STRAIGHT-WEIGHT PERFORMANCE

HIGH PERFORMANCE MINERAL DRAG RACING OIL

Mineral based engine oil designed to enable maximum power while providing ultimate protection under the most severe race conditions.

• Unique friction modifier system enables maximum power output

• “Stay-in-place” chemistry and 2X Zinc anti-wear system provide lasting protection

• High quality base stocks enable effective ring seal

• Advanced, proprietary additive system keeps your engine clean

• Designed to prevent separation caused by fuel dilution

• Available in 50WT, 60WT & 70WT

Made in the USA MaximaUSA.com

RPM Magazine is a REGISTERED TRADEMARK of Revolution Publishing & Media Inc. RPM Magazine is a worldwide motorsports publication distributed online.

To subscribe to RPM go to www.rpmmag.com or email Trish Biro at trish@rpmmag.com, or call 519752-3705.

The focus of RPM is to bring a diverse mix of high performance street and race automobiles to life within its pages including race cars, muscle cars, hot rods and street legal machines with an emphasis on the “EXTREME,” including fast doorslammer and outlaw forms of drag racing. Not familiar with these types of cars? They are considered to be the top-shelf of the industry and are on the edge with regard to design, performance, and power!

RPM Magazine does not sell its mailing list or share any of the confidential information regarding its subscribers.

RPM Magazine has been a world leader in motorsports publishing for 23 years and has support locations in Ontario, Canada, Alabama, Texas, and Virginia, along with contributing writers and photojournalists worldwide.

If you have a story that may fit within the focus and scope of RPM Magazine’s coverage, please email our Editor In Chief at editor@rpmmag.com. Submission of an article does not guarantee that it will be published.

Revolution Publishing & Media Inc. (RPM) / RPM Magazine IS NOT responsible for errors or omissions in ANY advertisement or article. Advertisements may be rearranged or altered at the sole discretion of RPM to allow the ad to fit in the space purchased by the advertiser.

It’s safe to say that re-running my CONGRATULATIONS! Editor’s Rant has now become tradition in RPM in the first issue of every year.

Before you read on, just to be clear, I am all for progress, innovation, advances in safety, science, better health and moving forward, however, some things– read “some” things, just might make more sense the way we used to do them. The point is, learning how to deal with responsibility and challenges as well as success and failure at a young can go a long way in life as years pass. With that being said, I hope you enjoy this with the spirit in which it was written.

Congratulations! CONGRATULATIONS to all of our 40+ year old readers.

First, we survived being born to mothers who smoked and/or drank while they carried us and lived in houses made of asbestos. They took aspirin, ate blue cheese, raw egg products, loads of bacon and processed meat, white bread and tuna from a can. Then, after that trauma, our baby cribs were covered with bright colored leadbased paints. We had no childproofed medicine bottles, doors or cabinets and when we rode our bikes, we had no helmets, not to mention the risks we took hitchhiking! Mom didn’t have to go to work to help dad make ends meet, she worked only if she wanted to.

We would ride in cars with no seat belts or air bags, and riding in the back of a pick-up on a warm spring day was always a special treat, not a crime. If someone cut us off while driving we’d flip them the bird, and they would return the favor, without getting out a bat, knife or gun at the next stoplight.

We drank water from the garden hose and NOT from a bottle. Take-out food was limited to hot dogs, fish and chips and pizza. You didn’t line up at the drive-thru for your morning coffee but got up earlier and made it yourself.

Even though all the stores closed at 6:00pm and didn’t open on Sundays, somehow we didn’t starve to death. We shared one soft drink with four friends from one bottle and NO ONE actually died from this. We could collect bottles and cash them in at the corner store and buy a whole bag of penny candy, sports cards, bubble gum and some fire crackers.

We ate cupcakes, white bread and real butter and drank soft drinks with sugar in them, but we weren’t overweight because... WE WERE ALWAYS OUTSIDE PLAYING! We’d leave home in the morning and play all day, as long as we were back when the streetlights came on. No one was able to reach us, yet we were somehow O.K. We would spend hours building our go-carts out of scraps and then ride down the hill, only to find out we forgot the brakes, which consisted of a wooden stick on a screw that scraped the ground to slow us down! We’d hop-up our bikes with banana seats and long forks and didn’t need some slick dude on a TV reality show of the month to tell us how to do it.

We built tree houses and played in river beds with Hot Wheels and Matchbox cars. We did not have any video games at all, and when we did finally get them it was for occasional entertainment with the whole family. No on-demand TV

or 200 channels on satellite, no DVD or streaming movies, no surround sound, no personal computers, no internet, internet message boards and forums or social media, no cell phones or other handheld devices and no texting... we did have friends though, and we went outside and found them!

We fell out of trees, got cut, broke bones and teeth and there were no lawsuits. We were given pellet guns, jack knives and slingshots for our 10th birthdays. We played with toy guns that looked like real guns, only because it was cool, not because we wanted to be a gangster. And every young boy wanted to be a policeman or fireman!

At 13 we learned to drive the family car at the empty mall parking lot on Sunday. We rode bikes or walked to a friend’s house and knocked on the door or rang the bell, or just yelled out for them.

Christmas was Christmas not Xmas, no really it was! No Black Friday or Cyber Monday either. We went shopping for our gifts at actual stores and most everything was made here at home. Football, baseball and hockey had tryouts and not everyone made the team. And those who didn’t had to learn to deal with disappointment. Imagine that! Getting on the team was a privilege based on ability and merit, and not due to special rules, threats, fear or guilt... There were very few football, hockey or soccer moms and dads who cared more about their kids becoming the next superstar over just letting them play and have fun. I know this all sounds strange, but it’s true!

If a company we bought something from made a mistake, we gave them the benefit of the doubt and simply called them about it. And they either fixed it or they didn’t, and they would live with the word of mouth (good or bad) AFTER we gave them a shot at fixing it. We didn’t go on social media (because there was none) and smear the company’s name first.

We did not talk back to our parents or we’d get spanked, and knowing that kept us in line… most of the time. Our teachers used to belt us with rulers or leather straps, and knowing that kept us in line… most of the time. Grade school bullies didn’t have guns and knives. The idea of a mom or dad bailing us out if we broke the law was unheard of. They actually sided with the law! And police were given respect, because they deserved it.

This generation has produced some of the best risk-takers, problem solvers and inventors ever! The past 70 years have been an explosion of innovation and new ideas. We had freedom, failure, success and responsibility, and we LEARNED how to deal with it all! And YOU are one of them! CONGRATULATIONS! You were allowed to grow up as kids, before the lawyers, governments and big businesses regulated our lives “for our own good”. You may want to let your kids read this so they will know how brave their parents truly are.

Once again, have a fantastic 2023!

