16 Specialists in Tough Technology for Tough Territories and Terrains

By Buck Biblehouse, Senior Editor

16 Specialists in Tough Technology for Tough Territories and Terrains

By Buck Biblehouse, Senior Editor

20 Generative AI Predictions for the Defense Market

By

John Reardon,

, Editor-in-Chief, COTS Journal

Cover Image: Sailing Pals

The USS Kansas City leads the USS Hopper as the ships sail in formation while underway for Navy surface warfare advanced tactical training in the Pacific Ocean, March 18, 2023.

COTS (kots), n. 1. Commercial off-the-shelf. Terminology popularized in 1994 within U.S. DoD by SECDEF Wm. Perry’s “Perry Memo” that changed military industry purchasing and design guidelines, making Mil-Specs acceptable only by waiver. COTS is generally defined for technology, goods and services as: a) using commercial business practices and specifications, b) not developed under government funding, c) offered for sale to the general market, d) still must meet the program ORD. 2. Commercial business practices include the accepted practice of customer-paid minor modification to standard COTS products to meet the customer’s unique requirements.

—Ant. When applied to the procurement of electronics for he U.S. Military, COTS is a procurement philosophy and does not imply commercial, office environment or any other durability grade. E.g., rad-hard components designed and offered for sale to the general market are COTS if they were developed by the company and not under government funding.

6 The Inside Track

The Journal of Military Electronics & Computing

EDITORIAL

EDITORIAL SUBMISSION AND RELEASES

johnr@rtc-media.com

PUBLISHER/CEO

John Reardon • Johnr@rtc-media.com

CONTRIBUTING EDITORS

Tom Williams, Glenn ImObersteg Buck Biblehouse

ART AND PRODUCTION

CREATIVE DIRECTOR

David Ramos • drdesignservices@ymail.com

DIGITAL MARKETING MANAGER

Scott Blair • Scott@blair-media.com

AD TRAFFIC

Vaughn Orchard • Vaughno@rtc-media.com

FINANCE AND ACCOUNTING

Paige Reardon • paiger@rtc-media.com

ADMINISTRATION/CIRCULATION

Dawn Dunaway • dawnr@rtc-media.com

ACCOUNT MANAGER

SALES MANAGER

Vaughn Orchard • Vaughno@rtc-media.com

CUSTOM AND CONTRACT SERVICES

John Reardon • Johnr@rtc-media.com

COTS Journal

CORPORATE OFFICE

RTC Media

3180 Sitio Sendero, Carlsbad, CA. 92009

Phone: (949) 226-2023 Fax: (949) 226-2050 www.rtc-media.com

PUBLISHED BY RTC MEDIA

Copyright 2024, RTC Media. Printed in the United States. All rights reserved. All related graphics are trademarks of The RTC Group. All other brand and product names are the property of their holders.

RTX awarded a $677 million U.S. Navy contract for the SPY-6 family of radars Production progress continues for the U.S. Navy’s new radar

Raytheon was awarded a $677 million contract to continue producing AN/SPY-6(V) radars for the U.S. Navy. This is the third option exercised from the March 2022 hardware, production, and sustainment contract, which is valued at up to $3 billion over five years.

Under this contract, the U.S. Navy will receive seven additional radars, increasing the total amount under contract for procurement to 38.

“SPY-6 provides the fleet with superior

air surveillance, electronic warfare protection, and enhanced detection abilities,” said Barbara Borgonovi, president of Naval Power at Raytheon. “This contract is a significant step forward in ensuring this technology is delivered to ships to improve the overall self-defense of the fleet.”

The U.S. Navy is integrating SPY-6 into its surface fleet, beginning with the USS Jack H. Lucas (DDG 125) commissioned in October 2023. The USS Richard M. McCool Jr. (LPD 29) is the second ship and the first to deploy

the (V)2 variant. LPD 29 was delivered to the U.S. Navy on April 11 following completion of builder’s and acceptance trials in the Gulf of Mexico. The SPY-6(V)2 radar not only provides defense against missile threats but will also provide air traffic control capability.

The SPY-6 family of radars is the most tested and advanced radar technology in production today. Over the next ten years, it will be deployed on 65 U.S. Navy ships to defend against air, surface, and ballistic threats.

RapidFlight Secures $10 Million USAF AFWERX Autonomy Prime Contract

RapidFlight, a pioneering integrated designer and manufacturer of Unmanned Aircraft Systems (UAS), has been awarded a contract valued up to $10 million by the United States Department of the Air Force (DAF) AFWERX Autonomy Prime program to develop and produce a 3D-printed, autonomous, fixed-wing aircraft system, the SPX.

The DAF created AFWERX to bring cutting-edge American ingenuity from small businesses and startups, such as RapidFlight, to address its most pressing challenges. The Autonomy Prime branch focuses on the collaborative development of autonomous technologies with industry to accelerate the transition into Air Force programs of record.

“Our collaboration with the AFWERX Autonomy Prime Program positions RapidFlight as a leading innovator for delivering mission-customized, autonomous aircraft with up to 80% reduced design to manufacturing time and platform costs

as compared to existing solutions,” said Michael Uffelman, Director of Growth and Customer Programs at RapidFlight. “This contract will enable the DAF to explore RapidFlight’s digital engineering process and its modern development approach to produce customizable aircraft with novel technologies critical for national security.”

“Autonomy Prime is excited about this innovative approach to unmanned autonomous aviation,” said Lt Col Josh Fehd, AFWERX Autonomy Prime Branch Chief. “It represents a promising opportunity to continue our mission of creating a rapid, affordable, and iterative autonomy testing and transition capability for the DAF.”

For the first phase of the 36-month contract, RapidFlight will design SPX UAVs for developmental testing and evaluation at the Autonomy Prime Proving Ground, a state-of-the-art facility designed to facilitate swift and iterative testing and development of autonomous UAS technologies. RapidFlight will then conduct a contractor-owned, contractor-operated (COCO) demonstration of the SPX to the United States Air Force (USAF) at RapidFlight’s flight test facility

in Manassas, Va. Throughout the contract, RapidFlight will provide comprehensive operations and maintenance training for SPX to USAF operators.

The SPX is a Group 2 UAS with a 12 lb. payload capacity and 150 nm range. It also features a modular payload bay to accommodate various payload types, sensors, and autonomy packages. To facilitate research and development, developers will utilize the RapidFlight Common Avionics 2.0 modular interface, which can support developmental payloads and enable autonomous flight developers to generate real-world flight test data faster and more economically than ever before.

