SUMMARY TABLE

SIMPLE JOINT

SIMPLE JOINT

SIMPLE JOINT

SIMPLE JOINT

FIRE RESISTANCE OF CLT JOINTS | TEST REPORT | 5

GAP 2

mm

GAP 2

mm

GAP 2 mm

GAP 10 mm

1ST SEALING LEVEL (top) 2ND SEALING LEVEL (bottom) FIRE FOAM Joint 16 page 21 1ST SEALING LEVEL (top) 2ND SEALING LEVEL (bottom) FIRE SEALING SILICONE Joint 2 page 7 FIRE SEALING ACRYLIC Joint 3 page 8 FIRE STRIPE GRAPHITE Joint 4 page 9 FLEXI BAND Joint 1 page 6 EXPAND BAND EXPAND BAND Joint 8 page 13 FLEXI BAND FIRE SEALING SILICONE Joint 5 page 10 FLEXI BAND FIRE STRIPE GRAPHITE Joint 6 page 11 EXPAND BAND FIRE STRIPE GRAPHITE Joint 13 page 18 CONSTRUCTION SEALING CONSTRUCTION SEALING Joint 11 page 16 CONSTRUCTION SEALING FIRE STRIPE GRAPHITE Joint 12 page 17 1ST SEALING LEVEL (top) 2ND SEALING LEVEL (bottom) EXPAND BAND EXPAND BAND Joint 9 page 14 FLEXI BAND FIRE STRIPE GRAPHITE Joint 14 page 19 1ST SEALING LEVEL (top) 2ND SEALING LEVEL (bottom) EXPAND BAND EXPAND BAND Joint 7 page 12 FLEXI BAND FIRE STRIPE GRAPHITE Joint 10 page 15 FIRE SEALING SILICONE Joint 15 page 20

JOINT NO. 1 - TesT repOrT

SIMPLE JOINT WITH CROSSED SCREWS VGZ9220, 2 mm GAP AND FLEXI BAND

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 440 460 480 500 520 540 560 580 600 620 640 660 680 700 720 740 760 780 800 820 840 860 880 900 10 20 30 40 50 60 70 80 90 100 TC 55 TC 56 TC 57 TC 58 TC 59 TC 60 TC 61 TC 62 45° FLEXI BAND GIUNTO 1 40 40 40 40 40 GAP = 2 mm 200 6 | TEST REPORT | FIRE RESISTANCE OF CLT JOINTS Reference standard: UNI EN 1363-1:2020 Temperature [°C] Time [min] TOP SEALANT FLEXI BAND Description

Material

BOTTOM SEALANT - -

Universal single-sided high-adhesive tape

PE film/glue/reinforcing polyester grid/silicone coated paper

ΔT measured at the test end (after 160 minutes) Thermocouple [TC no.] Temperature 60 mm from slab bottom (non-exposed face) TC 55 785°C 140 mm from slab bottom TC 56 72°C on the unexposed face of the slab TC 60 75°C

Time Cotton swab > 102 min

TIGHTNESS

6-mm gauge 25-mm gauge

Thermocouple [TC no.] Time n.a > 102 min

FLEXI BAND

Persistent flame INSULATION

PERFORMANCE CRITERIA

JOINT NO. 2 - TesT repOrT

SIMPLE JOINT WITH CROSSED SCREWS VGZ9220, 2mm GAP AND FIRE SEALING SILICONE (EXPANDED ON PANEL SIDE)

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 440 460 480 500 520 540 560 580 600 620 640 660 680 700 720 740 760 780 800 820 840 860 880 900 TC 81 TC 82 TC 83 TC 84 TC 85 TC 86 TC 87 TC 88 10 20 30 40 50 60 70 80 90 100 45° 40 40 40 40 40 200 GIUNTO 2 GAP = 2 mm FIRE SEALING ACRYLIC FIRE SEALING SILICONE FIRE RESISTANCE OF CLT JOINTS | TEST REPORT | 7 TOP SEALANT -BOTTOM SEALANT FIRE SEALING SILICONE Description High fire-resistant acrylic sealant Material Silicone