Chris Biro, Editor In Chief

Centers 110

PBM Products 83 Profiler ................................ 80

PRW-USA 18

Rage Wraps 92

RAM Clutches 74

RCD ..................................... 71

Ross Racing Pistons 7,78

RPM Magazine 18,49,64

RPM Magazine Subscribe! ..................... 28,41

SPEEDTube TV 17

Summit Racing Equip. 27,59,79

T & D Machine ..................... 49

The Supercharger Store 83

Thermo-Tec 19 Ti64 38

Total Seal Rings ................... 68

Trailer Alarms.com 28

TREMEC 93

Trick Flow 15,93

Tuned By Shane T ................ 23

Ultimate Headers ................ 46

VFN Fiberglass Inc. 28 Vortech 10,81

VP Racing Fuels ................... 56

Weinle Motorsports ............ 58

World Domination – RPM 37

World Products 46

Advertising Info: Contact Trish Biro 519.752.3705 trish@rpmmag.com

Story & Photos: Wes Taylor

Story & Photos: Wes Taylor

Anthony Sellars is one of those guys who became hooked on racing a bit later in life.

It all started when he was helping a buddy with his 1998 Chevy Camaro at the track. Feeling his own need for speed, Sellars got into street racing and became pretty good at tuning his car, winning races, and making a name for himself. In 2007 he decided to take his skills off the street and apply them to a safer, legal form of racing. Anthony continued to make waves in racing at the track and built a solid team to help with the heavy lifting of running a race program. As the car continued to get faster, he changed over from more street-oriented parts to strictly race-proven ones. Unfortunately, in 2019 at Middle Georgia Motorsports Park, Sellars wrecked the car he’d worked so hard on. It was a total loss and he considered quitting drag racing, but after coming so far and starting to gain traction in the no-time grudge race world, he decided that wasn’t an option and bought “Vendetta”.

V is for Vendetta, and upon Anthony Sellars’ return to drag racing after a devastating accident, his revenge would be exacted through this wicked Fox Body Stang.

The 1992 Ford Mustang Fox

Body platform came as a roller out of Lucas Weldon Race Parts. It’d been a race car in previous years, but nothing like what An thony had in mind for the level he would be competing in, so pretty much everything was gut ted and or reworked by Carl Ste vens of Xtreme Race Cars. As a result, a Certified 25.1 cage and a custom-built chassis reside in the factory-looking shell. The front-end subsection was cut off in favor of a lightweight version for strength, not to mention ease of maintenance between rounds.

The body tub, pillars, rocker pan els, and roof back remain steel, but the firewall, floor pan, and tubs are all carbon fiber. The car uses a strut style suspension in the front with double adjustable coilovers.

Your Recipe for

High Power Certified.

There’s no place for middle of the road in high performance engines. That’s why Trick Flow developed CNC-ported GenX® series cathedral port cylinder heads for GM LS engines. Trick Flow engineers changed the valve angles to 13.5° to decrease valve shrouding, increase airflow, and improve rocker arm clearance. Relocating the spark plugs boosts mid-lift airflow and rocker arm clearance, and extra material added to the rocker arm mounting points enhances highRPM valvetrain stability. Trick Flow’s top-of-the-line CNC Competition Ported runner treatment delivers large amounts of smooth moving airflow for making big power.

GenX CNC-ported cylinder heads are offered in 205cc, 215cc, 225cc, 235cc, and 245cc intake port sizes. A 6-bolt mounting pattern is also available (optional GenX 235; standard GenX 245) for extremely high compression, high boost applications.

Track Max® Camshafts

Give your GM LS an even bigger power boost with a Track Max camshaft. Available in several hydraulic roller designs up to 230°/238° duration and .625"/.625" of lift, they are dyno proven to produce significant power increases over the entire RPM range.

Active Fuel Management and Variable Valve Timing Delete Kits

The problem: most performance camshafts don’t work on engines equipped with AFM or VVT. The solution? Ditch them with these delete kits! They include everything to completely remove AFM and VVT the right way so your engine will make the power you expect with no hiccups.

Cylinder Head Bolt Kits

Keep combustion where it belongs! These high-quality cylinder head bolt kits provide consistent clamping force. The bolts are made from premium quality alloy steel with cold-formed heads and rolled threads. The kit contains all the bolts you need to install a pair of heads.

Some parts are not legal for sale or use on any pollution-controlled motor vehicles.

Even the heavily modded Fox Body Mustang rear suspensions of today that are considered “stock-style” will take a program far, but not as far as Sellars wanted to go, so Vendetta received a four-link suspension with custom valved coilovers in the rear. Although much of the car is pure race car, it does resemble a factory-looking Mustang from the 90s. The composite front clip incorporates a cowl hood that resembles that same cowl that many Mustang owners installed within days of purchasing their street car. The bumper adds to the appealing low stance, reaching closer to the ground, which helps channel wind around the car. And there’s no mistaking the molded center-mounted turbo inlet and exhaust dump in front of the tires. In addition, an elongated trunk-mounted

wing was fabricated to help with downforce. Both doors are also composite, and windows were swapped to Optic Armor for the front and rear. A low-slung Fox Body deserves a wicked paint job; Vendetta was sent to Dinks Body Shop for that task. Not only that, but Anthony decided on keeping it in the Ford family, choosing a factory Grabber Blue color used

on many Fords over the years, most commonly found on earlier Muscle cars. Black Weld Racing V-Series spindle mounted 17inch skinnies wrapped in Mickeys reside up front, and 15x12 beadlocked versions with 275 class legal radials hang out on the rear.

While a number of Mustang teams have switched to running LS or Chevy-based platforms for the past number of years, Anthony decided he would stay a purist and keep the Ford Blue Oval alive in his build, using factory Ford paint and running a Ford motor. Sellars tasked Kevin Mullins of TKM Performance with building him a race-winning small-block Ford mill.

The TKM crew started with a solid Carroll Shelby aluminum 351 block and worked their magic from there.

A lowslung Fox Body deserves a wicked paint job...

The Mustang Coupe is one of the top platforms to build a drag car with, and while not much of the factory parts remain on this build, the body tub is a production piece with a composite front end, doors and trunk lid added to the mix.

A 98mm turbo adds extra fun to the package and the system was designed and fabricated by David Knight.

The innards are comprised of a 4.0 Callies Ultra billet crank, 6.125 MGP aluminum rods and forged boost-spec pistons. The mill totals 430 inches of small block

Ford goodness. Topshelf parts continue into the top end, with Kuntz and Company SC-1 aluminum heads, T&D rockers and PAC springs, retainers and locks.

This Ford is ALL Ford

Sellars chose to stay with a Ford based mill and had TKM create a nasty small block around a solid Carroll Shelby aluminum 351 block. A Callies Ultra billet crank with MGP aluminum rods and forged boost-spec pistons rotate inside what works out to be 430 inches of small block Ford goodness. Kuntz SC-1 aluminum heads are fitted with T&D rockers and PAC springs, retainers, and locks and the exterior bling of the package is topped off by a stunning, yet very functional, Marcella Manifolds intake.