Meanwhile, the RapidFlight proprietary AgileAviation process will drastically reduce the development lifecycle within the first phase of UAV development, the completion of which includes aircraft delivery and flight crew training, scheduled to be completed in seven months. Each SPX system comprises four airframes, a ground control station, a field kit, and a compact launcher.

Mobix Labs Chosen to Supply HighPerformance Connectors for U.S. Navy’s Standard Missile-6 Program

Mobix Labs Inc. announces a milestone achievement in collaboration with the U.S. defense sector. Mobix Labs has been selected as a supplier of connectors for the Navy’s Standard Missile-6 program and has completed its initial product delivery.

The Standard Missile-6 is an integral component of the U.S. Navy’s defense arsenal and the only weapon capable of performing anti-air warfare, anti-surface warfare, ballistic missile defense, and sea-based missions. Its deployment enhances America’s naval fleet’s ability to defend

Bell Awarded Funding for Phase 1B of DARPA Speed and Runway Independent Technologies (SPRINT) X-Plane Program

Bell completes the conceptual design phase for the X-plane program.

Bell Textron Inc. has been down-selected for Phase 1B of the Defense Advanced Research Projects Agency (DARPA) Speed and Runway Independent Technologies (SPRINT) X-Plane program. The SPRINT program intends to design, build, and fly an X-Plane, an experimental aircraft to demonstrate enabling technologies and integrated concepts necessary for a transformational combination of aircraft speed and runway inde-

against threats ranging from enemy aircraft to ballistic missiles.

Mobix Labs’ connectors have undergone rigorous testing and will be used in the Standard Missile-6 guidance system to ensure precise and reliable communications. This significant milestone reflects Mobix Labs’ unwavering dedication to delivering high-performance, reliable solutions essential for our national defense.

“The integration of Mobix Labs’ connectors significantly bolsters the capabilities and effec-

pendence for the next generation of air mobility platforms. In Phase 1A, Bell executed a conceptual design review and will move into preliminary design efforts for the SPRINT X-plane.

“Bell is honored to be selected for the next phase of this revolutionary program and ready to execute the preliminary design,” said Jason Hurst, executive vice president of engineering at Bell. “We completed our initial risk reduction efforts with our sled test demonstration at Holloman Air Force Base, and we look forward to building on this success with our continued work with DARPA.”

Bell completed risk reduction testing at Holloman Air Force Base in late 2023, showcas-

tiveness of the U.S. Navy’s Standard Missile-6 program,” said Fabian Battaglia, CEO of Mobix Labs. “Our parts deliver high performance and enable high-reliability communications in the Standard Missile-6 guidance system, with the ability to withstand big shock, vibration, and extreme temperatures. Completing our first delivery of connectors marks a significant milestone, and we look forward to more orders on this important U.S. defense program. This approval validates that mission-critical systems can rely on Mobix Labs’ connectors for predictable performance.”

ing folding rotor, integrated propulsion, and flight control technologies. Bell is building on its investment in high-speed vertical takeoff and landing (HSVTOL) technology and past X-plane experience to inform the X-plane development of this program.

Bell’s HSVTOL technology blends the hover capability of a helicopter with speed (400+ kits), range, and survivability of jet aircraft. For more than 85 years, Bell has developed high-speed vertical lift technology, pioneering innovative VTOL configurations like the X-14, X-22, XV-3, and XV15 for NASA, the U.S. Army, and the U.S. Air Force. It continues to build on its proven history of fast flight from the Bell X-1.

BAE Systems’ fourth Armored Multi-Purpose Vehicle (AMPV) prototype is showcased at Eurosatory this week. Configured with a standard top plate, the External Mission Equipment Package (ExMEP), the prototype showcases the vehicle’s ability to integrate capabilities and equipment packages internationally.

This AMPV prototype features Oshkosh Defense’s Medium Caliber Weapon System (MCWS), a 30mm weapon system with planned fielding to the U.S. Army’s Stryker Brigade Combat Teams. The vehicle’s ExMEP can adapt to more than 30 different turret systems and build on the vehicle’s modularity. This creates a seamless path for international customers to address various mission needs with the AMPV platform.

“This latest prototype demonstrates the ca-

Rheinmetall has set new standards with its innovative and powerful Gladius 2.0 soldier system. Its open, modular, scalable architecture makes the system unrivaled worldwide as a user-centric soldier system solution. Up-to-date situational awareness with a consistent, stable communication infrastructure enables operational sensor-to-shooter networks. Gladius 2.0 guarantees a decisive advantage on the digital battlefield under even the most challenging of conditions.

Rheinmetall continues to improve its systems and has partnered with QUS in vital data tracking to develop a solution in this area. Live tracking of vital data allows training units to be adjusted during training to ensure optimal fitness development. During operations, information on the physical condition of individual soldiers or the entire unit is available, which is essential for further tactical decisions. This is particularly crucial for soldiers in complex operational scenarios under challenging conditions.

QUS, with its established system, already meets many requirements relevant to successful integration into soldier systems. Therefore, it can be easily integrated and significantly expands the capabilities of soldier systems.

pabilities of a common top plate and the options it provides our allies and NATO partners for rapid integration of next-generation technology onto a proven vehicle,” said Bill Sheehy, AMPV program director for BAE Systems. “The adaptability of the AMPV design means we can execute new capability integration quickly and efficiently, further proving the platform’s future-proofed design.”

forward to furthering conversations with our allied nations about how fast and effectively we can adapt the AMPV for any needed operation or role.”

BAE Systems integrated and successfully demonstrated a C-UAS prototype in November 2023 while also integrating and delivering a 120mm unmanned Turreted Mortar capability to the U.S. Army in January 2024. The AMPV NxT prototype debuted with a 30mm turret at AUSA Global Force in March 2024—all three prototypes using the standard top plate.

“No matter the mission, the AMPV will continue to provide the support troops need in battle for generations to come,” Sheehy said. “We look

“We are very pleased about the new partnership with Rheinmetall. We will develop a system that seamlessly integrates into Rheinmetall’s battlefield management system, creating additional value in this area. Knowing and assessing the vital data of soldiers at any time is very important for performance,” says Hannes Steiner, QUS CEO & Founder.