ΔT measured at the test end (after 160 minutes) Thermocouple [TC no.] Temperature 60 mm from slab bottom (non-exposed face) TC 81 702°C 140 mm from slab bottom TC 82 6°C on the unexposed face of the slab TC 85 29°C TIGHTNESS Time Cotton swab > 102 min 6-mm gauge 25-mm gauge

flame INSULATION Thermocouple [TC no.] Time n.a > 102 min

Temperature [°C] Time [min] Reference standard: UNI EN 1363-1:2020

Persistent

PERFORMANCE CRITERIA

JOINT NO. 3 - TesT repOrT

SIMPLE JOINT WITH CROSSED SCREWS VGZ9220, 2 mm GAP AND FIRE SEALING ACRYLIC (EXPANDED ON PANEL SIDE)

TOP SEALANT - -

BOTTOM SEALANT FIRE SEALING ACRYLIC

sealant

PERFORMANCE

CRITERIA

Persistent flame

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 440 460 480 500 520 540 560 580 600 620 640 660 680 700 720 740 760 780 800 820 840 860 880 900 TC 89 TC 90 TC 91 TC 92 TC 93 TC 94 TC 95 TC 96 10 20 30 40 50 60 70 80 90 100 FIRE SEALING ACRYLIC 45° 40 40 40 40 40 200 GIUNTO 3 GAP = 2 mm FIRE SEALING ACRYLIC 8 | TEST REPORT | FIRE RESISTANCE OF CLT JOINTS Reference standard: UNI EN 1363-1:2020 Temperature [°C] Time [min] ΔT measured at the test end (after 160 minutes) Thermocouple [TC no.] Temperature 60 mm from slab bottom (non-exposed face) TC 90 727°C 140 mm from slab bottom TC 89 124°C on the unexposed face of the slab TC 93 38°C TIGHTNESS Time

> 102 min

Cotton swab

6-mm gauge 25-mm gauge

Time n.a > 102 min

Description High fire-resistant acrylic

Material Acrylic polymers in aqueous dispersion INSULATION Thermocouple [TC no.]

SIMPLE JOINT WITH VGZ9220 CROSSED SCREWS, 2 mm GAP AND FIRE STRIPE GRAPHITE

10 20 30 40 50 60 70 80 90 100 0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 440 460 480 500 520 540 560 580 600 620 640 660 680 700 720 740 760 780 800 820 840 860 880 900 TC 97 TC 98 TC 99 TC 100 TC 101 TC 102 TC 103 TC 104 FIRE STRIPE GRAPHITE 45° 40 40 40 40 40 200 GIUNTO 16 GIUNTO 4 GAP = 2 mm FIRE STRIPE GRAPHITE FIRE RESISTANCE OF CLT JOINTS | TEST REPORT | 9 Reference standard: UNI EN 1363-1:2020

NO. 4 - TesT repOrT

SEALANT

Material

ΔT measured at the test end (after 160 minutes) Thermocouple [TC no.] Temperature 60 mm from slab bottom (non-exposed face) TC 97 858°C 140 mm from slab bottom TC 98 245°C on the unexposed face of the slab TC 99 67°C

Time Cotton swab > 102 min

Thermocouple [TC no.] Time n.a > 102 min Temperature [°C] Time [min]

JOINT

TOP

-BOTTOM SEALANT FIRE STRIPE GRAPHITE Description Flexible intumescent gasket

Graphite

TIGHTNESS

6-mm gauge 25-mm gauge Persistent flame INSULATION

PERFORMANCE CRITERIA

JOINT NO. 5 - TesT repOrT

SIMPLE JOINT WITH VGZ9220 CROSSED SCREWS, 2 mm GAP, FIRE SEALING SILICONE (APPLIED ON THE SIDE OF THE PANEL) AND FLEXI BAND

TC 01 TC 02 TC 03 TC 04 TC 05 TC 06 TC 07 TC 08 0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 440 460 480 500 520 540 560 580 600 620 640 660 680 700 720 740 760 780 800 820 840 860 880 900 920 940 960 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 FLEXI BAND FIRE SEALING SILICONE 10 | TEST REPORT | FIRE RESISTANCE OF CLT JOINTS PERFORMANCE CRITERIA TOP SEALANT FLEXI

Description

single-sided

Material

BOTTOM SEALANT FIRE SEALING SILICONE Description High fire-resistant silicone sealant Material Silicone ΔT measured at the test end (after 160 minutes) Thermocouple [TC no.] Temperature 60 mm from slab bottom (non-exposed face) TC 1 873°C 140 mm from slab bottom TC 2 86°C on the unexposed face of the slab TC 3 15°C TIGHTNESS Time Cotton swab > 161 min 6-mm gauge 25-mm gauge Persistent flame Reference standard: UNI EN 1363-1:2020 Temperature [°C]