A trick piece from Marcella Manifolds tops the long block, along with a set of machined TKM Performance valve covers.

Oiling and fuel delivery are essential; a Schaeffers dry sump system takes care of the oil cycling, while a combination of a Lil Bertha 18 GPM fuel pump and 800 PPH

injectors supply adequate amounts of fuel to the 430. Anthony’s new power would only be complete with boost and David Knight welded up a simple yet very effective turbo system using a massive 98mm turbo with a blow-off valve and wastegate incorporated into the system, regulating boost pressure.

Anthony Sellars’ 1992 Ford Mustang LX Coupe

this is one potent pony...

There is zero factory equipment left in the interior of this Mustang, instead everything has to do with the business of winning races and doing so safely. A complete fire suppression system has been installed and the massive 12inch Holley EFI screen relays info to the driver in real time.

Devin Vanderhoof of HCRI Innovations meticulously wired in the Holley Dominator EFI and MSD 600 systems to control the package.

Anthony decided on a two-speed TH400 for Vendetta’s transmission. The M&M case houses a 1.40 first gear and a host of other goodies along with their bolt-together torque converter and shifter.

Power continues through the chain of command to a Mark Williams full floater 9-inch stuffed with 40 spline axles, an aluminum center section with spool and a 3.70 gear set.

The Vendetta team has taken hold of the No Time race scene on the east coast over the past few years...

Anthony Sellars’ Ford powered boosted Fox Body Coupe wins races and gets up and dances to the tune of…oh wait, we can’t share that info as this is a No Time Grudge car and some things are just best left unsaid.

Grudge car will knock your socks off!

Aftermarket drag brakes are used on all four corners.

The interior of Vendetta is all go, with all the safety amenities a race car of this caliber should have. This includes a fire suppression system within easy reach and a Holley digital dash that allows Anthony to keep an eye on things before,

during and after a run. All electronics are easily accessible on the passenger side kick panel. Sellars also runs an M&M shifter, Xtreme Race Cars quick disconnect steering wheel, and sits in an aluminum race seat.

There’s no doubt that the accident knocked Sellars down for a bit… but he was down, not

out, and quickly decided to re-enter the No Time Grudge race game with a new car and a score to settle with it. Over the past few years, the Vendetta team has taken a hold of the No Time race scene on the east coast, and it seems they have no interest in slowing down any time soon!

Story & Photos: Eddie Maloney

Story & Photos: Eddie Maloney

The Chevelle was a midsized automobile that was produced by Chevrolet in three generations for the 1964 through 1978 model years, and it became an iconic symbol of the muscle car era.

It was a part of General Motors A-body platform, and would become one Chevrolet’s most successful nameplates. Body styles included coupes, sedans, convertibles, and station wagons. Not only was the Chevelle successful in production numbers, but they held their own on the street and track as well. Although there were several variations of the Chevelle produced, many were purchased for one reason, racing! If, you look at tracks across the globe, even today the Chevelle is still a favorite of both competitors and fans.

What’s not to love about a cool ’68 big block Chevelle SS with a wicked stance that can hang the hoops and bust out bottom 9-second ETs in street trim on Friday night!

By 1968, the Chevelle adopted a more aerodynamic shape over the former, more boxy models. The optional 396 engine came with 325 horsepower but could be upped to 350 and 375, and the SS (Super Sport) package had buyers waiting in line to pay the whopping $2,899 price tag for the capable street machine.

In 1970, you could’ve picked up an LS6 version Chevelle for about $3,500 bucks that would get you almost 1 horsepower per cubic inch – the 454-inch mill pounded out 450 horses at 5600 rpm. Today, a numbers

matching 1970 Chevelle SS LS6 version is fetching into the six figures.

But despite their outstanding power and performance for the day, none of the above would come out of the gate with wheels high in the air, crank off bottom 9-second ETs at the dragstrip and drive you home again, not even close; Chris French’s will though!

Chris has owned his 1968 Chevelle for over 11 years and credits his father Lloyd who had a passion for them and passed this on to Chris.

In fact, Chris has owned 7 other Chevelles before this one. Growing up in Michigan, there was no better place in the world to develop a love for cars. “I grew up surrounded by hot rods,” He explained. “My father was the inspiration for me and my brother. I grew up racing, my brothers started at the dirt track and I started drag racing when I was 16.”

It was November of 2012 when

Chris’ dad found this car at the annual Daytona Turkey Run car show and swap meet. Lloyd bought it and would later sell the car to Chris’ brother, and eventually Chris would buy it from him.

With plenty of ideas in mind regarding modifications, Chris began to outline a game plan of his upcoming project. The goal was always to keep the Chevelle streetable but have enough power

to enjoy it fully on both the street and track. He wanted to build the car to run in as many classes as possible, including bracket classes and “real street” style heads-up events.

Step one was to develop a pump gas combination with plenty of naturally aspirated power to get him into the 9-second zone in the quarter-mile, and be able to dip into the eights with a little N20.

The 548 cubic inch big block Chevy started life as a Dart Big M block.

SRP 10.5:1 compression Nitrous-spec pistons are swung by an Eagle forged crankshaft and Eagle H-beam rods. Up next was adding a custom ground Bullet camshaft, Morel Ultra Pro lifters, and heavy duty Clevite bearings. For the top end, Chris went with a set of Air Flow Research (AFR) 335cc rectangle port cylinder heads. To make sure his valvetrain was indestructible, the heads were outfitted with a Jesel shaft rocker system, Manley pushrods, and

Ferrea valves.

Induction and fuel delivery is handled by a Weldon fuel pump and regulator flowing to the Quick Fuel 1050 cfm carb. For those days where more power is needed, Chris plumbed a “little” Edelbrock nitrous oxide plate system into the mix and is currently dialling the nitrous in to get that 8-second run under his belt.

Transferring the power rearward is a custom-built Turbo 400 and torque converter with a reverse manual valve body by FTI.

The Chevelle has nearly of its stock interior along with a few race-essential parts including race seats and a 10-point cage.

Chassis wise, the Chevelle is a full frame design and needs little, if anything, to make it race ready. Chris left the frame and its attaching suspension parts in the factory location and even kept stock GM front control arms but added Moroso Trick Springs and QA1-R series single-adjustable shocks. Out back boasts

TRZ upper and lower control arms, a TRZ anti-roll bar, BMR lower arm relocation brackets, stock GM springs and QA1 double-adjustable shocks.

Being a GM man through and through, the rear differential on the Chevelle is a beefedup GM 12-bolt with a Motive 3.90 ratio gearset for both street driv-

A wood SS steering wheel, you can’t get any cooler than that!

The heartbeat of this heavy Chevy is a pump gas 548 CI BBC with a little bit of nitrous oxide. A Dart Big M block was filled with an Eagle forged crankshaft, Eagle H-beam rods and SRP small dome forged pistons that offer a nice comfortable 10.5:1 compression for use on the street but are nitrous-spec’d with the intention of spraying the already healthy Rat.

ing and strip duty, a spool, and aftermarket axles.