Timo Haas, Chief Digital Officer (CDO) of Rheinmetall AG and Managing Director of Rheinmetall Electronics GmbH: “Biomonitoring, as we know it from competitive sports, will also play an important role for soldiers in the future to optimize operational readiness. For us as a system provider, QUS’s solution offers an additional component to our modular soldier system. And with a view to digitization, AI-supported data can make

Most recently, BAE Systems received a $754 million contract award from the U.S. Army to continue manufacturing the AMPV Family of Vehicles (FoV), guaranteeing a second phase of full-rate production (FRP) volumes through February 2027. This follows the original $797 million FRP contract awarded in August 2023.

The five variants currently in production provide enhanced survivability and performance over the legacy M113 FoV. The AMPV’s modular chassis and commonality have proven it to be a low-risk and cost-effective solution that rapidly delivers continued combat overmatch solutions to troops ready for the battlefield.

an important contribution to tactical decisions at higher command levels.”

The joint solution of QUS and Rheinmetall within the partnership will combine everything related to body data and fully exploit its potential. The ability to combine already proven sensors (heart rate, respiratory rate) with other external sensors (such as temperature, etc.) enables a new basis for tactical decisions based on the knowledge of the soldiers’ current condition.

Fusing this data with tactical information represents a new dimension of information superiority regarding one’s own troops and will improve soldiers’ performance and the command process.

Swedish deep tech startup Sinonus selects the first CEO to launch energystoring carbon fiber composites.

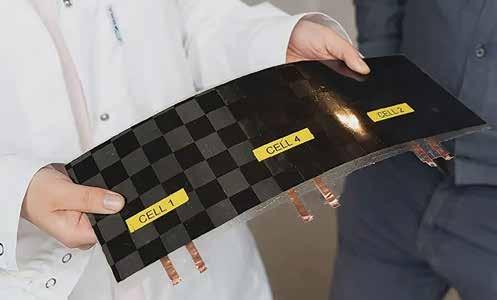

Chalmers Ventures’ new portfolio company, Sinonus, a spinout from Chalmers Technical University, has hired ex-Maurten and SKF manager Markus Zetterström as its new CEO. The company’s unique carbon fiber material can store electrical energy, enabling energy storage in existing structures for a variety of industries, from E.V.s to airplanes.

Markus Zetterström has been appointed CEO of Sinonus, a spinout from Chalmers Technical UniversityTechnical University and KTH that is part of Chalmers Ventures’ portfolio. At Sinonus, Markus Zetterström will focus on commercializing the groundbreaking technology of carbon fibers that double as battery electrodes, which the company is currently developing.

Sinonus has already demonstrated the potential of its technology by replacing AAA batteries in low-power products in its lab. The goal is to expand the technology to larger applications such as IoT devices and eventually to drones, computers, larger vehicles, and airplanes.

Carbon fiber is a strong, light construction material that can store energy electrochemically. Sinonus uses this multi-functionality to make true carbon fiber-based structural batteries that

The Global Military Artificial Intelligence (A.I.) market is projected to grow at a CAGR of 14.49% from 2024 to 2031, according to a new report published by Verified Market Research®. The report reveals that the market was valued at USD 13.24 billion in 2024 and is expected to reach USD 35.54 billion by the end of the forecast period.

store energy and become an integral part of the product’s structure. This patented innovation represents a significant step forward in streamlining batteries and their use.

The carbon fiber technology in Sinonus originates from Oxeon, another of Chalmers Venture’s portfolio companies. The carbon fiber was used in the propeller blades for NASA’s Ingenuity helicopter on Mars, chosen by the engineering team due to their ultralight weight and thinness.

“I’m thrilled to be joining Sinonus as CEO.

The company’s innovative breakthrough in adding the dimension of electrical energy storage to carbon fiber has the potential to be truly transformative across a wide range of industries. I’m excited to work with the talented Sinonus team to unlock the full potential of this groundbreaking technology,” Markus Zetterström says.

For passenger aircraft to be powered by electricity, they need to be much lighter than they are today. Weight reduction is also very important for road vehicles, allowing them to extend the driving range per battery charge.

A Memorandum of Understanding formalized collaboration to drive the industrialization of quantum technologies in Japan and around the world.

Harnessing the power of quantum technologies promises to spur widespread innovation by using the fundamental laws of quantum mechanics to solve impossible problems using current technologies. However, building a strong quantum ecosystem takes time and requires significant investments from both national governments and private industry. These efforts also need the cooperation of the academic and government quantum research communities.

Recognizing this need, Keysight and Japan’s National Institute of Advanced Industrial Science and Technology (AIST) have signed a Memorandum of Understanding (MoU) to collaborate on quantum research and to drive the industrializa-

tion of quantum technologies.

Keysight’s Dr. Eric Holland (left) and AIST’s Norimitsu Murayama signed the agreement to collaborate on quantum research and drive quantum industrialization Keysight’s Dr. Eric Holland (left) and AIST’s Norimitsu Murayama signed the agreement to collaborate on quantum research and drive quantum industrialization.

“We’re in the early days of quantum, and while there is steady scientific progress, we need sustained collaboration among all members of the quantum community to make this a viable commercial technology,” said Dr. Eric Holland, General Manager for Keysight’s Quantum Engineering Solutions group. “By formalizing a quantum collaboration with our long-time partner AIST, Keysight will be able to help quantum move forward as an industry with our unique expertise and solutions.”

Under the terms of the agreement, Keysight and AIST will focus extensively on exploring quantum control technologies, low-temperature elec-

tronics device technology, and modeling and simulation, as well as the standardization of these items in fields such as quantum computing and quantum sensing.

The Global Research Center for Quantum-AI Fusion Technology Business Development (G-QuAT), a revolutionary research facility featuring a 1,000-qubit quantum computer, will be at the center of the collaboration. AIST will integrate and link G-QuAT’s evaluation testbeds, device manufacturing capabilities, and computing infrastructure with Keysight’s quantum control technologies and 5G / 6G evaluation technologies.

“Japan has an ambitious 10-year plan to become a quantum leader, and Keysight is synergistically aligned to help deliver on these plans,” said Holland. “Linking our quantum control technologies to the G-QuAT facility will truly make it a world-class quantum research facility.”

Northrop Grumman Delivers First Full Set of Integrated Battle Command System Equipment to the U.S. Army

IBCS (Integrated Air and Missile Defense Battle Command System) • Missile Defense June 17, 2024.