BAND

Universal

high-adhesive tape

PE film/glue/reinforcing polyester grid/silicone coated paper

INSULATION Thermocouple [TC no.] Time n.a > 161 min 45° FLEXI BAND 40 40 40 40 40 200 GIUNTO 5 GAP = 2 mm FIRE SEALING ACRYLIC

TC 09 TC 10 TC 11 TC 12 TC 13 TC 14 TC 15 TC 16 0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 440 460 480 500 520 540 560 580 600 620 640 660 680 700 720 740 760 780 800 820 840 860 880 900 920 940 960 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 FLEXI BAND FIRE STRIPE GRAPHITE FIRE RESISTANCE OF CLT JOINTS | TEST REPORT | 11 JOINT NO. 6 - TesT repOrT SIMPLE JOINT

VGZ9220 CROSSED SCREWS,

FIRE

GRAPHITE

FLEXI BAND Temperature [°C] Time [min] TOP SEALANT FLEXI BAND

Material

SEALANT FIRE

Material

Reference standard: UNI EN 1363-1:2020 ΔT measured at the test end (after 160 minutes) Thermocouple [TC no.] Temperature 60 mm from slab bottom (non-exposed face) TC 9 886°C 140 mm from slab bottom TC 10 93°C on the unexposed face of the slab TC 13 33°C TIGHTNESS Time Cotton swab > 161 min 6-mm

25-mm

INSULATION Thermocouple [TC no.] Time n.a > 161 min PERFORMANCE CRITERIA 45° FLEXI BAND 40 40 40 40 40 200 GIUNTO 6 GAP = 2 mm FIRE STRIPE GRAPHITE

WITH

2 mm GAP AND

STRIPE

AND

Description Universal single-sided high-adhesive tape

PE film/glue/reinforcing polyester grid/silicone coated paper BOTTOM

STRIPE GRAPHITE Description Flexible intumescent gasket

Graphite

gauge

gauge Persistent flame

JOINT NO. 7 - TesT repOrT

JOINT WITH COVER PLATE AND PARTIAL THREAD SCREWS HBS6120, 2 mm GAP AND EXPAND BAND

TOP SEALANT EXPAND BAND

Description Self-expanding sealing tape

Material Elastic polyurethane foam with additives/silicone paper release liner

BOTTOM SEALANT without sealant

PERFORMANCE CRITERIA

TC 17 TC 18 TC 19 TC 20 TC 21 TC 22 TC 23 TC 24 TC 25 TC 26 TC 27 0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 440 460 480 500 520 540 560 580 600 620 640 660 680 700 720 740 760 780 800 820 840 860 880 900 920 940 960 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 EXPAND BAND 12 | TEST REPORT | FIRE RESISTANCE OF CLT JOINTS Temperature [°C] Time [min] Reference standard: UNI EN 1363-1:2020 ΔT measured at the test end (after 160 minutes) Thermocouple [TC no.] Temperature 60 mm from slab bottom (non-exposed face) TC 17 907°C 140 mm from slab bottom TC 18 90°C on the unexposed face of the slab TC 23 24°C TIGHTNESS Time Cotton swab > 161 min 6-mm gauge 25-mm

Persistent

INSULATION Thermocouple [TC no.] Time n.a > 161 min

gauge

flame

27 150 80 200

7 GAP = 2 mm EXPAND BAND 40 40 40 40 40

GIUNTO

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 440 460 480 500 520 540 560 580 600 620 640 660 680 700 720 740 760 780 800 820 840 860 880 900 920 940 960 TC 28 TC 29 TC 30 TC 31 TC 32 TC 33 TC 34 TC 35 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 EXPAND BAND FIRE RESISTANCE OF CLT JOINTS | TEST REPORT | 13