For the wheel/tire set up, Chris wanted the big and little look fitting of an iconic muscle car such as the Chevelle. He once again needed something that would hold up to track pounding and street driving and went with a set of Champion 15” wheels wrapped in radials all the way around with the rears being beadlocked

275/60/15 M/T Pro Drag Radials.

As the build was coming to an end, the interior was the last on the to-do list… for now of course. Chris is adamant that his car is a street car and should look like one, and the interior was no exception. Inside the Chevelle you will find as many factory appearing parts as he could find, and, aside from the race necessities, when you step inside

Chris French’s 1968 Big Block Street/Strip Chevelle

■ Suspension: Front Stock GM control arms, Moroso Trick Springs, QA1-R series single adjustable shocks.

Rear - TRZ upper and lower control arms, TRZ anti-roll, BMR lower arm relocation brackets, stock GM springs, QA1 double adjustable shocks.

■ Engine: 548 cid using a Dart Big M block. Eagle forged crankshaft, Eagle H beam rods with ARP bolt upgrade, SRP small dome pistons (10.5:1 compression ratio), Bullet solid roller custom camshaft (.731 lift, 276 / 286 duration at @.050, 110 lobe separation), Morel Ultra Pro lifters, Liberty billet double roller timing chain.

■ Cylinder Heads: Air Flow Research Cylinder 335 cc heads.

■ Induction & Fuel Delivery: Edelbrock Victor Jr. R intake, Quick Fuel Technology Q-1050 4150-style carburetor.

■ Power Adder: Edelbrock Performer RPM plate nitrous system.

■ Transmission: Turbo 400 transmission, stock gear set, steel drum with 34 element sprag, transbrake, FTI Performance SST series 9-inch converter.

■ Rear: 12-bolt rear, 3.90 gear set, 33 spline Strange axles and spool.

■ Brakes: Aerospace disc brakes.

■ Tires & Wheels: Champion wheels, rear-275/60/15 M/T Pro Drag radials, M&H Racemaster front runners.

■ Interior:

Autometer gauges, new factory carpet, headliner, door panels, glass, back seat, wood SS steering wheel, and a 10-point Chromoly cage that is certified to 8.50.

■ ET & MPH: 9.16 at 146mph, 3800 lbs with driver.

■ Special Thanks:

• Lloyd French

• Jason Rollins- Rollins Speed and Custom • Mike and MaryAnne French

• Chris Morris

A host of TRZ parts suspend a beefed up Chevy 12-bolt rear differential that sends power outward to the Champion wheels and sticky Mickeys.

it takes you back to 1968.

To make it legal for racing competition, he added racing seats complete w/ 5-point harnesses and a Chromoly 10-point roll cage that is certified to go 8.50 ET in the ¼ mile, but we appreciate the authentic wood SS steering wheel most!

We all know that no project is ever really done. Chris has been building his Chevelle for well over 10 years and thanks to his father, he

has no intention of being finished. He loves working on improvements or even just tinkering on the car to see how he can pull more power out of what is already there. At over 3,800 pounds with Chris in the seat, he’s running bottom nines in the quarter and looking for the 8-second time slip this year, but rest assured, no matter how fast things get, this Chevelle will always be a street car!

...this Chevelle will always be a street car!

Story: George Pich

Photos: Blake Farnan

Story: George Pich

Photos: Blake Farnan

It’s a luxury family 2-door...right?

There’s just something about a full-figured ride like the GM G-Bodies. There’s no doubt it’s a refreshing change in appearance alone, but when they launch hard like Bryon’s does, they just seem to defy gravity.

One thing we’re pretty sure that everyone can agree on though is that Bryon Terveld’s 1983 Oldsmobile Cutlass Supreme is definitely a street car. With a mostly OEM steel body, all the factory interior including seats, factory frame and a long list of non-exotic parts, this potent big block powered G-Body gets the job done. This car takes

dad was an auto body professional who grew up with muscle cars and I heard and enjoyed all the stories he and his buddies would tell,” Terveld explained. “Our family car growing up that I remember first was a ’71 GTO, but my dad always showed me a pic of ‘the one that got away’, a 1965 Beaumont. I guess I always remembered that story and that’s part of the reason I’ve kept my car so long; I didn’t want it to get away.”

“My

Just working on and owning cars wasn’t quite enough and Bryon soon discovered drag racing...

Bryon bought the car in March of 1988 as a bench seat V6 car with A/C for $8000, a lot for a high school student, but it was his car. “I went there to buy a Z24 but couldn’t afford it, thank God!” He added with a smile. “My parents weren’t happy because I was still in high school and got roped in by the salesman, but I needed them to co-sign for the loan.”

The Cutlass was admittedly “torture tested” by a young 17-year-old hungry for a cool car, and Bryon would put over 3,000 miles on it a month! Eventually the V6 got to a point where it burned so much oil that oil changes weren’t even needed, it was cycled that quick. Not only was the Cutlass his daily driver that he beat on, but Bryon would even tow his snowmobiles in the winter with it.

He finally decided that the car deserved better and that’s when he cleaned it up for summer use only, completely redid the engine bay and threw a 350 in it.

Just working on and owning cars wasn’t quite enough and Bryon soon discovered drag racing through a friend, Keith Moore. He worked with Keith at the time and heard more ‘good old days’ muscle car stories of all the Mopars he had back in the day. At the time, Moore had a Fox Body Mustang that had been worked over a bit and he invited Bryon for a race at the track, and of course as you might guess, he was instantly hooked! “I raced with the stock 350 and open 7.5” diff doing the ‘1 tire fire’ hallway down the track for quite a while and the announcer was always impressed.”

With mostly all original body steel and the original frame (with the rear rails moved inward for tire clearance) along with all of the OEM trim and emblems, this Cutlass puts about as much “street” in fast street car as you can get.

