Story & Photos By Wes Taylor

Story & Photos By Wes Taylor

The Nissan R35 GTR surfaced in 2009, shedding new light on the performance car world.

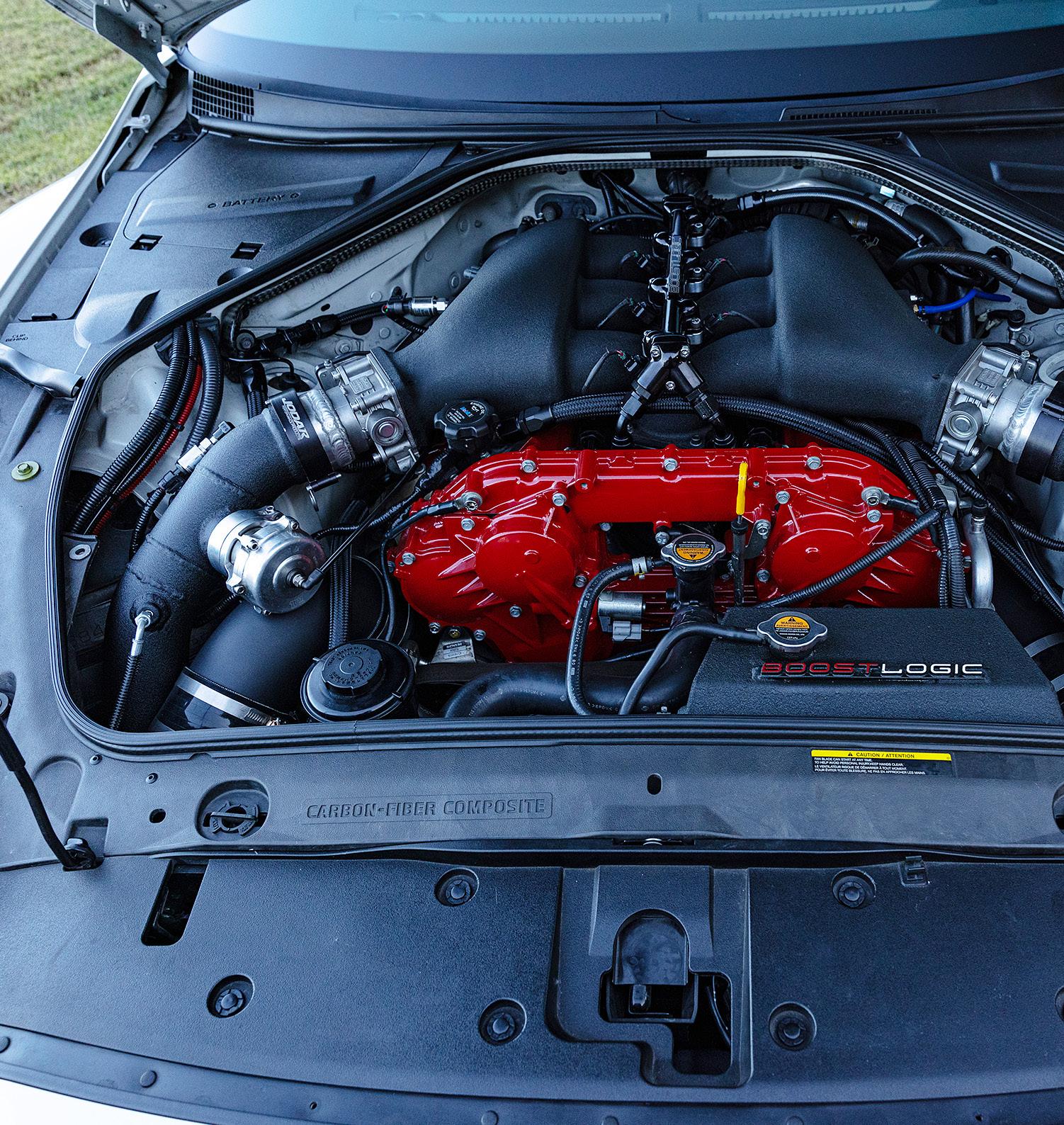

Sporting a paddle-shifted dual-clutch transmission, all-wheel drive, and a twin-turbo V-6 engine for quick responsiveness, they quickly became terrors of the street, and it didn’t take long for the aftermarket and drag racing sector to catch on to this unique platform.

