3 minute read

Technology

from 47 ROTECNA WORLD

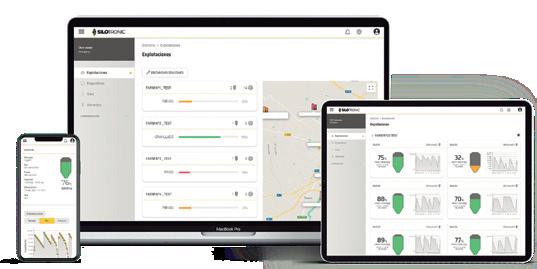

SILOTRONIC

Advertisement

Ensuring the availability of feed in silos, calculating the replenishment periods of silos and having up-to-date information on the levels that can be shared with the integrator or feed factory are factors that optimise supply logistics and represent significant time and cost savings for both parties, livestock and the feed supply company.

ACCURACY

To provide a solution to this need, Rotecna has the Silotronic, a sensor that uses laser technology to measure the level of feed inside silos very accurately. This allows the farmer to know, in real-time and from any device with an internet connection, the level of feed available on the premises.

The Silotronic can be installed in all types of storage systems: silos, tanks or hoppers in any shape, dimension and material. With a measuring range of up to 25 meters, the device is quickly and easily installed on top of the silo. In addition, it does not need cables or commissioning, as it is factory programmed.

RESOURCE OPTIMISATION

The installation of the Silotronic system represents a significant improvement in the control of feedstocks on farms, both for the farmer and the suppliers. In addition, resources are optimised in planning loads and distribution

WIRELESS REAL-TIME SILO CONTENT CONTROL SYSTEM

routes since it has a geolocation system that allows efficient management of procurement logistics. All this helps calculate the optimal way to supply the silos, thus reducing transport costs and avoiding the return of the excess product.

SILOTRONIC SOFTWARE

Access to the data can be done very quickly through Silotronic software, which means that, in addition to checking stocks in real-time, you can also access historical data on the evolution of silo content to detect possible anomalies in consumption, see replenishment periods and schedule low-level warning alarms.

The software is designed to be an easy to use and practical tool. Each user creates their profile to access all the information regarding their installations from any device connected to the Internet (computer or mobile).

HOW DOES IT WORK?

Through the Silotronic software, the user can visualise the status of all the sensors installed, control the history of readings, see the evolution of the state of the silos and modify parameters such as feed density.

Through a very intuitive colour-code, it shows the status of the silos. FEATURES

• Laser reading. • Avoids visual control from the top of the silo. • Long battery life. • Extensive coverage network. • Communication of readings to the data query platform by radiofrequency or Ethernet. • Access to the data platform through any device with an internet connection.

ADVANTAGES

• Real-time feed level monitoring. • Watertight system. • Read data every two hours (customisable). • Easy installation, no wiring and factory scheduled. • Significant savings in logistical costs. • Increases job security. • Virtually maintenance-free.

Technology

READER AND SMARTPHONE DOSITRONIC

With the desire to improve the daily work of farmers and animal welfare, Rotecna has redesigned the dositronic e-feed system’s chip reading and communication system, incorporating a new reader and smartphone that complement the range of this product family.

With the new reader, you can perform RFID chip readings on the bristle crotals at a greater distance, without disturbing the animal; simultaneously, the farmer’s safety is guaranteed, and it is possible to maintain permanent user communication with the dositronic’s central software.

On the other hand, the new smartphone offers immediate access to the data and allows you to make queries and make changes to the software from the same farrowing room or gestation areas.

FEATURES

• Connection to the server via wifi. • Read HDX and FDX transponders. • Device is suitable for working in corrosive environments and is impact-resistant.

ADVANTAGES

• Allows a greater reading distance, which reduces the stress of the bristles. • Offers more excellent safety for the operator, as the reading of the crotal can be carried out without the need to insert the hand into the cage. • The reader has enough autonomy for the whole day.