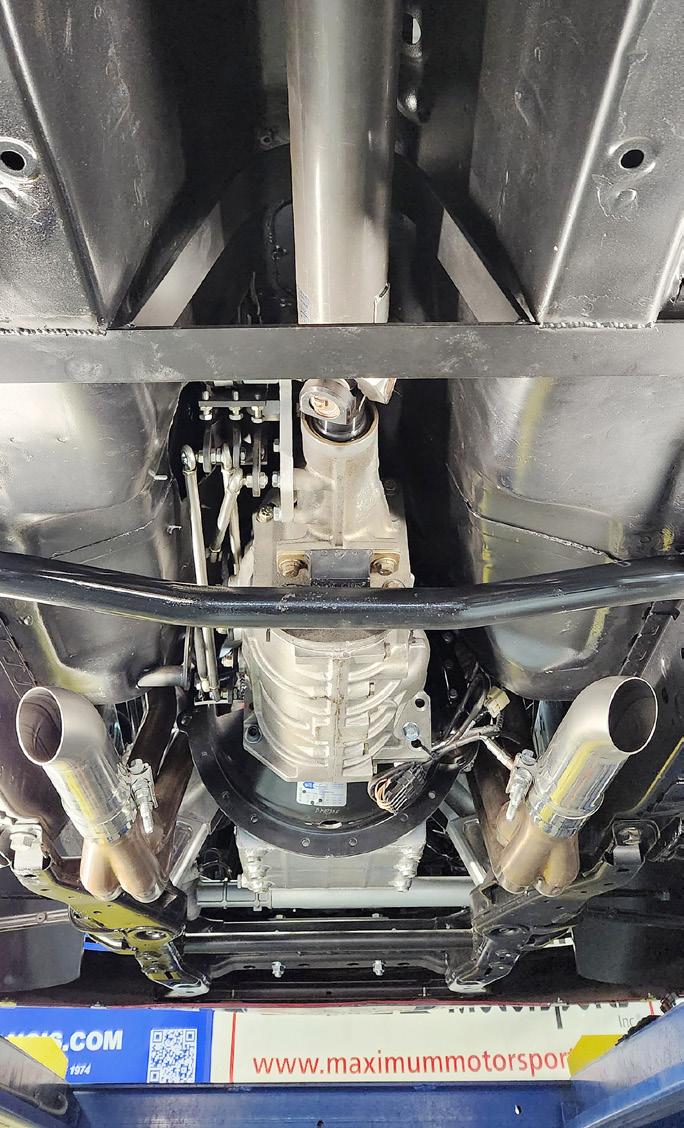

There’s no overly exotic parts here, just good old fashioned know-how on what works and what doesn’t. The engine is backed by a Hutch 400 trans and Bear’s 9-inch rear and Terveld simply changes the nitrous tune to run either timed classes or no-time gigs

Terveld’s Cutlass Stand Out!

Next was a modified 350 that Terveld would add parts to every year as funds permitted. Bryon eventually met a fellow gearhead, Andy Ego of Custom Engines, and the two would become close friends; Andy helped Bryon in his efforts and was a huge inspiration to him.. When it came time to step-up, Andy built Bryon’s first big block Chevy, a 460-incher and once again, with Andy’s guidance, Bryon would tweak the big block each year. Unfortunately, Andy passed away in 2005 and left a hole in Terveld’s life and efforts on the Cutlass, but when he did find inspiration once again, he was considering adding nitrous oxide to the Rat. “I went back and forth on it and said to my wife Teresa, “You know what Andy would say…’go for it p***y’. So I did it and the first time I left the line on a 100 shot I thought I was in the back seat! I was hooked again!”

Bryon Terveld’s 1983 Oldsmobile Cutlass Supreme

■ Occupation: Owner/Operator of Ultimate Car & Truck Refinishing & Collision Center since September 2009.

■ Body & Paint: Completed by owner approx. 1997, “but needs some touch ups now”.

■ Chassis Mods: Roll Cage by Custom Welding. Narrowed rear frame rails for tire fitment and Merillat upper and lower torque boxes plus all bracing completed by owner.

■ Suspension: Stock style. Front is TRZ upper and lower control arms. Rear is Merillat torque boxes and upper arms, TRZ under axle anti roll bar. TRZ radial valved Afco shocks all around, ■ Engine: Shafiroff 598 with Dart Big M block. Manley 4.5” crank, Molnar rods, SRP pistons. Brodix BB3 Extra 380 CNC cylinder heads with 2.35” intake and 1.88” exhaust valves. Comp Magnum roller rockers. Manley springs.

■ Induction & Fuel Delivery: AED 1250 Carb, Aeromotive Eliminator pump, stock sumped tank.

■ Power Adder: Inductions Solutions flowed NOS Fogger and Sledgehammer Plate, controlled by a Maximizer 5.

■ Transmission: Hutch built 3 speed Turbo 400, PTC converter.

■ Rearend: 9” from Bears Performance, Ultra Case with 3.50 gear, spool, 40 spline gun drilled axles.

■ Brakes: Wilwood all around

■ Tires and Wheels

RC Components Exile wheels, single beadlock on the rear. M/T Pro Bracket Radials or ET Street Radial Pros depending on rules.

■ Interior: Stock interior with stock bucket seats replacing factory bench. Hurst pistol-grip shifter, Autometer gauges, Leaf Racewear 5 point harness.

■ E.T.: 5.50s @ 128-130mph in timed events and of course no-time is no-time.

■ Unique Features: “3900+ lb mid-low 8 sec street capable. I think that’s pretty cool.”

■ Special reason for building this car: “Just for my entertainment.”

■ How long to build the car: “Forever. It’s constantly evolving and always has.”

■ Thanks to:

“My wife Teresa for always being there and helping to get to the track and helping at the track. To Don Palmer who is always there with parts and advice, he has helped me with so much. Thanks to Ed Szram for always being there with parts and advice and helping with shortening and bracing the rear end, and to everyone else who has helped with the car.

Don Palmer always there with parts and advice, he has helped me with so much. There is too much to list here. Ed Szram for always being there with parts and advice and helping with shortening and bracing the rear end.”

■ Most Memorable Experience:

“It has to be getting to go to Oklahoma with the OSO. Even though we were knowingly out gunned, and I didn’t get a race, it was a great experience. Winning an OSO championship and just winning the Canada Heads UP Street 275 Championship are up there too. “

Twin Induction Solutions nitrous bottles hang out in the trunk. You will notice there is no fuel cell here, instead the original tank remains underneath and hides the Bear’s 9-inch rearend equipped with a full compliment of TRZ parts, including TRZ-valved Afco coilover shocks. The front end was also treated to the TRZ treatment with their upper and lower tubular control arms.

As time passed, Terveld raced with success in the OSCA (Ontario Street Car Association) 10.90 index class and dabbled in some headsup stuff where he could. When the now well-seasoned motor dropped a valve late in the year as he was gunning for a Championship, Bryon decided to have more power added to the mix and before long he was running 9.50s in the

quarter with a bit more sauce added. Then, the big change came when he had Shafiroff Racing build the current motor, a pump gas friendly 598 making over 900hp! This was beyond anything Bryon ever imagined, so why not add

Check it out – Bryon kept almost all the original interior and even swapped out the bench seat with factory buckets. A cage and aftermarket gauges have been added along with a Hurst Pistol-Grip shifter and a Leaf Racewear 5-point harness.

more nitrous!

And with the current setup, an Induction Solutions-flowed Fogger and Induction Solutions Sledgehammer plate system, he is capable of well over 1,100hp and has sprayed as much as a 600hp hit into the mix,

but only when he absolutely needed to. “I usually only use the Fogger system with a pretty soft ramp in the Maximizer 5 right now to race in Street 275 on a 5.50 index,” he added.