Gene Wilson comes from a long line of muscle car enthusiasts. “The first time I got to ride in something fast, my father took me down the road in his ’67 427/435hp 4-speed Corvette. It made such an impression on me, from that day forward my thoughts were consumed with engines and cars,” he explained. As a teen, Gene worked at a grocery store where he saved all the money he could to buy go-fast parts for his 1987 Mustang street machine that he eventually built into an Outlaw 10.5 car with a 408 twin carb small block, Powerglide and nitrous. It was the early ’90s, and the Fox Body experience gave Wilson a bunch of seat time and introduced him to

Evenwiththeparachutehangin’off theback,whowouldeverthinkthat thisalmoststocklookingNissanwould bepackin2000ponies?

many like-mined friends, such as Tim Lynch, who he would race with in Outlaw 10.5 and years later would become instrumental in the GTR build.

From a very young age, Gene’s dream was to drive at a professional level such as Pro Mod or Pro Stock. He eventually took a job at his friend Keith Swafford’s machine shop where he learned the trade of engine machining and assembly, which definitely opened some doors towards his goals.

“Working with Keith gave me a good general knowledge that allowed me to start building my own engines after our workday was complete,” Wilson explained.

And soon, by 1995, his dream to compete at higher level would become reality when he stuffed a 604-incher into a Mustang to hit local Pro Mod races. “It gave me an understanding of how to set up and adjust a clutch and also how driving a Lenco equipped car feels. It was trial and error for a long time, more error than anything actually, but we learned, and the only guy at the races with me was Keith.”

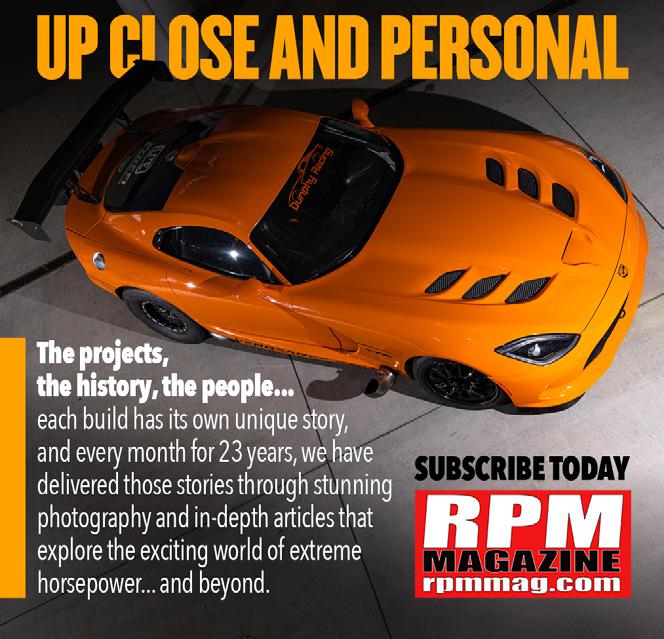

The exterior body panels, trim and paint are completely factory, the only addition is the rear wing.

The exterior body panels, trim and paint are completely factory, the only addition is the rear wing.

1998 would see Gene’s first Pro Stock event with Keith, and after getting their feet wet, and getting tired of not qualifying, they got their hands on a Jon Kasse-built Ford 815ci for the following season. “After that we qualified for almost all of the races and finished 9th in Pro Stock points in 1999,” he said. And then Wilson’s Pro Stock career really blossomed – in 2000 shoeing for Charlie Hunt, they finished 6th, and in 2001 won 8 of 11 races in a new Cougar and also took the IHRA Championship. But he wasn’t done there. In 2002 he was asked to drive with Mopar on their two-car NHRA Pro Stock team and also won NHRA Rookie Of The Year.

Following his Pro Stock success, Wilson went on to build a turbo Mustang and a Focus and dabbled in a Pro Stock seat from time to time. For the next decade, however, he moved into racing motocross, that is until Tim Lynch took him for a spin in his 1,600HP GTR, and from there he was immediately hooked!

15-inch rear mixed with 18inch front wheels give the car a unique look and also provide better hook than the previous 20-inch all around combination. Both front and rear are wrapped in Mickey Thompson street legal sticky radials.