Northrop Grumman Corporation delivered the first production Integrated Battle Command System (IBCS) Engagement Operations Center (EOC) and Integrated Fire Control Network (IFCN) Relay to the U.S. Army. The delivery of this equipment, coupled with the Integrated Collaborative Environment (ICE) delivered in December 2023, completes the first full set of IBCS delivered under the low-rate initial production (LRIP) award.

A complete IBCS set allows the Army to conduct the necessary training to deploy IBCS’ ready now, cutting-edge command and control system powering unprecedented multi-domain integration.

The EOC hosts the battle management software, communications, and computing power, enabling IBCS operators to plan and fight the battle. The IFCN Relay forms the IBCS communications network and serves as the interface for sensors and weapons integrated into IBCS. The U.S. Army awarded Northrop Grumman a fullrate production (FRP) contract for IBCS in May. The fiscal year 2024 FRP award of $145 million will support the production and deployment of IBCS’ revolutionary command and control capabilities to support U.S. warfighters. Northrop Grumman Delivers First Full Set of Integrated Battle Command System Equipment to the U.S. Army. The Engagement Operations Center (EOC) loaded onto an M1085 Long Wheel Base truck at the Huntsville Manufacturing Center in Alabama.

(Photo Credit: Northrop Grumman)

Rebecca Torzone, vice president and general manager, combat systems and mission readiness, Northrop Grumman: “IBCS is ready now to provide our warfighters more decision time in the battlespace to outpace tomorrow’s threats. Northrop Grumman is committed to putting IBCS in the hands of our warfighters at an accelerated delivery rate so they can lead the way in modernized air and missile defense.”

The EOC and IFCN Relay deliveries follow the initial December 2023 delivery of the ICE to the Army, of which the Army has accepted 13. This first complete set of equipment will support initial activities leading to the IBCS Full Operational Test and Evaluation in 2025.

The recently issued Full Rate Production contract award for IBCS is a critical milestone. It reflects successful IBCS performance at numerous air and missile defense test events, integrating Patriot, Lower Tier Air and Missile Defense, Indirect Fire Protection Capability, and other sensors and effectors. It also reflects Northrop Grumman’s successful delivery of LRIP systems to the U.S. Army.

IBCS is a revolutionary command and control system unifying current and future assets in the battlespace, regardless of source, service, or domain. Through its modular, open, and scalable architecture, IBCS gives warfighters capabilities not previously available by fusing sensor data for a single actionable picture of the full battlespace, enabling rapid, informed decisions to optimize shooters. This capability gives warfighters more time to decide how best to defeat threats. IBCS is the centerpiece of the U.S. Army’s air and missile defense modernization strategy, and it is currently fielded in Poland. IBCS is a foundational element for the multi-domain, multi-national future.

Celebrating 50 Years of American Excellence:

Celebrating 50 Years of American Excellence:

By Buck Biblehouse, Senior Editor

OTEK Corporation proudly stands as an emblem of American ingenuity and perseverance in the dynamic realm of instrumentation and measurement technology. As the company marks its illustrious 50th anniversary alongside the esteemed Otto Fest, the narrative of relentless innovation, unwavering dedication, and staunch commitment to excellence takes center stage.

At the nucleus of OTEK’s triumph lies its formidable intellectual property (IP) arsenal, comprising a remarkable array of 18 leading patents and two pending. These patents, spanning groundbreaking analog meter direct replacement innovations to cutting-edge digital instrumentation solutions, epitomize OTEK’s relentless pursuit of advancement and steadfast dedication to redefining industry benchmarks. They showcase the company’s technological prowess and underscore its visionary outlook and commitment to pushing the boundaries of possibility.

A cornerstone of OTEK’s ascent to prominence has been the unwavering support it has garnered from industry peers and collaborators. Through steadfast partnerships and alliances forged over the years, OTEK has earned the trust and admiration of its customers, solidifying its position as a preeminent provider of innovative solutions that consistently surpass expectations. Established on the principle that the most challenging problems necessitate the most straightforward solutions, OTEK is a leader in the field of innovative solutions.

Central to OTEK’s ethos is the indelible imprint of its visionary leader, Dr. Otto Fest. Infused with a relentless pursuit of excellence, Dr. Fest has cultivated a corporate culture steeped in integrity, dedication, and customercentricity principles. This culture permeates every facet of OTEK’s operations, ensuring that the company remains unwaveringly committed to delivering unparalleled value and reliability to its clientele. Dr. Fest proudly conveys, “OTEK guarantees all its products for life—not just the product itself, but the company! When used according to specifications, there is no reason for our products ever to fail.”

Dr. Fest’s unyielding dedication to OTEK’s clientele and the various industries it serves is ingrained deeply within the fabric of OTEK’s identity. Dr. Fest, alongside his proficient and innovative team, has become renowned for their willingness to embrace challenges head-

on, customizing their industry-leading digital measurement solutions despite seemingly insurmountable challenges. Their commitment to innovation and problem-solving has led one impressed customer to coin OTEK the moniker affectionately “the digitizers,” lending further credibility to Dr. Fest’s commitment to his esteemed technology.

Dr. Fest’s profound love for family, heritage, and his adopted homeland of the United States resonates throughout OTEK’s operations. Since 1974, OTEK has stood unwavering by the side of the military, demonstrating steadfast support. In the beginning, the US military entrusted OTEK with the development of its pioneering “flatpack” digital meter, a revolutionary creation that remains unparalleled to this day. Remarkably, these meters continue to serve our nation’s defense forces flawlessly, a testament to OTEK’s enduring commitment to excellence and reliability in military technology.

At the heart of Dr. Fest’s leadership philosophy lies a steadfast commitment to prioritizing people above all else. Whether it’s his unwavering dedication to his family, friends, or employees, Dr. Fest’s emphasis on fostering meaningful relationships underscores OTEK’s human-centric approach to business. In an era characterized by rapid technological advancement, OTEK’s enduring success is a testament to the transformative power of people-first leadership and an unwavering commitment to excellence. His journey began in 1976, shaping DIN Standards and lecturing across Germany. Transitioning to NASA, he was pivotal in multiple Apollo missions, contributing to landing a man on the moon.