The big block is backed by a host of goodies including a

The Cutlass easily wrinkles the Mickey radials as it hooks on the soft hit launch but tends to carry the wheels a bit under more strenuous conditions.

Hutch Turbo 400 and Bear’s 9-inch Ford rearend and although Bryon has taken weight out where he can, like in front suspension, make no mistake, this is a 3,900-plus pound mid to low 8-second street car! But exactly what this heavyweight hitter

is capable of will have to remain a secret as Terveld runs no-time with OSO (Ontario Street Outlaws) and as he said, “no time means no time”, so you will just have to judge for yourself if he’s on both kits for the win!

Things moved along quite nicely this past fall with project HomeGrown COPO, and as promised last month in RPM, this article will be the final installment, full of everything that we have worked so hard for over the past 5 years. A er getting the car running and mobile, we focused on getting this badboy on the dyno and then to the track if the weather would cooperate. Among others things, we still had to install the rest of the interior and add some safety gear in order to get some shakedown passes in before the season ran out. is year in Southern Ontario, Canada, our late October and early November weather was surprisingly good which meant the tracks stayed open a little longer than normal, and we wanted to take advantage of that. It’s very important to me that we get a jump on this 5 year project now in preparation for next season if we want to go anywhere with it.

When I say shakedown passes, I mean shakedown passes. It’s important to remember in any project that you are building the car for you and, despite all of our egos and pride, we don’t have anything to prove…at least not yet.

So why would I take all these years of time, effort and some pretty serious coin only to go out and try to be an ET

Having a CNC plasma table at the shop now enables us to fabricate all of our brackets and such. You can see the work of our Plasma Table Special ist Rob Ajandi in everything from the trick bracket on the front of the engine that holds up the water manifold, to the parachute lever, throttle return spring bracket and seat and harness mounts.

hero the first time out? Instead, I want to make sure we have a fully functional and safe car first and foremost. We also want to get some sort of mild tune and ensure the car shi s through all the gears smoothly, that the clutch works to my liking, and that it drives straight and stops properly. Since every car is dif-

ferent, we also want to get a feel for this particular car. I can say now with confidence that this Camaro is completely different from my Coyote Fox Body that I have raced for 20 years.

First things first, we hauled the car over to my work shop where I have a lot more tools and equipment to finish things up. Once at

We previously mounted our Midwest Chassis parachute mount out back of the Camaro which was a very simple bolt-on process and now that we have the lever in place we were able to run the cable and install the parachute. While in the trunk we did a final check and tidy up as well.

We previously mounted our Midwest Chassis parachute mount out back of the Camaro which was a very simple bolt-on process and now that we have the lever in place we were able to run the cable and install the parachute. While in the trunk we did a final check and tidy up as well.

Just so you know we’re not shooting you a line on how nice this car turned out, check out the undercar video of this beast…now that’s a rags-to-riches story considering this Camaro was once a mistreated body-in-white from a local wrecking yard.

CHECK OUT THE VIDEO!

CHECK OUT THE VIDEO!

We hit dyno for a number of runs and made 777rwhp on the very first pull. Everything checked out A-OK and we kept a light tune in it. We spun the tires on the dyno so installed our new Mickey Thompson ST slicks, and then we slipped through the clutch on the next run.

the shop I turned some of the fabrication stuff over to Rob Ajandi who now works for us running our CNC plasma table. You might notice a new ni y little bracket on the front of the engine now that holds up the water manifold that feeds the front and rear of each cylinder head as well as the radiator. is was designed and made by Rob on our CNC plasma table. Rob then made some cover panels for the firewall so we could neatly closeoff some of the factory holes in the dash and floor that were no longer being used. He then made a small bracket for the parachute cable lever and installed it in a spot that I could easily reach. Next was a bracket to mount our roller switch for the 2-step to the floor so the clutch pedal would contact it when it is depressed. Rob also drew up and

cut out a bracket for the throttle return spring on the throttle body linkage, an adjustable seat mount and a bracket for the 5-point harness. e CNC plasma table has been an amazing tool investment for the shop as we can now offer our customers custom options for most anything their individual project might require, not to mention we can fab up some killer fun stuff like shop signs, personalized fire-pits, emblems and fender badges and anything else you can think of.

Previously, we installed a parachute mount from the fine folks at Midwest Chassis and this mount fit perfect and installed effortlessly; I simply removed the rear bumper of the car and bolted it exactly where the factory bumper would normally mount. And now that we have the chute

handle mounted too, we can run the release cable and install the chute itself.

Next we turned our attention to the interior and my good buddy Rob Walton offered his guidance to install and wire up the Copo Switch panel we purchased. I have to say, I really think this small piece looks super clean and really finishes off the dash. It’s amazing how something so small in a project can make such a noticeable difference. A er that, we called in the pro, Willy “ e Stitch” Clugston to trim and fit the carpet as well as modify our Racequip SFI shi er boot to fit the Long V-gate shi er. “ e Stitch” also made a rear seat delete and re installed the seats and the door panels, this guy is an artist!

On to the dyno we go. I had a general idea where this car would want to be as far as timing and air/fuel ratio, so we made about a half a dozen pulls to get it close and we will do the final tuning at the track. I figured going in that the car should make right around the 800rwhp mark working the driveline loss into the equation, and I wasn’t far off as the first pull it made 777rwhp. It seemed like it was spinning the tires though, so I took the mock-up tires off and installed the new Mickey ompson 29.5x9x15 ST on the car. Yes I said “ST”, and now you’re asking what is an “ST”? e Mickey ompson ST tire is actually a stick shi slick. While it is not a well-known tire, we really like it on our stick shi Coyote Mustang. It has a real stiff side wall and we have had solid

used our Proform scale set to weigh the total package in at 3,165 pounds and get a reading on the corner weights, which we will tweak during the winter.

results with it. With the new tires installed we spun up a couple more hits on the dyno, only now the tires were sticking but the clutch was slipping. Given our time constraints, and knowing the car ran and all systems worked well, instead of pulling it off the dyno to add weight to the clutch and make a few more runs, I decided it was track time as the car made more than enough power to make a couple shakedown passes. So let’s do it!

Sunday November 6th we hit the strip. at’s right, I said November 6th in Can-

We

American

We

American

Instead of adding clutch weight and getting back on the dyno, with track time running out in the north, we made the executive decision to head to the dragstrip while we still could. On a VERY mild pass, we went 155mph, and that was awesome! On top of that we found some little issues and challenges that will need to be corrected for spring. Be sure to watch for the RPM Project HomeGrown COPO full feature with videos coming mid 2023!

CHECK OUT THE VIDEO!

American Racing Headers

Lentech Automatics

CHECK OUT THE VIDEO!