CROSSED

Temperature [°C] Time [min] TOP SEALANT EXPAND BAND Description Self-expanding sealing tape Material

polyurethane foam with additives/silicone paper release

BOTTOM SEALANT EXPAND BAND Description

Material

additives/silicone

Reference standard: UNI EN 1363-1:2020 ΔT measured at the test end (after 160 minutes) Thermocouple [TC no.] Temperature 60 mm from slab bottom (non-exposed face) TC 28 921°C 140 mm from slab bottom TC 29 83°C on the unexposed face of the slab TC 31 42°C TIGHTNESS Time

swab > 161 min

gauge

gauge

INSULATION Thermocouple [TC no.] Time n.a > 161 min PERFORMANCE

GIUNTO 8 GAP = 2 mm 45° EXPAND BAND 200 EXPAND BAND 40 40 40 40 40

JOINT NO. 8 - TesT repOrT SIMPLE JOINT WITH

SCREWS VGZ9220, 2 mm GAP AND EXPAND BAND

Elastic

liner

Self-expanding sealing tape

Elastic polyurethane foam with

paper release liner

Cotton

6-mm

25-mm

Persistent flame

CRITERIA

PERFORMANCE CRITERIA

TC 36 TC 37 TC 38 TC 39 TC 40 TC 41 TC 42 TC 43 0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 440 460 480 500 520 540 560 580 600 620 640 660 680 700 720 740 760 780 800 820 840 860 880 900 920 940 960 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 EXPAND BAND 14 | TEST REPORT | FIRE RESISTANCE OF CLT JOINTS

TOP SEALANT EXPAND BAND Description Self-expanding sealing tape Material Elastic polyurethane foam with additives/silicone paper release liner BOTTOM SEALANT EXPAND BAND Description Self-expanding sealing tape Material

polyurethane foam with additives/silicone paper release liner ΔT measured at the test end (after 160 minutes) Thermocouple [TC no.] Temperature 60 mm from slab bottom (non-exposed face) TC 36 863°C 140 mm from slab bottom TC 37 774°C on the unexposed face of the slab TC 40 199°C TIGHTNESS Time Cotton swab > 161 min

INSULATION Thermocouple [TC no.] Time TC 40 > 161 min

Temperature [°C] Time [min] Reference standard: UNI EN 1363-1:2020 GIUNTO 9 GAP = 2 mm EXPAND BAND 200 80 120 EXPAND BAND 40 40 40 40 40

JOINT NO. 9 - TesT repOrT HALF-LAP JOINT WITH PARTIAL THREAD SCREWS HBS8160, 2 mm GAP AND EXPAND BAND

Elastic

6-mm gauge 25-mm gauge Persistent flame

JOINT NO. 10 - TesT repOrT

JOINT WITH COVER PLATE AND PARTIAL THREAD SCREWS HBS6120, 2 mm GAP, FIRE STRIPE

ITE AND FLEXI BAND

TC 44 TC 45 TC 46 TC 47 TC 48 TC 49 TC 50 TC 51 0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 440 460 480 500 520 540 560 580 600 620 640 660 680 700 720 740 760 780 800 820 840 860 880 900 920 940 960 TC 52 TC 53 TC 54 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 FLEXI BAND FIRE STRIPE GRAPHITE FIRE RESISTANCE OF CLT JOINTS | TEST REPORT | 15 TOP SEALANT FLEXI BAND Description Universal single-sided high-adhesive

Material PE

BOTTOM SEALANT FIRE STRIPE GRAPHITE Description Flexible intumescent gasket Material Graphite

tape

film/glue/reinforcing polyester grid/silicone coated paper

GRAPH-

Temperature [°C] Time [min] Reference standard: UNI EN 1363-1:2020 ΔT measured at the test end (after 160 minutes) Thermocouple [TC no.] Temperature 60 mm from slab bottom (non-exposed face) TC 44 916°C 140 mm from slab bottom TC 45 208°C on the unexposed face of the slab TC 50 19°C TIGHTNESS Time Cotton swab > 161 min 6-mm gauge 25-mm gauge Persistent flame INSULATION Thermocouple [TC no.] Time n.a > 161 min PERFORMANCE CRITERIA 27 150 200 FIRE STRIPE GRAPHITE FLEXI BAND GIUNTO 10 GAP = 2 mm 80 40 40 40 40 40

JOINT NO. 11 - TesT repOrT

SIMPLE JOINT WITH CROSSED SCREWS VGZ9220, 2 mm GAP AND CONSTRUCTION SEALING

TOP SEALANT CONSTRUCTION SEALING

Description Compressible sealing gasket for regular joints

Material Expanded EPDM

BOTTOM SEALANT

CONSTRUCTION SEALING

Description Compressible sealing gasket for regular joints Material Expanded EPDM

