat at the supermarket at the moment it is no surprise that Australian consumers on average are eating more than 200 eggs per year”. Jasmine enters her final year of University next year and will be conducting an honours project in the egg industry partnering with the CSIRO. The project will investigate the effect of different rearing environment on the behaviour of the pullets. Dana Campbell, Research Scientist at CSIRO said “Research is critical to solve industry issues and I find it really beneficial to involve young researchers in our projects”. A few years ago Jasmine Whitten was certain that she would end up working in the beef industry but if you ask her today it’s a very different story as a result of Australian Egg Limited supporting her through the Horizon Scholarship. This demonstrates how beneficial the capacity building programs can be

JoJo Jackson from Australian Eggs. if industry players step-up to take these students into the businesses to show them first-hand what’s exciting opportunities exist in the egg industry. For the future of the egg industry fostering the development of the next industry talent is incredibly important. If Jasmine’s story represents anything it is that a background in poultry isn’t essential to become captivated by the egg industry. However, it does show that it is possible to find the skill level we seek in employees.

Australian Made Poultry Winches

Certified to Australian Standards AS/NZS1418 Crane, Hoist & Winches

• Built-in easy-to-set limit switches • Robust direct drive gear box • Cable Winch rated to 800kg & 1200kg direct lift • Belt Winch rated to 400 kg direct lift

36

1800 GRIFCO grifco.com.au poultry@chamberlainanz.com

NEWS

Aviagen to acquire Hubbard Breeders Aviagen has signed an agreement to purchase Hubbard Breeders, the broiler genetics division of Groupe Grimaud. The agreement between the two companies was signed on July 31 and will be concluded later this year. As part of the agreement, Hubbard will operate as a wholly owned subsidiary of Aviagen Group, under the direction of Aviagen CEO Jan Henriksen. It will remain an independent broiler breeding company with separate breeding and commercial activities, and will continue to be headquartered in France. Recognising the business advantages “We welcome Hubbard into the Aviagen family,” said Mr Henriksen. “ Hubbard’s diversity of genetic products and in-depth expertise in the different segments of the broiler breeding market will greatly contribute to Aviagen’s expanding product line offerings. “We look forward to leveraging the full

strength of the Aviagen group to further enhance Hubbard’s position as an important player in the global broiler breeder market.” Hubbard CEO Olivier Rochard agrees that the close association with Aviagen will add great value to Hubbard`s global customer base. “My management team and I are delighted to become part of such a worldclass organization as Aviagen. “We are looking forward to utilising the strengths of both organizations, particularly in the areas of technology, R&D, production efficiencies and distribution capabilities,” he said. “We share with Aviagen the ultimate goal of continually advancing the genetic

potential of our birds and safeguarding the security of supply to global markets, which will profit our valued customers all around the world.” Providing customers a seamless transition and greater benefits “The two companies will continue to operate and support their customers independently, with no disruption to their customary products and services. “At the same time, customers will benefit from the combined best practices, experience and knowledge, as well as the strong dedication to customer success shared by both companies,” Mr Rochard concluded.