American Racing Headers

Lentech Automatics

ada we were heading to the track with Project HGC to shake it down. We made just two passes, but the knowledge we gained about this car was invaluable. First, the rear throttle plate on the throttle body wanted to stick and that made idling consistently very difficult. We also learned that the 4.86 rear-end gear is a little too much with this engine as it hits the rev limiter before the end of the track in 5th gear. e G-Force GF5R transmission works great and is a totally different feeling then our G-Force 101A that’s in the Mustang. is transmission drops RPM half as much on gear changes compared to the G101A which is

ET in the bank for sure. We also learned it needs a fresh clutch. e car drives straight, does wicked burnouts, and made some serious steam and we also found out quickly that we need to use the parachute as the car went 155mph the first time out! Yes sir, 155mph on a pass where I le the starting line off idle, rolled it out before I put the throttle down and the car then spun the tires and slipped the clutch a little but was starting to pull hard by the time I shied 3rd, 4th and then 5th (where we hit the rev limiter just before the traps and still went 155mph). In my books that’s super promis-

HITMAN CARD

ing from a car that weighs almost 3200lbs with driver. Although we only made 2 passes, I have to say that I am more than happy with the outcome on a day where there were only 20 cars out and the track conditions were certainly not optimal by any stretch.

therefore much respect is due to it.

Where do we go from here? While the project is complete, there’s still lot of work to complete it. Over the winter we’ll get the paint damage from the garage fire fully repaired by Stacy at CT Auto Collision and once that’s done we will have all the sponsor decals cut and installed, install a different rear gear set, repair the throttle body, tackle a few more odds and ends and its go feature on the RPM COPO in spring 2023 in the pages of Until then, have start to 2023!

All in all, not only was getting Project HGC on the dyno and to the track an amazingly fun and rewarding experience, it was educational as well. Plus, we now know that this wicked COPO tribute Ca

Jim Sciortino’s 1970 Barracuda

For some of us, it takes a while to settle on the perfect car for a build. We scour the available targets, consider the pros and cons of each, hunt for a good buy, and eventually we make our choice.

But for others like Trumbull, Connecticut’s Jim Sciortino, it is a far simpler choice.

“I saw a purple ’Cuda in 1970 when I was 11 years old, and that was it,” the 10/10 Lube Center owner acknowledged. In 1976, Sciortino bought his first musclecar, an all-original 1970 Dodge T/A 340 Six-Pack, and over the

years owned and customized a number of other Pentastar projects including a back-halfed and tunnel-rammed 1971 440 ’Cuda, and a ’68 Barracuda with an Indy-headed 499 mill. However, in 1982, Sciortino purchased a very rough 440/4-speed Dana rear 1970 Barracuda and embarked on what he described as an “onagain/off-again project” for the next 20 years. However, in 2000, he decided it was time to get serious about the build and the car was sent to Mark Markow and MRC Racecars in Windsor, Connecticut.

Terry Hall entered the project to further set the nasty fish even further into the outer stratosphere of Pro Street stardom. After Markow partnered with Bruce Comboni to construct and tweak an initial plug, Hall created a mold for a complete 1970 Barracuda fiberglass body. Once the body was complete, it was shipped to Ron’s Auto Madness, where Ron Martin completed all bodywork and prepped the lightweight shell for paint. MRC added a custom fabricated aluminum wing and fit the car with a complete set of Lexan windows. Martin then laid down a flawless House of Kolors purple pearl basecoat before Robert Gorske at Roade Studio added an incredible set of multi-layered silver airbrushed flames and graphics.

The all-business cockpit has been treated to a full complement of Carbon Fiber Series gauges. The pro stock-style theme is obvious, with a gaggle of Jeffco shift levers proudly and prominently perched atop the polished trans. Twin racing buckets have been threaded with a pair of 5-point harnesses for safety, while a window net and on-board fire system have also been added. A Grant GT 13-inch wheel and a passenger-side nitrous bottle rounds out the interior touches.

After assessing the classic Mopar, MRC started from scratch, constructing a full tube 4130 chromoly chassis with Santhuff struts up front and a custom MRC-constructed 4-link with Koni double-adjustable shocks out back. The MRC-fabricated rear housing was stuffed with a Strange Ultra center section, 4.10 gears, and 40-spline axles.

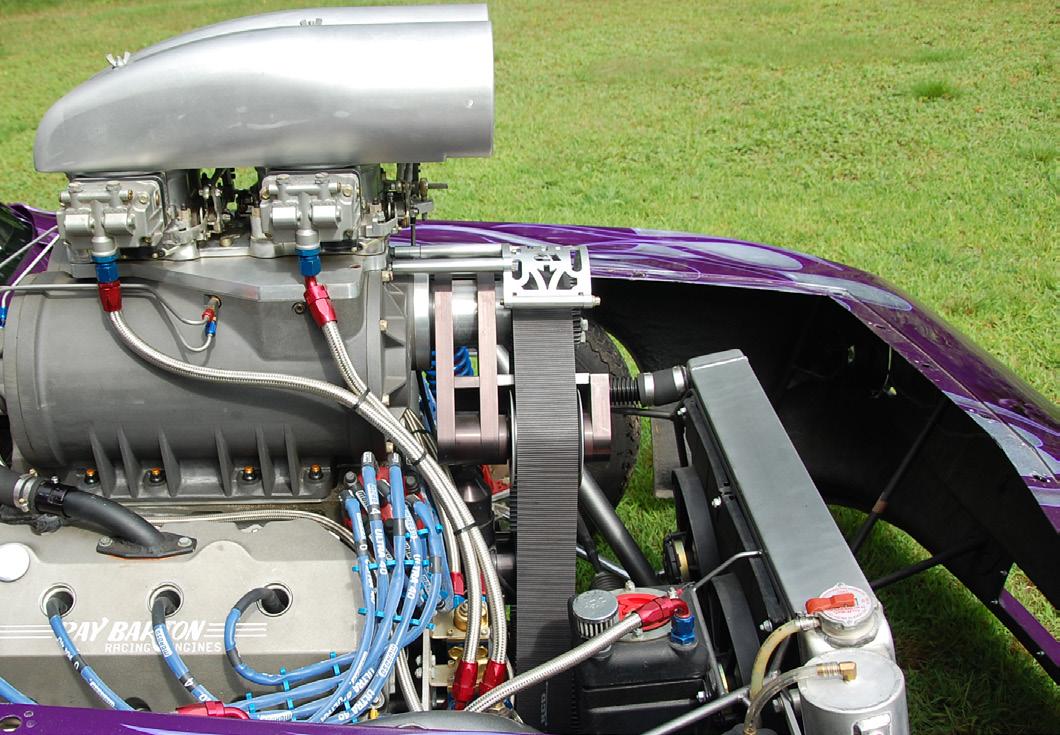

Sciortino turned his attention to the driveline of what was shaping up to be one wild Plymouth. Ray Barton of Ray Barton Racing Engines was charged with putting together a brutal 1,629 horsepower (8,000 rpm) and 1,197 ft./lbs. (6,600 rpm) monster screw-blown Hemi mill. Barton started with a Mopar block bored to 4.310 and fitted it with a 4.500-stroke Callies crank, good for a spacious and glorious 526 cubic inches. 9.6:1 pistons were mated to GRP aluminum rods and the entire rotating assembly was balanced and blueprinted before being sealed within the confines of a 9-quart fabricated aluminum pan.