TC 55 TC 56 TC 57 TC 58 TC 59 TC 60 TC 61 TC 62 0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 440 460 480 500 520 540 560 580 600 620 640 660 680 700 720 740 760 780 800 820 840 860 880 900 920 940 960 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 CONSTRUCTION SEALING 16 | TEST REPORT | FIRE RESISTANCE OF CLT JOINTS Reference standard: UNI EN 1363-1:2020 ΔT measured at the test end (after 160 minutes) Thermocouple [TC no.] Temperature 60 mm from slab bottom (non-exposed face) TC 55 899°C 140 mm from slab bottom TC 56 87°C on the unexposed face of the slab TC 59 12°C TIGHTNESS Time Cotton swab > 161 min 6-mm gauge 25-mm gauge Persistent flame INSULATION Thermocouple [TC no.] Time TC 40 > 161 min PERFORMANCE CRITERIA Temperature [°C] Time [min]

11 GAP = 2 mm CONSTRUCTION SEALING 45° 200 CONSTRUCTION SEALING 40 40 40 40 40

GIUNTO

TC 65 TC 66 TC 67 TC 68 TC 69 TC 70 TC 71 TC 72 0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 440 460 480 500 520 540 560 580 600 620 640 660 680 700 720 740 760 780 800 820 840 860 880 900 920 940 960 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 CONSTRUCTION SEALING FIRE STRIPE GRAPHITE FIRE RESISTANCE OF CLT JOINTS | TEST REPORT | 17 JOINT NO. 12 - TesT repOrT VGZ9220 SIMPLE JOINT

CROSSED

CONSTRUCTION SEALING

FIRE STRIPE GRAPHITE Temperature [°C] Time [min] TOP SEALANT CONSTRUCTION SEALING Description Compressible sealing gasket for regular joints Material Expanded EPDM

SEALANT FIRE

GRAPHITE Description Flexible intumescent gasket Material Graphite Reference standard: UNI EN 1363-1:2020 ΔT measured at the test end (after 160 minutes) Thermocouple [TC no.] Temperature 60 mm from slab bottom (non-exposed face) TC 65 895°C 140 mm from slab bottom TC 66 263°C on the unexposed face of the slab TC 69 11°C TIGHTNESS Time Cotton swab > 161 min

gauge 25-mm gauge

flame INSULATION Thermocouple [TC no.] Time n.a > 161 min

GIUNTO 12 GAP = 2 mm 45° 200 CONSTRUCTION SEALING FIRE STRIPE GRAPHITE 40 40 40 40 40

WITH

SCREWS, 2 mm GAP,

AND

BOTTOM

STRIPE

6-mm

Persistent

PERFORMANCE CRITERIA

JOINT NO. 13 - TesT repOrT

SIMPLE JOINT WITH CROSSED SCREWS VGZ9220, 2 mm GAP, EXPAND BAND AND FIRE STRIPE GRAPHITE

Material Elastic polyurethane foam with additives/silicone paper release liner

BOTTOM SEALANT FIRE STRIPE GRAPHITE

Flexible intumescent gasket

PERFORMANCE CRITERIA

TC 73 TC 74 TC 75 TC 76 TC 77 TC 78 TC 79 TC 80 0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 440 460 480 500 520 540 560 580 600 620 640 660 680 700 720 740 760 780 800 820 840 860 880 900 920 940 960 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 FIRE STRIPE GRAPHITE EXPAND BAND 18 | TEST REPORT | FIRE RESISTANCE OF CLT JOINTS Temperature [°C] Time [min]

TOP SEALANT EXPAND BAND Description Self-expanding sealing tape

Description

Material

Reference standard: UNI EN 1363-1:2020 ΔT measured at the test end (after 160 minutes) Thermocouple [TC no.] Temperature 60 mm from slab bottom (non-exposed face) TC 73 912°C 140 mm from slab bottom TC 74 452°C on the unexposed face of the slab TC 75 11°C TIGHTNESS Time Cotton swab > 161 min 6-mm