As OTEK celebrates its 50th anniversary alongside the remarkable legacy of Dr. Otto Fest, the journey of innovation, integrity, and impact continues unabated. Guided by a vision of excellence that remains as resolute as ever, OTEK stands poised to embark on the next chapter of its storied history, propelled by the spirit of American ingenuity and the enduring legacy of Otto Fest, a true patriot in every sense of the word.

4016 E. Tennessee St. Tucson, AZ 85714 USA Sales@otekcorp.com

520-748-7900 • Fax: 520-790-2808 877-227-6835

By Buck Biblehouse, Senior Editor

In San Diego, Core Systems is an expert in providing top-of-the-line, rugged industrial and military-grade technology solutions.

Whether providing cuttingedge equipment for industrial operations or reliable technology for military applications, Core Systems can meet the unique requirements of organizations with critical needs.

As a reliable partner, the company specializes in manufacturing best-in-class rugged industrial computers, displays, handheld units, and other systems that can withstand shocks, vibrations, humidity, and

extreme temperatures.

With two premier vertically integrated production facilities equipped with top-tier engineering and fabrication teams, Core Systems stands out for its comprehensive strategy towards product development and integration. This approach ensures that every aspect of its products is meticulously designed and tested to meet the highest standards.

From the conceptualization phase to the meticulous environmental testing stage, Core Systems manages every aspect of the process in-house. It also has a complete machine shop on the premises, which enables it to rapidly create prototypes and tailor products to meet clients’ precise requirements.

In addition, it builds and integrates systems with Graphics Processing Unit (GPU) boards,

which are used for artificial intelligence (AI) purposes. Moreover, the metal shop executes computer numerical control (CNC), punch fold, paint, and welding, and has its own environmental testing, integration, and cable manufacturing facilities.

Core Systems has achieved a significant milestone by successfully participating in the renowned Lockheed Martin HDR-G program, a testament to its capabilities.

This program, known for its advanced data processing and communication capabilities, trusted Core Systems’ expertise to deliver robust and reliable solutions.

By being chosen for rack integration, the company played a pivotal role in ensuring the seamless integration and functionality of critical systems.

The HDR-G program relies on Core Systems’ expertise to deliver robust and reliable solutions.

Renowned for its distinctive, rugged military-grade versions of the top server brands in the market, such as repackaging Hewlett Packard Enterprise (HPE), CISCO, and Arista, Core Systems stands alone in providing this service. This exceptional offering underscores its engineering prowess and unwavering commitment to delivering solutions that surpass industry standards.

Core Systems is a highly regarded company that specializes in providing cutting-edge hardware solutions and advanced AI technology to military forces across the globe. We create the only rugged HPE servers that support certain AI capabilities.

Furthermore, machine learning (ML) is designed to adapt to ever-changing and challenging environments, enhance security, and safeguard robust encryption for sensitive data. At the same time, AI-powered simulation offers realistic combat training scenarios. Rugged systems are built with extreme durability in mind to withstand harsh conditions.

With its innovative technology, Core Systems has gained recognition and adoption from military forces worldwide, including the Army, Navy, and other defense agencies. The company’s solutions have proved to be highly effective in enhancing the accuracy, speed, and reliability of military operations, thereby increasing the safety and success of personnel on the ground.

Through ongoing R&D, Core Systems continues to push the boundaries of AI technology, enabling military forces to stay ahead of the curve and maintain a competitive edge. Its commitment to excellence and an unwavering focus on safety and security make it a trusted partner for military forces worldwide.

With a relentless focus on quality, reliability, and customer satisfaction, Core Systems has a proven track record of success. A portfolio of groundbreaking solutions ensures that the company is committed to its vision of empowering its customers to achieve their goals.

As an industry leader in technological

innovation, Core Systems is dedicated to providing cutting-edge solutions that meet the evolving needs of the industrial and military sectors globally.

Core Systems follows a design strategy that involves collaboration with its engineering team to ensure efficient product realization, whilst its world-class mechanical design engineering team provides product design. The next stage of the process involves a vertically integrated facility that enables rapid prototyping capabilities. After that, an on-site product test laboratory validates each new design to meet military specifications (MIL-Specs). Product assembly occurs at Core Systems’ facility with multiple production floors.

Additionally, every product comes with a standard warranty and lifetime support.

Core Systems has extensive experience in commercial and defense programs spanning aerospace, transportation, military, security, and intelligence across the land, sea, air, space, cyberspace, and joint all-domains.

The company has expertise in developing mission-critical systems for various applications designed to meet environmental demands and adapt to an everchanging battlefield. Its history dates back to 2007 when it created sensor signal processing for defense applications, missioncritical airborne systems, and other purpose-built systems that exceeded expectations.

Core Systems provides a diverse selection

of top-quality openframe racks, server racks, and enclosures suitable for a wide range of missions. In addition, the company offers integration services that involve assembling a fully configured rack cabinet system ready for deployment on the same day it is shipped. Its team of experts is always available to help select the best cabinet for specific mission requirements.

Specializing in developing mission-critical systems for various applications, Core Systems’ solutions are designed to meet the environmental demands of each unique mission and adapt to the constantly changing battlefield.

With a strong track record of creating sensor processing systems and designing and developing mission-critical airborne systems for various military and defense applications, the company is a trusted leader in the industry.

Core Systems’ portfolio of rugged solutions and one-off designs is purpose-built to exceed mission expectations. It adapts to the battlefield’s changing demands to ensure its products perform optimally in any environment.

From advanced radar technology to improving intelligence, surveillance, and reconnaissance (ISR) capabilities, it is committed to providing customized solutions that meet the unique needs of military operations. Dedicated to ensuring excellence from start to finish, Core Systems offers a reliable solution for every possible military application with precision, expertise, and unmatched reliability on the battlefield.

Core Systems has a rich experience in creating robust computing solutions for the military. Its portfolio includes a wide range of projects with both commercial and defense programs. The company works closely with all military branches, designing customized solutions that suit specific deployments and ensuring that every challenge is met with innovation.

The Rugged ATMOS server is an independent stackable node computer with the latest Intel® Xeon® scalable CPU.

The AR7 is a small, rugged, and SWaP optimized tactical mission computer with the latest Intel Gen Quad Core CPU.

For years, Core Systems has worked tirelessly to create secure and reliable solutions for military aircraft, navigation, and other airborne applications. The company’s advanced computing solutions, including highdefinition displays and SWaPC-optimized mission computers, are among the most powerful and dependable in the world, designed to withstand the most challenging environments and ensure the safety and security of military personnel.