A solid roller cam pushing 0.850 intake and 0.870 exhaust was placed into position and is spun via a Jesel belt drive. COMP Cams solid roller lifters transfer the valve signals northward through the valvetrain, while a pair of aluminum Stage V Engineering Hemi heads provide unparalleled flow— and when partnered with RBRE valve covers, unsurpassed levels of under-hood awesomeness. A full MSD Digital 7 ignition and MSD distributor both generate and hand out the spark.

Induction for the healthy elephant is no less remarkable, with a WAR magnesium intake mated to a massive PSI screw blower overdriven to produce upwards of 20 pounds of boost. As if that wasn’t added power enough, a Jeff Prock 100-hp dual-nozzle direct port nitrous system has been added for good measure. Fuel metering is managed by a pair of 1250 cfm Dominators fed by a Product Engineering electric fuel pump. A body-color shotgun scoop has been added to help keep the heavy-breathing pachyderm adequately oxygenated.

The car rides on a set of Weld wheels, with 15x3.5s up front and 16x16 double-beadlock rears out back. The super-skinny Mickey Thompson Sportsman fronts provide remarkable contrast for the morbidly obese 34.5x17-16 meats out back. A matched quartet of Strange cross-drilled discs help slow all four corners of the car.

Sciortino says that while he’s been working on the car since he got it back in 1982, the current iteration represents about four solid years of steady work.

What’s Old Is New if you haven’t read it yet!

Once the body was complete, it was shipped to Ron’s Auto Madness, where Ron Martin completed all bodywork and prepped the lightweight shell for paint. MRC added a custom fabricated aluminum wing and fit the car with a complete set of Lexan windows. Martin then laid down a flawless House of Kolors purple pearl basecoat before Robert Gorske at Roade Studio added an incredible set of multi-layered silver airbrushed flames and graphics.

With the car all but complete (Sciortino literally finished buttoning it up the day of our photo shoot), he has not yet had a chance to make any passes down the strip but plans to in the future. However, he has had an opportunity to take it to a few shows as well as a shakedown cruise or two around the neighborhood. “ e first time I ever drove the car in my hometown of Trumbull, a police car followed me back to my house to see if the car was properly tagged to drive on public roads,” Sciortino said. “He couldn’t believe it was on the street and all the paperwork was up to date. We had a nice conversation about the car, and I answered about 100,000 questions,” he added with a laugh. at officer might want to be careful, though, because getting too close to this purple ’Cuda is likely to result in the same type of vicious fish bite as Jim Sciortino sustained way back in 1970 at the tender age of 11. Just as rabies can be transmitted through the bite of an infected mammal, we have reason to believe that Pro Street Fever may be transmitted through one bite of this wicked fish.

Photo Exclusive

get info

A 1967 Pontiac Firebird sales brochure boasted: “Leave it to Pontiac to do it right. To build a sports car that’s completely different.” 56 years later, Tyree Smith’s ‘Bird more than lives up to that claim. In 1967, all Firebirds came with manual steering, manual brakes and monoleaf rear suspension. All models, except the base version, got traction bars on the right rear, while those equipped with the 326 HO and 400 ci V-8s got bars on both sides. The design of the bars used on the Firebirds differed from that of the bars used on the Camaro, and they were adjustable. Power steering, power brakes and power front disc brakes were all optional. Standard tires on all Firebirds were E70X14s, optionally you could order B.F. Goodrich 990 FR70x14s on Rally II wheels. The car featured a 120mph Speedometer, 8,000 RPM Tach, and the standard guages: Ammeter, Fuel, Oil Pressure and a clock. It was advertised to have a seating capacity of 4 + 1, but anyone who has ridden in one might dispute that claim. Assembled in Lordstown, Ohio, Firebird production totals for 1967 reached an impressive 82,560.

As a result of Division Chief John Delorean’s persistence, the First Generation F-Body Firebird was introduced on February 23, 1967, 5 months after the debut of its cousin, the Camaro. Loosely based on the GM Banshee concept, it was designed as a pony car to compete with the Ford Mustang. You wouldn’t be mistaken if you see hints of the Corvette and Opel GT in the styling.

I’ve always loved the car and Pontiacs in general, so when Gregg Haun, a friend of mine since I was 15, said ‘let’s put the car back together for a drag and drive event’... I did...

TYREE SMITH

TYREE SMITH

The interior features plenty of safety, comfort and modern tech including the addtion of a digital display, but the style and ambiance of this grand old ‘Bird hasn’t been lost in the transition from 60s Pony Car to 21st Century drag strip warrior.

Tyree Smith’s Naturally Aspirated Street/Strip 1967 Pontiac Firebird

■ Occupation: Owner TY Tech Performance. ■ Owner/Driver History: I’ve personally raced since 1984 starting with street racing and various class racing with multiple championships and records set.

■ Vehicle History: I first built the Firebird in the late 90s as a tribute to the one I had while I was in the air force.

■ Body & Paint: The paint and body was done by Ryan Gartman owner of Insane Paint in Atmore Alabama.

■ Chassis Modifications: Mini tubed with custom carbon tubs that we make here. We also installed an 8.50 cert cage.

■ Suspension (Front & Rear): TRZ a-arms and rack setup. Viking coilover front shocks and rear shocks as well. Calvert springs and bars in the rear.

■ Engine: Pontiac 565 cubic inch. Crower built the crank and rods for us (Pete is the man!). 2nd gen Tiger heads from All Pontiac with Jesel custom rocker system, Pac springs and retainers.

■ Induction & Fuel Delivery: BOP intake with Holley terminator throttle body. ■ Power Adder: None! ■ Horsepower: 1150 hp 911 lb ft torque, naturally aspirated.

■ Transmission: PTC TH400 trans with PTC converter. ■ Rearend: Custom 9-inch with 3.50 gear and 40 spline axles. ■ Brakes: Wilwood front and rear. ■ Tires & Wheels: Race Star wheels with Mickey tires. ■ Interior: Stroud safety belts and window net and chute as well. Holley LCD dash covers all instruments. ■ ET & MPH: 1/8th-mile, 5.30 @ 129 MPH. ■ Most Unique Feature(s): The custom titanium exhaust all the way over the rear to the tag. ■ How Long Did It Take To Build The Car? Around a year. ■ Thanks To: Chad Gower, Travis Quillen, Lane & Kenny from PTC, Ryan Gartman, Kelli jones, Doug and Ryan from Holley, Pete from Crower, Frank from All Pontiac and Preston from BES.

■ Most Memorable Experience To Date: Winning the mid-west Drag Week event.

Photo Exclusive

This ‘67 screams class, power and performance no matter where you choose to look.

STICKEY MICKEYS