25-mm

INSULATION

ple

no.] Time n.a. > 161 min

Graphite

gauge

gauge Persistent flame

Thermocou-

[TC

45° 200 GIUNTO 13 GAP = 2 mm EXPAND BAND FIRE STRIPE GRAPHITE 40 40 40 40 40

TOP SEALANT FLEXI BAND

Description Universal single-sided high-adhesive tape

PE film/glue/reinforcing polyester grid/silicone coated paper

BOTTOM SEALANT FIRE STRIPE GRAPHITE

TC 81 TC 82 TC 83 TC 84 TC 85 TC 86 TC 87 TC 88 0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 440 460 480 500 520 540 560 580 600 620 640 660 680 700 720 740 760 780 800 820 840 860 880 900 920 940 960 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 FLEXI BAND FIRE STRIPE GRAPHITE FIRE RESISTANCE OF CLT JOINTS | TEST REPORT | 19 JOINT NO. 14 - TesT repOrT HALF-LAP JOINT WITH PARTIAL THREAD SCREWS HBS8160, 2 mm GAP, FLEXI BAND AND FIRE STRIPE GRAPHITE Temperature [°C] Time [min] Reference standard: UNI EN 1363-1:2020 ΔT measured at the test end (after 160 minutes) Thermocouple [TC no.] Temperature 60 mm from slab bottom (non-exposed face) TC 81 848°C 140 mm from slab bottom TC 82 89°C on the unexposed face of the slab TC 83-86 25°C TIGHTNESS Time Cotton swab > 161 min 6-mm gauge 25-mm gauge Persistent flame INSULATION Thermocouple [TC no.] Time n.a > 161 min PERFORMANCE

CRITERIA

Material

Description Flexible intumescent

Material Graphite GIUNTO 14 GAP = 2 mm 200 80 120 FLEXI BAND 40 40 40 40 40 FIRE STRIPE GRAPHITE

gasket

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 440 460 480 500 520 540 560 580 600 620 640 660 680 700 720 740 760 780 800 820 840 860 880 900 920 940 960 TC 89 TC 90 TC 91 TC 92 TC 93 TC 94 TC 95 TC 96 TC 97 TC 98 TC 99 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 FIRE SEALING SILICONE 20 | TEST REPORT | FIRE RESISTANCE OF CLT JOINTS JOINT NO. 15 - TesT repOrT JOINT WITH COVER PLATE AND PARTIAL THREAD SCREWS HBS6120, 2 mm GAP AND FIRE SEALING SILICONE Temperature [°C] Time [min] TOP SEALANT FIRE SEALING SILICONE Description High fire-resistant silicone sealant Material Silicone BOTTOM SEALANT without sealant Reference standard: UNI EN 1363-1:2020 ΔT measured at the test end (after 160 minutes) Thermocouple [TC no.] Temperature 60 mm from slab bottom (non-exposed face) TC 89 870°C 140 mm from slab bottom TC 90 86°C on the unexposed face of the slab TC 95 8°C TIGHTNESS Time Cotton swab > 161 min 6-mm gauge 25-mm gauge

flame INSULATION Thermocouple [TC no.] Time n.a. > 161 min PERFORMANCE CRITERIA GAP = 2 mm 27 150 80 40 40 40 40 40 200 FIRE SEALING SILICONE

Persistent

GIUNTO 15

GIUNTO 4

SIMPLE JOINT WITH CROSSED SCREWS VGZ9220, 10 mm GAP AND FIRE FOAM

TOP SEALANT FIRE FOAM

Description High fire-resistant sealing foam

Material Single component PU

BOTTOM SEALANT FIRE FOAM

Description High fire-resistant sealing foam Material Single component PU

GIUNTO 16

PERFORMANCE CRITERIA

TC 81 TC 82 TC 83 TC 84 TC 85 TC 86 TC 87 TC 88 0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 440 460 480 500 520 540 560 580 600 620 640 660 680 700 720 740 760 780 800 820 840 860 880 900 920 940 960 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 FIRE FOAM FIRE RESISTANCE OF CLT JOINTS | TEST REPORT | 21 Temperature [°C] Time [min] Reference standard: UNI EN 1363-1:2020 ΔT measured at the test end (after 160 minutes) Thermocouple [TC no.] Temperature 60 mm from slab bottom (non-exposed face) TC 100 864°C 140 mm from slab bottom TC 101 90°C on the unexposed face of the slab TC 104 8°C TIGHTNESS Time

swab > 161 min

Cotton

6-mm gauge 25-mm gauge

INSULATION Thermocouple [TC no.] Time n.a > 161 min

Persistent flame

JOINT NO. 16 - TesT repOrT

45° 40 40 40 40 40 200 FIRE FOAM

GAP = 10 mm

If well protected, timber lasts forever.