Taking pride in its commitment to providing industry-leading products tailored to meet specific needs, Core Systems ensures that customers can complete their missions efficiently and confidently.

Core Systems delivers rugged, reliable technology for multidomain operations worldwide. It showcases its ability to overcome complex problems with versatile systems that thrive in extreme environments. It also has a long history of creating defense solutions for naval platforms built with size and safety in mind.

As the US Space Force continues to make great strides and push boundaries in the field of space exploration, Core Systems is proud to work alongside NASA in developing cutting-edge computing solutions designed to withstand outer space’s harsh and demanding conditions.

The team is committed to providing the necessary tools and technology to support space missions at all orbit levels, ensuring that astronauts and researchers can access reliable and efficient computing resources while exploring the final frontier.

The military’s primary concern is the growing speed of cyber threats worldwide. Core Systems has spent years diagnosing, preventing, and solving these threats, providing multi-domain solutions that can operate independently or together across missioncritical infrastructure. The company ensures that systems operate without interruption and that missions are covered at all attack points.

Collaborate with Core Systems to blend cutting-edge technology with dependable systems to meet modern military demands.

The AR2 is a small, rugged, and SWaP-optimized tactical mission computer with the latest Intel Gen Quad Core CPU.

By John Reardon, Editor-in-Chief, COTS Journal

The Western world has witnessed the emergence of numerous companies backed by an eager investment community, ready to make their mark in this dynamic and growing market. With superfunds, many exceeding billions of dollars, and a drive to develop breakthrough technologies, the market is burgeoning with possibilities.

Commercial markets have focused on using Large Language Models (LLMs) to handle simple tasks by analyzing vast amounts of open-source data. While these models can answer questions and predict text, they often tolerate errors in precision. However, this tolerance may not be acceptable in the defense sector.

High-power GPUs, such as those from Nvidia, require significant energy, posing challenges in remote military operations. With modern GPUs consuming up to 700 watts, power and heat dissipation become critical issues. The commercial sector’s high energy consumption has led Nvidia to predict potential strain on the US power grid.

To address heat generation, companies are exploring advanced cooling techniques, including single and two-phase cooling methods, exotic dielectric fluids, and heat pumps. One lab innovation involves a system monitoring solution that modulates the GPU’s clock speed, reducing heat by 40% but at the cost of overall system performance.

The defense sector, with its high energy demands, continues to explore small modular reactors for propulsion and sustainable energy. Companies like Helion, backed by Sam Altman with over $500 million in initial funding, are advancing fusion technology for high-energy output in compact forms. These advancements could lead to future replacements for conventional propulsion systems in the Navy.

The effectiveness of LLMs and machine learning tools depends on high-quality data. Relying on suspect open-source data can lead to diminishing returns and potential collapse

The defense sector, with its high energy demands, continues to explore small modular reactors for propulsion and sustainable energy.

due to data “inbreeding.” The rapid adoption of AI across consumer platforms exacerbates this issue. As primary sources challenge copyright laws and shift marketing dollars away from data-scraping companies, the trend towards synthetic data is likely to continue.

The shortage of Nvidia’s H100 GPUs is wellknown, with TSMC’s CoWoS technology unable to meet demand. Secondary markets have emerged, supporting high markups for those willing to pay. However, production levels are gradually catching up.

Nvidia faces competition from its largest customers, including Google and Amazon, who are developing their own solutions. Intel and AMD remain strong contenders, with Intel partnering with Nvidia to address TSMC production shortfalls.

Confidential data breaches and data

poisoning are growing concerns, particularly in the defense sector. The possibility of a wearable solution with data center performance creating an open link to enemies raises significant security fears. Exposed battle plans and technologies could be exploited by adversaries.

The fragmented Machine Learning Operations (MLOps) market sees the defense sector favoring single-source solutions, as evidenced by Amazon’s market share gains. Analysts predict valuation declines and consolidation similar to the cybersecurity market trends related to consumer devices.

Developing tools that extract information from various sources and combine data from different modalities is promising for military solutions. Multimodal AI can integrate images, videos, and text, enhancing data validation and coordination. In medical applications, this could improve battlefield casualty survival rates. As complexity increases, multimodal AI solutions

become invaluable, handling numerous variables that exceed human capacity.

While commercial AI discussions often focus on dating apps, entertainment, and deep fakes, these seemingly trivial applications drive significant technological advancements. The ability to create deep fakes or identify targets in complex environments parallels military needs, showcasing the broader impact of commercial AI innovations.

The defense market stands at the brink of significant transformation through generative AI. As the sector grapples with power consumption, data quality, security, and technological advancements, the integration of AI promises to reshape military operations and strategies, driving both innovation and complexity.

The possibility of a wearable solution with data center performance creating an open link to enemies raises significant security fears.

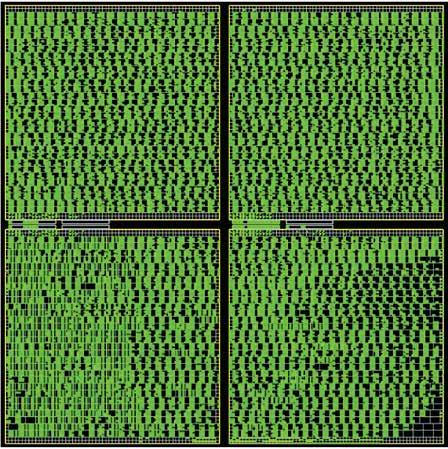

EXPRESO™ EFPGA Compiler Achieves Record 98.6% LUT Packing Density

Up to 1.5x higher Fmax, 2x packing density, and 10x faster compile times.

Flex Logix® Technologies, Inc., the leading supplier of embedded FPGA (eFPGA) I.P. and reconfigurable DSP/SDR/AI solutions, announced the availability of espresso, its powerful second-generation EFLX eFPGA compiler. eXpreso, which has been developed for years, is shipping to alpha customers for evaluation. The new compiler delivers up to 1.5x higher frequency, 2x denser LUT packing, and 10x faster compile times for all existing EFLX tiles and arrays. Flex Logix plans to release eXpreso for production later this year.