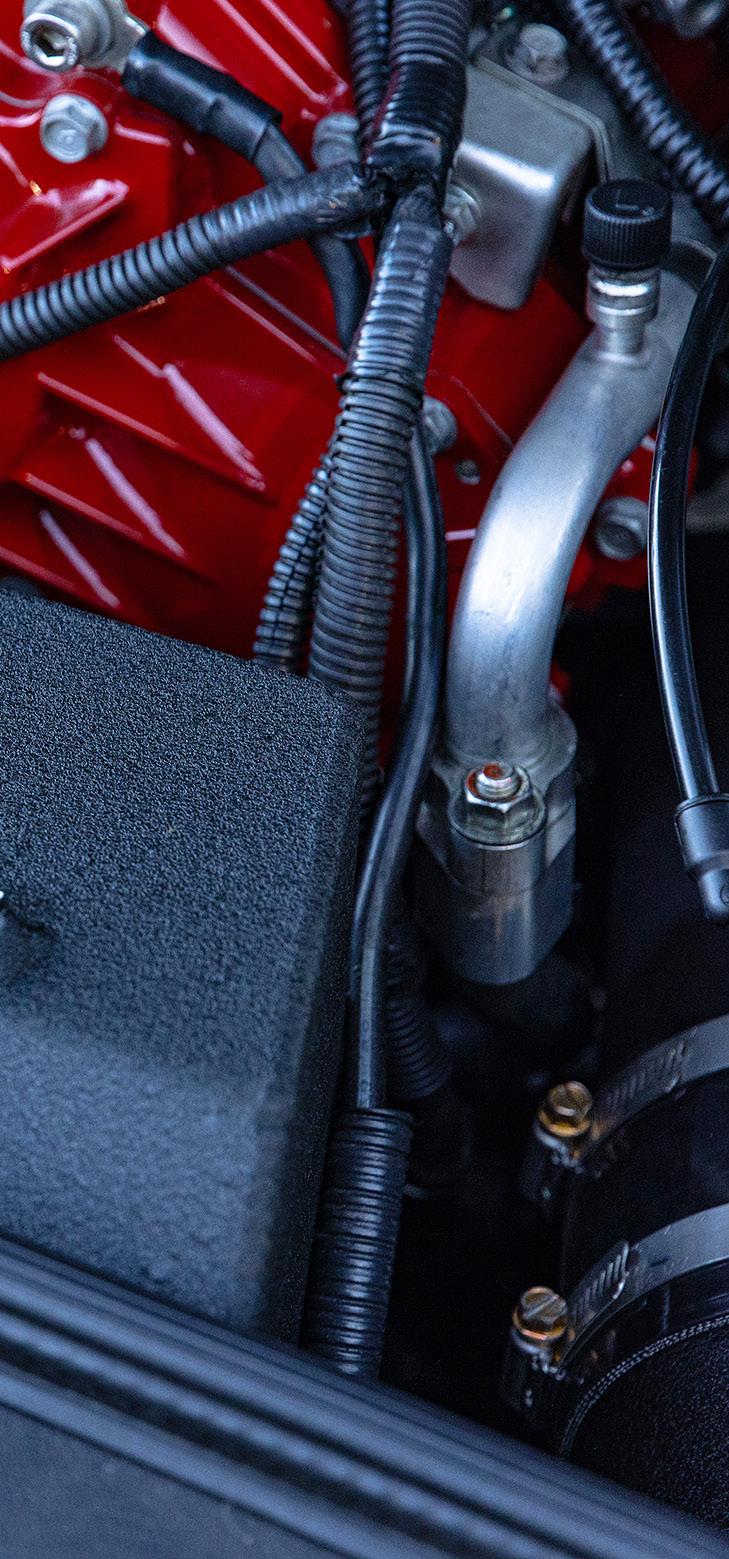

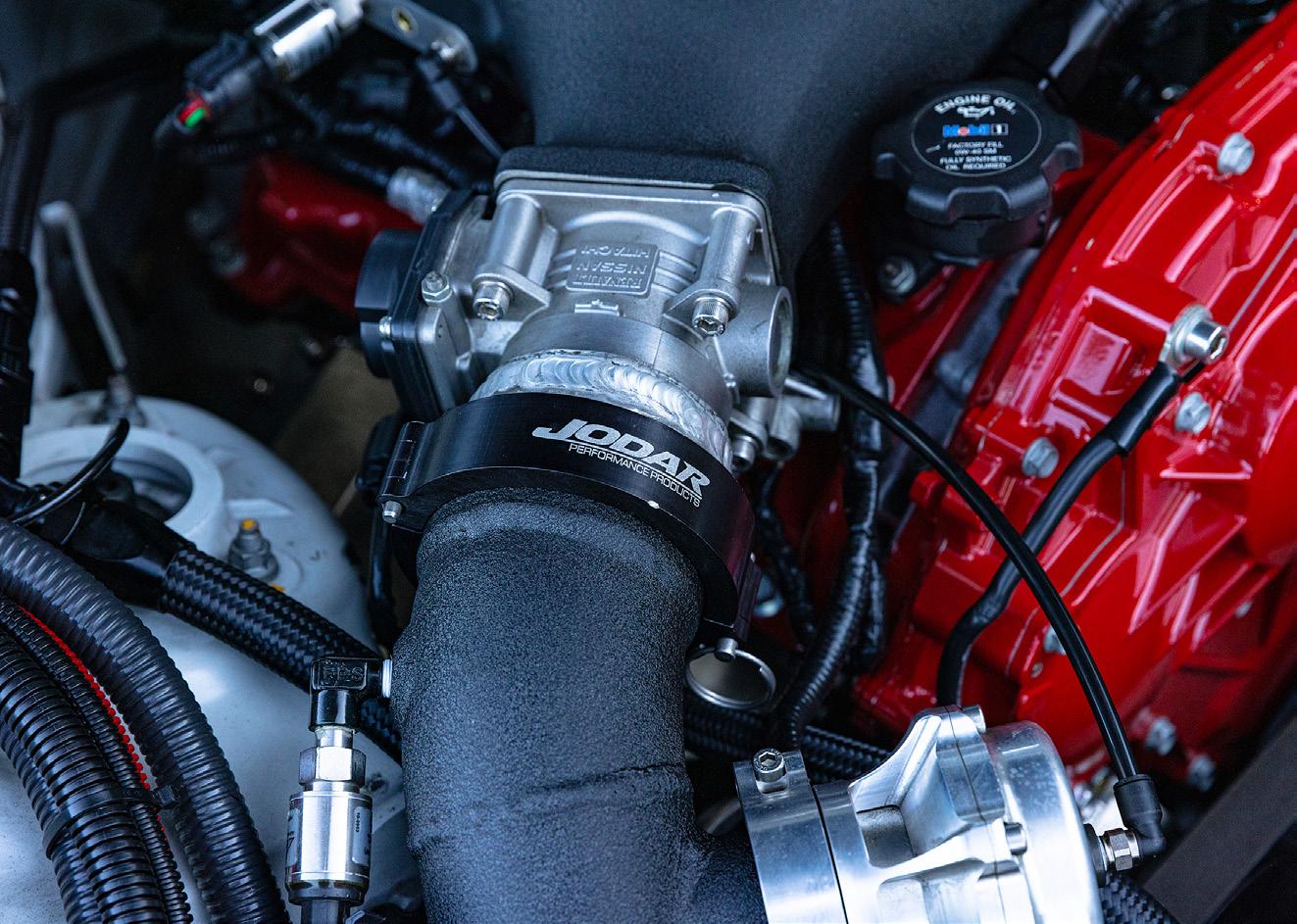

He purchased an already modded 2015 GTR from Florida and the 860HP kept him satisfied… for a while. While Gene has always completed his own motor work, since the 3.8 VR38 V6 motors from Nissan are pretty complicated, when he decided to up the ante, he left it up to someone already well acquainted with the platform to get the job done, Tim Lynch. Lynch started with the factory 3.8 aluminum block and used a combination of a Bryant billet crank, Manley rods, and Wiseco pistons to create a 4.1 stroker. Factory CNC ported heads with Ferrea valves and aftermarket springs, and GSC billet cams were next on the list along with new timing chains, oil pump

...Gene hit the road with 1,600 wheel horsepower at his command...

The almost completely factory interior is joined

a

The rear seats remain, as does the air conditioning, heat and even the navigation system!

harness bar, and lightweight racing

The factory Nissan fuel tank saddles the transmission, creating higher fuel and trans temps and eventually overheating the fuel in high power applications. To solve the challenge, Gene built this one-off 16-gallon fuel cell for the trunk similar to what a typical drag car would run.

by

carbon steering wheel,

seats.

by

carbon steering wheel,

seats.

steering remain, system!

and pan. A Boost Logic 12 injector intake manifold tops things off. Aftermarket turbos were added and Gene hit the road with 1,600 wheel horsepower at his command.

After 5,000 “less-than-easy” miles, Gene had Lynch tear the engine down to check out wear and tear. The pair were amazed at just how good everything looked, which got Wilson thinking that more power is always better, right? With that, the heads were fire-ringed, pistons freshened,

along with a few other tweaks, and new turbos were ordered.

Power-adder wise, all of the big power GTR guys reach a limit with the stock turbo placement due to what fits in the allotted space, and that’s where the Verkline lightweight tubular front subframe comes into play. With this most recent iteration, the fabricated turbo kit uses twin Precision 76/75 turbos and modifications to the front also allow for a custom air to air intercooler setup.

Yes, it looks factory!

Sporting in the vicinity of 2000 horsepower, the Nissan factory 3.8 now sits at 4.1 liters and was host to a load of quality parts during the build by Tim Lynch. A Bryant billet crank with Manley rods and Wiseco pistons now rotate inside, and billet GSC cams were used with a Boost Logic 12-injector intake topping things off.