It adheres perfectly and protects timber against weathering, UV radiation and the spread of flames with a fire rating of B-s1,d0.

Protect your construction, discover TRASPIR EVO UV ADHESIVE 250 "

B-s1,d0

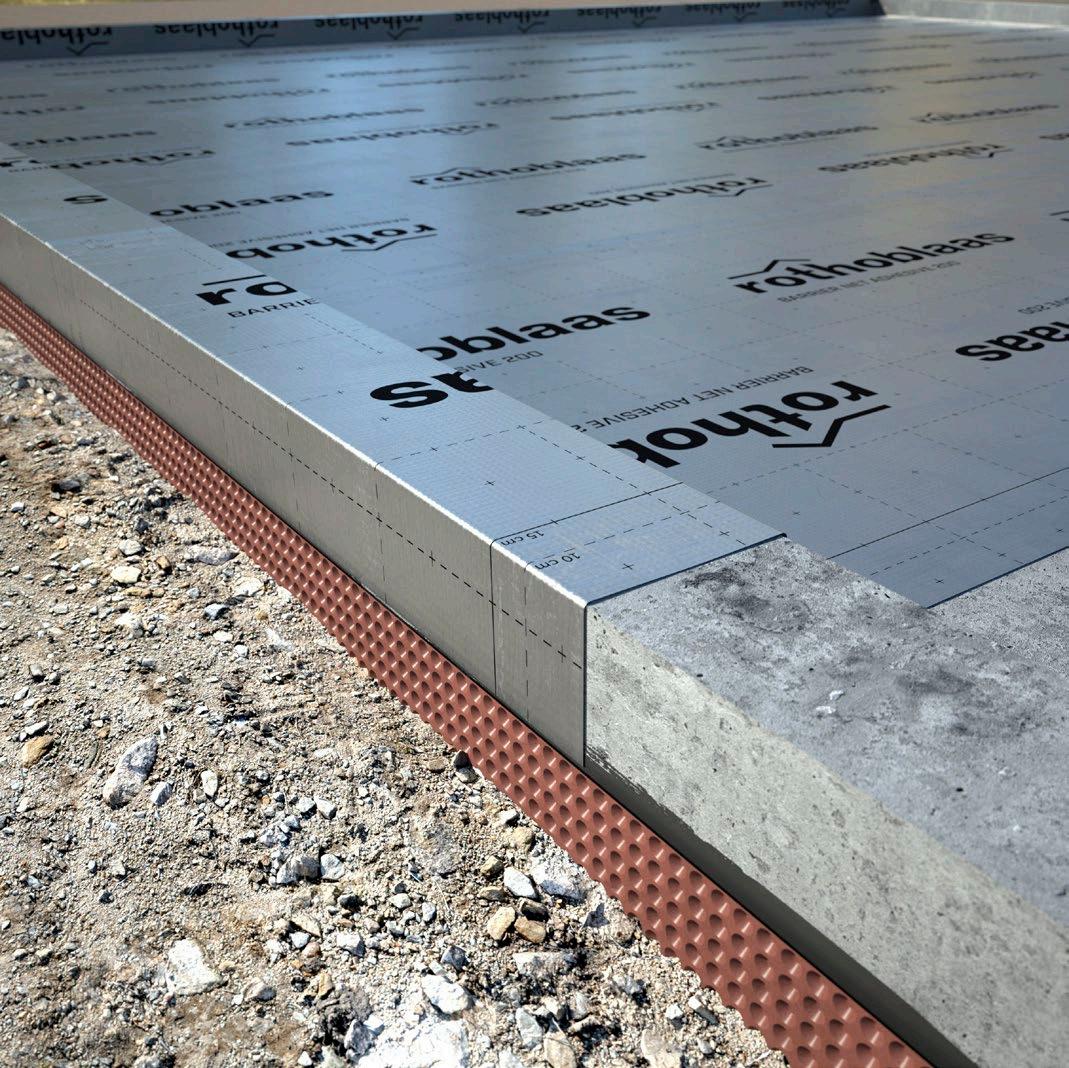

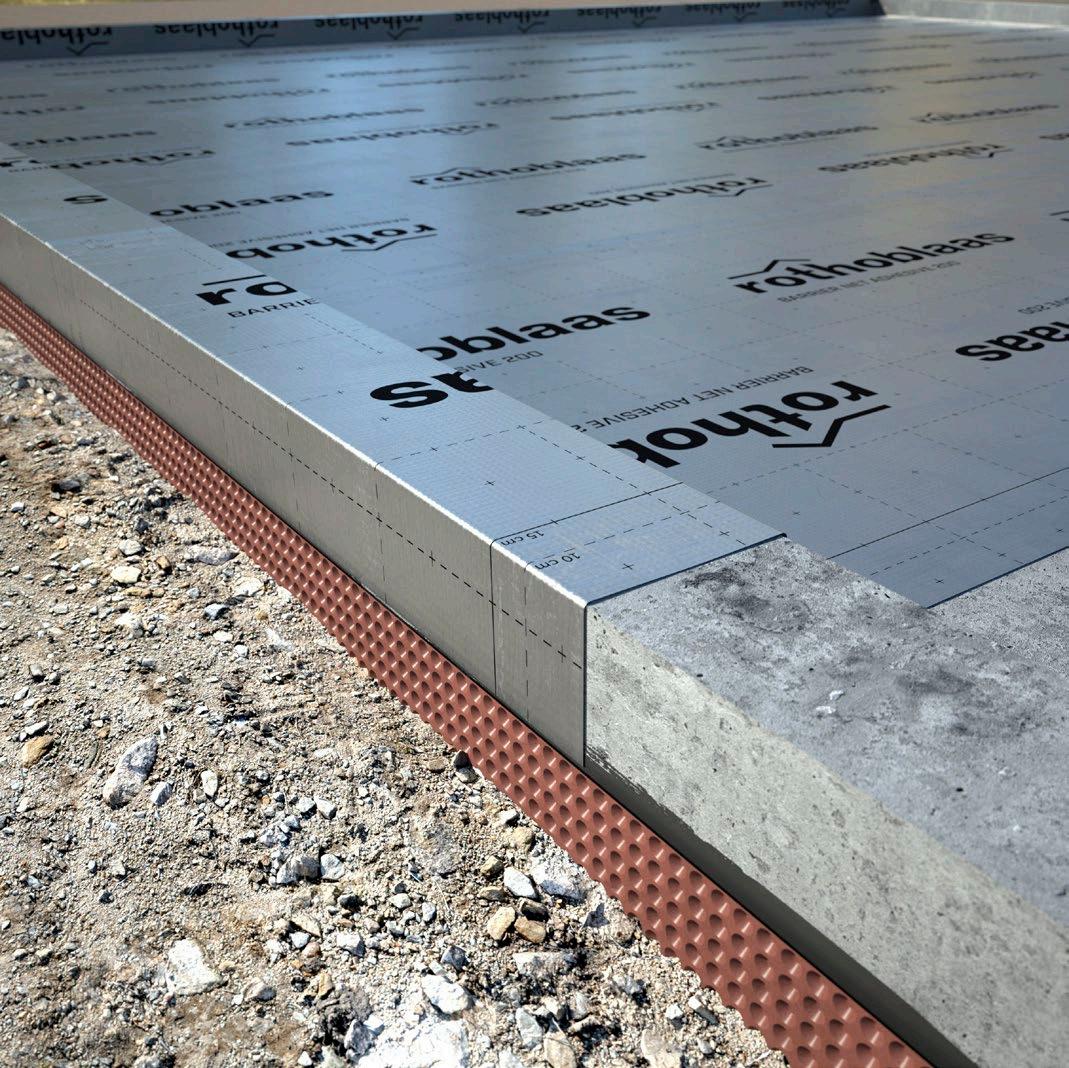

The secure foundation of comfort and health.

It adheres perfectly to the substrate and protects structures from the passage of moisture and radon gas. It reflects heat and improves thermal performance, with a fire rating of B-s1,d0

Protect your construction, discover BARRIER ALU NET ADHESIVE 300 "

B-s1,d0

Rotho Blaas Srl

Via dell‘Adige N.2/1 | 39040, Cortaccia (BZ) | Italia

Tel: +39 0471 81 84 00 | Fax: +39 0471 81 84 84 info@rothoblaas.com | www.rothoblaas.com