Embedded FPGA provides crucial flexibility, allowing SoCs to adapt to changing standards, protocols, customer requirements, and post-quantum cryptography algorithms; it also enables software acceleration and deterministic processing. eXpreso significantly enhances the value of eFPGA by minimizing the silicon die area, saving cost and power.

“I am proud of our eFPGA Software team for the tremendous results delivered by eXpreso,” said Cheng Wang, CTO & SVP Software/Architecture of Flex Logix. “Designs like AES256 are compressed into two tiles that used to take 6. One cryptography algorithm achieved 98.6% LUT utilization – something not achievable even by Xilinx. We can achieve this on EFLX because of our interconnect inventions and excellent place and route algorithms. We are working with initial customers now to apply eXpreso to their designs and are

seeing good results.”

Flex Logix flex-logix.com

Pixus Technologies, a provider of embedded computing and enclosure solutions, has released its most compact test/development chassis, the Mini Cube. The chassis is used for prototyping 3U OpenVPX and SOSA-aligned systems.

The Mini Cube supports 5x VPX/SOSA aligned slots with a VITA 62 PSU or 4x slots with an internal low-cost 600W Pixus modular power supply with universal A.C. input. Backplanes at various speeds, SOSA-aligned slot profiles, and power and ground-only format options are available. Card guides are interchangeable for air-cooled or conduction-cooled boards.

The compact Pixus Mini Cube chassis has a convenient, foldable carry handle and flip-up feet for a more presentable display. The enclosure also supports Rear Transition Modules (RTMs).

Pixus offers OpenVPX backplanes, chassis platforms, managers, and specialty products. The company also provides enclosure solutions in VME, cPCI Serial, AdvancedTCA, and instrumentation case formats.

Pixus Technologies pixustechnologies.com

Percepio® Announces Tracealyzer® Version 4.9 With Major Improvements for Linux Users

Percepio AB, the leading provider of continuous observability solutions for embedded edge systems, announces the immediate availability of Tracealyzer® version 4.9—the latest update to its flagship observability tool for embedded software.

This release focuses on improving the user experience when installing and running Tracealyzer on a Linux host computer. A new standalone installation package that includes everything needed to run Tracealyzer has dramatically simplified installation. A new user can run on most Linux distributions in a few minutes.

“Providing great Linux support is of key

Anritsu Corporation unveils its groundbreaking advancements in field testing equipment—the Site Master™ MS2085A Cable and Antenna Analyzer and the MS2089A with Integrated Spectrum Analyzer. These latest entries to the Anritsu lineup are designed from the ground up to further Anritsu’s dominance in the installation and maintenance arena and address the multifaceted demands of the general-purpose market. They redefine industry standards for functionality, precision, and user-friendly operation, marking a transformative leap forward in field testing technology.

The Site Master MS2085A and MS2089A encapsulate the pinnacle of modern engineering, combining Anritsu’s extensive experience and commitment to customer-focused innovation. This dual offering merges the functions of cable and antenna analysis with spectrum analysis and monitoring in a seamless, integrated solution. It is tailored to support various industries, including telecommunications, broadcasting, aerospace, satellite, and defense. It facilitates multiple applications, from Distributed Antenna Systems (DAS) and satellite monitoring to interference analysis and routine installation and maintenance tasks.

importance to us at Percepio. Many software developers prefer Linux, and we have a growing developer community that has contributed with a lot of feedback and testimonials over the years. We are very grateful for their support and want to give back to the Linux community with this Tracealyzer release, where the main objective is improved user experience for Linux users,” says Johan Kraft, founder and CTO at Percepio.

The user experience and performance on Linux have been improved significantly. Several Linux-related bugs and GUI issues have been fixed, the application starts up faster, and traces load faster.

The new version also updates the TraceRecorder support for Eclipse ThreadX and SA-

Highlighted Features and Advantages:

· Multi-functional Capability: The Site Master’s integration of cable and antenna analysis alongside spectrum analysis equips professionals with a singular, versatile tool for various testing and analysis needs. It is a comprehensive solution for assessing antenna systems, diagnosing wireless networks, or monitoring spectrum signals.

· Operational Efficiency: By merging multiple testing functions into one device, the Site Master significantly optimizes field testing workflows. This consolidation reduces the need for various instruments, streamlines testing processes, and allows for more significant achievements in shorter timeframes—effectively enhancing productivity while minimizing operational costs.

FERTOS® to improve recorder integration and support the most recent RTOS features. SAFERTOS support is provided via WITTENSTEIN high integrity systems.

Tracealyzer 4.9 also improves support for LynxOS-178®, the standards-based RTOS for safety-critical real-time applications from Lynx Software Technologies. This includes the ability to record process data in the TraceRecorder

brary and group threads by process in the trace view. Lynx Software Technologies provides LynxOS-178 support.

Percepio percepio.com

and streaming, and PIM hunting, we’re not just meeting industry standards; we’re creating them.

Accuracy and Dependability: Engineered for precision and built to withstand rigorous field conditions, the Site Master ensures consistent, reliable outcomes. Its superior measurement accuracy and robust construction instill confidence in every test result, allowing for precise, informed decisions under any circumstances.

Advanced Features: With features like Real-Time Spectrum Analysis (RTSA), I.Q. capture

Raymond Chan, Product Manager at Anritsu Corporation, said, “We are thrilled to launch the Site Master MS2085A and MS2089A, signifying a monumental stride in field testing technology. These innovations underscore our dedication to advancing testing and measurement technologies that meet and exceed our customers’ evolving requirements across various sectors. They testify to Anritsu’s unwavering commitment to excellence, setting a new benchmark for field testing proficiency.”

Anritsu anritsu.com

Arctic Semiconductor Announces 3GPP Compliant Platform for 5G Private Networks Featuring Products from Skyworks and Synergy

Arctic Semiconductor, a pioneer in low-power, versatile RF, and mixed-signal chipsets, today announced that its low-power, high-performance 4x4 transceiver IceWings is powering a new small cell platform that has passed 3GPP specification and will soon be available in mass production. In addition to Arctic’s IceWings, the platform includes Skyworks Solutions, Inc.’s (Skyworks) family of power amplifiers and timing products and Synergy Design’s carrier-grade 5G vRAN solutions. This cost-optimized platform enables service providers and private network developers to deploy custom 5G networks at scale, a pivotal milestone in 5G infrastructure development.

Private 5G networks offer unparalleled connectivity within defined boundaries. Embracing a 5G private network empowers enterprises across diverse sectors, such as factories, ports, mines, and hotels, with enhanced data transmission speeds and reduced latency, all while upholding rigorous control over the security and management of their customized network architecture. Leveraging distributed small cells, known for their efficient power usage, lays the foundation for these exclusive networks, reducing costs and enhancing the feasibility of such tailored solutions for businesses.

The 5G platform is one of the first open software small cell platforms with the highest performance, meeting 3GPP standard requirements at the lowest power consumption. The platform brings together best-in-class components from leading component manufacturers to offer the best coverage, lowest power consumption, and value-added features for a much lower cost of deployment. The open, universal small cell platform operates at any 5G FR1 frequency band from 600MHz to 7.2GHz. Two different platform variants are available for bands n78 and n79 working in multiple countries.

“Our solutions are architected to integrate with performance- and cost-optimized, industry-leading components easily. For this solution, we collaborated with key industry leaders Skyworks and Synergy to bring this platform to market and enable 5G deployment for private networks,” said Vahid Toosi, founder and CEO of Arctic Semiconductor. “Our family of transceiver products provides the best R.F.

performance in terms of noise and linearity with the lowest power solution that meets and exceeds all the 5G performance requirements cost-effectively. We believe this will kick start a 5G private network movement.”

Skyworks’ power amplifiers (P.A.) are a key component to the low-power offering of the new 3GPP-compliant small cell platform. Arctic’s digital-pre distortion (DPD) model and methodology leverage the efficiency of Skyworks power amplifiers with intelligent algorithms, creating an extremely efficient, low-power design while maintaining the highest signal quality and uncompromised coverage.

“As a long-standing and significant contributor to the 3GPP standards, Skyworks’ in-depth system knowledge and R.F. front-end expertise have allowed us to develop best-in-class high-efficiency P.A.s and ultra-low jitter timing solutions,” said Eid Alsabbagh, senior director of product marketing, infrastructure at Skyworks. “Our complete portfolio of R.F. and timing products maximizes the data throughput and range of this design, enabling manufacturers to create cost-effective small cell products that best meet market requirements.”

The small cell platform also includes Synergy Design’s leading 5G Smart RAN solution, which delivers carrier-grade RAN performance while allowing a rapid time-to-market for the small cell platform.

“We are always looking for opportunities where our leading PHY and Software solutions can make a big impact. That’s why we worked closely with the Arctic to integrate our Smart RAN solution on the NXP platform for the 5G market,” said Krystie Chen, CMO of Synergy Design. “This new 5G N.R. small cell platform will enable 5G private networks deployments to proliferate sooner than anticipated.”

“Achieving 3GPP compliance marks a significant milestone for Arctic Semiconductor, Skyworks, and Synergy,” said Brandon Hoff, research director at IDC. “Their new transceiver will enable telecommunications providers to reduce costs and power requirements for 5G, support enterprises in deploying private 5G networks, and offer cost-effective solutions for Fixed Wireless Access.”

Arctic Semiconductor arcticsemiconductor.com

Curtiss-Wright Expands Axon Airborne Data Acquisition Product Family with Miniature 8-Channel ADC DAU that Supports PoE and Daisy-Chain Connectivity

The new Axon Pico AXP/ADC/401 brings flexible, remote analog data capture to flight test instrumentation programs.

Curtiss-Wright’s Defense Solutions Division introduced the Axon™ Pico (AXP/ ADC/401) 8-channel ADC data acquisition unit (DAU), the latest addition to its expansive range of data acquisition systems designed for demanding flight test programs. Flight test engineers seek to reduce their FTI system’s wire weight and complexity while easing installation. They also want to leverage distributed architectures that enable remote data acquisition from hard-to-reach places on the test platform while also being

able to acquire accurate data in locations that experience extreme shock and vibration. The Axon Pico, Curtiss-Wright’s first DAU to support Power over Ethernet (PoE), helps address these challenging requirements.

This size, weight, and power (SWaP) optimized Axon Pico DAU is designed to be as small as possible without compromising key features. It significantly reduces wiring weight and complexity, enables the remote capture of critical data, and supports daisy-chain connectivity to other Axon Picos without requiring a switch. Axon Picos connect using IEEE 1588 PTP system synchronization. Even better, the high-performance unit delivers data throughput rated at 50 kbps per channel (max.) on its eight analog input channels while supporting all typical FTI analog sensor types. This flexible analog-to-data converter FTI module is ideal for demanding flight test programs like Missile and EVTOL.

commitment to delivering the most comprehensive FTI product range available.”

“We believe the Axon Pico is the FTI industry’s first miniature standalone analog data acquisition unit with support for Power over Ethernet and daisy-chain connectivity,” said Brian Perry, Senior Vice President and General Manager of Curtiss-Wright Defense Solutions. “Our Axon data acquisition systems for critical flight test applications provide flight test engineers with high-speed, flexible solutions for demanding FTI programs. With the introduction of the Axon Pico, we further demonstrate our

The Axon Pico supports a programmable input range of ±2.4 mV to ±10V and delivers high accuracy up to 0.02% FSR (typical). The DAU supports full-bridge, half-bridge, differential-ended, single-ended, RTD, thermocouple, ICP, and A.C. coupled measurements with both voltage and current excitation. Data is packetized directly from the unit, eliminating the need for a separate chassis. Each unit features two ports carrying 100BASE-TX Ethernet and power over CAT5 (or better) cable.

The Axon product family is the most advanced airborne data acquisition system available today. It offers low SWaP and the best feature set, data acquisition, and thermal performance on the market. The Axon product family builds on Curtiss-Wright’s heritage as the leading supplier of rugged, reliable data acquisition for aerospace applications.

Axon’s future-proof design, using a highspeed serial backplane (1 Gbps dedicated link per module), supports future high data rates. Its optimized SWaP design enables an Axon module to be located in tight spaces and operate reliably without requiring bulky heatsinks. Axon modules can be hosted in ultra-miniature “Axonite” housings and located remotely, separated from the chassis by up to 10 meters. Locating data acquisition closer to the sensors can significantly decrease the installation time and cost of the instrumentation while reducing wiring weight. Axonites can also save significant system costs in larger installations by minimizing the number of DAUs required in remote locations and eliminating the need for extra chassis controllers and power supplies.

Curtiss-Wright curtisswright.com

Periodicals

POSTMASTER: